- Article

Divergent Responses of Inorganic and Organic Carbon Sinks to Climate Change over the Recent Decades in Lake Yamzhog Yumco, Tibetan Plateau

- Han Zhou,

- He Chang and

- Ping Pan

- + 7 authors

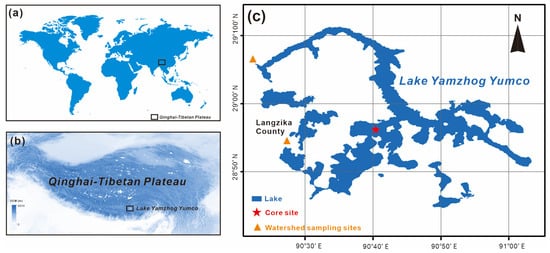

Lake sediments on the Tibetan Plateau serve as crucial carbon sinks in the regional carbon cycles. In recent decades, climate change has triggered significant hydrological changes in many lakes across this region, potentially impacting their carbon-sink functions. Previous studies have predominantly focused on the dynamics of organic carbon burial, largely overlooking the contribution of inorganic carbon sinks, and particularly lacking systematic investigation into the carbon burial processes in lakes experiencing water level decline. Therefore, this study examines a sediment core from Lake Yamzhog Yumco, a lake in the southern Tibetan Plateau with a gradually declining water level. The mineralogical and geochemical analyses of both lake and catchment sediments show that the inorganic carbon (carbonates are dominated by aragonite) and organic carbon are primarily authigenic origin. Over the past four decades, the inorganic carbon burial rate (ICBR) in Lake Yamzhog Yumco has been primarily controlled by water level fluctuations and is closely related to hydrochemical processes regulated by regional climate change. In contrast, the increase in the organic carbon burial rate (OCBR) has been co-influenced by both water level changes and regional temperature. During this period, the ICBR reached as high as 186 g m−2 yr−1, approximately five times the OCBR. This demonstrates that in lakes in semi-arid regions, the sink potential of inorganic carbon significantly exceeds that of organic carbon, highlighting the necessity of incorporating inorganic carbon burial into carbon-sink assessments. This study provides novel perspectives for a deeper understanding of the driving mechanisms behind carbon burial in Tibetan Plateau lakes and offers a scientific basis for accurately assessing and predicting regional carbon-sink potential.

2 January 2026