A Miniaturized Piezoelectric MEMS Accelerometer with Polygon Topological Cantilever Structure

Abstract

1. Introduction

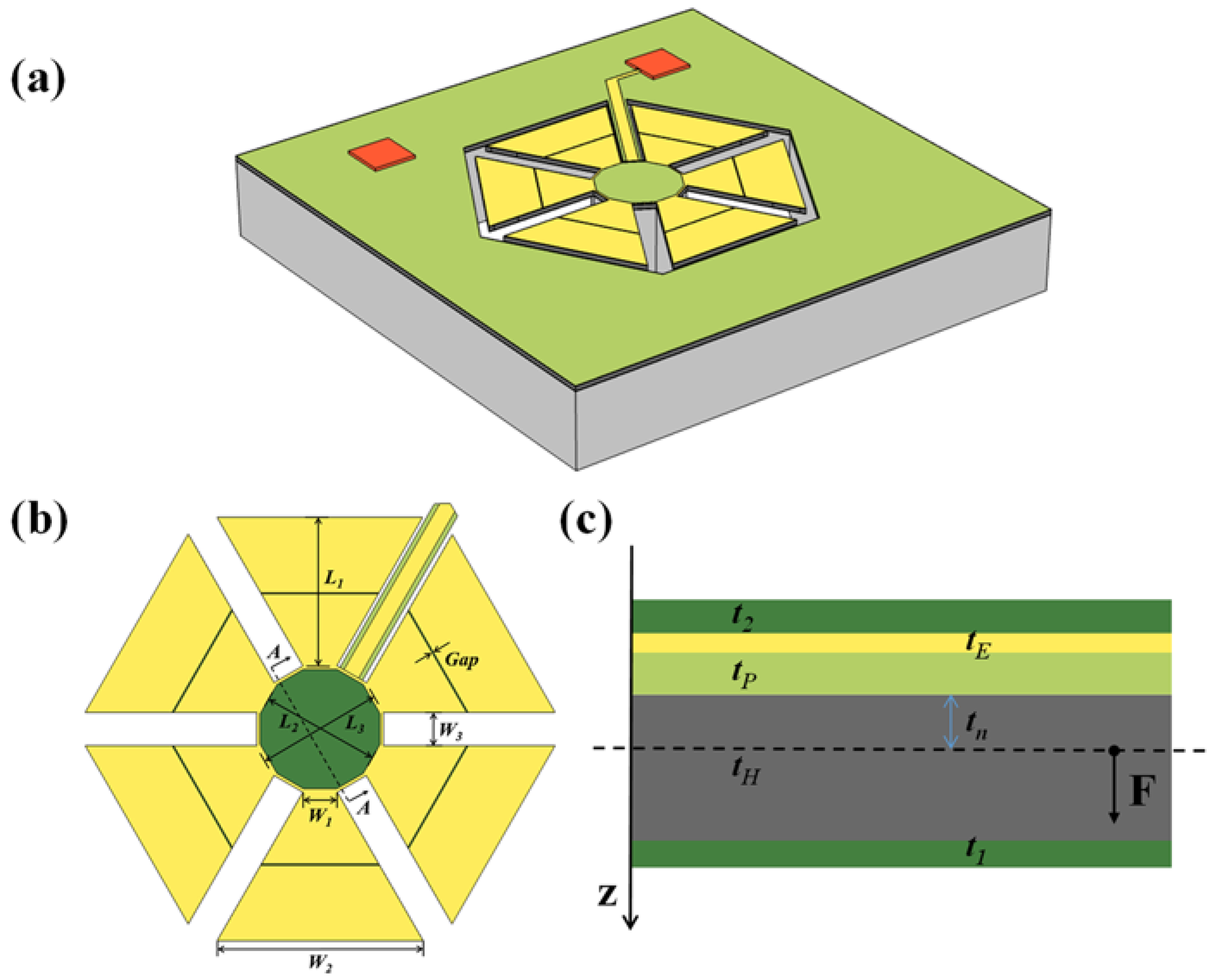

2. Device and Simulation

2.1. Structural Design

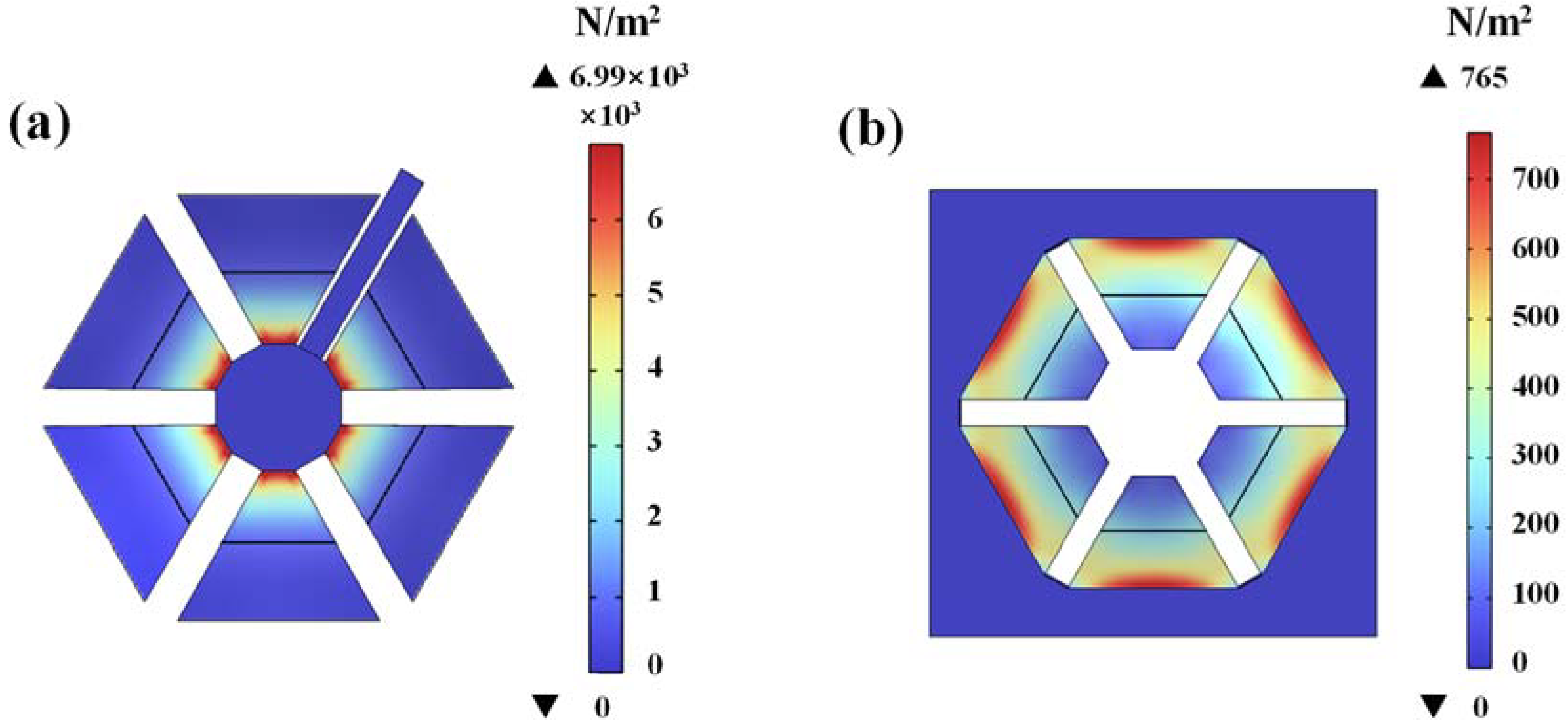

2.2. Finite Element Simulation

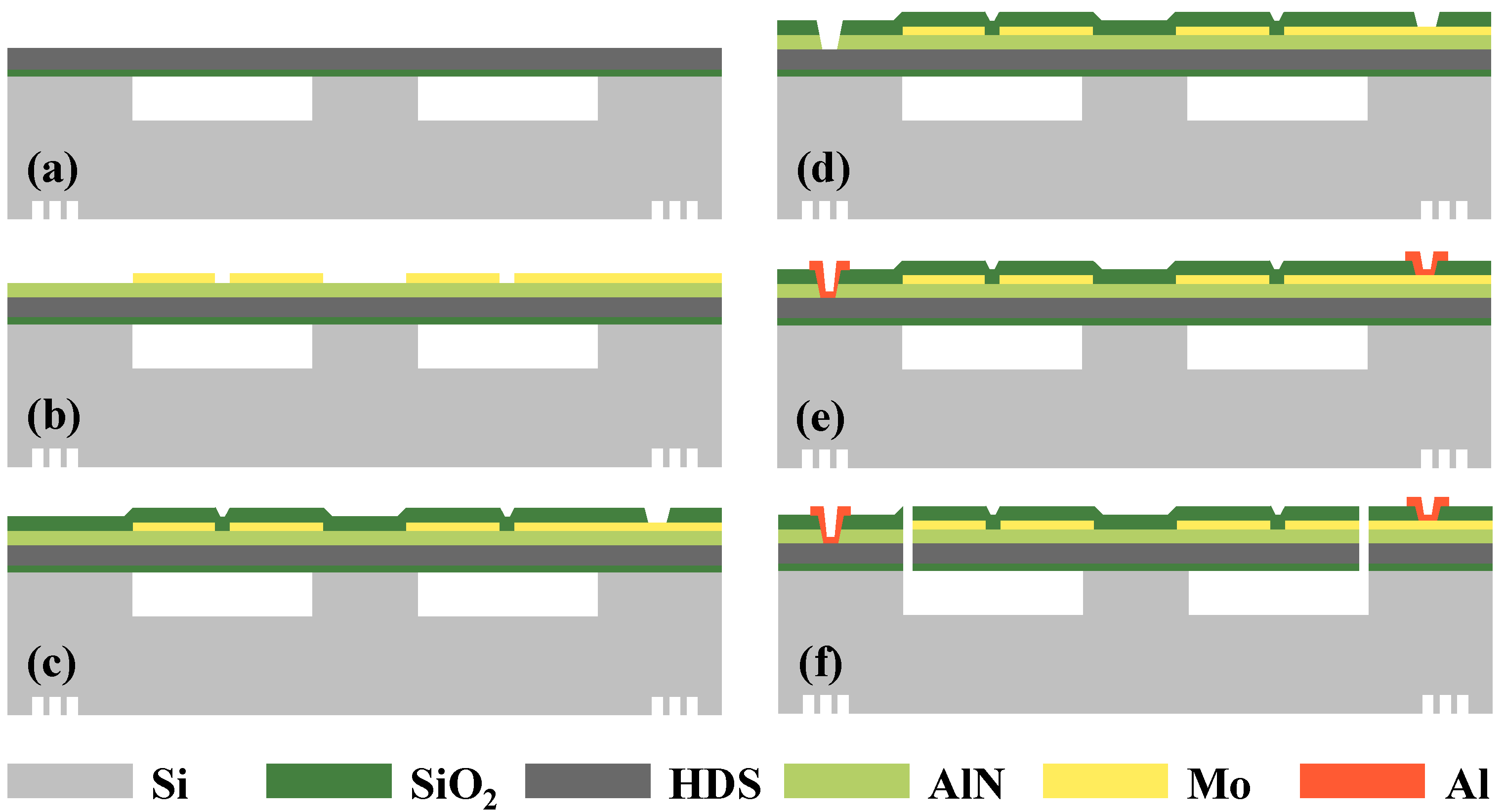

3. Fabrication and Characterization

3.1. Fabrication Process

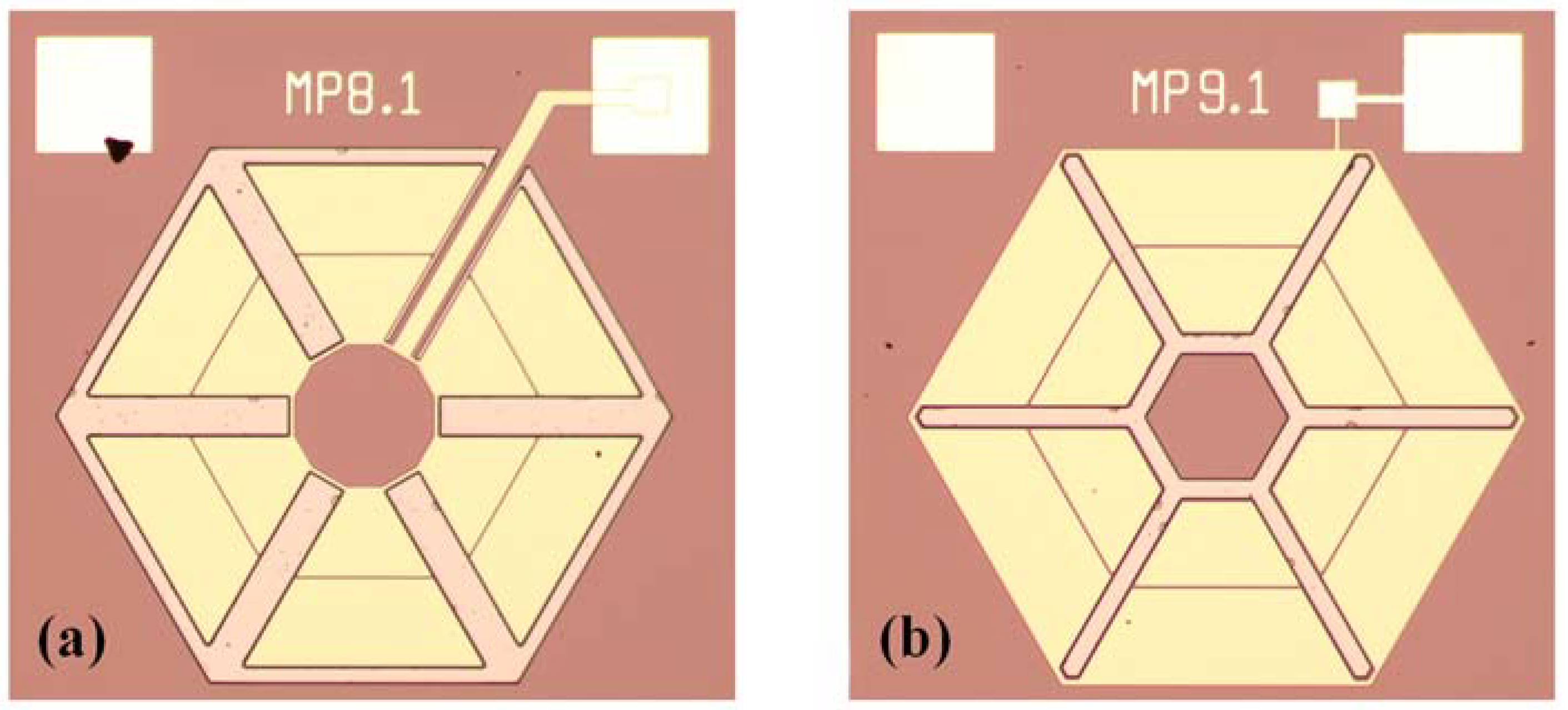

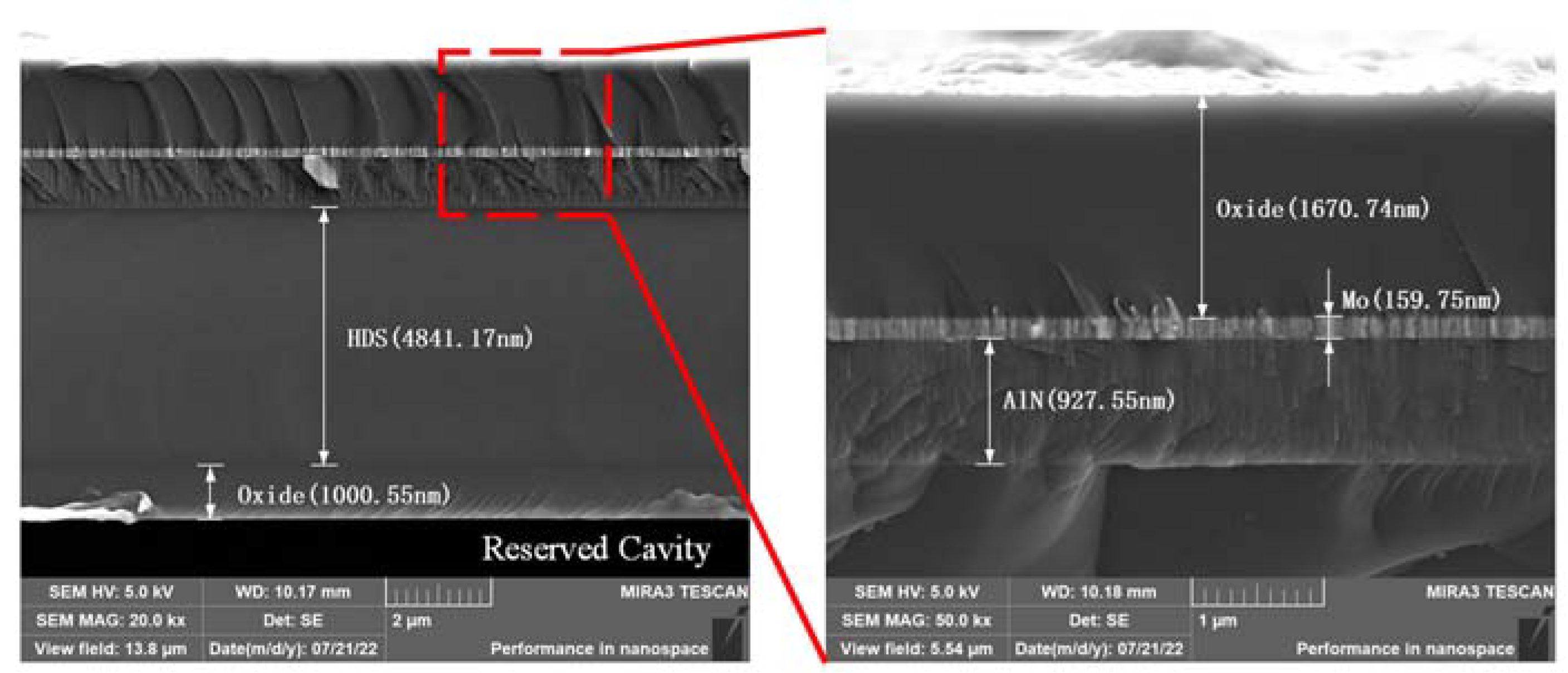

3.2. Morphological Characterization

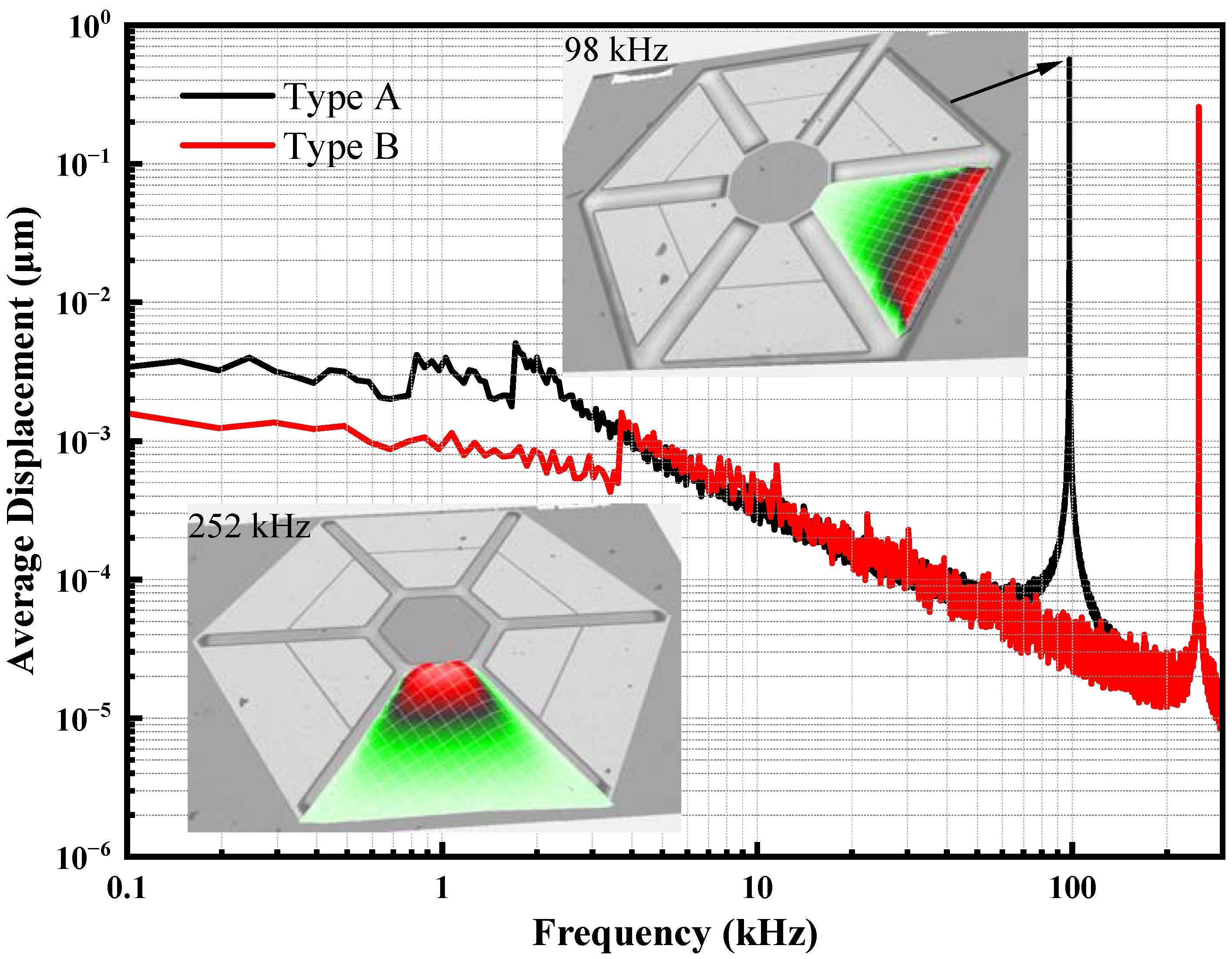

3.3. Dynamic Characterization

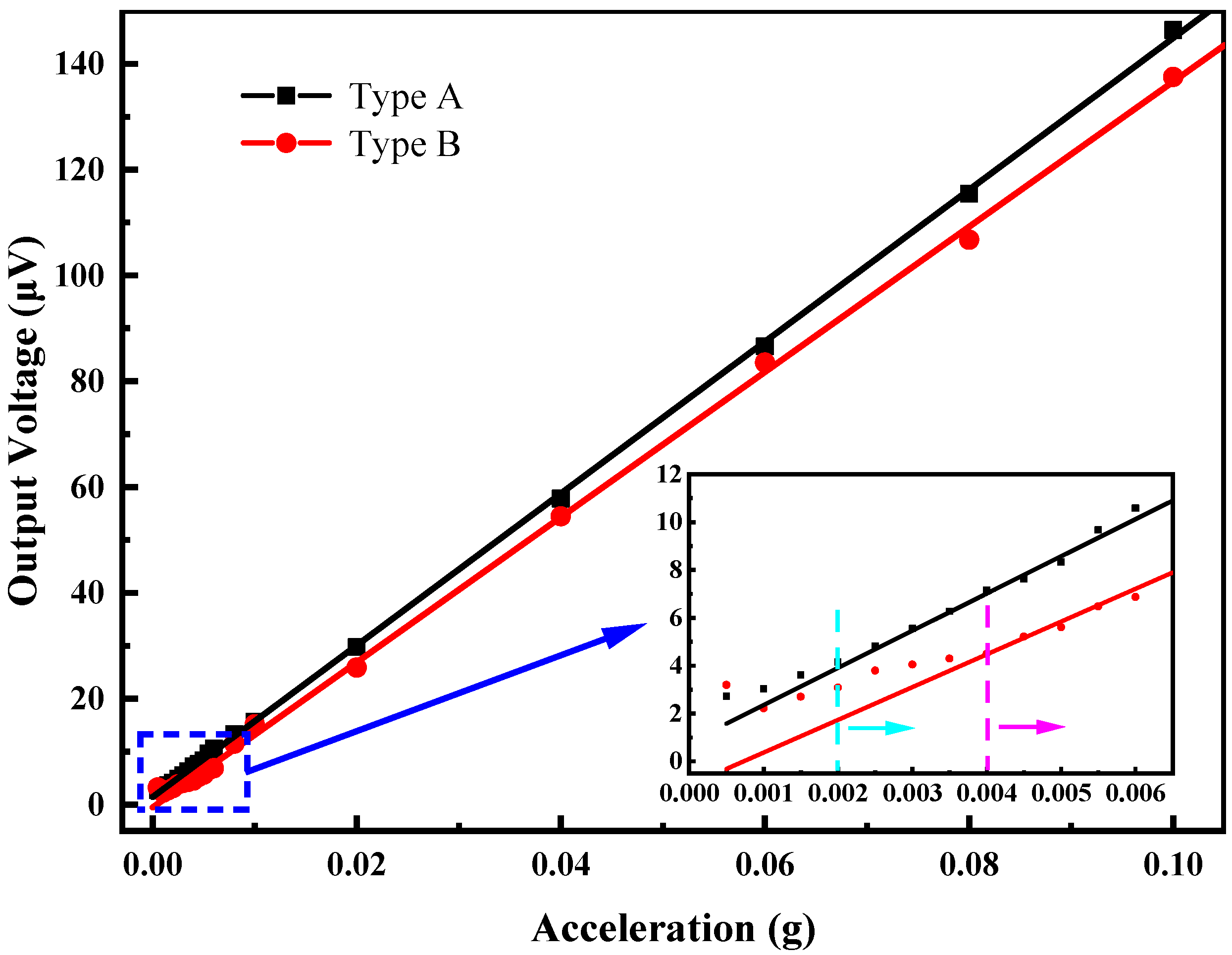

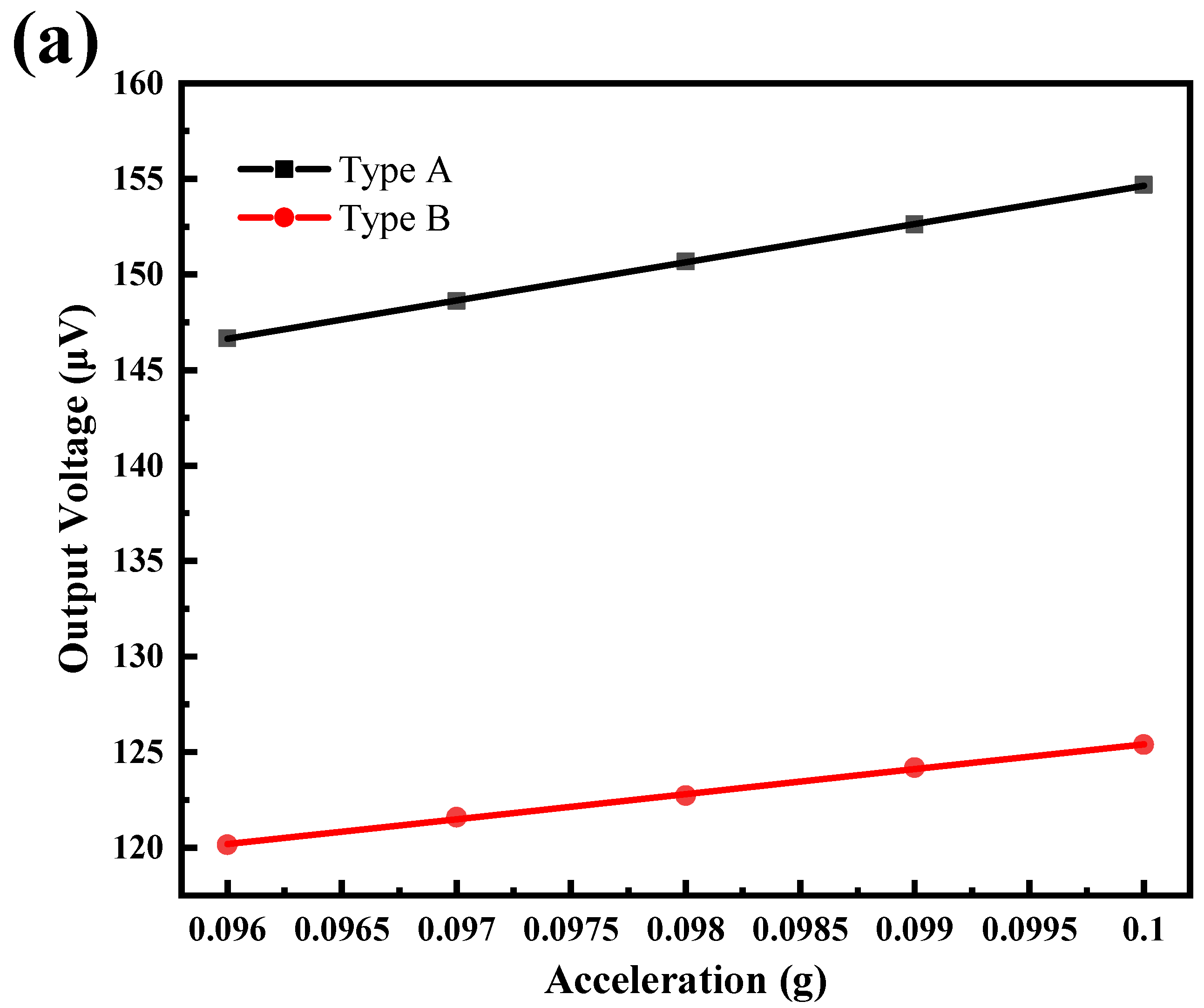

4. Results and Analysis

