2. Method

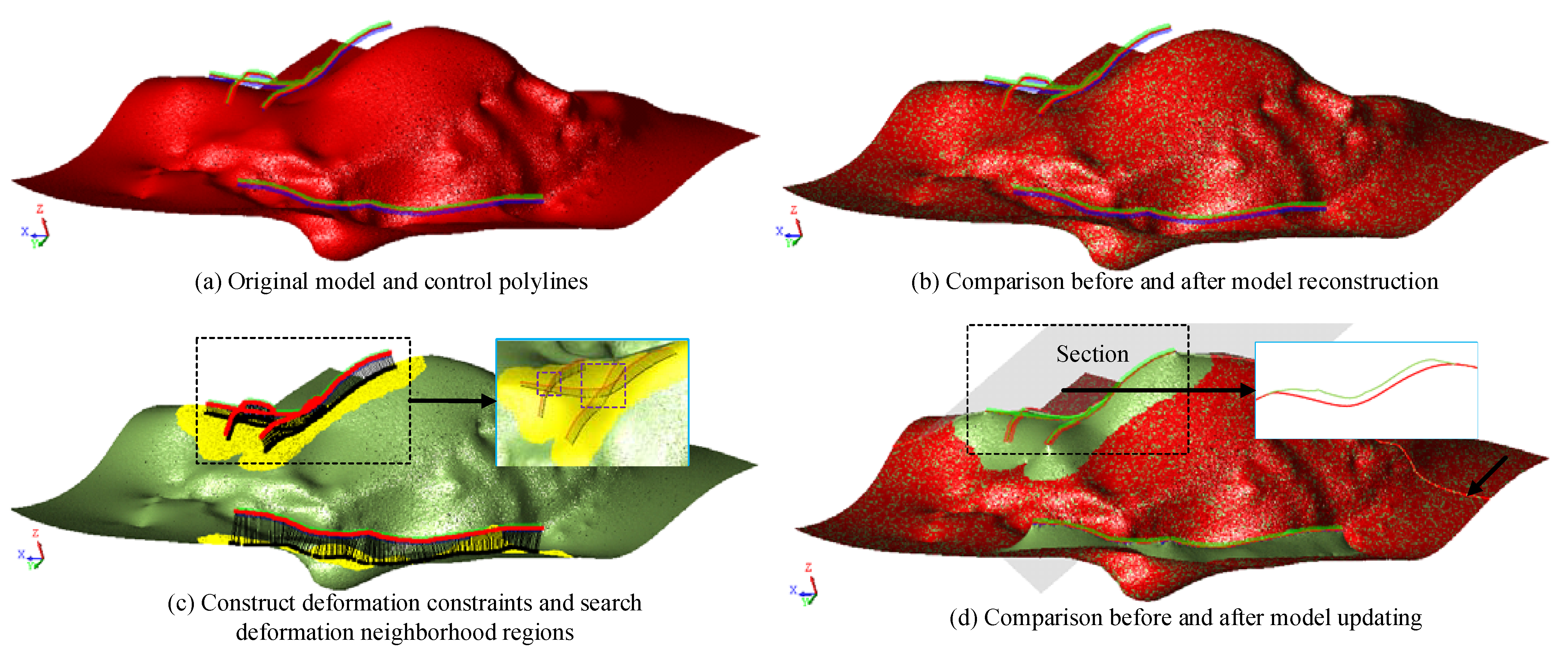

It is necessary to dynamically update the orebody model according to the latest geological logging data with the continuous exposure of local geological characteristics of the orebody in the process of production and exploration. We attempted to construct a local dynamic updating method of the orebody model based on mesh reconstruction and mesh deformation. It constructs deformation constraint conditions between the model and geological logging data.

The geological interpretation polylines and interpretation points obtained from geological logging data were the main sources of model updating data. They were transformed into control polylines and control points through preprocessing, which were used to represent the polylines and points of controlling the external shape trend of model updating, respectively. In addition, the deformation points were used to represent the deformation constraint point on the original orebody model corresponding to the control points. The deformation neighborhood region was used to represent the mesh deformation range affected by the deformation points on the orebody model, that is, the region of interest (ROI).

