Martensite Formation and Decomposition during Traditional and AM Processing of Two-Phase Titanium Alloys—An Overview

Abstract

1. Introduction

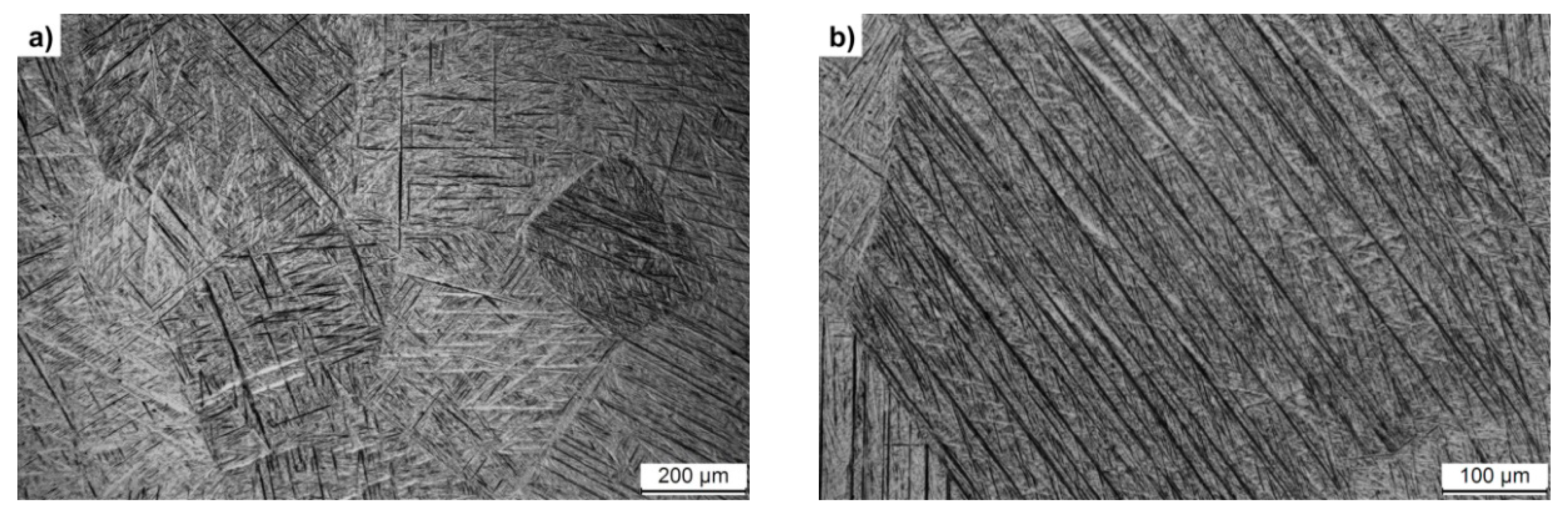

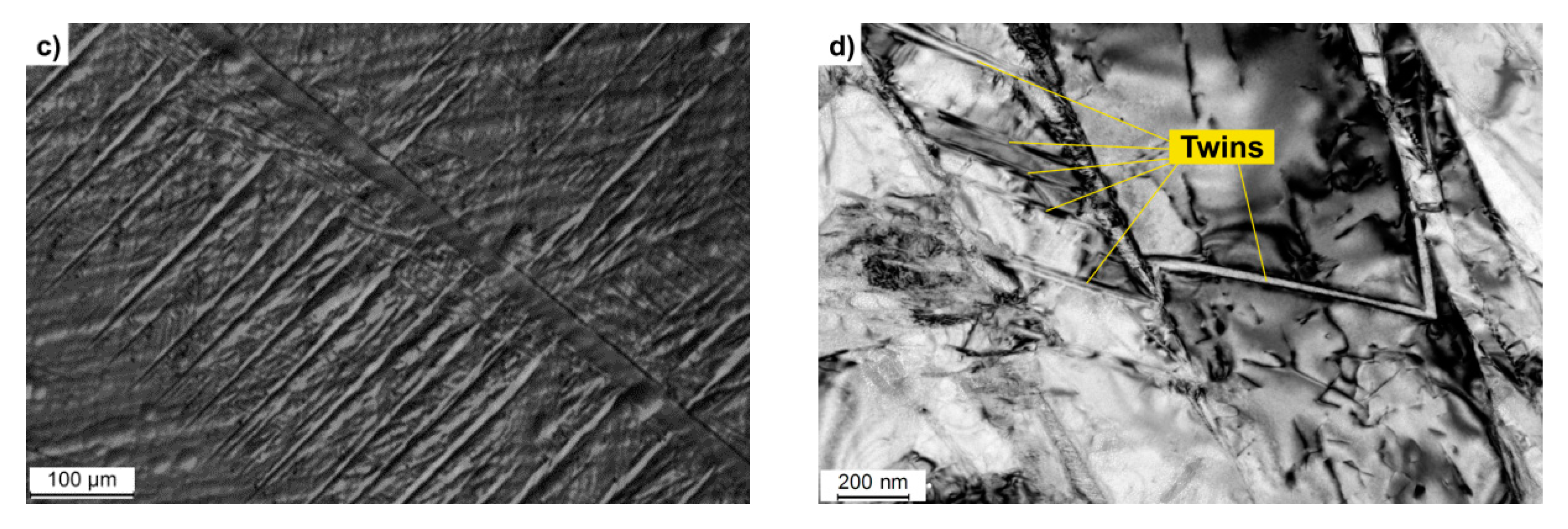

2. Martensitic Transformation and Martensitic Phases

