Effect of Carbon Nanofibers on the Viscoelastic Response of Epoxy Resins

Abstract

1. Introduction

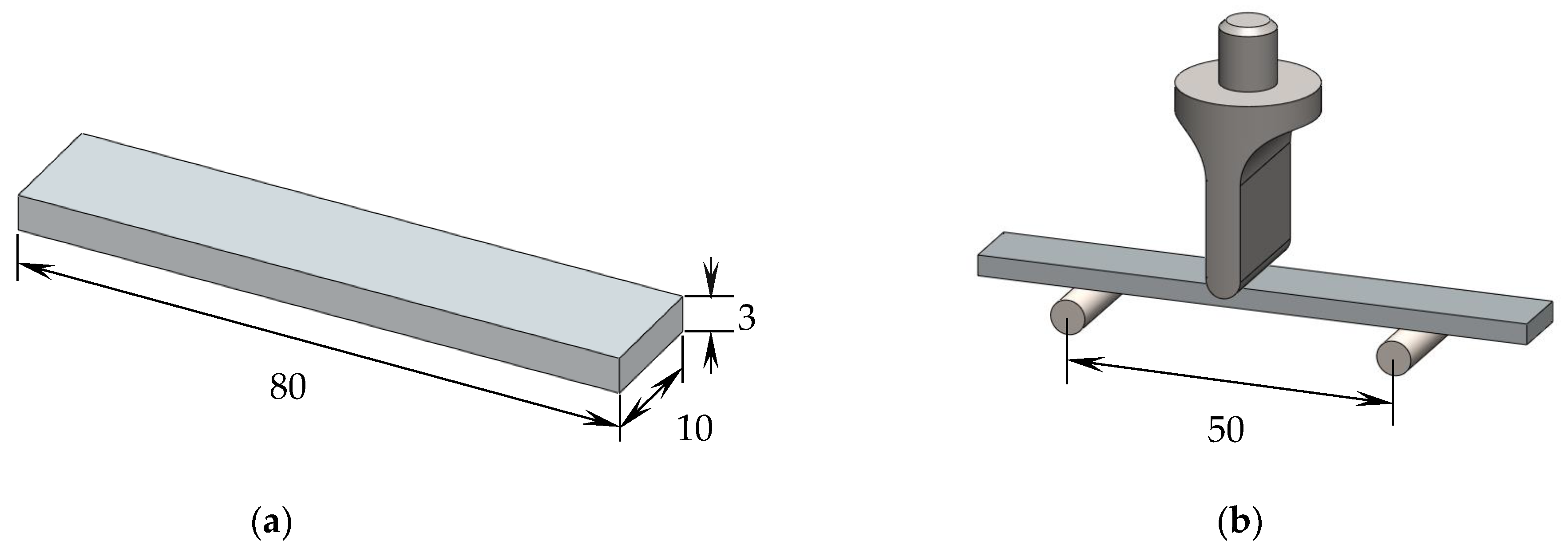

2. Materials and Experimental Procedure

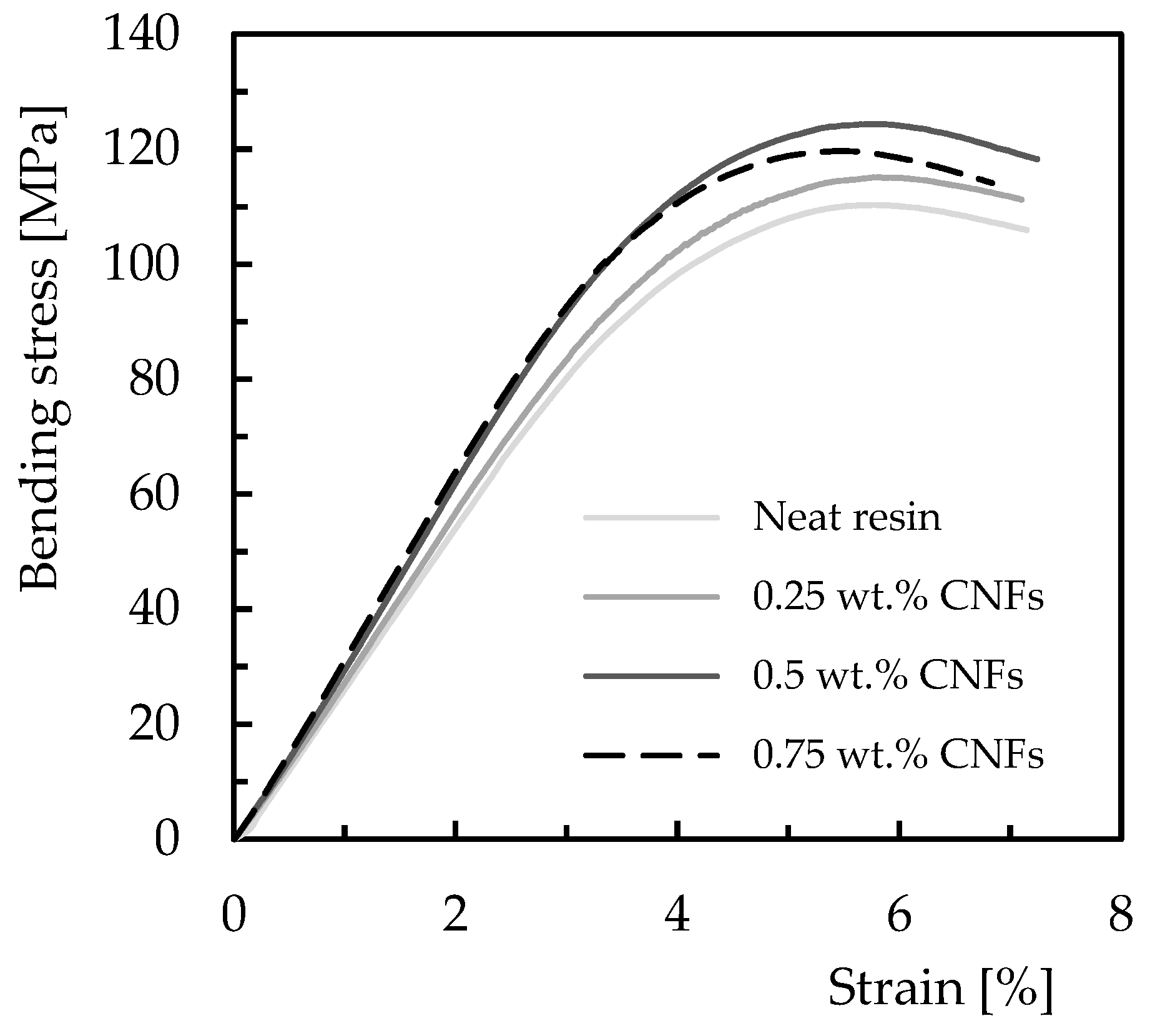

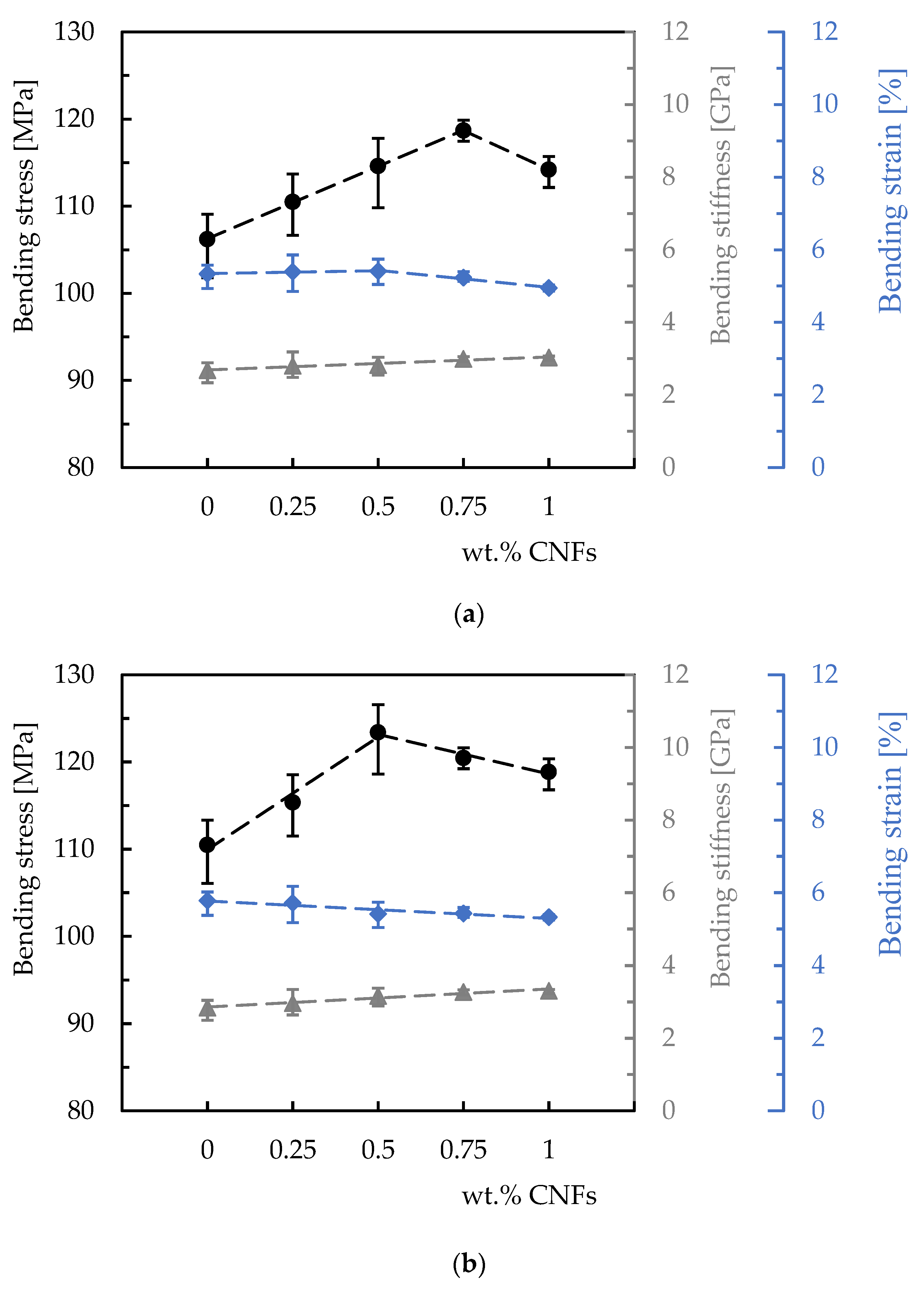

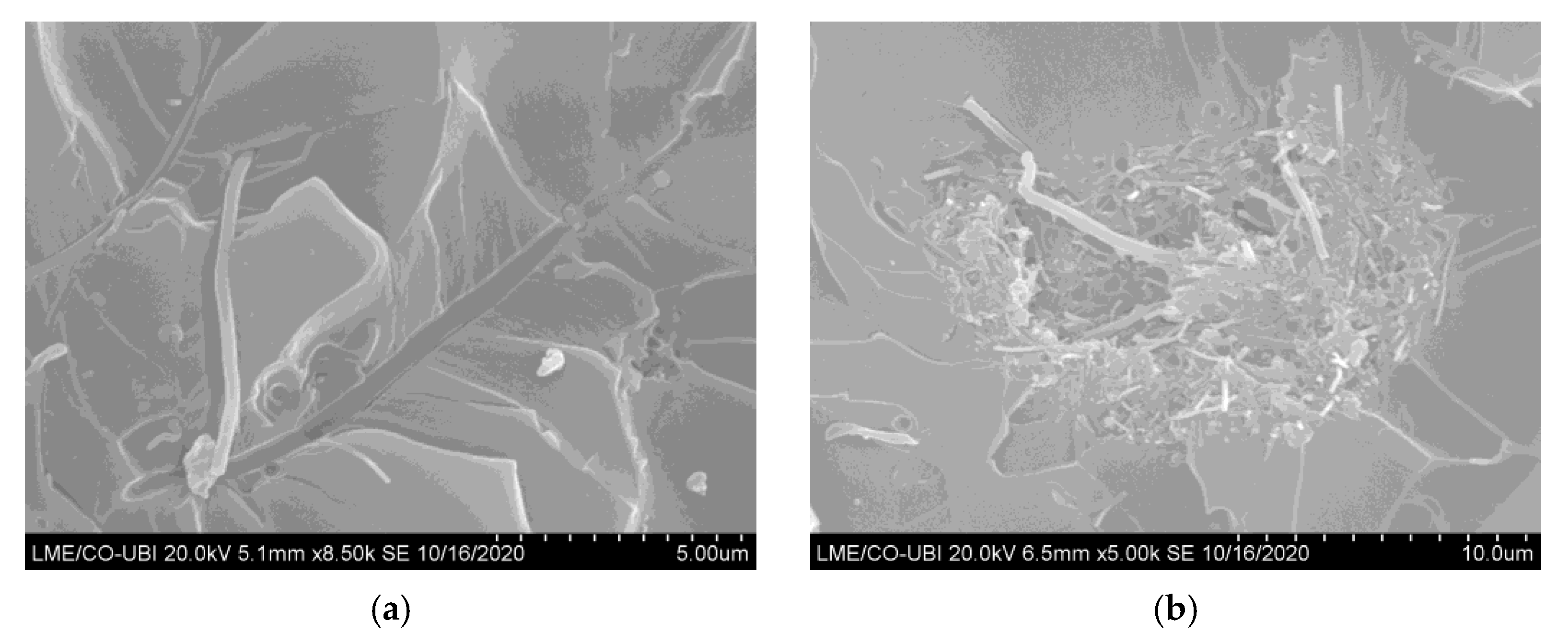

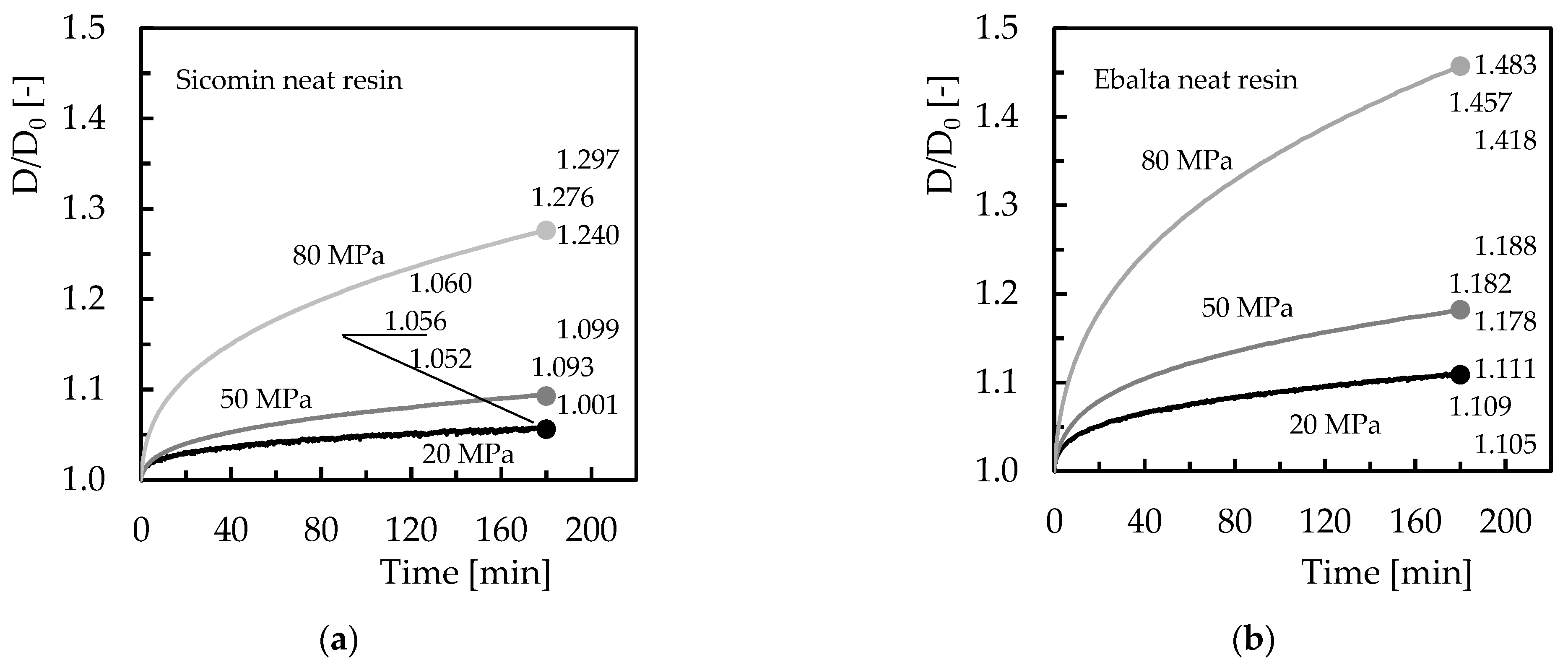

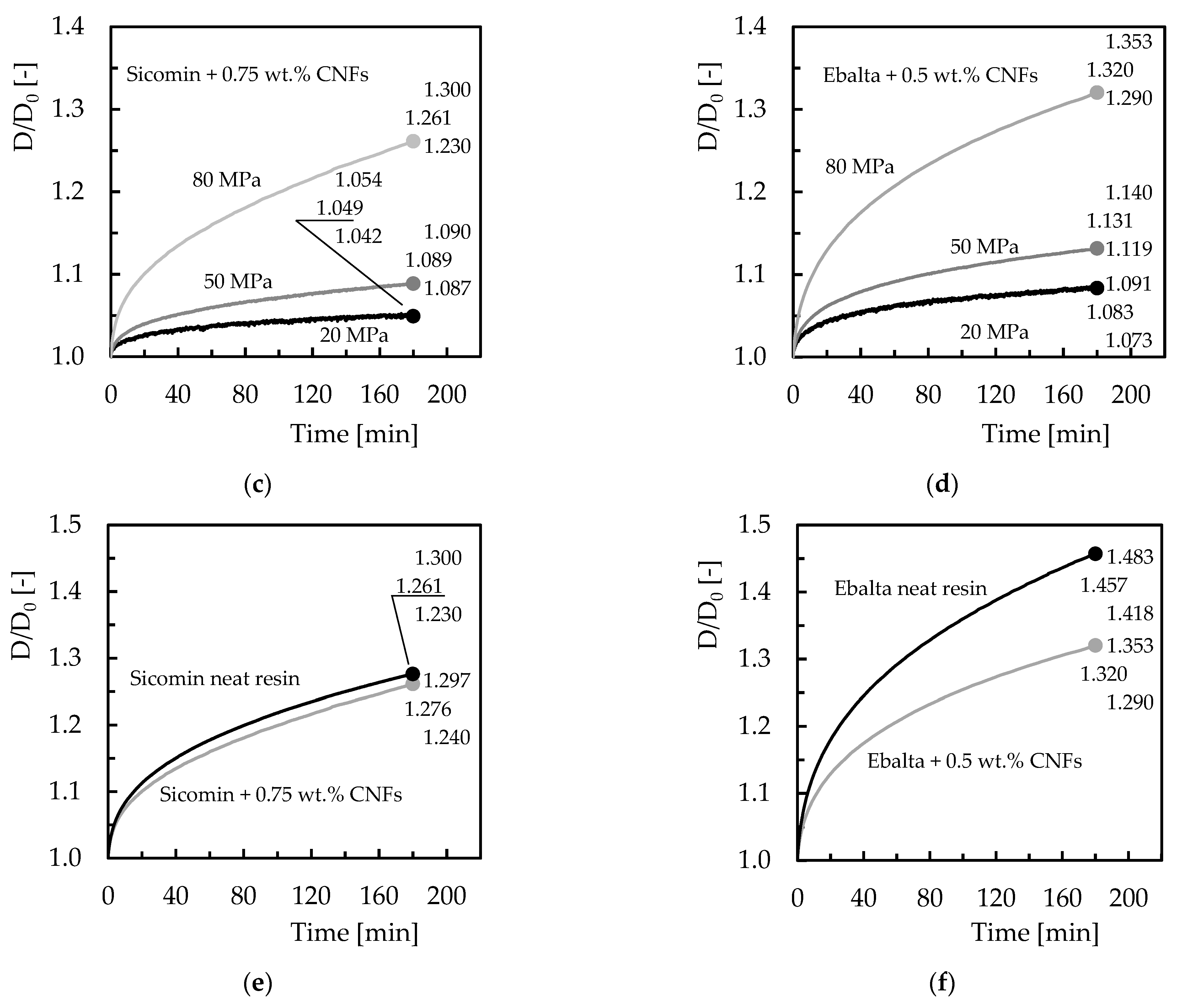

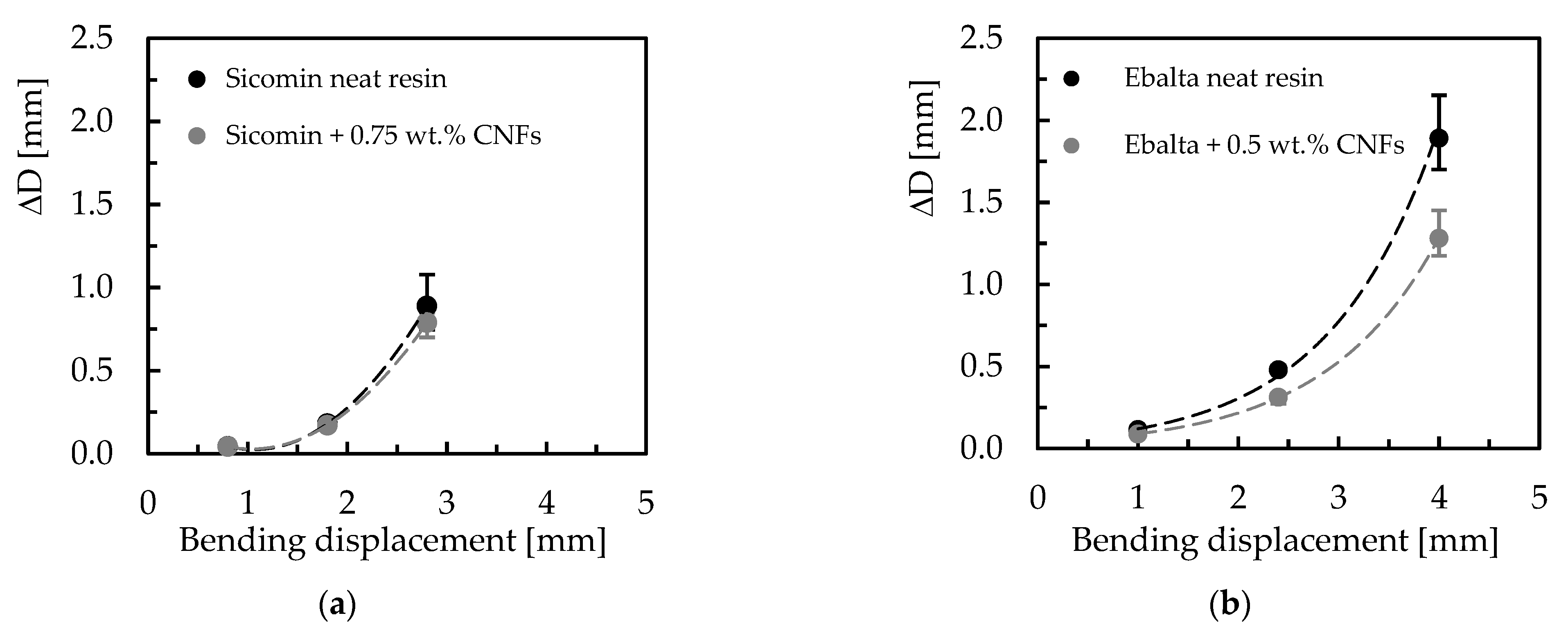

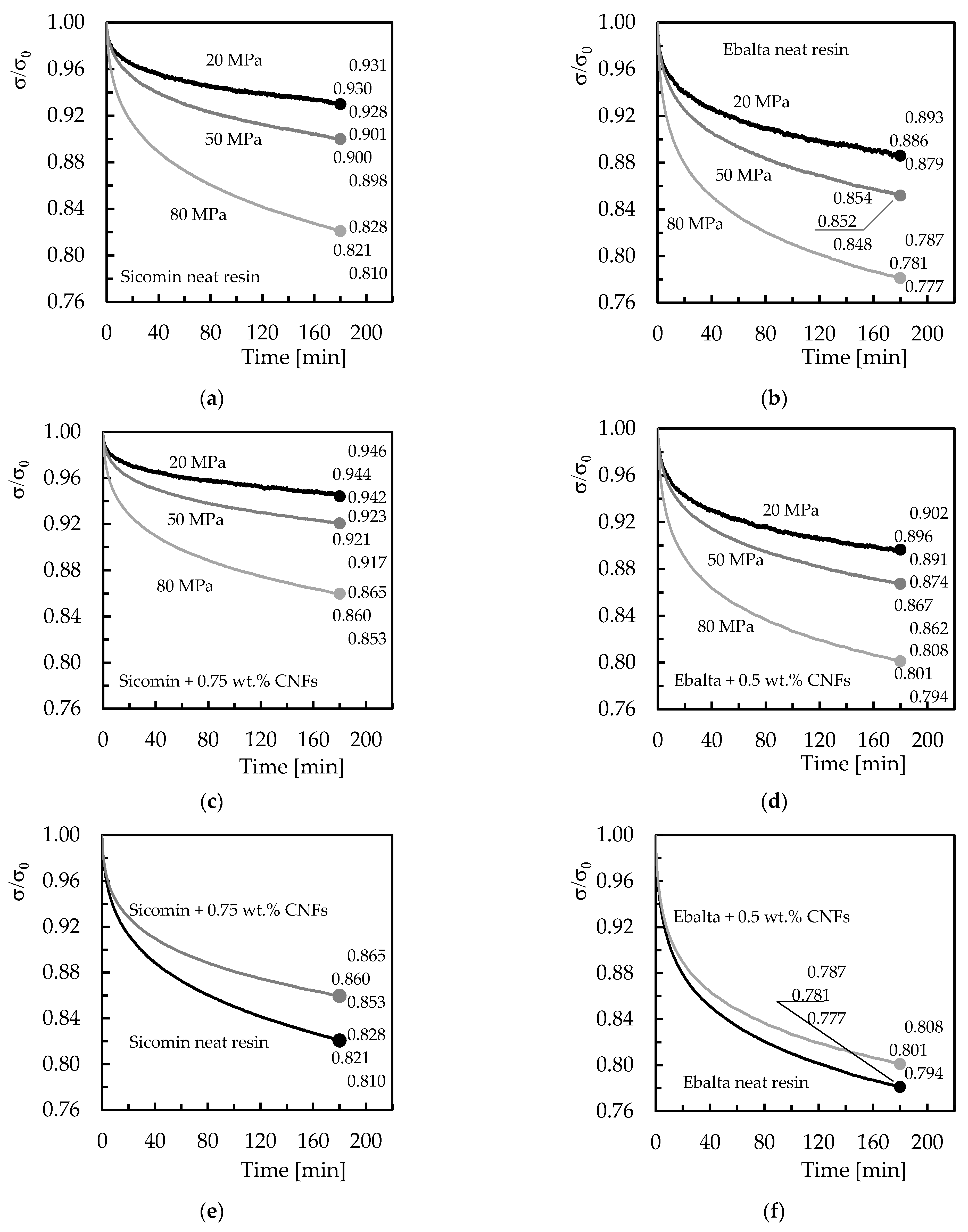

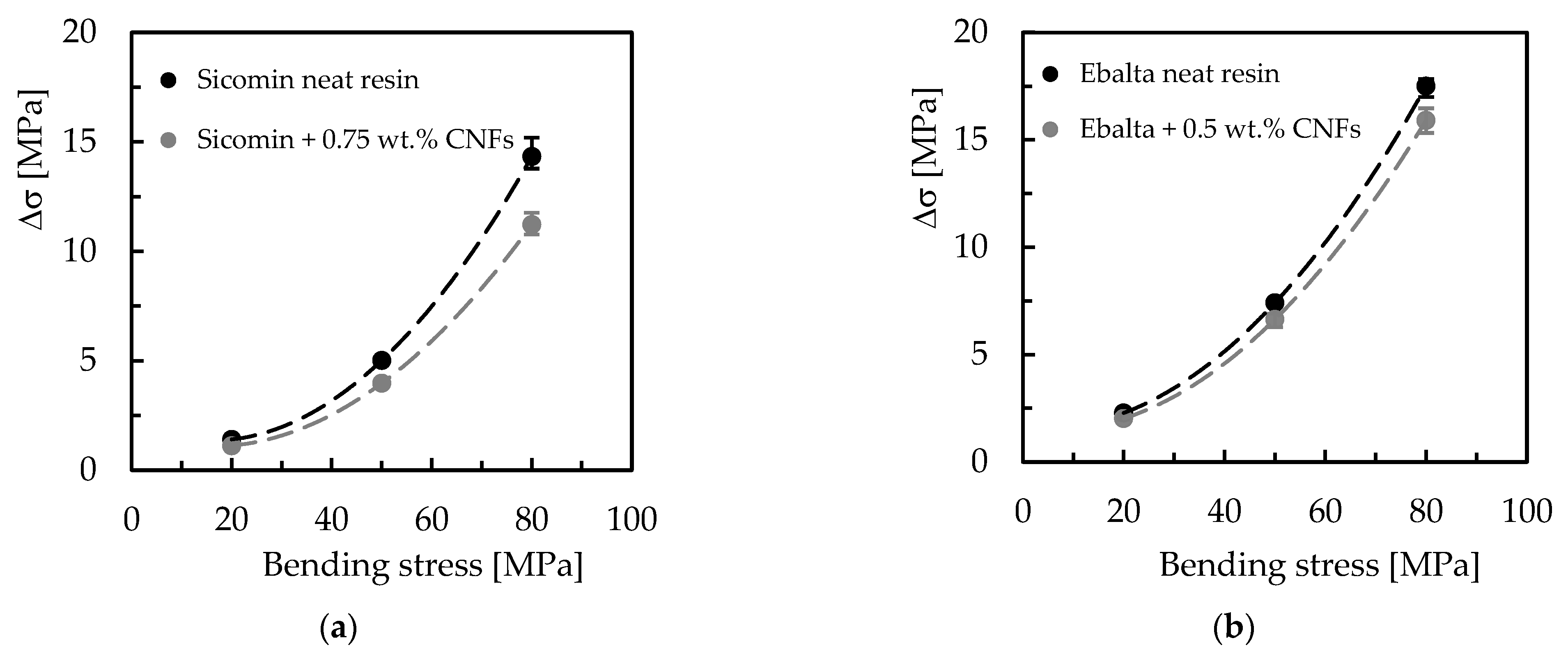

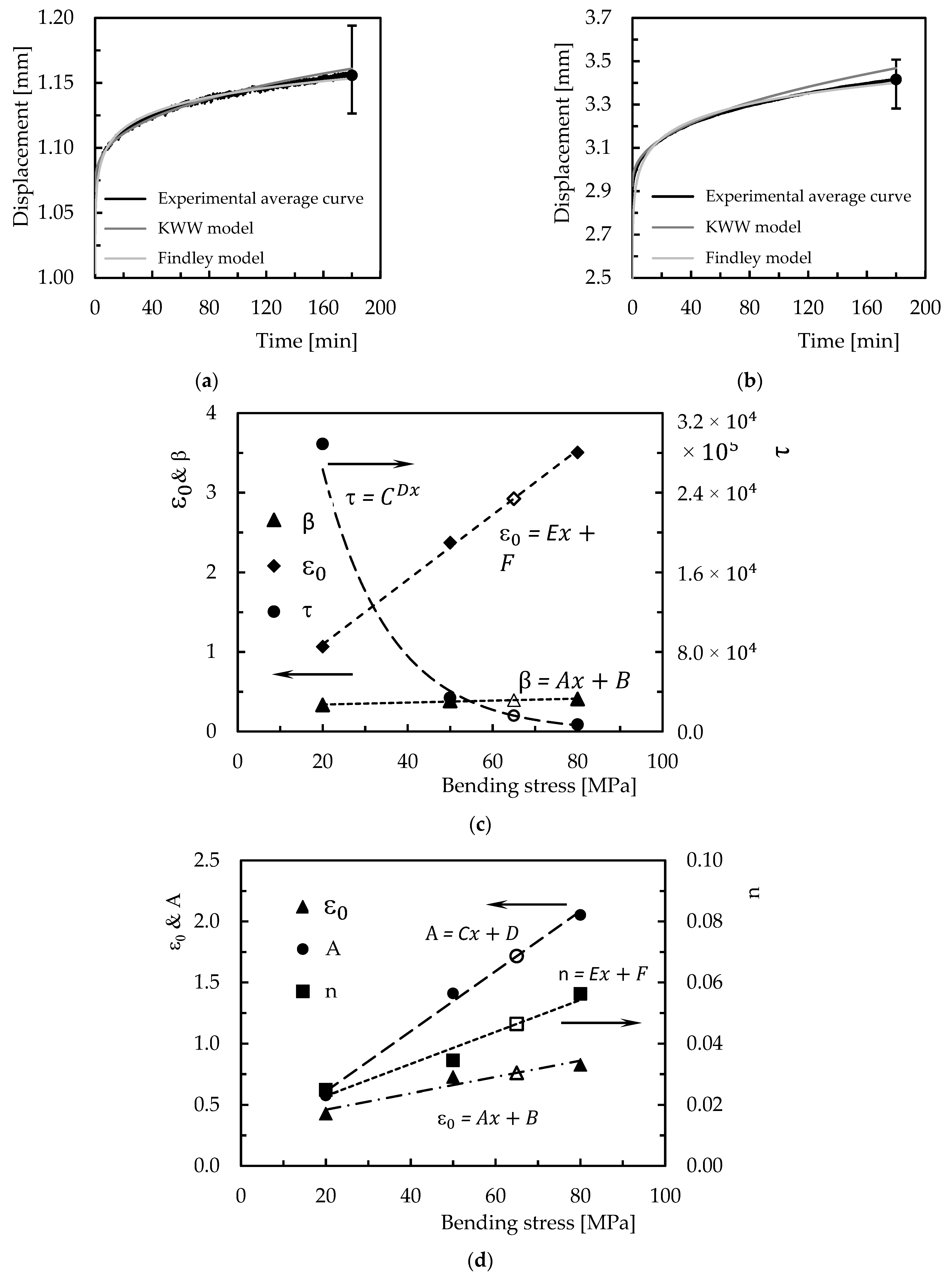

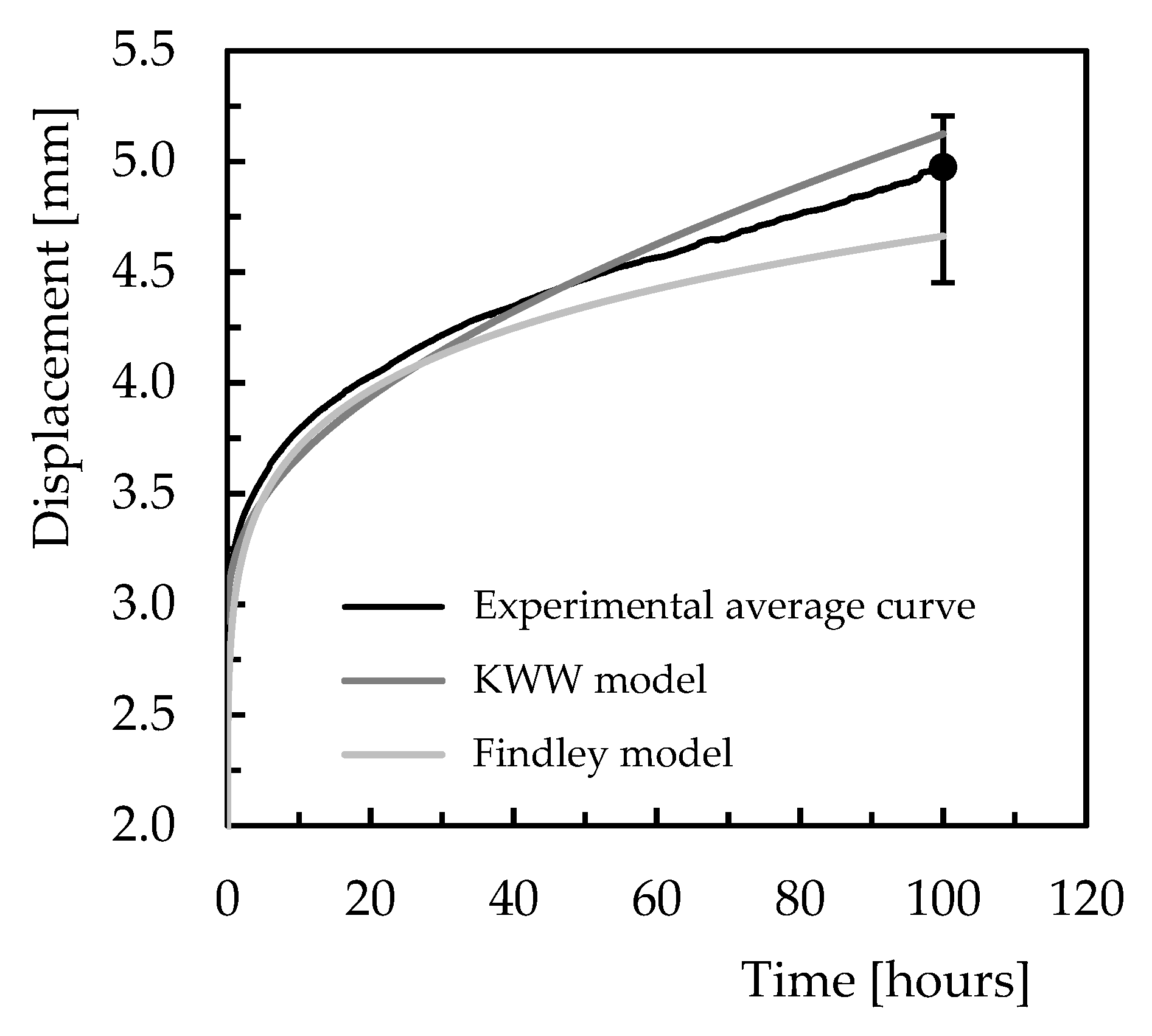

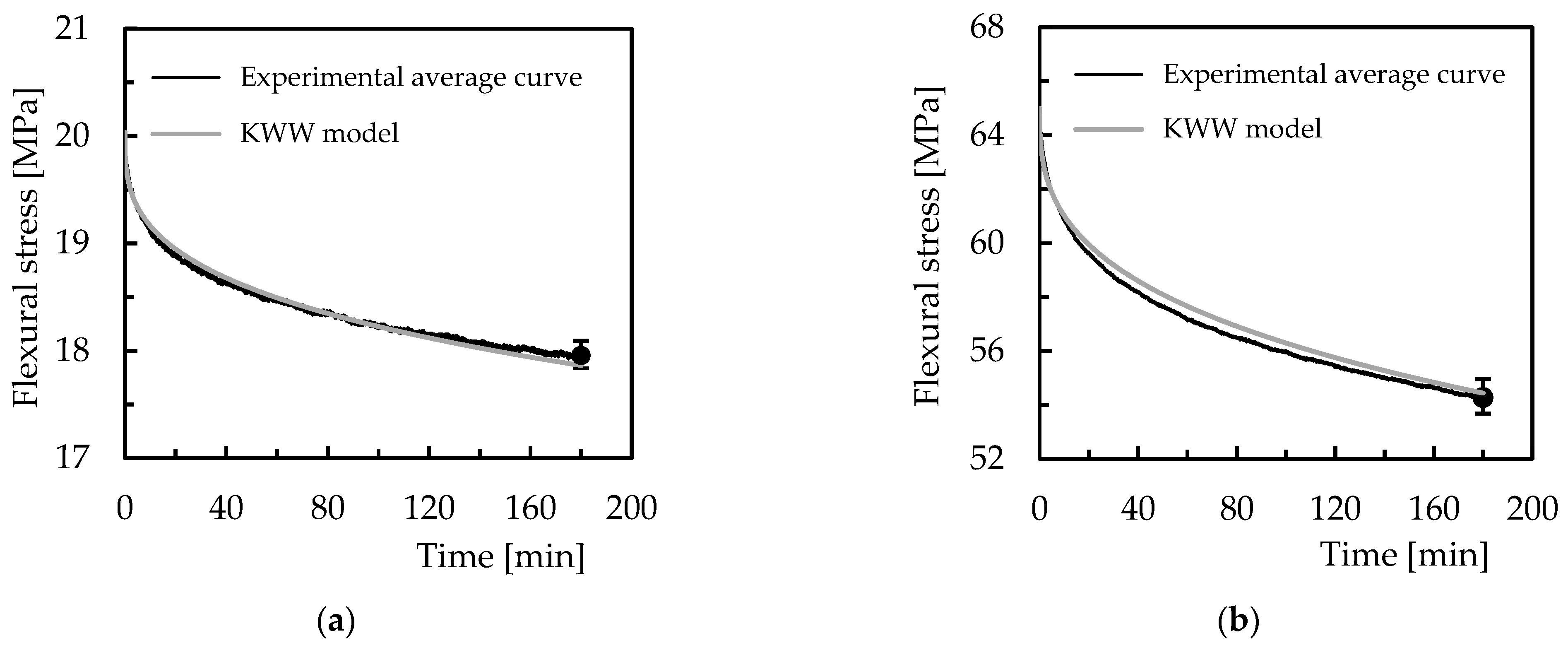

