Analysis and Characterization of the Weld Pool and Bead Geometry of Inconel 625 Super-TIG Welds

Abstract

1. Introduction

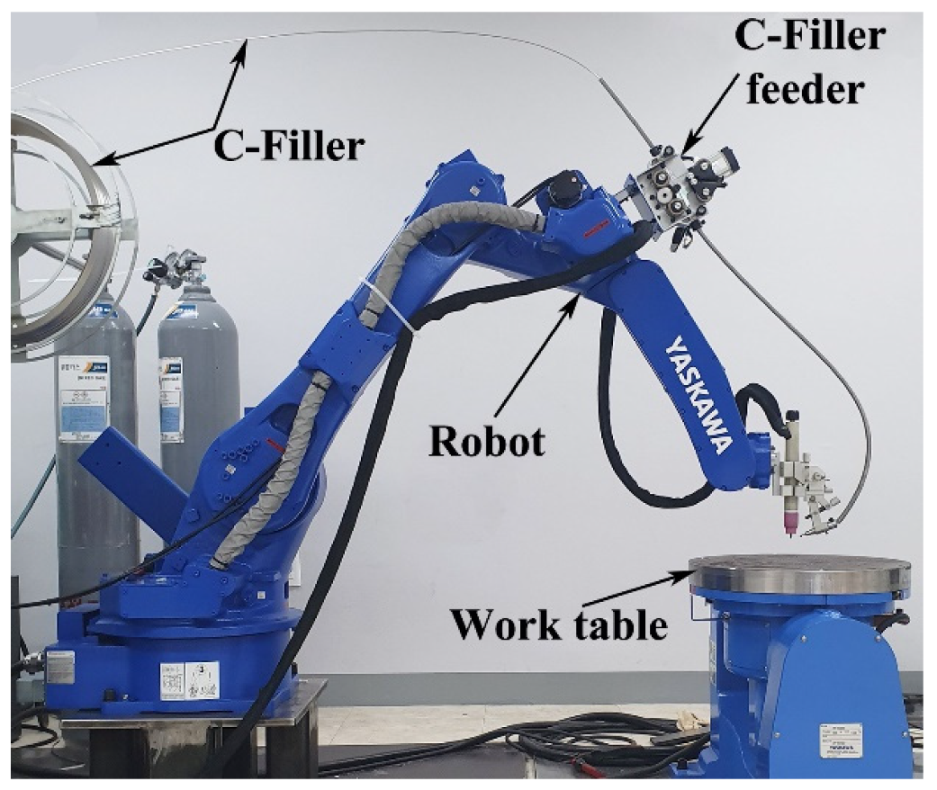

2. Materials and Methods

3. Results

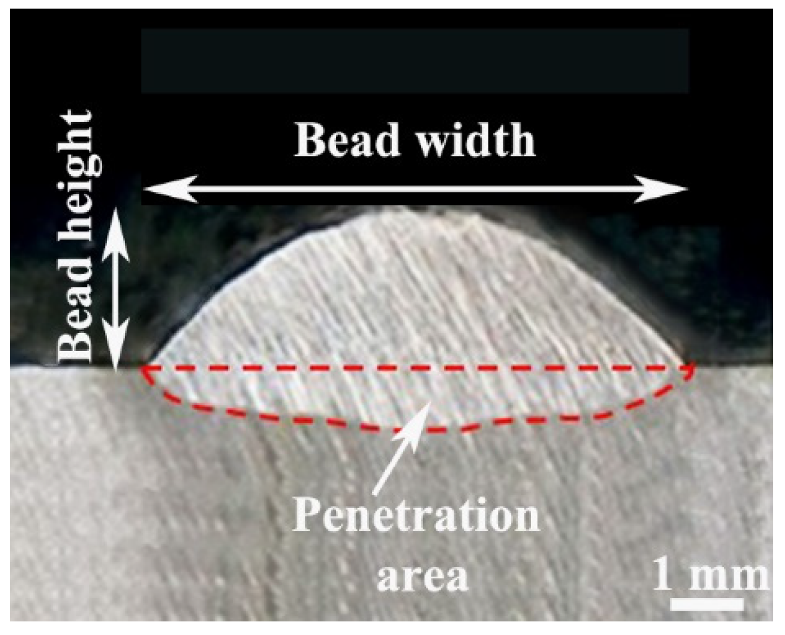

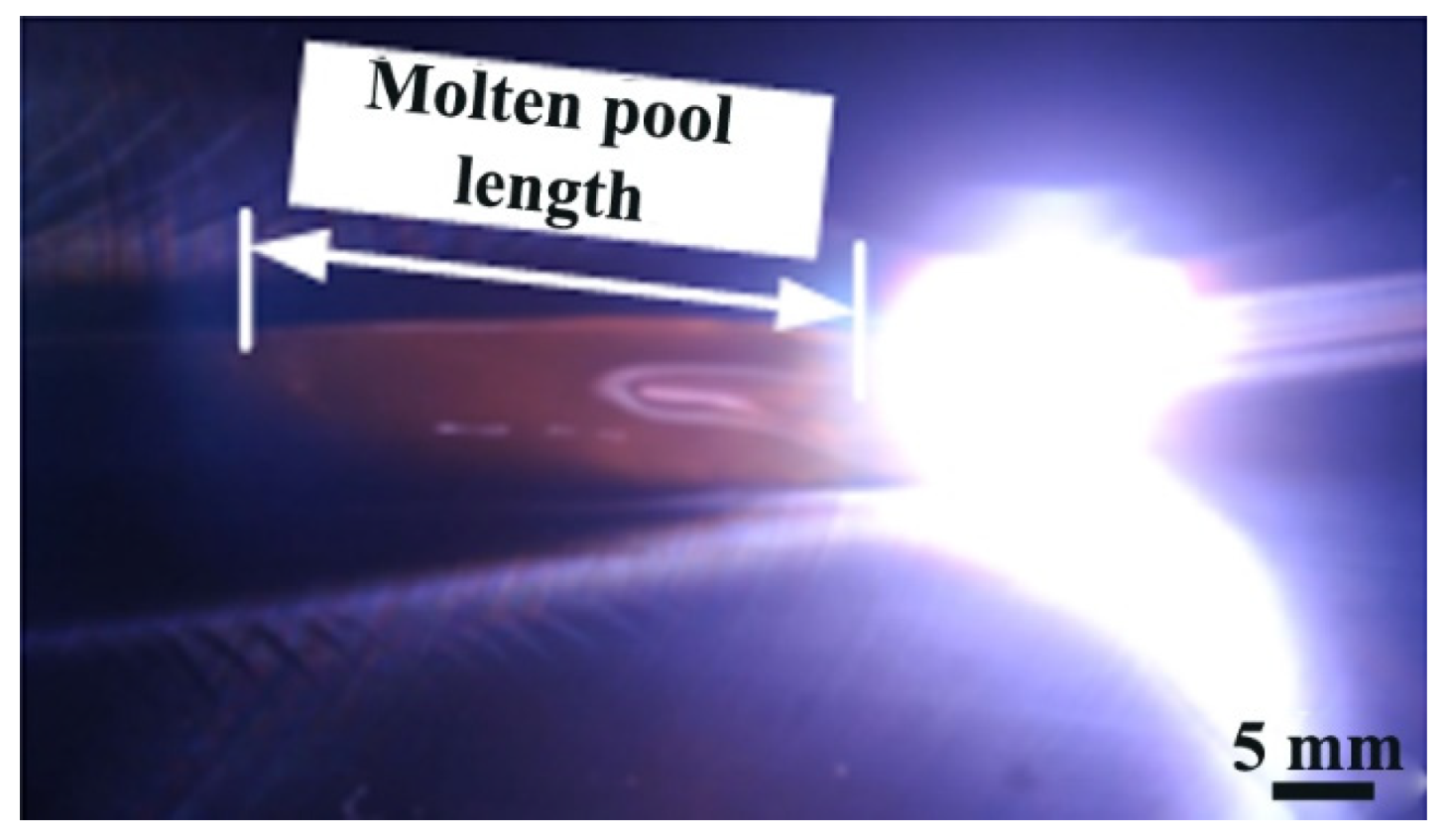

