Evolution of the Microstructure and Mechanical Properties of a Ti35Nb2Sn Alloy Post-Processed by Hot Isostatic Pressing for Biomedical Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Processing Conditions

2.2. Characterization

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kuroda, D.; Niinomi, M.; Morinaga, M.; Kato, Y.; Yashiro, T. Design and mechanical properties of new β type titanium alloys for implant materials. Mater. Sci. Eng. A 1998, 243, 244–249. [Google Scholar] [CrossRef]

- Long, M.; Rack, H.J. Titanium alloys in total joint replacement—A materials science perspective. Biomaterials 1998, 19, 1621–1639. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2008, 1, 30–42. [Google Scholar] [CrossRef]

- Miura, K.; Yamada, N.; Hanada, S.; Jung, T.K.; Itoi, E. The bone tissue compatibility of a new Ti-Nb-Sn alloy with a low Young’s modulus. Acta Biomater. 2011, 7, 2320–2326. [Google Scholar] [CrossRef]

- Bjursten, L.M.; Rasmusson, L.; Oh, S.; Smith, G.C.; Brammer, K.S.; Jin, S. Titanium dioxide nanotubes enhance bone bonding in vivo. J. Biomed. Mater. Res. Part A 2010, 92, 1218–1224. [Google Scholar] [CrossRef]

- de Mello, M.G.; Dainese, B.P.; Caram, R.; Cremasco, A. Influence of heating rate and aging temperature on omega and alpha phase precipitation in Ti–35Nb alloy. Mater. Charact. 2018, 145, 268–276. [Google Scholar] [CrossRef]

- Málek, J.; Hnilica, F.; Veselý, J.; Smola, B. Heat treatment and mechanical properties of powder metallurgy processed Ti-35.5Nb-5.7Ta beta-titanium alloy. Mater. Charact. 2013, 84, 225–231. [Google Scholar] [CrossRef]

- Cui, C.; Hu, B.M.; Zhao, L.; Liu, S. Titanium alloy production technology, market prospects and industry development. Mater. Des. 2011, 32, 1684–1691. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys. Fundamentals and Applications; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003; ISBN 3-527-30534-3. [Google Scholar]

- Li, Y.; Yang, C.; Zhao, H.; Qu, S.; Li, X.; Li, Y. New Developments of Ti-Based Alloys for Biomedical Applications. Materials 2014, 7, 1709–1800. [Google Scholar] [CrossRef]

- Duan, W.; Yin, Y.; Zhou, J.; Wang, M.; Nan, H.; Zhang, P. Dynamic research on Ti6Al4V powder HIP densification process based on intermittent experiments. J. Alloy. Compd. 2019, 771, 489–497. [Google Scholar] [CrossRef]

- Cao, L.; Wu, X.; Zhu, S.; Mei, J.; Wu, X.; Bettles, C. The effect of HIPping pressure on phase transformations in Ti-5Al-5Mo-5V-3Cr. Mater. Sci. Eng. A 2014, 598, 207–216. [Google Scholar] [CrossRef]

- Dekhtyar, A.I.; Bondarchuk, V.I.; Nevdacha, V.V.; Kotko, A.V. The effect of microstructure on porosity healing mechanism of powder near-β titanium alloys under hot isostatic pressing in α + β-region: Ti-10V-2Fe-3Al. Mater. Charact. 2020, 165, 110393. [Google Scholar] [CrossRef]

- Atkinson, H.V.; Davies, S. Fundamental aspects of hot isostatic pressing: An overview. Metall. Mater. Sci. 2000, 31, 2981–3000. [Google Scholar] [CrossRef]

- Bolzoni, L.; Ruiz-Navas, E.M.; Zhang, D.; Gordo, E. Modification of sintered titanium alloys by hot isostatic pressing. Key Eng. Mater. 2012, 520, 63–69. [Google Scholar] [CrossRef]

- Molaei, R.; Fatemi, A.; Phan, N. Significance of hot isostatic pressing (HIP) on multiaxial deformation and fatigue behaviors of additive manufactured Ti-6Al-4V including build orientation and surface roughness effects. Int. J. Fatigue 2018, 117, 352–370. [Google Scholar] [CrossRef]

- Lopez, M.; Pickett, C.; Arrieta, E.; Murr, L.E.; Wicker, R.B.; Ahlfors, M.; Godfrey, D.; Medina, F. Effects of postprocess hot isostatic pressing treatments on the mechanical performance of EBM fabricated TI-6Al-2Sn-4Zr-2Mo. Materials 2020, 13, 2604. [Google Scholar] [CrossRef] [PubMed]