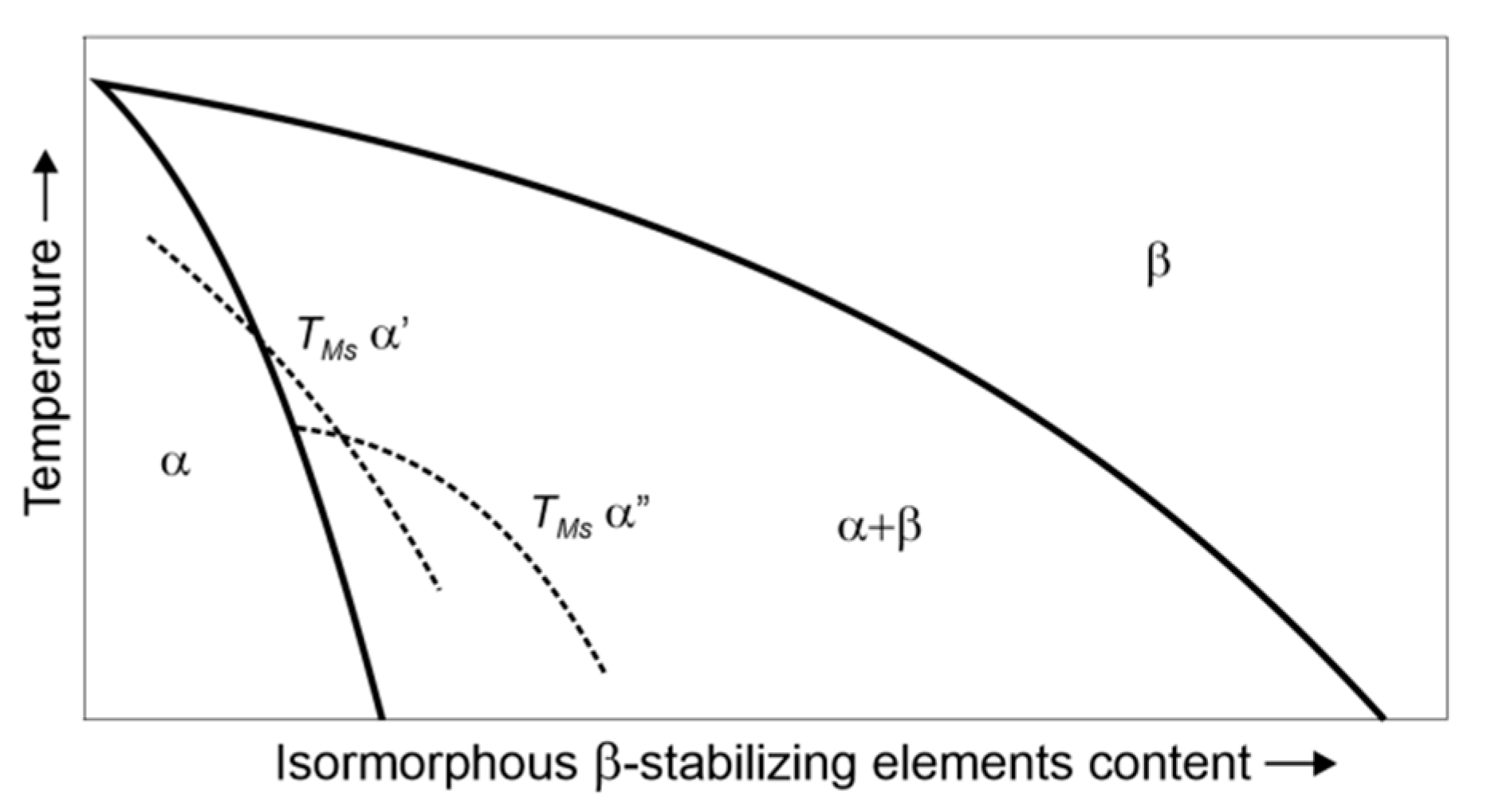

3. Martensite Decomposition

- precipitation of metastable βM phase from martensitic α″ phase, and then α″depl phase depleted in the β-stabilizing elements transforms into α′ phase and, next, into α phase:α″ → α″depl + βM → α′ + βM → α + β;

