Abstract

Enhancing the sustainability of activities is an undebatable need for decision makers regarding the economy as well as society. Fuel cells and their application in different areas, such as energy supply or mobility, are viewed as a promising means towards more sustainability. However, fuel cells as well as fuel-cell-based application systems cause a couple of possibly conflictive impacts in terms of ecological, economic, and social targets—their positive contribution to sustainability is not confident. Consequently, a significant assessment of sustainability is needed to enable a targeted development of fuel cells and their application systems, including the selection of alternative design variants. Furthermore, such assessment is necessary to provide evidence for the intended improvements and thereby contribute to market success and implementation of the systems. However, an overview of the existing methods for sustainability-related assessment of fuel cells and fuel-cell-based systems as well as the outcomes of the assessments does not exist. Therefore, a systematic literature review is conducted without restriction of fuel cell types and evaluation methods. Such a comprehensive overview does not yet exist to the best of the authors’ knowledge. With regard to the suggested or applied methods, the results show, amongst others, that the economic assessment does not refer to the methodical state-of-art, the social dimension is neglected, and an overall assessment of sustainability, aggregating all three dimensions, is not conducted. Due to the variety of analyzed objects as well as applied methods, the outcomes of the studies provide not more than scattered knowledge about the relevance of components and the advantageousness of fuel cells, their variants, and their application systems regarding sustainability. To contribute to avoiding methodological deficiencies, a procedure model for an integrated assessment is presented.

1. Introduction

Striving for sustainability becomes more and more imperative for all institutions and individuals in the economy as well as society. However, the systematic development of companies and their products, processes, and resources towards sustainability still faces considerable challenges. Firstly, despite a significant increase in publications on the concept of sustainability in recent years, sustainability still remains an open concept with different interpretations [1]. Nevertheless, a couple of approaches describe sustainability referring to environmental, economic, and social “pillars”, “dimensions”, “components”, or “perspectives”, etc.—the so-called triple bottom line [2,3]. Secondly, several interrelationships between the pillars do exist. Amongst others, activities intended to improve one dimension of sustainability may cause negative effects on another dimension. The systematic handling of such conflicts, the well-informed development of solutions, as well as the proof of an enhancement necessitate a significant assessment of the sustainability of measures, products, processes, and resources. However, thirdly, no mature and widely accepted methods for conducting such an assessment do exist.

These challenges can also be observed for the systematic development and application of fuel cells and fuel-cell-based systems. Exemplarily referring to the mobility sector and compared with conventional combustion engines, fuel cell engines promise higher levels of efficiency, low pollutant and noise emissions, and a low-maintenance system structure [4,5,6]. Thereby, they show considerable potential for enhanced sustainability. However, the sustainability-related advantageousness of fuel-cell-based systems, system components, and system variants seems to be dependent on the use case and hardly proven until now. This raises the necessity of a systematic and significant assessment of fuel cell components, fuel cells, and their variants, as well as fuel-cell-based systems. An exhaustive review that focusses on the Life Cycle Sustainability Assessment (LCSA) for solid oxide fuel cells (SOFCs) already exists [7]. However, to the best of our knowledge, a comprehensive overview of the existing methods for sustainability-related assessment of fuel cells without a limitation to a specific application area or fuel cell type does not exist.

This motivates the paper: it is intended to provide an overview of the existing literature on the sustainability-related assessment of fuel cell components, fuel cells, and their variants, as well as fuel-cell-based systems. On the one hand, this concerns the methodology applied for the assessment and the objects analyzed. On the other hand, it addresses the sustainability-related outcomes of the studies: the insights generated with reference to the relevance and/or advantageousness of the studied objects.

The remainder of the paper is organized as follows. In the next section, an overview of fuel cells and their analysis as well sustainability and its assessment are presented (Section 2). Afterwards, the methodology regarding the literature review is described (Section 3). Subsequently, the results of the literature review are presented: the methods applied, the target figures regarded, and the objects analyzed in the studies (Section 4.1), as well as the outcomes of the studies regarding the sustainability of the objects under consideration (Section 4.2). This is followed by a discussion of limitations and gained insights (Section 5.1), the presentation of a procedure model for an integrated assessment (Section 5.2), as well as conclusions and outlook (Section 6).

2. Theoretical Backgrounds

2.1. Fuel Cells and Their Analysis

Fuel cells are complex systems that are used in even more complex applications that can be understood as systems as well. Depending on the specific applications (e.g., stationary, mobile, or portable), they have a wide range of functions. Overall, fuel cells are devices with the task to convert a fuel together with the associated combustion air into electrical energy and heat [8]. Pure hydrogen, almost all known hydrocarbons, and pure carbon can be used as fuels. Ambient air with the oxygen it contains is usually used as combustion air or an oxidizing agent [9]. In addition to electricity and heat, there is also a combustion product. In most cases, depending on the type of fuel cell, it is water or water vapor.

As noted, there are different types of fuel cells [8]. They differ essentially on the materials used, the electrolytes for the internal ion conduction, the combustion gases or liquid fuels used, and the operating temperatures. The most popular types of fuel cells are [10]

- PEMFC—Polymer Electrolyte Membrane Fuel Cell (High Temperature/Low Temperature)

- DMFC—Direct Methanol Fuel Cell (because of the proton exchange membrane, the DMFC can be regarded as a subcategory of the PEMFC. However, since it uses methanol as fuel, unlike the PEMFC, it is listed here and in relevant literature as a separate type.)

- PAFC—Phosphoric Acid Fuel Cell

- AFC—Alkaline Fuel Cell

- MCFC—Molten Carbonate Fuel Cell

- SOFC—Solid Oxide Fuel Cell

Fuel cells consist of a couple of components. An individual cell (using the example of the PEMFC) has a proton-conducting polymer film, the membrane. The membrane works as an electrolyte between the anode and cathode catalyst. The catalysts contain precious metals so that the reaction can be started. In addition to the catalysts, electrically conductive gas diffusion layers are connected. The electrons flow through the gas diffusion layer to the bipolar plate or end plate. In summary, a PEMFC consists of a bipolar plate, a gas diffusion layer, the anode catalyst, the membrane, the cathode catalyst, again the gas diffusion layer, and the bipolar plate [10]. Furthermore, seals are required [9].

A fuel cell stack is usually required for a fuel cell system as well. The stack consists of individual cells that are combined in a modular format by electrically connecting the cells to form units with the desired output capacity. The total output capacity depends on the number and area of the individual cells. The other components are the endplates, seal gaskets, and the current collectors [11].

In addition to the stack, however, further mechanical and electrical components are required for the process of the electrochemical reaction. These components are usually summarized under the term balance of plant (BoP). The tasks of the BoP include the supply of the fuel and air and the assurance of constant stack temperatures among other things. Similar to the selection of the materials used, the structure of the balance of plant varies depending on the type of fuel cell. The BoP includes, e.g., a fluidic system for cooling, fuel and air supply, voltage converters for converting electrical energy to the desired voltage level, as well as an overall control, including safety technology [10].

There are several different fuel-cell-based systems in which fuel cells can be used. These range from portable applications (e.g., in power banks, mobile phones, or notebooks) via mobile applications (e.g., in e-bikes, cars, buses, trains, ships, or even airplanes) to stationary applications (e.g., for heating or power generation) [12,13].

Concluding, significant variety regarding different types of fuel cells, different components of fuel cells, as well as the systems in which they are embedded and used does exist. This implies that studies of fuel cells, fuel cell components, as well as systems applying fuel cells can differ considerably regarding the object that is analyzed. Therefore, it is necessary to clearly define this object or system under consideration and its system boundaries.

Accordingly, the object under consideration can differ from single materials that are used for the production or manufacture of the fuel cell components via components of fuel cells (e.g., a catalyst), a fuel cell stack, other fuel cells components, and the complete fuel cell system up to products that use fuel cells [11]. In this last case, the fuel cell system is an essential part of a product under consideration.

Additionally, system boundaries of fuel-cell-related studies can vary with respect to the life cycle concept that is considered. The most common approaches are “cradle to grave”, “cradle to gate”, “gate to grave”, and “gate to gate” [11]. When considering “cradle to grave”, all life cycle phases from the exploitation of the materials used to produce fuel cells or their components via the preparation, the production to the use phase, and finally the disposal are included. The corresponding types of studies encompass all the life cycle phases. The approach “cradle to gate” includes all the phases from the exploitation of the materials to the production of the fuel cell or its components. The use phase and the step of the disposal are not included. In “gate to grave” studies, the use phase as well as the disposal phase are analyzed. The approach “gate to gate” only focuses on the production phase of the fuel cell system or the single components.