- Samarov, V.; Seliverstov, D.; Froes, F.H. Fabrication of near-net-shape cost-effective titanium components by use of prealloyed powders and hot isostatic pressing. In Titanium Powder Metallurgy: Science, Technology and Applications; Elsevier Inc.: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Yudin, S.N.; Kasimtsev, A.V.; Tabachkova, N.Y.; Sviridova, T.A.; Markova, G.V.; Volod’Ko, S.S.; Alimov, I.A.; Alpatov, A.V.; Titov, D.D. Features of β-Phase Decay in Ti–22Nb–6Zr Alloy. Inorg. Mater. Appl. Res. 2019, 10, 1115–1122. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Dyakonov, G.S.; Salem, A.A.; Malysheva, S.P.; Salishchev, G.A.; Semiatin, S.L. Evolution of grain and subgrain structure during cold rolling of commercial-purity titanium. Mater. Sci. Eng. A 2011, 528, 3474–3479. [Google Scholar] [CrossRef]

- Tan, L.; He, G.; Liu, F.; Li, Y.; Jiang, L. Effects of temperature and pressure of hot isostatic pressing on the grain structure of powder metallurgy superalloy. Materials 2018, 11, 328. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhou, Y.; Ebel, T.; Liu, L.; Shen, X.; Yu, P. The influence of heat treatment processing on microstructure and mechanical properties of Ti–24Nb–4Zr–8Sn alloy by powder metallurgy. Materialia 2020, 13, 100803. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, B.; Wang, Y.; Topping, T.; Zhou, Y.; Valiev, R.Z.; Shan, A.; Lavernia, E.J. Ultrafine-grained Ti-Nb-Ta-Zr alloy produced by ECAP at room temperature. J. Mater. Sci. 2014, 49, 6656–6666. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Semenova, I.P.; Latysh, V.V.; Rack, H.; Lowe, T.C.; Petruzelka, J.; Dluhos, L.; Hrusak, D.; Sochova, J. Nanostructured titanium for biomedical applications. Adv. Eng. Mater. 2008, 10, 8–11. [Google Scholar] [CrossRef]

- Langdon, T.G. Processing of ultrafine-grained materials using severe plastic deformation: Potential for achieving exceptional properties. Rev. Metal. (Madr.) 2008, 44, 556–564. [Google Scholar] [CrossRef][Green Version]

- Amigó-Borrás, V.; Lario-Femenía, J.; Amigó-Mata, A.; Vicente-Escuder, Á. Titanium, Titanium Alloys and Composites. Ref. Modul. Mater. Sci. Mater. Eng. 2020, 1. [Google Scholar] [CrossRef]

- Ahlfors, M.; Hjärne, J.; Shipley, J. Cost effective Hot Isostatic Pressing. A cost calculation study for AM parts. Quintus Technol. 2018, 12, 1–6. [Google Scholar]

- Torralba, J.M.; Campos, M. Toward high performance in Powder Metallurgy. Rev. Metal. 2014, 50. [Google Scholar] [CrossRef]

- Lario-Femenía, J.; Amigó-mata, A.; Vicente-escuder, Á.; Segovia-lópez, F. Desarrollo de las aleaciones de titanio y tratamientos superficiales para incrementar la vida útil de los implantes. Rev. Metal. 2016, 52, 1–13. [Google Scholar] [CrossRef]

