Sustainability Outcomes of Green Processes in Relation to Industry 4.0 in Manufacturing: Systematic Review

Abstract

1. Introduction

2. Theoretical Background

2.1. Review Papers in Literature

2.2. Main Concepts and Terms

3. Materials and Methods

- Clearly define the research questions or hypotheses.

- Determine the databases, search terms and types of relevant studies.

- Carry out a comprehensive literature search.

- Screen the results of the search (selection and exclusion criteria).

- Critically appraise the included studies.

- Synthesize the studies.

- Disseminate the findings of the review.

3.1. Objectives and Research Questions

- How to classify Industry 4.0 technologies that provide sustainability outcomes of green processes in manufacturing?

- Which conventional green processes produce sustainability outcomes as part of Industry 4.0 in manufacturing?

- What are the sustainability outcomes of the conventional green processes in the context of Industry 4.0 in manufacturing?

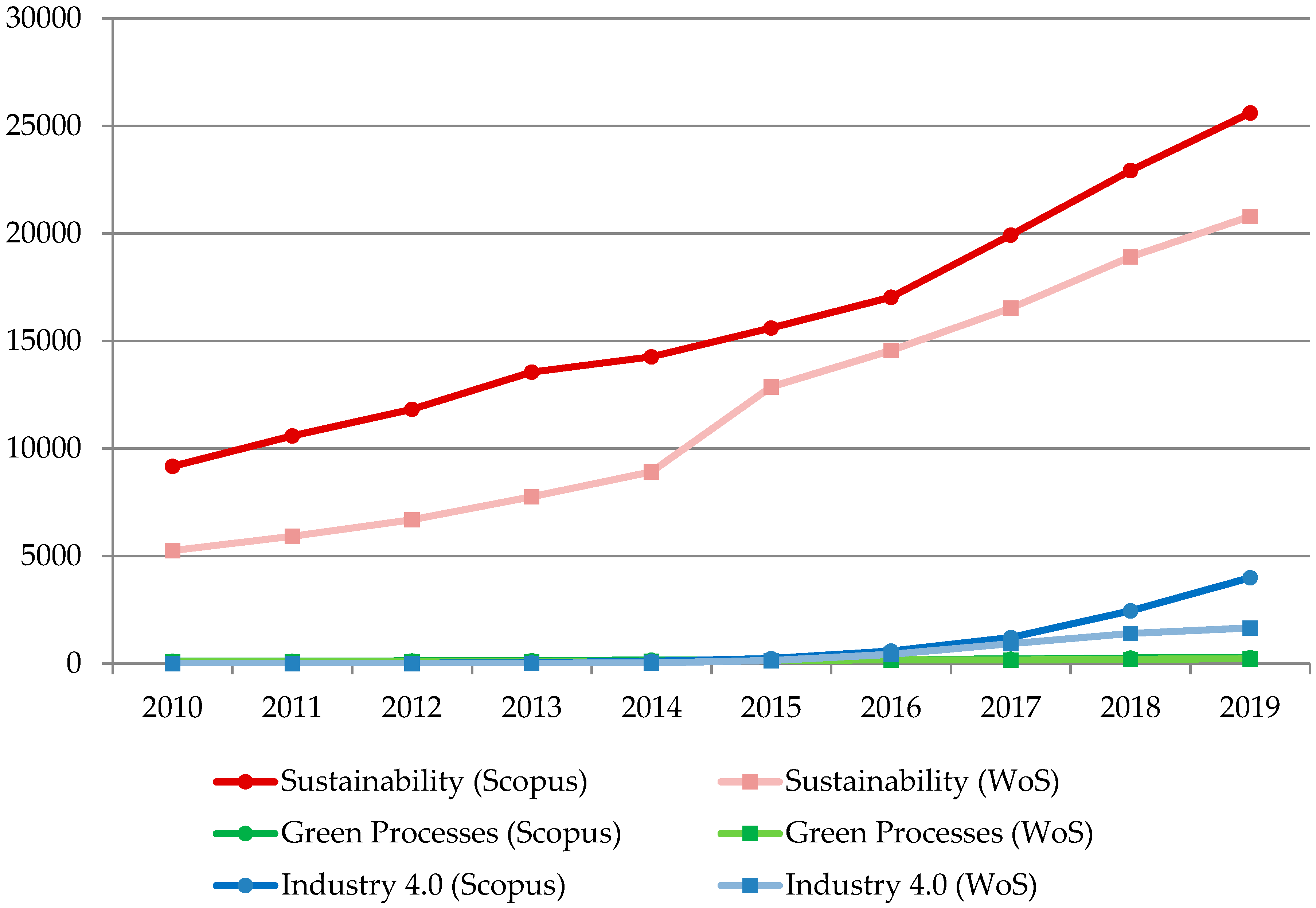

3.2. Information Sources

3.3. Topics and Keywords

3.4. Search Strategy

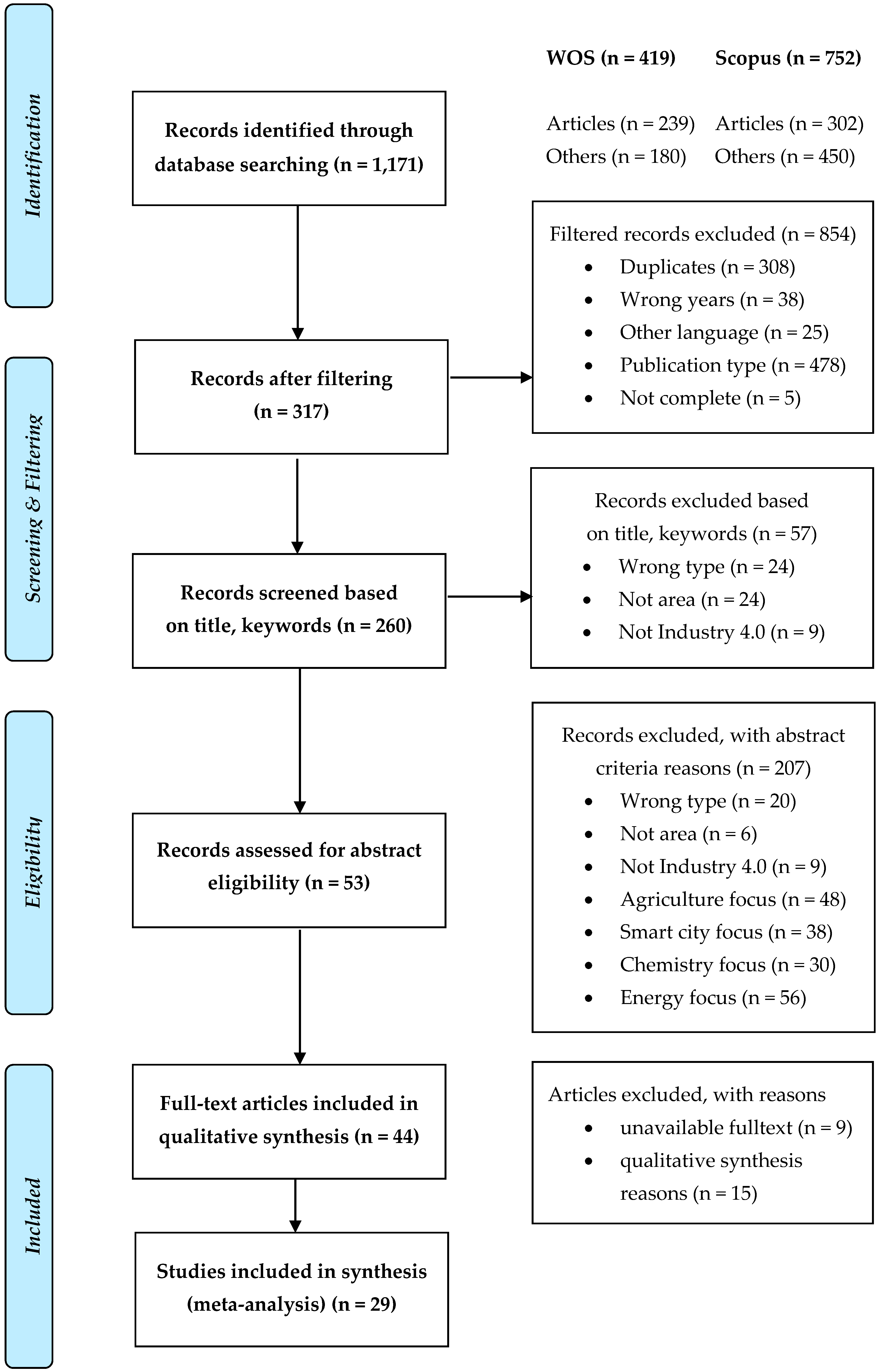

3.5. Selection and Exclusion Criteria, Filters

- Not duplicated;

- Published from 2010 to April 2020;

- Written in English;

- Type of publication: journal paper (not review, white paper, book, etc.);

- Publications with completed information (authors, year, journal name, etc.).

- Having more main topics as its core subject;

- Focusing on the Industry 4.0;

- Focusing on green processes;

- Focusing on sustainability;

- Focusing on the interconnection of the main topics;

- The paper is not a review (paper is not focused only on challenges or future perspectives).

- Discussing only the specification and theoretical description of a particular definition, methodology or review, for example, “Industry 4.0” or “sustainability” or “green processess”;

- Discussing the application of topics in areas other than industry and manufacturing (for example, agriculture, physics, construction);

- Application of topics in smart cities or houses (for example “smart city New York”);

- Chemistry studies focused on the chemical processes, reactions or production of chemicals (for example, “Nanotubes with Lutetium Chloride”);

- Energy studies focused on methods or processes of energy production in plants or plant design (for example, “application of technology in biorefineries”, “solar plant innovations”);

- Dealing with the topic sustainability without specific outcomes (for example, sustainability of a region vs. sustainability of clean transportation).

3.6. Data Extraction and Screening

3.7. Synthesis and Assesment of Bias

3.8. Content Analysis

- Methodology (type of research, method of analysis etc.);

- Industry 4.0 variables (technologies);

- Green context (processes and their importance for sustainability);

- Sustainability outcomes (key findings).