2.2. Sustainability and Its Assessment

The term sustainability was first mentioned in 1713 by Hans Carl von Carlowitz in his work “Sylvicultura Oeconomica”. There, the author requests a “sustainable handling of the forest” in the region around Chemnitz since a great deal of wood was needed there due to mining [14]. The concept of sustainability received great global attention in 1987 within the framework of the World Commission on Environment and Development of the United Nations (later also known as the Brundlandt Report), where sustainable development was defined as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs” [15]. In 1992 (Rio de Janeiro) and 2002 (Johannesburg), the United Nations held world summits at which an “Implementation Plan for Sustainable Development” was elaborated and a commitment to sustainable development was made by the representatives of the peoples [16]. Nevertheless, there is still an ongoing discussion about the exact concept of sustainability and whether the definition mentioned above is clear enough. Furthermore, the idea of sustainable development as well as the defined Sustainable Development Goals are criticized. For an overview, see, for example, [17] or [18]. However, there is broad agreement that economic, ecological, and social goals are pursued within sustainable development [19,20,21]. These three components are also known as the three pillars or dimensions of sustainability and influence each other [22,23,24].

An evaluation of products or manufacturing processes that include one, two, or even all three dimensions of sustainability is a very challenging task. There are several different assessment methods, instruments, and approaches. A very detailed list of these instruments can be found in [24]. For the ecological dimension, the best-known method is probably the life cycle assessment (LCA) [25], and, for the economic dimension, life cycle costing (LCC) is often used [26,27]. One instrument for evaluating the social dimension is the Social Life Cycle Assessment (sLCA) [28]. An example of evaluating two dimensions is life cycle engineering (LCE), where both the economic and the ecological dimension are evaluated [29]. A concept for evaluating all three dimensions integratively is the LCSA, which became known through [30]. In order to show which of these methods for sustainability-related assessment—including the dimensions of the triple bottom line—are used and which dimensions are considered specifically for fuel cells and fuel cell systems, the following analysis was carried out.

3. Methodology of Literature Research

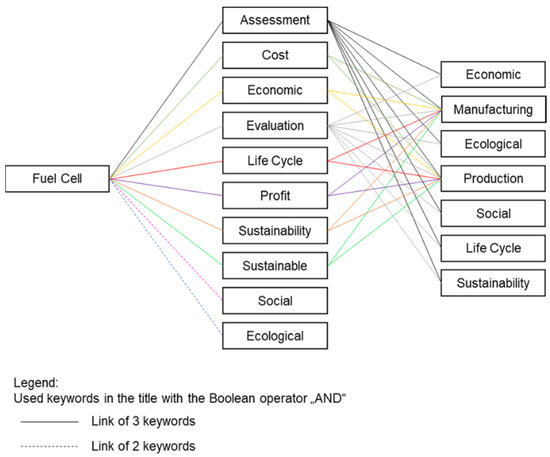

As the goal of the paper is a literature review of approaches to evaluate the economic, ecological, and/or social sustainability of fuel cells and the outcomes of their application, we decided to use the methodology of systematic literature research by using databases for the searching. Research was conducted in December 2022. In the following Figure 1, the keywords we searched are presented.

Figure 1.

Used keywords.

As can be seen in Figure 1, the keyword fuel cell was included in every search combination since our consideration object is the fuel cell. The search words must always be included in the title of the searched papers. In order to specify the search, further search terms were combined with the first keyword with the Boolean operator “AND”, which either have a reference to production, a connection to a general evaluation, or a sustainability link. A search with two keywords resulted in two exceptions (fuel cell AND social; fuel cell AND ecological) in each case in so many hits that in these cases a third search term was added, also with the Boolean operator “AND”. For example, the two keywords fuel cell and assessment were linked with many other keywords, e.g., fuel cell AND assessment AND economic. The way of collecting literature can be observed in Table 1. Altogether, we received 1169 results, including doublings within the databases, and 1030 results without doublings within the single databases. Afterwards, we excluded all database-comprehensive doublings with a remainder of 375 results. Then, we checked all titles to only include papers with reference to economic, ecological, and/or social evaluation of fuel cells. The abstracts of the remaining 178 papers were read, with the result of exclusion of 29 papers. From the resulting 149 papers, 86 were chosen for an in-depth reading—the ones with an H-index of more than 80 and/or a VHB (VHB is the abbreviation for “Verband der Hochschullehrer für Betriebswirtschaft”. One of the tasks of the association is to provide a rating for journals in terms of their academic quality in order to support transparency and orientation) ranking of A, B, or C.

Table 1.

Literature research.

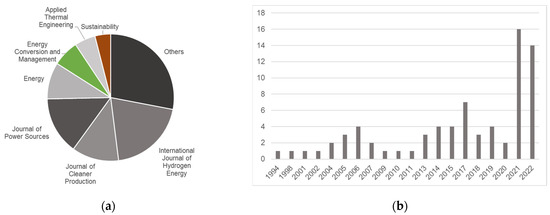

The remaining 75 papers were analyzed in more detail. An overview of the papers can be found in Appendix A. In terms of the journals they are published in, it is conspicuous that they cover a wide range of more technical, more economic, or more ecological focus (see Figure 2a). For example, 15 of the papers are published in the International Journal of Hydrogen Energy (more ecological focus), whereas there are also publications in journals with a more technical background (e.g., Journal of Power Sources). Furthermore, it is remarkable that there is a large increase in publications in 2021 and 2022. However, publications are available since 1994, with quite a balanced distribution of papers throughout the years until 2020 (see Figure 2b).

Figure 2.

(a) Journals with publications; (b) publications per year.

4. Results of the Literature Review—Approaches and Outcomes of Sustainability-Oriented Assessment of Fuel Cells

4.1. Methods, Target Figures, and Objects

We analyzed the papers regarding several aspects, especially their focus of evaluation (economic, ecological, and/or social) as well as the methods and target figures they used. In the following, we distinguish papers with economic, ecological, and social areas of focus. Additionally, we consider the papers focusing on an integrated analysis (e.g., by considering economic and ecological factors). For these different categories, we consider which target figures as well as methods are applied. Additionally, we analyze the objects considered in the studies. Thereby, we distinguish between the type of fuel cell (e.g., SOFC or PEMFC), the application field (e.g., automotive sector or stationary), and the system boundaries (e.g., the whole fuel cell system or parts of the fuel cell system).

- Economic focus

Twenty of the seventy-five papers concentrate on economic aspects. Often, production costs are in the center of these ones (e.g., [31,32,33,34,35,36,37]). Other target figures/indicators used are fuel cell system costs [38,39], costs of electricity or energy [40,41,42,43,44], total product unit costs [45], capital costs [46], costs for fuels [47], the net present value (NPV) [48,49], or ownership costs [50].

To calculate these target figures or indicators, different methods are applied. Nelson et al. determine the economic performance of the fuel cell in the form of calculating an NPV and a benefit-to-cost ratio [40]. The NPV method is used by Reyes-Valenzuela and Jia et al. as well [48,49]. A manufacturing cost model is used [31] as well as a bottom-up cost model in combination with the learning curve methodology [32]. The learning curve methodology is also applied by [34]. Two times, the design for manufacture and assembly (DFMA) methodology is presented [38,46]. Xue and Dong use an optimization-based design method for an economic evaluation of the costs of a fuel cell system [35]. For a variation in specific parameters, sensitivity analysis is applied as well. Chen and Melaina, for example, vary the energy prices to identify the impact on results (e.g., the impact on the manufacturing costs) to support their cost comparison [50]. Itoh et al. consider costs of different stack components without applying a specific method [33]. The levelized cost of energy (LCoE) [43,44] as well as the net present cost are calculated by Pal and Mukherjee [42]. Some authors apply specific equations and formulas for calculating the costs for hydrogen production [47] or for system and component costs [39,45]. For the determination of the total production costs, Ma et al. use equations as well [37]. Like Chen and Melaina, these four papers perform a sensitivity analysis as well to address uncertainties in their analyses. Sadeghi and Askari calculate unit costs of electricity as well as of fresh water [41]. One of the papers with an economic focus is presenting a literature review, and, thus, a specific evaluation method is not applied [51].