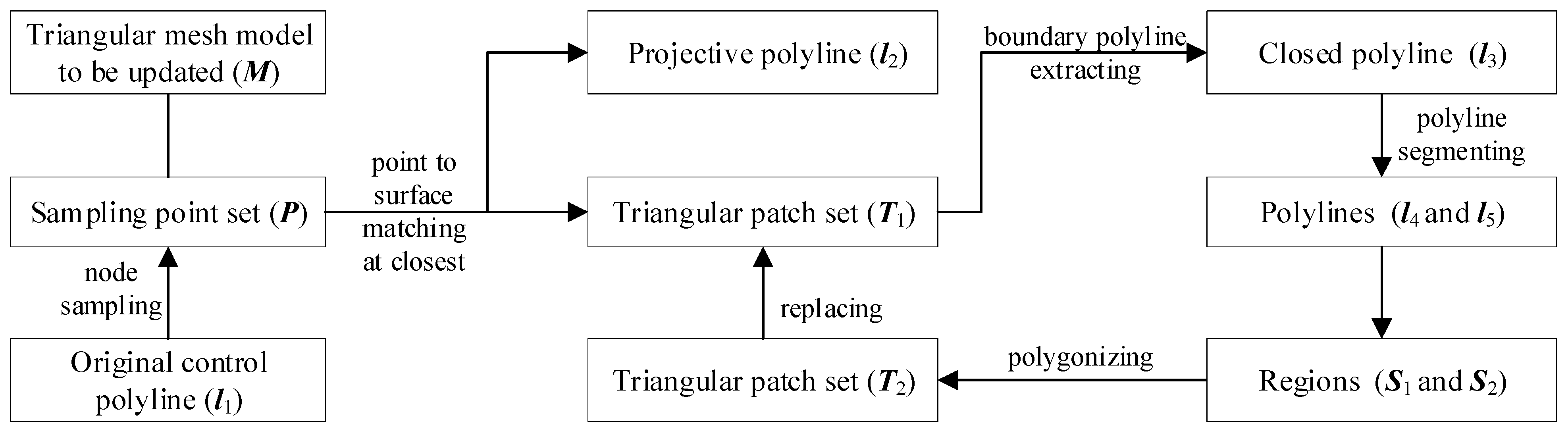

According to the updating idea of 3D orebody mesh reconstruction and mesh deformation, as shown in

Figure 1, the model-updating method was divided into five main steps:

Step 1 (preprocessing of geological data): The newly obtained geological logging data were transformed into control polylines and control points to obtain geometric constraint information with consistent topology.

Step 2 (mesh reconstruction of feature preservation): Based on feature detection, the original input mesh model was reconstructed with feature preservation to obtain a better mesh model with high quality.

Step 3 (construction of deformation constraints): The deformation constraints of the orebody model were constructed by matching the deformation points through the control polylines. Furthermore, a similar path with the same number of points was searched on the orebody mesh model based on the control points sampled on the control polylines.

Step 4 (optimization of updating deformation neighborhood region): The mesh area that allowed deformation near the deformation points was optimized and adjusted according to the distance between the model and control polylines, the morphological characteristics of the model and local deformation trend, etc.

Step 5 (constrained mesh deformation): Combined with Laplace coordinate transformation and other methods, the locally updated orebody model was obtained based on the optimized local updating deformation neighborhood region.

Finally, the mesh simplification and mesh repairing of the updated orebody model were carried out to obtain a valid mesh model that satisfied the manifold characteristics. We will describe each step in detail in the following sections. In the Results section, the real data will be tested and analyzed. In the Discussion section, we will analyze the limitations and extensions of this method.

2.1. Preprocessing of Original Geological Data

Before updating the orebody model locally, first, the geological interpretation lines and points obtained from the original geological logging data needed to be preprocessed with de-weighting and simplification to construct topologically consistent geometric constraint information. Second, all valid geological interpretation lines and points needed to be transformed into control polylines and control points, respectively, so that we could construct deformation constraints based on control polylines and control points in the later stage.

In addition, it was necessary to adjust the intersection position of control polylines to ensure the accurate intersection of each control polyline, so that the updated orebody model could snap all control polylines accurately. Furthermore, we used the spatial searching method (e.g., the OBB tree) to speed up the calculation of the exact intersection points between all control polylines.

In the stage of constructing deformation constraints, the optimal deformation point corresponding to the control point was searched according to the corresponding projection direction. To ensure that the model updating effect satisfied the geological characteristics, geological engineers were allowed to adjust the projection direction of the control polylines and points relative to the orebody model.

