EBSD Study of Delta-Processed Ni-Based Superalloy

Abstract

1. Introduction

2. Materials and Methods

3. Results

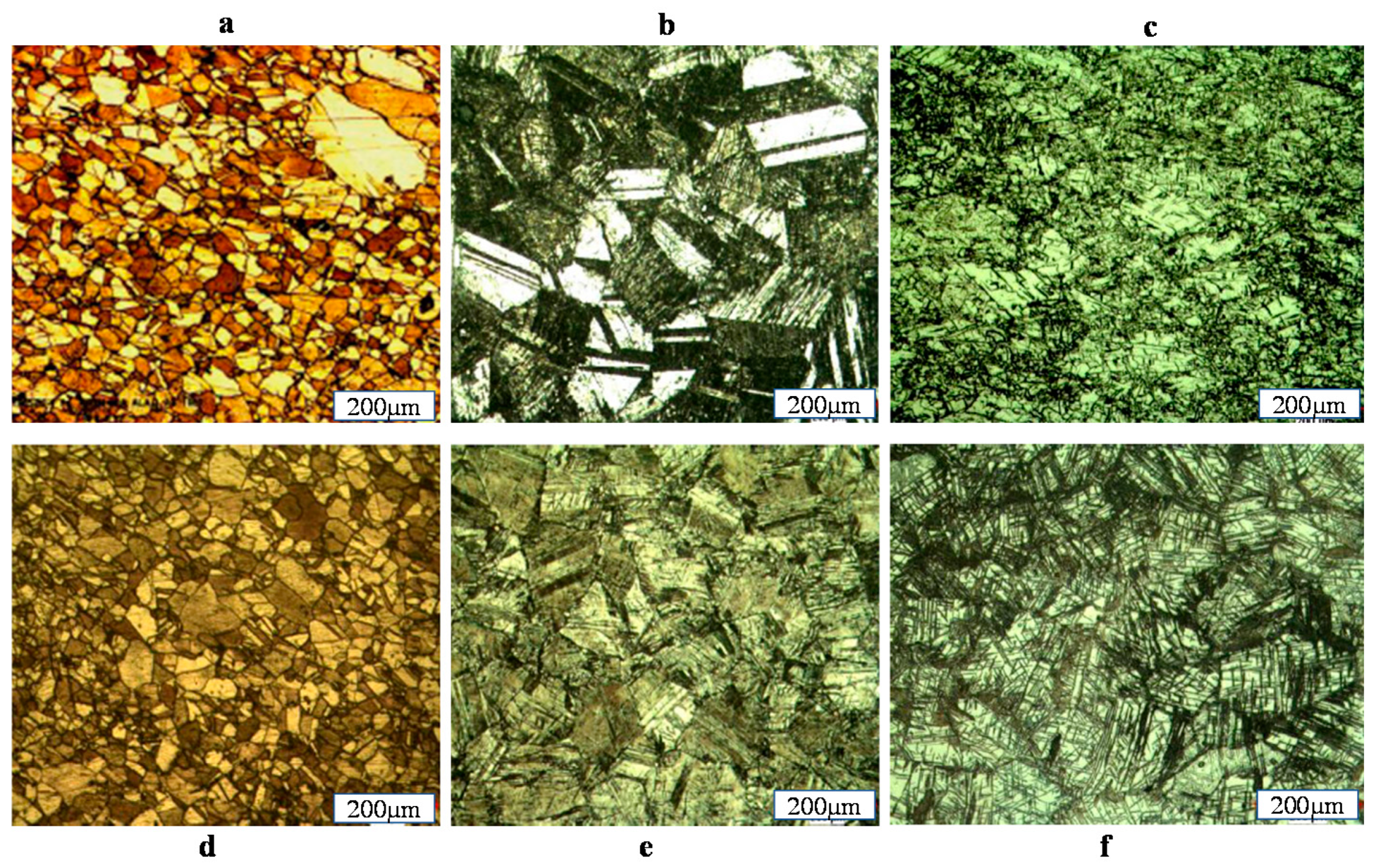

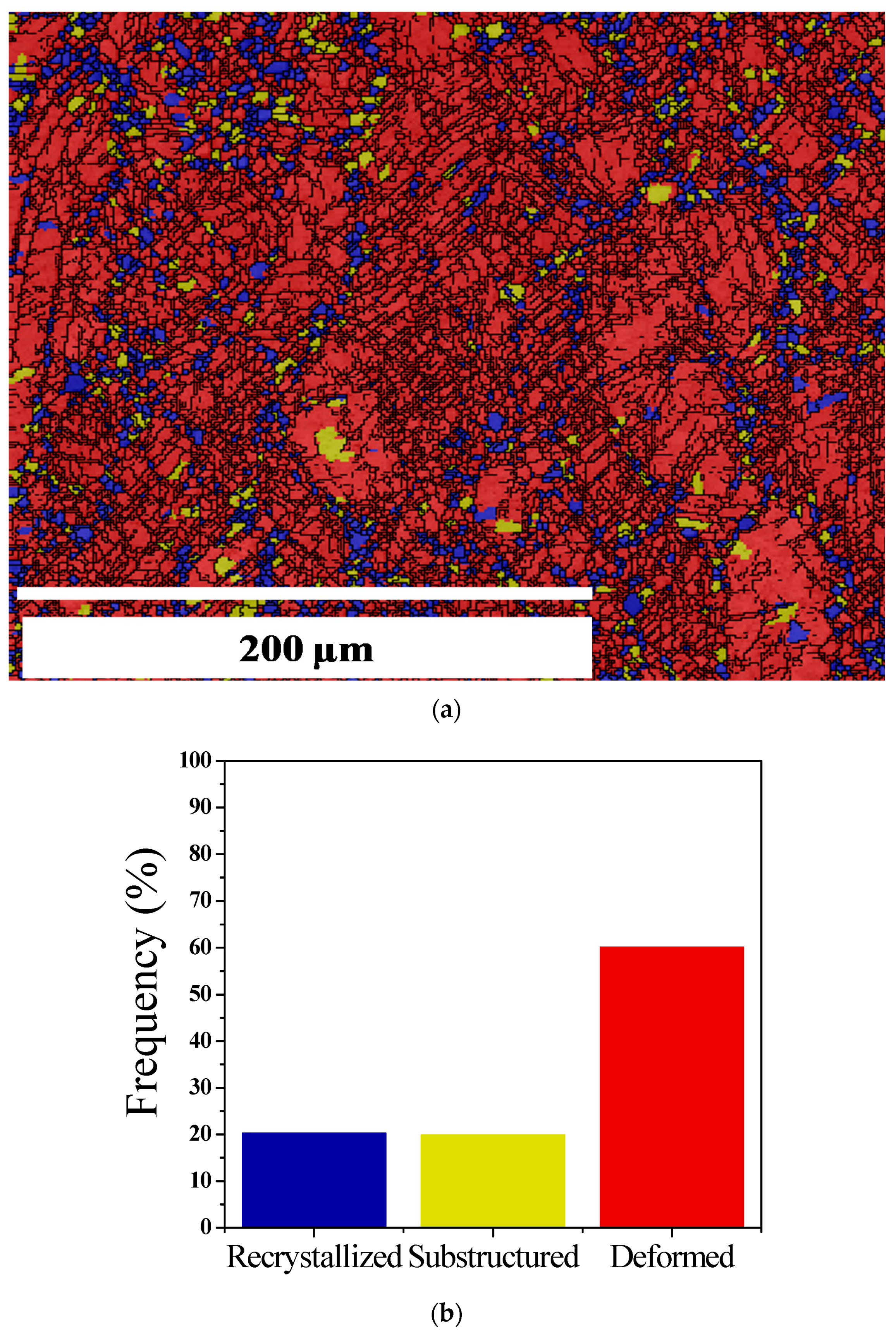

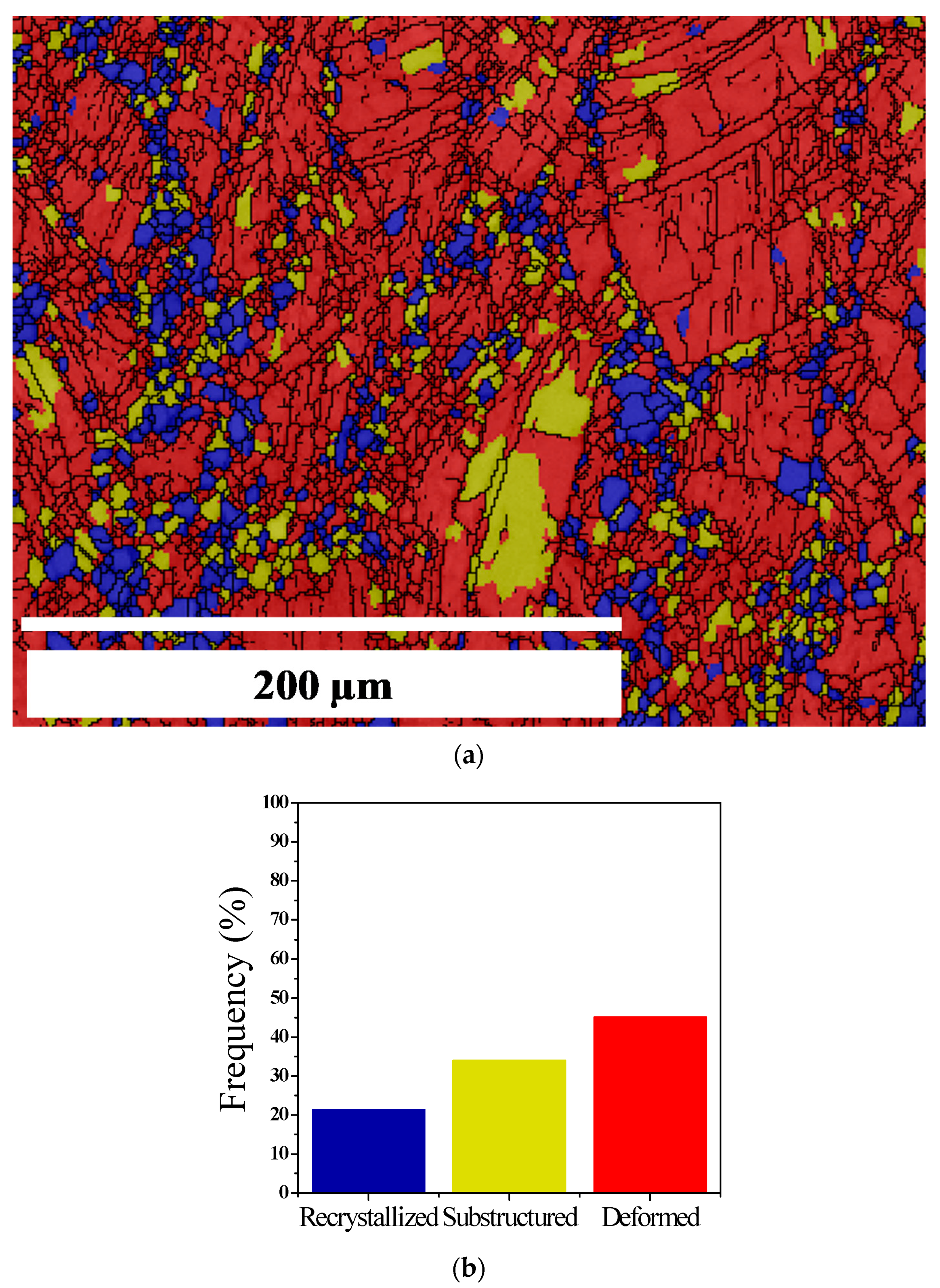

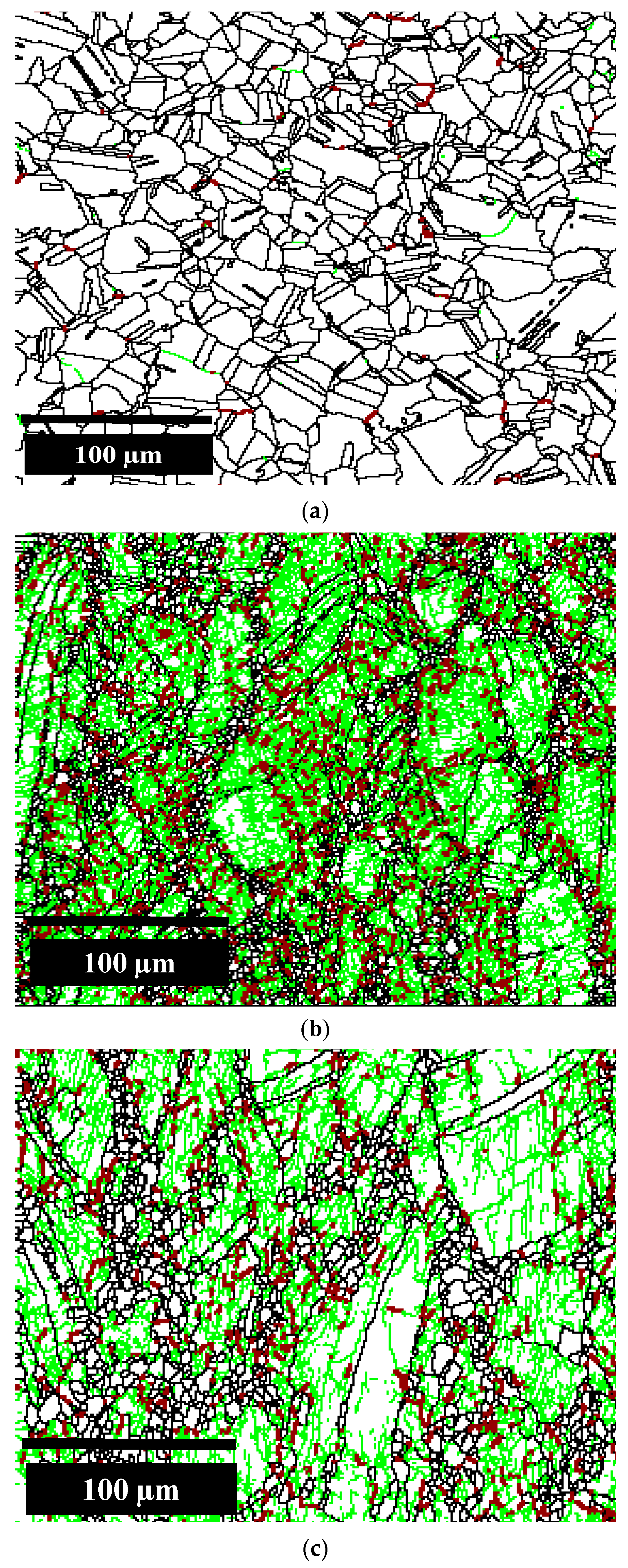

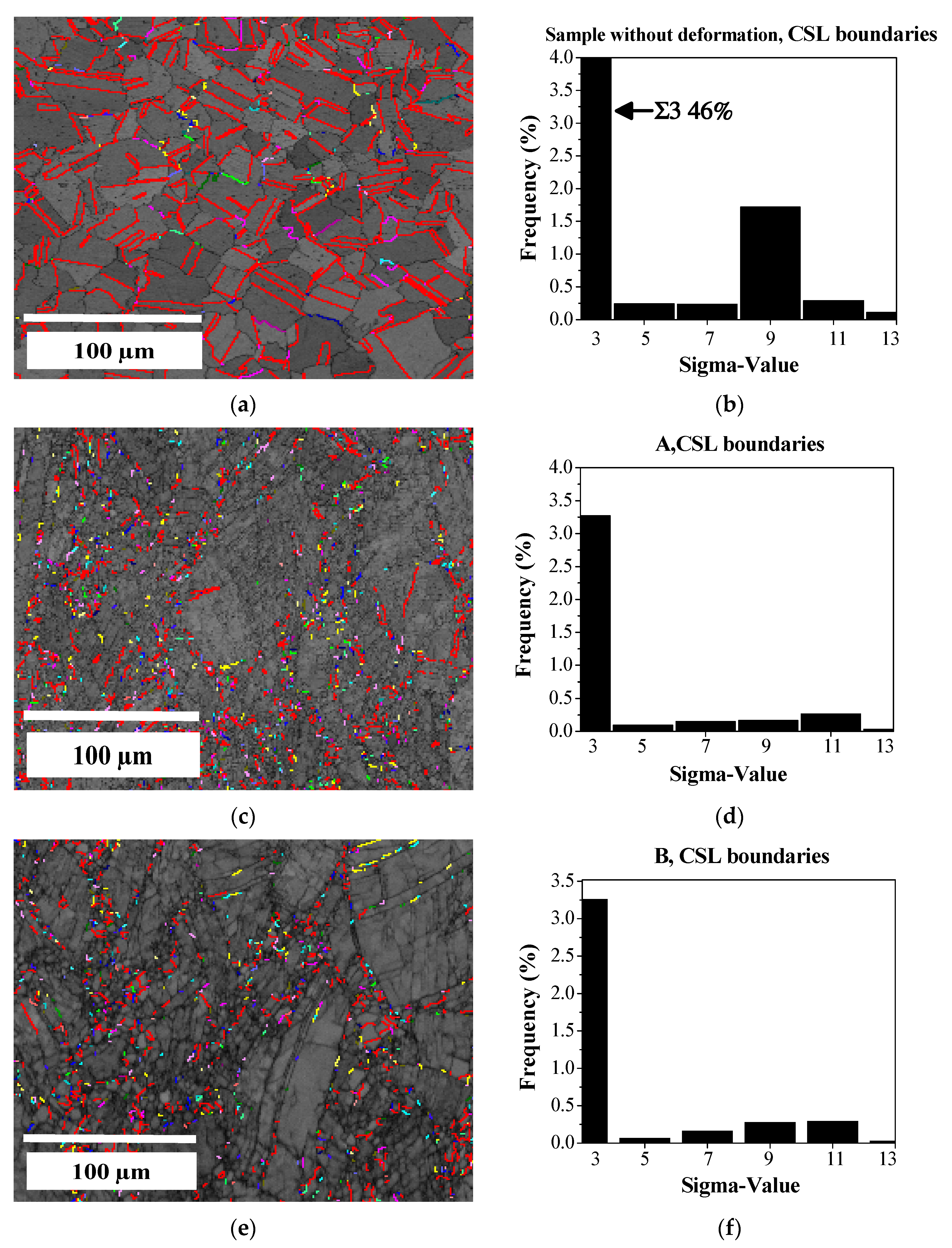

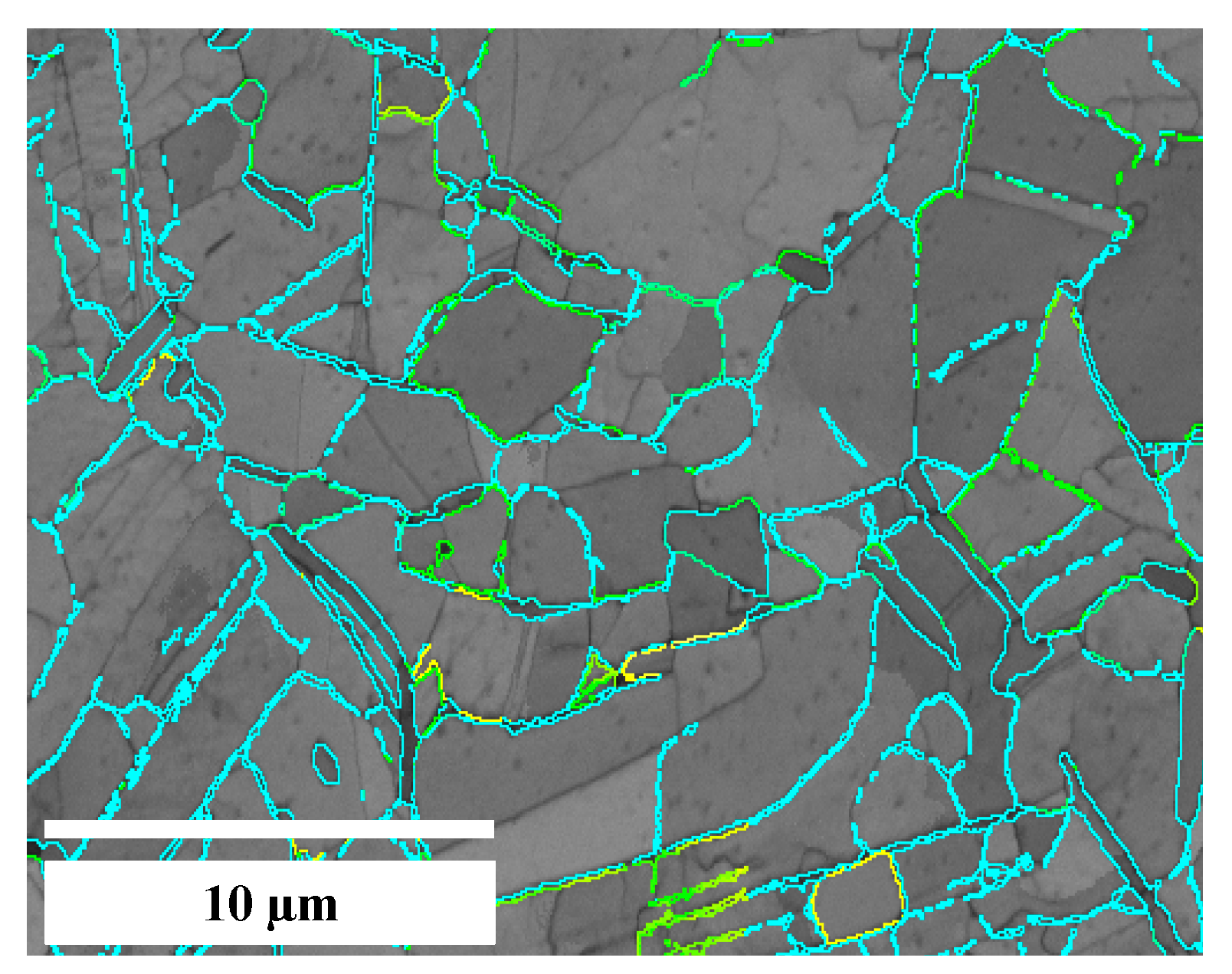

3.1. Grains and Grain Boundaries Behavior of the γ-Phase with Delta-Processing

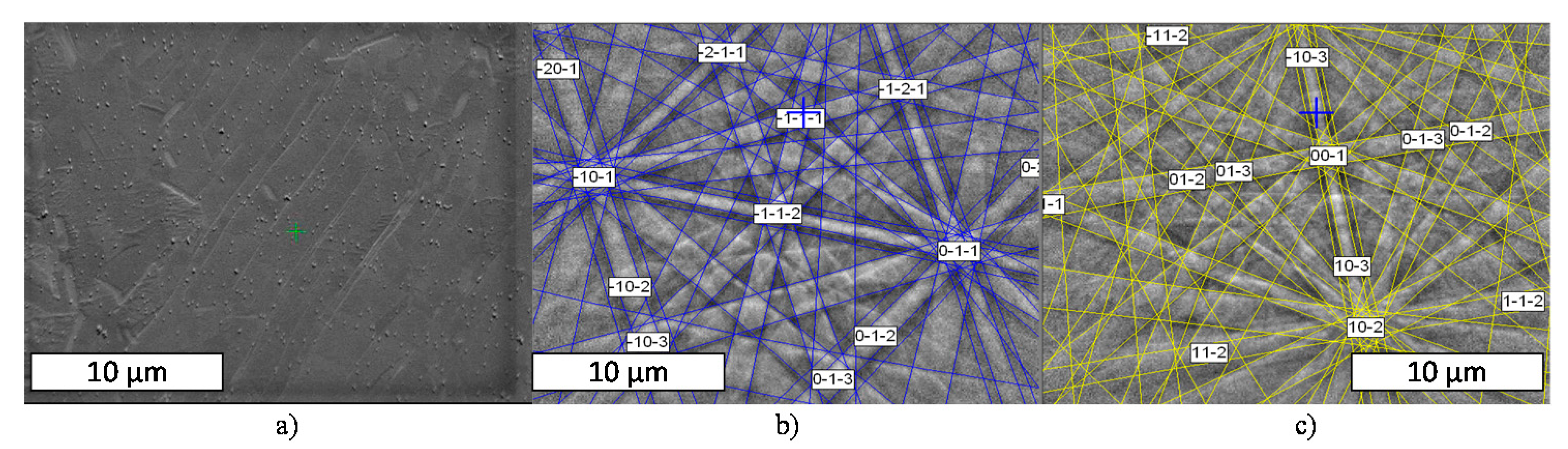