- precipitation of α, causing gradual enrichment of α″enr phase (in the β-stabilizing elements) and then its transition into metastable βM and, finally, β phase:α″ → α + α″enr → α + βM → α + β;

- formation of zones with different concentration of alloying elements (α″depl and α″enr) which transform into metastable α″depl and βM and, finally, stable α and β phases:α″ → α″depl + α″enr → α″depl + βM → α + β.

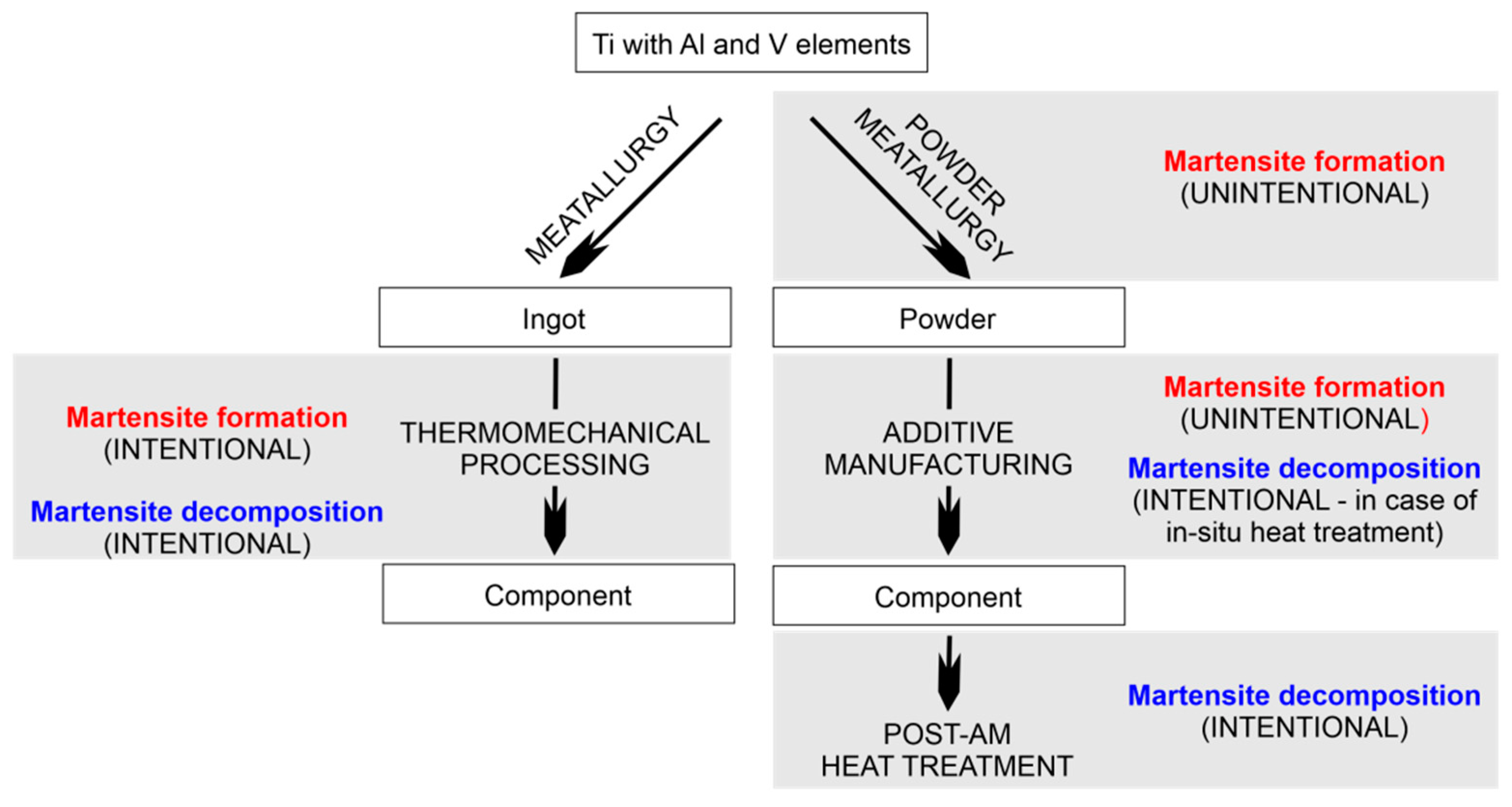

4. The Role of α′(α″) Martensitic Phase in the Development of Microstructure of Two-Phase Titanium Alloys

5. Martensite Formation during Additive Manufacturing Processes

5.1. PBF Methods

5.2. DED Methods

6. Summary

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leyens, P.; Peters, M. Titanium and Titanium Alloys—Fundamentals and Applications, 1st ed.; WILEY-VCH GmbH & Co. KGaA: Weinheim, Germany, 2003. [Google Scholar]