2.2. Mesh Reconstruction of Geological Models

To ensure that the original input orebody model had a smooth deformation trend and higher mesh quality, mesh reconstruction for the original geological models was important. There were three main problems that needed to be considered, including the size of the mesh reconstruction, the feature protection, and the reconstruction method.

The reconstruction size represents the facet side length of the reconstructed model, and it corresponds to the side length of the triangular patch for the triangular mesh model. In the process of mesh reconstruction, it is better to ensure that the size of mesh reconstruction is less than or equal to the interval of control points sampled on the control polyline. It is worth noting that the reconstructed result should preserve the features of the original model. Therefore, it was necessary to automatically extract the sharp features of the mesh model through the feature detection algorithm, including feature lines and feature points. In addition, artificial additional feature lines and points were allowed to ensure the quality of geological models after mesh reconstruction, such as the alignment of the original model edge, and the retention of the crease feature between patches.

In this paper, we used the implicit reconstruction method while taking feature preservation into account. It transformed feature lines and feature points into constraint lines and constraint points as spatial interpolation constraints and implicitly expressed the geometric model of orebody through the implicit function. Finally, the implicit function was transformed into the mesh model by the surface reconstruction method, taking into account feature preservation.

2.3. Construction of Deformation Constraints

The deformation constraints are the precondition and important link for updating a model. We constructed the deformation constraints of the orebody model by matching deformation points with control polylines. The key idea of the algorithm was to search a similar path with the same number of points as the control polyline on the mesh model. Furthermore, it was imperative that the deformation points on the path be adjacent, otherwise, holes could have appeared in the updated model.

