In-Situ Measurements in Microscale Gas Flows—Conventional Sensors or Something Else?

Abstract

1. Introduction

2. Parameters, Measurement Methods and Scaling

2.1. Temperature Measurement

2.1.1. Measurements Using Conventional Intrusive Sensors

2.1.2. Measurements Using Non-Intrusive Methods

2.2. Measurements of Other Parameters

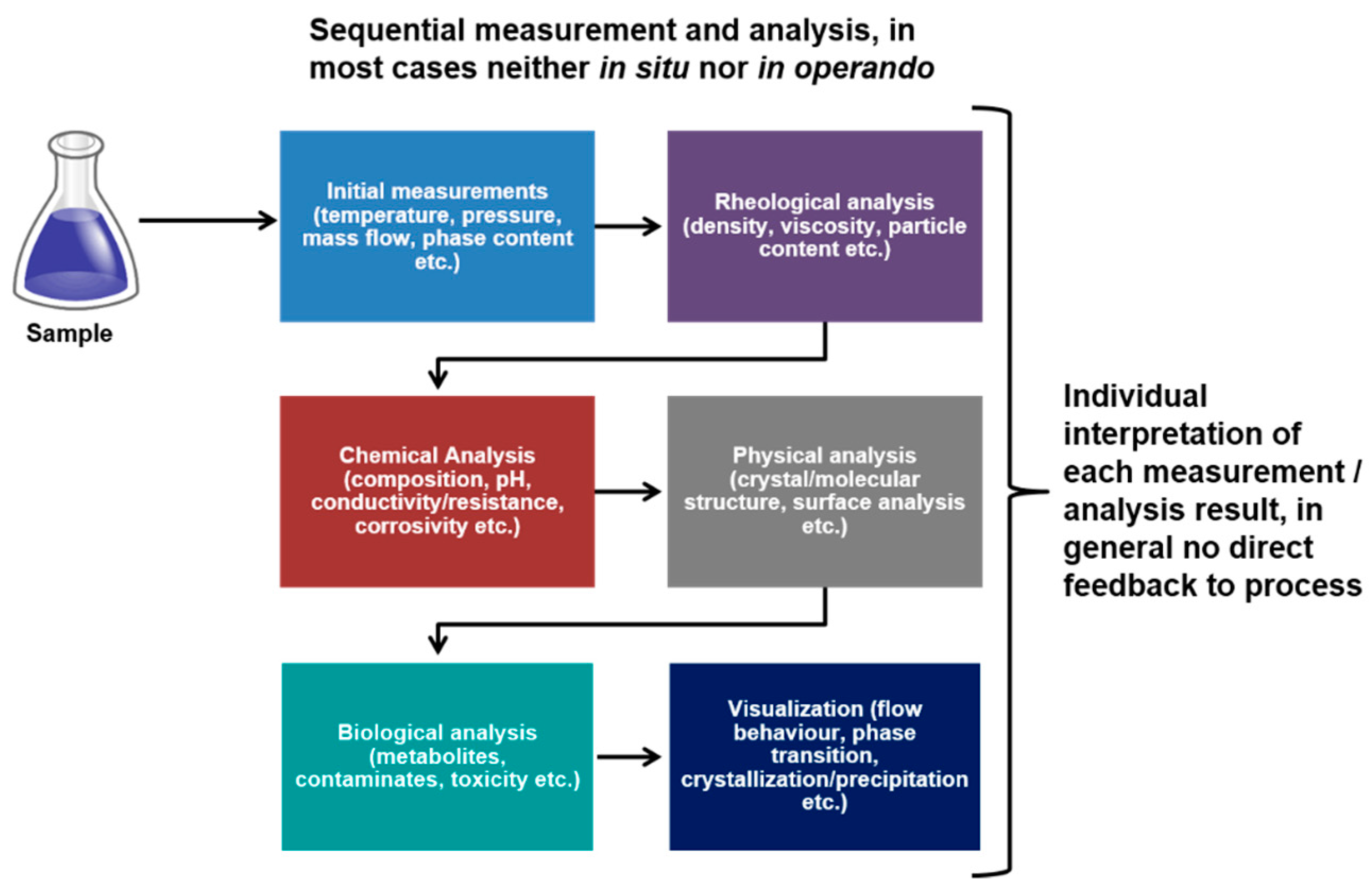

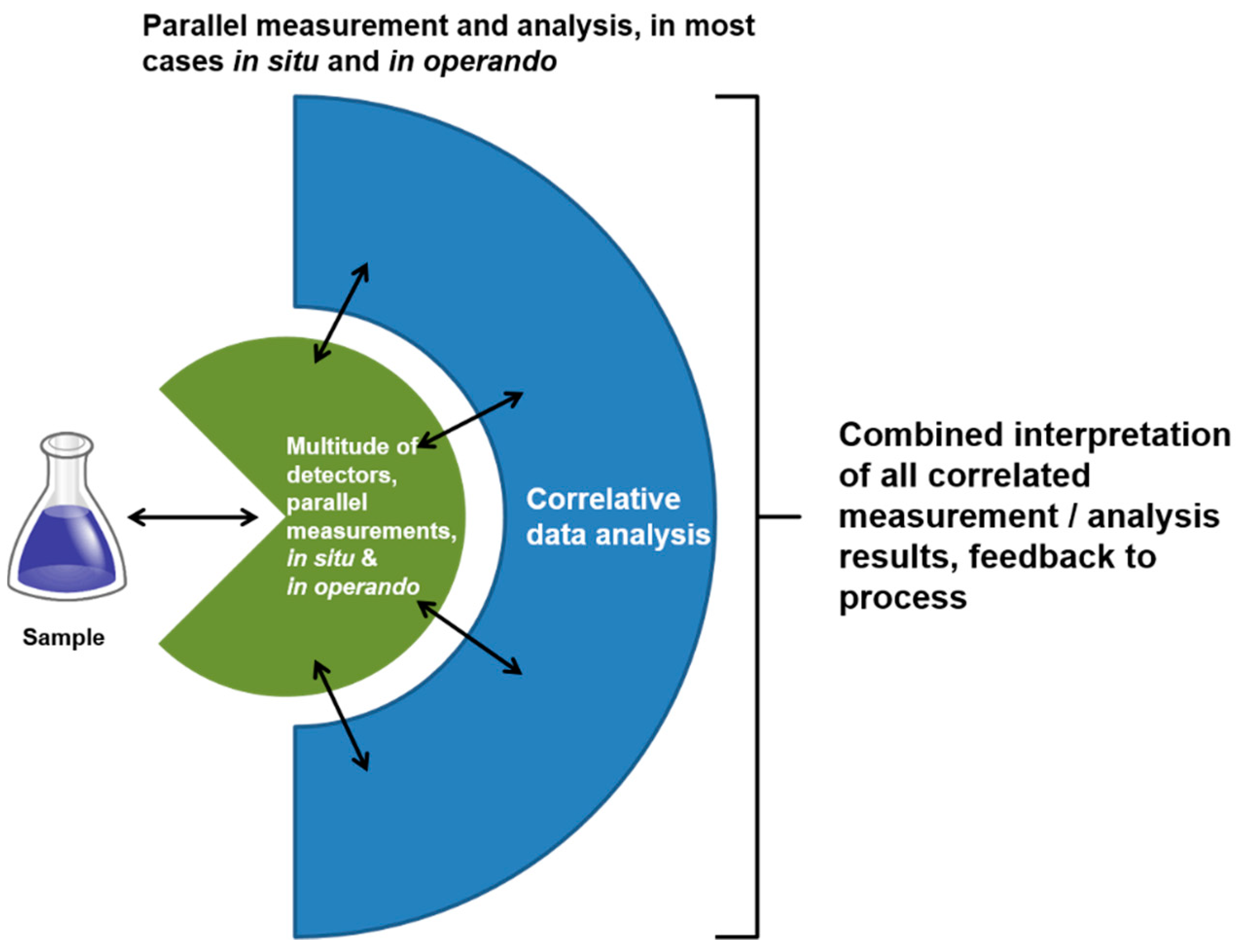

2.3. Combined and Correlated Measurement System

3. Discussion

4. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Kandlikar, S.G.; Colin, S.; Peles, Y.; Garimella, S.; Pease, R.F.; Brandner, J.J.; Tuckerman, D.B. Heat Transfer in Microchannels—2012 Status and Research Needs. J. Heat Transf. 2013, 135, 091001. [Google Scholar] [CrossRef]

- Morini, G.L. Single-phase convective heat transfer in microchannels: A review of experimental results. Int. J. Therm. Sci. 2004, 43, 631–651. [Google Scholar] [CrossRef]

- Mohammed, H.A.; Bhaskaran, G.; Shuaib, N.H.; Saidur, R. Heat transfer and fluid flow characteristics in microchannels heat exchanger using nanofluids: A review. Renew. Sustain. Energy Rev. 2011, 15, 1502–1512. [Google Scholar] [CrossRef]

- Han, Y.; Liu, Y.; Li, M.; Huang, J. A review of development of micro-channel heat exchanger applied in air-conditioning system. Energy Procedia 2012, 14, 148–153. [Google Scholar] [CrossRef]

- Dixit, T.; Ghosh, I. Review of micro- and mini-channel heat sinks and heat exchangers for single phase fluids. Renew. Sustain. Energy Rev. 2015, 41, 1298–1311. [Google Scholar] [CrossRef]

- Rosa, P.; Karayiannis, T.G.; Collins, M.W. Single-phase heat transfer in microchannels: The importance of scaling effects. Appl. Therm. Eng. 2009, 29, 3447–3468. [Google Scholar] [CrossRef]

- Mohammed Adham, A.; Mohd-Ghazali, N.; Ahmad, R. Thermal and hydrodynamic analysis of microchannel heat sinks: A review. Renew. Sustain. Energy Rev. 2013, 21, 614–622. [Google Scholar] [CrossRef]

- Colin, S. Gas Microflows in the Slip Flow Regime: A Critical Review on Convective Heat Transfer. J. Heat Transf. 2011, 134, 020908. [Google Scholar] [CrossRef]

- Yin, S.; Meyer, M.; Li, W.; Liao, H.; Lupoi, R. Gas Flow, Particle Acceleration, and Heat Transfer in Cold Spray: A review. J. Therm. Spray Technol. 2016, 25, 874–896. [Google Scholar] [CrossRef]

- Asadi, M.; Xie, G.; Sunden, B. A review of heat transfer and pressure drop characteristics of single and two-phase microchannels. Int. J. Heat Mass Transf. 2014, 79, 34–53. [Google Scholar] [CrossRef]