The objects considered in the different economic-focused papers vary as well. Some of them concentrate on the application field of automotive—e.g., regarding a transportation fuel cell system [35], an automotive fuel cell system [46], and vehicle technologies [48,50], whereas other papers focus on energy systems, like off-grid solar photovoltaic systems [42]. Additionally, the system boundaries are different—from the whole system to single components. Mock and Schmid analyze the whole fuel cell system [32], whereas Wannek et al. examine the fuel cell membranes [51]. Finally, different types of fuel cells are central to the papers. Some of them consider the SOFC [31,33,37,43,44,49], the PEMFC [34,39,45,47], the MCFC [41], and the PCFC [31].

Ten of the twenty papers are from 2021 and 2022, which shows that the economic consideration of fuel cells moves into focus. Regarding the target figures, costs of energy are often examined in these papers. Furthermore, the NPV is considered, which implies that increased attention is paid to the investigation of the economic long-term impacts of fuel cells. Additionally, it is noticeable that most of the papers of 2021 and 2022 refer to an SOFC.

- Ecological focust

Thirty-four of the seventy-five papers concentrate on ecological aspects. All of them except one study use LCA, which can be seen as an established standard for ecological assessment, e.g., [52,53,54]. Once, a parametric trend LCA is applied instead of the classical LCA [55]. Additionally, one time, a comparative analysis based on theoretical aspects of LCA is conducted [56]. As a support of the method, different software solutions were used—mainly SimaPro [54,57,58,59,60], GaBi [52,53,55,61,62,63,64], and openLCA [65]. Additionally, in most cases, the ecological data and impact indicators come from the EcoInvent database, which was integrated in the software, e.g., [57,60,66]. For the impact assessment (LCIA), parts of LCA, mainly CML [52,57,61,64,67] and ReCiPe [59,65,66,68,69,70,71], were applied. In single cases, EcoIndicator 99 [54], Carbon Footprint (CFP) [72], as well as the Cumulative Energy Demand (CED) method [60,66] were used. The target figures are partially predetermined by the methods chosen. Only three of the authors focus on endpoint impact categories, such as human health (HH), ecosystem quality (EQ), and resource availability (RA) [58,71,73], whereas most of the authors concentrate on midpoint impact categories and therefore impact category indicators—especially global warming potential (GWP), acidification potential (AP), eutrophication potential (EP), photochemical ozone creation potential (POCP), particulate matter formation potential (PMFP), ozone depletion potential (ODP), primary energy demand (PED), abiotic depletion potential (ADP), human toxicity potential (HTP), terrestrial acidification potential (TAP), freshwater ecotoxicity potential (FETP), and marine ecotoxicity potential (METP) [52,53,55,56,57,59,62,63,64,65,66,67,68,69,70,74,75,76,77,78,79,80,81,82]. Moreover, greenhouse gas emissions (GHG) and (primary) energy consumption/CED are a quite frequent combination of target figures [60,83,84,85].

The objects regarded by the papers with ecological evaluation in focus are in some cases vehicles [52,56,65,70,72,77,78,79,81,84,85] or auxiliary power units (APUs) [60,76]. Another differentiation regarding objects refers to the types of fuel cells: some papers refer to the SOFC [55,60,67,69,70,73,76,82], some to the MCFC [54,57,80,86], and some to the PEMFC [52,53,55,56,64,65,67,68,70,71,72,78,79,81,83,85]. As for the economic-oriented papers, the objects under consideration for the ecological-oriented papers differ as well regarding their scope. Some papers consider the whole system [57,68,69,74,75,87], and others refer to the fuel cell stack [53,57,82,83]. Only one paper concentrates on one part of the stack—the catalyst [61].

Sixteen of the thirty-four ecological-focused papers are from 2021 and 2022, which shows that the literature pays increasing attention to the ecological consideration of fuel cells as well. As in the papers of earlier years, the method that was applied is mostly still LCA. The more recent papers primarily use the ReCiPe method for the impact assessment. When looking at the objects of interest, nearly all kinds of fuel cells and their applications are considered in papers of 2021 and 2022, except for APUs.

- Social focus

It is worth noting that there are no articles focusing exclusively on the social dimension or on the social dimension in combination with either the economic or ecological dimension.

- Ecological and economic focus

Seventeen of the seventy-five papers concentrate on ecological and economic aspects. Here, it is difficult to name prioritized combinations of methods and target figures the authors used. It is noteworthy that, in contrast to studies that focus on the ecologic dimension exclusively, only nine of the seventeen papers consider the LCA method for the ecological evaluation in addition to different methods for the economic assessment. Referring to these nine studies, for the economic evaluation, the LCoE or levelized cost of methanol were used by three of the nine authors [88,89,90]. Two studies refer to the vehicle costs [91,92]. The last four studies compare capital costs [93], manufacturing costs, including the costs for energy [94], investment costs based on the NPV [73], and fuel costs [95]. The other eight papers use formulas [96], equations [97,98,99], ecological and economic indicators [100], and functions [101,102] for the economic and ecological evaluation as well as the carbon footprint and production cost [103].

The target figures of LCAs used by the authors are mostly midpoint impact category indicators, such as GWP, TAP, HTP, PMFP, metal depletion, GHG emissions, ADP, GWP, ODP, AP, EP, and total energy use [91,92,93,94,95,100]. However, there are three papers that refer not only to midpoint impact categories but also to the three endpoint categories HH, EQ, and RA [73,89,90]. Regarding the economic-oriented target figures, the heterogeneity is particularly noticeable because no two studies take the same ones into account. Instead, different target figures were used, like capital investment effectiveness [100], grid cost of electricity and natural gas, initial capital and maintenance cost [102], cost rate as well as cost per unit exergy [96], electricity cost produced by the system [97], operational cost [98], operational cost together with capital and maintenance costs [101], LCoE [88], capital costs [93], energy costs [95], system costs [94], LCoE in combination with costs of renewable energy spreadsheet tool [89], levelized cost of methanol [90], the payback period [73], cost comparison of vehicles [91], and finally system costs within an LCC [92].

The system boundaries of the objects under consideration differ for the economic–ecological-oriented papers as well. Again, some automotive-related papers do exist [90,91,92,95,100]; others refer to combined heat and power systems [98,102]. Additionally, different types of fuel cells are analyzed—SOFC [73,98,99,101], MCFC [93,96,103], PMFC [92,97], AFC [88], and PAFC [102]. Finally, all the papers concentrate on fuel cell systems, not considering only parts of them, like the membrane.

Three of the seventeen papers are from 2021 and 2022, which indicates that the economic–ecological consideration of fuel cells is viewed as constantly relevant over the years.

- Ecological, economic and social focus

Only four papers refer to all three sustainability dimensions [104,105,106,107]. Chen and Kim use indicators for evaluating all three dimensions—heat rate and efficiency percentage as indicators for energy efficiency calculation (ecological dimension), employment and payroll as indicators for the economic dimension, and a surcharge, a special tariff, as an indicator for the social dimension. The ecological indicators are determined by formulas. The economic indicators are identified by using statistics, reports, and news. The input for the social indicator was found in reports, newspapers, and information from public hearings [104]. Acar et al. use a fuzzy-set-based analytical hierarchy process (AHP) method with four primary and fifteen sub-criteria, including criteria for each sustainability dimension. The economic performance is calculated by initial and running costs, whereas the environmental performance is determined by environmental impact categories like GHG emissions and land use. Impacts on public health, employment opportunities, training opportunities, as well as public acceptance influence the social performance [106]. Garraín et al. focus on LCA for evaluating the ecological dimension. Additionally, they conduct a multi-regional input–output assessment for analyzing the economical as well as the social dimensions [107]. Lozanovski et al. use LCA, the total cost of ownership (TCO) methodology, and interviews to determine their ecological, economic, and social target figures. For the ecological analysis, CC in form of GWP is used as a target figure. Ownership costs are determined as economic target figures and influencing factors for the acceptance of the higher costs of technology are social target figures identified by interviews. Lozanovski et al. consider fuel-cell-driven buses based on hydrogen as a fuel [105]. Chen and Kim refer to energy provision while considering the SOFC [104]. Acar et al. compare the sustainability performance of different fuel cell types (PEMFC, AFC, PAFC, MCFC, and SOFC) in the residential and transportation application fields [106]. Finally, Garraín et al. focus on the sustainability assessment of a PEMFC, especially for its manufacturing and use phase [107]. It turns out that LCA is the most widely used method for ecological assessment suggested or applied in both purely ecological-oriented papers and ecological–economic or ecological–economic–social-oriented articles. For a condensed overview, all the studies dealing with LCA are tabulated in Appendix B. It is noteworthy that a holistic sustainability assessment of fuel cells is only carried out at all since 2018, and, therefore, it is quite a current research area.