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jin, F.-L.; Li, X.; Park, S.-J. Synthesis and Application of Epoxy Resins: A Review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Higgins, C.; Cahill, J.; Jolanki, R.; Nixon, R. Epoxy Resins. In Kanerva’s Occupational Dermatology; Springer International Publishing: Cham, Switzerland, 2018; Volume 11, pp. 1–43. ISBN 9783319402215. [Google Scholar]

- Pina dos Santos, P.S.; Maceiras, A.; Valvez, S.; Reis, P.N.B. Mechanical Characterization of Different Epoxy Resins Enhanced with Carbon Nanofibers. Frat. Integrità Strutt. 2020, 15, 198–212. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Masania, K.; Taylor, A.C.; Sprenger, S. The Mechanisms and Mechanics of the Toughening of Epoxy Polymers Modified with Silica Nanoparticles. Polymer 2010, 51, 6284–6294. [Google Scholar] [CrossRef]

- Cho, J.; Joshi, M.S.; Sun, C.T. Effect of Inclusion Size on Mechanical Properties of Polymeric Composites with Micro and Nano Particles. Compos. Sci. Technol. 2006, 66, 1941–1952. [Google Scholar] [CrossRef]

- Bazrgari, D.; Moztarzadeh, F.; Sabbagh-Alvani, A.A.; Rasoulianboroujeni, M.; Tahriri, M.; Tayebi, L. Mechanical Properties and Tribological Performance of Epoxy/Al2O3 Nanocomposite. Ceram. Int. 2018, 44, 1220–1224. [Google Scholar] [CrossRef]