- Salman, B.H.; Mohammed, H.A.; Munisamy, K.M.; Kherbeet, A.S. Characteristics of heat transfer and fluid flow in microtube and microchannel using conventional fluids and nanofluids: A review. Renew. Sustain. Energy Rev. 2013, 28, 848–880. [Google Scholar] [CrossRef]

- Zhai, Y.; Xia, G.; Li, Z.; Wang, H. Experimental investigation and empirical correlations of single and laminar convective heat transfer in microchannel heat sinks. Exp. Therm. Fluid Sci. 2017, 83, 207–214. [Google Scholar] [CrossRef]

- Sahar, A.M.; Özdemir, M.R.; Fayyadh, E.M.; Wissink, J.; Mahmoud, M.M.; Karayiannis, T.G. Single phase flow pressure drop and heat transfer in rectangular metallic microchannels. Appl. Therm. Eng. 2016, 93, 1324–1336. [Google Scholar] [CrossRef]

- Kim, B. An experimental study on fully developed laminar flow and heat transfer in rectangular microchannels. Int. J. Heat Fluid Flow 2016, 62, 224–232. [Google Scholar] [CrossRef]

- Mokrani, O.; Bourouga, B.; Castelain, C.; Peerhossaini, H. Fluid flow and convective heat transfer in flat microchannels. Int. J. Heat Mass Transf. 2009, 52, 1337–1352. [Google Scholar] [CrossRef]

- Sahar, A.M.; Wissink, J.; Mahmoud, M.M.; Karayiannis, T.G.; Ashrul Ishak, M.S. Effect of hydraulic diameter and aspect ratio on single phase flow and heat transfer in a rectangular microchannel. Appl. Therm. Eng. 2017, 115, 793–814. [Google Scholar] [CrossRef]

- Hessel, V.; Angeli, P.; Gavriilidis, A.; Löwe, H. Gas−Liquid and Gas−Liquid−Solid Microstructured Reactors: Contacting Principles and Applications. Ind. Eng. Chem. Res. 2005, 44, 9750–9769. [Google Scholar] [CrossRef]

- Doku, G.N.; Verboom, W.; Reinhoudt, D.N.; van den Berg, A. On-microchip multiphase chemistry—A review of microreactor design principles and reagent contacting modes. Tetrahedron 2005, 61, 2733–2742. [Google Scholar] [CrossRef]

- Su, Y.; Zhao, Y.; Chen, G.; Yuan, Q. Liquid–liquid two-phase flow and mass transfer characteristics in packed microchannels. Chem. Eng. Sci. 2010, 65, 3947–3956. [Google Scholar] [CrossRef]

- Woitalka, A.; Kuhn, S.; Jensen, K.F. Scalability of mass transfer in liquid–liquid flow. Chem. Eng. Sci. 2014, 116, 1–8. [Google Scholar] [CrossRef]

- Kashid, M.N.; Renken, A.; Kiwi-Minsker, L. Gas–liquid and liquid–liquid mass transfer in microstructured reactors. Chem. Eng. Sci. 2011, 66, 3876–3897. [Google Scholar] [CrossRef]

- Reichmann, F.; Tollkötter, A.; Körner, S.; Kockmann, N. Gas-liquid dispersion in micronozzles and microreactor design for high interfacial area. Chem. Eng. Sci. 2017, 169, 151–163. [Google Scholar] [CrossRef]