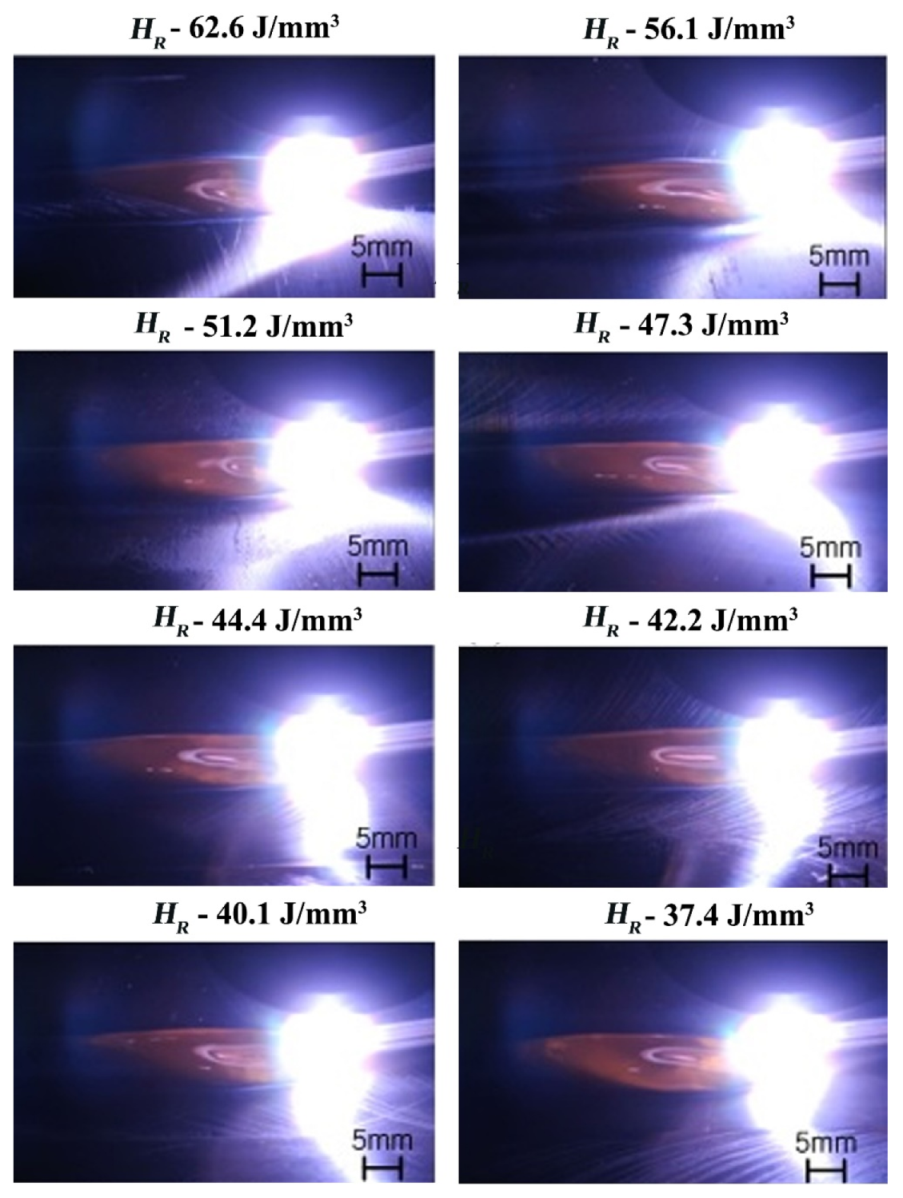

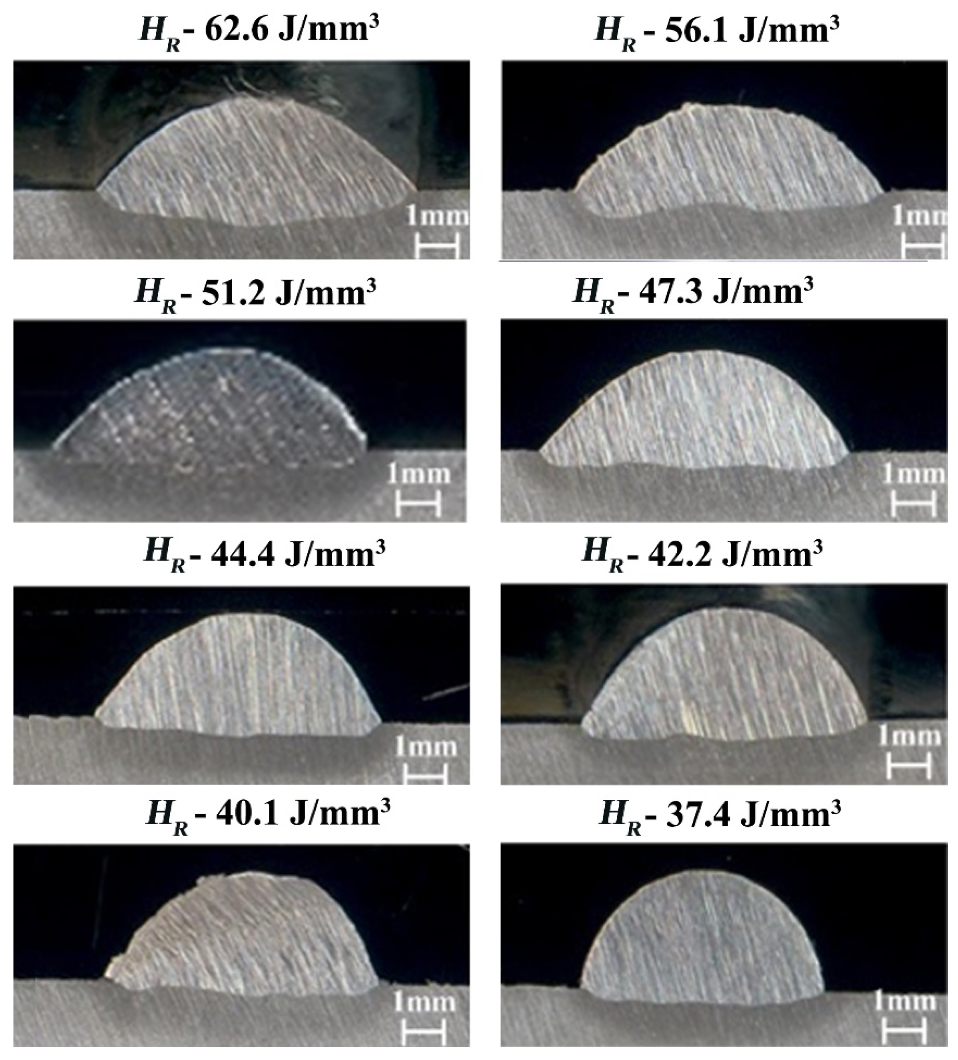

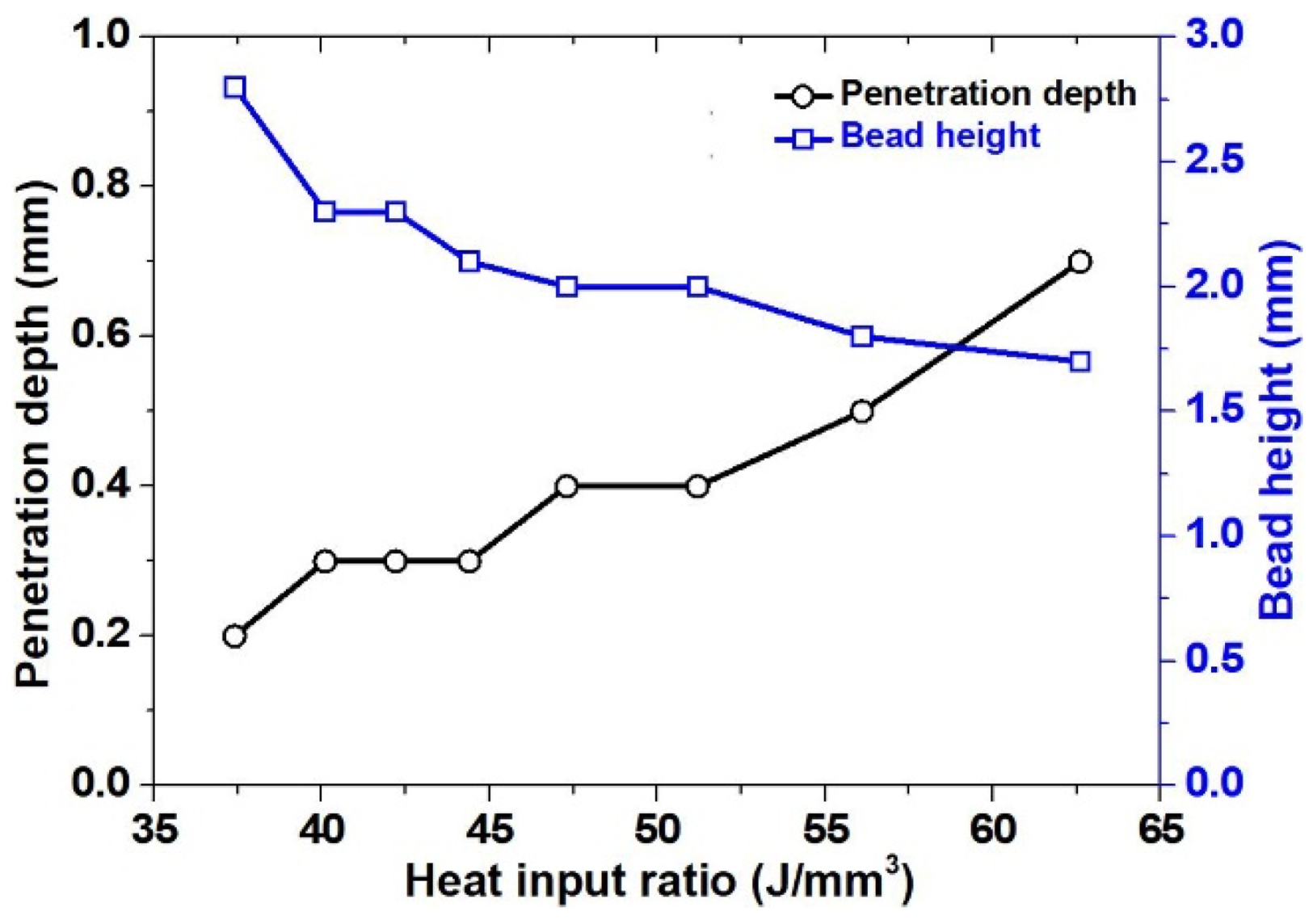

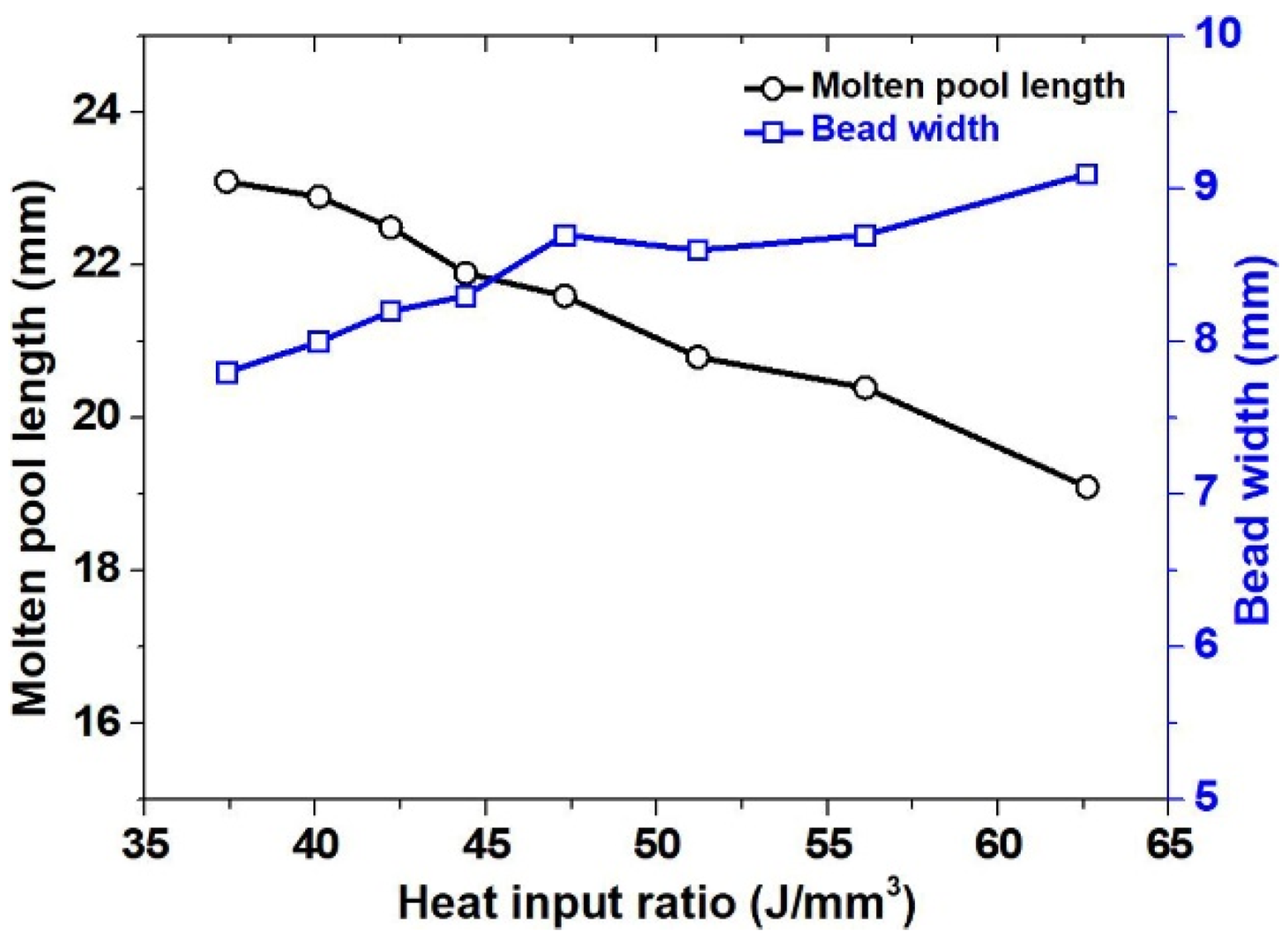

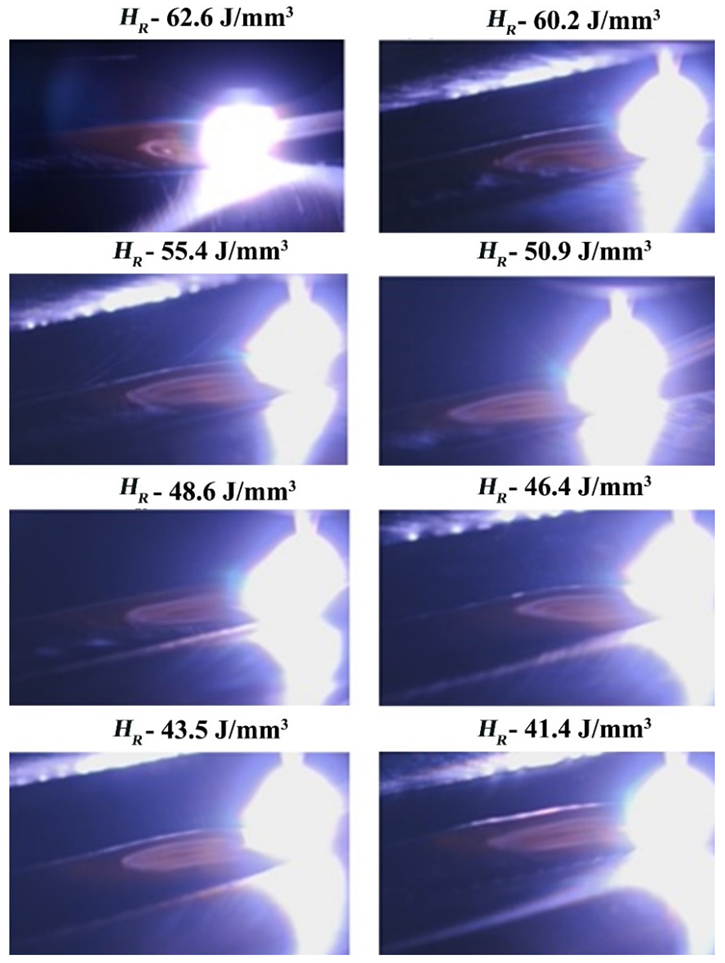

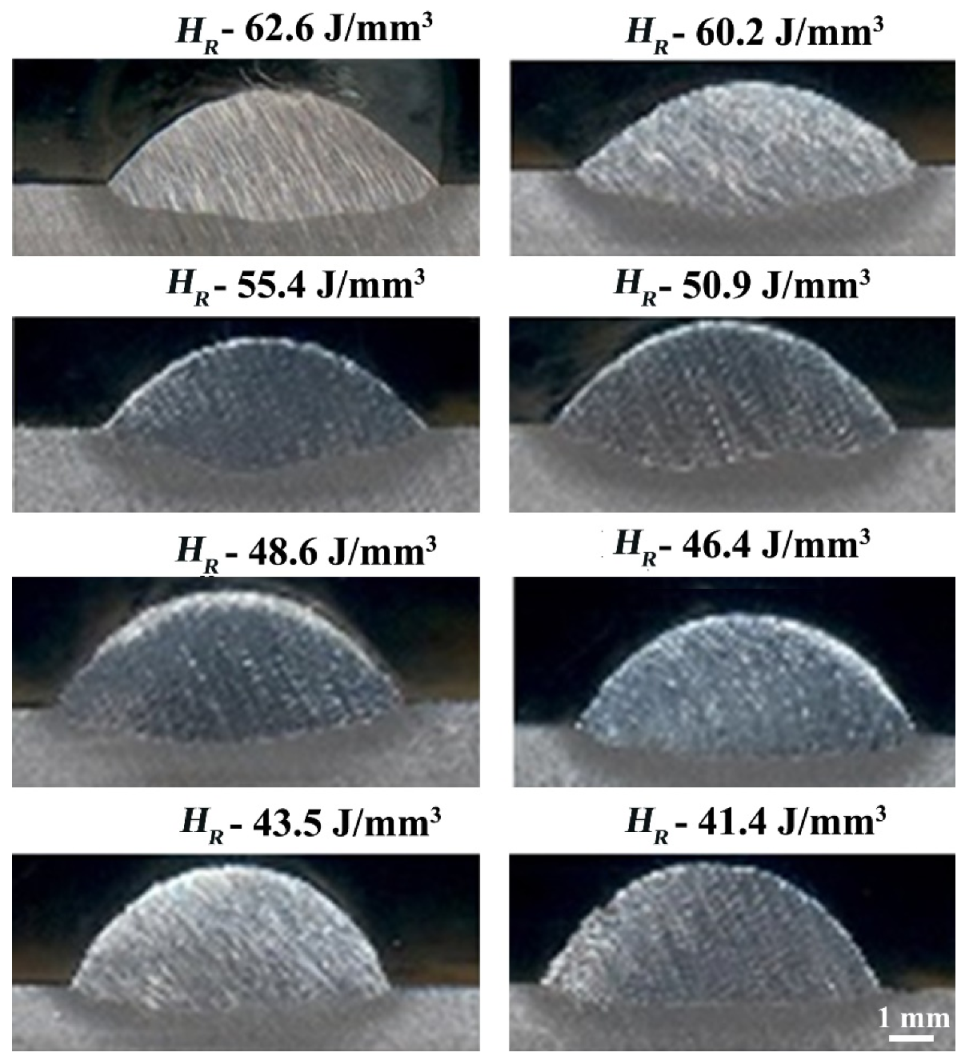

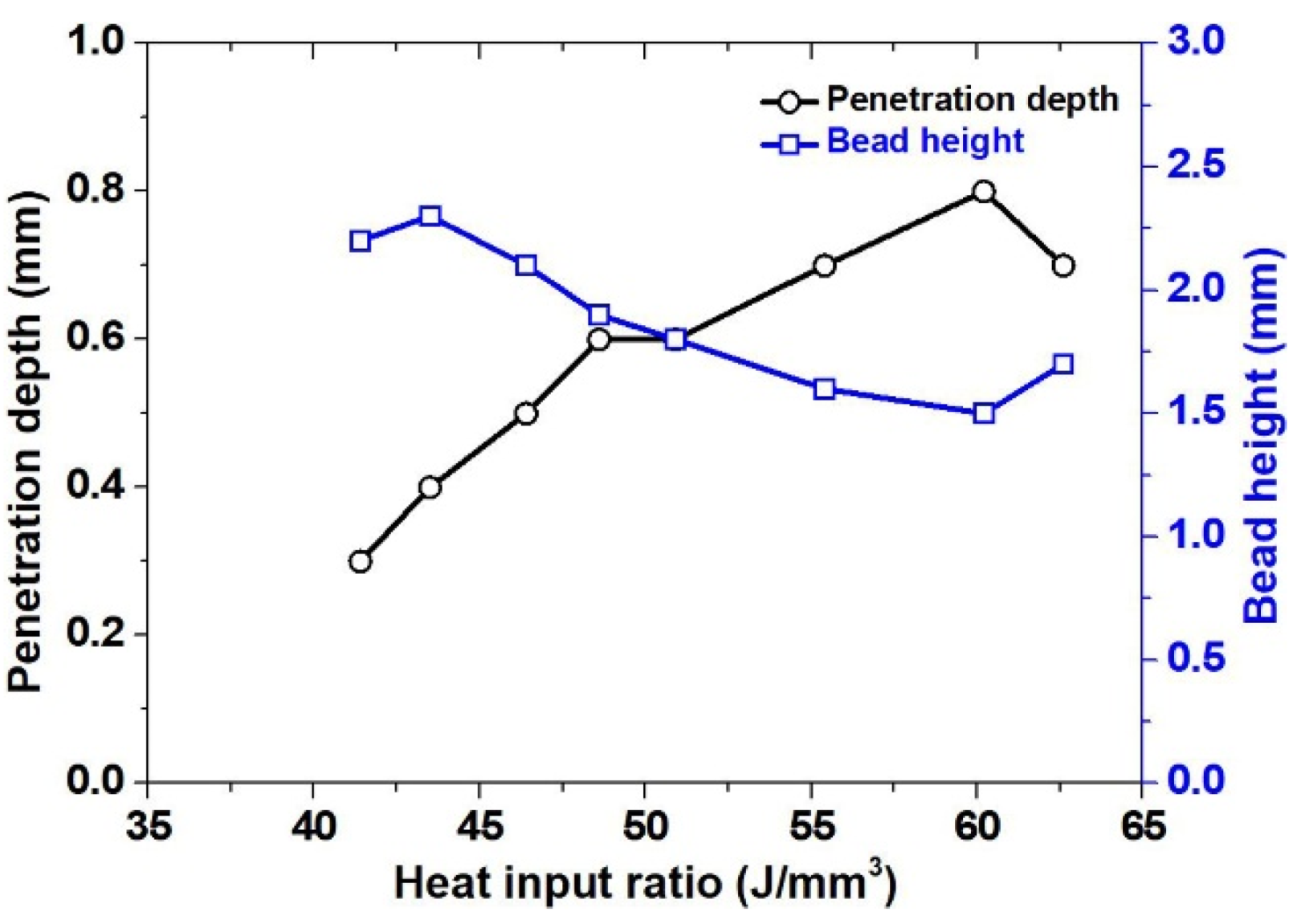