- Motyka, M.; Ziaja, W.; Sieniawski, J. Introductory Chapter: Novel Aspects of Titanium Alloys’ Applications. In Titanium Alloys—Novel Aspects of Their Manufacturing and Processing, 1st ed.; Motyka, M., Ziaja, W., Sieniawski, J., Eds.; IntechOpen: London, UK, 2019; pp. 3–6. [Google Scholar] [CrossRef]

- Motyka, M.; Kubiak, K.; Sieniawski, J.; Ziaja, W. Phase transformations and characterization of α+β titanium alloys. In Comprehensive Materials Processing, 1st ed.; Hashmi, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 2, pp. 7–36. [Google Scholar] [CrossRef]

- Lütjering, G.; Williams, J.C. Titanium, 1st ed.; Springer: Berlin, Germany, 2003. [Google Scholar]

- Peters, M.; Lütjering, G.; Ziegler, G. Control of microstructures of (α+β) titanium alloys. Z. Metallkd. 1983, 74, 274–282. [Google Scholar]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Wu, H.; Sun, Z.; Cao, J.; Yin, Z. Formation and evolution of tri-modal microstructure during dual heat treatment for TA15 Ti-alloy. J. Alloys Compd. 2019, 786, 894–905. [Google Scholar] [CrossRef]

- Sieniawski, J.; Ziaja, W.; Kubiak, K.; Motyka, M. Microstructure and mechanical properties of high strength two-phase titanium alloys. In Titanium Alloys—Advances in Properties Control, 1st ed.; Sieniawski, J., Ziaja, W., Eds.; InTech: Rijeka, Croatia, 2013; Volume 2, pp. 69–80. [Google Scholar] [CrossRef]

- Semiatin, S.L. An overview of the thermomechanical processing of α/β titanium alloys: Current status and future research opportunities. Metall. Mater. Trans. A 2020, 51, 2593–2625. [Google Scholar] [CrossRef]

- Inagaki, H. Enhanced superplasticity in high strength Ti alloys. Z. Metallkd. 1995, 86, 643–650. [Google Scholar]

- Zherebtsov, S.V.; Salishchev, G.A.; Galeyev, R.M.; Valiakhmetov, O.R.; Mironov, S.Y.; Semaitin, S.L. Production of submicrocrystalline structure in large-scale Ti–6Al–4V billet by warm severe deformation processing. Scripta Mater. 2004, 51, 1147–1151. [Google Scholar] [CrossRef]

- Motyka, M.; Sieniawski, J.; Ziaja, W. Microstructural aspects of superplasticity in Ti–6Al–4V alloy. Mater. Sci. Eng. A 2014, 599, 57–63. [Google Scholar] [CrossRef]

- Chao, Q.; Hodgson, P.D.; Beladi, H. Ultrafine grain formation in a Ti-6Al-4V alloy by thermomechanical processing of a martensitic microstructure. Metall. Mater. Trans. A 2014, 45, 2659–2671. [Google Scholar] [CrossRef]

- Markovsky, P.E. Preparation and properties of ultrafine (submicron) structure titanium alloys. Mater. Sci. Eng. A 1995, 203, L1–L4. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F.H. The additive manufacturing (AM) of titanium alloys. In Titanium Powder Metallurgy—Science, Technology and Applications, 1st ed.; Qian, M., Froes, F.H., Eds.; Butterworth-Heinemann: Waltham, MA, USA, 2015; pp. 447–468. [Google Scholar] [CrossRef]

- Dutta, B.; Froes, F.H. The additive manufacturing (AM) of titanium alloys. Met. Powder Rep. 2017, 72, 96–106. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- He, J.; Li, D.; Jiang, W.; Ke, L.; Qin, G.; Ye, Y.; Qin, Q.; Qiu, D. The martensitic transformation and mechanical properties of Ti6Al4V prepared via selective laser melting. Materials 2019, 12, 321. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, D.; Guo, Y.; Hu, S.; Wu, X.; Jiang, Y. Microstructural tailoring of As-Selective Laser Melted Ti6Al4V alloy for high mechanical properties. J. Alloys Compd. 2020, 816, 152536. [Google Scholar] [CrossRef]