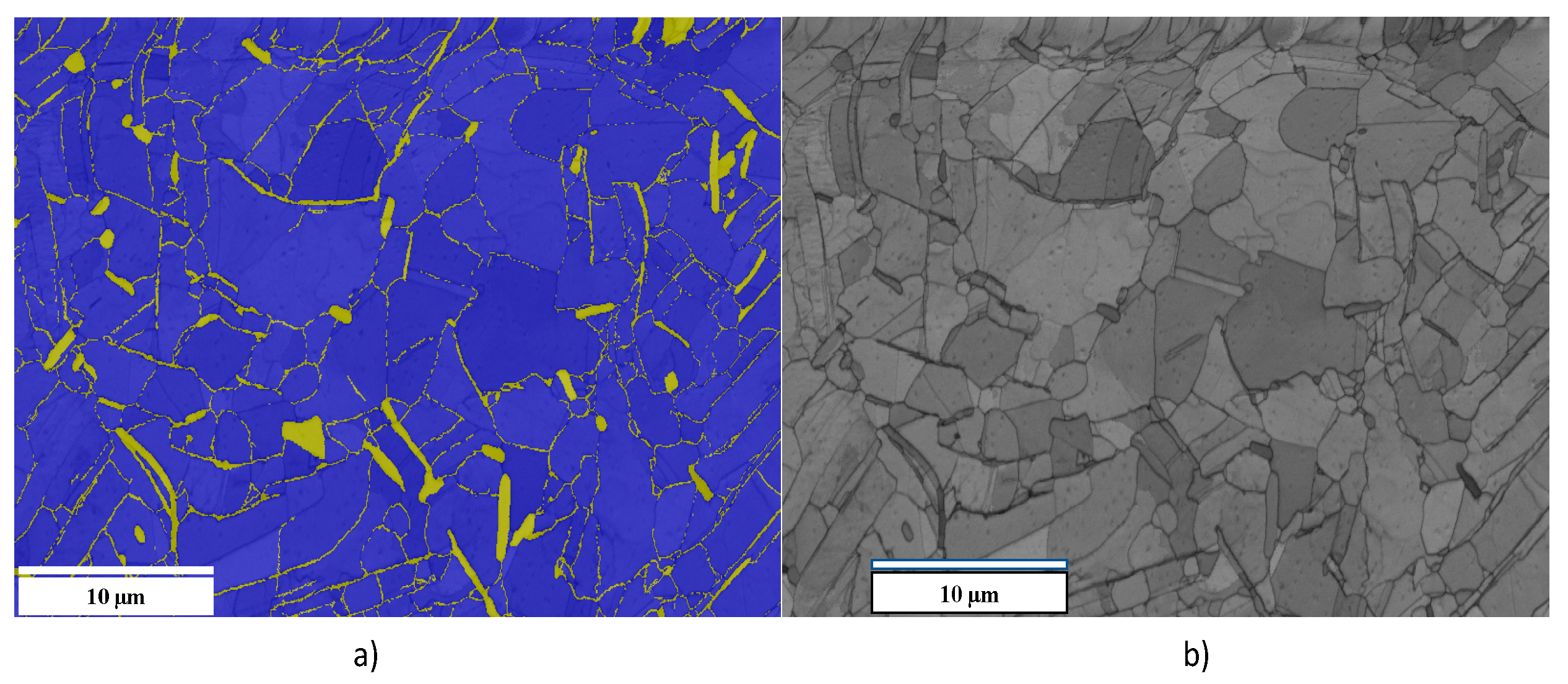

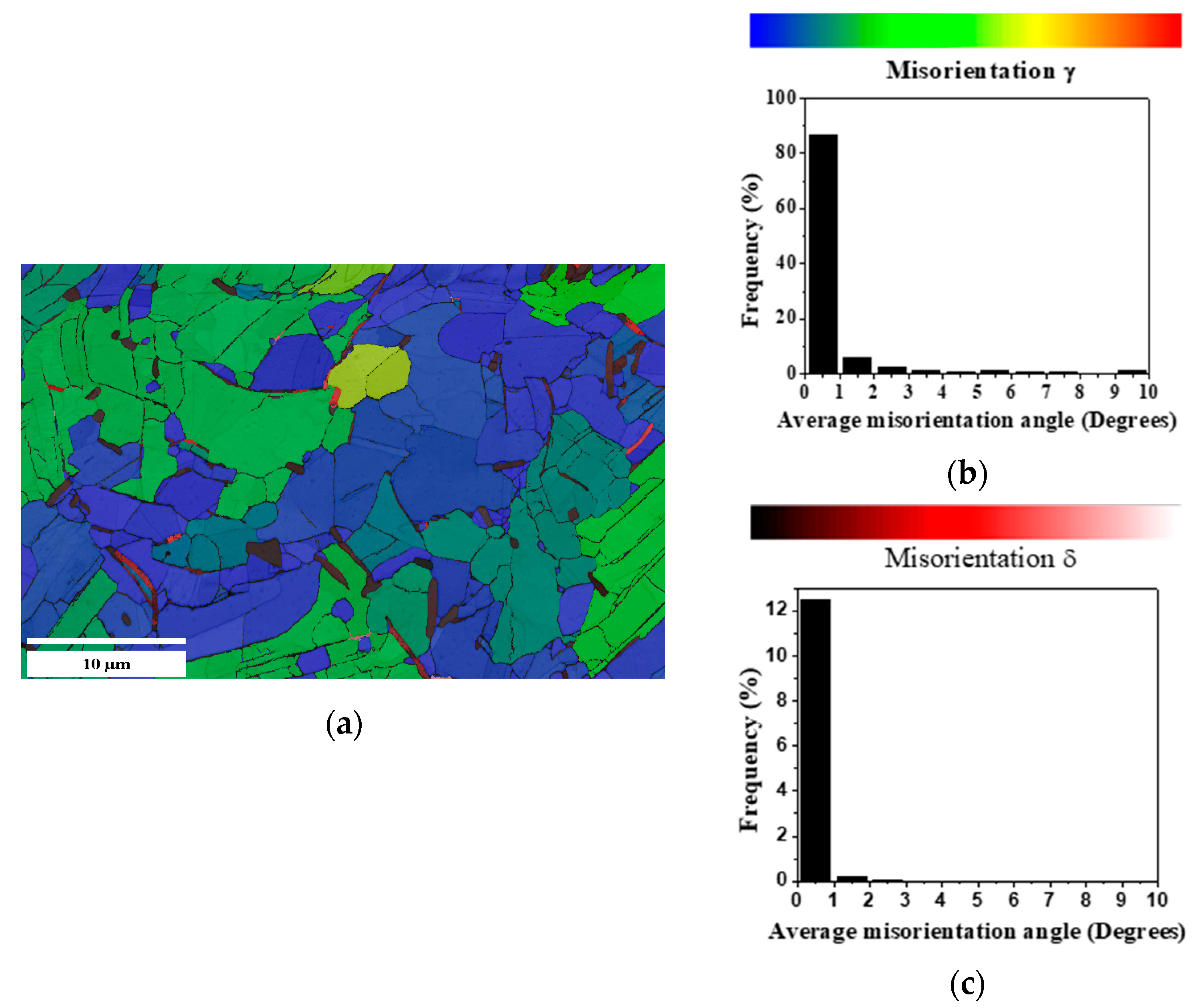

3.2. Identification of δ Phase and Orientation Relationship with the γ-Phase

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Basoalto, H.C.; Brooks, J.W.; Di Martino, I. Multiscale microstructure modelling for nickel based superalloys. Mater. Sci. Technol. 2009, 25, 221–227. [Google Scholar] [CrossRef]

- Reyes, L.; Páramo, P.; Zamarripa, A.S.; De La Garza, M.; Mata, M.G. Grain size modeling of a Ni-base superalloy using