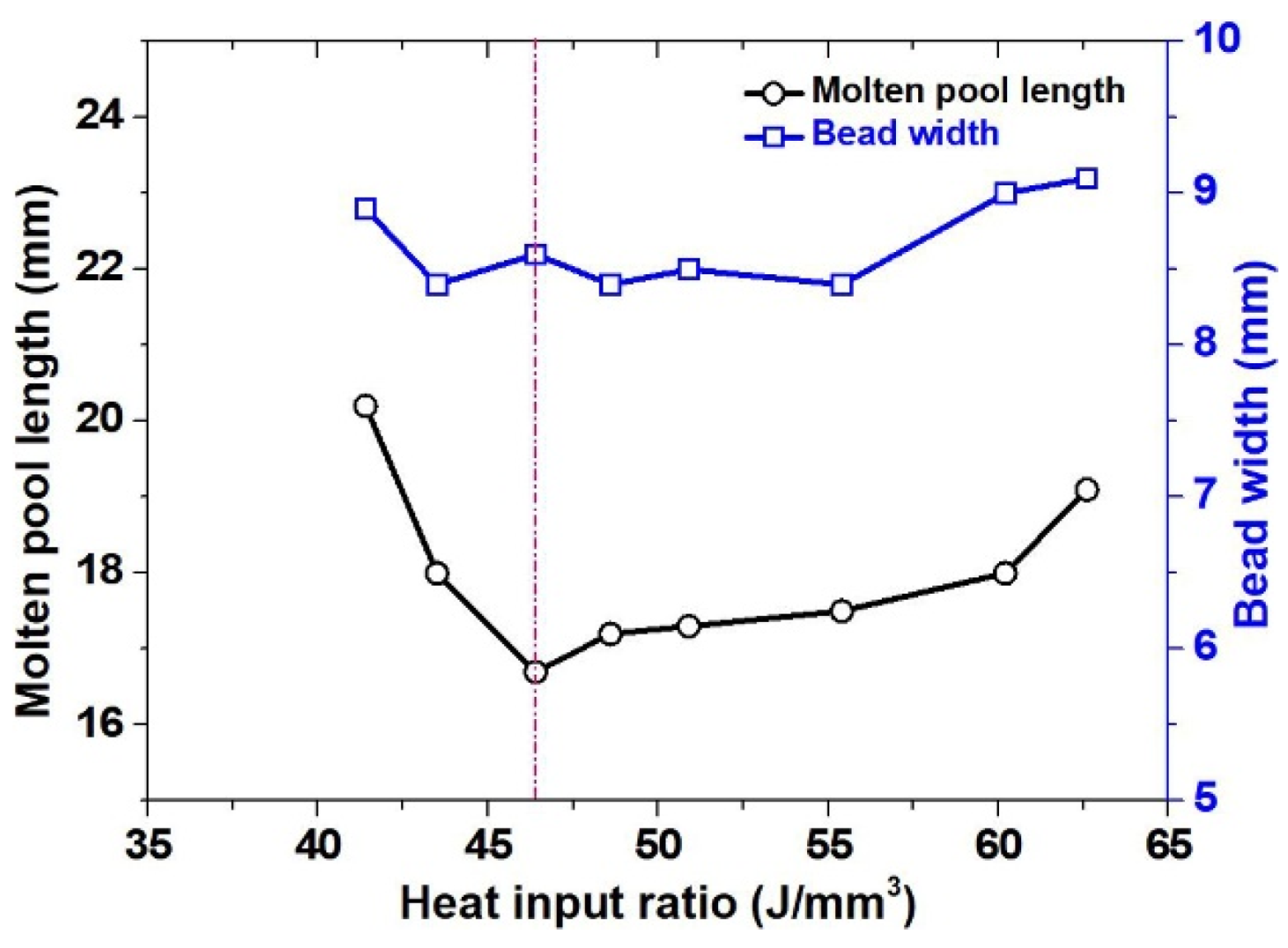

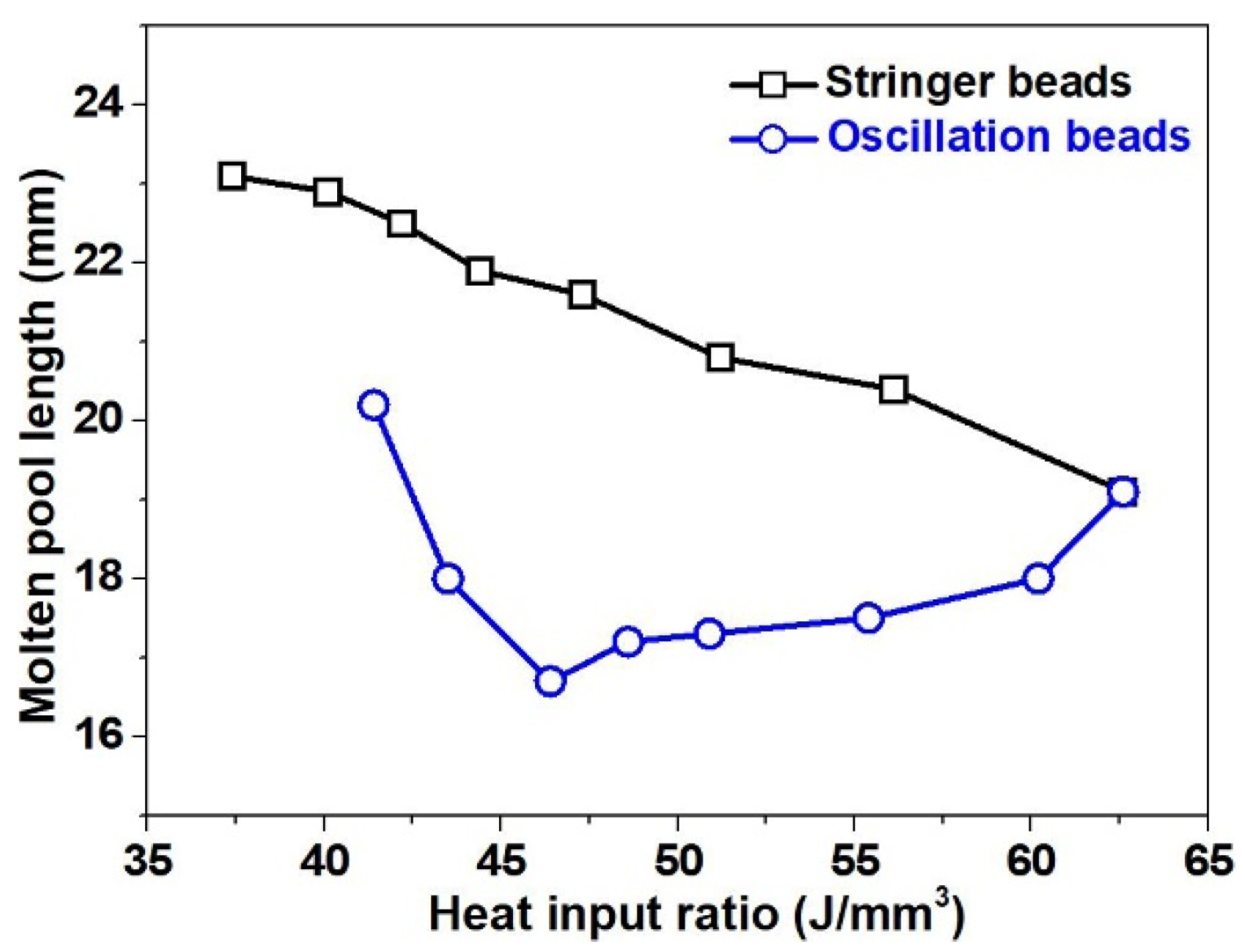

3.1. Sringer Bead Test (Non-OS)

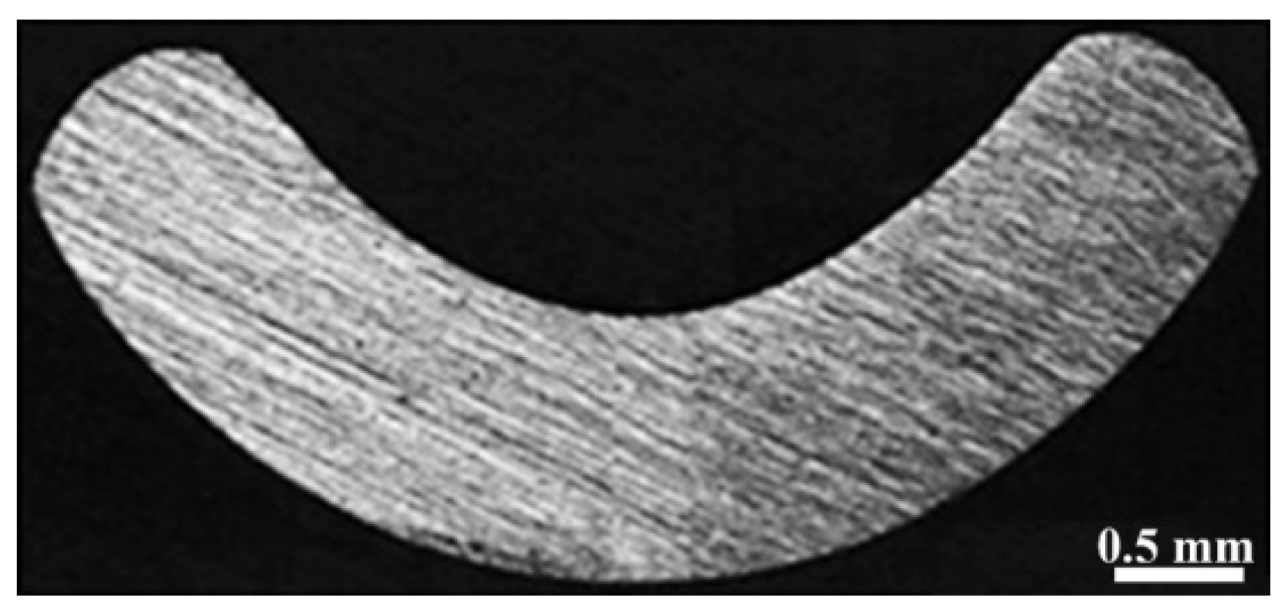

3.2. Oscilaltion Bead Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Baghel, P.K.; Nagesh, D.S. Multiattribute Assessment of Consumables for