3.9. Data Analysis

4. Results

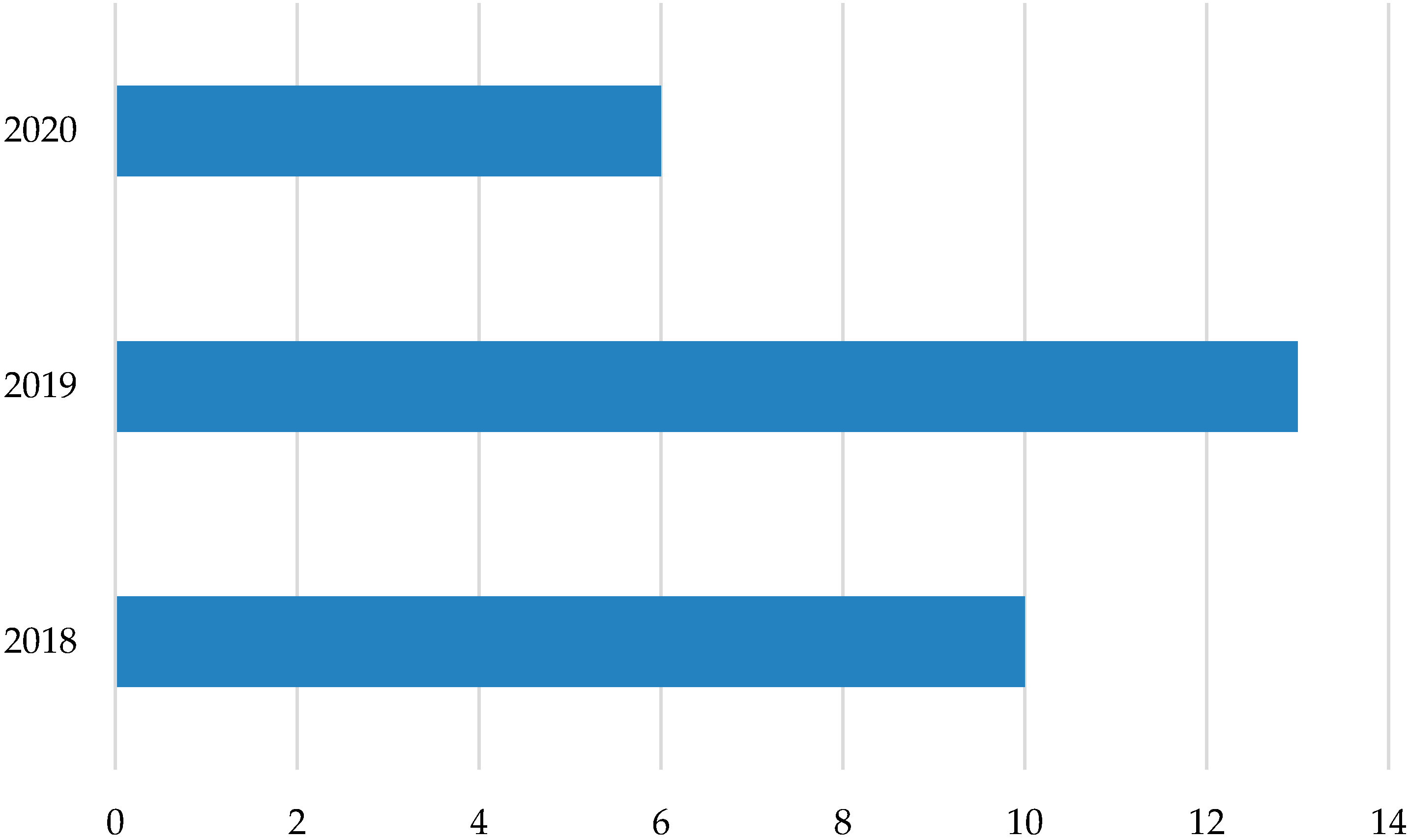

4.1. Year of Publication

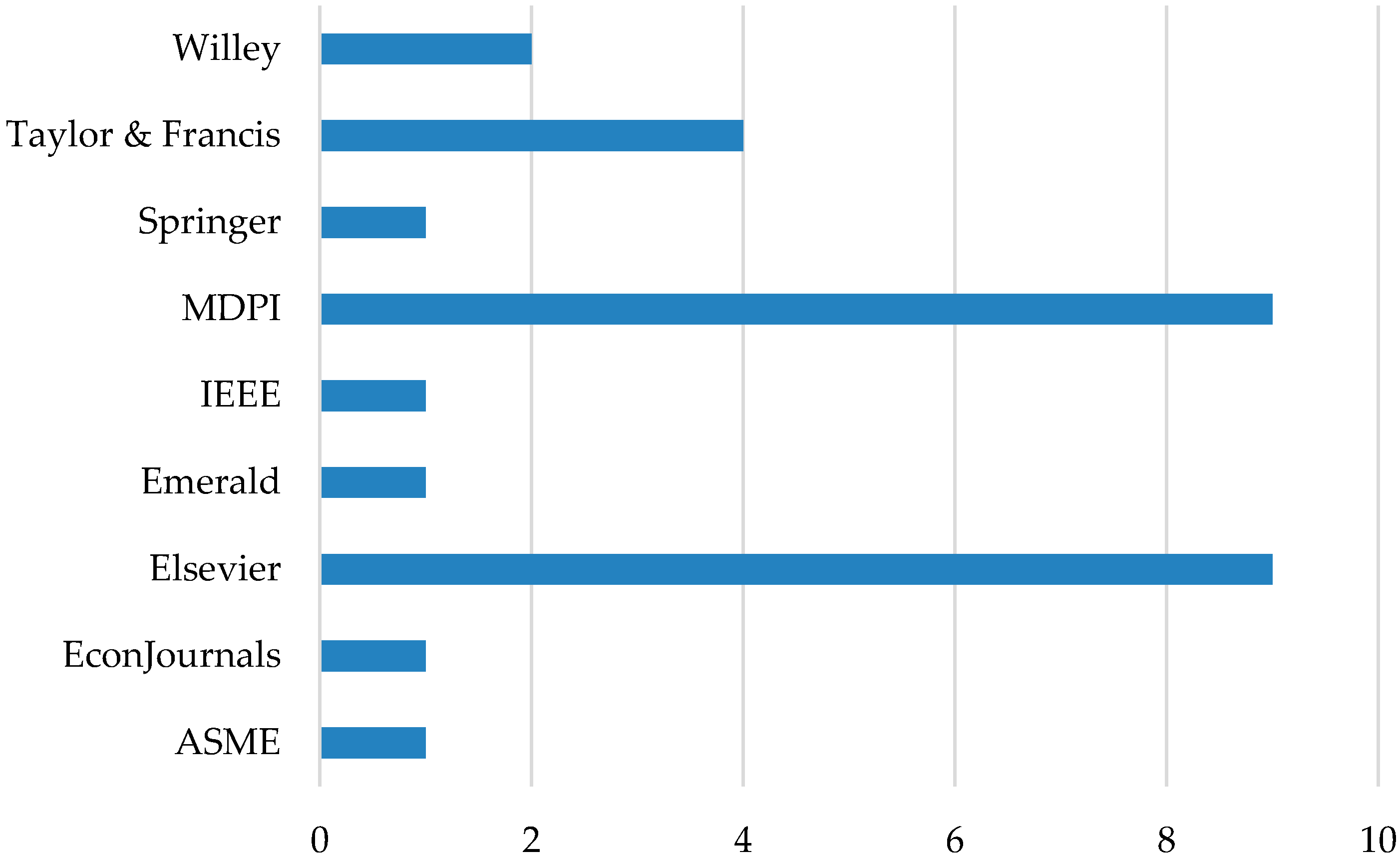

4.2. Contribution by Publishers and Journals

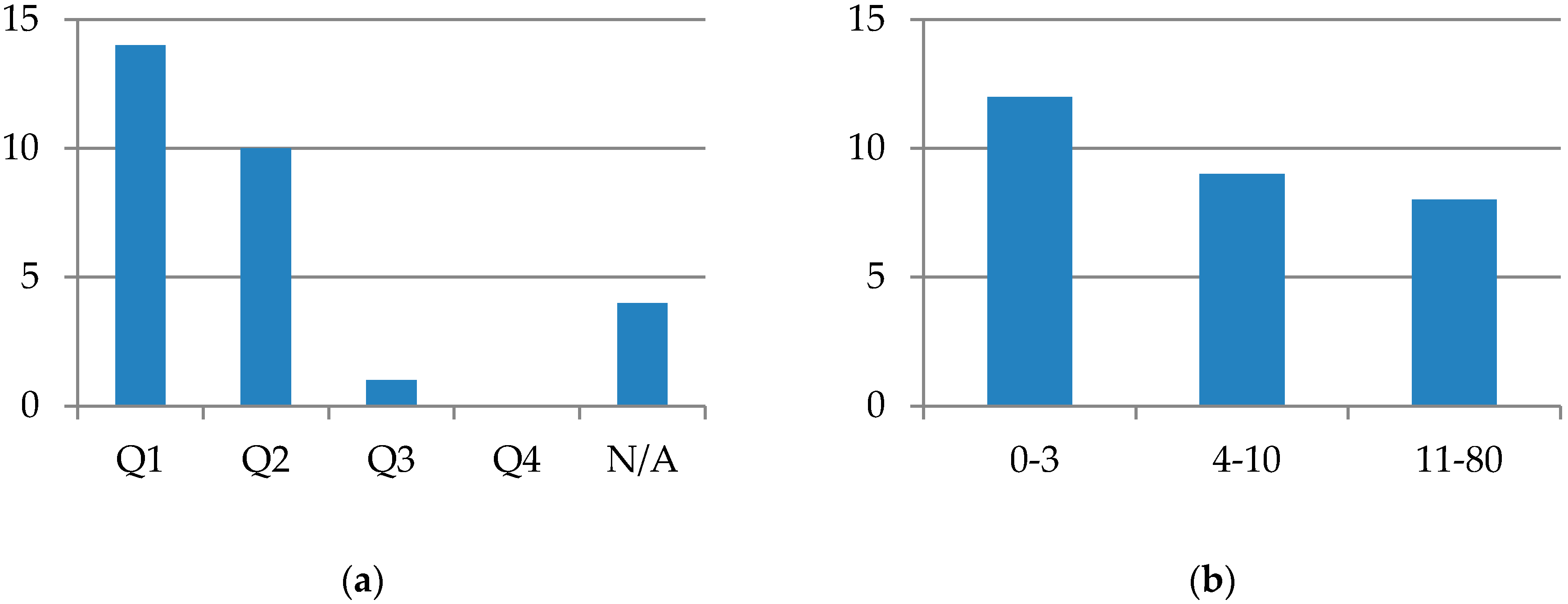

4.3. Quality of Included Studies

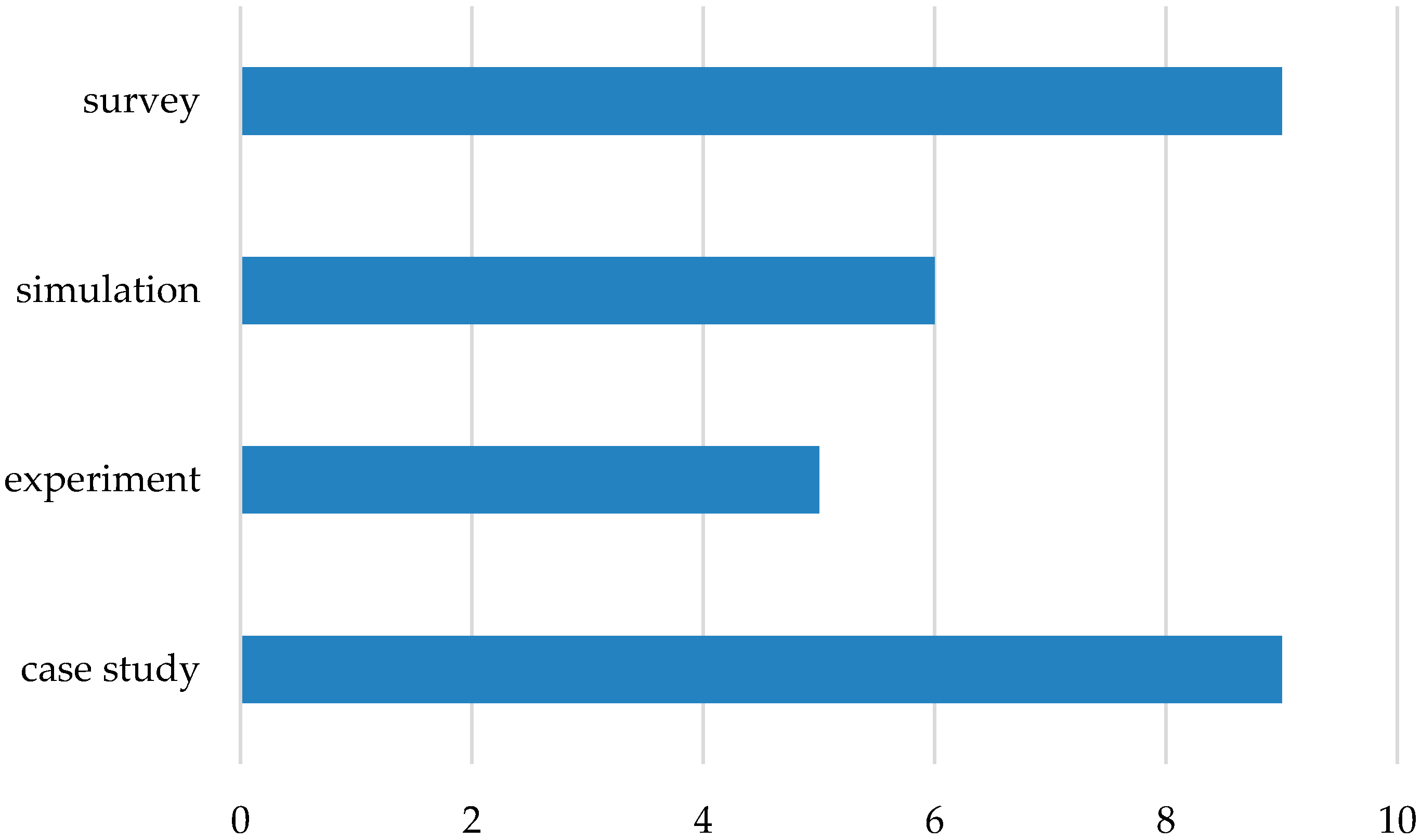

4.4. Type of Research

4.5. Excluded Studies

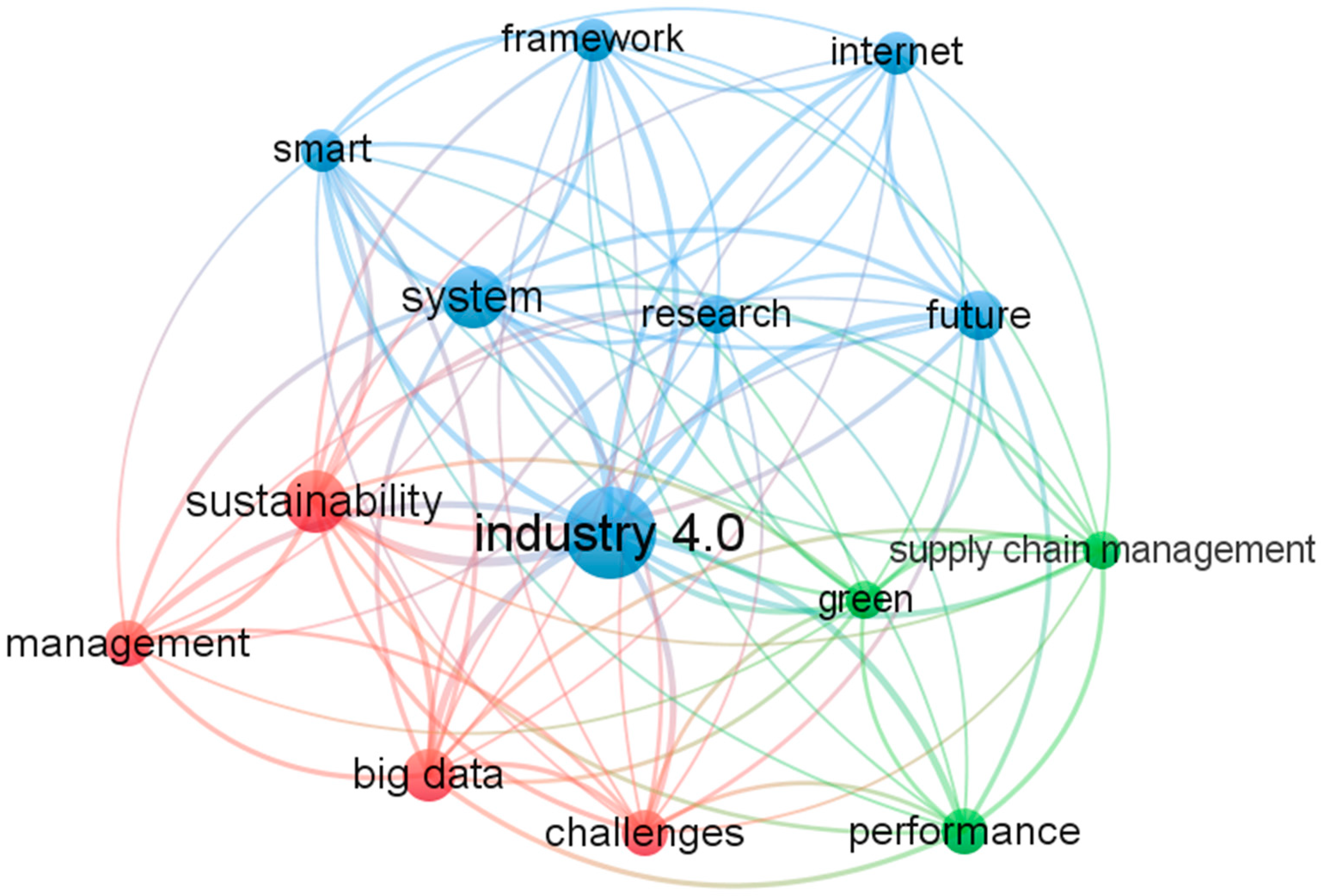

4.6. Keyword Analysis

4.7. Industry 4.0 Variables Analysis

- A: Industry 4.0 and Smart Systems Implementation

- B: Use of Big Data in Information Systems and Smart Factories

- C: Cyber-Physical Systems and Interconnection of Real and Digital World

- D: IIoT and Sensors in Robotics and Communication

4.8. Green Context Analysis

- X: Green Logistics and Supply Chain;

- Y: Green Manufacturing;

- Z: Green Design and Development.

4.9. Sustainability Outcomes Overview

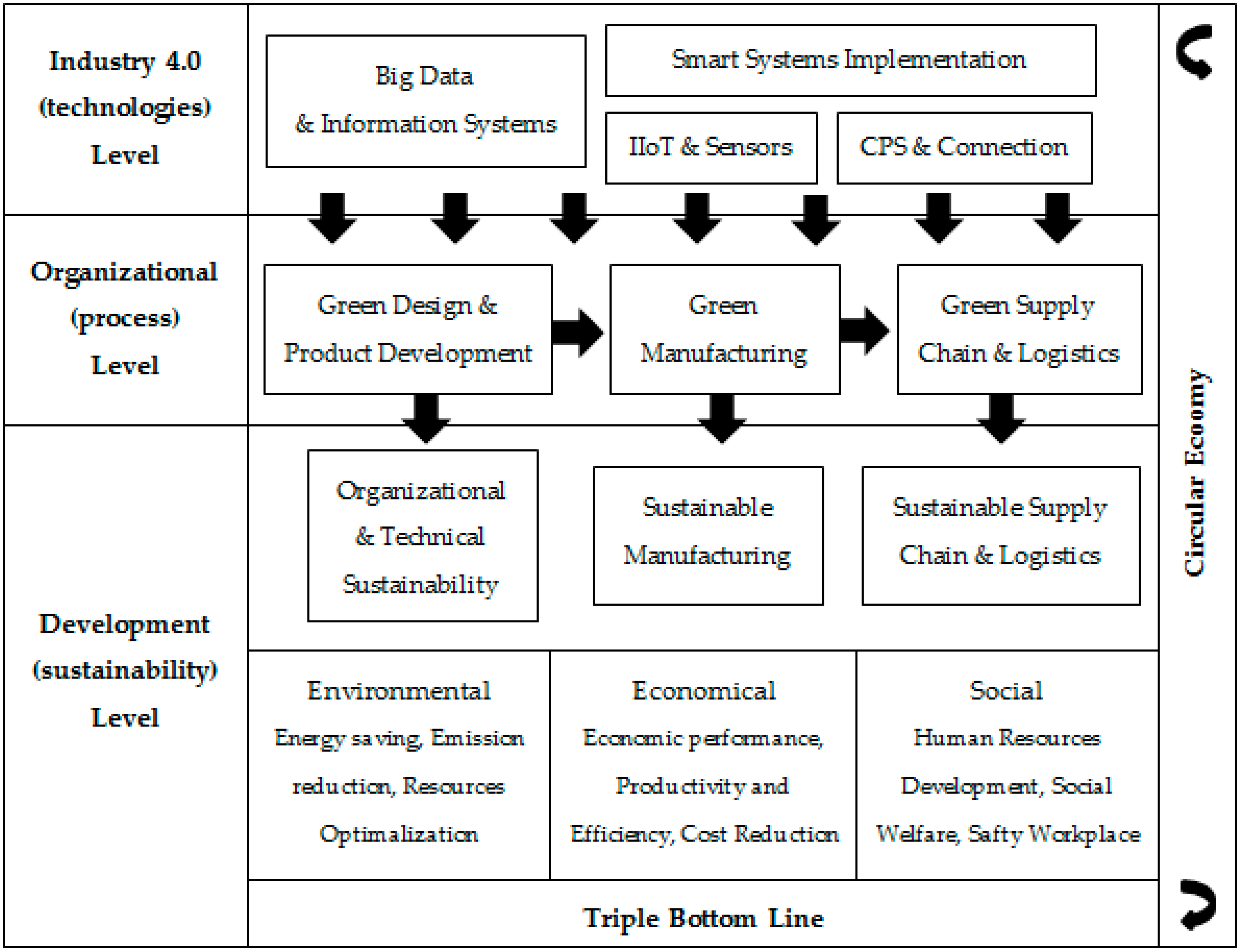

4.10. Synthesis and Development of New Framework

- The supporting function of green processes connects organizational and technical sustainability with technologies. Green processes use current technologies to create an environment for innovations, working, social and technical conditions at the workplace. This includes processes of eco-design, innovation, maintenance and desirable recovery.

- The facilitating function of green processes refers to technologies and systems that ensure a continuous and uninterrupted material and information flow from suppliers to end customers. These processes also include reverse flow based on reverse logistics of packaging, recycling, reuse and dismantling of products.

- Activation function of green processes means the creation of sustainable production system via green value creation, appropriate lean practices, monitoring and the possibility of reprocessing products. Finished manufactured products through these processes minimize negative environmental impacts by conserving energy and natural resources.

- Big data and information systems—in the context of using information systems for big data analytics. This part of the framework allows using information systems for the processing of large volumes of data (big data are quantified in petabytes 1015) stored on the servers and on the Internet in the Cloud through real-time information systems. The information systems and data are the backbone of smart factories, integrated into ERP and visualized through business intelligence technologies. The users access the data using a web browser and a software client for the application virtually from anywhere.

- IIoT and sensors—includes the technologies (sensors, switches), which are a source of information for a control system (computer, brain), and technical devices (robot, machine), which measure certain physical and technical quantities (temperature, pressure, speed, humidity, movement, position, sound, power, time, etc.) and convert them into a signal that is transmitted and further processed remotely. The IIoT devices are useful because they are able to communicate with each other thanks to the CPS systems (i.e., they can receive and send information).

- CPS and Connection—The basis is the cooperation of independent control (computer) units, which are able to make autonomous decisions, manage the technological unit and especially to become an independent and full member of complex production units. This intelligent connection (Bluetooth, RFID, Z-Wave, Zigbee, WiFi, etc.) of various products and devices brings new functions to each other and connects the virtual world with people. Their goal is to connect the real and digital world in production through MES and Digital Twin technologies, in the field of development using CAD tools, augmented (AR) and virtual reality (VR) and in logistics in various CRM (customer relationship management) and SCM (supply chain managmeent) applications.

- Smart Systems Implementation—the area includes the integration of the above-mentioned technologies into a fully functional system. The implementation is associated with digitization, development of robotics and processes based on automation and artificial intelligence. The smart systems are based on technologies that allow sensors, databases, and wireless to work together, adapt, and modify their behaviour to adapt to the environment and their users. They are able to learn, use experience, anticipate future behaviour and use the skills of self-management and self-regulation. This area also includes other Industry 4.0 technologies such as 3D printing used in additive manufacturing.

- Green Design and Product Development—eco-design of the product means the use of recyclable and recycled materials, recovery parts, reductions in chemicals, energy saving in products, the possibility of further use (re-use), long product life cycle (LCA), possibility of product sharing, durability, disclosure of environmental information, low carbon footprint measure, using standards, renewable resources.

