Cold-Rolling Strain Hardening Effect on the Microstructure, Serration-Flow Behaviour and Dislocation Density of Friction Stir Welded AA5083

Abstract

1. Introduction

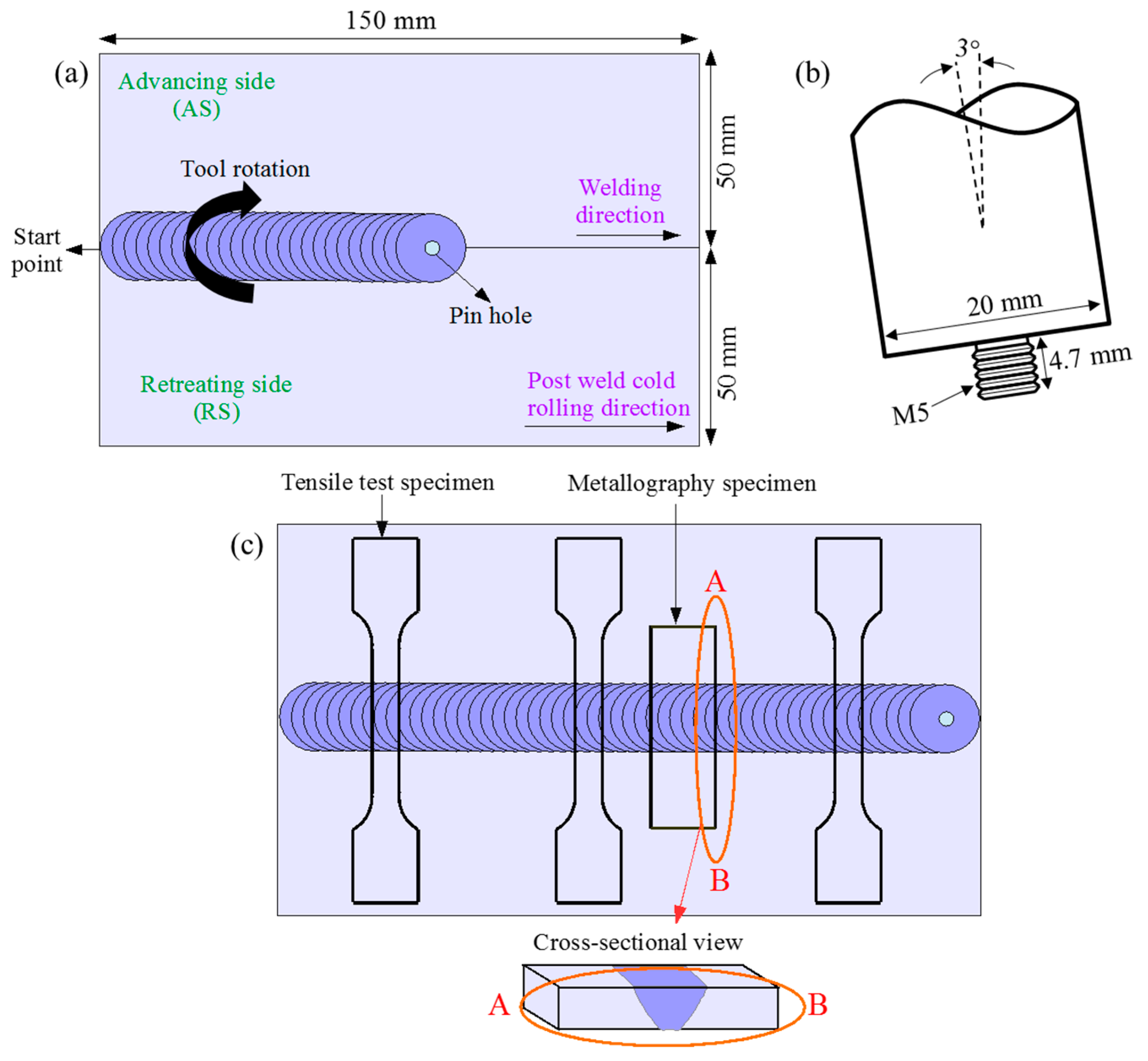

2. Materials and Methods

3. Results and Discussion

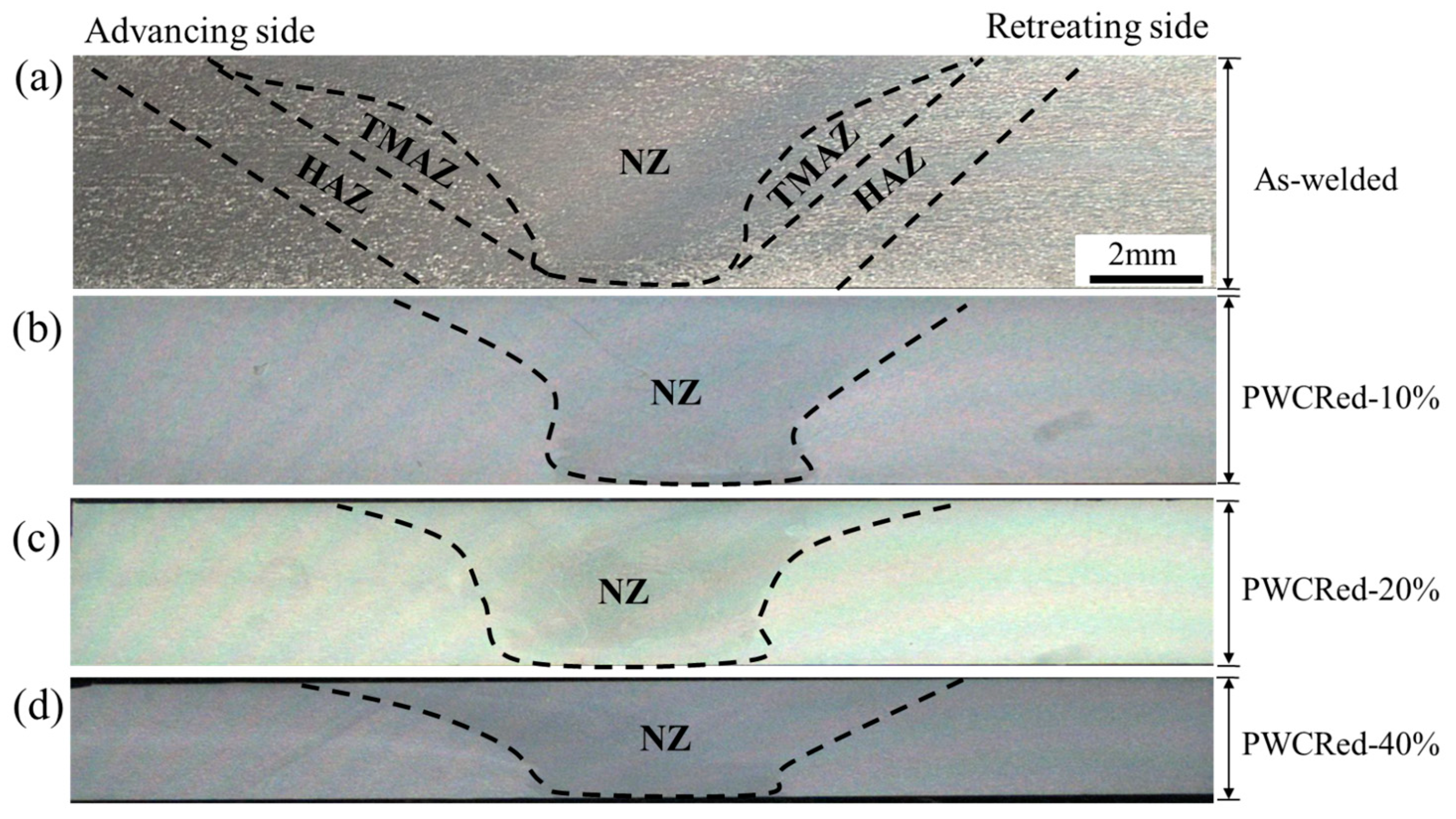

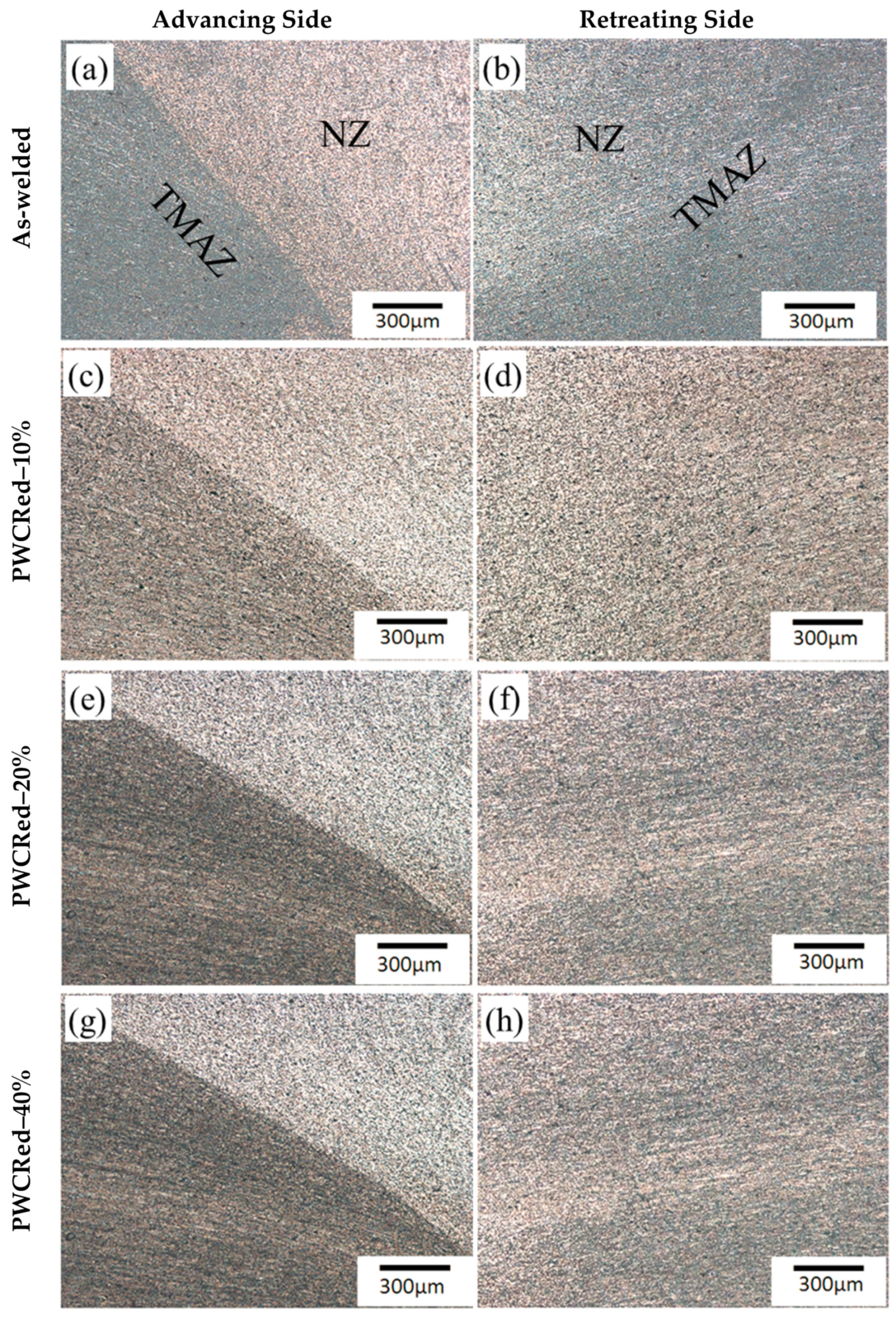

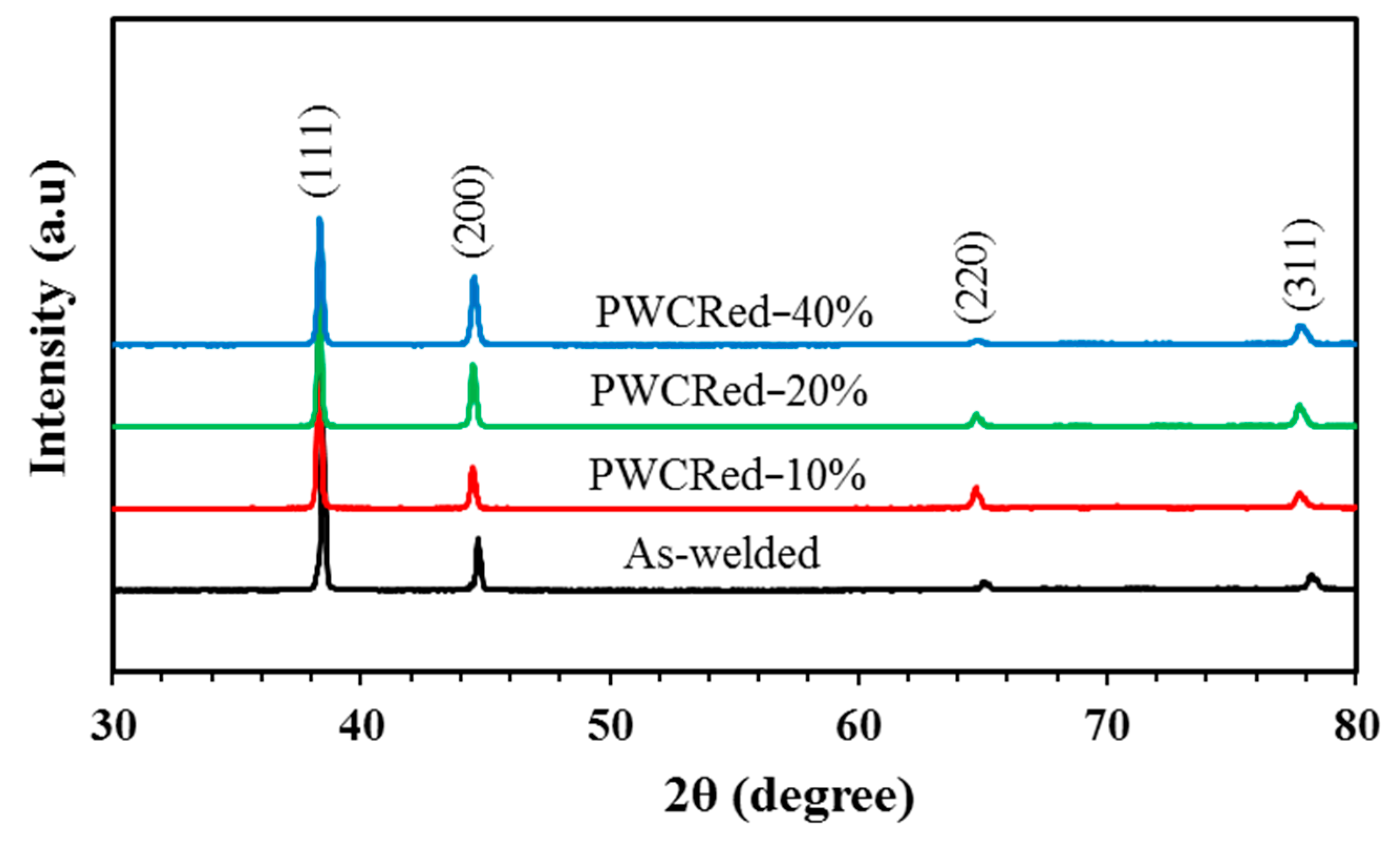

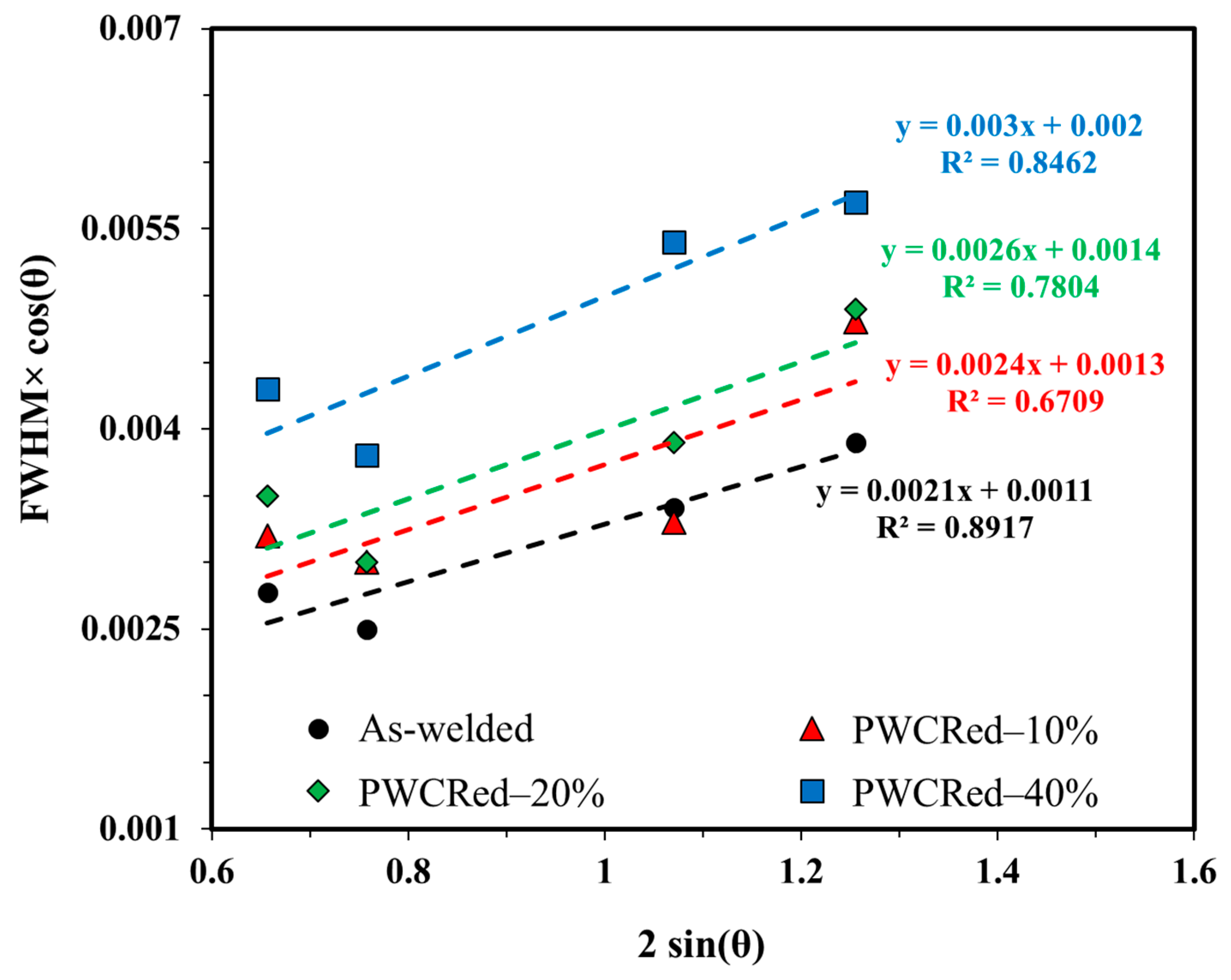

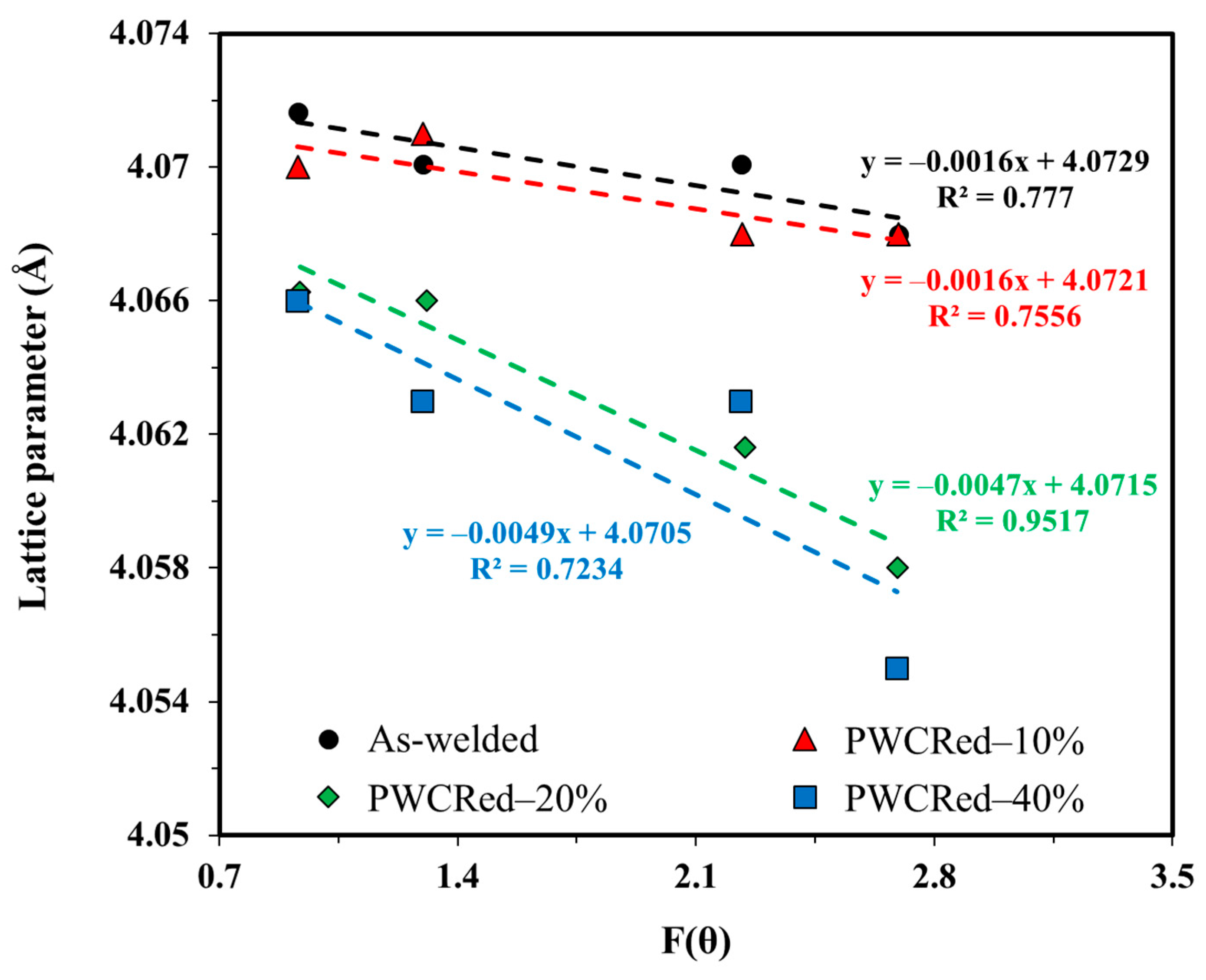

3.1. Microstructure

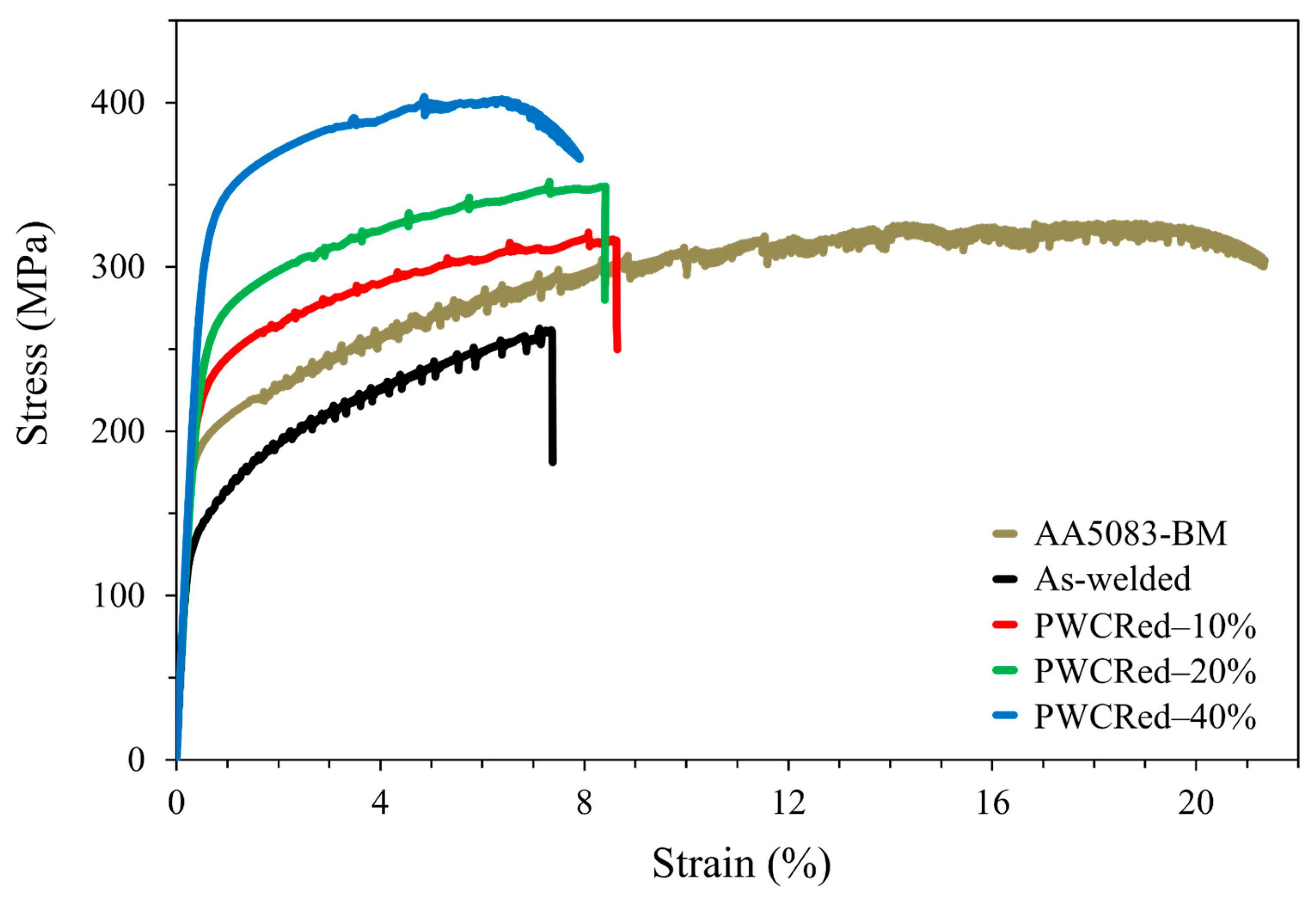

3.2. Tensile Properties

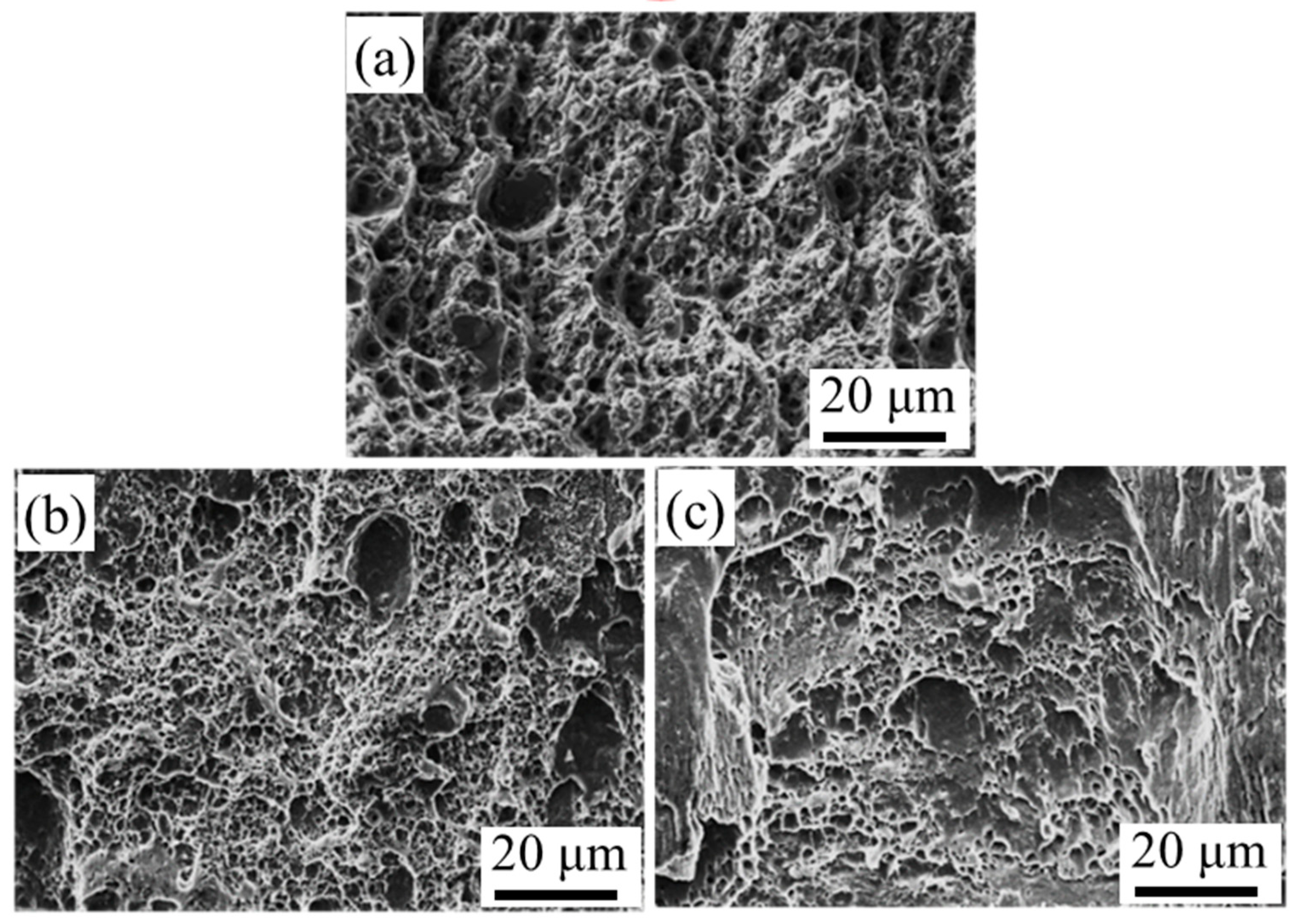

3.3. Fractography

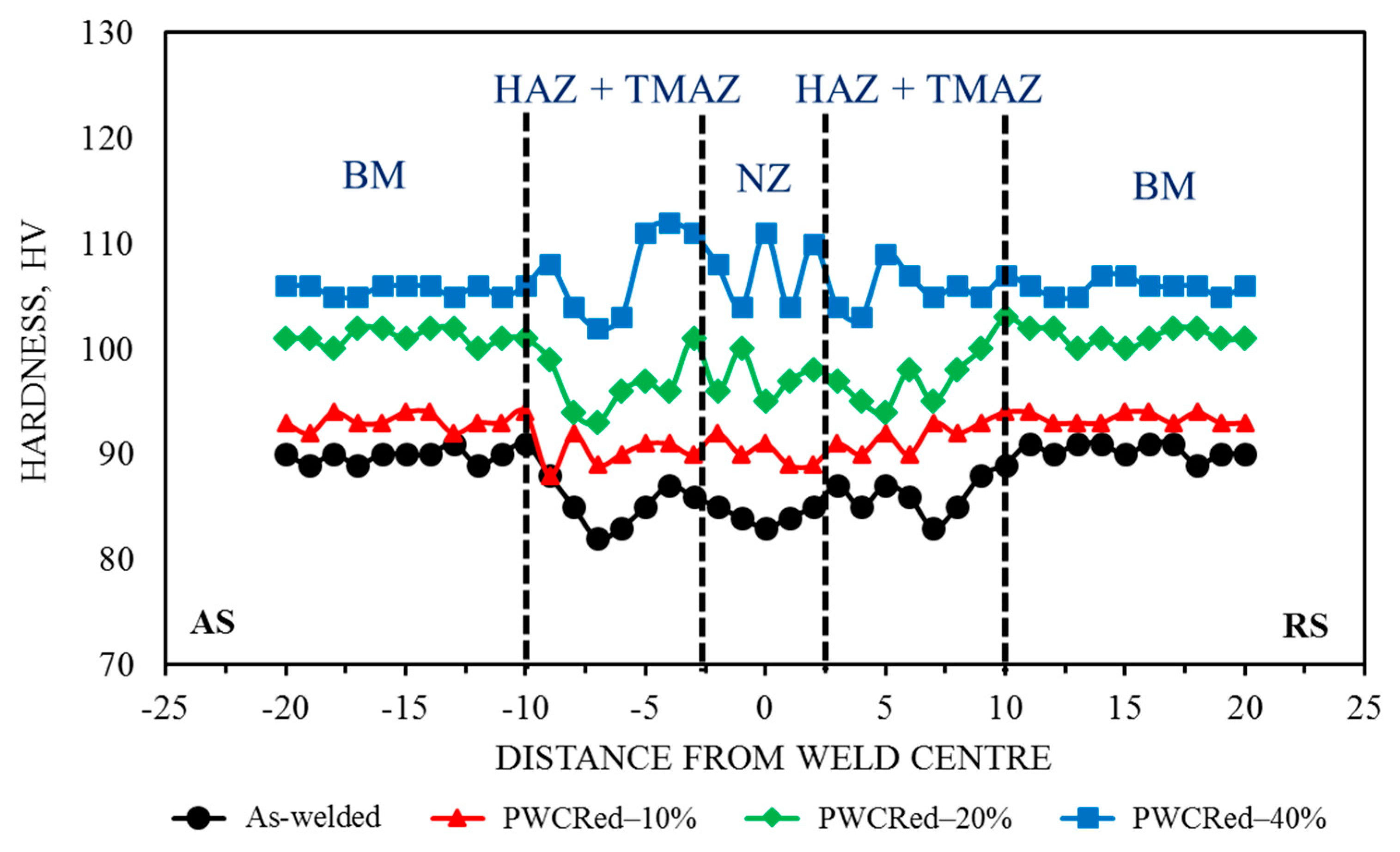

3.4. Vickers Hardness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Missori, S.; Sili, A. Mechanical behaviour of 6082-T6 aluminium alloy welds. Metall. Sci. Technol. 2000, 18, 12–18. [Google Scholar]