TIG Welding of Aluminum Alloys. Int. J. Manuf. Eng. 2016, 2016, 1–9. [Google Scholar] [CrossRef]

- Lathabai, S.; Jarvis, B.L.; Barton, K.J. Keyhole gas tungsten arc welding of commercially pure zirconium. Sci. Technol. Weld. Join. 2008, 13, 573–581. [Google Scholar] [CrossRef]

- Lin, M.L.; Eagar, T.W. Pressures produced by gas tungsten arcs. Metall. Trans. B 1986, 17, 601–607. [Google Scholar] [CrossRef]

- Savage, W.F.; Nippes, E.F.; Agusa, K. Effect of arc force on defect formation in GTA welding. Weld. J. 1979, 58, 212–224. [Google Scholar]

- Oh, D.S.; Kim, Y.S.; Cho, S.M. Derivation of current density distribution by arc pressure measurement in GTA welding. Sci. Technol. Weld. Join. 2005, 10, 442–446. [Google Scholar] [CrossRef]

- Mendez, P.F.; Niece, K.L.; Eagar, T.W. Humping formation in high current GTA welding. In Proceedings of the International Conferences on Joining of Advanced and Specialty Materials II., Cincinnati, OH, USA, 1–4 November 1999; pp. 151–158. [Google Scholar]

- Nomura, K.; Ogino, Y.; Hirata, Y. Shape control of TIG arc plasma by cusp type magnetic field with permanent magnets. Weld. Int. 2012, 26, 759–764. [Google Scholar] [CrossRef]

