Hot Deformation Behavior and Constitutive Analysis of As-Extruded Mg–6Zn–5Ca–3Ce Alloy Fabricated by Rapid Solidification

Abstract

1. Introduction

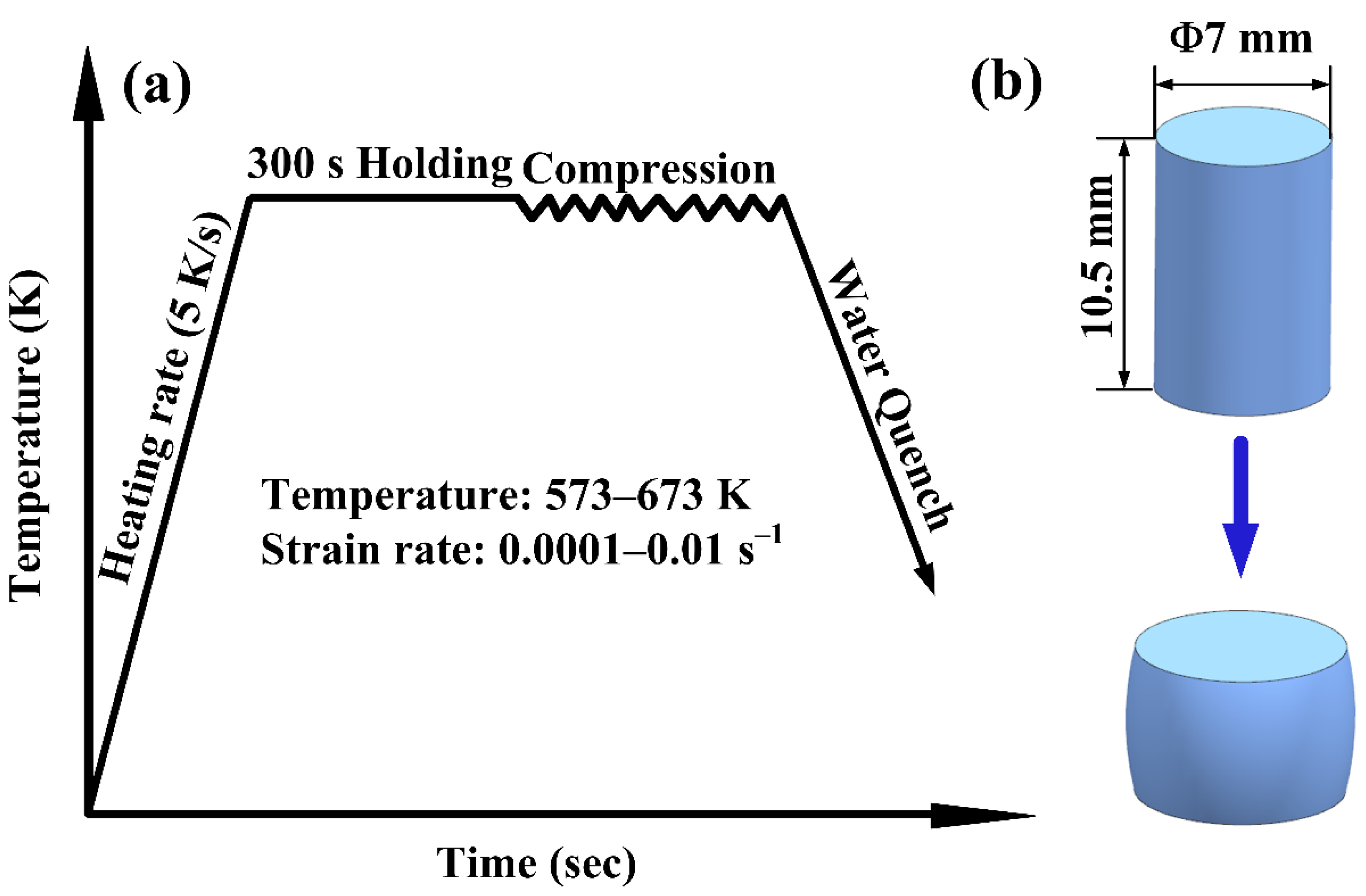

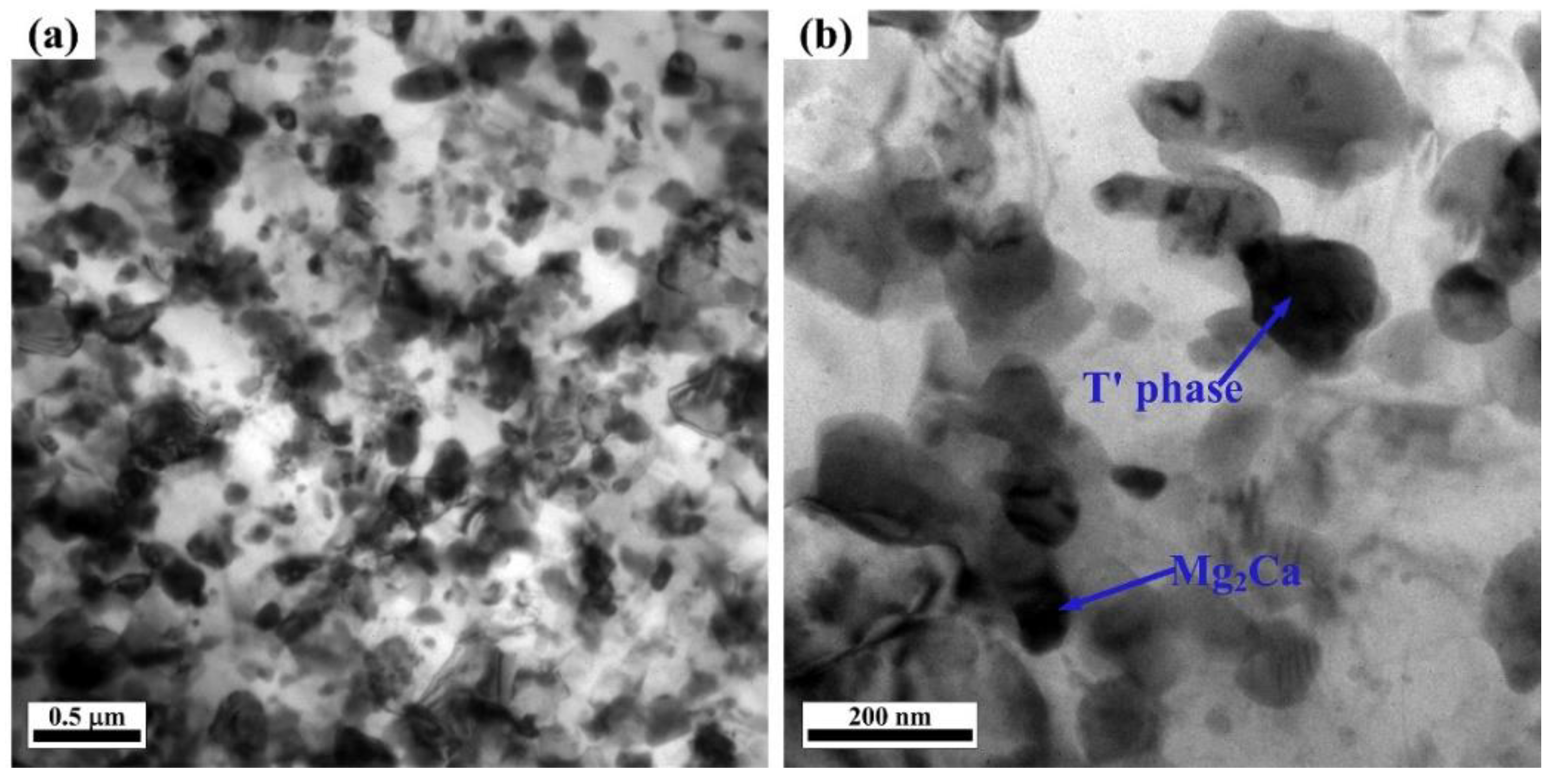

2. Material and Methods

3. Results and Discussion

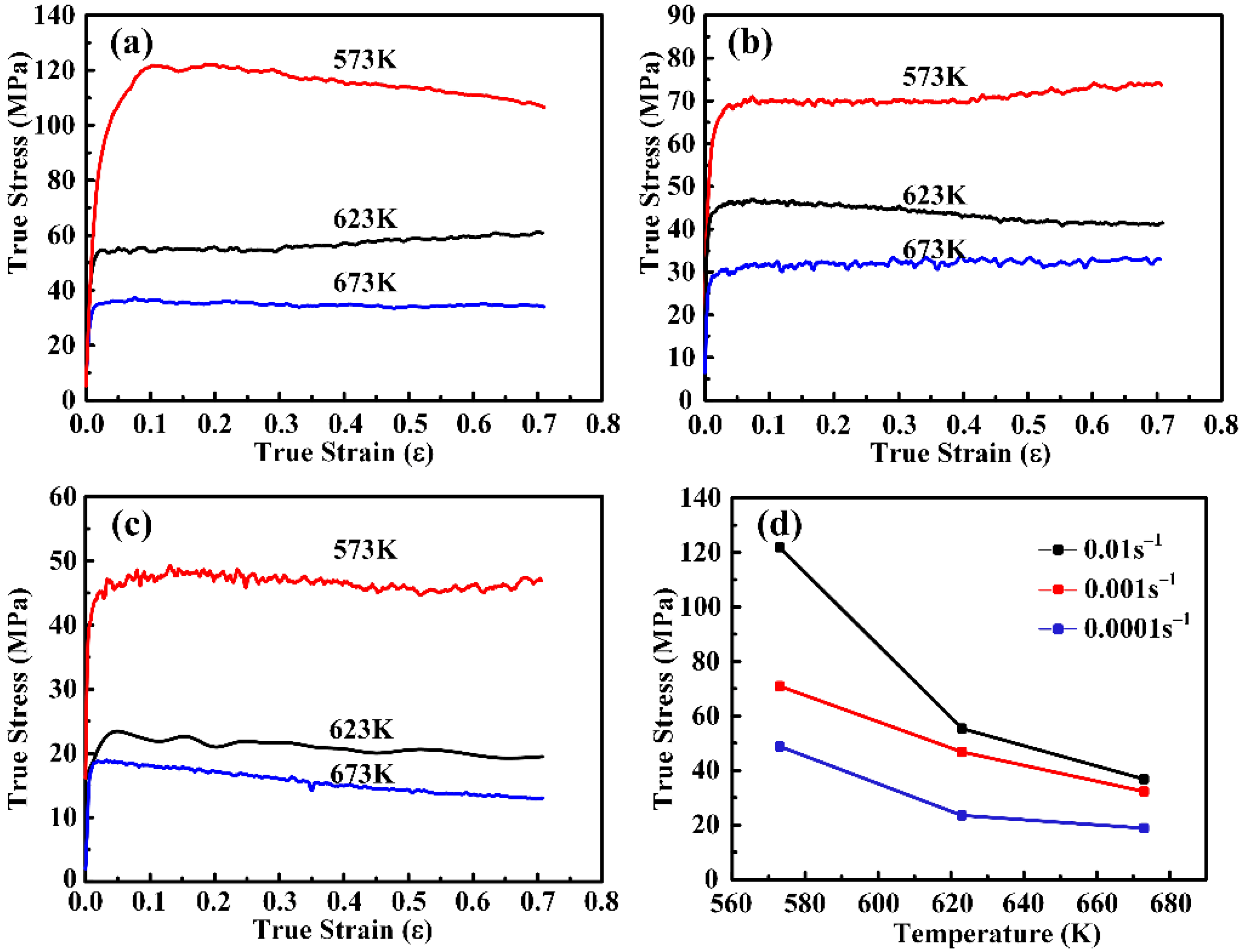

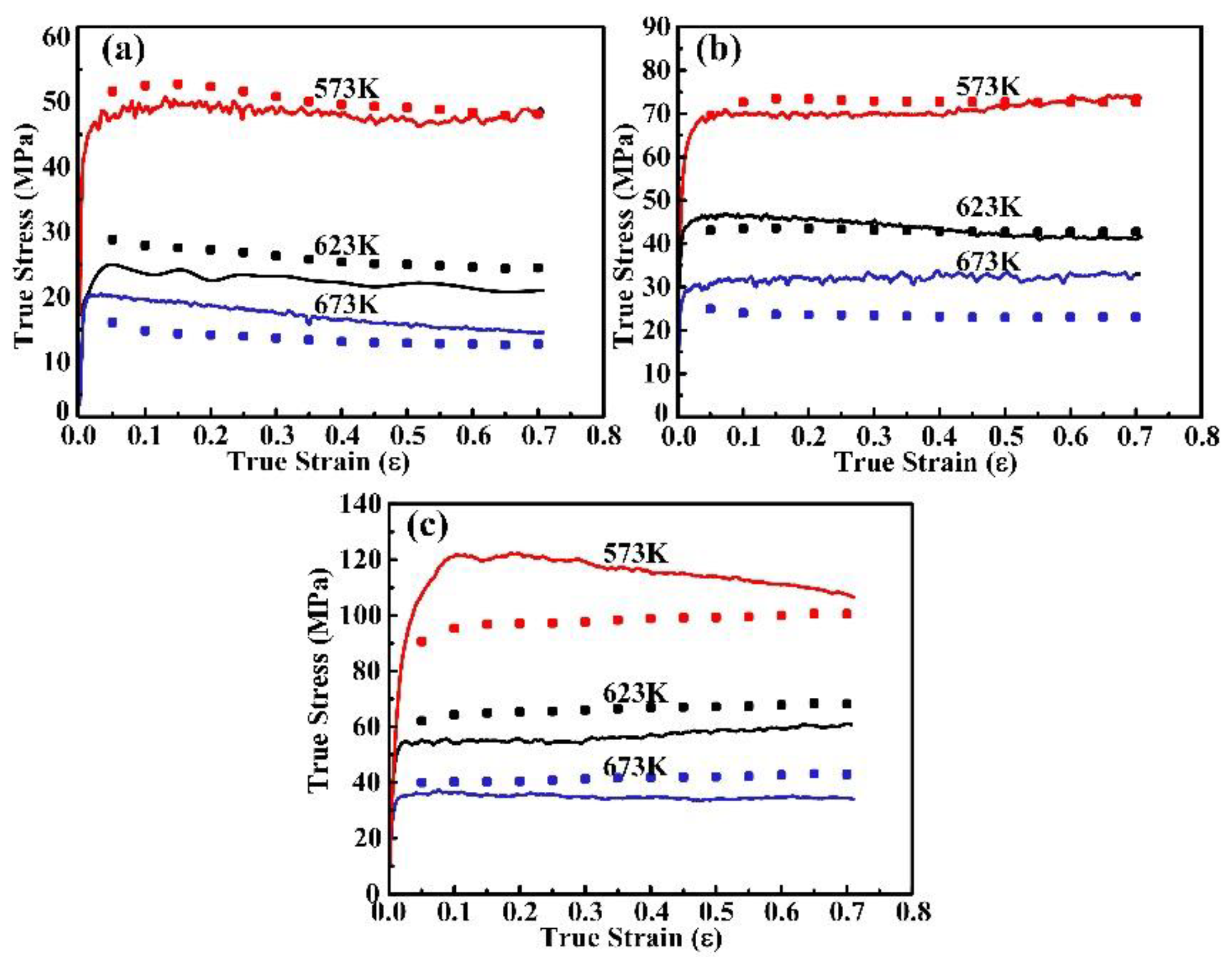

3.1. Flow Stress Behavior

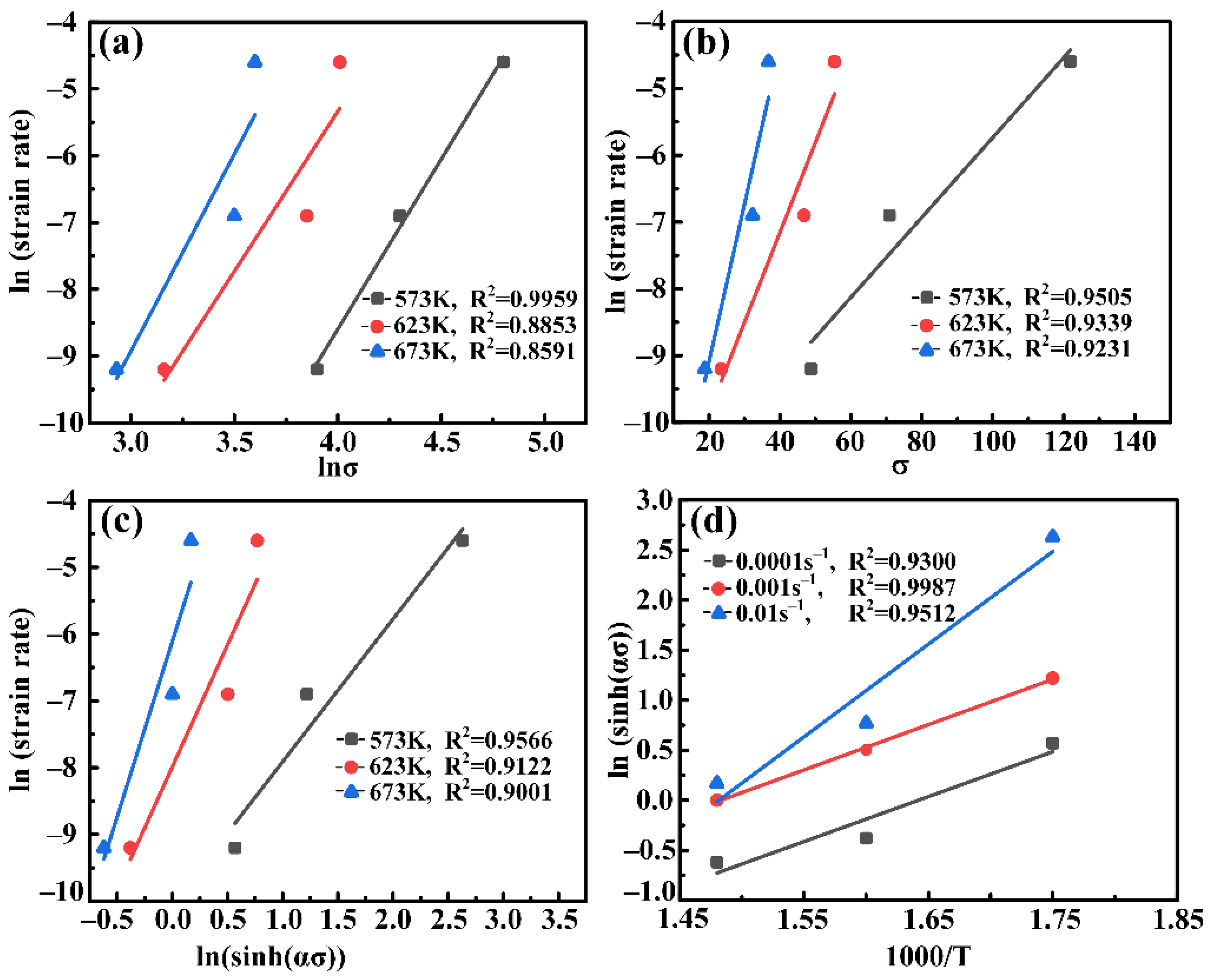

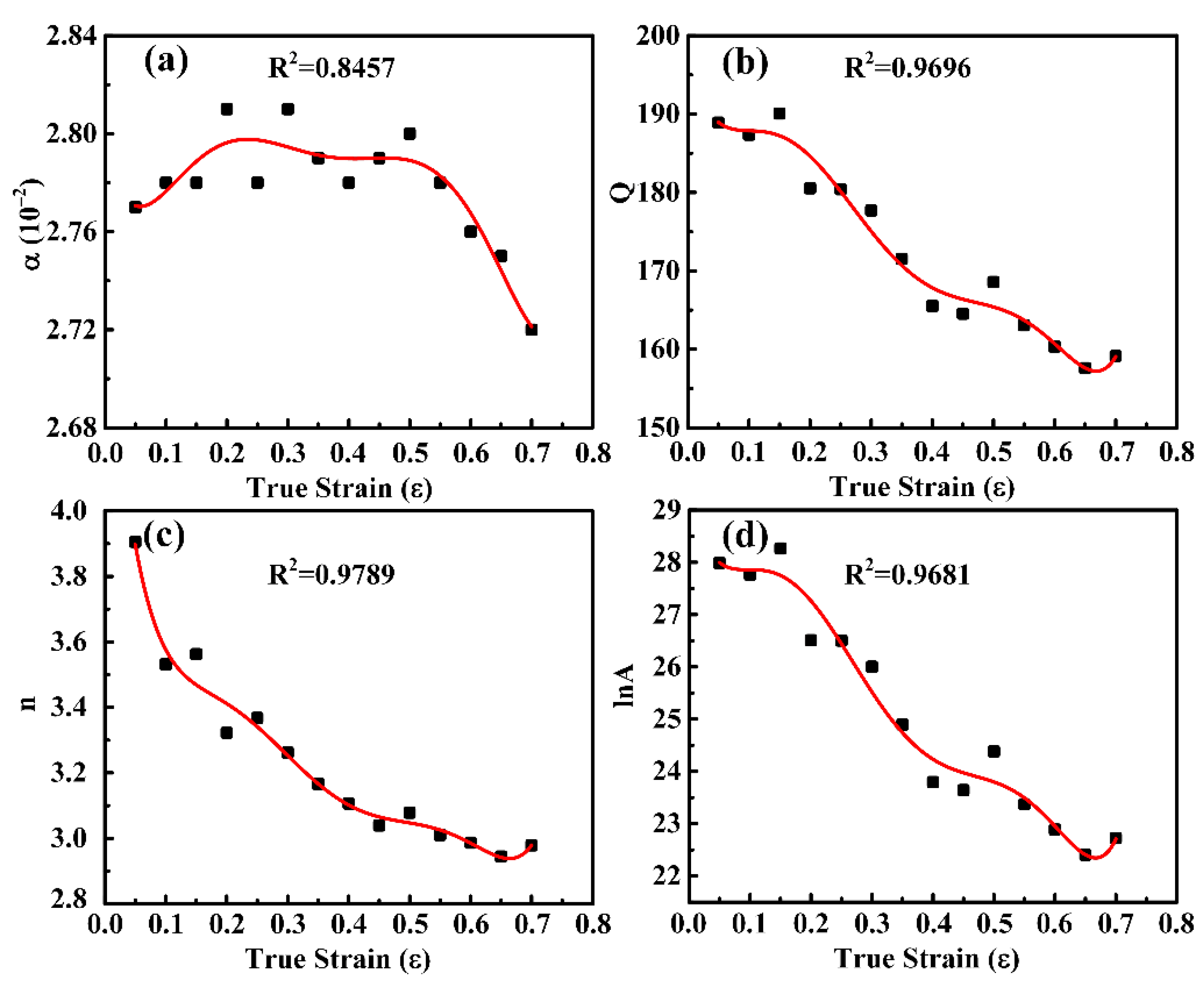

3.2. Constitutive Analysis Based on Arrhenius Equation

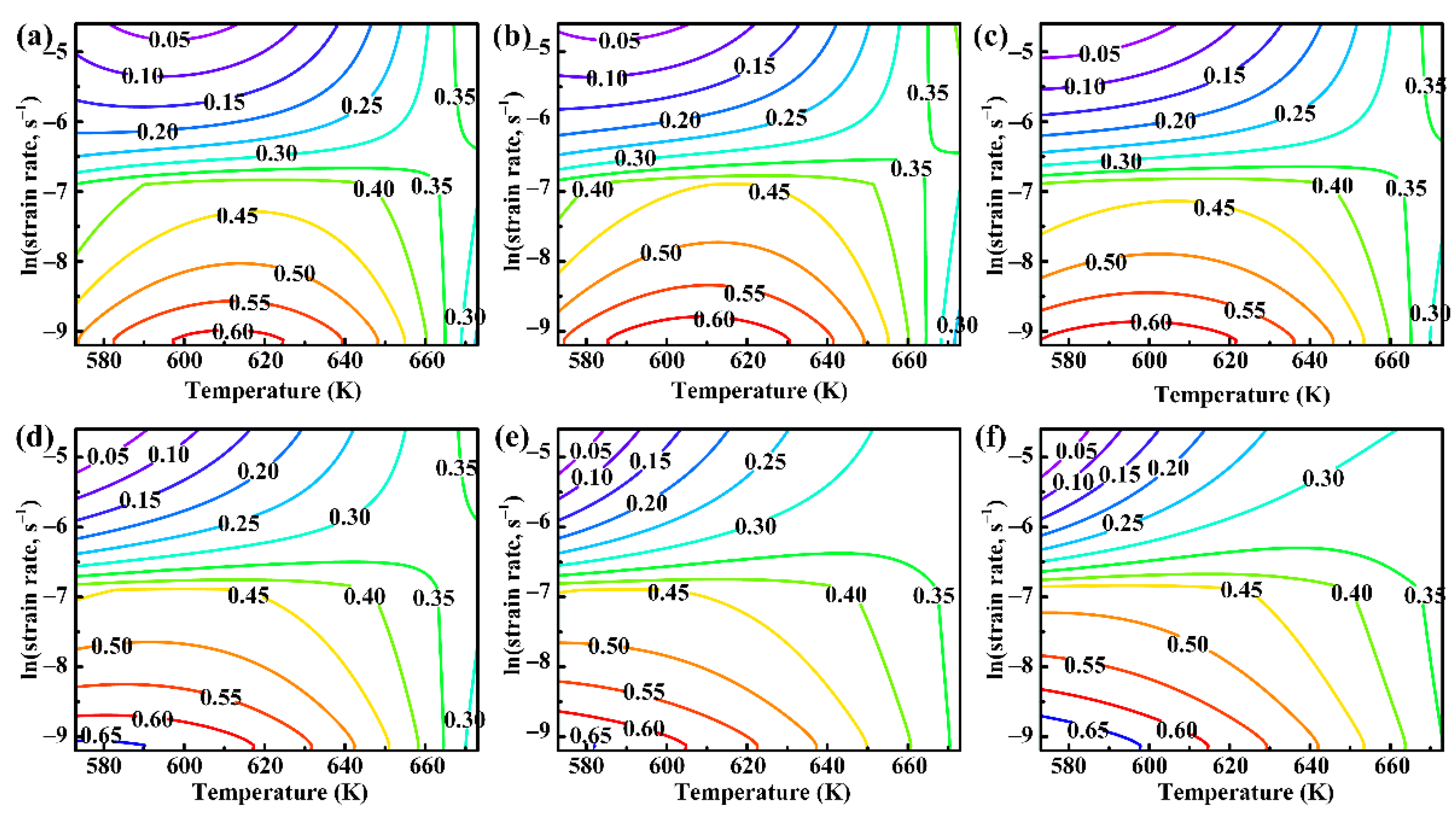

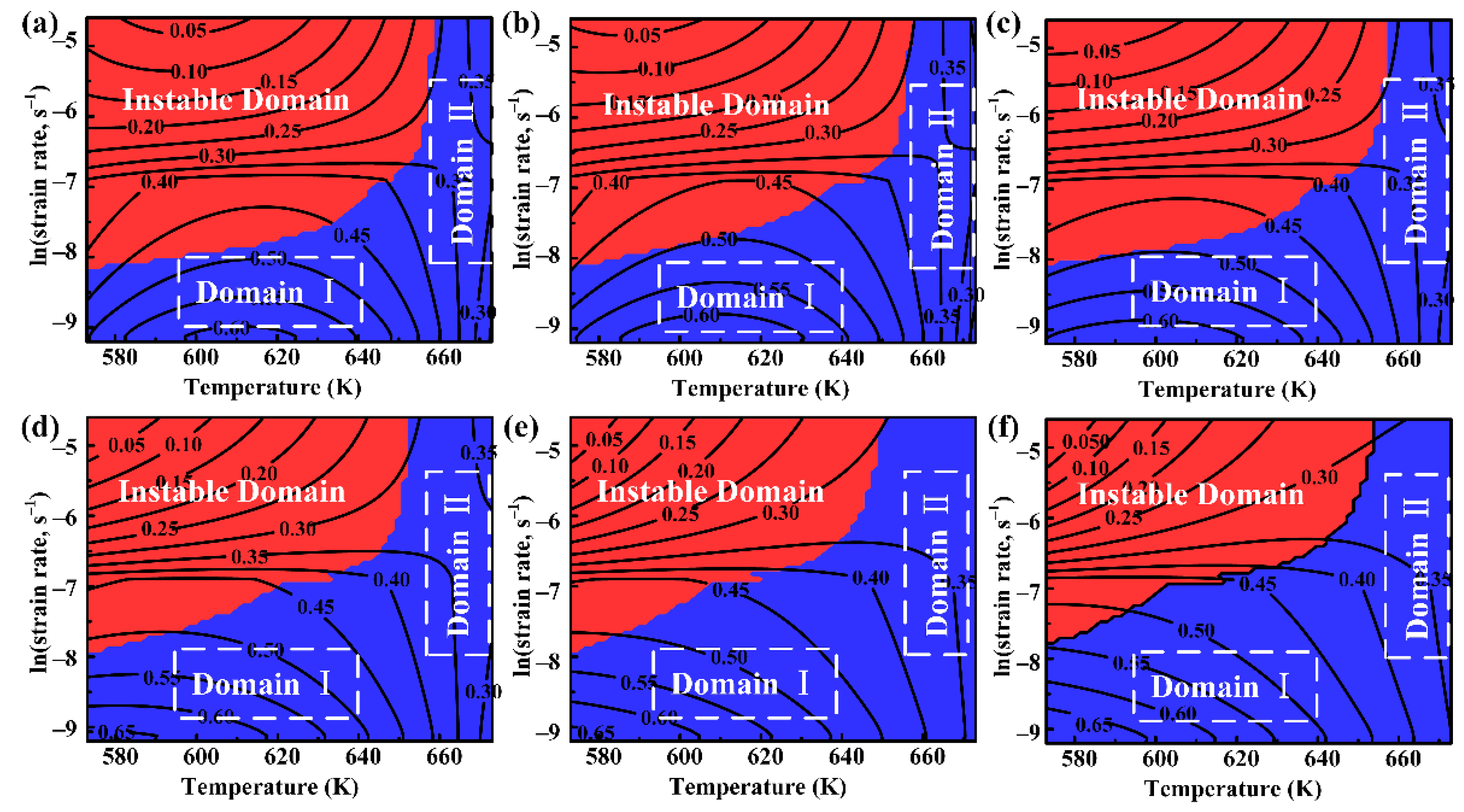

3.3. Processing Maps