4.1. Experimental Procedure

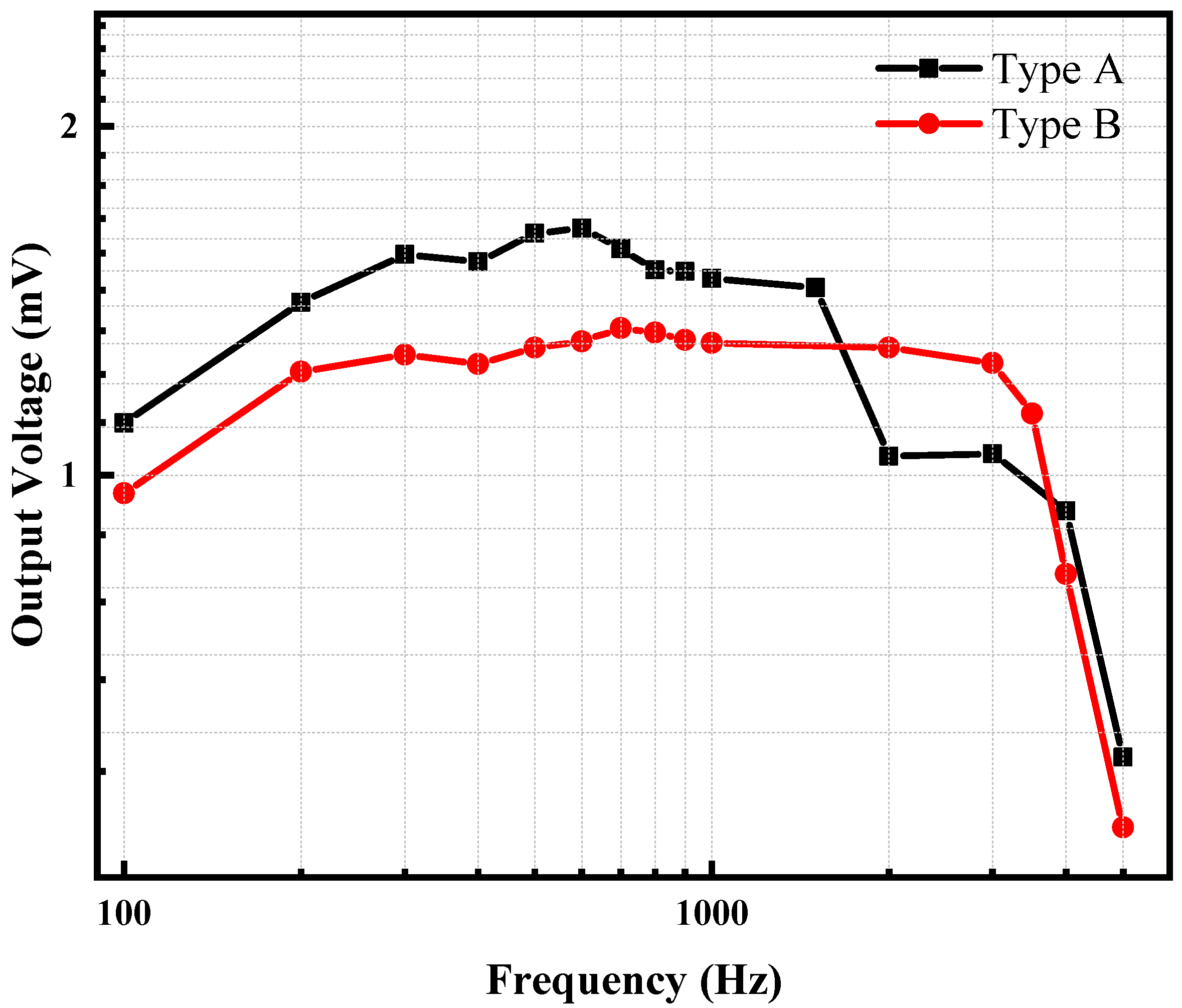

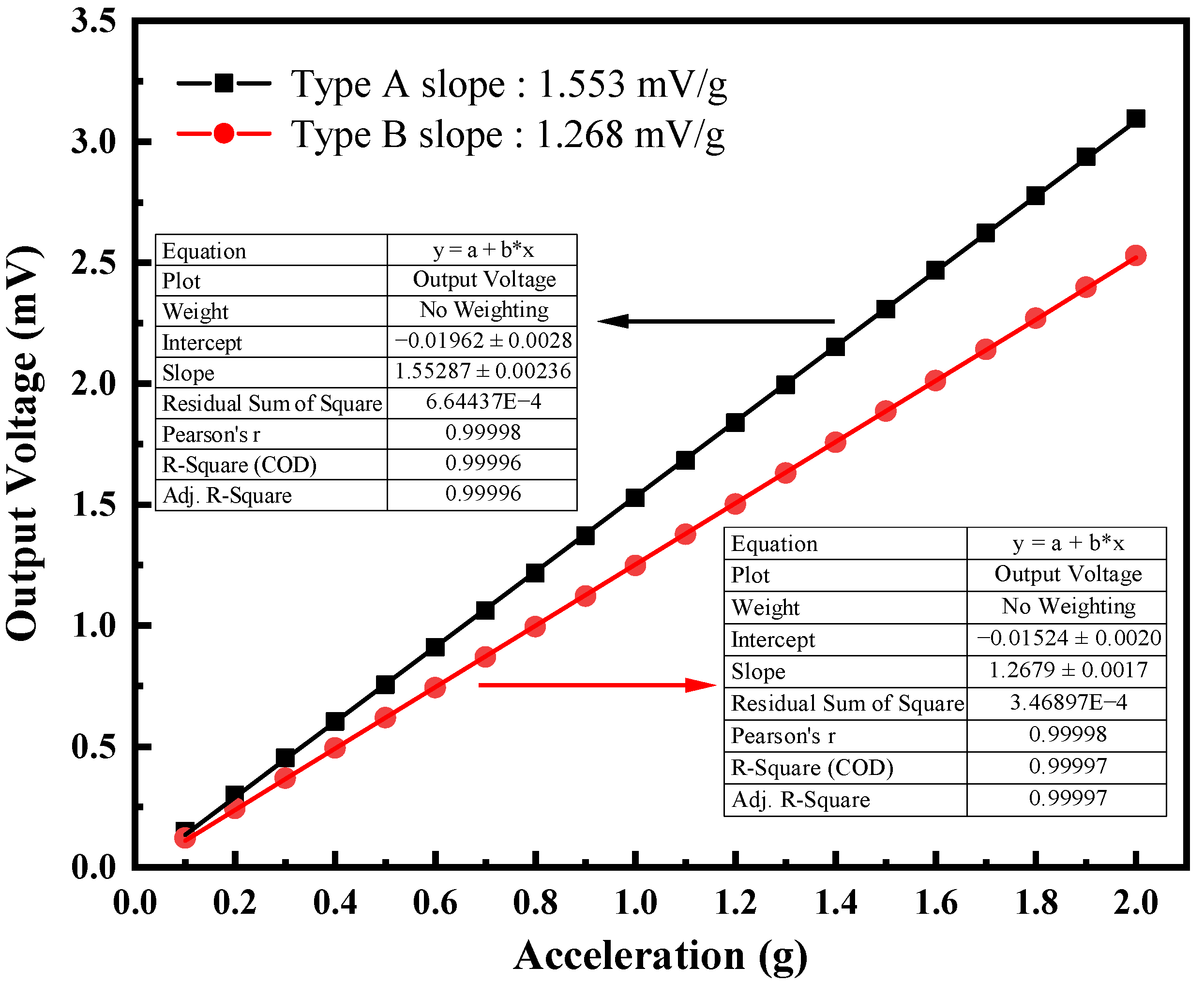

4.2. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, J.; Zhang, M.; He, Y.; Su, Y.; Han, G.; Si, C.; Ning, J.; Yang, F.; Wang, X. A Resonant Z-Axis Aluminum Nitride Thin-Film Piezoelectric MEMS Accelerometer. Micromachines 2019, 10, 589. [Google Scholar] [CrossRef] [PubMed]

- Scheeper, P.; Gulløv, J.O.; Kofoed, L.M. A piezoelectric triaxial accelerometer. J. Micromechanics Microengineering 1996, 6, 131–133. [Google Scholar] [CrossRef]

- Koene, I.; Viitala, R.; Kuosmanen, P. Internet of Things Based Monitoring of Large Rotor Vibration with a