- Szafrańska, A.; Antolak-Dudka, A.; Baranowski, P.; Bogusz, P.; Zasada, D.; Małachowski, J.; Czujko, T. Identification of mechanical properties for titanium alloy Ti-6Al-4V produced using LENS technology. Materials 2019, 12, 886. [Google Scholar] [CrossRef]

- Kazantseva, N.; Krakhmalev, P.; Thuvander, M.; Yadroitsev, I.; Vinogradova, N.; Ezhov, I. Martensitic transformations in Ti-6Al-4V (ELI) alloy manufactured by 3D Printing. Mater. Charact. 2018, 146, 101–112. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Toh, W.Q.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Revealing martensitic transformation and α/β interface evolution in electron beam melting three-dimensional-printed Ti-6Al-4V. Sci. Rep. 2016, 6, 26039. [Google Scholar] [CrossRef] [PubMed]

- Zafari, A.; Xia, K. High ductility in a fully martensitic microstructure: A paradox in a Ti alloy produced by selective laser melting. Mater. Res. Lett. 2018, 6, 627–633. [Google Scholar] [CrossRef]

- De Formanoir, C.; Martin, G.; Prima, F.; Allain, S.Y.P.; Dessolier, T.; Sun, F.; Vivès, S.; Hary, B.; Bréchet, Y.; Godeta, S. Micromechanical behavior and thermal stability of a dual-phase α+α′ titanium alloy produced by additive manufacturing. Acta Mater. 2019, 162, 149–162. [Google Scholar] [CrossRef]

- Zwicker, U. Titanium and Titanium Alloys, 1st ed.; Springer: Berlin, Germany, 1974. (In German) [Google Scholar]

- Chai, Y.W.; Kim, H.Y.; Hosoda, H.; Miyazaki, S. Interfacial defects in Ti–Nb shape memory alloys. Acta Mater. 2008, 56, 3088–3097. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Moiseev, V.N.; Polyak, É.V.; Sokolova, A.Y. Martensite strengthening of titanium alloys. Met. Sci. Heat Treat. 1975, 17, 687–691. [Google Scholar] [CrossRef]

- Moiseyev, V.N. Titanium Alloys—Russian Aircraft and Aerospace Applications, 1st ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2006. [Google Scholar]

- Venkatesh, B.D.; Chen, D.L.; Bhole, S.D. Effect of heat treatment on mechanical properties of Ti–6Al–4V ELI alloy. Mater. Sci. Eng. A 2009, 506, 117–124. [Google Scholar] [CrossRef]

- Jovanović, M.T.; Tadić, S.; Zec, S.; Mišković, Z.; Bobić, I. The effect of annealing temperatures and cooling rates on microstructure and mechanical properties of investment cast Ti–6Al–4V alloy. Mater. Des. 2006, 27, 192–199. [Google Scholar] [CrossRef]

- Chong, Y.; Bhattacharjee, T.; Yi, J.; Shibata, A.; Tsuji, N. Mechanical properties of fully martensite microstructure in Ti-6Al-4V alloy transformed from refined beta grains obtained by rapid heat treatment (RHT). Scripta Mater. 2017, 138, 66–70. [Google Scholar] [CrossRef]

- Mantani, Y.; Tajima, M. Phase transformation of quenched α″ martensite by aging in Ti-Nb alloys. Mater. Sci. Eng. A 2006, 438–440, 315–319. [Google Scholar] [CrossRef]

- Sato, K.; Matsumoto, H.; Kodaira, K.; Konno, T.J.; Chiba, A. Phase transformation and age-hardening of hexagonal α′ martensite in Ti–12 mass%V–2 mass%Al alloys studied by transmission electron microscopy. J. Alloys Compd. 2010, 506, 607–614. [Google Scholar] [CrossRef]

- Zeng, L.; Bieler, T.R. Effects of working, heat treatment, and aging on microstructural evolution and crystallographic texture of α, α′, α″ and α phases in Ti-6Al-4V wire. Mater. Sci. Eng. A 2005, 392, 403–414. [Google Scholar] [CrossRef]

- Bylica, A.; Sieniawski, J. Tytan i Jego Stopy, 1st ed.; PWN: Warsaw, Poland, 1985. (In Polish) [Google Scholar]

- Gil Mur, F.X.; Rodríguez, D.; Planell, J.A. Influence of tempering temperature and time on the α″-Ti-6Al-4V martensite. J. Alloys Compd. 1996, 234, 287–289. [Google Scholar] [CrossRef]

- Qazi, J.I.; Senkov, O.N.; Rahim, J.; Froes, F.H. Kinetics of martensite decomposition in Ti-6Al-4V-xH alloys. Mater. Sci. Eng. A 2003, 359, 137–149. [Google Scholar] [CrossRef]