- Eskizeybek, V.; Ulus, H.; Kaybal, H.B.; Şahin, Ö.S.; Avcı, A. Static and Dynamic Mechanical Responses of CaCO3 Nanoparticle Modified Epoxy/Carbon Fiber Nanocomposites. Compos. Part B Eng. 2018, 140, 223–231. [Google Scholar] [CrossRef]

- Singh, S.K.; Singh, S.; Kohli, R.; Jain, A.; Kumar, A. Effect of TiO2 Dispersion on Mechanical Properties of Epoxy Polymer. AIP Conf. Proc. 2016, 1728, 020586. [Google Scholar] [CrossRef]

- Yadav, P.S.; Purohit, R.; Kothari, A. Study of Friction and Wear Behaviour of Epoxy/Nano SiO2 Based Polymer Matrix Composites-A Review. Mater. Today Proc. 2019, 18, 5530–5539. [Google Scholar] [CrossRef]

- Molina, J.; Szczucka-Lasota, B.; Węgrzyn, T.; Silva, A.P.; Maceiras, A. Manufacturing and Characterization of Epoxy Resin with Fe3O4 and SiO2 Particles. KnE Eng. 2020, 2020, 117–128. [Google Scholar] [CrossRef]

- Sun, T.; Fan, H.; Wang, Z.; Liu, X.; Wu, Z. Modified Nano Fe2O3-Epoxy Composite with Enhanced Mechanical Properties. Mater. Des. 2015, 87, 10–16. [Google Scholar] [CrossRef]

- Liu, S.; Chevali, V.S.; Xu, Z.; Hui, D.; Wang, H. A Review of Extending Performance of Epoxy Resins Using Carbon Nanomaterials. Compos. Part B Eng. 2018, 136, 197–214. [Google Scholar] [CrossRef]

- Kausar, A.; Rafique, I.; Muhammad, B. Review of Applications of Polymer/Carbon Nanotubes and Epoxy/CNT Composites. Polym.–Plast. Technol. Eng. 2016, 55, 1167–1191. [Google Scholar] [CrossRef]