- Yao, C.; Dong, Z.; Zhao, Y.; Chen, G. Gas-liquid flow and mass transfer in a microchannel under elevated pressures. Chem. Eng. Sci. 2015, 123, 137–145. [Google Scholar] [CrossRef]

- Haase, S.; Murzin, D.Y.; Salmi, T. Review on hydrodynamics and mass transfer in minichannel wall reactors with gas–liquid Taylor flow. Chem. Eng. Res. Des. 2016, 113, 304–329. [Google Scholar] [CrossRef]

- Yue, J. Multiphase flow processing in microreactors combined with heterogeneous catalysis for efficient and sustainable chemical synthesis. Catal. Today 2018, 308, 3–19. [Google Scholar] [CrossRef]

- Tanimu, A.; Jaenicke, S.; Alhooshani, K. Heterogeneous catalysis in continuous flow microreactors: A review of methods and applications. Chem. Eng. J. 2017, 327, 792–821. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, Y.; Du, L.; Liu, J.; Yao, J. Review of the applications of microreactors. Renew. Sustain. Energy Rev. 2015, 47, 519–539. [Google Scholar] [CrossRef]

- Kolb, G. Review: Microstructured reactors for distributed and renewable production of fuels and electrical energy. Chem. Eng. Process. Process Intensif. 2013, 65, 1–44. [Google Scholar] [CrossRef]

- Pennemann, H.; Kolb, G. Review: Microstructured reactors as efficient tool for the operation of selective oxidation reactions. Catal. Today 2016, 278, 3–21. [Google Scholar] [CrossRef]

- Rossetti, I.; Compagnoni, M. Chemical reaction engineering, process design and scale-up issues at the frontier of synthesis: Flow chemistry. Chem. Eng. J. 2016, 296, 56–70. [Google Scholar] [CrossRef]

- Zhao, J.; Yao, J.; Zhang, M.; Zhang, L.; Yang, Y.; Sun, H.; An, S.; Li, A. Study of Gas Flow Characteristics in Tight Porous Media with a Microscale Lattice Boltzmann Model. Sci. Rep. 2016, 6, 32393. [Google Scholar] [CrossRef] [PubMed]

- Harley, J.C.; Huang, Y.; Bau, H.H.; Zemel, J.N. Gas flow in micro-channels. J. Fluid Mech. 2006, 284, 257–274. [Google Scholar] [CrossRef]

- Ho, C.-M.; Tai, Y.-C. Micro-electro-mechanical-systems (MEMS) and fluid flows. Annu. Rev. Fluid Mech. 1998, 30, 579–612. [Google Scholar] [CrossRef]

- Hetsroni, G.; Mosyak, A.; Pogrebnyak, E.; Yarin, L.P. Fluid flow in micro-channels. Int. J. Heat Mass Transf. 2005, 48, 1982–1998. [Google Scholar] [CrossRef]

- Goldstein, R. Fluid Mechanics Measurements, 2nd ed.; Taylor & Francis: Abingdon, UK, 2017. [Google Scholar]

- Web of Science. Gas Sensors; Clarivate Analytics: Philadelphia, PA, USA, 2019. [Google Scholar]

- Yunusa, Z.; Hamidon, M.N.; Kaiser, A.; Awang, Z. Gas Sensors: A Review. Sens. Transducers 2014, 168, 61–75. [Google Scholar]

- Llobet, E. Gas sensors using carbon nanomaterials: A review. Sens. Actuators B Chem. 2013, 179, 32–45. [Google Scholar] [CrossRef]

- Varghese, S.S.; Lonkar, S.; Singh, K.K.; Swaminathan, S.; Abdala, A. Recent advances in graphene based gas sensors. Sens. Actuators B Chem. 2015, 218, 160–183. [Google Scholar] [CrossRef]

- Meng, F.-L.; Guo, Z.; Huang, X.-J. Graphene-based hybrids for chemiresistive gas sensors. TRAC Trends Anal. Chem. 2015, 68, 37–47. [Google Scholar] [CrossRef]

- Pandey, S. Highly sensitive and selective chemiresistor gas/vapor sensors based on polyaniline nanocomposite: A comprehensive review. J. Sci. Adv. Mater. Devices 2016, 1, 431–453. [Google Scholar] [CrossRef]

- Kuberský, P.; Syrový, T.; Hamáček, A.; Nešpůrek, S.; Stejskal, J. Printed Flexible Gas Sensors based on Organic Materials. Procedia Eng. 2015, 120, 614–617. [Google Scholar] [CrossRef][Green Version]

- Elhaes, H.; Fakhry, A.; Ibrahim, M. Carbon nano materials as gas sensors. Mater. Today Proc. 2016, 3, 2483–2492. [Google Scholar] [CrossRef]

- Basu, S.; Bhattacharyya, P. Recent developments on graphene and graphene oxide based solid state gas sensors. Sens. Actuators B Chem. 2012, 173, 1–21. [Google Scholar] [CrossRef]

- Toda, K.; Furue, R.; Hayami, S. Recent progress in applications of graphene oxide for gas sensing: A review. Anal. Chim. Acta 2015, 878, 43–53. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Fu, C.; Gao, Z.; Wei, F.; Ying, Y.; Xu, C.; Fu, G. Nanomaterial-based gas sensors: A review. Instrum. Sci. Technol. 2018, 46, 115–145. [Google Scholar] [CrossRef]

- Bogue, R. Nanomaterials for gas sensing: A review of recent research. Sens. Rev. 2014, 34, 1–8. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Neri, G.; Pinna, N. Nanostructured Materials for Room-Temperature Gas Sensors. Adv. Mater. 2016, 28, 795–831. [Google Scholar] [CrossRef] [PubMed]

- Joshi, N.; Hayasaka, T.; Liu, Y.; Liu, H.; Oliveira, O.; Lin, L. A review on chemiresistive room temperature gas sensors based on metal oxide nanostructures, graphene and 2D transition metal dichalcogenides. Microchim. Acta 2018, 185, 213. [Google Scholar] [CrossRef]

- Liu, X.; Ma, T.; Pinna, N.; Zhang, J. Two-Dimensional Nanostructured Materials for Gas Sensing. Adv. Funct. Mater. 2017, 27, 1702168. [Google Scholar] [CrossRef]

- Mabeck, J.T.; Malliaras, G.G. Chemical and biological sensors based on organic thin-film transistors. Anal. Bioanal. Chem. 2006, 384, 343–353. [Google Scholar] [CrossRef] [PubMed]

- Liedberg, B.; Nylander, C.; Lunström, I. Surface plasmon resonance for gas detection and biosensing. Sens. Actuators 1983, 4, 299–304. [Google Scholar] [CrossRef]

- Diamond, D.; Coyle, S.; Scarmagnani, S.; Hayes, J. Wireless Sensor Networks and Chemo-/Biosensing. Chem. Rev. 2008, 108, 652–679. [Google Scholar] [CrossRef]