- Wu, H.; Yunlong, C.; Qiang, M.; Dan, L. Research advances in high-energy TIG arc welding. Int. J. Adv. Manuf. Technol. 2019, 104, 391–410. [Google Scholar] [CrossRef]

- Venkatesan, G.; Muthupandi, V.; Justine, J. Activated TIG welding of 304L using mono-and tri-component fluxes. Int. J. Adv. Manuf. Technol. 2017, 93, 329–336. [Google Scholar] [CrossRef]

- Liu, Z.; Shi, Y.C.; Xin, Y.; Qi, Z.; Tao, Z.; Zhen, L. Magnetic-enhanced keyhole TIG welding process. Int. J. Adv. Manuf. Technol. 2018, 99, 275–285. [Google Scholar] [CrossRef]

- Silwal, B.; James, W.; Daniel, W. Hot-wire GTAW cladding: Inconel 625 on 347 stainless steel. Int. J. Adv. Manuf. Technol. 2019, 102, 3839–3848. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, Y.H.; Baek, H.J.; Cho, S.M. A study on process development of super-TIG welding for 9% nickel steel with Alloy 625. J. Manuf. Processes 2019, 40, 140–148. [Google Scholar] [CrossRef]

- Ho, J.J.; Park, J.H.; Cheepu, M.; Cho, S.M. Observation and analysis of metal transfer phenomena for high-current super-TIG welding process. Sci. Technol. Weld. Join. 2020, 25, 106–111. [Google Scholar] [CrossRef]

- Cho, S.M.; Son, M.S.; Park, J.H. Development of welding quality monitoring method for TIG cladding. J. Weld. Join. 2014, 31, 90–95. [Google Scholar] [CrossRef][Green Version]

- Wahab, M.A.; Painter, M.J.; Davies, M.H. The prediction of the temperature distribution and weld pool geometry in the gas metal arc welding process. J. Mater. Process. Technol. 1998, 77, 233–239. [Google Scholar] [CrossRef]

- Mukherjee, T.; Wei, H.L.; De, A.; DebRoy, T. Heat and fluid flow in additive manufacturing–Part II. Comput. Mater. Sci. 2018, 150, 369–380. [Google Scholar] [CrossRef]

- Welding and Repair Technology Center, Measures to Minimize 52M Hot Cracking on Stainless Steel Base Materials; EPRI: Palo Alto, CA, USA, 2012; p. 1025167.

- McCracken, S.L.; Smith, R.E. Behavior and hot cracking susceptibility of filler metal 52 M overlays on cast austenitic stainless steel base materials. In Hot Cracking Phenomena in Welds III; Böllinghaus, T., Lippold, J., Cross, C.E., Eds.; Springer: Berlin, Germany, 2011; pp. 333–352. [Google Scholar] [CrossRef]

- Venukumar, S.; Cheepu, M.; Babu, T.V.; Venkateswarlu, D. TIG arc welding-brazing of dissimilar metals-An Ooverview. Mater. Sci. Forum 2019, 969, 768–774. [Google Scholar] [CrossRef]

- Venukumar, S.; Cheepu, M.; Babu, T.V.; Venkateswarlu, D. Cold metal transfer (cmt) welding of dissimilar materials: An overview. Mater. Sci. Forum 2019, 969, 685–690. [Google Scholar] [CrossRef]

- Cheepu, M.; Lee, C.I.; Cho, S.M. Microstructural characteristics of wire arc additive manufacturing with Inconel 625 by super-TIG welding. Trans. Indian. Inst. Met. (in press). [CrossRef]

| Material | C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|---|

| SS400 Base Metal | 0.155 | 0.163 | 0.455 | 0.007 | 0.009 | 0.019 | 0.0101 |

| Inconel 625 C-Filler | 0.10 | 0.50 | 0.50 | 23.0 | 58.0 | 10.0 | 5.0 |

| Base Metal | SS400 (50 mm × 150 mm × 10 mm) | |||||||

| Filler Metal | Inconel 625(C-Filler, 5mm2) | |||||||

| Shield Gas (L/min) | 20 (Ar 93% + H2 7% ) | |||||||

| Arc Length (mm) | 5 | |||||||

| Current (A) | 300 | |||||||

| Welding Speed (cm/min) | 50 | |||||||

| Experiment No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Feed Rate (cm/min) | 125 | 135 | 145 | 155 | 165 | 175 | 185 | 195 |

| Deposition Area DA (mm2) | 13.8 | 14.9 | 16.0 | 17.1 | 18.2 | 19.3 | 20.4 | 21.5 |

| Deposition Rate DR (kg/h) | 3.3 | 3.6 | 3.8 | 4.1 | 4.4 | 4.6 | 4.9 | 5.1 |

| Oscillation Test | ||||||||

| Oscillation Width (mm) | 0 | 1.8 | 2.4 | 3.0 | 3.6 | 4.2 | 4.8 | 5.4 |

| Frequency (Hz) | 3.5 | - | - | - | - | - | - | - |

| Camera | Nikon—V1 |

|---|---|

| Lens | AF MICRO NIKKOR 105 mm |

| Filter | UV 62 mm + ND2-2000 52 mm |

| Lens to work distance (mm) | 350 |

| Filming angle (o) | −37o |

| Shutter | 1/640, F14 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.H.; Cheepu, M.; Cho, S.M. Analysis and Characterization of the Weld Pool and Bead Geometry of Inconel 625 Super-TIG Welds. Metals 2020, 10, 365. https://doi.org/10.3390/met10030365

Park JH, Cheepu M, Cho SM. Analysis and Characterization of the Weld Pool and Bead Geometry of Inconel 625 Super-TIG Welds. Metals. 2020; 10(3):365. https://doi.org/10.3390/met10030365

Chicago/Turabian StylePark, Jung Hyun, Muralimohan Cheepu, and Sang Myung Cho. 2020. "Analysis and Characterization of the Weld Pool and Bead Geometry of Inconel 625 Super-TIG Welds" Metals 10, no. 3: 365. https://doi.org/10.3390/met10030365

APA StylePark, J. H., Cheepu, M., & Cho, S. M. (2020). Analysis and Characterization of the Weld Pool and Bead Geometry of Inconel 625 Super-TIG Welds. Metals, 10(3), 365. https://doi.org/10.3390/met10030365