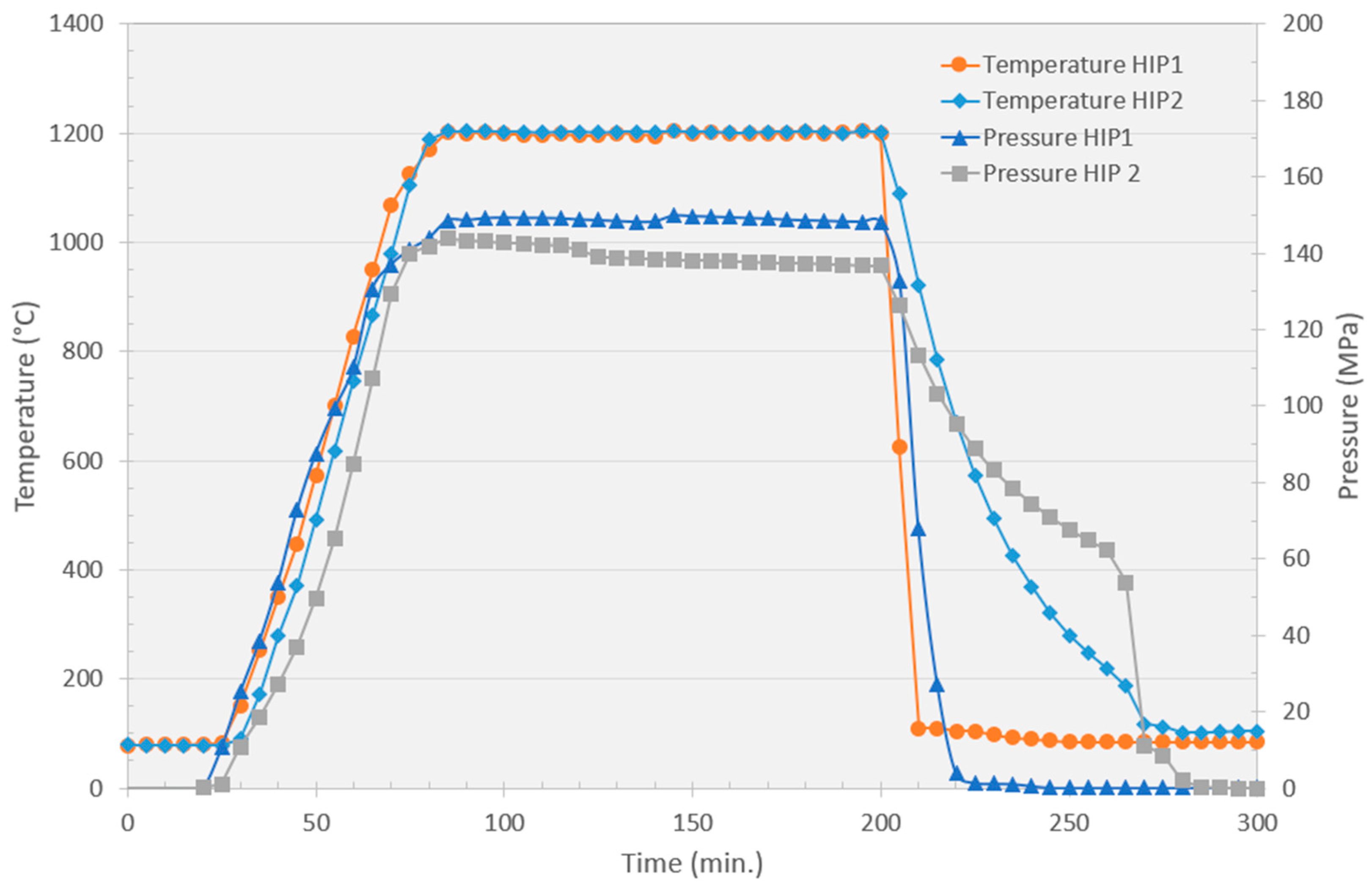

| Processing Route | Pressure (MPa) | Maximum Temperature (°C) | Time (minutes) | Cooling Rate (°C/min) |