- Green Manufacturing—it is basically the production of the products used in less energy-intensive equipment and the products that minimize the impact on the environment. At the same time, it is a method of production that reduces the occurrence of harmful emissions and waste of natural resources, using the renewable resources and “clean” technologies.

- Green Supply Chain and Logistics—includes the introduction of systemic measures and the implementation of logistics activities enabling recycling and reusing the waste and reducing emissions. It involves the use of renewable and recyclable packaging, environmentally friendly fuels, means of transport (meeting emission standards), etc.

- Organizational and Technical Sustainability—such type of sustainability is focused on the inside of the enterprise. It deals with the optimal use of the resources. It involves the use of human labour, maintenance of technical equipment and machinery and IT infrastructure.

- Sustainable Manufacturing—it includes the sustainability of production processes in the production of environmentally friendly products in accordance with the conditions arising from the requirements of environmental protection and optimization of the production costs.

- Sustainable Supply Chain and Logistics—the sustainability of the supply chain and logistics networks is based on the requirements for continuous security of supply, with careful waste management at the same time. The key in terms of the management and optimization of supplier networks is the cooperation between enterprises in the distribution, warehousing, transport and implementation of other logistics functions. In the area of logistics, it is mainly about sustainability resulting from the negative impact of transport on the environment.

- Triple Bottom Line—a basic concept of sustainability based on the concept of 3P (People, Planet and Profit). The triple bottom line includes meeting human needs and achieving a satisfactory quality of life while allocating resources efficiently (economically), conserving natural resources, including ecosystems and their biodiversity (ecologically), and social resources accessible to all while preserving cultural diversity (socially).

- Circular Economy (circularity)—an economic system aimed at reducing waste through the unlimited use of resources. In the SGI 4.0 framework, it consolidates the use of technologies and resources through the green processes enabling long-term sustainability.

- Sustainability Outcomes—these outcomes are divided into three groups (economic, environmental, social) and are characterized by the most frequently found benefits for each dimension.

5. Discussion

5.1. Industry 4.0 Technologies Classification Discussion

5.2. Green Processes and Technologies Classification Discussion

5.3. Sustainability Classification Discussion

5.4. New Conceptual Framework Discussion

5.5. Limitations and Potential Biases

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Lai, K.H.; Wong, C.W.Y. Green logistics management and performance: Some empirical evidence from Chinese manufacturing exporters. Omega 2012, 40, 267–282. [Google Scholar] [CrossRef]

- Heng, X.; Zou, C. How Can Green Technology Be Possible. Asian Soc. Sci. 2010, 6. [Google Scholar] [CrossRef][Green Version]

- Chen, Y.-S. The Drivers of Green Brand Equity: Green Brand Image, Green Satisfaction, and Green Trust. J. Bus. Ethics 2010, 93, 307–319. [Google Scholar] [CrossRef]

- Paul, I.D.; Bhole, G.P.; Chaudhari, J.R. A Review on Green Manufacturing: It’s Important, Methodology and its Application. Procedia Mater. Sci. 2014, 6, 1644–1649. [Google Scholar] [CrossRef]

- Singh, A.; Philip, D.; Ramkumar, J. Quantifying Green Manufacturability of a Unit Production Process Using Simulation. Procedia CIRP 2015, 29, 257–262. [Google Scholar] [CrossRef]

- Xie, X.; Huo, J.; Zou, H. Green process innovation, green product innovation, and corporate financial performance: A content analysis method. J. Bus. Res. 2019, 101, 697–706. [Google Scholar] [CrossRef]

- Rajput, S.P.S.; Datta, S. Sustainable and green manufacturing–A narrative literature review. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Cherrafi, A.; Garza-Reyes, J.A.; Kumar, V.; Mishra, N.; Ghobadian, A.; Elfezazi, S. Lean, green practices and process innovation: A model for green supply chain performance. Int. J. Prod. Econ. 2018, 206, 79–92. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Jabbour, C.J.C.; Maria Da Silva, E.; Paiva, E.L.; Almada Santos, F.C. Environmental management in Brazil: Is it a completely competitive priority? J. Clean. Prod. 2012, 21, 11–22. [Google Scholar] [CrossRef]

