Characterization of Microstructure of Crept Nb and Ta-Rich γ-TiAl Alloys by Automated Crystal Orientation Mapping and Electron Back Scatter Diffraction

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

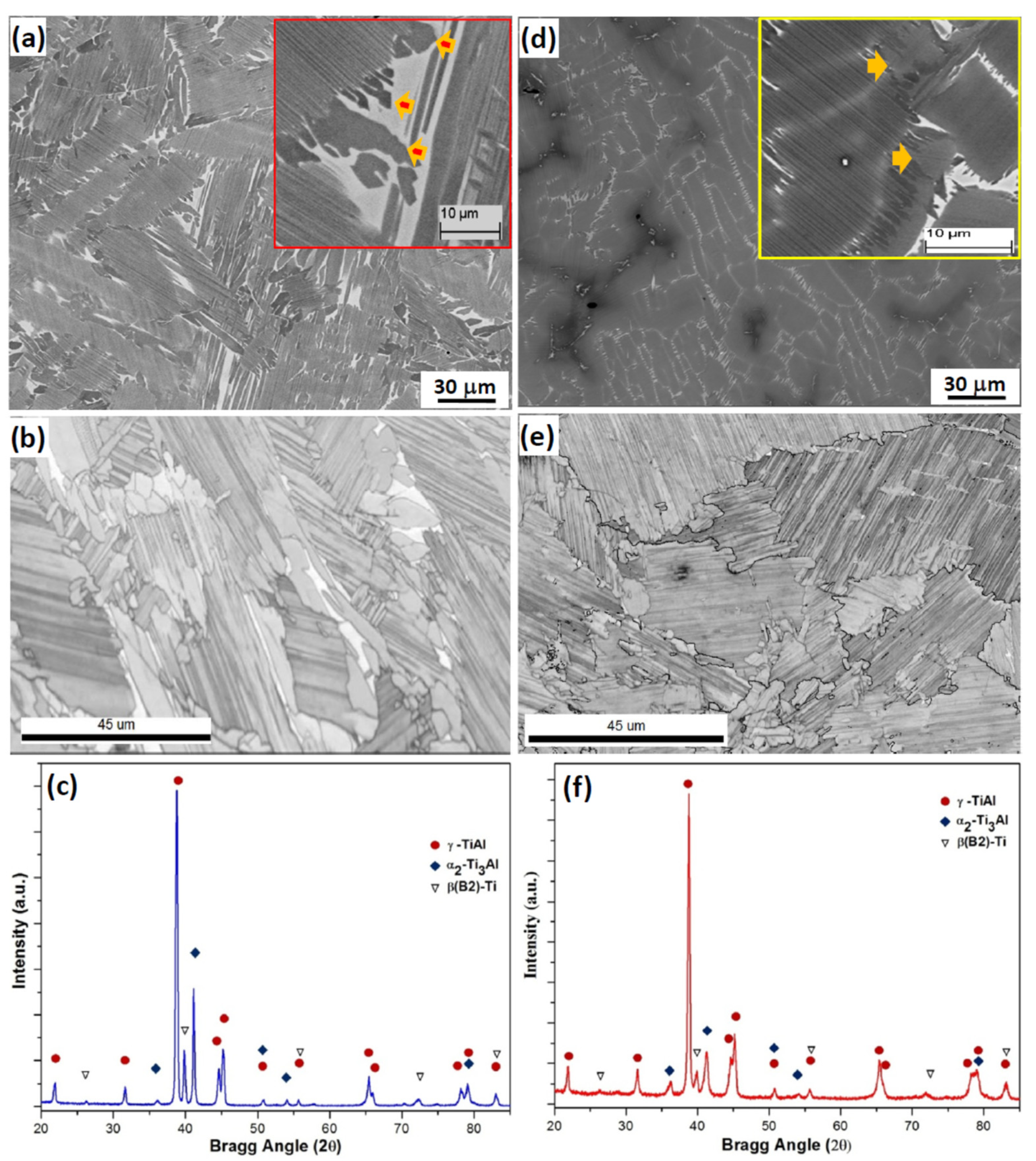

3.1. Microstructure of the As-Cast Materials

3.2. Compressive Creep Behavior

3.3. Microstructural Characterization of Crept Samples

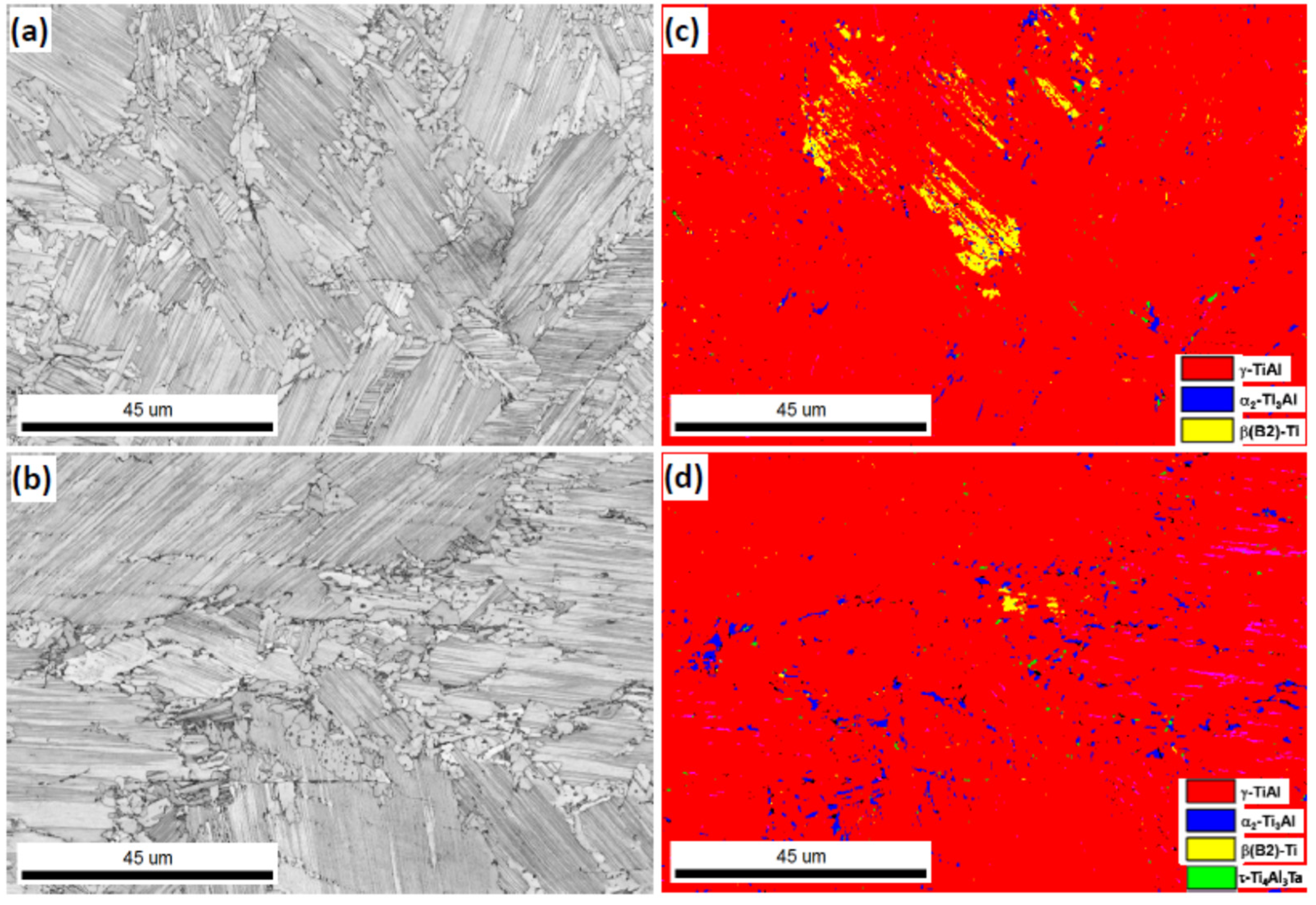

3.3.1. EBSD Mapping

3.3.2. Transmission Electron Microscopy

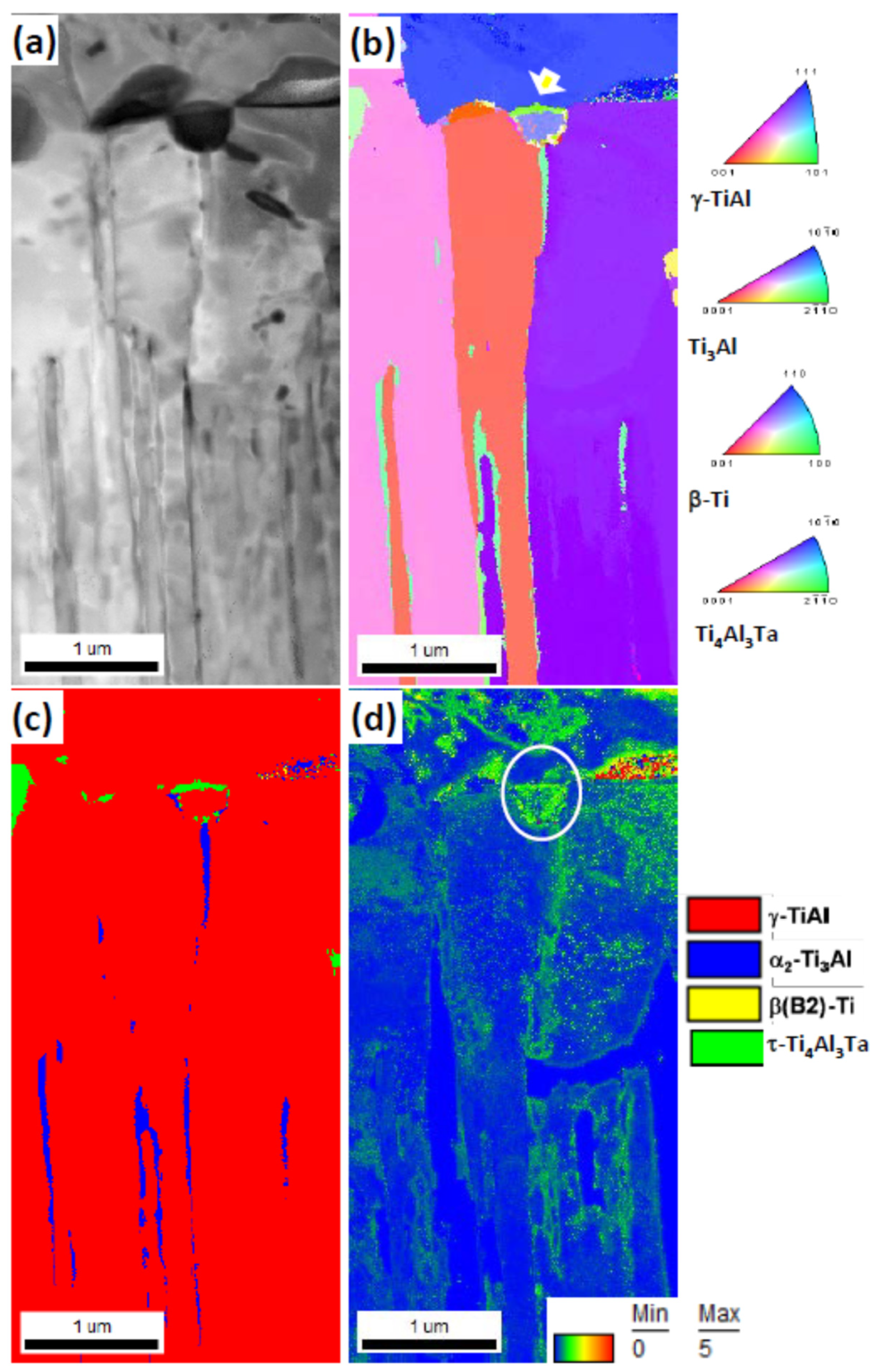

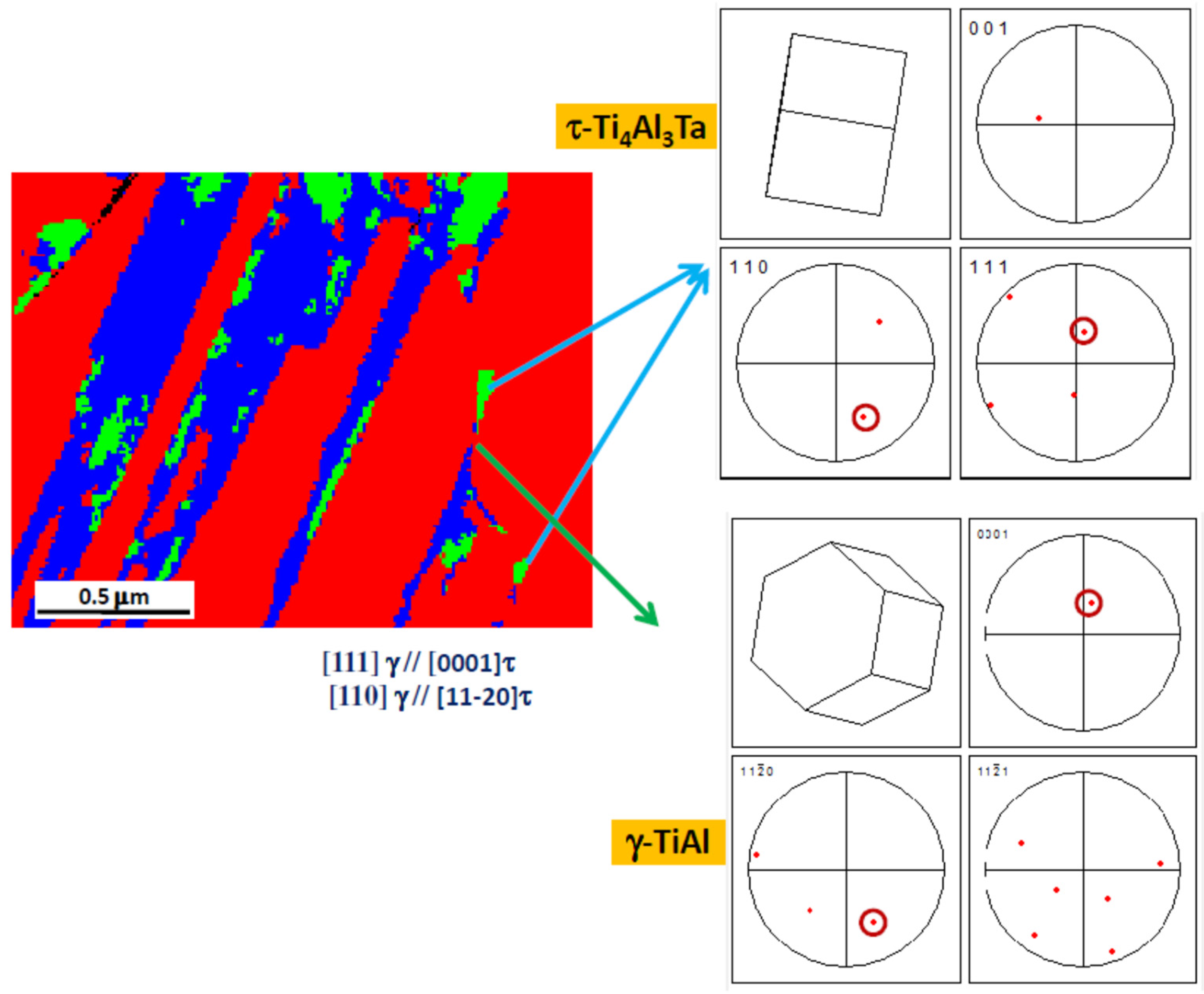