- Zhang, B.; Zheng, X.; Li, H.; Lin, J. Analytica Chimica Acta Application of Carbon-Based Nanomaterials in Sample Preparation: A Review. Anal. Chim. Acta 2013, 784, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Liu, Y.; You, T. Carbon Nanofiber Based Electrochemical Biosensors: A Review. Anal. Methods 2010, 2, 202–211. [Google Scholar] [CrossRef]

- Feng, L.; Xie, N.; Zhong, J. Carbon Nanofibers and Their Composites: A Review of Synthesizing, Properties and Applications. Materials 2014, 7, 3919–3945. [Google Scholar] [CrossRef]

- Meek, N.; Penumadu, D.; Hosseinaei, O.; Harper, D.; Young, S.; Rials, T. Synthesis and Characterization of Lignin Carbon Fiber and Composites. Compos. Sci. Technol. 2016, 137, 60–68. [Google Scholar] [CrossRef]

- Lee, K.M.; Lee, S.E.; Lee, Y.S. Improved Mechanical and Electromagnetic Interference Shielding Properties of Epoxy Composites through the Introduction of Oxyfluorinated Multiwalled Carbon Nanotubes. J. Ind. Eng. Chem. 2017, 56, 435–442. [Google Scholar] [CrossRef]

- Santos, P.; Maceiras, A.; Reis, P.N.B. Influence of Manufacturing Parameters on the Mechanical Properties of Nano-Reinforced CFRP by Carbon Nanofibers. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1126, 012012. [Google Scholar] [CrossRef]

- Shokrieh, M.M.; Esmkhani, M.; Vahedi, F.; Shahverdi, H.R. Improvement of Mechanical and Electrical Properties of Epoxy Resin with Carbon Nanofibers. Iran. Polym. J. 2013, 22, 721–727. [Google Scholar] [CrossRef]

- Sun, L.-H.; Ounaies, Z.; Gao, X.-L.; Whalen, C.A.; Yang, Z.-G. Preparation, Characterization, and Modeling of Carbon Nanofiber/Epoxy Nanocomposites. J. Nanomater. 2011, 2011, 1–8. [Google Scholar] [CrossRef]

- Chen, D.L.; Yang, P.F.; Lai, Y.S. A Review of Three-Dimensional Viscoelastic Models with an Application to Viscoelasticity Characterization Using Nanoindentation. Microelectron. Reliab. 2012, 52, 541–558. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Silva, M.P.; Santos, P.; Parente, J.M.; Bezazi, A. Viscoelastic Behaviour of Composites with Epoxy Matrix Filled by Cork Powder. Compos. Struct. 2020, 234, 111669. [Google Scholar] [CrossRef]

- Farzaneh, A.; Rostami, A.; Nazockdast, H. Mono-Filler and Bi-Filler Composites Based on Thermoplastic Polyurethane, Carbon Fibers and Carbon Nanotubes with Improved Physicomechanical and Engineering Properties. Polym. Int. 2022, 71, 232–242. [Google Scholar] [CrossRef]

- Rana, S.; Alagirusamy, R.; Joshi, M. Mechanical Behavior of Carbon Nanofibre-Reinforced Epoxy Composites. J. Appl. Polym. Sci. 2010, 48, 2276–2283. [Google Scholar] [CrossRef]

- Oberdisse, J. Aggregation of Colloidal Nanoparticles in Polymer Matrices. Soft Matter 2006, 2, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Padmanabhan, V.; Frischknecht, A.L.; Mackay, M.E. Effect of Chain Stiffness on Nanoparticle Segregation in Polymer/Nanoparticle Blends Near a Substrate. Macromol. Theory Simul. 2012, 21, 98–105. [Google Scholar] [CrossRef]

- Zare, Y. The Roles of Nanoparticles Accumulation and Interphase Properties in Properties of Polymer Particulate Nanocomposites by a Multi-Step Methodology. Compos. Part A Appl. Sci. Manuf. 2016, 91, 127–132. [Google Scholar] [CrossRef]

- Ma, X.; Zare, Y.; Rhee, K.Y. A Two-Step Methodology to Study the Influence of Aggregation/Agglomeration of Nanoparticles on Young’s Modulus of Polymer Nanocomposites. Nanoscale Res. Lett. 2017, 12, 621. [Google Scholar] [CrossRef] [PubMed]

- Shaffer, M.S.P.; Fan, X.; Windle, A.H. Dispersion and Packing of Carbon Nanotubes. Carbon 1998, 36, 1603–1612. [Google Scholar] [CrossRef]

- Fiedler, B.; Gojny, F.H.; Wichmann, M.H.G.; Nolte, M.C.M.; Schulte, K. Fundamental Aspects of Nano-Reinforced Composites. Compos. Sci. Technol. 2006, 66, 3115–3125. [Google Scholar] [CrossRef]

- Zhou, T.H.; Ruan, W.H.; Yang, J.L.; Rong, M.Z.; Zhang, M.Q.; Zhang, Z. A Novel Route for Improving Creep Resistance of Polymers Using Nanoparticles. Compos. Sci. Technol. 2007, 67, 2297–2302. [Google Scholar] [CrossRef]

- Lim, S.D.; Rhee, J.M.; Nah, C.; Lee, S.-H.; Lyu, M.-Y. Predicting the Long-Term Creep Behavior of Plastics Using the Short-Term Creep Test. Int. Polym. Process. 2004, 19, 313–319. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.-L.; Friedrich, K. Creep Resistant Polymeric Nanocomposites. Polymer 2004, 45, 3481–3485. [Google Scholar] [CrossRef]

- Yang, J.-L.; Zhang, Z.; Schlarb, A.K.; Friedrich, K. On the Characterization of Tensile Creep Resistance of Polyamide 66 Nanocomposites. Part I. Experimental Results and General Discussions. Polymer 2006, 47, 2791–2801. [Google Scholar] [CrossRef]

- Park, B.-D.; Balatinecz, J.J. Short Term Flexural Creep Behavior of Wood-Fiber/Polypropylene Composites. Polym. Compos. 1998, 19, 377–382. [Google Scholar] [CrossRef]

- Houshyar, S.; Shanks, R.A.; Hodzic, A. Tensile Creep Behaviour of Polypropylene Fibre Reinforced Polypropylene Composites. Polym. Test. 2005, 24, 257–264. [Google Scholar] [CrossRef]

- Wang, W.-H.; Huang, H.-B.; Du, H.-H.; Wang, H. Effects of Fiber Size on Short-Term Creep Behavior of Wood Fiber/HDPE Composites. Polym. Eng. Sci. 2015, 55, 693–700. [Google Scholar] [CrossRef]

- Jian, W.; Lau, D. Creep Performance of CNT-Based Nanocomposites: A Parametric Study. Carbon 2019, 153, 745–756. [Google Scholar] [CrossRef]

- Bouafif, H.; Koubaa, A.; Perré, P.; Cloutier, A. Creep Behaviour of HDPE/Wood Particle Composites. Int. J. Microstruct. Mater. Prop. 2013, 8, 225. [Google Scholar] [CrossRef]

- Vlasveld, D.P.N.; Bersee, H.E.N.; Picken, S.J. Creep and Physical Aging Behaviour of PA6 Nanocomposites. Polymer 2005, 46, 12539–12545. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Z.; Friedrich, K.; Schlarb, A.K. Creep Resistant Polymer Nanocomposites Reinforced with Multiwalled Carbon Nanotubes. Macromol. Rapid Commun. 2007, 28, 955–961. [Google Scholar] [CrossRef]

- Ferreira, J.A.; Costa, J.D.; Reis, P.N. Static and Fatigue Behaviour of Glass-Fibre-Reinforced Polypropylene Composites. Theor. Appl. Fract. Mech. 1999, 31, 67–74. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Gorbatikh, L.; Ivens, J.; Lomov, S.V. Strain-Rate Sensitivity and Stress Relaxation of Hybrid Self-Reinforced Polypropylene Composites under Bending Loads. Compos. Struct. 2019, 209, 802–810. [Google Scholar] [CrossRef]

- Varghese, S.; Kuriakose, B.; Thomas, S. Stress Relaxation in Short Sisal-fiber-reinforced Natural Rubber Composites. J. Appl. Polym. Sci. 1994, 53, 1051–1060. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S.; Bhagawan, S.S.; Neelakantan, N.R. Stress Relaxation Behavior of Short Pineapple Fiber Reinforced Polyethylene Composites. J. Reinf. Plast. Compos. 1998, 17, 651–672. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Joseph, R.; Thomas, S. Stress-Relaxation Behaviour in Composites Based on Short Oil-Palm Fibres and Phenol Formaldehyde Resin. Compos. Sci. Technol. 2001, 61, 1175–1188. [Google Scholar] [CrossRef]

- Scott, D.W.; Lai, J.S.; Zureick, A.H. Creep Behavior of Fiber-Reinforced Polymeric Composites: A Review of the Technical Literature. J. Reinf. Plast. Compos. 1995, 14, 588–617. [Google Scholar] [CrossRef]