Microelectromechanical Systems Accelerometer. IEEE Access 2019, 7, 92210–92219. [Google Scholar] [CrossRef]

- Tsai, J.-M.; Sun, I.-C.; Chen, K.-S. Realization and performance evaluation of a machine tool vibration monitoring module by multiple MEMS accelerometer integrations. Int. J. Adv. Manuf. Technol. 2021, 114, 465–479. [Google Scholar] [CrossRef]

- Reze, M.; Osajda, M. MEMS sensors for automotive vehicle stability control applications. In MEMS for Automotive and Aerospace Applications; Woodhead Publishing: Sawston, UK, 2013; pp. 29–53. [Google Scholar]

- Mukhiya, R.; Agarwal, P.; Badjatya, S.; Garg, M.; Gaikwad, P.; Sinha, S.; Singh, A.K.; Gopal, R. Design, modelling and system level simulations of DRIE-based MEMS differential capacitive accelerometer. Microsyst. Technol. 2019, 25, 3521–3532. [Google Scholar] [CrossRef]

- Pang, G.; Liu, H. Evaluation of a Low-cost MEMS Accelerometer for Distance Measurement. J. Intell. Robot. Syst. 2001, 30, 249–265. [Google Scholar] [CrossRef]

- Sheng, H.; Zhang, T. MEMS-based low-cost strap-down AHRS research. Measurement 2015, 59, 63–72. [Google Scholar] [CrossRef]

- Chao, M.Y.; Ali, A.; Ghosh, S.; Lee, J.E.-Y. An Aluminum Nitride on Silicon resonant MEMS accelerometer operating in ambient pressure. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 607–610. [Google Scholar] [CrossRef]