4.2. Fuel-Cell-Related Outcomes of the Studies

Additionally, we analyzed the papers regarding their results concerning the advantageousness and relevance of the objects under consideration. There, we first considered the fuel cells themselves and the fuel cells within systems (e.g., PEMFC in a system). Afterwards, we analyzed the results of studies that compare different fuel cell types (e.g., the comparison of SOFC and PEMFC). Because of the wide range of possible system boundaries mentioned before, we also considered the results of papers that refer to fuels and tanks. In each section, the analysis was conducted for economic, ecological, economic–ecological, as well as economic–ecological–social-focused papers (if existing).

- PEMFC

Regarding the economic evaluation, the hydrogen tank was identified as the most expensive component followed by the stack [32,38,94]. Referring to the fuel cell stack, the highest cost factors are the catalyst layers [32,38,51]. Additionally, the system costs are, in general, dependent on the active area of the matrix [35] and can be varied by adapting different parameters of the fuel cell. For example, by raising the current density, the system cost can decrease [39]. The same applies to total unit product costs [45]. Furthermore, the region of a country where the fuel cell is used has an impact on the LCoE [42].

There are several studies analyzing the ecological impact of the components of PEMFCs. It is noticeable that, in addition to the stack, the production of the tank has a major ecological impact, e.g., to the GWP and AP [52,65,68,92,94]. Results can change if other types of tanks are included in the consideration [94]. The study of Benitez et al. additionally states that, besides the stack and the tank, the glider causes high environmental impacts as well [65]. The stack contributes particularly to the ecological impacts, like the GWP, the HTP, and the TAP, due to the catalyst and especially because of the platinum consumed [52,53,68,74,92]. Furthermore, the flow field or bipolar plates and the gas diffusion layer have a large ecological impact as well [52,53], while the membrane is not that relevant from an ecological point of view due to its low energy consumption [53,68]. Focusing on single materials used in PEMFCs, platinum causes the highest impacts in each environmental impact category. Other materials that have high impacts are Nafion, (polyetheretherketone) PEEK, (polytetrafluoroethylene) PTFE, and silicone [67]. Taking the platinum loading for a 1 kWe PEMFC system by an operation time of 20,000 h into account, a reduction from 0.75 g/kW to 0.125 g/kW can result in a reduction of 107 kg CO2 eq [64].

A sustainability assessment of a specific PEMFC, which includes the environmental, economic, and social dimensions, shows that the anodic plates are the main contributors to the environmental footprint. This is caused by the high-performance engineering plastics they are made of. The economic and social dimensions are represented by an index that determines the benefits in terms of value added as well as employment creation. It is stated that they are highly dependent on imported components. The manufacture of fuel cell components creates value added and employment in the country where they are produced [107].

- PEMFCs in a system

Regarding economic aspects, the investment costs of the fuel cell system are much higher than those of the internal combustion engine (ICE) [97]. Concerning the costs, the internal combustion engine vehicle (ICEV) is the cheapest vehicle, followed by battery electric vehicles (BEVs) and fuel cell vehicles (FCVs). These results can partly vary depending on the way the electricity is produced [92].

Within the economic evaluation, a comparison of the TCO of a hydrogen-driven bus and a diesel-driven bus shows that a diesel-driven bus is not as expensive as a hydrogen-driven bus [105].

Reyes-Valenzuela et al. show within their economic evaluation that the NPV can vary when the hydrogen price changes and also if a possible CO2 tax is introduced [48].

Looking at the ecological comparison of different types of vehicles, many studies exist. Most of the studies found out that FCVs powered by hydrogen (from electrolysis) induce fewer GWP emissions than ICEVs [52,53,78,84,85,92,95], whereby Pehnt adds that, for this case, a recycling infrastructure for the platinum group metals has to be established. Only Joshi et al. consider three different scenarios, and, in one of them, the current scenario, unlike the other studies, the FCEV causes the most GHG emissions, followed by the ICEV. This order may change in scenarios with future development of technologies [65]. The reason for the ranking in the current scenario is the inefficiency of the hydrogen fuel system. For (B)EVs, the results of the studies differ. Evangelisti et al. and Benitez et al. state that BEVs lead to the lowest GHG emissions of all the considered vehicle types [52,65], whereas the considered EVs in the studies of Yang et al. as well as Singh et al. contribute the highest amounts of GHG emissions [77,84]. The analysis of Kannangara et al. shows that the use of low-electricity-grid BEV and FCEV leads to nearly the same amount of GHG emissions [78]. In addition, the rankings of the vehicles change when other electricity mixes are considered and carbon capture and storage (CCS) is included or not [77,84,95]. A comparison of hydrogen vehicles with gasoline vehicles shows that, no matter which method is used to produce hydrogen, hydrogen vehicles lead to fewer GHG emissions than gasoline vehicles. The fewest emissions are emitted when hydrogen is manufactured by solar energy or nuclear energy [81]. Another comparison shows that the well-to-wheel energy efficiency of hydrogen fuel cell vehicles is the lowest of all vehicle and fuel types considered [56].

The life cycle phases are also considered regarding their ecological impacts. Regarding single vehicles, the use phase is the one that causes the most emissions for the ICEV. For the FCV, the most emissions are produced during the manufacturing phase [52,95]. Regarding the BEV, the contributions of the use and manufacturing phases are similar [52].

When comparing a bus driven by diesel, crude natural gas, or fuel cell, the bus driven by diesel leads to the lowest ecological impact of global warming potential. The fuel-cell- driven bus causes the second-lowest global warming emissions, whereas the bus powered by compressed natural gas (CNG) has the highest impacts in this category [62]. This ranking changes when different impact categories are considered or when a different method of hydrogen production is assumed. By using green hydrogen instead of grey hydrogen, the hydrogen-driven bus generates the lowest GWP emissions [105].

For the social evaluation of a hydrogen-driven bus and a diesel-driven bus, the acceptance of the technologies is considered. Currently, the hydrogen technology is still not well-understood by the users as well as the transport decision makers so that there is quite significant work to complete on informing and engaging [105].

- SOFC

In the impact categories considered within the ecological assessment of Al-Khori et al., it is stated that the manufacturing phase has lower impacts in the category indicators GWP and AP but produces higher emissions in the EP, ODP, and HTP categories than the operation phase [82]. Naeini et al. partly consider other impact categories, but they also come to the conclusion that the manufacturing phase leads to lower GWP emissions than the operation phase. The same applies to other indicators, such as TAP and water consumption potential (WCP) [69]. This is due to the fact that SOFCs use natural gas to generate power, which leads to low emissions within the operation phase. A closer look at the manufacturing phase shows that the fuel blower and slurry preparation processes are responsible for about 70% of the emissions. For the fuel cell itself, the manufacturing of the BoP causes by far the most GWP emissions (about 81% of the total GWP of the manufacturing phase). The reason for this is the fuel blower [82]. Focusing on single materials used in SOFCs, cerium, lanthanum–strontium–cobalt–ferrite, lanthanum–strontium–manganite, yttria-stabilized zirconia, lanthanum–chromate, as well as nickel, leads to high environmental impacts [67].

Concerning SOFCs, only one study focusing on economic–ecological evaluation was identified. It is noticeable that the most energy-efficient design of the investigated turbine does not lead to the minimum total cost rate but to a good exergy efficiency, whereas the most economical design leads to the lowest exergetic efficiency [101].

- SOFC in a system

An economic comparison of an SOFC micro combined heat and power system (mCHP) and a base scenario (grid electricity as well as gas boiler) shows a higher NPV (considering a time span of 15 years) of the base scenario. So, it is economically better to invest in the boiler and grid electricity system than in the SOFC system. This is because of the high investment cost [98].

The result of an economic analysis of a novel integrated cooling, heating, and power (CCHP) system with an integrated SOFC shows that the investment cost for the SOFC is almost half the total investment cost of the whole CCHP system. The NPV becomes positive after about 7 years (payback period is equal to 6.91 years) [49].

In the context of another economic evaluation, a further NPV analysis shows how the NPV of an SOFC system changes depending on the variation in the selling price of the electricity generated. An increase from USD 0.04/kWh to USD 0.1/kWh changes the advantageousness as the NPV switches from negative to positive [99].

An economic evaluation of a novel biomass gasification syngas fermentation for ethanol production system coupled with an SOFC shows that, if optimization is performed, potentials for profitability exist [37].