4. Conclusions

- During isothermal compression, the flow stress of the alloy increases significantly with the increasing strain rate and the declining temperature.

- The Arrhenius constitutive equation of the studied material can be described as . Strain compensation is considered to introduce the effect of plastic strain on material parameters. The calculated flow stresses at various deformation conditions are generally consistent with the experimental results.

- The dissipation maps and processing maps of as-extruded Mg–6Zn–5Ca–3Ce alloy fabricated by RS in the temperature range of 573–673 K and the strain rate range of 0.0001–0.01 s−1 were constructed. The preferential processing domains can be identified, which lie in the domain Ⅰ (T = 590–640 K, = 0.0001–0.0003 s−1) and domain Ⅱ (T = 650–670 K, = 0.0003–0.004 s−1).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, J.J.; Mao, Y.; Fu, Y.J.; Jiang, B.; Xiong, K.; Zhang, S.M.; Pan, F.S. Improving the room-temperature formability of Mg-3Al-1Zn alloy sheet by introducing an orthogonal four-peak texture. J. Alloys Compd. 2019, 797, 443–455. [Google Scholar] [CrossRef]

- Li, K.; Chen, Z.Y.; Chen, T.; Shao, J.B.; Wang, R.K.; Liu, C.M. Hot deformation and dynamic recrystallization behaviors of Mg-Gd-Zn alloy with LPSO phases. J. Alloys Compd. 2019, 792, 894–906. [Google Scholar] [CrossRef]