- Tiwari, K.; Khan, M.S. Sustainability accounting and reporting in the industry 4.0. J. Clean. Prod. 2020, 258, 120783. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Couckuyt, D.; Van Looy, A. Green BPM as a Business-Oriented Discipline: A Systematic Mapping Study and Research Agenda. Sustainability 2019, 11, 4200. [Google Scholar] [CrossRef]

- Couckuyt, D.; Van Looy, A. A systematic review of Green Business Process Management. Bus. Process Manag. J. 2019, 26, 421–446. [Google Scholar] [CrossRef]

- Abdelbasir, S.M.; El-Sheltawy, C.T.; Abdo, D.M. Green Processes for Electronic Waste Recycling: A Review. J. Sustain. Metall. 2018, 4, 295–311. [Google Scholar] [CrossRef]

- Chemat, F.; Rombaut, N.; Meullemiestre, A.; Turk, M.; Perino, S.; Fabiano-Tixier, A.S.; Abert-Vian, M. Review of Green Food Processing techniques. Preservation, transformation, and extraction. Innov. Food Sci. Emerg. Technol. 2017, 41, 357–377. [Google Scholar] [CrossRef]

- Kumar, N.; Agrahari, R.P.; Roy, D. Review of Green Supply Chain Processes. Ifac Pap. 2015, 48, 374–381. [Google Scholar] [CrossRef]

- Gephart, J.S.; Petersen, H.D.; Bratkovich, S.M. Green Dimensioning-A review of processing, handling, drying, and marketing. For. Prod. J. 1995, 45, 69–73. [Google Scholar]

- Ramsey, E.; Sun, Q.B.; Zhang, Z.Q.; Zhang, C.M.; Gou, W. Mini-Review: Green sustainable processes using supercritical fluid carbon dioxide. J. Environ. Sci. 2009, 21, 720–726. [Google Scholar] [CrossRef]

- Singh, N.K.; Pandey, P.M.; Singh, K.K.; Sharma, M.K. Steps towards green manufacturing through EDM process: A review. Cogent Eng. 2016, 3. [Google Scholar] [CrossRef]

- Kralisch, D.; Ott, D.; Gericke, D. Rules and benefits of Life Cycle Assessment in green chemical process and synthesis design: A tutorial review. Green Chem. 2015, 17, 123–145. [Google Scholar] [CrossRef]

- Kolb, M.V. Green Organic Chemistry and Its Interdisciplinary Applications; Taylor Francis: Boca Raton, FL, USA, 2017. [Google Scholar]

- Mendoza-Fong, R.J.; García-Alcaraz, L.J.; Díaz-Reza, R.J.; Jiménez-Macías, E.; Blanco-Fernández, J. The Role of Green Attributes in Production Processes as Well as Their Impact on Operational, Commercial, and Economic Benefits. Sustainability 2019, 11, 1294. [Google Scholar] [CrossRef]

- Shi, Q.; Lai, X.D. Identifying the underpin of green and low carbon technology innovation research: A literature review from 1994 to 2010. Technol. Forecast. Soc. Chang. 2013, 80, 839–864. [Google Scholar] [CrossRef]

- Schiederig, T.; Tietze, F.; Herstatt, C. Green innovation in technology and innovation management-an exploratory literature review. R D Manag. 2012, 42, 180–192. [Google Scholar] [CrossRef]

- Zhao, J.; Zuo, H.B.; Wang, Y.J.; Wang, J.S.; Xue, Q.G. Review of green and low-carbon ironmaking technology. Ironmak. Steelmak. 2019. [Google Scholar] [CrossRef]

- Adnan, N.; Nordin, S.M.; Bahruddin, M.A.; Tareq, A.H. A state-of-the-art review on facilitating sustainable agriculture through green fertilizer technology adoption: Assessing farmers behavior. Trends Food Sci. Technol. 2019, 86, 439–452. [Google Scholar] [CrossRef]

- Naqi, A.; Jang, J.G. Recent Progress in Green Cement Technology Utilizing Low-Carbon Emission Fuels and Raw Materials: A Review. Sustainability 2019, 11, 537. [Google Scholar] [CrossRef]

- Tong, H.H.; Yao, Z.Y.; Lim, J.W.; Mao, L.W.; Zhang, J.X.; Ge, T.S.; Peng, Y.H.; Wang, C.H.; Tong, Y.W. Harvest green energy through energy recovery from waste: A technology review and an assessment of Singapore. Renew. Sust. Energ. Rev. 2018, 98, 163–178. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, S.P.; Lamba, K. Sustainable robust layout using Big Data approach: A key towards industry 4.0. J. Clean Prod. 2018, 204, 643–659. [Google Scholar] [CrossRef]

- Ramli, N.; Mazlan, N.; Ando, Y.; Leman, Z.; Abdan, K.; Aziz, A.A.; Sairy, N.A. Natural fiber for green technology in automotive industry: A brief review. In Wood and Biofiber International Conference; Jawaid, M., Mazlan, N., Eds.; IOP Conference Series-Materials Science and Engineering; Iop Publishing Ltd.: Bristol, UK, 2018; Volume 368, ISBN 1757-8981. [Google Scholar]

- Ahn, D.G. Direct Metal Additive Manufacturing Processes and Their Sustainable Applications for Green Technology: A Review. Int. J. Precis Eng Manuf-Green Technol. 2016, 3, 381–395. [Google Scholar] [CrossRef]

- Gumba, R.E.; Saallah, S.; Misson, M.; Ongkudon, C.M.; Anton, A. Green biodiesel production: A review on feedstock, catalyst, monolithic reactor, and supercritical fluid technology. Biofuel Res. J. 2016, 3, 431–447. [Google Scholar] [CrossRef]

- Quader, M.A.; Ahmed, S.; Ghazilla, R.A.R.; Dahari, M. A comprehensive review on energy efficient CO2 breakthrough technologies for sustainable green iron and steel manufacturing. Renew. Sust. Energ. Rev. 2015, 50, 594–614. [Google Scholar] [CrossRef]

- Abdelmoez, W.; Ashour, E.; Naguib, S.M. A Review on Green Trend for Oil Extraction Using Subcritical Water Technology and Biodiesel Production. J. Oleo Sci. 2015, 64, 467–478. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Alcacer, V.; Cruz-Machado, V. Scanning the Industry 4.0: A Literature Review on Technologies for Manufacturing Systems. Eng. Sci. Technol. 2019, 22, 899–919. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2018. [Google Scholar] [CrossRef]

- Liao, Y.X.; Deschamps, F.; Loures, E.D.R.; Ramos, L.F.P. Past, present and future of Industry 4.0-a systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Cobo, M.J.; Jurgens, B.; Herrero-Solana, V.; Martinez, M.A.; Herrera-Viedma, E. Industry 4.0: A perspective based on bibliometric analysis. In 6th International Conference on Information Technology and Quantitative Management; Shi, Y., Wolcott, P., Kwak, W., Chen, Z., Tian, Y., Lee, H., Eds.; Procedia Computer Science; Elsevier Science Bv: Amsterdam, The Netherlands, 2018; Volume 139, pp. 364–371. ISBN 1877-0509. [Google Scholar]

- Maresova, P.; Soukal, I.; Svobodova, L.; Hedvicakova, M.; Javanmardi, E.; Selamat, A.; Krejcar, O. Consequences of Industry 4.0 in Business and Economics. Economies 2018, 6, 46. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Aquailani, B.; Gatti, C. Industry 4.0 in Management Studies: A Systematic Literature Review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Ali, N.K.; Maresova, P.; Krejcar, O. Industry 4.0 for the Construction Industry—How Ready Is the Industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- Kumar, S.B.V.; Reddy, K.P.N.; Reddy, Y.C. A Review on Globalization and Green Technologies to Mitigate Pollution. Int. J. Adv. Res. Sci. Eng. 2016, 5, 225–236. [Google Scholar]

- Davison, A. Technology and the Contested Meanings of Sustainability; SUNY Press: New York, NY, USA, 2001. [Google Scholar]

- Shaikh, Z. Towards Sustainable Development: A Review of Green Technologies. Trends Renew. Energy 2017, 4, 1–14. [Google Scholar] [CrossRef]

- Ma, Y.; Hou, G.; Xin, B. Green Process Innovation and Innovation Benefit: The Mediating Effect of Firm Image. Sustainability 2017, 9, 1778. [Google Scholar] [CrossRef]

- Patel, D.; Kellici, S.; Saha, B. Green Process Engineering as the Key to Future Processes. Processes 2014, 2, 311–332. [Google Scholar] [CrossRef]

- Cheng, C.C.J.; Yang, C.; Sheu, C. The link between eco-innovation and business performance: A Taiwanese industry context. J. Clean. Prod. 2014, 64, 81–90. [Google Scholar] [CrossRef]

- Dangelico, R.M.; Pontrandolfo, P. Being ‘Green and Competitive’: The Impact of Environmental Actions and Collaborations on Firm Performance: Being “Green and Competitive”. Bus. Strat. Env. 2015, 24, 413–430. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, S. Green Technologies and Environmental Sustainability; Springer: Berlin, Germany, 2017. [Google Scholar]

- Purohit, D.; Malvi, B. Review on Green Technology for Sustainable Development. Am. J. Eng. Res. (AJER) 2019, 8, 296–300. [Google Scholar]

- Jeong, Y.J.; Kang, I.; Choi, S.K.; Lee, B.H. Network Analysis on Green Technology in National Research and Development Projects in Korea. Sustainability 2018, 10, 1043. [Google Scholar] [CrossRef]

- Mukhtarova, K.; Trifilova, A.; Zhidebekkyzy, A. Commercialization of Green Technologies: An Exploratory Literature Review. J. Int. Stud. 2016, 9, 75–87. [Google Scholar] [CrossRef][Green Version]

- Zhang, Y.; Huang, T.; Bompard, E.F. Big data analytics in smart grids: A review. Energy Inf. 2018, 1, 8. [Google Scholar] [CrossRef]

- Shakhovska, N.; Boyko, N.; Zasoba, Y.; Benova, E. Big Data Processing Technologies in Distributed Information Systems. Procedia Comput. Sci. 2019, 160, 561–566. [Google Scholar] [CrossRef]

- Zhang, Z. Healthcare Information System Architecture Design Based on Big Data. In Proceedings of the 2017 2nd International Conference on Automation, Mechanical Control and Computational Engineering (AMCCE 2017); Atlantis Press: Beijing, China, 2017. [Google Scholar]

- Matsebula, F.; Mnkandla, E. Information systems innovation adoption in higher education: Big data and analytics. In Proceedings of the 2016 International Conference on Advances in Computing and Communication Engineering (ICACCE); IEEE: Durban, South Africa, 2016; pp. 326–329. [Google Scholar]

- Sarker, S.; Aalto University; Chiang, R.; University of Cincinnati. Big Data Research in Information Systems: Toward an Inclusive Research Agenda. JAIS 2016, 17, I–XXXII. [Google Scholar] [CrossRef]

- Müller, O.; Junglas, I.; vom Brocke, J.; Debortoli, S. Utilizing big data analytics for information systems research: Challenges, promises and guidelines. Eur. J. Inf. Syst. 2016, 25, 289–302. [Google Scholar] [CrossRef]

- Sivaparthipan, C.B.; Karthikeyan, N.; Karthik, S. Designing statistical assessment healthcare information system for diabetics analysis using big data. Multimed Tools Appl. 2020, 79, 8431–8444. [Google Scholar] [CrossRef]

- Chu, W.-S.; Chun, D.-M.; Ahn, S.-H. Research advancement of green technologies. Int. J. Precis. Eng. Manuf. 2014, 15, 973–977. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Vrchota, J.; Mařiková, M.; Řehoř, P.; Rolínek, L.; Toušek, R. Human Resources Readiness for Industry 4.0. JOItmC 2019, 6, 3. [Google Scholar] [CrossRef]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Ingaldi, M.; Ulewicz, R. Problems with the implementation of industry 4.0 in enterprises from the SME sector. Sustainability 2020, 12, 217. [Google Scholar] [CrossRef]

- Frankó, A.; Vida, G.; Varga, P. Reliable Identification Schemes for Asset and Production Tracking in Industry 4.0. Sensors 2020, 20, 3709. [Google Scholar] [CrossRef]

- Ferrero, R.; Collotta, M.; Bueno-Delgado, M.V.; Chen, H.-C. Smart Management Energy Systems in Industry 4.0. Energies 2020, 13, 382. [Google Scholar] [CrossRef]

- Črešnar, R.; Nedelko, Z. Understanding Future Leaders: How Are Personal Values of Generations Y and Z Tailored to Leadership in Industry 4.0? Sustainability 2020, 12, 4417. [Google Scholar] [CrossRef]

- Butt, J. Exploring the Interrelationship between Additive Manufacturing and Industry 4.0. Designs 2020, 4, 13. [Google Scholar] [CrossRef]

- Boccella, A.R.; Centobelli, P.; Cerchione, R.; Murino, T.; Riedel, R. Evaluating Centralized and Heterarchical Control of Smart Manufacturing Systems in the Era of Industry 4.0. Appl. Sci. 2020, 10, 755. [Google Scholar] [CrossRef]