- Kopetz, H. Real-time systems: Design principles for distributed embedded applications. Comput. Math. Appl. 1997, 34, 142. [Google Scholar]

- Narasimhan, V.; Li, H.; Jianmin, M. Micromachined high-g accelerometers: A review. J. Micromechanics Microengineering 2015, 25, 033001. [Google Scholar] [CrossRef]

- Wang, L.P.; Ginsburg, E.; Gerfers, F.; Samara-Rubio, D.; Weinfeld, B.; Ma, Q.; Rao, V.; He, M.Y. Sputtered AlN Thin Films for Piezoelectric MEMS Devices. In Proceedings of the SENSORS, 2006 IEEE, Daegu, Korea, 22–25 October 2006; pp. 10–13. [Google Scholar]

- Hindrichsen, C.C.; Almind, N.S.; Brodersen, S.H.; Hansen, O.; Thomsen, E.V. Analytical Model of a PZT Thick-Film Triaxial Accelerometer for Optimum Design. IEEE Sens. J. 2009, 9, 419–429. [Google Scholar] [CrossRef]

- Wang, L.P.; Wolf, R.A.; Wang, Y.; Deng, K.K.; Zou, L.; Davis, R.J.; Trolier-McKinstry, S. Design, fabrication, and measurement of high-sensitivity piezoelectric microelectromechanical systems accelerometers. J. Microelectromechanical Syst. 2003, 12, 433–439. [Google Scholar] [CrossRef]

- Yu, H.G.; Zou, L.; Deng, K.; Wolf, R.; Tadigadapa, S.; Trolier-McKinstry, S. Lead zirconate titanate MEMS accelerometer using interdigitated electrodes. Sens. Actuators A Phys. 2003, 107, 26–35. [Google Scholar] [CrossRef]

- Chen, Z.-H.; Li, C.-Y.; Chu, S.-Y.; Tsai, C.-C.; Wang, Y.-H.; Kao, H.-Y.; Wei, C.-L.; Huang, Y.-H.; Hsiao, P.-Y.; Liu, Y.-H. The Design of Aluminum Nitride-Based Lead-Free Piezoelectric MEMS Accelerometer System. IEEE Trans. Electron Devices 2020, 67, 4399–4404. [Google Scholar] [CrossRef]

- Gupta, N.; Dutta, S.; Pandey, A.; Vanjari, S.R.K.; Kaur, D. Effect of growth and residual stress in AlN (0002) thin films on MEMS accelerometer design. J. Mater. Sci. Mater. Electron. 2020, 31, 17281–17290. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, M.; Si, C.; Han, G.; Ning, J.; Yang, F.; Wang, X. A T-Shape Aluminum Nitride Thin-Film Piezoelectric MEMS Resonant Accelerometer. J. Microelectromechanical Syst. 2019, 28, 776–781. [Google Scholar] [CrossRef]