- Shao, J.B.; Chen, Z.Y.; Chen, T.; Wang, R.K.; Liu, Y.L.; Liu, C.M. Texture evolution, deformation mechanism and mechanical properties of the hot rolled Mg-Gd-Y-Zn-Zr alloy containing LPSO phase. Mater. Sci. Eng. A 2018, 731, 479–486. [Google Scholar] [CrossRef]

- Zhou, T.; Chen, D.; Chen, Z.H.; Chen, J.H. Investigation on microstructures and properties of rapidly solidified Mg–6wt.% Zn–5wt.% Ca–3wt.% Ce alloy. J. Alloys Compd. 2009, 475, L1–L4. [Google Scholar] [CrossRef]

- Yin, P.; Li, N.F.; Lei, T.; Liu, L.; Ouyang, C. Effects of Ca on microstructure, mechanical and corrosion properties and biocompatibility of Mg–Zn–Ca alloys. J. Mater. Sci. Mater. M 2013, 24, 1365–1373. [Google Scholar] [CrossRef]

- Du, Y.Z.; Zheng, M.Y.; Qiao, X.G.; Wu, K.; Liu, X.D.; Wang, G.J.; Lv, X.Y. Microstructure and mechanical properties of Mg–Zn–Ca–Ce alloy processed by semi-continuous casting. Mater. Sci. Eng. A 2013, 582, 134–139. [Google Scholar] [CrossRef]

- Du, Y.Z.; Liu, D.J.; Ge, Y.F. Effects of Ce addition on mechanical and corrosion properties of the as-extruded Mg-Zn-Ca Alloy. J. Mater. Eng. Perform. 2020, 30, 488–496. [Google Scholar] [CrossRef]

- Zhou, T.; Yang, M.B.; Zhou, Z.M.; Hu, J.J.; Chen, Z.H. Microstructure and mechanical properties of rapidly solidified/powder metallurgy Mg–6Zn and Mg–6Zn–5Ca at room and elevated temperatures. J. Alloys Compd. 2013, 560, 161–166. [Google Scholar] [CrossRef]

- You, J.; Huang, Y.J.; Liu, C.M.; Zhan, H.Y.; Huang, L.X.; Zeng, G. Microstructural study of a Mg–Zn–Zr alloy hot compressed at a high strain rate. Materials 2020, 13, 2348. [Google Scholar] [CrossRef]

- Kang, Q.; Jiang, H.T.; Kuai, Z.; Zhang, Y.; Wang, Y.J.; Cai, Z.X. Optimization of the hot compression constitutive equation and processing map of Mg–4Zn–0.8Ca (wt%) alloy. Mater. Res. Express 2019, 6, 086526–086543. [Google Scholar] [CrossRef]