- Han, Z.J.; Mehdipour, H.; Li, X.; Shen, J.; Randeniya, L.; Yang, H.Y.; Ostrikov, K. SWCNT Networks on Nanoporous Silica Catalyst Support: Morphological and Connectivity Control for Nanoelectronic, Gas-Sensing, and Biosensing Devices. ACS Nano 2012, 6, 5809–5819. [Google Scholar] [CrossRef]

- Emiliyanov, G.; Høiby, P.E.; Pedersen, L.H.; Bang, O. Selective Serial Multi-Antibody Biosensing with TOPAS Microstructured Polymer Optical Fibers. Sensors 2013, 13, 3242. [Google Scholar] [CrossRef] [PubMed]

- Papkovsky, D.B. New oxygen sensors and their application to biosensing. Sens. Actuators B Chem. 1995, 29, 213–218. [Google Scholar] [CrossRef]

- Temiz, Y.; Lovchik, R.D.; Kaigala, G.V.; Delamarche, E. Lab-on-a-chip devices: How to close and plug the lab? Microelectron. Eng. 2015, 132, 156–175. [Google Scholar] [CrossRef]

- Walsh, D.I.; Kong, D.S.; Murthy, S.K.; Carr, P.A. Enabling Microfluidics: From Clean Rooms to Makerspaces. Trends Biotechnol. 2017, 35, 383–392. [Google Scholar] [CrossRef]

- Chiu, D.T.; deMello, A.J.; Di Carlo, D.; Doyle, P.S.; Hansen, C.; Maceiczyk, R.M.; Wootton, R.C.R. Small but Perfectly Formed? Successes, Challenges, and Opportunities for Microfluidics in the Chemical and Biological Sciences. Chem 2017, 2, 201–223. [Google Scholar] [CrossRef]

- Childs, P.R.N.; Greenwood, J.R.; Long, C.A. Review of temperature measurement. Rev. Sci. Instrum. 2000, 71, 2959–2978. [Google Scholar] [CrossRef]

- Bacci da Silva, M.; Wallbank, J. Cutting temperature: Prediction and measurement methods—A review. J. Mater. Process. Technol. 1999, 88, 195–202. [Google Scholar] [CrossRef]

- Azad, A.M.; Akbar, S.A.; Mhaisalkar, S.G.; Birkefeld, L.D.; Goto, K.S. Solid-State Gas Sensors: A Review. J. Electrochem. Soc. 1992, 139, 3690–3704. [Google Scholar] [CrossRef]

- Hodgkinson, J.; Tatam, R.P. Optical gas sensing: A review. Meas. Sci. Technol. 2012, 24, 012004. [Google Scholar] [CrossRef]

- Warneke, B.A.; Pister, K.S.J. MEMS for distributed wireless sensor networks. In Proceedings of the 9th International Conference on Electronics, Circuits and Systems, Dubrovnik, Croatia, 15–18 September 2002; Volume 291, pp. 291–294. [Google Scholar]

- Lakafosis, V.; Rida, A.; Vyas, R.; Yang, L.; Nikolaou, S.; Tentzeris, M.M. Progress Towards the First Wireless Sensor Networks Consisting of Inkjet-Printed, Paper-Based RFID-Enabled Sensor Tags. Proc. IEEE 2010, 98, 1601–1609. [Google Scholar] [CrossRef]

- Yao, W.; Chu, C.-H.; Li, Z. The Adoption and Implementation of RFID Technologies in Healthcare: A Literature Review. J. Med Syst. 2012, 36, 3507–3525. [Google Scholar] [CrossRef] [PubMed]

- Abad, E.; Zampolli, S.; Marco, S.; Scorzoni, A.; Mazzolai, B.; Juarros, A.; Gómez, D.; Elmi, I.; Cardinali, G.C.; Gómez, J.M.; et al. Flexible tag microlab development: Gas sensors integration in RFID flexible tags for food logistic. Sens. Actuators B Chem. 2007, 127, 2–7. [Google Scholar] [CrossRef]

- Kassal, P.; Steinberg, M.D.; Steinberg, I.M. Wireless chemical sensors and biosensors: A review. Sens. Actuators B Chem. 2018, 266, 228–245. [Google Scholar] [CrossRef]

- Strömmer, E.; Hillukkala, M.; Ylisaukko-oja, A. Ultra-low Power Sensors with Near Field Communication for Mobile Applications. In Proceedings of the WSAN 2007: Wireless Sensor and Actor Networks, Albacete, Spain, 24–26 September 2007. [Google Scholar]

- Kuswandi, B.; Nuriman; Huskens, J.; Verboom, W. Optical sensing systems for microfluidic devices: A review. Anal. Chim. Acta 2007, 601, 141–155. [Google Scholar] [CrossRef]

- Choi, J.-R.; Song, H.; Sung, J.H.; Kim, D.; Kim, K. Microfluidic assay-based optical measurement techniques for cell analysis: A review of recent progress. Biosens. Bioelectron. 2016, 77, 227–236. [Google Scholar] [CrossRef]

- Lin, S.-W.; Chang, C.-H.; Lin, C.-H. High-throughput Fluorescence Detections in Microfluidic Systems. Genom. Med. Biomark. Health Sci. 2011, 3, 27–38. [Google Scholar] [CrossRef]

- Yang, F.; Li, X.-C.; Zhang, W.; Pan, J.-B.; Chen, Z.-G. A facile light-emitting-diode induced fluorescence detector coupled to an integrated microfluidic device for microchip electrophoresis. Talanta 2011, 84, 1099–1106. [Google Scholar] [CrossRef] [PubMed]

- Geng, X.; Wu, D.; Wu, Q.; Guan, Y. Signal-to-noise ratio enhancement of the compact light-emitting diode-induced fluorescence detector. Talanta 2012, 100, 27–31. [Google Scholar] [CrossRef]

- Xu, B.; Yang, M.; Wang, H.; Zhang, H.; Jin, Q.; Zhao, J.; Wang, H. Line laser beam based laser-induced fluorescence detection system for microfluidic chip electrophoresis analysis. Sens. Actuators A Phys. 2009, 152, 168–175. [Google Scholar] [CrossRef]

- Wolfbeis, O.S. Fiber-Optic Chemical Sensors and Biosensors. Anal. Chem. 2008, 80, 4269–4283. [Google Scholar] [CrossRef]