- Hu, B.; Liu, Y.; Lin, B.; Wu, G.; Liu, W.; Sun, C. A Novel Trapezoidal ScAlN/AlN-Based MEMS Piezoelectric Accelerometer. IEEE Sens. J. 2021, 21, 21277–21284. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, B.; Cai, Y.; Liu, W.; Tovstopyat, A.; Sun, C. A Novel Tri-Axial Piezoelectric MEMS Accelerometer with Folded Beams. Sensors 2021, 21, 453. [Google Scholar] [CrossRef]

- Kim, S.-G. Piezoelectric Micro Power Generator (PMPG): A MEMS-Based Energy Scavenger. Doctoral Dissertation, Massachusetts Institute of Technology, Cambridge, MA, USA, 2005. [Google Scholar]

- Schachtele, J.; Goll, E.; Muralt, P.; Kaltenbacher, D. Admittance matrix of a trapezoidal piezoelectric heterogeneous bimorph. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 2765–2776. [Google Scholar] [CrossRef]

- Chen, Z.S.; Yang, Y.M.; Deng, G.Q. Analytical and experimental study on vibration energy harvesting behaviors of piezoelectric cantilevers with different geometries. In Proceedings of the 2009 International Conference on Sustainable Power Generation and Supply, Nanjing, China, 6–7 April 2009; pp. 1–6. [Google Scholar] [CrossRef]

- Tsubouchi, K.; Mikoshiba, N. Zero-Temperature-Coefficient SAW Devices on AlN Epitaxial Films. IEEE Trans. Sonics Ultrason. 1985, 32, 634–644. [Google Scholar] [CrossRef]

- Zhang, S.; Fu, W.Y.; Holec, D.; Humphreys, C.J.; Moram, M.A. Elastic constants and critical thicknesses of ScGaN and ScAlN. J. Appl. Phys. 2013, 114, 243516. [Google Scholar] [CrossRef]

- Trivedi, S.; Shen, T.; Chang, C.-Y.; Huang, P.-W.; Li, S.-S. Design of Piezoelectric MEMS Accelerometer Module and its Application in Surface Roughness Prediction of Fused Silica Substrate. IEEE Sens. J. 2021, 21, 21979–21988. [Google Scholar] [CrossRef]

- Manikandan, K.G.; Pannirselvam, K.; Kenned, J.J.; Kumar, C.S. Investigations on suitability of MEMS based accelerometer for vibration measurements. Mater. Today Proc. 2020, 45, 6183–6192. [Google Scholar] [CrossRef]

- Saayujya, C.; Tan, J.S.-Q.; Yuan, Y.; Wong, Y.-R.; Du, H. Design, fabrication and characterization of a zinc oxide thin-film piezoelectric accelerometer. In Proceedings of the 2014 IEEE Ninth International Conference on Intelligent Sensors, Sensor Networks and Information Processing (ISSNIP), Singapore, 21–24 April 2014; pp. 1–6. [Google Scholar] [CrossRef]

| Symbol | Parameter | Value (μm) |

|---|---|---|

| Buried oxide thickness | 1 | |

| HDS thickness | 5.2 | |

| AlN thickness | 1 | |

| Mo thickness | 0.15 | |

| Top oxide thickness | 1.8 | |

| Neutral plane position of a simplified model | 1.63 | |

| Trapezoidal beam length | 226 | |

| Distance between opposite beams | 182 | |

| Width of the support column | 192 | |

| Break width between electrodes | 2 | |

| Short side width of the trapezoidal beam | 50 | |

| Long side width of the trapezoidal beam | 305 | |

| Spacing distance between beams | 54 |

| Material | Piezoelectric Strain Coefficient | Young’s Modulus E | Poisson’s Ratio | |

|---|---|---|---|---|

| AlN | −2.65 [24] | 244 | 3300 | 0.24 [24,25] |

| Si | - | 170 | 2329 | 0.28 |

| HDS | - | 125.4 | 2329 | 0.198 |

| Mo | - | 312 | 10200 | 0.31 |

| SiO2 | - | 70 | 2200 | 0.17 |

| Author | C. C. Hindrichsen et al. [28] | Z. H. Chen et al. [16] | B. H. HU et al. [19] | This Work |

|---|---|---|---|---|

| Piezoelectric material | PZT | AlN | ScAlN/AlN | AlN |

| Device size [mm2] | 7.84 | 63.62 | 14.25 | 0.723 |

| Sensitivity | 0.31 mV/g (2 kHz) | 1.49 mV/g (7.2 kHz) | 7.95 mV/g (400 Hz) | 1.533 mV/g (400 Hz) |

| Resonance frequency [kHz] | 11 | 7.2 | 1.29 | 98 |

| Device structure | Seismic mass suspended by four beams | Circular membrane | TWC membrane | Polygon topological cantilevers |

| Compatible with CMOS process | No | Yes | Yes | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Hu, B.; Lu, L.; Wang, Z.; Liu, W.; Sun, C. A Miniaturized Piezoelectric MEMS Accelerometer with Polygon Topological Cantilever Structure. Micromachines 2022, 13, 1608. https://doi.org/10.3390/mi13101608

Yang C, Hu B, Lu L, Wang Z, Liu W, Sun C. A Miniaturized Piezoelectric MEMS Accelerometer with Polygon Topological Cantilever Structure. Micromachines. 2022; 13(10):1608. https://doi.org/10.3390/mi13101608

Chicago/Turabian StyleYang, Chaoxiang, Bohao Hu, Liangyu Lu, Zekai Wang, Wenjuan Liu, and Chengliang Sun. 2022. "A Miniaturized Piezoelectric MEMS Accelerometer with Polygon Topological Cantilever Structure" Micromachines 13, no. 10: 1608. https://doi.org/10.3390/mi13101608

APA StyleYang, C., Hu, B., Lu, L., Wang, Z., Liu, W., & Sun, C. (2022). A Miniaturized Piezoelectric MEMS Accelerometer with Polygon Topological Cantilever Structure. Micromachines, 13(10), 1608. https://doi.org/10.3390/mi13101608