cellular automata algorithm. Mater. Des. 2015, 83, 301–307. [Google Scholar] [CrossRef]

- Desvalles, Y.; Bouzidi, M.; Boisand, F.; Beaude, N. Delta phase in inconel 718: Mechanical properties and forging process requirements. Superalloys 1994, 718, 281–291. [Google Scholar] [CrossRef]

- Azadian, S.; Wei, L.-Y.; Warren, R. Delta phase precipitation in Inconel 718. Mater. Charact. 2004, 53, 7–16. [Google Scholar] [CrossRef]

- Nalawade, S.; Sundararaman, M.; Singh, J.; Verma, A.; Kishore, R. Precipitation of γ′ phase in δ-precipitated Alloy 718 during deformation at elevated temperatures. Mater. Sci. Eng. A 2010, 527, 2906–2909. [Google Scholar] [CrossRef]

- Antonov, S.; Detrois, M.; Helmink, R.C.; Tin, S. Precipitate phase stability and compositional dependence on alloying additions in γ–γ′–δ–η Ni-base superalloys. J. Alloy. Compd. 2015, 626, 76–86. [Google Scholar] [CrossRef]

- Park, N.; Kim, I.; Na, Y.; Yeom, J. Hot forging of a nickel-base superalloy. J. Mater. Process. Technol. 2001, 111, 98–102. [Google Scholar] [CrossRef]

- Semiatin, S.; Weaver, D.S.; Kramb, R.C.; Fagin, P.N.; Glavicic, M.G.; Goetz, R.L.; Frey, N.D.; Antony, M.M. Deformation and recrystallization behavior during hot working of a coarse-grain, nickel-base superalloy ingot material. Met. Mater. Trans. A 2004, 35, 679–693. [Google Scholar] [CrossRef]

- Nalawade, S.; Sundararaman, M.; Singh, J.B.; Verma, A.; Kishore, R. Comparison of deformation induced precipitation behaviour in Alloy 718 under two microstructural conditions. Trans. Indian Inst. Met. 2010, 63, 35–41. [Google Scholar] [CrossRef]

- Hongbo, D.; Gaochao, W. Effect of Deformation Process on Superplasticity of Inconel 718 Alloy. Rare Met. Mater. Eng. 2015, 44, 298–302. [Google Scholar] [CrossRef]

- Mei, Y.; Liu, Y.; Liu, C.; Li, C.; Yu, L.; Guo, Q.; Li, H. Effects of cold rolling on the precipitation kinetics and the morphology evolution of intermediate phases in Inconel 718 alloy. J. Alloy. Compd. 2015, 649, 949–960. [Google Scholar] [CrossRef]