- Zambon, I.; Cecchini, M.; Egidi, G.; Saporito, M.G.; Colantoni, A. Revolution 4.0: Industry vs. Agriculture in a Future Development for SMEs. Processes 2019, 7, 36. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Li, D.; Landström, A.; Fast-Berglund, Å.; Almström, P. Human-Centred Dissemination of Data, Information and Knowledge in Industry 4.0. Procedia CIRP 2019, 84, 380–386. [Google Scholar] [CrossRef]

- Vrchota, J.; Pech, M. Readiness of Enterprises in Czech Republic to Implement Industry 4.0: Index of Industry 4.0. Appl. Sci. 2019, 9, 5405. [Google Scholar] [CrossRef]

- Show, P.L.; Thangalazhy-Gopakumar, S.; Foo, D.C.Y. Special Issue “Green Technologies: Bridging Conventional Practices and Industry 4.0”. Processes 2020, 8, 552. [Google Scholar] [CrossRef]

- Liu, B.; De Giovanni, P. Green process innovation through Industry 4.0 technologies and supply chain coordination. Ann. Oper. Res. 2019. [Google Scholar] [CrossRef]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.-I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Int. J. Innov. Mgt. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Choudhary, A. Strategic design for inventory and production planning in closed-loop hybrid systems. Int. J. Prod. Econ. 2017, 183, 345–353. [Google Scholar] [CrossRef]

- Wang, L.; Lu, K.; Liu, P.; Ranjan, R.; Chen, L. IK-SVD: Dictionary Learning for Spatial Big Data via Incremental Atom Update. Comput. Sci. Eng. 2014, 16, 41–52. [Google Scholar] [CrossRef]

- Buer, S.-V.; Strandhagen, J.O.; Chan, F.T.S. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Arshad, R.; Zahoor, S.; Shah, M.A.; Wahid, A.; Yu, H. Green IoT: An Investigation on Energy Saving Practices for 2020 and Beyond. IEEE Access 2017, 5, 15667–15681. [Google Scholar] [CrossRef]

- Xu, L.D.; He, W.; Li, S. Internet of Things in Industries: A Survey. IEEE Trans. Ind. Inf. 2014, 10, 2233–2243. [Google Scholar] [CrossRef]

- Deif, A.M. A system model for green manufacturing. J. Clean. Prod. 2011, 19, 1553–1559. [Google Scholar] [CrossRef]

- Gandhi, N.S.; Thanki, S.J.; Thakkar, J.J. Ranking of drivers for integrated lean-green manufacturing for Indian manufacturing SMEs. J. Clean. Prod. 2018, 171, 675–689. [Google Scholar] [CrossRef]

- Govindan, K.; Diabat, A.; Madan Shankar, K. Analyzing the drivers of green manufacturing with fuzzy approach. J. Clean. Prod. 2015, 96, 182–193. [Google Scholar] [CrossRef]

- Green Technologies in Food Production and Processing; Boye, J.I., Arcand, Y., Eds.; Food engineering series; Springer: New York, NY, USA, 2012; ISBN 978-1-4614-1587-9. [Google Scholar]

- Loiseau, E.; Saikku, L.; Antikainen, R.; Droste, N.; Hansjürgens, B.; Pitkänen, K.; Leskinen, P.; Kuikman, P.; Thomsen, M. Green economy and related concepts: An overview. J. Clean. Prod. 2016, 139, 361–371. [Google Scholar] [CrossRef]

- Bina, O. The Green Economy and Sustainable Development: An Uneasy Balance? Environ. Plann. C Gov. Policy 2013, 31, 1023–1047. [Google Scholar] [CrossRef]

- Brand, U. Green economy–the next oxymoron? No lessons learned from failures of implementing sustainable development. GAIA-Ecol. Perspect. Sci. Soc. 2012, 21, 28–32. [Google Scholar] [CrossRef]

- Slaper, T.F.; Krause, R.A. The Green Economy: What Does Green Mean? Indiana Bus. Rev. Bloomingt. 2009, 84, 10–13. [Google Scholar]

- Gasparatos, A.; Doll, C.N.H.; Esteban, M.; Ahmed, A.; Olang, T.A. Renewable energy and biodiversity: Implications for transitioning to a Green Economy. Renew. Sustain. Energy Rev. 2017, 70, 161–184. [Google Scholar] [CrossRef]

- Willis, K. Biodiversity in the Green Economy. Available online: https://books.google.cz/books?hl=cs&lr=&id=21_LCQAAQBAJ&oi=fnd&pg=PP1&dq=Biodiversity+in+the+green+economy&ots=9knswi-_GE&sig=ghZNPGf_13iYB9kORVldDpEd5Bw&redir_esc=y#v=onepage&q=Biodiversity%20in%20the%20green%20economy&f=false (accessed on 27 February 2020).

- Borel-Saladin, J.M.; Turok, I.N. The Green Economy: Incremental Change or Transformation?: The Green Economy: Incremental Change or Transformation? Env. Pol. Gov. 2013, 23, 209–220. [Google Scholar] [CrossRef]

- Cudlinova, E.; Sobrinho, V.G.; Lapka, M.; Salvati, L. New Forms of Land Grabbing Due to the Bioeconomy: The Case of Brazil. Sustainability 2020, 12, 3395. [Google Scholar] [CrossRef]

- Fercoq, A.; Lamouri, S.; Carbone, V. Lean/Green integration focused on waste reduction techniques. J. Clean. Prod. 2016, 137, 567–578. [Google Scholar] [CrossRef]

- Wen, Z.; Wang, Y.; De Clercq, D. What is the true value of food waste? A case study of technology integration in urban food waste treatment in Suzhou City, China. J. Clean. Prod. 2016, 118, 88–96. [Google Scholar] [CrossRef]

- Tisserant, A.; Pauliuk, S.; Merciai, S.; Schmidt, J.; Fry, J.; Wood, R.; Tukker, A. Solid Waste and the Circular Economy: A Global Analysis of Waste Treatment and Waste Footprints: Global Analysis of Solid Waste and Waste Footprint. J. Ind. Ecol. 2017, 21, 628–640. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Lehr, U.; Lutz, C.; Edler, D. Green jobs? Economic impacts of renewable energy in Germany. Energy Policy 2012, 47, 358–364. [Google Scholar] [CrossRef]

- Hansmann, R.; Mieg, H.A.; Frischknecht, P. Principal sustainability components: Empirical analysis of synergies between the three pillars of sustainability. Int. J. Sustain. Dev. World Ecol. 2012, 19, 451–459. [Google Scholar] [CrossRef]

- Purvis, B.; Mao, Y.; Robinson, D. Three pillars of sustainability: In search of conceptual origins. Sustain. Sci. 2019, 14, 681–695. [Google Scholar] [CrossRef]

- Rodríguez-Serrano, I.; Caldés, N.; de la Rúa, C.; Lechón, Y. Assessing the three sustainability pillars through the Framework for Integrated Sustainability Assessment (FISA): Case study of a Solar Thermal Electricity project in Mexico. J. Clean. Prod. 2017, 149, 1127–1143. [Google Scholar] [CrossRef]

- Harazin, P.; Horváth, G. Relation between Environmental Accounting and Pillars of Sustainability. World Acad. Sci. Eng. Technol. 2011, 5, 6. [Google Scholar]

- Pojasek, R.B. Understanding sustainability: An organizational perspective. Environ. Qual. Manag. 2012, 21, 93–100. [Google Scholar] [CrossRef]

- Searcy, C. Corporate Sustainability Performance Measurement Systems: A Review and Research Agenda. J. Bus Ethics 2012, 107, 239–253. [Google Scholar] [CrossRef]

- Dyllick, T.; Hockerts, K. Beyond the business case for corporate sustainability. Bus. Strat. Env. 2002, 11, 130–141. [Google Scholar] [CrossRef]

- Linnenluecke, M.K.; Griffiths, A. Corporate sustainability and organizational culture. J. World Bus. 2010, 45, 357–366. [Google Scholar] [CrossRef]

- Baumgartner, R.J.; Ebner, D. Corporate sustainability strategies: Sustainability profiles and maturity levels. Sust. Dev. 2010, 18, 76–89. [Google Scholar] [CrossRef]

- Petticrew, M.; Roberts, H. Systematic Reviews in the Social Sciences. A Practical Guide; Blackwell Publishing: Oxford, UK, 2006. [Google Scholar]

- Pai, M.; McCulloch, M.; Gorman, J.D.; Pai, N.; Enanoria, W.; Kennedy, G.; Tharyan, P.; Colford, J.M., Jr. Systematic reviews and meta-analyses: An illustrated, step-by-step guide. Clin. Res. Methods 2004, 17, 86–95. [Google Scholar]

- Aromataris, E.; Ritano, D. Constructing a Search Strategy and Searching for Evidence. A guide to the literature search for a systematic review. Am. J. Nurs. 2014, 114, 49–56. [Google Scholar] [CrossRef] [PubMed]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Van Eck, N.J.; Waltman, L. Visualizing bibliometric networks. In Measuring Scholarly Impact: Methods and Practice; Ding, Y., Rousseau, R., Wolfram, D., Eds.; Springer: Berlin, Germany, 2014; pp. 285–320. [Google Scholar]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Group, T.P. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef]

- Hooper, L.; Bartlett, C.; Davey Smith, G.; Ebrahim, S. Reduced dietary salt for prevention of cardiovascular disease (Cochrane Review). In The Cochrane Library (Issue 1); Update Softwar: Oxford, UK, 2003. [Google Scholar]

- Letts, L.; Wilkins, S.; Law, M.; Stewart, D.; Bosch, J.; Westmorland, M. Guidelines for critical review form: Qualitative studies (version 2.0). McMaster Univ. Occup. Ther. Evid. -Based Pract. Res. Group 2007, 31, 1–12. [Google Scholar]

- Gaur, A.; Kumar, M. A systematic approach to conducting review studies: An assessment of content analysis in 25years of IB research. J. World Bus. 2018, 53, 280–289. [Google Scholar] [CrossRef]

- Cabot, M.I.; Luque, A.; De Las Heras, A.; Aguayo, F. Aspects of sustainability and design engineering for the production of interconnected smart food packaging. PLoS ONE 2019, 14. [Google Scholar] [CrossRef]

- He, X.; Zi, Y.L.; Yu, H.; Zhang, S.L.; Wang, J.; Ding, W.B.; Zou, H.Y.; Zhang, W.; Lu, C.H.; Wang, Z.L. An ultrathin paper-based self-powered system for portable electronics and wireless human-machine interaction. Nano Energy 2017, 39, 328–336. [Google Scholar] [CrossRef]

- Van der Velden, N.M.; Kuusk, K.; Kohler, A.R. Life cycle assessment and eco-design of smart textiles: The importance of material selection demonstrated through e-textile product redesign. Mater. Des. 2015, 84, 313–324. [Google Scholar] [CrossRef]

- Park, K.T.; Im, S.J.; Kang, Y.S.; Noh, S.D.; Kang, Y.T.; Yang, S.G. Service-oriented platform for smart operation of dyeing and finishing industry. Int. J. Comput. Integr. Manuf. 2019, 32, 307–326. [Google Scholar] [CrossRef]

- Park, K.T.; Kang, Y.T.; Yang, S.G.; Zhao, W.B.; Kang, Y.S.; Im, S.J.; Kim, D.H.; Choi, S.Y.; Noh, S.D. Cyber Physical Energy System for Saving Energy of the Dyeing Process with Industrial Internet of Things and Manufacturing Big Data. Int. J. Precis Eng. Manuf-Green Technol. 2020, 7, 219–238. [Google Scholar] [CrossRef]

- Rajabion, L.; Khorraminia, M.; Andjomshoaa, A.; Ghafouri-Azar, M.; Molavi, H. A new model for assessing the impact of the urban intelligent transportation system, farmers’ knowledge and business processes on the success of green supply chain management system for urban distribution of agricultural products. J. Retail. Consum. Serv. 2019, 50, 154–162. [Google Scholar] [CrossRef]

- Manupati, V.K.; Schoenherr, T.; Ramkumar, M.; Wagner, S.M.; Pabba, S.K.; Singh, R.I.R. A blockchain-based approach for a multi-echelon sustainable supply chain. Int. J. Prod. Res. 2020, 58, 2222–2241. [Google Scholar] [CrossRef]

- Pervin, N.; Ramasubbu, N.; Dutta, K. Habitat Traps in Mobile Platform Ecosystems. Prod. Oper. Manag. 2019, 28, 2594–2608. [Google Scholar] [CrossRef]

- Wan, N.; Li, L.; Ye, C.M.; Wang, B. Risk Assessment in Intelligent Manufacturing Process: A Case Study of an Optical Cable Automatic Arranging Robot. IEEE Access 2019, 7, 105892–105901. [Google Scholar] [CrossRef]

- de Leonardo, L.; Zoppi, M.; Xiong, L.; Zlatanov, D.; Molfino, R.M. SwarmItFIX: A multi-robot-based reconfigurable fixture. Ind. Robot 2013, 40, 320–328. [Google Scholar] [CrossRef]

- Khaksar, E.; Abbasnejad, T.; Esmaeili, A.; Tamosaitiene, J. The effect of green supply chain management practices on environmental performance and competitive advantage: A case study of the cement industry. Technol. Econ. Dev. Econ. 2016, 22, 293–308. [Google Scholar] [CrossRef]