- Poznak, A.; Freiberg, D.; Sanders, P. Automotive Wrought Aluminium Alloys. In Fundamentals of Aluminium Metallurgy; Elsevier: Amsterdam, The Netherlands, 2018; pp. 333–386. [Google Scholar]

- Demir, H.; Gündüz, S. The effects of aging on machinability of 6061 aluminium alloy. Mater. Des. 2009, 30, 1480–1483. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of post-weld heat treatment on tensile properties of friction stir-welded AA6061 aluminum alloy joints. Mater. Charact. 2008, 59, 1168–1177. [Google Scholar] [CrossRef]

- Wang, B.; Xue, S.; Ma, C.; Wang, J.; Lin, Z. Effects of porosity, heat input and post-weld heat treatment on the microstructure and mechanical properties of TIG welded joints of AA6082-T6. Metals 2017, 7, 463. [Google Scholar] [CrossRef]

- Deekhunthod, R.N. Weld Quality in Aluminium Alloys. Master’s Thesis, University of Uppsala, Uppsala, Sweden, 23 May 2014. [Google Scholar]

- Carron, D.; Bastid, P.; Yin, Y.; Faulkner, R.G. Modelling of precipitation during friction stir welding of an Al-Mg-Si alloy. Tech. Mech. 2010, 30, 29–44. [Google Scholar]

- Dong, J.; Zhang, D.; Zhang, W.; Zhang, W.; Qiu, C. Microstructure evolution during dissimilar friction stir welding of AA7003-T4 and AA6060-T4. Materials 2018, 11, 342. [Google Scholar] [CrossRef]

- Selamat, N.F.M.; Baghdadi, A.H.; Sajuri, Z.; Kokabi, A.H. Friction stir welding of similar and dissimilar aluminium alloys for automotive applications. Int. J. Automot. Mech. Eng. 2016, 13, 3401. [Google Scholar] [CrossRef]