- Wen, D.-X.; Lin, Y.; Chen, J.; Chen, X.-M.; Zhang, J.-L.; Liang, Y.-J.; Li, L.-T. Work-hardening behaviors of typical solution-treated and aged Ni-based superalloys during hot deformation. J. Alloy. Compd. 2015, 618, 372–379. [Google Scholar] [CrossRef]

- Yao, Z.; Wang, H.; Dong, J.-X.; Wang, J.; Jiang, H.; Zhou, B. Characterization of Hot Deformation Behavior and Dislocation Structure Evolution of an Advanced Nickel-Based Superalloy. Metals 2020, 10, 920. [Google Scholar] [CrossRef]

- Díaz-Álvarez, J.; Díaz-Álvarez, A.; Miguelez, M.H.; Cantero, J.L. Finishing Turning of Ni Superalloy Haynes 282. Metals 2018, 8, 843. [Google Scholar] [CrossRef]

- Chang, B.; Yang, S.; Liu, G.; Li, W.; Du, D.; Ma, N. Influences of Cooling Conditions on the Liquation Cracking in Laser Metal Deposition of a Directionally Solidified Superalloy. Metals 2020, 10, 466. [Google Scholar] [CrossRef]

- Konyashin, I.Y.; Lachmann, F.F.; Ries, B.H.; Mazilkin, A.A.; Straumal, B.B.; Kübel, C.; Llanes, L.; Baretzky, B. Strengthening zones in the Co matrix of WC–Co cemented carbides. Scr. Mater. 2014, 83, 17–20. [Google Scholar] [CrossRef]

- Wang, X.; Xu, W.; Xu, P.; Zhou, H.; Kong, F.; Chen, Y. High Nb–TiAl Intermetallic Blades Fabricated by Isothermal Die Forging Process at Low Temperature. Metals 2020, 10, 757. [Google Scholar] [CrossRef]

- Zhu, Q.; Chen, G.; Wang, C.; Cheng, L.; Qin, H.; Zhang, P. Effect of the δ Phase on the Tensile Properties of a Nickel-Based Superalloy. Metals 2019, 9, 1153. [Google Scholar] [CrossRef]

- Wang, Y.; Zhen, L.; Shao, W.; Yang, L.; Zhang, X. Hot working characteristics and dynamic recrystallization of delta-processed superalloy 718. J. Alloy. Compd. 2009, 474, 341–346. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, S.-H.; Cheng, M.; Li, Z. Deformation characteristics of δ phase in the delta-processed Inconel 718 alloy. Mater. Charact. 2010, 61, 49–53. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, W.; Zhen, L.; Zhang, B. Hot deformation behavior of delta-processed superalloy 718. Mater. Sci. Eng. A 2011, 528, 3218–3227. [Google Scholar] [CrossRef]

- Zhang, S.-H.; Zhang, H.-Y.; Cheng, M. Tensile deformation and fracture characteristics of delta-processed Inconel 718 alloy at elevated temperature. Mater. Sci. Eng. A 2011, 528, 6253–6258. [Google Scholar] [CrossRef]

- Cheng, M.; Zhang, H.Y.; Zhang, S.H. Microstructure evolution of delta-processed IN718 during holding period after hot deformation. J. Mater. Sci. 2011, 47, 251–256. [Google Scholar] [CrossRef]

- Kañetas, P.P.; Osorio, L.R.; Mata, M.P.G.; De La Garza, M.; López, V.P. Influence of the Delta Phase in the Microstructure of the Inconel 718 subjected to “Delta-processing” Heat Treatment and Hot Deformed. Procedia Mater. Sci. 2015, 8, 1160–1165. [Google Scholar] [CrossRef]

- Brown, E.E.; Boettner, R.C.; Ruckle, D.L. Minigrain Processing of Nickel—Base 718. U.S. Patent No. 3,660,177, 2 May 1972. [Google Scholar]

- Banik, T.; Keefe, P.; Maurer, G.; Petzold, L. Ultra Fine Grain/Ultra Low Carbon 718. Superalloys 1991, 913–924. [Google Scholar] [CrossRef]

- Petri, C.; Deragon, T.; Schweizer, F.; Schirra, J. Ultra Fine Grain Processed UDIMET Alloy 718 for Isothermal Forging. Superalloys 1997, 718, 267–277. [Google Scholar] [CrossRef]

- Gourgues-Lorenzon, A.F. Application of electron backscatter diffraction to the study of phase transformations. Int. Mater. Rev. 2007, 52, 65–128. [Google Scholar] [CrossRef]

- Feijoo, I.; Merino, P.; Pena, G.; Rey, P.; Cabeza, M. Microstructure and Mechanical Properties of an Extruded 6005A Al Alloy Composite Reinforced with TiC Nanosized Particles and Strengthened by Precipitation Hardening. Metals 2020, 10, 1050. [Google Scholar] [CrossRef]

- Maitland, T.; Sitzman, S. Electron Backscatter Diffraction (EBSD) Technique and Materials Characterization Examples; Springer: Berlin, Germany, 2007. [Google Scholar]

- Randle, V. Application of electron backscatter diffraction to grain boundary characterisation. Int. Mater. Rev. 2004, 49, 1–11. [Google Scholar] [CrossRef]

- Wang, Y.; Shao, W.; Zhen, L.; Zhang, X. Microstructure evolution during dynamic recrystallization of hot deformed superalloy 718. Mater. Sci. Eng. A 2008, 486, 321–332. [Google Scholar] [CrossRef]

- Pickering, E.; Mathur, H.; Bhowmik, A.C.; Messe, O.M.D.M.; Barnard, J.; Hardy, M.; Krakow, R.; Loehnert, K.; Stone, H.; Rae, C. Grain-boundary precipitation in Allvac 718Plus. Acta Mater. 2012, 60, 2757–2769. [Google Scholar] [CrossRef]

- Guo, Z.; Zhou, J.; Yin, Y.; Shen, X.; Ji, X. Numerical Simulation of Three-Dimensional Mesoscopic Grain Evolution: Model Development, Validation, and Application to Nickel-Based Superalloys. Metals 2019, 9, 57. [Google Scholar] [CrossRef]