- Sieniawski, J.; Filip, R.; Kubiak, K. Influence of ageing time and temperature on mechanical properties of two-phase titanium alloy Ti-6Al-2Mo-2Cr at high temperature. Inz. Materialowa 1998, 19, 536–539. [Google Scholar]

- Barriobero-Vila, P.; Oliveira, V.B.; Schwarz, S.; Buslaps, T.; Requena, G. Tracking the α″ martensite decomposition during continuous heating of a Ti-6Al-6V-2Sn alloy. Acta Mater. 2017, 135, 132–143. [Google Scholar] [CrossRef]

- Yu, H.; Li, W.; Li, S.; Zou, H.; Zhai, T.; Liu, L. Study on transformation mechanism and kinetics of α′ martensite in TC4 alloy isothermal aging process. Crystals 2020, 10, 229. [Google Scholar] [CrossRef]

- Lee, S.W.; Park, C.H.; Hong, J.K.; Yeom, J.-T. Aging temperature dependence of α″-martensite decomposition mechanism in Ti-Al-Fe-Si alloy. Metall. Mater. Trans. A 2018, 49, 5913–5918. [Google Scholar] [CrossRef]

- Li, X.; Sha, M.; Chu, J. Compressive deformability of hardened titanium alloy VT16. Met. Sci. Heat Treat. 2009, 51, 594–598. [Google Scholar] [CrossRef]

- Illarionov, A.G.; Demakov, S.L.; Stepanov, S.I.; Illarionova, S.M. Structural and phase transformations in a quenched two-phase titanium alloy upon cold deformation and subsequent annealing. Phys. Met. Metallogr. 2015, 116, 267–273. [Google Scholar] [CrossRef]

- Matsumoto, H.; Kodaira, K.; Sato, K.; Konno, T.J.; Chiba, A. Microstructure and mechanical properties of α′ martensite type Ti alloys deformed under α′ the processing. Mater. Trans. 2009, 50, 2744–2750. [Google Scholar] [CrossRef]

- Gu, J.L.; Sun, X.J.; Bai, B.Z.; Chen, N.P. Microstructural evolution during fabrication of ultrafine grained alpha+beta titanium alloy. Mater. Sci. Technol. 2001, 17, 1516–1524. [Google Scholar] [CrossRef]

- Motyka, M.; Baran-Sadleja, A.; Sieniawski, J.; Wierzbińska, M.; Gancarczyk, K. Decomposition of deformed α′(α″) martensitic phase in Ti-6Al-4V alloy. Mater. Sci. Technol. 2019, 35, 260–272. [Google Scholar] [CrossRef]

- Motyka, M.; Ziaja, W.; Baran-Sadleja, A.; Ślemp, K. The effect of plastic deformation on martensite decomposition process in Ti-6Al-4V alloy. In Proceedings of the 14th World Conference on Titanium (Ti 2019), Nantes, France, 10–14 June 2019; Volume 21, p. 12034. [Google Scholar] [CrossRef]

- Kubiak, K.; Sieniawski, J. Development of the microstructure and fatigue strength of two phase titanium alloys in the processes of forging and heat treatment. J. Mater. Process. Technol. 1998, 78, 117–121. [Google Scholar] [CrossRef]

- Motyka, M.; Sieniawski, J. The influence of initial plastic deformation on microstructure and hot plasticity of α+β titanium alloys. Arch. Mat. Sci. Eng. 2010, 41, 95–103. [Google Scholar]

- Nieh, T.G.; Wadsworth, J.; Sherby, O.D. Superplasticity in Metals and Ceramics, 1st ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar] [CrossRef]

- Jackson, M. Superplastic forming and diffusion bonding of titanium alloys. In Superplastic Forming of Advanced Metallic Materials—Methods and Applications, 1st ed.; Giuliano, G., Ed.; Woodhead Publishing: Cambridge, UK, 2011. [Google Scholar] [CrossRef]

- Valiev, R.; Islamgaliev, R.; Semenova, I.; Yunusova, N. New trends in superplasticity in SPD-processed nanostructured materials. Int. J. Mater. Res. 2007, 98, 314–319. [Google Scholar] [CrossRef]

- Inagaki, H. Mechanism of enhanced superplasticity in thermomechanically processed Ti-6Al-4V. Z. Metallkd. 1996, 87, 179–186. [Google Scholar]

- Shell, E.B.; Semiatin, S.L. Effect of initial microstructure on plastic flow and dynamic globularization during hot working of Ti-6Al-4V. Metall. Mater. Trans. A 1999, 30, 3219–3229. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Bieler, T.R. The effect of alpha platelet thickness on plastic flow during hot working of TI–6Al–4V with a transformed microstructure. Acta Mater. 2001, 49, 3565–3573. [Google Scholar] [CrossRef]