- Baghdadi, A.H.; Selamat, N.F.M.; Sajuri, Z. Effect of tool offsetting on microstructure and mechanical properties dissimilar friction stir welded Mg-Al alloys. IOP Conf. Ser. Mater. Sci. Eng. 2017, 238, 12018. [Google Scholar] [CrossRef]

- Nakamura, T.; Obikawa, T.; Nishizaki, I.; Enomoto, M.; Fang, Z. Friction stir welding of non-heat-treatable high-strength alloy 5083-O. Metals 2018, 8, 208. [Google Scholar] [CrossRef]

- Picot, F.; Gueydan, A.; Martinez, M.; Moisy, F.; Hug, E. A correlation between the ultimate shear stress and the thickness affected by intermetallic compounds in friction stir welding of dissimilar aluminum alloy–stainless steel joints. Metals 2018, 8, 179. [Google Scholar] [CrossRef]

- Osman, N.; Sajuri, Z.; Baghdadi, A.H.; Omar, M.Z. Effect of process parameters on interfacial bonding properties of aluminium-copper clad sheet processed by multi-pass friction stir-welding technique. Metals 2019, 9, 1159. [Google Scholar] [CrossRef]

- Shah, S.; Tosunoglu, S. Friction stir welding: Current state of the art and future prospects. In Proceedings of the 16th World Multi-Conference on Systemics, Cybernetics and Informatics, Orlando, FA, USA, 17–20 July 2012; pp. 17–20. [Google Scholar]

- Sibalic, N.; Vukcevic, M. Numerical Simulation for FSW Process at Welding Aluminium Alloy AA6082-T6. Metals 2019, 9, 747. [Google Scholar] [CrossRef]

- Amini, A.; Asadi, P.; Zolghadr, P. Friction stir welding applications in industry. In Advances in Friction-Stir Welding and Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 671–722. [Google Scholar]

- Selamat, N.M.; Baghdadi, A.H.; Sajuri, Z.; Kokabi, A.H.; Junaidi, S. Effect of rolling on strength of friction stir welded joint of aluminium alloys. J. Kejuruter. 2018, 1, 9–15. [Google Scholar]

- Baghdadi, A.H.; Selamat, N.F.M.; Sajuri, Z.; Kokabi, A.H. Effect of travel speed on quality and welding efficiency of friction stir welded AZ31B magnesium alloy. Int. J. Eng. Technol. (UAE) 2018, 7, 94–99. [Google Scholar] [CrossRef]

- Baghdadi, A.H.; Sajuri, Z.; MohamadSelamat, N.F.; Omar, M.Z.; Miyashita, Y.; Kokabi, A.H. Effect of intermetallic compounds on the fracture behavior of dissimilar friction stir welding joints of Mg and Al alloys. Int. J. Miner. Metall. Mater. 2019. Accepted. [Google Scholar] [CrossRef]

- Baragetti, S.; Urso, G.D. Aluminum 6060-T6 friction stir welded butt joints: Fatigue resistance with different tools and feed rates. J. Mech. Sci. Technol. 2014, 28, 11–14. [Google Scholar] [CrossRef]