- Lin, Y.; Wu, X.-Y.; Chen, X.-M.; Chen, J.; Wen, D.-X.; Zhang, J.-L.; Li, L.-T. EBSD study of a hot deformed nickel-based superalloy. J. Alloy. Compd. 2015, 640, 101–113. [Google Scholar] [CrossRef]

- Huang, L.; Qi, F.; Hua, P.; Yu, L.; Liu, F.; Sun, W.; Hu, Z. Discontinuous Dynamic Recrystallization of Inconel 718 Superalloy during the Superplastic Deformation. Met. Mater. Trans. A 2015, 46, 4276–4285. [Google Scholar] [CrossRef]

- Dehmas, M.; Lacaze, J.; Niang, A.; Viguier, B. TEM Study of High-Temperature Precipitation of Delta Phase in Inconel 718 Alloy. Adv. Mater. Sci. Eng. 2011, 2011, 1–9. [Google Scholar] [CrossRef]

- Fang, T.; Kennedy, S.J.; Quan, L.; Hicks, T.J. The structure and paramagnetism of Ni3Nb. J. Phys. Condens. Matter 1992, 4, 2405–2414. [Google Scholar] [CrossRef]

- Clair, A.; Foucault, M.; Calonne, O.; Lacroute, Y.; Markey, L.; Salazar, M.; Vignal, V.; Finot, E. Strain mapping near a triple junction in strained Ni-based alloy using EBSD and biaxial nanogauges. Acta Mater. 2011, 59, 3116–3123. [Google Scholar] [CrossRef]

- Gertsman, V.Y. Coincidence site lattice theory of triple junctions and quadruple points. Sci. Technol. Interfaces 2002, 387–392. [Google Scholar] [CrossRef]

- Cayron, C. Multiple twinning in cubic crystals: Geometric/algebraic study and its application for the identification of the Σ3ngrain boundaries. Acta Crystallogr. Sect. A Found. Crystallogr. 2006, 63, 11–29. [Google Scholar] [CrossRef]

- Sangid, M.D.; Sehitoglu, H.; Maier, H.J.; Niendorf, T. Grain boundary characterization and energetics of superalloys. Mater. Sci. Eng. A 2010, 527, 7115–7125. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.; Sarma, V.S. Origin and Role of Σ3 Boundaries during Thermo-Mechanical Processing of a Ti-Modified Austenitic Stainless Steel. Mater. Sci. Forum 2011, 702–703, 714–717. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Sarma, V.S. Role of Twinning on Dynamic Recrystallization and Microstructure during Moderate to High Strain Rate Hot Deformation of a Ti-Modified Austenitic Stainless Steel. Met. Mater. Trans. A 2012, 43, 2056–2068. [Google Scholar] [CrossRef]

- Gornakova, A.S.; Straumal, B.B.; Nekrasov, A.N.; Kilmametov, A.; Afonikova, N.S. Grain Boundary Wetting by a Second Solid Phase in Ti-Fe Alloys. J. Mater. Eng. Perform. 2018, 27, 4989–4992. [Google Scholar] [CrossRef]

- Tan, L.; Sridharan, K.; Allen, T. Effect of thermomechanical processing on grain boundary character distribution of a Ni-based superalloy. J. Nucl. Mater. 2007, 371, 171–175. [Google Scholar] [CrossRef]

- Dahmen, U. Orientation relationships in precipitation systems. Acta Met. 1982, 30, 63–73. [Google Scholar] [CrossRef]

| Sample | Grain size Average ASTM (µm) | ||

|---|---|---|---|

| After Industrial Deformation without DP718 | After Thermal Treatment DP718 before DP718 Deformation | After DP718 Deformation | |

| A | 6 (45 µm) ALA 3 (127 µm) | 3 (127 µm) ALA 2 (180 µm) | 6 (45 µm) 60%, (16 μm) 40% ALA 5 (63 µm) |

| B | 7 (31 μm) 70%, 6 (45 µm) 30% ALA 5 (63 µm) | 4 (90 μm) ALA 3 (127 µm) | 4 (90 µm) 70%, 5 (63 µm) 30% |

| Element | Wyckoff | x | y | z | Occupation |

|---|---|---|---|---|---|

| Ni (1) | 2a | 0 | 0 | 0.3182 | 1 |

| Ni (2) | 4f | 0.7494 | 0 | 0.8414 | 1 |

| Nb (1) | 2b | 0 | 1/2 | 0.6513 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kañetas, P.J.P.; Calvo, J.; Rodriguez-Calvillo, P.; Cabrera Marrero, J.M.; Zamora Antuñano, M.A.; Guerrero-Mata, M.P. EBSD Study of Delta-Processed Ni-Based Superalloy. Metals 2020, 10, 1466. https://doi.org/10.3390/met10111466

Kañetas PJP, Calvo J, Rodriguez-Calvillo P, Cabrera Marrero JM, Zamora Antuñano MA, Guerrero-Mata MP. EBSD Study of Delta-Processed Ni-Based Superalloy. Metals. 2020; 10(11):1466. https://doi.org/10.3390/met10111466

Chicago/Turabian StyleKañetas, Pedro Jacinto Páramo, Jessica Calvo, Pablo Rodriguez-Calvillo, José María Cabrera Marrero, Marco Antonio Zamora Antuñano, and Martha Patricia Guerrero-Mata. 2020. "EBSD Study of Delta-Processed Ni-Based Superalloy" Metals 10, no. 11: 1466. https://doi.org/10.3390/met10111466

APA StyleKañetas, P. J. P., Calvo, J., Rodriguez-Calvillo, P., Cabrera Marrero, J. M., Zamora Antuñano, M. A., & Guerrero-Mata, M. P. (2020). EBSD Study of Delta-Processed Ni-Based Superalloy. Metals, 10(11), 1466. https://doi.org/10.3390/met10111466