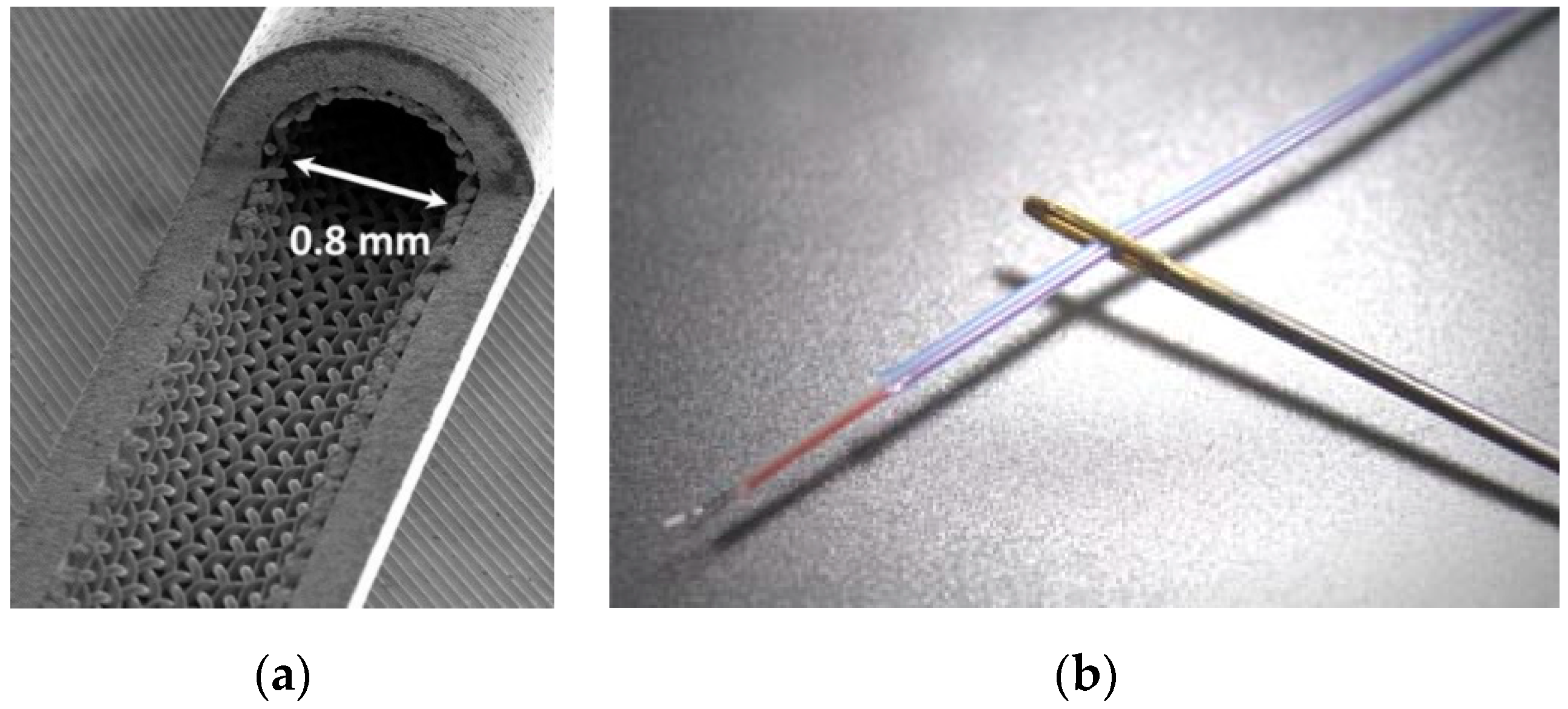

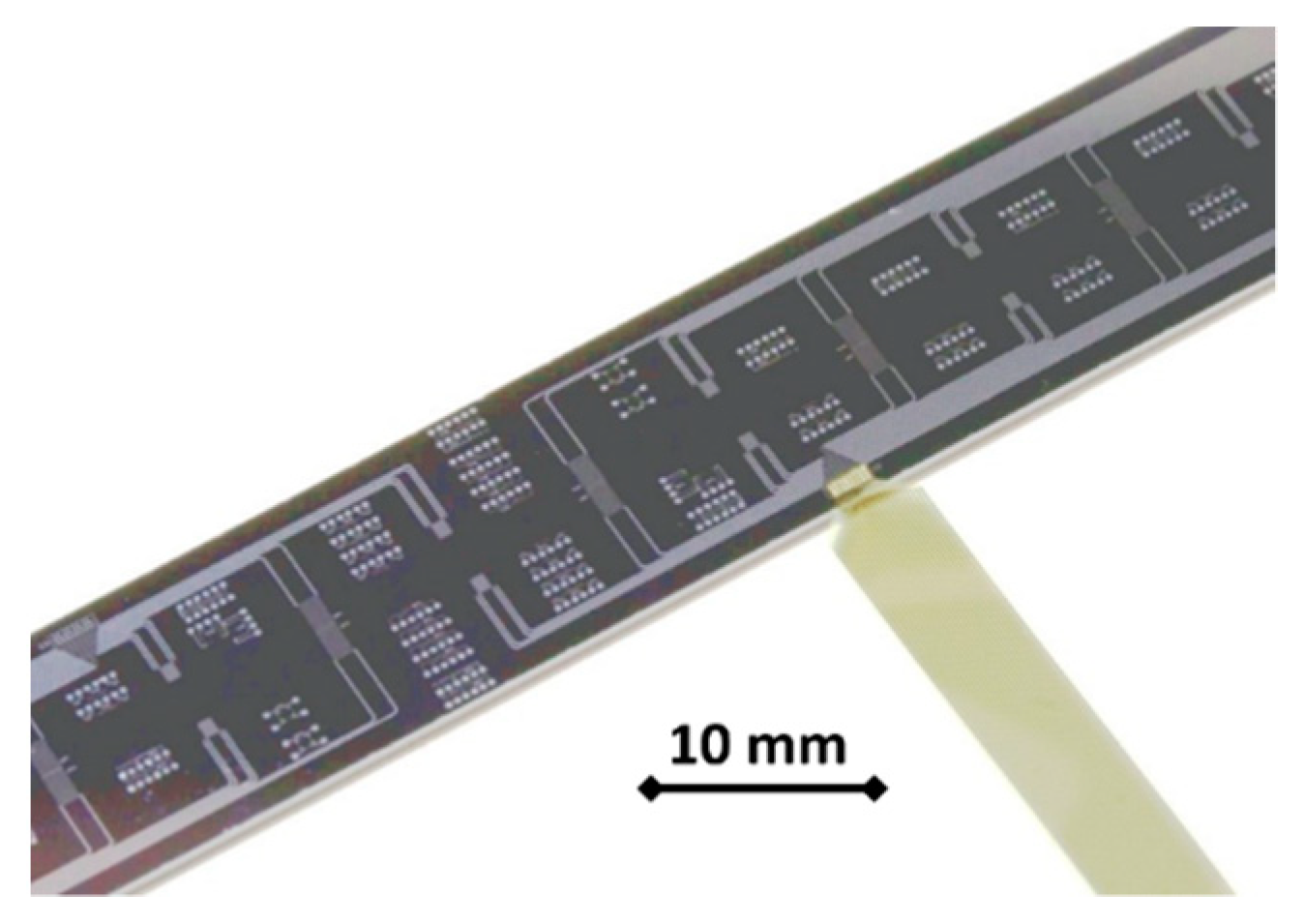

- Vittoriosi, A.; Brandner, J.J.; Dittmeyer, R. Integrated temperature microsensors for the characterization of gas heat transfer. J. Phys. Conf. Ser. 2012, 362, 012021. [Google Scholar] [CrossRef]

- Vittoriosi, A.; Brandner, J.J.; Dittmeyer, R. A sensor-equipped microchannel system for the thermal characterization of rarefied gas flows. Exp. Therm. Fluid Sci. 2012, 41, 112–120. [Google Scholar] [CrossRef]