When comparing different scenarios of hybrid renewable energy systems containing a solar field (consisting of commercial photovoltaic), wind turbine, battery storage, SOFC, PEME, and lithium bromide absorption refrigeration cycle, the scenario with the highest number of photovoltaic (PV) units, the lowest number of wind turbines, the lowest amount of AC supply, and the highest amount of DC supply shows by far the lowest LCoE (0.034 USD/kW compared to the other scenarios with LCoE of 0.081 USD/kW, 0.084 USD/kW, 0.079 USD/kW, and 0.083 USD/kW, respectively) [43].

In an analysis regarding the influence that individual parameters exert on the performance of a hybrid SOFC-RR (recuperative–regenerative)/ORC (organic Rankine cycle)/PEM system, the following economic results were obtained amongst others: higher current density leads to decreased LCoE since the net power output is decreased. An increase in the steam to carbon ratio causes lower efficiency, lower net power output, but higher LCoE [44].

Comparing the ecological impacts of APUs powered by SOFC with APUs powered by diesel, the SOFC-based APU leads to lower ecological impacts in every considered category, e.g., GWP [73]. Lin et al. found that all bio-fuel APU options emit fewer GHG emissions than diesel direct combustion and diesel APUs [60]. Additionally, a comparison of ICEs, gas turbines, and SOFCs shows that the SOFC leads to the lowest emissions within impact category indicators like GWP, PMFP, TAP, and WCP [69].

- MCFC

Considering the ecological consequences of the life cycle phases, the manufacturing phase is highly relevant for toxicity potential indicators like HH as well as marine and freshwater toxicity, amongst others. Taking the manufacturing stage into account, the stack causes the highest amount of emissions, and, within the stack, the anode is the main originator [80]. The high amount of emissions is caused by the needed metals, like platinum and palladium, for the cell, the stack, and the BoP (especially the reformer) [57,89]. The main contributor to the global warming potential is the operation phase. The reason for this is the use of liquified natural gas (LNG) and, as a consequence, the large quantities of primary resources, such as coal and natural gas, which are needed to produce LNG for use in the MCFC [80]. Regarding the endpoint categories, the stack manufacturing leads to the highest HH impacts, whereas the operation phase is the main contributor for the EQ impact category. The ecological impacts for the third endpoint category RA are mainly caused due to natural gas supply [89].

Focusing on economic–ecological impacts, there is a relation between the operation temperature of an MCFC and the ecological impacts as well as the costs. While the CO2 emission rate decreases as the MCFC’s operation temperature rises, the overall energy efficiency, the cost per unit exergy, the overall cost rate, and the total investment cost rate increase. Additionally, an increase in the current density leads to a rise in the overall cost rate, the total investment cost rate, and the CO2 emissions [96].

- MCFC in systems

In the economic analysis of a new solar heliostat-molten carbonate fuel cell system for electricity and freshwater production, Sadeghi and Askari indicate that the LCoE increases as the system total power output decreases. Decisive for the performance of the system is the operating pressure [41]. Therefore, the higher the operating pressure of the MCFC system, the higher the LCoE.

When comparing power plants for stationary electricity generation regarding their ecological impacts, the MCFC-driven power plant leads to the highest CO2 emissions and has the highest material intensity factors in the categories abiotic and water factor. Contrary to that, considering NOx emissions, the gas-turbine-driven power plants lead to the highest emissions [86].

Looking at ecological impacts of an MCFC system fueled either with landfill gas or steam-reformed natural gas, Lunghi et al. come to the result that, using the landfill gas MCFC, the methane emissions compared to the natural gas MCFC are reduced. Furthermore, the N2O emissions are nearly equal, while the CO2 emissions are reduced as well. The overall result is a drastic reduction in CO2 equivalent emissions [54]. Comparing an MCFC system with a gas engine for marine application, the MCFC system causes lower GWP emissions. In addition to that, the use of the MCFC system leads to an overall ecological impact reduction compared to conventional power generation systems like ICEs as well as steam turbines [89].

Taking the analysis of a novel coal-based polygeneration process of methanol and power with carbon capture by integrating MCFC into account, both the economic and ecological dimensions were considered. It was found that the product cost of coal-to-methanol/power-MCFC (CTMP-MCFC) is 1.68% lower than that of CTMP. The system considered is also capable of capturing 44.56% of the exhausted gas. The CFP indicates great potential to reduce CO2 emissions [103].

- AFC

Taking ecological impacts of AFCs into account, the anode catalyst leads to the highest ecological impact amounts at many ecological impact categories like climate change because of the metals used [61]. Nevertheless, recycling of the components can attenuate the impacts. The overall contributions of transport and maintenance as well as the production of ancillary BoP to the ecological impacts are negligible [88].

- AFC in systems

Compared to the production of other system components of an AFC-based combined heat and power (CHP) system, the production of the AFC stack itself is not as ecologically relevant as the production of other CHP components, e.g., the fuel cell processing or the power conditioning system [58].

Focusing on the economic–ecological consequences of a generator system, the electricity from the generator powered by an AFC is more expensive than the electricity from a generator powered by diesel. The AFC system has a higher lifetime energy consumption as well. However, the AFC system leads to lower CO2 eq. emissions than the diesel-driven generator as well as to lower emissions at the impact category indicators TAP and PMFP. Nevertheless, it leads to higher amounts of emissions within the indicators HTP and metal depletion potential [88].

- Further Fuel cell types

Considering an osmotic microbial fuel cell, the catalyst is the main cause of ecological impacts, again due to the use of platinum [63].

Looking at a constructed wetland system coupled either with a gravel-based anode microbial fuel cell or a graphite-based anode MFC, the considered ecological impacts like AP and GWP emissions, amongst others, are mainly influenced by the manufacturing phase [93].

Taking the ecological performance of different bioelectrochemical systems, including microbial fuel cells, into account, Chin et al. state that the double-chamber air cathode microbial electrolysis cell is the most environmentally friendly option [71].

Comparing the ecological consequences of crude natural gas engine vehicles with gasoline- and diesel-driven as well as reformer-powered vehicles (PEFC vehicles driven by methanol derived from natural gas), the crude natural gas engine vehicles provide a CO2 emission benefit compared to gasoline- and diesel-driven vehicles. The reformer vehicle has a CO2 emission benefit relative to gasoline ICEs, but it is not beneficial relative to diesel or monofuel crude natural gas ICEVs [87].

Regarding an economic–ecological analysis, although a system coupled with an MFC is more expensive than a constructed wetland system without an MFC, the system coupled with a graphite-based anode MFC is the most ecologically friendly system [93].

- Comparison of different fuel cell types

Concerning the economic evaluation of a Protonic Ceramic Fuel Cell (PCFC), an SOFC, and a PEMFC, the stack manufacturing costs of a PCFC are lower than for the other two fuel cell types [31]. The LCoE of an MCFC system is higher than the costs from a photovoltaic plant and from a wind power plant [89]. Another study, focusing on economic evaluation, shows that the efficiency of the SOFC is higher than that of the PEMFC and the fuel costs of the SOFC are lower [40].

A comparison of the ecological impacts of a PEMFC, an SOFC, a PAFC, and an AFC indicates that the PEMFC leads to the lowest amounts, followed by the AFC as second best. The SOFC and the PAFC produce the highest amounts [58]. Contrary to that, a study comparing an SOFC with a PEMFC and a heat pump system concludes that the two fuel cell systems have the lowest impact amounts regarding the category climate change. Additionally, the SOFC leads to the lowest amounts in the categories HH and EQ as well as within the indicators freshwater acidification potential and TAP. Contrarily, the heat pump system has the lowest CED, followed by the SOFC and the PEMFC [66].

Taking the life cycle phases of the fuel cell systems into account, the manufacturing phase is the main contributor to ecological impacts when considering SOFC and PEMFC systems [75,76,77]. In this phase, the use of materials such as chromium steel, nickel, and the energy required for the production cause high environmental impacts in the categories of climate change and fossil depletion, amongst others [75]. The end-of-life phase does not play a significant ecological role [76].

A comparison of an MCFC to an SOFC, a PEMFC, a gas turbine, and a CHP system shows that the MCFC causes the highest ecological emissions in categories such as HH and the indicator ODP but leads to the lowest impacts in the category EQ [89].

Velandia Vargas and Seabra compare the ecological performance of vehicles powered by a PEMFC and an SOFC, respectively, with ICEVs and BEVs. Due to the hydrogen production, the PEMFC vehicles are disadvantageous to current BEVs and ethanol-fueled ICEVs but advantageous to gasoline ICEVs. The SOFC vehicles emit in the current scenario fewer GWP emissions than the PEMFC vehicles as well as the BEVs and gasoline-driven vehicles [70].