- Park, C.H.; Ko, Y.G.; Park, J.W.; Lee, C.S. High-temperature deformation behavior of ELI Grade Ti-6Al-4V alloy with martensite microstructure. Mater. Sci. Eng. A 2008, 496, 150–158. [Google Scholar] [CrossRef]

- Park, C.H.; Park, K.T.; Shin, D.H.; Lee, C.S. Microstructural mechanisms during dynamic globularization of Ti-6Al-4V alloy. Mater. Trans. 2008, 49, 2196–2200. [Google Scholar] [CrossRef]

- Matsumoto, H.; Bin, L.; Lee, S.-H.; Li, Y.; Ono, Y.; Chiba, A. Frequent occurrence of discontinuous dynamic recrystallization in Ti-6Al-4V alloy with α′ martensite starting microstructure. Metall. Mater. Trans. A 2013, 44, 3245–3260. [Google Scholar] [CrossRef]

- Senkov, O.N.; Jonas, J.J.; Froes, F.H. Recent advances in the thermohydrogen processing of titanium alloys. JOM 1996, 48, 42–47. [Google Scholar] [CrossRef]

- Yoshimura, H.; Kimura, K.; Hayashi, M. Ultra-fine equiaxed grain refinement of titanium alloys by hydrogenation, hot working, heat treatment and dehydrogenation. Nippon Steel Tech. Rep. 1994, 62, 80–84. [Google Scholar]

- Murzinova, M.A.; Salishev, G.A.; Afonichev, D.D. Formation of nanocrystalline structure in two-phase titanium alloy by combination of thermohydrogen processing with hot working. Int. J. Hydrogen Energy 2002, 27, 775–782. [Google Scholar] [CrossRef]

- Qazi, J.L.; Rahim, J.; Senkov, O.N.; Froes, F.H. Phase transformations in the Ti-6Al-4V-H system. JOM 2002, 54, 68–71. [Google Scholar] [CrossRef]

- Zong, Y.-Y.; Huang, S.-H.; Guo, B.; Shan, D.-B. In situ study of phase transformation in Ti-6Al-4V-xH alloys. Trans. Nonferrous Met. Soc. China 2015, 25, 2901–2911. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Qiao, B.; Dong, C.; Tong, S.; Kong, D.; Ni, X.; Zhang, H.; Wang, L.; Li, X. Anisotropy in α′ martensite and compression behavior of Ti6Al4V prepared by selective laser melting. Mater. Res. Express 2019, 6, 126548. [Google Scholar] [CrossRef]

- Qian, M.; Xu, W.; Brandt, M.; Tang, H.P. Additive manufacturing and postprocessing of Ti-6Al-4V for superior mechanical properties. MRS Bull. 2016, 41, 775–784. [Google Scholar] [CrossRef]

- Moridi, A.; Demir, A.G.; Caprio, L.; Hart, A.J.; Previtali, B.; Colosimo, B.M. Deformation and failure mechanisms of Ti–6Al–4V as built by selective laser melting. Mater. Sci. Eng. A 2019, 768, 1384568. [Google Scholar] [CrossRef]

- Barriobero-Vila, P.; Gussone, J.; Haubrich, J.; Sandlöbes, S.; Da Silva, J.C.; Cloetens, P.; Schell, N.; Requena, G. Inducing stable α + β microstructures during selective laser melting of Ti-6Al-4V using intensified intrinsic heat treatments. Materials 2017, 10, 268. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Sallica-Leva, E.; Caram, R.; Jardini, A.L.; Fogagnolo, J.B. Ductility improvement due to martensite α′ decomposition in porous Ti-6Al-4V parts produced by selective laser melting for orthopedic implants. J. Mech. Behav. Biomed. Mater. 2016, 54, 149–158. [Google Scholar] [CrossRef] [PubMed]

- Caoa, S.; Hu, Q.; Huang, A.; Chen, Z.; Sun, M.; Zhang, J.; Fu, C.; Jia, Q.; Lim, C.V.S.; Boyer, R.R.; et al. Static coarsening behaviour of lamellar microstructure in selective laser melted Ti-6Al-4V. J. Mater. Sci. Technol. 2019, 35, 1578–1586. [Google Scholar] [CrossRef]

- Neikter, M.; Huang, A.; Wu, X. Microstructural characterization of binary microstructure pattern in selective laser-melted Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2019, 104, 1381–1391. [Google Scholar] [CrossRef]