- Xu, Y.; Wu, Q.; Lei, Y.; Yao, F. Creep Behavior of Bagasse Fiber Reinforced Polymer Composites. Bioresour. Technol. 2010, 101, 3280–3286. [Google Scholar] [CrossRef] [PubMed]

- Georgiopoulos, P.; Kontou, E.; Christopoulos, A. Short-Term Creep Behavior of a Biodegradable Polymer Reinforced with Wood-Fibers. Compos. Part B Eng. 2015, 80, 134–144. [Google Scholar] [CrossRef]

- Vidya Bhushan Gupta; Lahiri, J. Non Linear Viscoelastic Behavior of Polypropylene and Glass Reinforced Polypropylene in Creep. J. Compos. Mater. 1980, 14, 286–296. [Google Scholar] [CrossRef]

- Almeida, J.H.S.; Ornaghi, H.L.; Lorandi, N.P.; Bregolin, B.P.; Amico, S.C. Creep and Interfacial Behavior of Carbon Fiber Reinforced Epoxy Filament Wound Laminates. Polym. Compos. 2018, 39, E2199–E2206. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Silva, M.P.; Santos, P.; Parente, J.M.; Valvez, S.; Bezazi, A. Mechanical Performance of an Optimized Cork Agglomerate Core-Glass Fibre Sandwich Panel. Compos. Struct. 2020, 245, 112375. [Google Scholar] [CrossRef]

- Vaidyanathan, T.K.; Vaidyanathan, J. Validity of Predictive Models of Stress Relaxation in Selected Dental Polymers. Dent. Mater. 2015, 31, 799–806. [Google Scholar] [CrossRef] [PubMed]

- Reis, P.N.B.; Neto, M.A.; Amaro, A.M. Effect of Hostile Solutions on Stress Relaxation of Carbon/Epoxy Composites. Polym. Degrad. Stab. 2019, 165, 60–67. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Silva, M.P.; Santos, P. Stress Relaxation in Delaminated Carbon/Epoxy Composites. Fibers Polym. 2019, 20, 1284–1289. [Google Scholar] [CrossRef]

| Bending Stress [MPa] | β | τ | Displacement after 3 h [mm] | |||

|---|---|---|---|---|---|---|

| Experimental Value | KWW Value | Error [%] | ||||

| Sicomin resin | ||||||

| 20 | 0.892 | 0.333 | 1.37 × 106 | 0.936 | 0.939 | 0.319 |

| 50 | 2.03 | 0.392 | 8.94 × 104 | 2.21 | 2.22 | 0.253 |

| 80 | 3.40 | 0.431 | 5.12 × 103 | 4.29 | 4.31 | 0.409 |

| Sicomin resin + 0.75 wt.% CNFs | ||||||

| 20 | 0.765 | 0.318 | 1.50 × 106 | 0.807 | 0.809 | 0.216 |

| 50 | 1.81 | 0.416 | 5.44 × 104 | 1.98 | 1.99 | 0.437 |

| 80 | 2.86 | 0.417 | 4.86 × 103 | 3.64 | 3.68 | 0.949 |

| Ebalta resin | ||||||

| 20 | 1.06 | 0.362 | 8.72 × 104 | 1.18 | 1.18 | 0.36 |

| 50 | 2.67 | 0.407 | 1.27 × 104 | 3.16 | 3.19 | 0.954 |

| 80 | 4.02 | 0.430 | 1.53 × 103 | 5.83 | 5.99 | 2.75 |

| Ebalta resin + 0.5 wt.% CNFs | ||||||

| 20 | 1.07 | 0.335 | 2.89 × 105 | 1.16 | 1.16 | 0.444 |

| 50 | 2.37 | 0.385 | 3.38 × 104 | 2.68 | 2.71 | 0.983 |

| 80 | 3.51 | 0.409 | 6.90 × 103 | 4.34 | 4.39 | 1.29 |

| Bending Stress [MPa] | A | n | Displacement after 3 h [mm] | |||

|---|---|---|---|---|---|---|

| Experimental Value | Findley Value | Error [%] | ||||

| Sicomin resin | ||||||

| 20 | 0.406 | 0.454 | 0.017 | 0.936 | 0.935 | 0.035 |

| 50 | 0.979 | 0.873 | 0.037 | 2.21 | 2.21 | 0.253 |

| 80 | 0.780 | 1.913 | 0.063 | 4.29 | 4.22 | 1.67 |

| Sicomin resin + 0.75 wt.% CNFs | ||||||

| 20 | 0.368 | 0.367 | 0.019 | 0.807 | 0.806 | 0.135 |

| 50 | 0.822 | 0.847 | 0.033 | 1.98 | 1.97 | 0.600 |

| 80 | 0.792 | 1.477 | 0.069 | 3.64 | 3.60 | 1.27 |

| Ebalta resin | ||||||

| 20 | 0.414 | 0.563 | 0.032 | 1.18 | 1.17 | 0.418 |

| 50 | 0.796 | 1.500 | 0.048 | 3.16 | 3.13 | 0.829 |

| 80 | 0.932 | 2.042 | 0.091 | 5.83 | 5.71 | 2.087 |

| Ebalta resin + 0.5 wt.% CNFs | ||||||

| 20 | 0.427 | 0.576 | 2.49 × 10−2 | 1.16 | 1.15 | 0.203 |

| 50 | 0.726 | 1.410 | 3.45 × 10−2 | 2.68 | 2.67 | 0.536 |

| 80 | 0.827 | 2.053 | 5.63 × 10−2 | 4.34 | 4.29 | 1.049 |

| Material | β | τ | |||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | R | C | D | R | E | F | R | |

| Sicomin | |||||||||

| Neat resin | 0.042 | 0.018 | 0.997 | 1.64 × 10−3 | 0.304 | 0.993 | 9.01 × 106 | −0.093 | 0.999 |

| Resin + 0.75 wt.% CNFs | 0.035 | 0.069 | 0.999 | 1.64 × 10−3 | 0.301 | 0.869 | 8.74 × 106 | −0.096 | 0.996 |

| Ebalta | |||||||||

| Neat resin | 0.049 | 0.120 | 0.999 | 1.13 × 10−3 | 0.343 | 0.982 | 3.46 × 105 | −0.067 | 0.999 |

| Resin + 0.5 wt.% CNFs | 0.041 | 0.282 | 0.999 | 1.24 × 10−3 | 0.314 | 0.980 | 9.15 × 105 | −0.062 | 0.999 |

| Material | A | n | |||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | R | C | D | R | E | F | R | |

| Sicomin | |||||||||

| Neat resin | 6.24 × 10−3 | 0.410 | 0.643 | 0.024 | −0.136 | 0.971 | 7.77 × 10−4 | 3.26 × 10−5 | 0.997 |

| Resin + 0.75 wt.% CNFs | 7.06 × 10−3 | 0.308 | 0.834 | 0.018 | −0.028 | 0.997 | 8.35 × 10−4 | −1.43 × 10−3 | 0.969 |

| Ebalta | |||||||||

| Neat resin | 8.64 × 10−3 | 0.282 | 0.964 | 0.025 | 0.136 | 0.988 | 9.85 × 10−4 | 7.98 × 10−3 | 0.964 |

| Resin + 0.5 wt.% CNFs | 6.66 × 10−3 | 0.327 | 0.961 | 0.025 | 0.116 | 0.997 | 5.24 × 10−4 | 1.24 × 10−2 | 0.976 |