- Kim, M.M.; Giry, A.; Mastiani, M.; Rodrigues, G.O.; Reis, A.; Mandin, P. Microscale thermometry: A review. Microelectron. Eng. 2015, 148, 129–142. [Google Scholar] [CrossRef]

- Yang, Y.; Morini, G.L.; Brandner, J.J. Experimental analysis of the influence of wall axial conduction on gas-to-gas micro heat exchanger effectiveness. Int. J. Heat Mass Transf. 2014, 69, 17–25. [Google Scholar] [CrossRef]

- Genix, M.; Vairac, P.; Cretin, B. Local temperature surface measurement with intrinsic thermocouple. Int. J. Therm. Sci. 2009, 48, 1679–1682. [Google Scholar] [CrossRef]

- Makinwa, K.A.A. Smart temperature sensors in standard CMOS. Procedia Eng. 2010, 5, 930–939. [Google Scholar] [CrossRef]

- Abram, C.; Fond, B.; Beyrau, F. Temperature measurement techniques for gas and liquid flows using thermographic phosphor tracer particles. Prog. Energy Combust. Sci. 2018, 64, 93–156. [Google Scholar] [CrossRef]

- Haslam, R.T.; Chappell, E.L. The Measurement of the Temperature of a Flowing Gas. Ind. Eng. Chem. 1925, 17, 402–408. [Google Scholar] [CrossRef]

- Hocker, G.B. Fiber-optic sensing of pressure and temperature. Appl. Opt. 1979, 18, 1445–1448. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, V.; Vengsarkar, A.M. Optical fiber long-period grating sensors. Opt. Lett. 1996, 21, 692–694. [Google Scholar] [CrossRef] [PubMed]

- Morey, W.W.; Meltz, G.; Glenn, W.H. Fiber Optic Bragg Grating Sensors. In Proceedings of the Fiber Optic and Laser Sensors VII, Boston, MA, USA, 5–7 September 1989; Voume 1169. [Google Scholar]

- Hayes, A. Available online: https://www.flowcontrolnetwork.com/rtds-vs-thermocouples/ (accessed on 1 April 2019).

- Kibble, B.P. Wheatstone Bridge; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Park, R.; Caroll, R.; Burns, G.B.; Desmaris, R.; Hall, F.; Herzkovitz, M.; MacKenzie, D.; McGuire, E.; Reed, R.; Sparks, L.; et al. Manual on the Use of Thermocouples in Temperature Measurement, 4th ed.; ASTM International: West Conshohocken, PA, USA, 1993. [Google Scholar] [CrossRef]

- Carullo, A.; Corbellini, S.; Parvis, M.; Vallan, A. A Wireless Sensor Network for Cold-Chain Monitoring. IEEE Trans. Instrum. Meas. 2009, 58, 1405–1411. [Google Scholar] [CrossRef]

- Yang, J. A Silicon Carbide Wireless Temperature Sensing System for High Temperature Applications. Sensors 2013, 13, 1884. [Google Scholar] [CrossRef] [PubMed]

- Popovic, Z.; Momenroodaki, P.; Scheeler, R. Toward wearable wireless thermometers for internal body temperature measurements. IEEE Commun. Mag. 2014, 52, 118–125. [Google Scholar] [CrossRef]

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring—A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Heyes, A.L.; Seefeldt, S.; Feist, J.P. Two-colour phosphor thermometry for surface temperature measurement. Opt. Laser Technol. 2006, 38, 257–265. [Google Scholar] [CrossRef]

- Chen, T.-F.; Nguyen, K.T.; Wen, S.-S.L.; Jen, C.-K. Temperature measurement of polymer extrusion by ultrasonic techniques. Meas. Sci. Technol. 1999, 10, 139–145. [Google Scholar] [CrossRef]

- Goss, L.P.; Smith, A.A.; Post, M.E. Surface Thermometry by Laser-Induced Fluorescence. Rev. Sci. Instrum. 1989, 60, 3702. [Google Scholar] [CrossRef]

- Moya, F.; Druet, S.A.J.; Taran, J.P.E. Gas spectroscopy and temperature measurement by coherent Raman anti-stokes scattering. Opt. Commun. 1975, 13, 169–174. [Google Scholar] [CrossRef]

- Bertsch, W. Two-Dimensional Gas Chromatography. Concepts, Instrumentation, and Applications—Part 1: Fundamentals, Conventional Two-Dimensional Gas Chromatography, Selected Applications. J. High Resolut. Chromatogr. 1999, 22, 647–665. [Google Scholar] [CrossRef]

- Bertsch, W. Two-Dimensional Gas Chromatography. Concepts, Instrumentation, and Applications—Part 2: Comprehensive Two-Dimensional Gas Chromatography. J. High Resolut. Chromatogr. 2000, 23, 167–181. [Google Scholar] [CrossRef]

- Suslick, K.S. Kirk-Othmer Encyclopedia of Chemical Technology; J. Wiley & Sons: New York, NY, USA. [CrossRef]

- Hirt, R.C.; Vandenbelt, J.M. Ultraviolet Spectrometry. Anal. Chem. 1964, 36, 308–312. [Google Scholar] [CrossRef]

- Schrötter, H.W. Update of reviews on Raman spectra of gases I. Linear Raman spectroscopy. J. Mol. Struct. 2003, 661–662, 465–468. [Google Scholar]

- Armentrout, P.B. Mass Spectrometric Methods for the Determination of Thermodynamic Data. In The Encyclopedia of Mass Spectrometry; Gross, M.L., Caprioli, R.M., Eds.; Elsevier: Boston, MD, USA, 2016; pp. 231–239. [Google Scholar] [CrossRef]

- Grayson, M.A. A History of Gas Chromatography Mass Spectrometry (GC/MS). In The Encyclopedia of Mass Spectrometry; Gross, M.L., Caprioli, R.M., Eds.; Elsevier: Boston, MD, USA, 2016; pp. 152–158. [Google Scholar] [CrossRef]

- Danieli, E.; Perlo, J.; Duchateau, A.L.L.; Verzijl, G.K.M.; Litvinov, V.M.; Blümich, B.; Casanova, F. On-Line Monitoring of Chemical Reactions by using Bench-Top Nuclear Magnetic Resonance Spectroscopy. ChemPhysChem 2014, 15, 3060–3066. [Google Scholar] [CrossRef]

- Guhl, S. Available online: https://opus4.kobv.de/opus4-bam/frontdoor/index/index/docId/39424 (accessed on 1 April 2019).