- Zafari, A.; Barati, M.R.; Xia, K. Controlling martensitic decomposition during selective laser melting to achieve best ductility in high strength Ti-6Al-4V. Mater. Sci. Eng. A 2019, 744, 445–455. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, Q.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Yamanaka, K.; Mori, M.; Chiba, A. Martensitic transformation and its effects on microstructural evolution and mechanical properties in electron beam melting of commercially pure titanium and Ti-6Al-4V alloy. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015; Venkatesh, V., Pilchak, A.L., Allison, J.E., Ankem, S., Boyer, R., Christodoulou, J., Fraser, H.L., Imam, M.A., Kosaka, Y., Rack, H.J., et al., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016. Chapter 218. [Google Scholar] [CrossRef]

- Ganor, Y.I.; Tiferet, E.; Vogel, S.C.; Brown, D.W.; Chonin, M.; Pesach, A.; Hajaj, A.; Garkun, A.; Samuha, S.; Shneck, R.Z.; et al. Tailoring microstructure and mechanical properties of additively-manufactured Ti6Al4V using post processing. Materials 2021, 14, 658. [Google Scholar] [CrossRef]

- Dumontet, N.; Connétable, D.; Malard, B.; Viguier, B. Elastic properties of the α′ martensitic phase in the Ti-6Al-4V alloy obtained by additive manufacturing. Scripta Mater. 2019, 167, 115–119. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Antolak-Dudka, A.; Płatek, P.; Durejko, T.; Baranowski, P.; Małachowski, J.; Sarzyński, M.; Czujko, T. Static and dynamic loading behavior of Ti6Al4V honeycomb structures manufactured by laser engineered net shaping (LENSTM) technology. Materials 2019, 12, 1225. [Google Scholar] [CrossRef]

- Qiu, C.; Ravi, G.A.; Dance, C.; Ranson, A.; Dilworth, S.; Attallah, M.M. Fabrication of large Ti–6Al–4V structures by direct laser deposition. J. Alloys Compd. 2015, 629, 351–361. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Wu, X.; Dargusch, M.S. Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes. Mater. Sci. Eng. A 2017, 705, 385–393. [Google Scholar] [CrossRef]

- Murgau, C.C. Microstructure Model for Ti-6Al-4V Used in Simulation of Additive Manufacturing. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, May 2016. [Google Scholar]

- Adamus, J.; Lacki, P.; Motyka, M. EBW titanium sheets as material for drawn parts. Arch. Civ. Mech. Eng. 2015, 15, 42–47. [Google Scholar] [CrossRef]

- Fan, Y.; Tian, W.; Guo, Y.; Sun, Z.; Xu, J. Relationships among the microstructure, mechanical properties, and fatigue behavior in thin Ti6Al4V. Adv. Mater. Sci. Eng. 2016, 7278267. [Google Scholar] [CrossRef]

- Molak, R.M.; Araki, H.; Watanabe, M.; Katanoda, H.; Ohno, N.; Kuroda, S. Warm spray forming of Ti-6Al-4V. J. Therm. Spray Technol. 2014, 23, 197–212. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, S.Y.; Tan, P.; Wang, J.; Xiang, C.S.; Tang, H.P. A comparative study of Ti-6Al-4V powders for additive manufacturing by gas atomization, plasma rotating electrode process and plasma atomization. Powder Technol. 2018, 333, 38–46. [Google Scholar] [CrossRef]

- Birt, A.M.; Champagne, V.K.J.; Sisson, R.D.; Apelian, D. Microstructural analysis of Ti–6Al–4V powder for cold gas dynamic spray applications. Adv. Powder Technol. 2015, 26, 1335–1347. [Google Scholar] [CrossRef]

- Ulhmann, E.; Kersting, R.; Klein, T.B.; Cruz, M.F.; Borille, A.V. Additive manufacturing of titanium alloy for aircraft components. Proc. CIRP 2015, 35, 55–60. [Google Scholar] [CrossRef]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I. Selective laser melting of Ti6Al4V alloy for biomedical applications: Temperature monitoring and microstructural evolution. J. Alloys Compd. 2014, 583, 404–409. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Motyka, M. Martensite Formation and Decomposition during Traditional and AM Processing of Two-Phase Titanium Alloys—An Overview. Metals 2021, 11, 481. https://doi.org/10.3390/met11030481

Motyka M. Martensite Formation and Decomposition during Traditional and AM Processing of Two-Phase Titanium Alloys—An Overview. Metals. 2021; 11(3):481. https://doi.org/10.3390/met11030481

Chicago/Turabian StyleMotyka, Maciej. 2021. "Martensite Formation and Decomposition during Traditional and AM Processing of Two-Phase Titanium Alloys—An Overview" Metals 11, no. 3: 481. https://doi.org/10.3390/met11030481

APA StyleMotyka, M. (2021). Martensite Formation and Decomposition during Traditional and AM Processing of Two-Phase Titanium Alloys—An Overview. Metals, 11(3), 481. https://doi.org/10.3390/met11030481