- Soltysik, M.; Urbaniec, M.; Wojnarowska, M. Innovation for Sustainable Entrepreneurship: Empirical Evidence from the Bioeconomy Sector in Poland. Adm. Sci. 2019, 9, 50. [Google Scholar] [CrossRef]

- Ma, X.L.; Wang, J.; Bai, Q.G.; Wang, S.Y. Optimization of a three-echelon cold chain considering freshness-keeping efforts under cap-and-trade regulation in Industry 4.0. Int. J. Prod. Econ. 2020, 220. [Google Scholar] [CrossRef]

- Adamatzky, A.; Ayres, P.; Belotti, G.; Wosten, H. Fungal Architecture Position Paper. Int. J. Unconv. Comput. 2019, 14, 397–411. [Google Scholar]

- Iuorio, O.; Wallace, A.; Simpson, K. Prefabs in the North of England: Technological, Environmental and Social Innovations. Sustainability 2019, 11, 3884. [Google Scholar] [CrossRef]

- Braccini, A.M.; Margherita, E.G. Exploring Organizational Sustainability of Industry 4.0 under the Triple Bottom Line: The Case of a Manufacturing Company. Sustainability 2019, 11, 36. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour. Conserv. Recycl. 2020, 153. [Google Scholar] [CrossRef]

- Chiarini, A.; Belvedere, V.; Grando, A. Industry 4.0 strategies and technological developments. An exploratory research from Italian manufacturing companies. Prod. Plan. Control 2020. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and lean manufacturing practices for sustainable organisational performance in Indian manufacturing companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Ali, S.M.; Kusi-Sarpong, S.; Shaikh, M.A.A. Assessing challenges for implementing Industry 4.0: Implications for process safety and environmental protection. Process Saf. Environ. Prot. 2018, 117, 730–741. [Google Scholar] [CrossRef]

- Muller, J.M.; Kiel, D.; Voigt, K.I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Saudi, M.H.M.; Sinaga, O.; Roespinoedji, D.; Razimi, M.S.A. Environmental sustainability in the fourth industrial revolution: The nexus between green product and green process innovation. Int. J. Energy Econ. Policy 2019, 9, 363–370. [Google Scholar] [CrossRef]

- Munodawafa, R.T.; Johl, S.K. Big Data Analytics Capabilities and Eco-Innovation: A Study of Energy Companies. Sustainability 2019, 11, 4254. [Google Scholar] [CrossRef]

- Thomas, A.; Haven-Tang, C.; Barton, R.; Mason-Jones, R.; Francis, M.; Byard, P. Smart Systems Implementation in UK Food Manufacturing Companies: A Sustainability Perspective. Sustainability 2018, 10, 4693. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lona, L.R.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Gupta, S.; Meissonier, R.; Drave, V.A.; Roubaud, D. Examining the impact of Cloud ERP on sustainable performance: A dynamic capability view. Int. J. Inf. Manag. 2020, 51. [Google Scholar] [CrossRef]

- Jena, M.C.; Mishra, S.K.; Moharana, H.S. Application of Industry 4.0 to enhance sustainable manufacturing. Environ. Prog. Sustain. Energy 2020, 39. [Google Scholar] [CrossRef]

- Raut, R.D.; Mangla, S.K.; Narwane, V.S.; Gardas, B.B.; Priyadarshinee, P.; Narkhede, B.E. Linking big data analytics and operational sustainability practices for sustainable business management. J. Clean Prod. 2019, 224, 10–24. [Google Scholar] [CrossRef]

- Tsai, W.H.; Lu, Y.H. A Framework of Production Planning and Control with Carbon Tax under Industry 4.0. Sustainability 2018, 10, 3221. [Google Scholar] [CrossRef]

- Zhang, W.J.; Gu, F.; Guo, J.F. Can smart factories bring environmental benefits to their products?: A case study of household refrigerators. J. Ind. Ecol. 2019, 23, 1381–1395. [Google Scholar] [CrossRef]

- Banyai, A.; Illes, B.; Glistau, E.; Machado, N.I.C.; Tamas, P.; Manzoor, F.; Banyai, T. Smart Cyber-Physical Manufacturing: Extended and Real-Time Optimization of Logistics Resources in Matrix Production. Appl. Sci. Basel 2019, 9, 1287. [Google Scholar] [CrossRef]

- Martin-Gomez, A.; Aguayo-Gonzalez, F.; Luque, A. A holonic framework for managing the sustainable supply chain in emerging economies with smart connected metabolism. Resour. Conserv. Recycl. 2019, 141, 219–232. [Google Scholar] [CrossRef]

- Senechal, O.; Trentesaux, D. A framework to help decision makers to be environmentally aware during the maintenance of cyber physical systems. Environ. Impact Assess. Rev. 2019, 77, 11–22. [Google Scholar] [CrossRef]

- Kannan, K.; Arunachalam, N. A Digital Twin for Grinding Wheel: An Information Sharing Platform for Sustainable Grinding Process. J. Manuf. Sci. Eng. Trans. ASME 2019, 141. [Google Scholar] [CrossRef]

- Garcia-Muiña, F.E.; González-Sánchez, R.; Ferrari, A.M.; Settembre-Blundo, D. The paradigms of Industry 4.0 and circular economy as enabling drivers for the competitiveness of businesses and territories: The case of an Italian ceramic tiles manufacturing company. Soc. Sci. 2018, 7, 255. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Swami, S. Diffusion of green products in industry 4.0: Reverse logistics issues during design of inventory and production planning system. Int. J. Prod. Econ. 2019. [Google Scholar] [CrossRef]

- Garcia-Muiña, F.E.; González-Sánchez, R.; Ferrari, A.M.; Volpi, L.; Pini, M.; Siligardi, C.; Settembre-Blundo, D. Identifying the equilibrium point between sustainability goals and circular economy practices in an Industry 4.0 manufacturing context using eco-design. Soc. Sci. 2019, 8, 241. [Google Scholar] [CrossRef]

- Garrido-Hidalgo, C.; Hortelano, D.; Roda-Sanchez, L.; Olivares, T.; Ruiz, M.C.; Lopez, V. IoT Heterogeneous Mesh Network Deployment for Human-in-the-Loop Challenges Towards a Social and Sustainable Industry 4.0. IEEE Access 2018, 6, 28417–28437. [Google Scholar] [CrossRef]

- Muller, J.M.; Voigt, K.I. Sustainable Industrial Value Creation in SMEs: A Comparison between Industry 4.0 and Made in China 2025. Int. J. Precis Eng. Manuf. Green Technol. 2018, 5, 659–670. [Google Scholar] [CrossRef]

- Tozanli, O.; Kongar, E.; Gupta, S.M. Trade-in-to-upgrade as a marketing strategy in disassembly-to-order systems at the edge of blockchain technology. Int. J. Prod. Res. 2020. [Google Scholar] [CrossRef]

- Santos, J.; Munoz-Villamizar, A.; Ormazabal, M.; Viles, E. Using problem-oriented monitoring to simultaneously improve productivity and environmental performance in manufacturing companies. Int. J. Comput. Integr. Manuf. 2019, 32, 183–193. [Google Scholar] [CrossRef]

- Yazdi, P.G.; Azizi, A.; Hashemipour, M. An Empirical Investigation of the Relationship between Overall Equipment Efficiency (OEE) and Manufacturing Sustainability in Industry 4.0 with Time Study Approach. Sustainability 2018, 10, 3031. [Google Scholar] [CrossRef]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Ham, D.J.; Lee, J.S. Transition Metal Carbides and Nitrides as Electrode Materials for Low Temperature Fuel Cells. Energies 2009, 2, 873–899. [Google Scholar] [CrossRef]

- Yao, E.; Wang, H.; Liu, L.; Xi, G. A Novel Constant-Pressure Pumped Hydro Combined with Compressed Air Energy Storage System. Energies 2015, 8, 154–171. [Google Scholar] [CrossRef]

- Blaabjerg, F.; Teodorescu, R.; Liserre, M.; Timbus, A.V. Overview of Control and Grid Synchronization for Distributed Power Generation Systems. IEEE Trans. Ind. Electron. 2006, 53, 1398–1409. [Google Scholar] [CrossRef]

- Klein, A.; Körber, C.; Wachau, A.; Säuberlich, F.; Gassenbauer, Y.; Harvey, S.P.; Proffit, D.E.; Mason, T.O. Transparent Conducting Oxides for Photovoltaics: Manipulation of Fermi Level, Work Function and Energy Band Alignment. Materials 2010, 3, 4892–4914. [Google Scholar] [CrossRef]

- Jacobson, M.Z.; Delucchi, M.A. Providing all global energy with wind, water, and solar power, Part I: Technologies, energy resources, quantities and areas of infrastructure, and materials. Energy Policy 2011, 39, 1154–1169. [Google Scholar] [CrossRef]

- Zsembinszki, G.; Solé, A.; Barreneche, C.; Prieto, C.; Fernández, A.I.; Cabeza, L.F. Review of Reactors with Potential Use in Thermochemical Energy Storage in Concentrated Solar Power Plants. Energies 2018, 11, 2358. [Google Scholar] [CrossRef]

- Larcher, D.; Tarascon, J.-M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015, 7, 19–29. [Google Scholar] [CrossRef]

- Biswas, K.; He, J.; Blum, I.D.; Wu, C.-I.; Hogan, T.P.; Seidman, D.N.; Dravid, V.P.; Kanatzidis, M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 2012, 489, 414–418. [Google Scholar] [CrossRef]

- Oksa, M.; Turunen, E.; Suhonen, T.; Varis, T.; Hannula, S.-P. Optimization and Characterization of High Velocity Oxy-fuel Sprayed Coatings: Techniques, Materials, and Applications. Coatings 2011, 1, 17–52. [Google Scholar] [CrossRef]

- Goodenough, J.B.; Huang, Y.-H. Alternative anode materials for solid oxide fuel cells. J. Power Sources 2007, 173, 1–10. [Google Scholar] [CrossRef]

- Subudhi, B.; Pradhan, R. A Comparative Study on Maximum Power Point Tracking Techniques for Photovoltaic Power Systems. IEEE Trans. Sustain. Energy 2013, 4, 89–98. [Google Scholar] [CrossRef]

- Berardi, U.; Tronchin, L.; Manfren, M.; Nastasi, B. On the Effects of Variation of Thermal Conductivity in Buildings in the Italian Construction Sector. Energies 2018, 11, 872. [Google Scholar] [CrossRef]

- Wolch, J.R.; Byrne, J.; Newell, J.P. Urban green space, public health, and environmental justice: The challenge of making cities ‘just green enough’. Landsc. Urban Plan. 2014, 125, 234–244. [Google Scholar] [CrossRef]

- Darwish, A.; Hassanien, A.E. Wearable and Implantable Wireless Sensor Network Solutions for Healthcare Monitoring. Sensors 2011, 11, 5561–5595. [Google Scholar] [CrossRef]

- Schefer, R.W.; Wicksall, D.M.; Agrawal, A.K. Combustion of hydrogen-enriched methane in a lean premixed swirl-stabilized burner. Proc. Combust. Inst. 2002, 29, 843–851. [Google Scholar] [CrossRef]

- Chemat, F.; Vian, M.A.; Cravotto, G. Green Extraction of Natural Products: Concept and Principles. Int. J. Mol. Sci. 2012, 13, 8615–8627. [Google Scholar] [CrossRef]

- Van Oost, G.; Hrabovsky, M.; Kopecky, V.; Konrad, M.; Hlina, M.; Kavka, T. Pyrolysis/gasification of biomass for synthetic fuel production using a hybrid gas–water stabilized plasma torch. Vacuum 2008, 83, 209–212. [Google Scholar] [CrossRef]

- Cantrell, K.B.; Ducey, T.; Ro, K.S.; Hunt, P.G. Livestock waste-to-bioenergy generation opportunities. Bioresour. Technol. 2008, 99, 7941–7953. [Google Scholar] [CrossRef]

- Clough, T.J.; Condron, L.M.; Kammann, C.; Müller, C. A Review of Biochar and Soil Nitrogen Dynamics. Agronomy 2013, 3, 275–293. [Google Scholar] [CrossRef]

- Zhang, Q.; Uchaker, E.; Candelaria, S.L.; Cao, G. Nanomaterials for energy conversion and storage. Chem. Soc. Rev. 2013, 42, 3127. [Google Scholar] [CrossRef]

- Barber, P.; Balasubramanian, S.; Anguchamy, Y.; Gong, S.; Wibowo, A.; Gao, H.; Ploehn, H.J.; Zur Loye, H.-C. Polymer Composite and Nanocomposite Dielectric Materials for Pulse Power Energy Storage. Materials 2009, 2, 1697–1733. [Google Scholar] [CrossRef]

- Jawad, A.M.; Nordin, R.; Gharghan, S.K.; Jawad, H.M.; Ismail, M. Opportunities and Challenges for Near-Field Wireless Power Transfer: A Review. Energies 2017, 10, 1022. [Google Scholar] [CrossRef]

- Nitta, N.; Wu, F.; Lee, J.T.; Yushin, G. Li-ion battery materials: Present and future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. A Comprehensive Review of Thermal Energy Storage. Sustainability 2018, 10, 191. [Google Scholar] [CrossRef]