A holistic sustainability assessment of the alternatives PEMFC, AFC, PAFC, MCFC, and SOFC shows that, when the environmental, economic, and social dimensions are included, the SOFC has the best performance in terms of sustainability, followed by the PEMFC. The PAFC shows the worst performance [106].

- Comparison of different fuels and tanks

An economic evaluation of the hydrogen product costs shows that nearly 58% are caused by biogas costs, which, therefore, are the main contributors of the product costs. Roughly 19 % are induced by operating costs, like utilities, labor, and maintenance, and the third-largest contributor to the product costs are costs for depreciation (approximately 15%) [47].

In the ecological analysis of hydrogen production, it can be stated that the methods coal gasification and steam methane reforming lead to the highest emissions in the impact category indicators GWP, AP, and EP, whereas the methods cracking and electrolysis cause fewer emissions [55]. Furthermore, the cleaner the production hydrogen used in fuel cell vehicles, the lower the environmental impact of the HFCVs emissions [72].

An ecological comparison of hydrogen tanks shows that the climate change emissions vary in their value depending on the considered tank type [94]. Within the production of a hydrogen tank ”type IV” consisting of carbon fiber, the main contributors for the environmental impact emissions are the polymerization of acrylonitrile, the stabilization of the fiber precursor, as well as the carbonization [65]. The same applies to the economic evaluation of hydrogen tanks regarding the system costs [94].

An economic–ecological analysis shows the following: gasoline and hydrogen from natural gas produce almost the same GHG emissions. Compared to that, hydrogen produced out of wind and solar energy leads to lower GHG emissions [83,95]. The highest costs are caused by gasoline [95]. Wu et al. obtain similar results. The production of methanol and hydrogen from natural gas causes higher emissions concerning the impact category climate change than the alternatives (methanol out of biogas and hydrogen by electrolysis with solar power), respectively. The levelized costs of methanol are roughly 19% higher when the methanol is produced out of biogas rather than natural gas [90]

5. Discussion

5.1. Limitations and Gained Insights

The paper provides a general overview of sustainability-oriented assessment approaches for fuel cells in general. Therefore, it covers a wider range of objects considered on the one hand and methods on the other hand. Existing reviews often focus on the development of the technology, e.g., [108,109], or specific fuel cell types or assessment approaches, e.g., [110,111]. However, because of this variety of objects and methods of consideration, in this review, different debatable issues occur. These can be divided into two different categories. The first category deals with methodological limitations of our study (1). The second category comprises the insights gained about the methods and outcomes of the considered studies (2).

- (1)

- With regard to methodological limitations, it should be noted that the results of the literature research are strongly influenced by the databases used and, above all, the keywords applied. To obtain a general overview of the sustainability assessment of fuel cells, the keywords were kept correspondingly general and broad. Since the results found are very heterogeneous, it could be advisable to adapt the search to a more specific question, such as by limiting it to a fuel cell type (e.g., PEMFC only) or a specific system application (e.g., vehicles only). Accordingly, the search terms would have to be adapted more specifically to the new question. In addition, a reduction in the keywords used would shorten the results found as well, and a variation in the keywords used would have led to different results (e.g., instead of the term ecological, the term environmental could have been used). Furthermore, the studies found may vary depending on which databases are used for literature research. Therefore, other databases, such as Google Scholar, could have been used. Aside from the search terms and databases used, the inclusion and exclusion criteria also limit the studies analyzed and influence the results achieved. In this case, 75 papers were selected for an in-depth reading from the 86 papers based on whether they have a VHB ranking of at least C and/or an H-index of at least 80. If one of these inclusion or exclusion criteria were changed (e.g., an H-index of at least 50 is sufficient), the number of papers included in the study would vary accordingly (here, the number of papers would rise).

- (2)

- The insights gained refer to the methods and results presented within the considered studies themselves and are discussed below.

Fields of application: The scope of analysis of the studies considered shows a wide range, from the evaluation of individual components of fuel cells and complete fuel cells to the application of fuel cells in systems. In addition, areas that do not have an impact on the production of the fuel cell itself, but only arise when it is used, such as the production of fuels, are also considered.

Dimension-related scope and methods: Since sustainability is based on the ecological, social, and economic dimensions [1,2,3], its assessment should also include all three dimensions. In contrast, a majority of the papers analyzed (54 of 75) focus only on one dimension of sustainability when assessing fuel cells. Most often, the ecological dimension is examined. It is also remarkable that there is no study that focuses exclusively on the social dimension. Furthermore, it can be stated that there are only two studies that deal with all three dimensions. In addition, uniform methods are used neither within these two studies nor within the other studies that consider more than just one sustainability dimension.

Economic: Referring to the economic evaluation, it is noticeable that a variety of methods are used (e.g., indicators, learning curve, and DFMA). Only a few studies applied the NPV, although its usage for a long-term economic evaluation of objects is well-known and the state-of-the-art; only one study uses LCC.

Ecological: Regarding the ecological evaluation, the situation is different. Here, the state-of-the-art method in the form of the LCA is used for all studies that relate only to the ecological dimension. However, no uniform impact categories are used. The studies that consider other dimensions in addition to the ecological dimension often deviate from the use of the LCA. Instead, for instance, they use formulas or indicators.

Social: Based on our database search with the keywords used (see the limitation mentioned above), no papers were found that evaluated only the social dimension of fuel cells or the social dimension in addition to either the economic or the ecological dimension. However, there are four studies that consider all three dimensions, including the social one. In these cases, again, a well-known method for assessing the social dimension, such as the sLCA, is not used. This stands in remarkable contrast to the relevance of the social dimension: Fuel cells have a major social impact during their life cycles, especially due to the use of platinum and other rare metals as well as toxic materials during the manufacturing phase.

Overarching sustainability assessment: Concerning the assessment of sustainability as a whole, sometimes even the system boundaries are different for the dimensions evaluated. It is also striking that, in nearly all the papers that consider more than one sustainability dimension, the dimensions are assessed individually. This is surprising against the background of aggregate target figures, such as eco-efficiency and the existence of LCSA and ternary diagrams as approaches intended to provide an integrated assessment of sustainability including all dimensions [29,112,113,114]. Moreover, a database that is used for the economic assessment can also be helpful for the ecological assessment. A common database can thus support an integrated assessment [115]. To contribute to closing this methodological gap and allowing the application of the state-of-the-art methods, a procedure model for an integrated assessment is presented in Section 5.2.

Outcome of the studies: Regarding the results of the studies examined, it can be said that there is no comprehensive picture of the results of the sustainability assessment of fuel cells. This is due to the large number of different objects under consideration, system boundaries, as well as the methods used for the evaluations. Additionally, the studies considered are very individual, each showing its own background (e.g., country-specific electricity mixes used in the assessments; comparison of different vehicle types). Therefore, it is difficult or even impossible to make comprehensive and uniform statements about the advantageousness and relevance of fuel cells and their types, fuel cell components, and/or fuel-cell-based systems. The use of established assessment methods such as LCC (economic), LCA (ecological), sLCA (social), as well as LCSA (aggregation of all three dimensions), the multiple realization of studies for one clearly defined object under comparable frame conditions, as well as high transparence and traceability of studies could counteract this issue.

5.2. Procedure Model for an Integrated Assessment

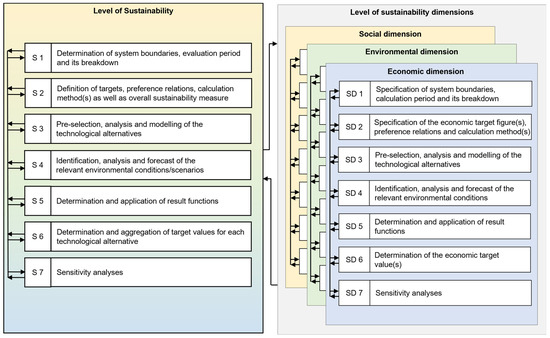

Various approaches already exist for a structured procedure for sustainability-oriented assessment. Basically, the concept of LCSA was suggested for an integrated sustainability-related assessment [30,116]. More specifically, Dinh (2023) proposed a model that is based on the LCA procedure according to ISO 14044 [117] and is applied for the selection of materials in the design phase of road construction projects. The four steps of the LCA (Goal and Scope Definition, Inventory Analysis, Impact assessment, Interpretation) are, respectively, used at a dimension-specific level for the economic, ecological, and social assessment and at the sustainability level for the integrated sustainability assessment [118]. A more differentiated procedure model was developed by Götze et al. (2010) for the analysis of the life cycle profit of materials [119]. It originally focuses on the economic dimension and has already been adapted and extended several times and used in case-specific applications. Götze et al. (2012), for example, applied it in the context of evaluating the energy and cost efficiency of machine tools [120]. In addition, the model has also been discussed in terms of an integrated assessment of several sustainability dimensions. Bierer et al. (2013) analyzed the integrated use of life cycle costing and life cycle assessment and thus the combined economic and ecological assessment based on the model [115]. Götze et al. (2020) modified and applied the procedure model for the integrated assessment of economic, ecological, and social sustainability [121]. This model is briefly presented in the following (see Figure 3).