- Papillon, J.; Salero, P.; Mercier, F.; Fabrègue, D.; Maire, É. Compressive deformation behavior of dendritic Mg–Ca(–Zn) alloys at high temperature. Mater. Sci. Eng. A 2019, 763, 138180–138187. [Google Scholar] [CrossRef]

- Zhang, Z.M.; Yan, Z.M.; Du, Y.; Zhang, G.S.; Zhu, J.X.; Ren, L.Y.; Wang, Y.D. Hot deformation behavior of homogenized Mg-13.5Gd-3.2Y-2.3Zn-0.5Zr alloy via hot compression tests. Materials 2018, 11, 2282. [Google Scholar] [CrossRef]

- Koike, J.; Ohyama, R.; Kobayashi, T.; Suzuki, M.; Maruyama, K. Grain-boundary sliding in AZ31 magnesium alloys at room temperature to 523K. Mater. Trans. 2003, 44, 445–451. [Google Scholar] [CrossRef]

- Zhang, H.X.; Chen, S.F.; Cheng, M.; Zheng, C.; Zhang, S.H. Modeling the dynamic recrystallization of Mg–11Gd–4Y–2Zn–0.4Zr alloy considering non-uniform deformation and LPSO kinking during hot compression. Acta Metall. Sin. Engl. Lett. 2019, 32, 1122–1134. [Google Scholar] [CrossRef]

- Alizadeh, R.; Mahmudi, R.; Ruano, O.A.; Ngan, A.H.W. Constitutive analysis and hot deformation behavior of fine-grained Mg-Gd-Y-Zr alloys. Metall. Mater. Trans. A 2017, 48, 5699–5709. [Google Scholar] [CrossRef]

- Li, B.; Teng, B.G.; Xu, W.C. Hot deformation characterization of homogenized Mg-Gd-Y-Zn-Zr alloy during isothermal compression. JOM 2019, 71, 4059–4070. [Google Scholar] [CrossRef]

- Liu, H.N.; Li, Y.J.; Zhang, K.; Li, X.G.; Ma, M.L.; Shi, G.L.; Yuan, J.W.; Wang, K.K. Microstructure, hot deformation behavior, and textural evolution of Mg–3wt%Zn–1wt%Ca–0.5wt%Sr Alloy. J. Mater. Sci. 2020, 55, 12434–12447. [Google Scholar] [CrossRef]

- Lei, G.; Luo, A.A. Hot deformation behavior of as-cast Mg–Zn–Mn–Ce alloy in compression. Mater. Sci. Eng. A 2013, 560, 492–499. [Google Scholar]

- Ma, Z.W.; Hu, F.Y.; Wang, Z.J.; Fu, K.J.; Wei, Z.X.; Wang, J.J.; Li, W.J. Constitutive equation and hot processing map of Mg-16Al magnesium alloy bars. Materials 2020, 13, 3107. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.H.; Li, S.P.; Ma, H.B. Evolution of microstructure, texture, and mechanical properties of as-extruded ND/ZK60 composite during hot compression deformation. Metals 2020, 10, 1191. [Google Scholar] [CrossRef]

- Li, M.A.; Xiao, S.L.; Xu, L.J.; Chen, Y.Y.; Tian, J.; Zhang, B.Y. Mechanical properties, deformation behavior and microstructure evolution of Ti-43Al-6Nb-1Mo-1Cr alloys. Mater. Charact. 2017, 136, 69–83. [Google Scholar] [CrossRef]

- Zhou, T.; Song, D.H.; Chen, Z.H. Microstructures, Mechanical and creep properties of rapidly solidification/powder metallurgy Mg-6wt.%Zn alloys with 5wt.%Ce and 1.5wt.%Ca additions. Mater. Sci. Forum 2016, 861, 253–263. [Google Scholar] [CrossRef]

- Shao, Z.W.; Zhu, X.R.; Wang, R.; Wang, J.; Xu, Y.D.; Zhao, B.R.; Ling, G.P. Hot deformation and processing map of as-homogenized Mg–9Gd–3Y–2Zn–0.5Zr alloy. Mater. Des. 2013, 51, 826–832. [Google Scholar] [CrossRef]

- Xu, C.; Pan, J.P.; Nakata, T.; Qiao, X.G.; Chi, Y.Q.; Zheng, M.Y.; Kamado, S. Hot compression deformation behavior of Mg-9Gd-2.9Y-1.9Zn-0.4Zr-0.2Ca (wt%) alloy. Mater. Charact. 2017, 124, 40–49. [Google Scholar] [CrossRef]

- Xue, Y.; Zhang, Z.M.; Lu, G.; Xie, Z.P.; Yang, Y.B.; Cui, Y. Study on flow stress model and processing map of homogenized Mg-Gd-Y-Zn-Zr alloy during thermomechanical processes. J. Mater. Eng. Perform. 2014, 24, 964–971. [Google Scholar] [CrossRef]

- Zhang, C.S.; Ding, J.; Dong, Y.Y.; Zhao, G.Q.; Gao, A.J.; Wang, L.J. Identification of friction coefficients and strain-compensated Arrhenius-type constitutive model by a two-stage inverse analysis technique. Int. J. Mech. Sci. 2015, 98, 195–204. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, Q.D.; Ye, B.; Guo, W. Hot deformation and processing maps of as-extruded Mg–9.8Gd–2.7Y–0.4Zr Mg alloy. Mater. Sci. Eng. A 2013, 576, 101–107. [Google Scholar] [CrossRef]

- Chen, B.; Zhou, W.M.; Li, S.; Li, X.L.; Lu, C. Hot compression deformation behavior and processing maps of Mg-Gd-Y-Zr alloy. J. Mater. Eng. Perform. 2013, 22, 2458–2466. [Google Scholar] [CrossRef]

- Zheng, H.R.; Yu, L.T.; Lyu, S.Y.; You, C.; Chen, M.F. Insight into the role and mechanism of nano MgO on the hot compressive deformation behavior of Mg-Zn-Ca alloys. Metals 2020, 10, 1357. [Google Scholar] [CrossRef]