- Dupont, J.; de Souza, R.F.; Suarez, P.A.Z. Ionic Liquid (Molten Salt) Phase Organometallic Catalysis. Chem. Rev. 2002, 102, 3667–3692. [Google Scholar] [CrossRef] [PubMed]

- Krames, M.R.; Shchekin, O.B.; Mueller-Mach, R.; Mueller, G.O.; Zhou, L.; Harbers, G.; Craford, M.G. Status and Future of High-Power Light-Emitting Diodes for Solid-State Lighting. J. Disp. Technol. 2007, 3, 160–175. [Google Scholar] [CrossRef]

- Stillwell, A.S.; Hoppock, D.C.; Webber, M.E. Energy Recovery from Wastewater Treatment Plants in the United States: A Case Study of the Energy-Water Nexus. Sustainability 2010, 2, 945–962. [Google Scholar] [CrossRef]

- Forrest, S.R. The path to ubiquitous and low-cost organic electronic appliances on plastic. Nature 2004, 428, 911–918. [Google Scholar] [CrossRef]

- Lobaccaro, G.; Carlucci, S.; Löfström, E. A Review of Systems and Technologies for Smart Homes and Smart Grids. Energies 2016, 9, 348. [Google Scholar] [CrossRef]

- Lee, S.-H.; Hwang, J.Y.; Kang, K.; Kang, H. Fabrication of organic light emitting display using inkjet printing technology. In Proceedings of the 2009 International Symposium on Optomechatronic Technologies; IEEE: Istanbul, Turkey, 2009; pp. 71–76. [Google Scholar]

- Hein, J.R.; Mizell, K.; Koschinsky, A.; Conrad, T.A. Deep-ocean mineral deposits as a source of critical metals for high- and green-technology applications: Comparison with land-based resources. Ore Geol. Rev. 2013, 51, 1–14. [Google Scholar] [CrossRef]

- Shen, B. Sustainable Fashion Supply Chain: Lessons from H&M. Sustainability 2014, 6, 6236–6249. [Google Scholar] [CrossRef]

- Ansari, S.A.; Khan, M.M.; Ansari, M.O.; Lee, J.; Cho, M.H. Biogenic Synthesis, Photocatalytic, and Photoelectrochemical Performance of Ag–ZnO Nanocomposite. J. Phys. Chem. C 2013, 117, 27023–27030. [Google Scholar] [CrossRef]

- Benedetti, M.; Bonfà, F.; Introna, V.; Santolamazza, A.; Ubertini, S. Real Time Energy Performance Control for Industrial Compressed Air Systems: Methodology and Applications. Energies 2019, 12, 3935. [Google Scholar] [CrossRef]

- Sun, Y.-Z.; Lin, J.; Song, Y.-H.; Xu, J.; Li, X.-M.; Dong, J.-X. An Industrial System Powered by Wind and Coal for Aluminum Production: A Case Study of Technical Demonstration and Economic Feasibility. Energies 2012, 5, 4844–4869. [Google Scholar] [CrossRef]

- Dudgeon, D.; Arthington, A.H.; Gessner, M.O.; Kawabata, Z.-I.; Knowler, D.J.; Lévêque, C.; Naiman, R.J.; Prieur-Richard, A.-H.; Soto, D.; Stiassny, M.L.J.; et al. Freshwater biodiversity: Importance, threats, status and conservation challenges. Biol. Rev. 2006, 81, 163. [Google Scholar] [CrossRef]

- Virto, I.; Imaz, M.J.; Fernández-Ugalde, O.; Gartzia-Bengoetxea, N.; Enrique, A.; Bescansa, P. Soil Degradation and Soil Quality in Western Europe: Current Situation and Future Perspectives. Sustainability 2015, 7, 313–365. [Google Scholar] [CrossRef]

- Jang, W.-D.; Kamruzzaman Selim, K.M.; Lee, C.-H.; Kang, I.-K. Bioinspired application of dendrimers: From bio-mimicry to biomedical applications. Prog. Polym. Sci. 2009, 34, 1–23. [Google Scholar] [CrossRef]

- Ho, H.-L.; Huang, R.; Hwang, L.-C.; Lin, W.-T.; Hsu, H.-M. Waste-Based Pervious Concrete for Climate-Resilient Pavements. Materials 2018, 11, 900. [Google Scholar] [CrossRef]

- Wei, D. Dye Sensitized Solar Cells. Int. J. Mol. Sci. 2010, 11, 1103–1113. [Google Scholar] [CrossRef]

- Huang, K.; Guo, J.; Xu, Z. Recycling of waste printed circuit boards: A review of current technologies and treatment status in China. J. Hazard. Mater. 2009, 164, 399–408. [Google Scholar] [CrossRef]

- Koo, B.-M.; Kim, J.-H.J.; Kim, S.-B.; Mun, S. Material and Structural Performance Evaluations of Hwangtoh Admixtures and Recycled PET Fiber-Added Eco-Friendly Concrete for CO2 Emission Reduction. Materials 2014, 7, 5959–5981. [Google Scholar] [CrossRef]

- Kumar, A.; Holuszko, M. Electronic Waste and Existing Processing Routes: A Canadian Perspective. Resources 2016, 5, 35. [Google Scholar] [CrossRef]

- Fu, F.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef]

- Wang, S.; Hao, J. Air quality management in China: Issues, challenges, and options. J. Environ. Sci. 2012, 24, 2–13. [Google Scholar] [CrossRef]

- Missimer, T.M.; Teaf, C.M.; Beeson, W.T.; Maliva, R.G.; Woolschlager, J.; Covert, D.J. Natural Background and Anthropogenic Arsenic Enrichment in Florida Soils, Surface Water, and Groundwater: A Review with a Discussion on Public Health Risk. Int. J. Environ. Res. Public Health 2018, 15, 2278. [Google Scholar] [CrossRef]

- Vasques, C.M.A.; Dias Rodrigues, J. Active vibration control of smart piezoelectric beams: Comparison of classical and optimal feedback control strategies. Comput. Struct. 2006, 84, 1402–1414. [Google Scholar] [CrossRef]

- Vymazal, J. Constructed Wetlands for Wastewater Treatment. Water 2010, 2, 530–549. [Google Scholar] [CrossRef]

- Keesstra, S.; Mol, G.; De Leeuw, J.; Okx, J.; Molenaar, C.; De Cleen, M.; Visser, S. Soil-Related Sustainable Development Goals: Four Concepts to Make Land Degradation Neutrality and Restoration Work. Land 2018, 7, 133. [Google Scholar] [CrossRef]

- Myers, N.; Mittermeier, R.A.; Mittermeier, C.G.; da Fonseca, G.A.B.; Kent, J. Biodiversity hotspots for conservation priorities. Nature 2000, 403, 853–858. [Google Scholar] [CrossRef] [PubMed]

- Odermatt, D.; Heege, T.; Nieke, J.; Kneubühler, M.; Itten, K. Water Quality Monitoring for Lake Constance with a Physically Based Algorithm for MERIS Data. Sensors 2008, 8, 4582–4599. [Google Scholar] [CrossRef] [PubMed]

- Jakeman, A.J.; Letcher, R.A.; Norton, J.P. Ten iterative steps in development and evaluation of environmental models. Environ. Model. Softw. 2006, 21, 602–614. [Google Scholar] [CrossRef]

- Schmidt, M.; Pringle, M.; Devadas, R.; Denham, R.; Tindall, D. A Framework for Large-Area Mapping of Past and Present Cropping Activity Using Seasonal Landsat Images and Time Series Metrics. Remote Sens. 2016, 8, 312. [Google Scholar] [CrossRef]

- Miura, T.; Yoshioka, H.; Fujiwara, K.; Yamamoto, H. Inter-Comparison of ASTER and MODIS Surface Reflectance and Vegetation Index Products for Synergistic Applications to Natural Resource Monitoring. Sensors 2008, 8, 2480–2499. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, S.; Pressey, R.L.; Faith, D.P.; Margules, C.R.; Fuller, T.; Stoms, D.M.; Moffett, A.; Wilson, K.A.; Williams, K.J.; Williams, P.H.; et al. Biodiversity Conservation Planning Tools: Present Status and Challenges for the Future. Annu. Rev. Environ. Resour. 2006, 31, 123–159. [Google Scholar] [CrossRef]

- Radu, L.-D. Determinants of Green ICT Adoption in Organizations: A Theoretical Perspective. Sustainability 2016, 8, 731. [Google Scholar] [CrossRef]

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen Fuel Cell Vehicles; Current Status and Future Prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- Xing, Y.; Ma, E.W.M.; Tsui, K.L.; Pecht, M. Battery Management Systems in Electric and Hybrid Vehicles. Energies 2011, 4, 1840–1857. [Google Scholar] [CrossRef]

- Debe, M.K. Electrocatalyst approaches and challenges for automotive fuel cells. Nature 2012, 486, 43–51. [Google Scholar] [CrossRef]

- Andreasen, J.G.; Meroni, A.; Haglind, F. A Comparison of Organic and Steam Rankine Cycle Power Systems for Waste Heat Recovery on Large Ships. Energies 2017, 10, 547. [Google Scholar] [CrossRef]

- Greenblatt, J.B.; Saxena, S. Autonomous taxis could greatly reduce greenhouse-gas emissions of US light-duty vehicles. Nat. Clim. Chang. 2015, 5, 860–863. [Google Scholar] [CrossRef]

- Rahman, R.O.A.; Ibrahium, H.A.; Hung, Y.-T. Liquid Radioactive Wastes Treatment: A Review. Water 2011, 3, 551–565. [Google Scholar] [CrossRef]

- Álvarez-Ayuso, E.; Querol, X.; Plana, F.; Alastuey, A.; Moreno, N.; Izquierdo, M.; Font, O.; Moreno, T.; Diez, S.; Vázquez, E.; et al. Environmental, physical and structural characterisation of geopolymer matrixes synthesised from coal (co-)combustion fly ashes. J. Hazard. Mater. 2008, 154, 175–183. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Guo, Q.; Li, L.; Jiang, P.; Jiao, Y.; Cheng, Y. Reuse of Boron Waste as an Additive in Road Base Material. Materials 2016, 9, 416. [Google Scholar] [CrossRef]

- Lay, J.-J.; Lee, Y.-J.; Noike, T. Feasibility of biological hydrogen production from organic fraction of municipal solid waste. Water Res. 1999, 33, 2579–2586. [Google Scholar] [CrossRef]

- Zhang, Y.; Kusch-Brandt, S.; Gu, S.; Heaven, S. Particle Size Distribution in Municipal Solid Waste Pre-Treated for Bioprocessing. Resources 2019, 8, 166. [Google Scholar] [CrossRef]

- Muñoz, R.; Guieysse, B. Algal–bacterial processes for the treatment of hazardous contaminants: A review. Water Res. 2006, 40, 2799–2815. [Google Scholar] [CrossRef]

- Thomas, S.C.; Martin, A.R. Carbon Content of Tree Tissues: A Synthesis. Forests 2012, 3, 332–352. [Google Scholar] [CrossRef]

- D’Orazio, J.; Jarrett, S.; Amaro-Ortiz, A.; Scott, T. UV Radiation and the Skin. Int. J. Mol. Sci. 2013, 14, 12222–12248. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and recovery routes of plastic solid waste (PSW): A review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef] [PubMed]

- Besar, N.A.; Suardi, H.; Phua, M.-H.; James, D.; Mokhtar, M.B.; Ahmed, M.F. Carbon Stock and Sequestration Potential of an Agroforestry System in Sabah, Malaysia. Forests 2020, 11, 210. [Google Scholar] [CrossRef]

- Yang, S.-Q.; Liu, P.-W. Strategy of water pollution prevention in Taihu Lake and its effects analysis. J. Great Lakes Res. 2010, 36, 150–158. [Google Scholar] [CrossRef]

- Dai, J.; Mumper, R.J. Plant Phenolics: Extraction, Analysis and Their Antioxidant and Anticancer Properties. Molecules 2010, 15, 7313–7352. [Google Scholar] [CrossRef] [PubMed]

- Silva, R.D.C.F.S.; Almeida, D.G.; Rufino, R.D.; Luna, J.M.; Santos, V.A.; Sarubbo, L.A. Applications of Biosurfactants in the Petroleum Industry and the Remediation of Oil Spills. Int. J. Mol. Sci. 2014, 15, 12523–12542. [Google Scholar] [CrossRef]

- Kuhl, K.P.; Cave, E.R.; Abram, D.N.; Jaramillo, T.F. New insights into the electrochemical reduction of carbon dioxide on metallic copper surfaces. Energy Environ. Sci. 2012, 5, 7050. [Google Scholar] [CrossRef]

- Bouaddi, S.; Fernández-García, A.; Sansom, C.; Sarasua, J.A.; Wolfertstetter, F.; Bouzekri, H.; Sutter, F.; Azpitarte, I. A Review of Conventional and Innovative- Sustainable Methods for Cleaning Reflectors in Concentrating Solar Power Plants. Sustainability 2018, 10, 3937. [Google Scholar] [CrossRef]

- Fang, P.; Tang, Z.; Chen, X.; Zhong, P.; Huang, J.; Tang, Z.; Cen, C. Simultaneous Removal of NOx and SO2 through a Simple Process Using a Composite Absorbent. Sustainability 2018, 10, 4350. [Google Scholar] [CrossRef]