Figure 3.

Procedure model for sustainability assessment (slightly modified; adapted from [121] and based on [122]).

The sequence of the procedure model is structured according to the basic elements of decision models (target figures, environmental conditions, and result functions) [122]. At the top level, the integrated sustainability assessment is conducted, while the second hierarchy level focuses on the assessment of the individual sustainability dimensions [121]. The methods for evaluation together with the associated target values, which were identified and analyzed in Section 4.1, can be embedded in this structured procedure model.

Step 1 of the procedure model focuses on the definition of the system boundaries. With regard to the product system to be investigated in the area of fuel cells, a decision is made at this point regarding the object of investigation—e.g., (different) fuel cells (e.g., PEMFC [107]), fuel cell components (e.g., fuel cell stacks [53]), or fuel cell systems (e.g., PEMFC embedded in a system like a bus [105]). In addition, the temporal horizon of the consideration must be defined [122], whereby, in particular, the inclusion of the life cycle phases of the fuel cell object is of importance (e.g., only production or also use). Step 2 focuses on the definition of target figures and methods for evaluation. For the economic evaluation in the field of fuel cells, for example, the NPV with the NPV method can be chosen [48,49], especially when considering several life cycle phases. LCA can be used for the ecological assessment. Depending on the methods used within LCA for impact assessment, target figures are selected (e.g., the combination of GHG and primary energy consumption) [60,83,84,85]. For the social assessment in the context of fuel cells, target figures such as employment can be used [104]. Methodologically, the sLCA could be applied. To aggregate the dimension-specific assessments into an overall sustainability measure, the utility value analysis method can be used (for example, [121]). In step 3, the alternatives are analyzed and modeled, e.g., the use of different materials or components within fuel cell stacks or fuel cell systems [94] and the (different) designs of a fuel cell or a fuel cell system (e.g., a vehicle that runs on diesel or on hydrogen [52]). The modeling and analysis can be supported methodically, e.g., by input–output models or process models [121]. Subsequently, the environmental factors to be included in the assessment are identified, also by creating scenarios (step 4) [122]. Afterwards, the result functions are set up (step 5) and the target values are determined for each alternative and dimension as well as for the integrated assessment (step 6) [121]. In the final step 7, sensitivity analyses can be carried out for individual elements. In the context of fuel cells, for example, energy prices and their impact on manufacturing costs could be investigated [50]. Furthermore, the weights of the single dimensions can be varied and the best options—depending on the weights—can be displayed in a ternary diagram [123]. Such a procedure model or a similar method contributes to avoid double work of data generation, to create a consistent database, and to integrate the state-of-the-art methods in the assessment process—enabling more significant sustainability assessments of different objects in the fuel cell domain.

6. Conclusions and Outlook

The present research was conducted in order to obtain an overview of the sustainability assessment of fuel cells. Therefore, systematic literature research was conducted. In particular, the focus was placed on the investigated sustainability dimensions and the methods used in the context of the evaluation. According to the sustainability dimensions, the applied methods were analyzed and existing gaps in the evaluation of individual sustainability dimensions as well as the methods used were identified. It is remarkable that there are no studies that deal exclusively with the evaluation of social sustainability and only four that consider social sustainability at all. One reason for this is that the study of social sustainability in general has only gained importance in recent years. In addition, there are a broad variety of methods for social sustainability assessment whose designs strongly depend on the specific question to be answered. It is also noticeable that there are a variety of methods used to assess the economic dimension, whereas the LCA is mainly used to assess the ecological dimension. Mostly, statements are made only for individual sustainability dimensions while no aggregation is intended or made towards a statement on sustainability of fuel cells or fuel-cell-based systems as a whole. Furthermore, the outcomes of the studies concerning the relevance and the advantageousness of specific components of fuel cells, types of fuel cells, and fuel-cell-based systems concerning the sustainability dimensions were analyzed. As an overall result, due to the variety of studies with regard to fields of application and methods, no clear picture of relevance and advantageousness is visible.

Therefore, further research should focus on a uniform assessment methodology for both the economic and social dimensions, such as LCC for the economic dimension and sLCA for the social dimension. Additionally, future research should also be carried out concerning the aggregation of the dimension-specific results of evaluations—analyzing in which way multi-criteria decision analysis methods such as AHP, utility value analysis, or ternary diagram could be applied for determining an overall sustainability value or statement. Furthermore, an integrated procedure of LCSA could be used to evaluate fuel cells and fuel-cell-based systems; the procedure model outlined in Section 5.2 is a contribution towards the development and establishment of such an overarching method. If there is a uniform methodology for the evaluation of fuel cells, generalizable or at least comparable results could be obtained in individual studies—contributing to provide a significant picture of the relevance and advantageousness of specific components of fuel cells, types of fuel cells, as well as fuel-cell-based systems and thereby to enhance sustainability.

Author Contributions

Conceptualization, A.T., K.H. and U.G.; methodology, A.T. and K.H.; resources, A.T. and K.H.; writing—original draft preparation, A.T., K.H. and U.G.; writing—review and editing, A.T., K.H. and U.G.; visualization, A.T. and K.H. All authors have read and agreed to the published version of the manuscript.

Funding

The publication of this article was funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) project number 491193532 and the Chemnitz University of Technology.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

This work was performed as a part of the research project NeMaCell (grant number 100382169), supported by the European Social Fund (ESF). Financial support is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Overview of papers included in the literature review.

Table A1.

Overview of papers included in the literature review.

| Source | Author | Title | Sustainability Dimension | ||

|---|---|---|---|---|---|

| Ecological | Economic | Social | |||

| [31] | Dubois, A., Ricote, S., & Braun, R. J. | Benchmarking the expected stack manufacturing cost of next generation, intermediate-temperature protonic ceramic fuel cells with solid oxide fuel cell technology | x | ||

| [100] | Granovskii, M., Dincer, I., & Rosen, M. A. | Environmental and economic aspects of hydrogen production and utilization in fuel cell vehicles | x | x | |

| [32] | Mock, P., & Schmid, S. A. | Fuel cells for automotive powertrains—A techno-economic assessment | x | ||

| [38] | Marcinkoski, J., James, B. D., Kalinoski, J. A., Podolski, W., Benjamin, T., & Kopasz, J. | Manufacturing process assumptions used in fuel cell system cost analyses | x | ||

| [35] | Xue, D., & Dong, Z. | Optimal fuel cell system design considering functional performance and production costs | x | ||

| [33] | Itoh, H., Mori, M., Mori, N., & Abe, T. | Production cost estimation of solid oxide fuel cells | x | ||

| [102] | Ito, H. | Economic and environmental assessment of phosphoric acid fuel cell-based combined heat and power system for an apartment complex | x | x | |

| [34] | Tsuchiya, H., & Kobayashi, O. | Mass production cost of PEM fuel cell by learning curve | x | ||

| [104] | Chen, W.-M., & Kim, H. | Energy, Economic, and Social Impacts of a Clean Energy Economic Policy: Fuel Cells Deployment in Delaware | x | x | x |

| [96] | Abdollahi Haghghi, M., Shamsaiee, M., Ghazanfari Holagh, S., Chitsaz, A., & Rosen, M. A. | Thermodynamic, exergoeconomic, and environmental evaluation of a new multi-generation system driven by a molten carbonate fuel cell for production of cooling, heating, electricity, and freshwater | x | x | |

| [51] | Wannek, C., Gluesen, A., & Stolten, D. | Materials, manufacturing technology and costs of fuel cell membranes | x | ||

| [40] | Nelson, D. B., Nehrir, M. H., & Gerez, V. | Economic evaluation of grid-connected fuel-cell systems | x | ||

| [97] | Braga, L. B., Silveira, J. L., Evaristo da Silva, M., Machin, E. B., Pedroso, D. T., & Tuna, C. E. | Comparative analysis between a PEM fuel cell and an internal combustion engine driving an electricity generator: Technical, economical and ecological aspects | x | x | |