3.3.3. ACOM with PED

4. Conclusions

- (a)

- Compressive creep curves of the alloys studied under a range of deformation conditions (800–850 °C, 125–200 MPa) exhibit typical primary regime followed by a well-defined steady state creep regime. The stress dependence of the steady state creep rates can be described by the Norton–Bailey power-law with stress exponent being in the range 3.6 to 4.5 and apparent activation energy in the range 375 to 398 kJ/mol. The observed values of stress exponent and activation energy suggest that the creep in the alloy is controlled by diffusion which is assisted by dislocation climb.

- (b)

- Detailed microstructural comparison of the pre- and post-creep samples reveals that compared to the Nb-rich alloy the Ta-rich alloy exhibit higher tendency of lamellar structure disintegration in terms of γ-lath coarsening and fragmentation of α2-laths in the creep deformation range studied here. Microstructure of the crept Ta-rich alloy is further decorated with precipitation of multiple phases. In addition to the α2-precipitates, τ-phase (Ti4Al3Ta), precipitation occurs during creep along the lath and the colony boundaries. Precipitation of τ-phase (Ti4Al3Nb) corresponding to the Nb-rich alloy is scarce in the crept microstructure.

- (c)

- It has been observed that a definite OR exists between the precipitated τ-phase and its surrounding matrix γ-phase in the form of 〈111〉γ//〈0001〉τ; 〈110〉γ//〈10–10〉τ. However, no such OR could be found between α2 and τ. This implies that the evolution of a hexagonal τ-phase could possibly occur through the transformation sequence of β(B2) → α2 + τ.