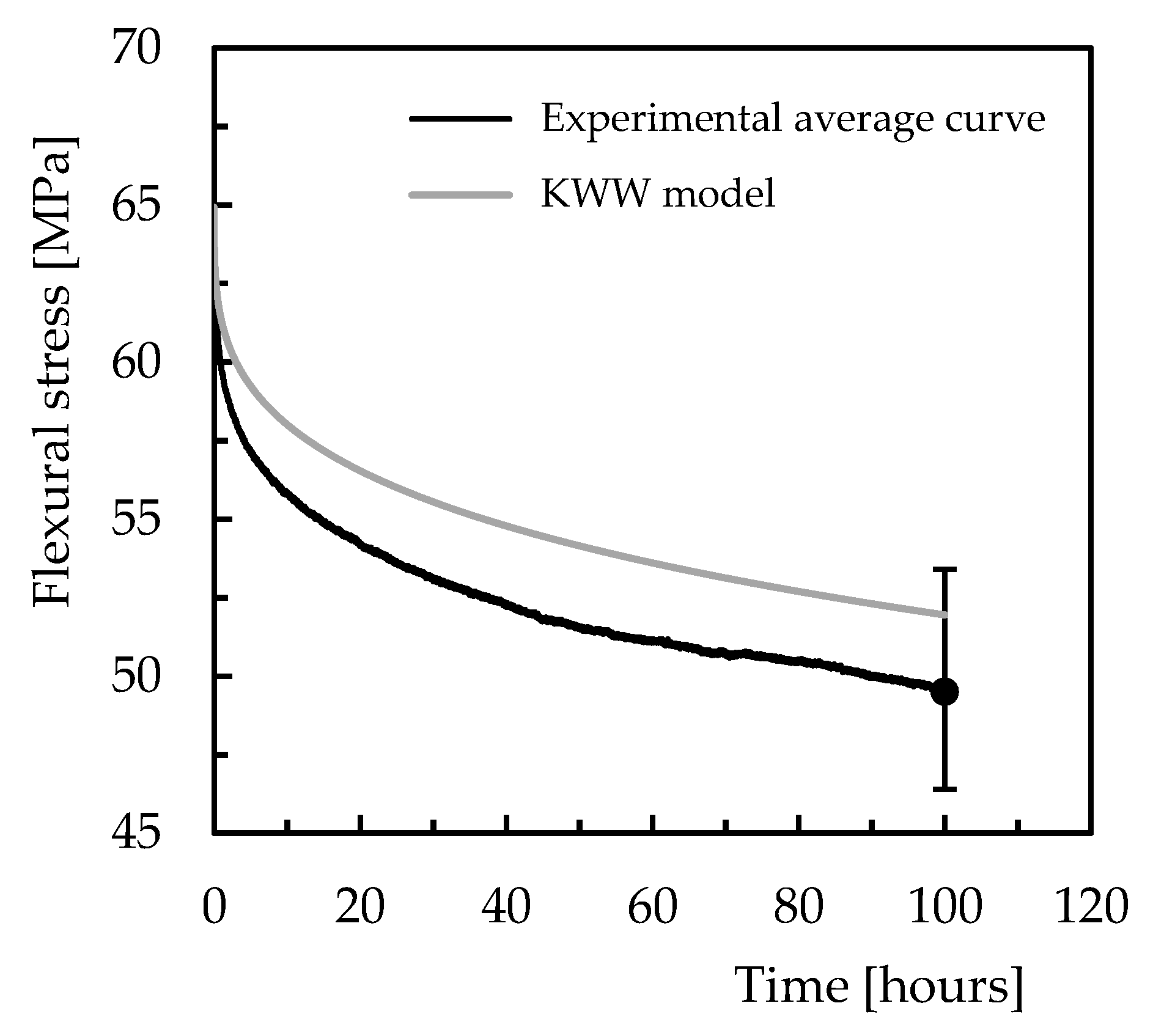

| Initial Bending Stress [MPa] | β | τ | Bending Stress after 3 h [MPa] | ||

|---|---|---|---|---|---|

| Experimental Value | KWW Value | Error [%] | |||

| Sicomin neat resin | |||||

| 20 | 0.321 | 6.36 × 105 | 18.62 | 18.63 | 0.012 |

| 50 | 0.388 | 5.56 × 104 | 45.07 | 44.90 | 0.378 |

| 80 | 0.394 | 1.15 × 104 | 66.24 | 65.88 | 0.554 |

| Sicomin resin + 0.75 wt.% CNFs | |||||

| 20 | 0.312 | 1.86 × 106 | 18.94 | 18.97 | 0.163 |

| 50 | 0.360 | 1.69 × 105 | 46.07 | 45.96 | 0.225 |

| 80 | 0.361 | 3.04 × 104 | 68.64 | 68.36 | 0.059 |

| Ebalta neat resin | |||||

| 20 | 0.338 | 8.57 × 104 | 17.73 | 17.68 | 0.299 |

| 50 | 0.376 | 2.12 × 104 | 42.59 | 42.33 | 0.622 |

| 80 | 0.349 | 8.60 × 103 | 62.47 | 61.69 | 1.255 |

| Ebalta resin + 0.5 wt.% CNFs | |||||

| 20 | 0.328 | 1.33 × 105 | 17.96 | 17.86 | 0.520 |

| 50 | 0.361 | 3.48 × 104 | 43.32 | 43.01 | 0.523 |

| 80 | 0.359 | 1.66 × 104 | 66.28 | 65.66 | 0.934 |

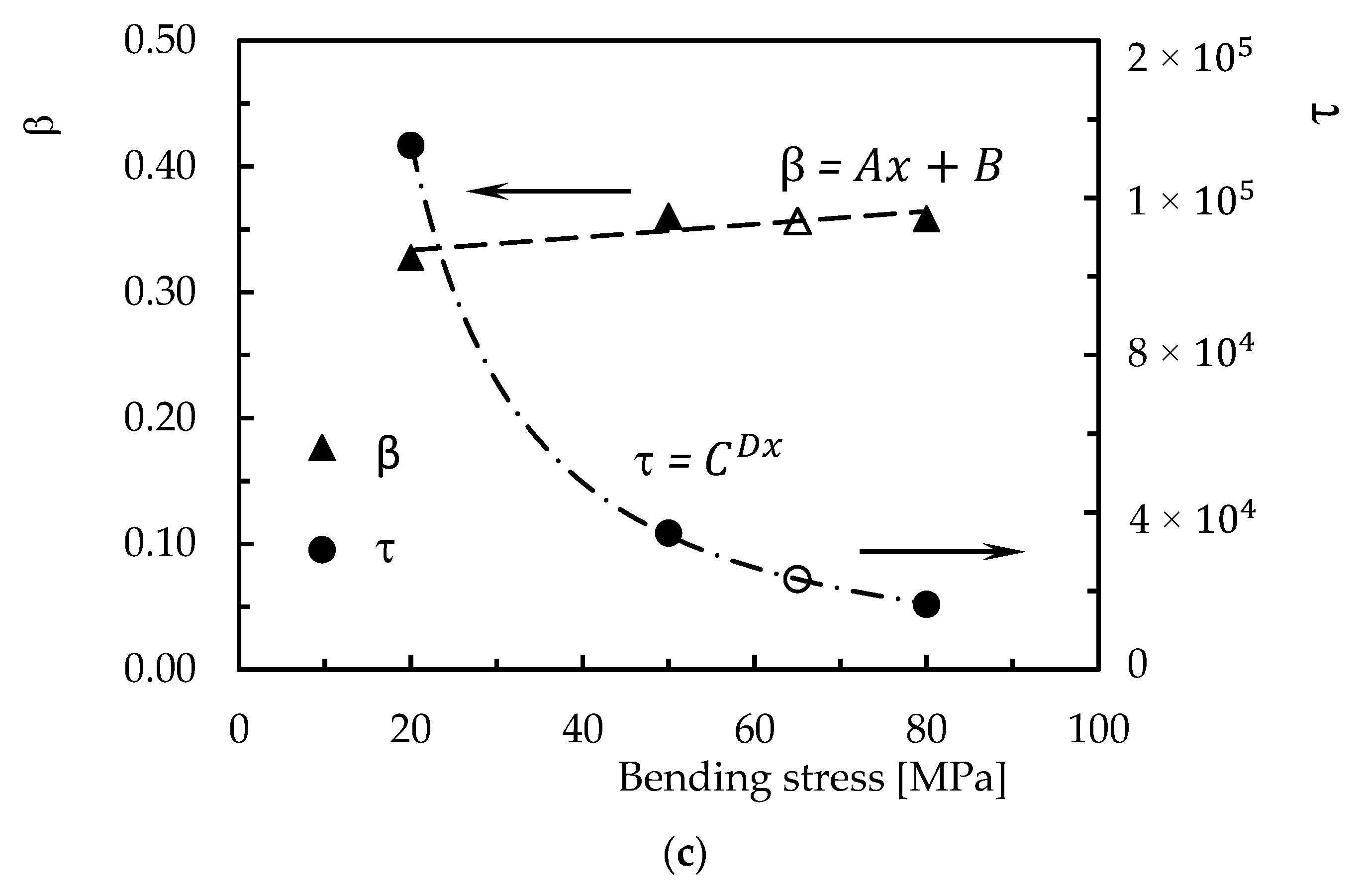

| Material | β | τ | ||||

|---|---|---|---|---|---|---|

| A | B | R | C | D | R | |

| Sicomin | ||||||

| Neat resin | 1.21 × 10−3 | 0.307 | 0.897 | 2.10 × 106 | −0.067 | 0.994 |

| Epoxy + 0.75 wt.% CNFs | 8.16 × 10−4 | 0.304 | 0.874 | 6.55 × 106 | −0.069 | 0.995 |

| Ebalta | ||||||

| Neat resin | 1.73 × 10−3 | 0.345 | 0.270 | 1.19 × 107 | −1.64 | 0.998 |

| Epoxy + 0.5 wt.% CNFs | 5.14 × 10−4 | 0.323 | 0.838 | 1.19 × 107 | −1.49 | 1.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, P.; Silva, A.P.; Reis, P.N.B. Effect of Carbon Nanofibers on the Viscoelastic Response of Epoxy Resins. Polymers 2023, 15, 821. https://doi.org/10.3390/polym15040821

Santos P, Silva AP, Reis PNB. Effect of Carbon Nanofibers on the Viscoelastic Response of Epoxy Resins. Polymers. 2023; 15(4):821. https://doi.org/10.3390/polym15040821

Chicago/Turabian StyleSantos, Paulo, Abílio P. Silva, and Paulo N. B. Reis. 2023. "Effect of Carbon Nanofibers on the Viscoelastic Response of Epoxy Resins" Polymers 15, no. 4: 821. https://doi.org/10.3390/polym15040821

APA StyleSantos, P., Silva, A. P., & Reis, P. N. B. (2023). Effect of Carbon Nanofibers on the Viscoelastic Response of Epoxy Resins. Polymers, 15(4), 821. https://doi.org/10.3390/polym15040821