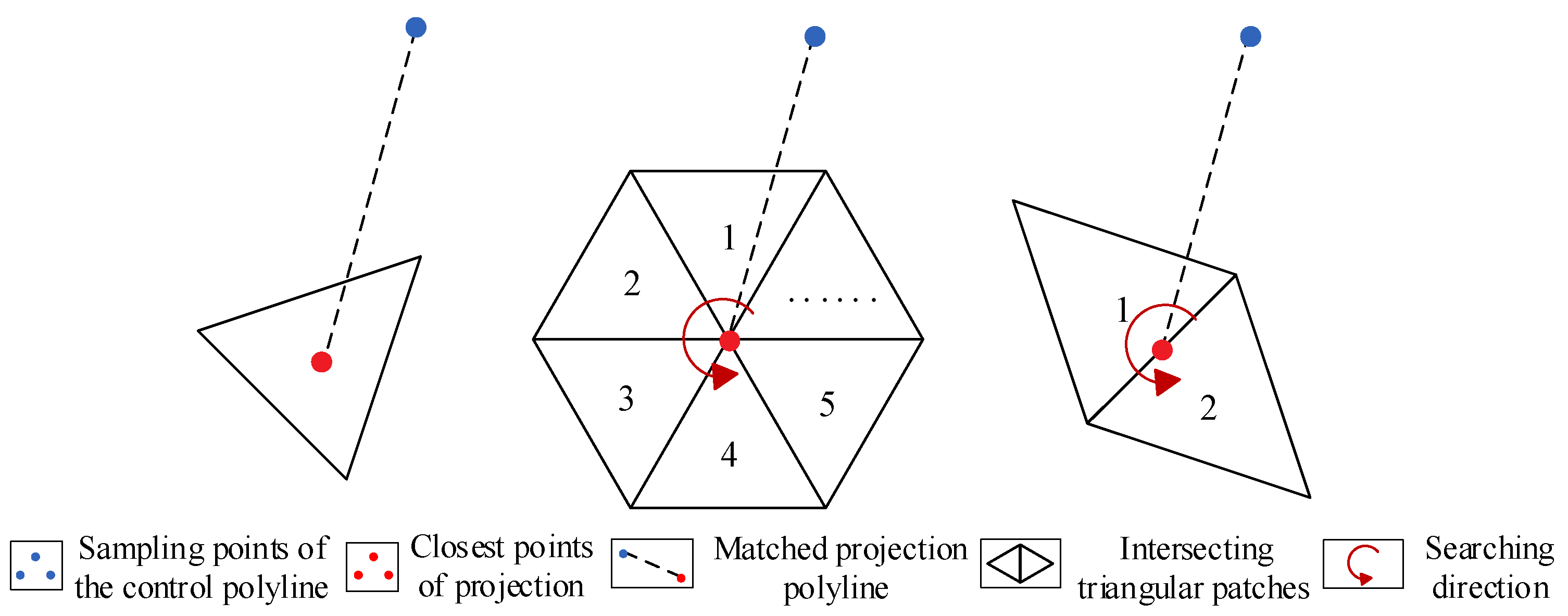

To construct deformation constraints, firstly, we needed to search the closest points of all control points corresponding to the model surface by point projection. Then, the projective polyline corresponding to the control polyline with the same number of points was determined by taking the closest point as the deformation point. The deformation point needed to be the vertex of the mesh. Since the closest projection point may not have been the vertex of the mesh, the projective neighborhood boundary polyline needed to be further extracted from triangular patches where the deformation point and projective polyline were located. Finally, the projective neighborhood was reconstructed by taking the deformation points on the projective polyline as mesh vertices. The detailed steps were as follows, and the process and demonstration are shown in

Figure 2 and

Figure 3, respectively.

Step 1: Under the condition of reserving all key nodes on the control polyline, the control polyline was sampled with a certain interval to obtain a set of sampling points .

Step 2: Traversing the set of sampling points , the corresponding projective polyline was obtained by searching the closest points of sampling points on the mesh. Then, a set of connected triangular patches, denoted as , were obtained, which intersected with the projective polyline.

Step 3: The closed polyline was obtained by extracting the boundary of the set of the intersecting triangular patches .

Step 4: The closest points from a start point and an endpoint of the projective polyline to the closed polyline , respectively, were searched. Then, the two closest points were used to divide the closed polyline into two polylines ( and ), respectively.

Step 5: The region between and was polygonized. Then, the region between and was polygonized to obtain a new set of triangular patches , which replaced the set of original triangular patches .

In Step 2, according to the position of the closest projection point (i.e., deformation point) of the control point to the triangular mesh model, it could be divided into three cases, namely, the vertex, the edge, and the patch of the triangular mesh. Therefore, different methods needed to be adopted to determine the triangular patches, as shown in

Figure 4. Firstly, if the deformation point was located at the mesh vertex, the adjacent triangular patches of the mesh vertex within a circle needed to be added to the set

. Secondly, if the deformation point was located on the mesh edge, the two adjacent triangular patches of the mesh edge needed to be added to the set

. Thirdly, if the deformation point was in the triangular mesh patch, the triangular patch needed to be added to the set

.

The triangular patches intersected by all matched projection polylines could be searched according to the method shown in

Figure 4. However, it required the searching of all triangular patches on the path of the projective polyline to conduct the subsequent work. In addition, there was an adaptive problem between the control polyline and the mesh model. If the adaptability was adequate, the control points could match the deformation points one by one, and the topological structure of the projective neighborhood triangular meshes was adequate. However, the adaptability was generalized in some conditions, such as the sampling interval being larger than the mesh size, the local shape trend of the model changing greatly, etc. For this case, the topological discontinuity may have occurred in some special locations, which required special methods to deal with. Therefore, we constructed a pseudo-cut surface between two adjacent deformation points, which was automatically generated by three points, including the two adjacent deformation points and the midpoint of two adjacent control points, as shown in

Figure 5. Then, the pseudo-cut surface intersected with the mesh model, and the intersecting triangular patches were extracted as a subset of

. Finally, all triangular patches between the deformation points could be extracted to maintain the topological continuity of the projective neighborhood.

It should be noted that the interlacing of matched projection polylines could easily have led to the self-intersection of the model after deformation. In the matching process between control points and deformation points, we needed to ensure one-to-one correspondence between points to avoid the phenomenon of cross-matching or repeated matching.

2.4. Determination and Adjustment of Deformation Neighborhood Region

To determine the local updating deformation neighborhood region of the model, we utilized a method of constructing the deformation neighborhood region based on the specified ring radius of the deformation point. For this method, the value of ring radius was used to quantify the neighborhood radius, and the greedy search strategy was used to automatically search the deformation neighborhood region around the deformation point, as shown in

Figure 6.

Generally, if the control polyline was close to the model, the neighborhood radius should have been small. If the control polyline was far away from the model, the neighborhood radius should have been large. To determine the optimal deformation neighborhood region of the mesh model, it was necessary to analyze the characteristics of the optimal deformation neighborhood region. Firstly, the size of the deformation neighborhood region needed to take into account the distance between the control polyline and the model. Secondly, the mesh deformation trend of the deformation neighborhood region needed to be adapted to the shape feature of geological models. Thirdly, the geological models needed to maintain reasonable characteristics and transition in the deformation neighborhood region before and after deformation. Based on the above analysis, the geological engineers could interactively adjust the initial deformation neighborhood region according to the actual conditions, as shown in

Figure 7.