- (d)

- In spite of a tendency for lamellar structure instability of the Ta-rich alloy, the creep resistance of the Ta-rich alloy is superior to that of the Nb-rich alloy. The microstructural attribute to such behavior has been found to be the dislocation pinning of precipitated second phases, in particular the τ-phase (Ti4Al3Ta).

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Appel, F.; Paul, J.D.H.; Oehring, M. Gamma Titanium Aluminide Alloys: Science and Technology; Wiley-VCH Verlag GmbH & Co: Weinheim, Germany, 2011. [Google Scholar]

- Kardashova, S.I.; Yu, A.; Razumovskii, L.; Razumovskii, I.M. Diffusion coarsening of the lamellar structure in two-phase Ti-47.5 at.% Al intermetallic alloy. Acta Metall. Mater. 1994, 42, 3341–3348. [Google Scholar] [CrossRef]

- Bartholomeusz, M.F.; Wert, J.A. The effect of thermal exposure on microstructural stability and creep resistance of a two-phase TiAl/Ti3Al lamellar alloy. Metall. Mater. Trans. A 1994, 25, 2371–2381. [Google Scholar] [CrossRef]

- Huang, S.C. Alloying Consideration in Gamma-Based Alloys, Structural Intermetallics; Darolia, R., Lewandowski, J.J., Liu, C.T., Martin, P.L., Miracle, D.B., Nathal, M.V., Eds.; TMS: Warrendale, PA, USA, 1993; pp. 299–307. [Google Scholar]

- Xiang, L.L.; Zhao, L.L.; Wang, Y.L.; Zhang, L.Q.; Lin, J.P. Synergistic effect of Y and Nb on the high temperature oxidation resistance of high Nb containing TiAl alloys. Intermetallics 2012, 27, 6–13. [Google Scholar] [CrossRef]

- Sienkiewicz, J.; Kuroda, S.; Murakami, H.; Araki, H.; Gizynski, M.; Kurzydlowski, K.J. Microstructure and Oxidation Performance of TiAl-(Cr,Nb,Ta) Coatings Fabricated by Warm Spray and High-Velocity Oxy-Fuel Spraying. J. Thermal. Spray Tech. 2019, 28, 563–579. [Google Scholar] [CrossRef] [Green Version]

- Singh, V.; Kumar, A.; Mondal, C.; Bhattacharjee, P.P.; Ghosal, P. Hot deformation of high-Nb-containing γ-TiAl alloy in the temperature range of 1000–1200 °C: Microstructural attributes to hot workability. SN Appl. Sci. 2019, 1, 366. [Google Scholar] [CrossRef] [Green Version]

- Lapin, J.; Pelachová, T.; Dománková, M. Creep behaviour of a new air-hardenable intermetallic Ti-46Al-8Ta alloy. Intermetallics 2011, 19, 814–819. [Google Scholar] [CrossRef]

- Clemens, H.; Smarsly, W. Light-weight intermetallic Titanium aluminides-status of research and development. Adv. Mater. Res. 2011, 278, 551–556. [Google Scholar] [CrossRef] [Green Version]

- Imayev, V.; Imayev, R.; Khismatullin, T.; Oleneva, T.; Gühter, V.; Fecht, H.-J. Microstructure and processing ability of β-solidifying TNM-based γ-TiAl alloys. Mater. Sci. Forum 2010, 638–642, 235–240. [Google Scholar] [CrossRef]

- Wang, J.G.; Nieh, T.G. Creep of a beta phase-containing TiAl alloy. Intermetallics 2000, 8, 737–748. [Google Scholar] [CrossRef]

- Gabrisch, H.; Stark, A.; Schimansky, F.-P.; Wang, L.; Schell, N.; Lorenz, U.; Pyczak, F. Investigation of carbides in Ti–45Al–5Nb–xC alloys (0 ≤ x ≤ 1) by transmission electron microscopy and high energy-XRD. Intermetallics 2013, 33, 44–53. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://www.ebsd.com/ois-ebsd-system/pseudosymmetry-correction (accessed on 23 November 2021).