- Selamat, N.F.M.; Baghdadi, A.H.; Sajuri, Z.; Kokabi, A.H. Weldability and mechanical properties of dissimilar al-mgsi to pure aluminium and al-mg using friction stir welding process. J. Teknol. 2019, 81, 143–149. [Google Scholar] [CrossRef]

- Threadgill, P.L.; Leonard, A.J.; Shercliff, H.R.; Withers, P.J. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93. [Google Scholar] [CrossRef]

- Liu, X.; Xie, P.; Wimpory, R.; Li, W.; Lai, R.; Li, M.; Chen, D.; Liu, Y.; Zhao, H. Residual stress, microstructure and mechanical properties in thick 6005A-T6 aluminium alloy friction stir welds. Metals 2019, 9, 803. [Google Scholar] [CrossRef]

- Behnagh, R.A.; Besharati Givi, M.K.; Akbari, M. Mechanical properties, corrosion resistance, and microstructural changes during friction stir processing of 5083 aluminum rolled plates. Mater. Manuf. Process. 2012, 27, 636–640. [Google Scholar] [CrossRef]

- Rao, D.; Huber, K.; Heerens, J.; Dos Santos, J.F.; Huber, N. Asymmetric mechanical properties and tensile behaviour prediction of aluminium alloy 5083 friction stir welding joints. Mater. Sci. Eng. 2013, 565, 44–50. [Google Scholar] [CrossRef]

- Borrego, L.P.; Costa, J.D.; Jesus, J.S.; Loureiro, A.R.; Ferreira, J.M. Fatigue life improvement by friction stir processing of 5083 aluminium alloy MIG butt welds. Theor. Appl. Fract. Mech. 2014, 70, 68–74. [Google Scholar] [CrossRef]

- Koilraj, M.; Sundareswaran, V.; Vijayan, S.; Koteswara Rao, S.R. Friction stir welding of dissimilar aluminum alloys AA2219 to AA5083-Optimization of process parameters using Taguchi technique. Mater. Des. 2012, 42, 1–7. [Google Scholar] [CrossRef]

- Bintu, A.; Vincze, G.; Picu, R.C.; Lopes, A.B. Effect of symmetric and asymmetric rolling on the mechanical properties of AA5182. Mater. Des. 2016, 100, 151–156. [Google Scholar] [CrossRef]

- Leal, R.M.; Loureiro, A. Effect of overlapping friction stir welding passes in the quality of welds of aluminium alloys. Mater. Des. 2008, 29, 982–991. [Google Scholar] [CrossRef]

- Gabrielli, F.; Forcellese, A.; El Mehtedi, M.; Simoncini, M. Mechanical properties and formability of cold rolled friction stir welded sheets in AA5754 for automotive applications. Procedia Eng. 2017, 183, 245–250. [Google Scholar] [CrossRef]

- Ozturk, F.; Sisman, A.; Toros, S.; Kilic, S.; Picu, R.C. Influence of aging treatment on mechanical properties of 6061 aluminum alloy. Mater. Des. 2010, 31, 972–975. [Google Scholar] [CrossRef]

- Bayley, C.J.; Pilkey, A.K. Influence of welding defects on the localization behaviour of an aluminum alloy tailor-welded blank. Mater. Sci. Eng. 2005, 403, 1–10. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enomoto, M.; Jogan, S. Microstructural evolution of 6063 aluminum during friction-stir welding. Metall. Mater. Trans. 1999, 30, 2429–2437. [Google Scholar] [CrossRef]

- Hamed, J.A. Effect of welding heat input and post-weld aging time on microstructure and mechanical properties in dissimilar friction stir welded AA7075–AA5086. Trans. Nonferr. Met. Soc. China 2017, 27, 1707–1715. [Google Scholar] [CrossRef]

- Pabandi, H.K.; Jashnani, H.R.; Paidar, M. Effect of precipitation hardening heat treatment on mechanical and microstructure features of dissimilar friction stir welded AA2024-T6 and AA6061-T6 alloys. J. Manuf. Process. 2018, 31, 214–220. [Google Scholar] [CrossRef]

- Syarif, J.; Nakashima, K.; Tsuchiyama, T.; Takaki, S. Effect of solute copper on yield strength in dislocation-strengthened steels. ISIJ Int. 2007, 47, 340–345. [Google Scholar] [CrossRef]

- Kozlov, E.V.; Koneva, N.A.; Popova, N.A. Grain structure, geometrically necessary dislocations and second-phase particles in polycrystals of micro-and mesolevels. Phys. Mesomech. 2009, 12, 280–292. [Google Scholar] [CrossRef]

- Abbass, M.K.; Ameen, H.A.; Hassan, K.S. Effect of heat treatment on corrosion resistance of friction stir welded AA 2024 aluminum alloy. Am. J. Sci. Ind. Res. 2011, 2, 297–306. [Google Scholar] [CrossRef]

- Lee, W.-B.; Kim, J.-W.; Yeon, Y.-M.; Jung, S.-B. The joint characteristics of friction stir welded AZ91D magnesium alloy. Mater. Trans. 2003, 44, 917–923. [Google Scholar] [CrossRef]

- Verdier, M.; Janecek, M.; Brechet, Y.; Guyot, P. Microstructural evolution during recovery in Al–2.5% Mg alloys. Mater. Sci. Eng. A 1998, 248, 187–197. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, J.P.; Chen, S.Y.; Xie, X.; Liaw, P.K.; Dahmen, K.A.; Qiao, J.W.; Wang, Y.L. Serration and noise behaviors in materials. Prog. Mater. Sci. 2017, 90, 358–460. [Google Scholar] [CrossRef]

- Härtel, M.; Illgen, C.; Frint, P.; Wagner, M. On the PLC effect in a particle reinforced AA2017 alloy. Metals 2018, 8, 88. [Google Scholar] [CrossRef]

- Sarkar, A.; Chatterjee, A.; Barat, P.; Mukherjee, P. Chaotic Behavior of the Portevin-Le Chatelier Effect in Low Carbon Steel. In Proceedings of the National Conference on Nonlinear Science and Dynamics, Chennai, India, 1–4 Feburay 2006. [Google Scholar]

- Yilmaz, A. The Portevin–Le Chatelier effect: A review of experimental findings. Sci. Technol. Adv. Mater. 2011, 12, 63001. [Google Scholar] [CrossRef]

- Pink, E. Features of the Portein-Le Chatelier effect in a low carbon steel. Scr. Metall. Mater. 1994, 30, 767–768. [Google Scholar] [CrossRef]

- Fu, S.; Zhang, Q.; Hu, Q.; Gong, M.; Cao, P.; Liu, H. The influence of temperature on the PLC effect in Al-Mg alloy. Sci. China Technol. Sci. 2011, 54, 1389–1393. [Google Scholar] [CrossRef]