|---|---|---|---|---|

| Vacuum Sintering | N/A | 1350 | 180 | 15 |

| HIP 1 (Fast cooling) | 150 | 1200 | 120 | 500 |

| HIP 2 (Slow cooling) | 150 | 1200 | 120 | 100 |

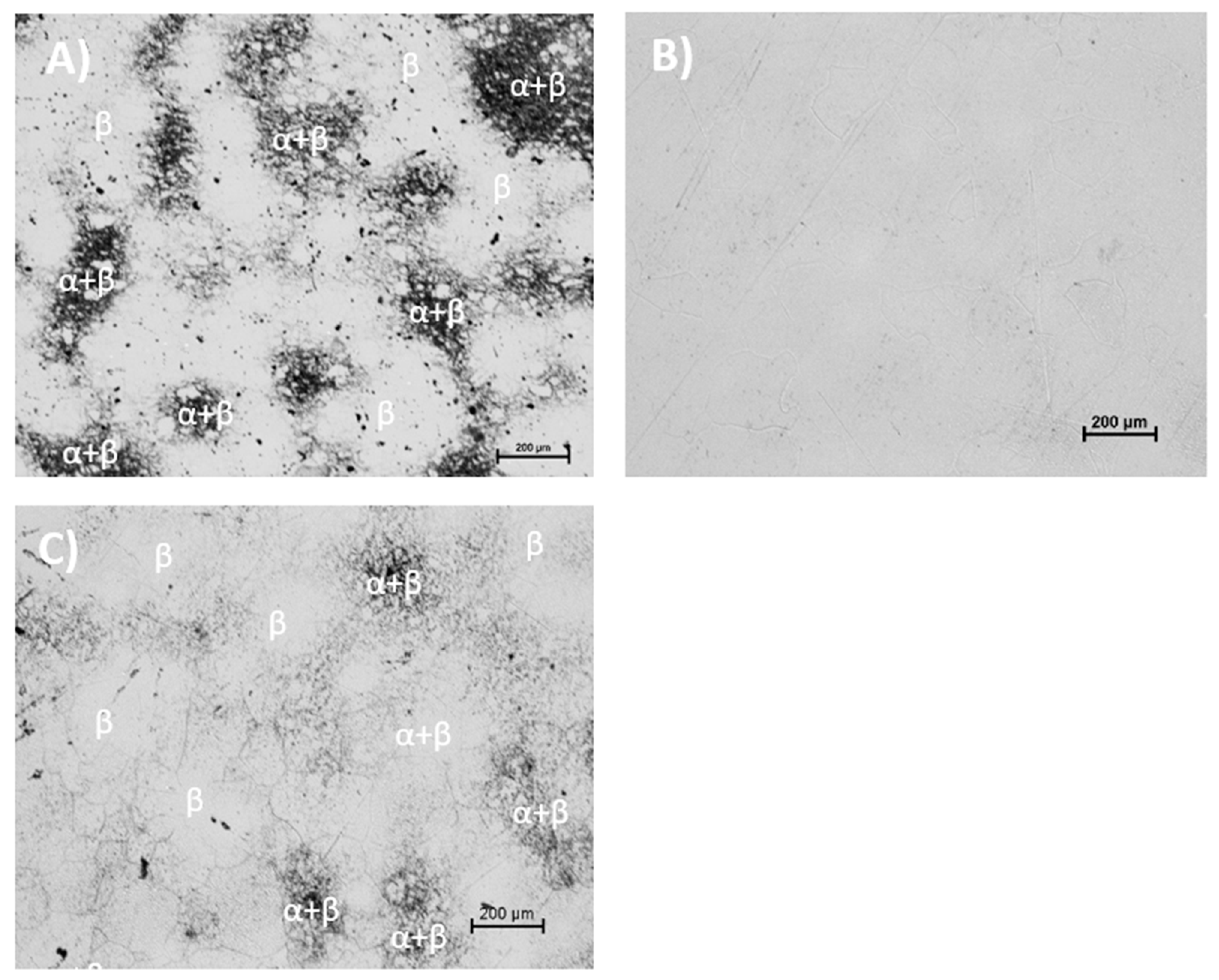

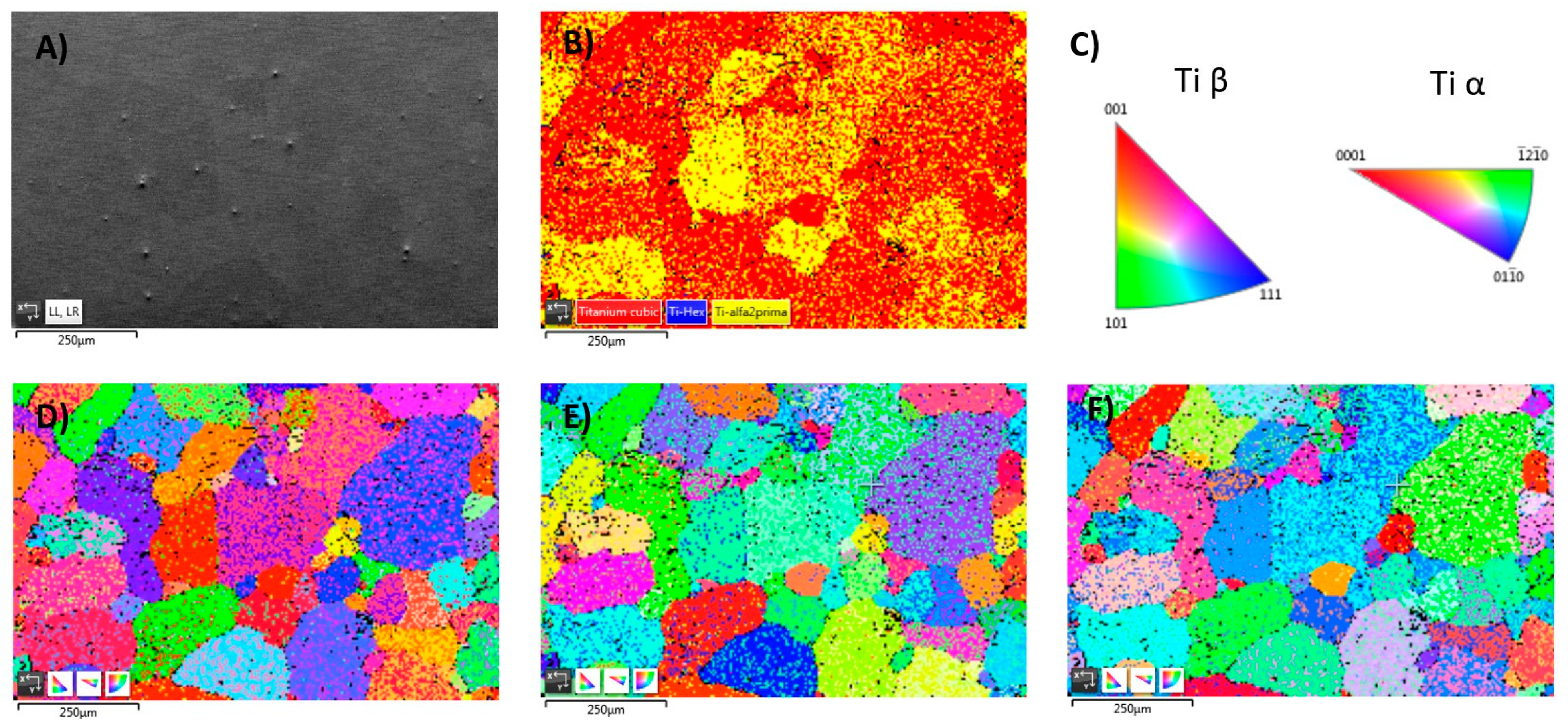

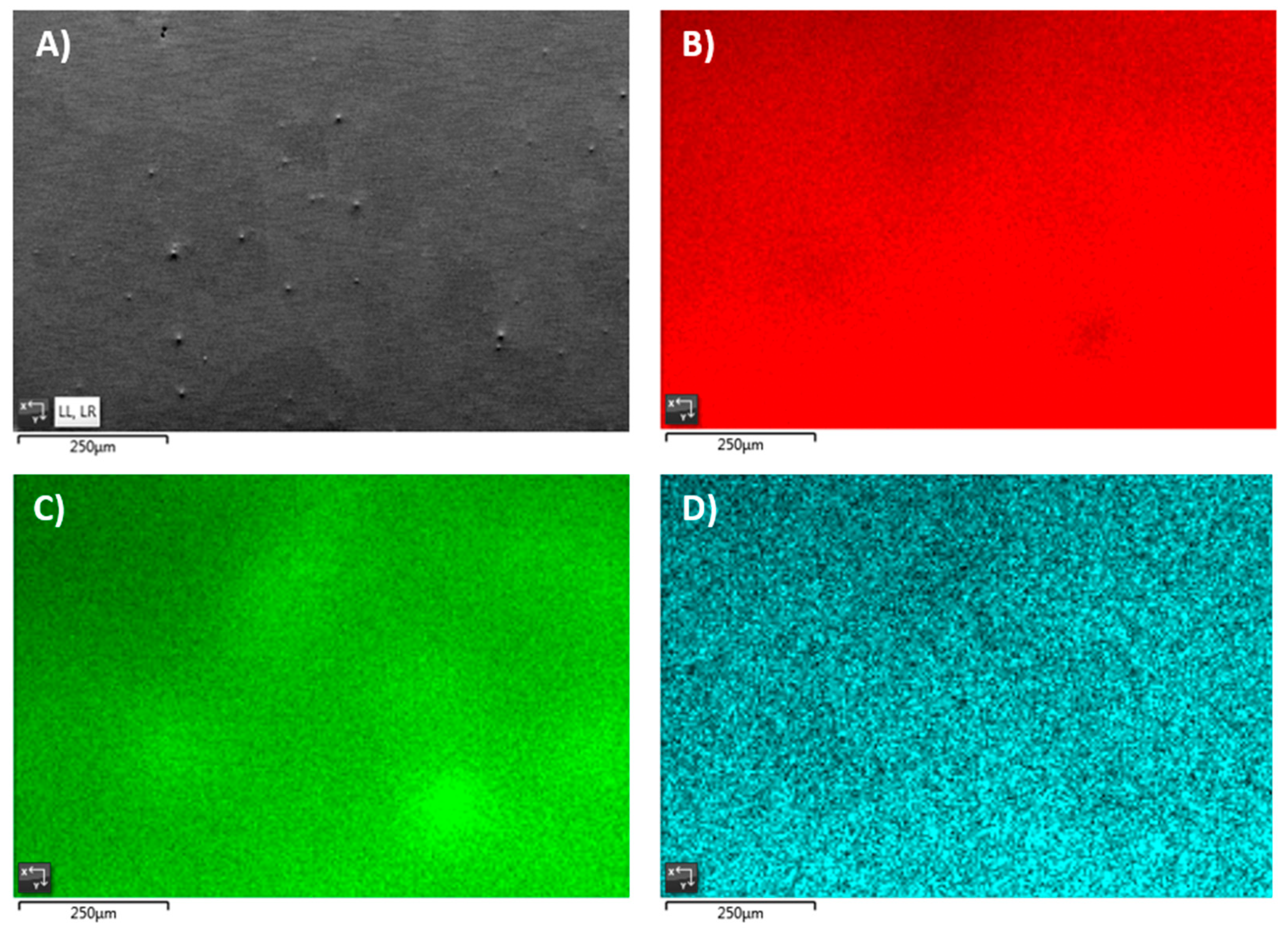

| Processing Route | Green Density (%) | Relative Density (%) | β Phase (%) | α + β Phase (%) | Grain Size (μm) |

|---|---|---|---|---|---|

| Vacuum Sintering | 80.2 ± 0.5 | 94.9 ± 0.1 | 38.4 | 56.5 | 19.1 ± 11.3 |

| HIP 1 (Fast cooling) | 100.1 ± 0.2 | 95.5 | 3.7 | 57.2 ± 32.3 | |

| HIP 2 (Slow cooling) | 100.2 ± 0.1 | 78.9 | 20.8 | 55.2 ± 33.5 |

| Processing Route | UTS (MPa) | ε (%) | E (GPa) | G (GPa) | Poisson’s Ratio |