| [98] | Elmer, T., Worall, M., Wu, S., & Riffat, S. B. | Emission and economic performance assessment of a solid oxide fuel cell micro-combined heat and power system in a domestic building | x | x | |

| [101] | Mamaghani, A. H., Najafi, B., Shirazi, A., & Rinaldi, F. | Exergetic, economic, and environmental evaluations and multi-objective optimization of a combined molten carbonate fuel cell-gas turbine system | x | x | |

| [46] | James, B. D., Spisak, A. B., & Colella, W. G. | Design for Manufacturing and Assembly Cost Estimate Methodology for Transportation Fuel Cell Systems | x | ||

| [50] | Chen, Y., & Melaina, M. | Model-Based Techno-Economic Evaluation of Fuel Cell Vehicles Considering Technology Uncertainties | x | ||

| [105] | Lozanovski, A., Whitehouse, N., Ko, N., & Whitehouse, S. | Sustainability Assessment of Fuel Cell Buses in Public Transport | x | x | x |

| [88] | Cox, B., & Treyer, K. | Environmental and economic assessment of a cracked ammonia fuelled alkaline fuel cell for off-grid power applications | x | x | |

| [73] | Baratto, F., & Diwekar, U. M. | Life cycle assessment of fuel cell-based APUs | x | x | |

| [61] | Wilson, B. P., Lavery, N. P., Jarvis, D. J., Anttila, T., Rantanen, J., Brown, S. G. R., & Adkins, N. J. | Life cycle assessment of gas atomised sponge nickel for use in alkaline hydrogen fuel cell applications | x | ||

| [62] | Ally, J., & Pryor, T. | Life-cycle assessment of diesel, natural gas and hydrogen fuel cell bus transportation systems | x | ||

| [54] | Lunghi, P., Bove, R., & Desideri, U. | Life-cycle-assessment of fuel-cells-based landfill-gas energy conversion technologies | x | ||

| [60] | Lin, J., Babbitt, C. W., & Trabold, T. A. | Life cycle assessment integrated with thermodynamic analysis of bio-fuel options for solid oxide fuel cells | x | ||

| [93] | Corbella, C., Puigagut, J., & Garfí, M. | Life cycle assessment of constructed wetland systems for wastewater treatment coupled with microbial fuel cells | x | x | |

| [86] | Raugei, M., Bargigli, S., & Ulgiati, S. | A multi-criteria life cycle assessment of molten carbonate fuel cells (MCFC)—a comparison to natural gas turbines | x | ||

| [95] | Ahmadi, P., & Kjeang, E. | Comparative life cycle assessment of hydrogen fuel cell passenger vehicles in different Canadian provinces | x | x | |

| [74] | Garraín, D., & Lechón, Y. | Exploratory environmental impact assessment of the manufacturing and disposal stages of a new PEM fuel cell | x | ||

| [57] | Zucaro, A., Fiorentino, G., Zamagni, A., Bargigli, S., Masoni, P., Moreno, A., & Ulgiati, S. | How can life cycle assessment foster environmentally sound fuel cell production and use? | x | ||

| [66] | Bachmann, T. M., Carnicelli, F., & Preiss, P. | Life cycle assessment of domestic fuel cell micro combined heat and power generation: Exploring influential factors | x | ||

| [83] | Granovskii, M., Dincer, I., & Rosen, M. A. | Life cycle assessment of hydrogen fuel cell and gasoline vehicles | x | ||

| [53] | Pehnt, M. | Life-cycle assessment of fuel cell stacks | x | ||

| [94] | Agostini, A., Belmonte, N., Masala, A., Hu, J., Rizzi, P., Fichtner, M., Moretto, P., Luetto, C., Sgroi, M., & Baricco, M. | Role of hydrogen tanks in the life cycle assessment of fuel cell-based auxiliary power units | x | x | |

| [89] | Mehmeti, A., Pedro Pérez-Trujillo, J., Elizalde-Blancas, F., Angelis-Dimakis, A., & McPhail, S. J. | Exergetic, environmental and economic sustainability assessment of stationary Molten Carbonate Fuel Cells | x | x | |

| [87] | Wagner, U., Eckl, R., & Tzscheutschler, P. | Energetic life cycle assessment of fuel cell powertrain systems and alternative fuels in Germany | x | ||

| [91] | Schäfer, A., Heywood, J. B., & Weiss, M. A. | Future fuel cell and internal combustion engine automobile technologies: A 25-year life cycle and fleet impact assessment | x | x | |

| [75] | Rillo, E., Gandiglio, M., Lanzini, A., Bobba, S., Santarelli, M., & Blengini, G. | Life Cycle Assessment (LCA) of biogas-fed Solid Oxide Fuel Cell (SOFC) plant | x | ||

| [52] | Evangelisti, S., Tagliaferri, C., Brett, D. J. L., & Lettieri, P. | Life cycle assessment of a polymer electrolyte membrane fuel cell system for passenger vehicles | x | ||

| [84] | Yang, Z., Wang, B., & Jiao, K. | Life cycle assessment of fuel cell, electric and internal combustion engine vehicles under different fuel scenarios and driving mileages in China | x | ||

| [76] | Benveniste, G., Pucciarelli, M., Torrell, M., Kendall, M., & Tarancón, A. | Life Cycle Assessment of microtubular solid oxide fuel cell based auxiliary power unit systems for recreational vehicles | x | ||

| [85] | Hussain, M. M., Dincer, I., & Li, X. | A preliminary life cycle assessment of PEM fuel cell powered automobiles | x | ||

| [92] | Miotti, M., Hofer, J., & Bauer, C. | Integrated environmental and economic assessment of current and future fuel cell vehicles | x | x | |

| [124] | Contadini, J. F., Moore, R. M., & Mokhtarian, P. L. | Life cycle assessment of fuel cell vehicles—A methodology example of input data treatment for future technologies | x | ||

| [63] | Zhang, J., Yuan, H., Deng, Y., Abu-Reesh, I. M., He, Z., & Yuan, C. | Life cycle assessment of osmotic microbial fuel cells for simultaneous wastewater treatment and resource recovery | x | ||

| [77] | Singh, B., Guest, G., Bright, R. M., & Stromman, A. H. | Life Cycle Assessment of Electric and Fuel Cell Vehicle Transport Based on Forest Biomass | x | ||

| [78] | Kannangara, M., Bensebaa, F., & Vasudev, M. | An adaptable life cycle greenhouse gas emissions assessment framework for electric, hybrid, fuel cell and conventional vehicles: Effect of electricity mix, mileage, battery capacity and battery chemistry in the context of Canada | x | ||

| [106] | Acar, C., Beskese, A., & Temur, G. T. | Comparative fuel cell sustainability assessment with a novel approach | x | x | x |

| [90] | Wu, W., Pai, C.-T., Viswanathan, K., & Chang, J.-S. | Comparative life cycle assessment and economic analysis of methanol/hydrogen production processes for fuel cell vehicles | x | x | |

| [79] | Joshi, A., Sharma, R., & Baral, B. | Comparative life cycle assessment of conventional combustion engine vehicle, battery electric vehicle and fuel cell electric vehicle in Nepal | x | ||

| [67] | Mori, M., Stropnik, R., Sekavčnik, M., & Lotrič, A. | Criticality and life-cycle assessment of materials used in fuel-cell and hydrogen technologies | x | ||

| [69] | Naeini, M., Cotton, J. S., & Adams II, T. A. | Dynamic life cycle assessment of solid oxide fuel cell system considering long-term degradation effects | x | ||

| [81] | Ahmadi, P., & Khoshnevisan, A. | Dynamic simulation and lifecycle assessment of hydrogen fuel cell electric vehicles considering various hydrogen production methods | x | ||

| [65] | Benitez, A., Wulf, C., de Palmenaer, A., Lengersdorf, M., Röding, T., Grube, T., Robinius, M., Stolten, D., & Kuckshinrichs, W. | Ecological assessment of fuel cell electric vehicles with special focus on type IV carbon fiber hydrogen tank | x | ||

| [48] | Reyes-Valenzuela, M., Sánchez-Squella, A., Barraza, R., Osses, M., & Valdivia-Lefort, P. | Economic evaluation of fuel cell-powered OFF-ROAD machinery using stochastic analysis | x | ||

| [49] | Jia, J., Zang, G., & Paul, M. C. | Energy, exergy, and economic (3E) evaluation of a CCHP system with biomass gasifier, solid oxide fuel cells, micro-gas turbine, and absorption chiller | x | ||