- Killner, M.H.M.; Garro Linck, Y.; Danieli, E.; Rohwedder, J.J.R.; Blümich, B. Compact NMR spectroscopy for real-time monitoring of a biodiesel production. Fuel 2015, 139, 240–247. [Google Scholar] [CrossRef]

- Kreyenschulte, D.; Paciok, E.; Regestein, L.; Blümich, B.; Büchs, J. Online monitoring of fermentation processes via non-invasive low-field NMR. Biotechnol. Bioeng. 2015, 112, 1810–1821. [Google Scholar] [CrossRef] [PubMed]

- Sanders, J.K.M.; Hunter, B.K. Modern NMR Spectroscopy: A Guide for Chemists; Oxford University Press: Oxford, UK, 1988. [Google Scholar]

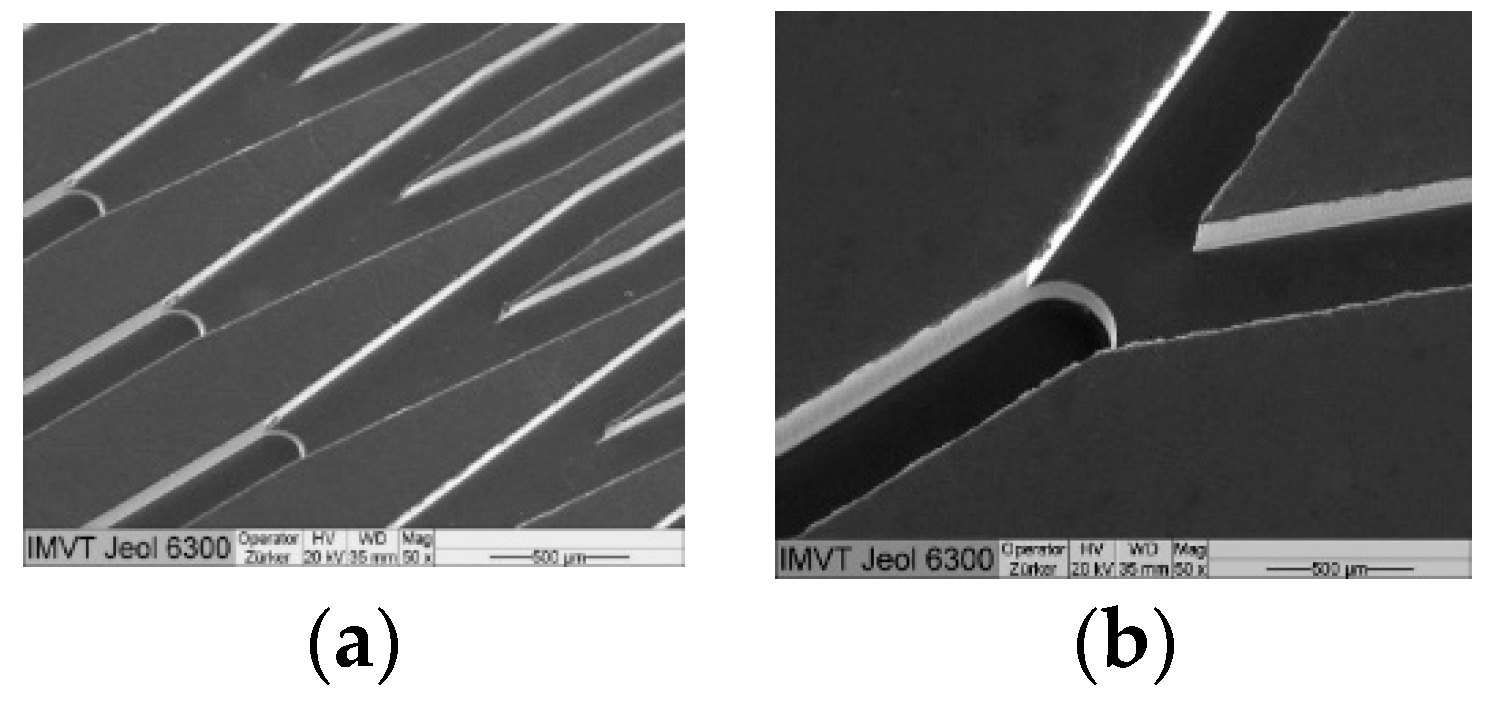

- Brandner, J.J.; Maikowske, S.; Vittoriosi, A. A New Microstructure Device for Efficient Evaporation of Liquids. J. Therm. Sci. Technol. 2012, 7, 414–424. [Google Scholar] [CrossRef][Green Version]

- Henning, T.; Brandner, J.J.; Schubert, K. High-speed imaging of flow in microchannel array water evaporators. Microfluid. Nanofluidics 2005, 1, 128–136. [Google Scholar] [CrossRef]

- Henning, T.; Brandner, J.J.; Schubert, K.; Lorenzini, M.; Morini, G.L. Low-Frequency Instabilities in the Operation of Metallic Multi-Microchannel Evaporators. Heat Transf. Eng. 2007, 28, 834–841. [Google Scholar] [CrossRef]

- Brandner, J.J.; Emig, G.; Liauw, M.A.; Schubert, K. Fast temperature cycling in microstructure devices. Chem. Eng. J. 2004, 101, 217–224. [Google Scholar] [CrossRef]

- Luther, M.; Brandner, J.J.; Kiwi-Minsker, L.; Renken, A.; Schubert, K. Forced periodic temperature cycling of chemical reactions in microstructure devices. Chem. Eng. Sci. 2008, 63, 4955–4961. [Google Scholar] [CrossRef]

- Luther, M.; Brandner, J.J.; Schubert, K.; Renken, A.; Kiwi-Minsker, L. Novel design of a microstructured reactor allowing fast temperature oscillations. Chem. Eng. J. 2007, 135, S254–S258. [Google Scholar] [CrossRef][Green Version]

- Hellén, H.; Schallhart, S.; Praplan, A.P.; Petäjä, T.; Hakola, H. Using in situ GC-MS for analysis of C2–C7 volatile organic acids in ambient air of a boreal forest site. Atmos. Meas. Tech. 2017, 10, 281–289. [Google Scholar] [CrossRef]