- Rauch, E.F.; Véron, M.; Portillo, J.; Bultreys, D.; Maniette, Y.; Nicolopoulos, S. Automatic Crystal Orientation and Phase Mapping in TEM by Precession Diffraction. Microsc. Anal. 2008, 22, s5–s8. [Google Scholar]

- Singh, V.; Mondal, C.; Bhattacharjee, P.P.; Ghosal, P. Microstructural Characterization by Automated Crystal Orientation and Phase Mapping by Precession Electron Diffraction in TEM: Application to Hot Deformation of a γ-TiAl based Alloy. Microsc. Micanalysis 2019, 25, 1457–1465. [Google Scholar] [CrossRef] [PubMed]

- Singh, V.; Mondal, C.; Sarkar, R.; Bhattacharjee, P.P.; Ghosal, P. Compressive creep behavior of a γ-TiAl based Ti–45Al–8Nb–2Cr-0.2B alloy: The role of β(B2)-phase and concurrent phase transformations. Mat. Sci. Eng. A 2020, 774, 138891. [Google Scholar] [CrossRef]

- Singh, V.; Sahoo, K.; Mondal, C.; Satyanarayana, D.V.V.; Ghosal, P. High Temperature Compressive Creep Properties of Ti–45Al–8Ta–2Cr-0.2B-0.2C Alloy for Aerospace Applications; DMRL Technical Report, DMRL-EMG-234-2020; DMRL: Hyderabad, India, October 2020. [Google Scholar]

- Herzig, C.H.; Przeorski, T.; Mishin, Y. Self-diffusion in γ-TiAl: An experimental study and atomistic calculations. Intermetallics 1999, 7, 389–404. [Google Scholar] [CrossRef]

- Lapin, J.; Pelachová, T.; Witusiewicz, V.T.; Dobročka, E. Effect of long-term ageing on microstructure stability and lattice parameters of coexisting phases in intermetallic Ti–46Al–8Ta alloy. Intermetallics 2011, 19, 121–124. [Google Scholar] [CrossRef]

- Lapin, J.; Gabalcová, Z.; Pelachová, T.; Bajana, O. Microstructure and mechanical properties of a cast intermetallic Ti-46Al-8Ta alloy. Mater. Sci. Forum 2010, 638–642, 54–60. [Google Scholar] [CrossRef]

- Witusiewicz, V.T.; Bondar, A.A.; Hecht, U.; Velikanova, T.Y. The Al–B–Nb–Ti system: IV. Experimental study and thermodynamic re-evaluation of the binary Al–Nb and ternary Al–Nb–Ti systems. J. Alloys Compd. 2009, 472, 133–161. [Google Scholar] [CrossRef]

- Bendersky, L.A.; Boettinger, W.J.; Bruton, B.P.; Biancaniello, F.S. The formation of ordered ω-Ordered related phases in alloys of composition Ti4Al3Nb. Acta Metal. Mater. 1990, 38, 931–943. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, V.; Mondal, C.; Sarkar, R.; Roy, S.; Omprakash, C.M.; Ghosal, P. Characterization of Microstructure of Crept Nb and Ta-Rich γ-TiAl Alloys by Automated Crystal Orientation Mapping and Electron Back Scatter Diffraction. Symmetry 2022, 14, 399. https://doi.org/10.3390/sym14020399

Singh V, Mondal C, Sarkar R, Roy S, Omprakash CM, Ghosal P. Characterization of Microstructure of Crept Nb and Ta-Rich γ-TiAl Alloys by Automated Crystal Orientation Mapping and Electron Back Scatter Diffraction. Symmetry. 2022; 14(2):399. https://doi.org/10.3390/sym14020399

Chicago/Turabian StyleSingh, Vajinder, Chandan Mondal, Rajdeep Sarkar, Satabdi Roy, Chiptalluri Mohan Omprakash, and Partha Ghosal. 2022. "Characterization of Microstructure of Crept Nb and Ta-Rich γ-TiAl Alloys by Automated Crystal Orientation Mapping and Electron Back Scatter Diffraction" Symmetry 14, no. 2: 399. https://doi.org/10.3390/sym14020399

APA StyleSingh, V., Mondal, C., Sarkar, R., Roy, S., Omprakash, C. M., & Ghosal, P. (2022). Characterization of Microstructure of Crept Nb and Ta-Rich γ-TiAl Alloys by Automated Crystal Orientation Mapping and Electron Back Scatter Diffraction. Symmetry, 14(2), 399. https://doi.org/10.3390/sym14020399