- Ling, C.P.; McCormick, P.G. The effect of temperature on strain rate sensitivity in an Al-Mg-Si alloy. Acta Metall. Mater. 1993, 41, 3127–3131. [Google Scholar] [CrossRef]

- Dini, G.; Ueji, R.; Najafizadeh, A.; Monir-Vaghefi, S.M. Flow stress analysis of TWIP steel via the XRD measurement of dislocation density. Mater. Sci. Eng. A 2010, 527, 2759–2763. [Google Scholar] [CrossRef]

- Baghdadi, A.H.; Rajabi, A.; Selamat, N.F.M.; Sajuri, Z.; Omar, M.Z. Effect of post-weld heat treatment on mechanical behaviour and dislocation density of FSWed Al 6061. Mater. Sci. Eng. A 2019, 754, 728–734. [Google Scholar] [CrossRef]

- Malopheyev, S.; Kulitskiy, V.; Mironov, S.; Zhemchuzhnikova, D.; Kaibyshev, R. Friction-stir welding of an Al-Mg-Sc-Zr alloy in as-fabricated and work-hardened conditions. Mater. Sci. Eng. A 2014, 600, 159–170. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, X.; Zhang, J.; Zhou, G.; Xu, X.; Zou, B. Effect of welding parameters on microstructure and mechanical properties of friction stir spot welded 5052 aluminum alloy. Mater. Des. 2011, 32, 4461–4470. [Google Scholar] [CrossRef]

- Razavi, M.; Rahimipour, M.R.; Rajabi, A. Prenucleation effect on characterisations of synthesised nanocrystalline tungsten carbide via mechanical milling. Mater. Technol. 2013, 28, 145–154. [Google Scholar] [CrossRef]

- Rajabi, A.; Ghazali, M.J. Quantitative analyses of TiC nanopowders via mechanical alloying method. Ceram. Int. 2017, 43, 14233–14243. [Google Scholar] [CrossRef]

- Kalita, M.P.C.; Deka, K.; Das, J.; Hazarika, N.; Dey, P.; Das, R.; Paul, S.; Sarmah, T.; Sarma, B.K. X-ray diffraction line profile analysis of chemically synthesized lead sulphide nanocrystals. Mater. Lett. 2012, 87, 84–86. [Google Scholar] [CrossRef]

- Deevi, S.; Deevi, S.C.; Verneker, V.R.P. Reactivities of aluminium and aluminium-magnesium alloy powders in polymeric composites. J. Mater. Sci. 1996, 31, 1043–1051. [Google Scholar] [CrossRef]

- Salahi, E.; Rajabi, A. Fabrication and characterisation of copper–alumina nanocomposites prepared by high-energy fast milling. Mater. Sci. Technol. 2016, 32, 1212–1217. [Google Scholar] [CrossRef]

- Sharma, C.; Upadhyay, V.; Dwivedi, D.K.; Kumar, P. Mechanical properties of friction stir welded armor grade Al–Zn–Mg alloy joints. Trans. Nonferr. Met. Soc. China 2017, 27, 493–506. [Google Scholar] [CrossRef]

- Armstrong, R.W. Hall–Petch Relationship: Use in Characterizing Properties of Aluminum and Aluminum Alloys. In Encyclopedia of Aluminum and It Alloys; Totton, G.E., Tiryakioglu, M., Eds.; Taylor & Francis Group: London, UK, 2016. [Google Scholar]

| Al | Mg | Mn | Cr | Si | Fe |

|---|---|---|---|---|---|

| Balance | 4.46 | 1.0 | 0.14 | 0.25 | 0.45 |

| Sample | Tensile Strength (MPa) | Elongation (%) | Welding Efficiency (%) |

|---|---|---|---|

| AA5083-BM | 328 | 22 | - |

| As-welded | 262 | 7.3 | 80 |

| PWCRed–10% | 321 | 8.6 | 98 |

| PWCRed–20% | 350 | 8.4 | 107 |

| PWCRed–40% | 403 | 7.9 | 123 |

| Sample | Y = αX + β | d (n.m) | ⴄ (%) | |

|---|---|---|---|---|

| α | β | |||

| As-welded | 0.0021 | 0.0011 | 126.08 | 0.21 |

| PWCRed–10% | 0.0024 | 0.0013 | 106.68 | 0.24 |

| PWCRed–20% | 0.0026 | 0.0014 | 99.06 | 0.26 |

| PWCRed–40% | 0.0030 | 0.0020 | 69.35 | 0.30 |

| Sample | a (Nelson–Riley Method) (Å) | b (10−10 m) | ρ × 1014 (m−2) |

|---|---|---|---|

| As-welded | 4.0729 | 2.87998 | 2.00340 |

| PWCRed–10% | 4.0721 | 2.87941 | 2.70643 |

| PWCRed–20% | 4.0715 | 2.87899 | 3.15797 |

| PWCRed–40% | 4.0705 | 2.87828 | 5.20672 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sajuri, Z.; Mohamad Selamat, N.F.; Baghdadi, A.H.; Rajabi, A.; Omar, M.Z.; Kokabi, A.H.; Syarif, J. Cold-Rolling Strain Hardening Effect on the Microstructure, Serration-Flow Behaviour and Dislocation Density of Friction Stir Welded AA5083. Metals 2020, 10, 70. https://doi.org/10.3390/met10010070

Sajuri Z, Mohamad Selamat NF, Baghdadi AH, Rajabi A, Omar MZ, Kokabi AH, Syarif J. Cold-Rolling Strain Hardening Effect on the Microstructure, Serration-Flow Behaviour and Dislocation Density of Friction Stir Welded AA5083. Metals. 2020; 10(1):70. https://doi.org/10.3390/met10010070

Chicago/Turabian StyleSajuri, Zainuddin, Nor Fazilah Mohamad Selamat, Amir Hossein Baghdadi, Armin Rajabi, Mohd Zaidi Omar, Amir Hossein Kokabi, and Junaidi Syarif. 2020. "Cold-Rolling Strain Hardening Effect on the Microstructure, Serration-Flow Behaviour and Dislocation Density of Friction Stir Welded AA5083" Metals 10, no. 1: 70. https://doi.org/10.3390/met10010070

APA StyleSajuri, Z., Mohamad Selamat, N. F., Baghdadi, A. H., Rajabi, A., Omar, M. Z., Kokabi, A. H., & Syarif, J. (2020). Cold-Rolling Strain Hardening Effect on the Microstructure, Serration-Flow Behaviour and Dislocation Density of Friction Stir Welded AA5083. Metals, 10(1), 70. https://doi.org/10.3390/met10010070