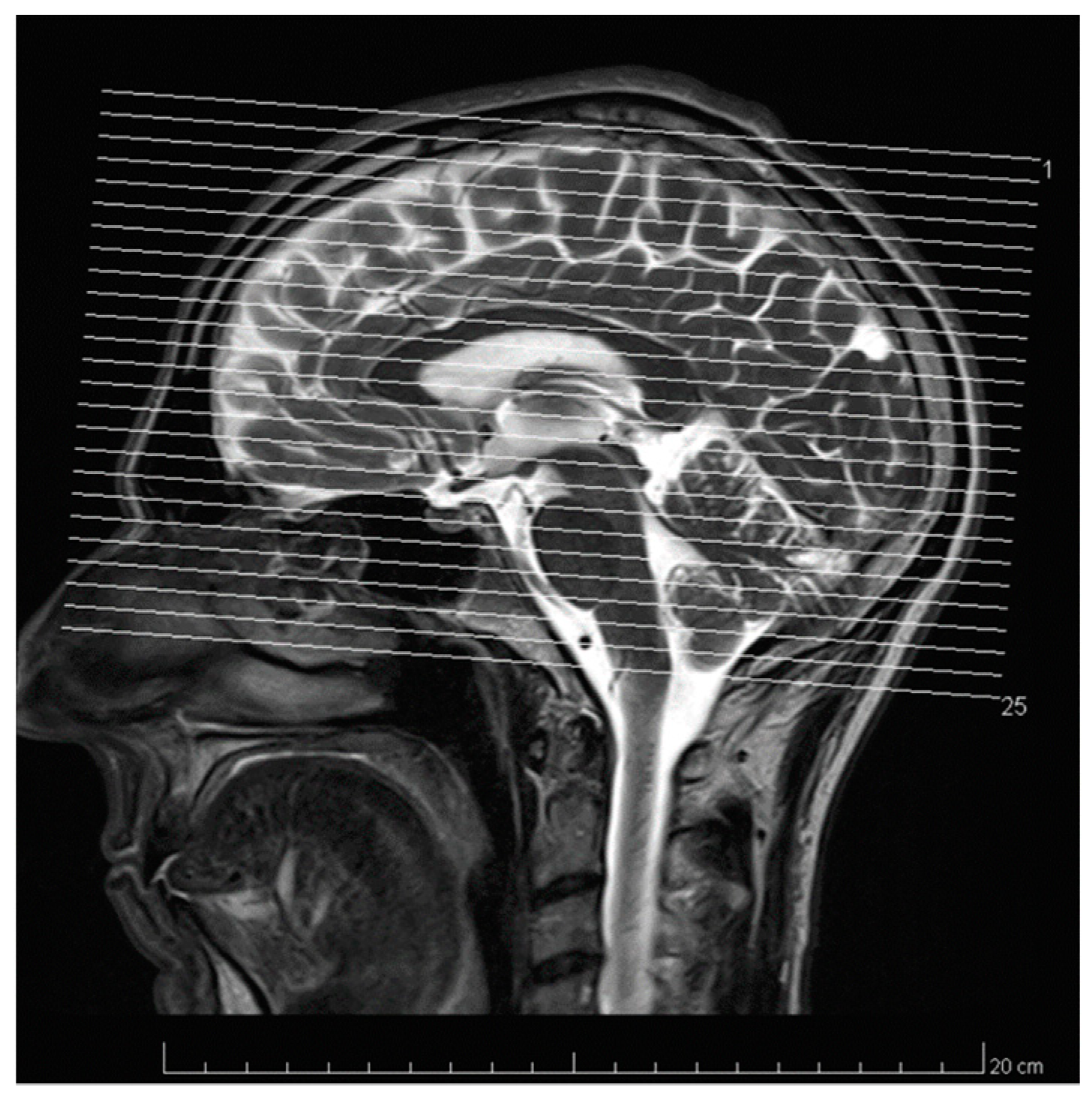

- Köckenberger, W.; Panfilis, C.D.; Santoro, D.; Dahiya, P.; Rawsthorne, S. High resolution NMR microscopy of plants and fungi. J. Microsc. 2004, 214, 182–189. [Google Scholar] [CrossRef] [PubMed]

- Uecker, M.; Zhang, S.; Voit, D.; Karaus, A.; Merboldt, K.D.; Frahm, J. Real-time MRI at a resolution of 20 ms. NMR Biomed. 2010, 23, 986–994. [Google Scholar] [CrossRef] [PubMed]

- Parker, D.L.; Smith, V.; Sheldon, P.; Crooks, L.E.; Fussell, L. Temperature distribution measurements in two-dimensional NMR imaging. Med. Phys. 1983, 10, 321–325. [Google Scholar] [CrossRef]

- Kleinberg, R.L. Utility of NMR T2 distributions, connection with capillary pressure, clay effect, and determination of the surface relaxivity parameter ρ2. Magn. Reson. Imaging 1996, 14, 761–767. [Google Scholar] [CrossRef]

- Thorn, R.; Johansen, G.A.; Hammer, E.A. Recent developments in three-phase flow measurement. Meas. Sci. Technol. 1997, 8, 691–701. [Google Scholar] [CrossRef]

- Weber, H.W.; Kimmich, R. Anomalous segment diffusion in polymers and NMR relaxation spectroscopy. Macromolecules 1993, 26, 2597–2606. [Google Scholar] [CrossRef]

- Akoka, S.; Barantin, L.; Trierweiler, M. Concentration Measurement by Proton NMR Using the ERETIC Method. Anal. Chem. 1999, 71, 2554–2557. [Google Scholar] [CrossRef]

- Korvink, J.G.; Badilita, V.; Bordonali, L.; Jouda, M.; Mager, D.; MacKinnon, N. Nuclear magnetic resonance microscopy for in vivo metabolomics, digitally twinned by computational systems biology, needs a sensitivity boost. Sens. Mater. 2018, 30, 157–166. [Google Scholar] [CrossRef]

- MacKinnon, N.; While, P.T.; Korvink, J.G. Novel selective TOCSY method enables NMR spectral elucidation of metabolomic mixtures. J. Magn. Reson. 2016, 272, 147–157. [Google Scholar] [CrossRef] [PubMed]

- Badilita, V.; Kratt, K.; Baxan, N.; Anders, J.; Elverfeldt, D.; Boero, G.; Hennig, J.; Korvink, J.G.; Wallrabe, U. 3D solenoidal microcoil arrays with CMOS integrated amplifiers for parallel MR imaging and spectroscopy. In Proceedings of the 2011 IEEE 24th International Conference on Micro Electro Mechanical Systems, Cancun, Mexico, 23–27 January 2011; pp. 809–812. [Google Scholar]

- Badilita, V.; Fassbender, B.; Kratt, K.; Wong, A.; Bonhomme, C.; Sakellariou, D.; Korvink, J.G.; Wallrabe, U. Microfabricated Inserts for Magic Angle Coil Spinning (MACS) Wireless NMR Spectroscopy. PLoS ONE 2012, 7, e42848. [Google Scholar] [CrossRef] [PubMed]

- Spengler, N.; Höfflin, J.; Moazenzadeh, A.; Mager, D.; MacKinnon, N.; Badilita, V.; Wallrabe, U.; Korvink, J.G. Heteronuclear Micro-Helmholtz Coil Facilitates µm-Range Spatial and Sub-Hz Spectral Resolution NMR of nL-Volume Samples on Customisable Microfluidic Chips. PLoS ONE 2016, 11, e0146384. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brandner, J.J. In-Situ Measurements in Microscale Gas Flows—Conventional Sensors or Something Else? Micromachines 2019, 10, 292. https://doi.org/10.3390/mi10050292

Brandner JJ. In-Situ Measurements in Microscale Gas Flows—Conventional Sensors or Something Else? Micromachines. 2019; 10(5):292. https://doi.org/10.3390/mi10050292

Chicago/Turabian StyleBrandner, Juergen J. 2019. "In-Situ Measurements in Microscale Gas Flows—Conventional Sensors or Something Else?" Micromachines 10, no. 5: 292. https://doi.org/10.3390/mi10050292

APA StyleBrandner, J. J. (2019). In-Situ Measurements in Microscale Gas Flows—Conventional Sensors or Something Else? Micromachines, 10(5), 292. https://doi.org/10.3390/mi10050292