|---|---|---|---|---|---|

| Vacuum Sintering | 993 ± 82 | 3.44 ± 0.36 | 70.49 ± 1.09 | 25.62 ± 0.39 | 0.38 ± 0.04 |

| HIP 1 (Fast cooling) | 997 ± 63 | 3.31 ± 0.23 | 71.23 ± 2.04 | 24.62 ± 0.85 | 0.45 ± 0.06 |

| HIP 2 (Slow cooling) | 702 ± 80 | 2.65 ± 0.12 | 72.29 ± 1.04 | 23.77 ± 1.73 | 0.53 ± 0.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lario, J.; Vicente, Á.; Amigó, V. Evolution of the Microstructure and Mechanical Properties of a Ti35Nb2Sn Alloy Post-Processed by Hot Isostatic Pressing for Biomedical Applications. Metals 2021, 11, 1027. https://doi.org/10.3390/met11071027

Lario J, Vicente Á, Amigó V. Evolution of the Microstructure and Mechanical Properties of a Ti35Nb2Sn Alloy Post-Processed by Hot Isostatic Pressing for Biomedical Applications. Metals. 2021; 11(7):1027. https://doi.org/10.3390/met11071027

Chicago/Turabian StyleLario, Joan, Ángel Vicente, and Vicente Amigó. 2021. "Evolution of the Microstructure and Mechanical Properties of a Ti35Nb2Sn Alloy Post-Processed by Hot Isostatic Pressing for Biomedical Applications" Metals 11, no. 7: 1027. https://doi.org/10.3390/met11071027

APA StyleLario, J., Vicente, Á., & Amigó, V. (2021). Evolution of the Microstructure and Mechanical Properties of a Ti35Nb2Sn Alloy Post-Processed by Hot Isostatic Pressing for Biomedical Applications. Metals, 11(7), 1027. https://doi.org/10.3390/met11071027