- Lin, Y.C.; Xia, Y.C.; Chen, X.M.; Chen, M.S. Constitutive descriptions for hot compressed 2124-T851 aluminum alloy over a wide range of temperature and strain rate. Comput. Mater. Sci. 2010, 50, 227–233. [Google Scholar] [CrossRef]

- Wang, Y.J.; Peng, J.; Zhong, L.P.; Pan, F.S. Modeling and application of constitutive model considering the compensation of strain during hot deformation. J. Alloys Compd. 2016, 681, 455–470. [Google Scholar] [CrossRef]

- Xu, W.C.; Jin, X.Z.; Shan, D.B.; Chai, B.X. Study on the effect of solution treatment on hot deformation behavior and workability of Mg-7Gd-5Y-0.6Zn-0.8Zr magnesium alloy. J. Alloys Compd. 2017, 720, 309–323. [Google Scholar] [CrossRef]

- Murty, S.V.S.N.; Rao, B.N. Instability map for hot working of 6061 Al-10 vol% metal matrix composite. J. Phys. D Appl. Phys. 1998, 31, 3306–3311. [Google Scholar] [CrossRef]

- Murty, S.V.S.N.; Rao, B.N. On the development of instability criteria during hot working with reference to IN 718. Mater. Sci. Eng. A 1998, 254, 76–82. [Google Scholar] [CrossRef]

- Xia, X.S.; Chen, Q.; Li, J.P.; Shu, D.Y.; Hu, C.K.; Huang, S.H.; Zhao, Z.D. Characterization of hot deformation behavior of as-extruded Mg–Gd–Y–Zn–Zr alloy. J. Alloys Compd. 2014, 610, 203–211. [Google Scholar] [CrossRef]

- Ullmann, M.; Kittner, K.; Prahl, U. Hot deformation and dynamic recrystallisation behaviour of twin-roll cast Mg-6.8Y-2.5Zn-0.4Zr magnesium alloy. Materials 2021, 14, 307. [Google Scholar] [CrossRef] [PubMed]

| Alloy | Zn (wt%) | Ca (wt%) | Ce (wt%) | Mg |

|---|---|---|---|---|

| Mg–6Zn–5Ca–3Ce | 6 | 5 | 3 | Balance |

| Strain rate(s−1) | |

| Strain | |

| Q | Activation energy (kJ/mol) |

| R | the universal gas constant (8.314 J/(mol*K)) |

| σ | Flow stress (MPa) |

| A | Temperature-independent constant |

| α | Stress level parameter |

| β | Hyperbolic sine exponent |

| n | Stress exponent |

| Z | Zener-Holloman parameter |

| η | Power dissipation coefficient |

| P | Total power |

| G | Consumption of plastic deformation |

| J | Consumption of microstructural evolution |

| m | Strain rate sensitivity index |

| TEM | Transmission electron microscopy |

| DRX | Dynamic recrystallization |

| DRV | Dynamic recovery |

| DDRX | Discontinuous dynamic recrystallization |

| Material Constant | ||||

|---|---|---|---|---|

| 0.05 | 0.0277 | 188,910 | 3.9056 | 27.9870 |

| 0.1 | 0.0278 | 187,360 | 3.5316 | 27.7654 |

| 0.15 | 0.0278 | 190,060 | 3.5626 | 28.2665 |

| 0.2 | 0.0281 | 180,540 | 3.3224 | 26.5097 |

| 0.25 | 0.0278 | 180,420 | 3.3674 | 26.5022 |

| 0.3 | 0.0281 | 177,710 | 3.2620 | 26.0034 |

| 0.35 | 0.0279 | 171,520 | 3.1663 | 24.8966 |

| 0.4 | 0.0278 | 165,520 | 3.1060 | 23.7974 |

| 0.45 | 0.0279 | 164,540 | 3.0390 | 23.6428 |

| 0.5 | 0.0280 | 168,580 | 3.0782 | 24.3824 |

| 0.55 | 0.0278 | 163,070 | 3.0099 | 23.3730 |

| 0.6 | 0.0276 | 160,340 | 2.9864 | 22.8882 |

| 0.65 | 0.0275 | 157,600 | 2.9442 | 22.4021 |

| 0.7 | 0.0272 | 159,140 | 2.9786 | 22.7239 |

| Material | Mg–6Zn–5Ca–3Ce |

|---|---|

| constant | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, C.; Zhou, T.; Shi, L.; Li, M.; Hu, L.; Yang, M.; Chen, Q. Hot Deformation Behavior and Constitutive Analysis of As-Extruded Mg–6Zn–5Ca–3Ce Alloy Fabricated by Rapid Solidification. Metals 2021, 11, 480. https://doi.org/10.3390/met11030480

Bao C, Zhou T, Shi L, Li M, Hu L, Yang M, Chen Q. Hot Deformation Behavior and Constitutive Analysis of As-Extruded Mg–6Zn–5Ca–3Ce Alloy Fabricated by Rapid Solidification. Metals. 2021; 11(3):480. https://doi.org/10.3390/met11030480

Chicago/Turabian StyleBao, Chengli, Tao Zhou, Laixin Shi, Mingao Li, Li Hu, Mingbo Yang, and Qiang Chen. 2021. "Hot Deformation Behavior and Constitutive Analysis of As-Extruded Mg–6Zn–5Ca–3Ce Alloy Fabricated by Rapid Solidification" Metals 11, no. 3: 480. https://doi.org/10.3390/met11030480

APA StyleBao, C., Zhou, T., Shi, L., Li, M., Hu, L., Yang, M., & Chen, Q. (2021). Hot Deformation Behavior and Constitutive Analysis of As-Extruded Mg–6Zn–5Ca–3Ce Alloy Fabricated by Rapid Solidification. Metals, 11(3), 480. https://doi.org/10.3390/met11030480