2.5. Constraint Deformation and Mesh Simplification

Based on the matched deformation constraints, we could conduct the local dynamic updating of the orebody mesh model based on the Laplace transformation method. The deformation method involved a set of control points used to control the external shape trend in the model updating process, a set of triangular mesh vertices (i.e., deformation points or deformation control points) from the projection of control points to control model deformation, a set of vertices of deformation regions (i.e., ROI), and a set of non-deformation points (i.e., non-deformation control points) in ROI.

We specified a unique target position for each deformation point, and the target position was determined according to the matching relation between the deformation point and the control point. The deformation constraint was defined at the target position of each deformation point. During the deformation process, the coordinates of the non-deformation points were updated by the deformation algorithm, which adopted the Laplace deformation algorithm.

The essence of Laplace mesh deformation is the obtaining of the 3D coordinates of each mesh vertex by solving the linear equations. In this way, a new 3D model can be reconstructed after obtaining new coordinates by solving the equations. The Laplace representation of points in surface mesh (i.e., Laplace coordinates) is a method used to encode the local neighborhood of vertices in surface mesh. In this representation, a vertex

is associated with a 3D vector, which is defined as follows:

where

is the set of vertices adjacent to

, and

is the weight of the directed edge

.

In addition, we simplified the mesh model by constructing mesh simplification constraints without changing the quality of the overall mesh model. Specifically, the triangular meshes around the control polyline were not simplified, while the remaining meshes were simplified by merging the fine meshes.

Finally, to ensure the validity of the mesh model after local updating, the method supported the validity detection of the mesh model. Furthermore, the self-intersecting triangular patches could be repaired, and the manifold valid characteristics that satisfied the orebody model could be obtained.

4. Discussion

4.1. Limitations

To make the process of orebody modeling and updating more automated and intelligent, it is necessary to establish a more automated, efficient, and robust local dynamic updating method. However, there are still some limitations to our work that need to be improved.

One of them is that the method proposed in this paper may be unsuitable for some special conditions. Firstly, the large difference between the control polylines and the model may lead to an abnormal matching between control points and deformation points. Secondly, if a control polyline is too long, the neighborhood radius may not satisfy the deformation trend. Thirdly, if the model or control polyline is complex, the matched projection polyline may be abnormal, resulting in distortion of the model after deformation. Therefore, based on the limitations of this method, to ensure the mesh quality, we should divide a complex control polyline into several segment lines and update the complex model iteratively.

Another limitation to this method is that, for orebody models with special shapes, or at special positions within the model, there may be feature loss during model updating. On the one hand, if there are many concave and convex shapes on the model surface, many detailed features may be lost after updating. On the other hand, if the model is updated at sharp points or the model is thin, the sharp features of the model may be lost. Therefore, for this kind of special orebody model, the defining of strict sharp feature constraint lines and points should be considered to ensure that these features can be retained.

4.2. Extensions

To enhance the robustness and adaptability of this method, it is necessary to satisfy the requirement of the algorithm for the inputs. Our approach requires that the input data should be a set of geological interpretation data and an orebody mesh model to be updated. When the orebody model is reconstructed, the shape of the model may change to a certain extent. An important extension is that only the deformation region is reconstructed, which can improve the quality of model updating. In this paper, there are some examples of mesh reconstruction for some regions, such as the mesh reconstruction of the projective neighborhood, which reflects the feasibility of this extended idea. Furthermore, this method is not only applicable to the orebody model but is also applicable to some other surface mesh models such as the orebody model. It is also applicable to the updating of the solid model, and thus, is not limited only to the surface mesh model.

Another important extension is that, according to the particularity of some models and the complexity of control polylines, we can study more abundant and reliable deformation constraint methods to improve not only the adaptability and robustness of the model-updating method but also the quality and efficiency of model updating. The particularity of the model can be reflected in the special morphology (e.g., the thin orebody or the orebody with many morphological changes), the special updating area (e.g., the position with sharp or large fluctuation of the model), etc. The complexity of control polylines includes intensive polylines, irregular polylines, lengthy polylines, etc. Therefore, we can define some additional constraint data according to different situations, improve the model-updating method, and make the model-updating method more adaptable and more robust.