- Ai, S.; Dong, S.; Nie, Z.; Zhu, S.; Ren, Q.; Bian, D. Study on Aeration Optimization and Sewage Treatment Efficiency of a Novel Micro-Pressure Swirl Reactor (MPSR). Water 2020, 12, 890. [Google Scholar] [CrossRef]

- Jin, Y.; Andersson, H.; Zhang, S. Air Pollution Control Policies in China: A Retrospective and Prospects. Int. J. Environ. Res. Public Health 2016, 13, 1219. [Google Scholar] [CrossRef]

- Israel, B.A.; Parker, E.A.; Rowe, Z.; Salvatore, A.; Minkler, M.; López, J.; Butz, A.; Mosley, A.; Coates, L.; Lambert, G.; et al. Community-Based Participatory Research: Lessons Learned from the Centers for Children’s Environmental Health and Disease Prevention Research. Environ. Health Perspect. 2005, 113, 1463–1471. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.; Shen, C.; Zheng, S.; Yang, W.; Hu, H.; Liu, J.; Shi, J. Transformation of CuO Nanoparticles in the Aquatic Environment: Influence of pH, Electrolytes and Natural Organic Matter. Nanomaterials 2017, 7, 326. [Google Scholar] [CrossRef] [PubMed]

- Joseph, P.; Tretsiakova-McNally, S. Sustainable Non-Metallic Building Materials. Sustainability 2010, 2, 400–427. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Peters, G.P. Carbon Footprint of Nations: A Global, Trade-Linked Analysis. Environ. Sci. Technol. 2009, 43, 6414–6420. [Google Scholar] [CrossRef]

- Martin, E.; Shaheen, S. The Impact of Carsharing on Public Transit and Non-Motorized Travel: An Exploration of North American Carsharing Survey Data. Energies 2011, 4, 2094–2114. [Google Scholar] [CrossRef]

- Harris, N.; Shealy, T.; Klotz, L. Choice Architecture as a Way to Encourage a Whole Systems Design Perspective for More Sustainable Infrastructure. Sustainability 2017, 9, 54. [Google Scholar] [CrossRef]

- Giovanis, E. The relationship between teleworking, traffic and air pollution. Atmos. Pollut. Res. 2018, 9, 1–14. [Google Scholar] [CrossRef]

- He, L.; Zhang, L.; Zhong, Z.; Wang, D.; Wang, F. Green credit, renewable energy investment and green economy development: Empirical analysis based on 150 listed companies of China. J. Clean. Prod. 2019, 208, 363–372. [Google Scholar] [CrossRef]

- Zhang, J.; Smith, K.R. Household Air Pollution from Coal and Biomass Fuels in China: Measurements, Health Impacts, and Interventions. Environ. Health Perspect. 2007, 115, 848–855. [Google Scholar] [CrossRef]

- Chung, P.-R.; Tzeng, C.-T.; Ke, M.-T.; Lee, C.-Y. Formaldehyde Gas Sensors: A Review. Sensors 2013, 13, 4468–4484. [Google Scholar] [CrossRef]

- Verlicchi, P.; Al Aukidy, M.; Zambello, E. Occurrence of pharmaceutical compounds in urban wastewater: Removal, mass load and environmental risk after a secondary treatment—A review. Sci. Total Environ. 2012, 429, 123–155. [Google Scholar] [CrossRef]

- Fedson, D.S. Preparing for Pandemic Vaccination: An International Policy Agenda for Vaccine Development. J. Public Health Pol. 2005, 26, 4–29. [Google Scholar] [CrossRef]

- Thanan, R.; Oikawa, S.; Hiraku, Y.; Ohnishi, S.; Ma, N.; Pinlaor, S.; Yongvanit, P.; Kawanishi, S.; Murata, M. Oxidative Stress and Its Significant Roles in Neurodegenerative Diseases and Cancer. Int. J. Mol. Sci. 2015, 16, 193–217. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Byrne, J.; Pickering, C. A systematic quantitative review of urban tree benefits, costs, and assessment methods across cities in different climatic zones. Urban For. Urban Green. 2012, 11, 351–363. [Google Scholar] [CrossRef]

- Ahmad, M.; Rajapaksha, A.U.; Lim, J.E.; Zhang, M.; Bolan, N.; Mohan, D.; Vithanage, M.; Lee, S.S.; Ok, Y.S. Biochar as a sorbent for contaminant management in soil and water: A review. Chemosphere 2014, 99, 19–33. [Google Scholar] [CrossRef] [PubMed]

- Monteny, G.-J.; Bannink, A.; Chadwick, D. Greenhouse gas abatement strategies for animal husbandry. Agric. Ecosyst. Environ. 2006, 112, 163–170. [Google Scholar] [CrossRef]

- Hashemi, M.; Karimi, H.A. A critical review of real-time map-matching algorithms: Current issues and future directions. Comput. Environ. Urban Syst. 2014, 48, 153–165. [Google Scholar] [CrossRef]

- Bailey-Serres, J.; Voesenek, L.A.C.J. Flooding Stress: Acclimations and Genetic Diversity. Annu. Rev. Plant Biol. 2008, 59, 313–339. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Espinoza, C.Z.; Khot, L.R.; Sankaran, S.; Jacoby, P.W. High Resolution Multispectral and Thermal Remote Sensing-Based Water Stress Assessment in Subsurface Irrigated Grapevines. Remote Sens. 2017, 9, 961. [Google Scholar] [CrossRef]

- Schar, C.M.; Onder, C.H.; Geering, H.P. Control of an SCR catalytic converter system for a mobile heavy-duty application. IEEE Trans. Contr. Syst. Technol. 2006, 14, 641–653. [Google Scholar] [CrossRef]

- Ndoye, B.; Sarr, M. Investigation on the Effect of Condensing Moisture before Heating Air on the Performance of a Batch Tray Dryer: Application to the Drying of Vanilla. Dry. Technol. 2006, 24, 1387–1396. [Google Scholar] [CrossRef]

- Hamid, S.A.; Alfonso, P.; Anticoi, H.; Guasch, E.; Oliva, J.; Dosbaba, M.; Garcia-Valles, M.; Chugunova, M. Quantitative Mineralogical Comparison between HPGR and Ball Mill Products of a Sn-Ta Ore. Minerals 2018, 8, 151. [Google Scholar] [CrossRef]

- Ferreira, A.; Fontaine, J.-G. Dynamic modeling and control of a conveyance microrobotic system using active friction drive. IEEE/ASME Trans. Mechatron. 2003, 8, 188–202. [Google Scholar] [CrossRef]

- Rodrigues, L.P.; De Holanda, J.N.F. Valorization of Municipal Waterworks Sludge to Produce Ceramic Floor Tiles. Recycling 2018, 3, 10. [Google Scholar] [CrossRef]

- Lin, M.-Y.; Khlystov, A. Investigation of Ultrafine Particle Deposition to Vegetation Branches in a Wind Tunnel. Aerosol Sci. Technol. 2012, 46, 465–472. [Google Scholar] [CrossRef]

- Khattri, S.K.; Log, T.; Kraaijeveld, A. Tunnel Fire Dynamics as a Function of Longitudinal Ventilation Air Oxygen Content. Sustainability 2019, 11, 203. [Google Scholar] [CrossRef]

- Srikhirin, P.; Aphornratana, S.; Chungpaibulpatana, S. A review of absorption refrigeration technologies. Renew. Sustain. Energy Rev. 2001, 5, 343–372. [Google Scholar] [CrossRef]

- Sarbu, I.; Sebarchievici, C. Performance Evaluation of Radiator and Radiant Floor Heating Systems for an Office Room Connected to a Ground-Coupled Heat Pump. Energies 2016, 9, 228. [Google Scholar] [CrossRef]

- Lundquist, J.D.; Loheide, S.P. How evaporative water losses vary between wet and dry water years as a function of elevation in the Sierra Nevada, California, and critical factors for modeling: Sierra et versus elevation. Water Resour. Res. 2011, 47. [Google Scholar] [CrossRef]

- Laadila, M.A.; Suresh, G.; Rouissi, T.; Kumar, P.; Brar, S.K.; Cheikh, R.B.; Abokitse, K.; Galvez, R.; Jacob, C. Biocomposite Fabrication from Enzymatically Treated Nanocellulosic Fibers and Recycled Polylactic Acid. Energies 2020, 13, 1003. [Google Scholar] [CrossRef]

- Nejati, M.; Dimitri, R.; Tornabene, F.; Hossein Yas, M. Thermal Buckling of Nanocomposite Stiffened Cylindrical Shells Reinforced by Functionally Graded Wavy Carbon Nanotubes with Temperature-Dependent Properties. Appl. Sci. 2017, 7, 1223. [Google Scholar] [CrossRef]

- Bert, V.; Allemon, J.; Sajet, P.; Dieu, S.; Papin, A.; Collet, S.; Gaucher, R.; Chalot, M.; Michiels, B.; Raventos, C. Torrefaction and pyrolysis of metal-enriched poplars from phytotechnologies: Effect of temperature and biomass chlorine content on metal distribution in end-products and valorization options. Biomass Bioenergy 2017, 96, 1–11. [Google Scholar] [CrossRef]

- Vu, B.; Chen, M.; Crawford, R.J.; Ivanova, E.P. Bacterial Extracellular Polysaccharides Involved in Biofilm Formation. Molecules 2009, 14, 2535–2554. [Google Scholar] [CrossRef] [PubMed]

- Balaji, S.; Gopi, K.; Muthuvelan, B. A review on production of poly β hydroxybutyrates from cyanobacteria for the production of bio plastics. Algal Res. 2013, 2, 278–285. [Google Scholar] [CrossRef]

- Voldsund, M.; Gardarsdottir, S.O.; De Lena, E.; Pérez-Calvo, J.-F.; Jamali, A.; Berstad, D.; Fu, C.; Romano, M.; Roussanaly, S.; Anantharaman, R.; et al. Comparison of Technologies for CO2 Capture from Cement Production—Part 1: Technical Evaluation. Energies 2019, 12, 559. [Google Scholar] [CrossRef]

- Peterson, A.A.; Vogel, F.; Lachance, R.P.; Fröling, M.; Antal, M.J., Jr.; Tester, J.W. Thermochemical biofuel production in hydrothermal media: A review of sub- and supercritical water technologies. Energy Environ. Sci. 2008, 1, 32. [Google Scholar] [CrossRef]

- Colindres, S.C.; Aguir, K.; Cervantes Sodi, F.; Vargas, L.V.; Salazar, J.A.M.; Febles, V.G. Ozone Sensing Based on Palladium Decorated Carbon Nanotubes. Sensors 2014, 14, 6806–6818. [Google Scholar] [CrossRef]

- Zhao, Y.; Park, R.-D.; Muzzarelli, R.A.A. Chitin Deacetylases: Properties and Applications. Mar. Drugs 2010, 8, 24–46. [Google Scholar] [CrossRef]

- Peterson, A.A.; Nørskov, J.K. Activity Descriptors for CO 2 Electroreduction to Methane on Transition-Metal Catalysts. J. Phys. Chem. Lett. 2012, 3, 251–258. [Google Scholar] [CrossRef]

- De Cazes, M.; Abejón, R.; Belleville, M.-P.; Sanchez-Marcano, J. Membrane Bioprocesses for Pharmaceutical Micropollutant Removal from Waters. Membranes 2014, 4, 692–729. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Onozuka, H.; Tsutsuminai, S.; Kondo, J.N.; Yokoi, T. Insight into the crystallization mechanism of the CON-type zeolite. Microporous Mesoporous Mater. 2020, 302, 110213. [Google Scholar] [CrossRef]

- Collivignarelli, M.C.; Abbà, A.; Benigna, I.; Sorlini, S.; Torretta, V. Overview of the Main Disinfection Processes for Wastewater and Drinking Water Treatment Plants. Sustainability 2018, 10, 86. [Google Scholar] [CrossRef]

- Jones, D.J.; Gibson, V.C.; Green, S.M.; Maddox, P.J.; White, A.J.P.; Williams, D.J. Discovery and Optimization of New Chromium Catalysts for Ethylene Oligomerization and Polymerization Aided by High-Throughput Screening. J. Am. Chem. Soc. 2005, 127, 11037–11046. [Google Scholar] [CrossRef] [PubMed]

- Nazir, M.T.; Butt, F.T.; Phung, B.T.; Yeoh, G.H.; Yasin, G.; Akram, S.; Bhutta, M.S.; Hussain, S.; Nguyen, T.A. Simulation and Experimental Investigation on Carbonized Tracking Failure of EPDM/BN-Based Electrical Insulation. Polymers 2020, 12, 582. [Google Scholar] [CrossRef]

- Laurienzo, P. Marine Polysaccharides in Pharmaceutical Applications: An Overview. Mar. Drugs 2010, 8, 2435–2465. [Google Scholar] [CrossRef]

- Neori, A.; Chopin, T.; Troell, M.; Buschmann, A.H.; Kraemer, G.P.; Halling, C.; Shpigel, M.; Yarish, C. Integrated aquaculture: Rationale, evolution and state of the art emphasizing seaweed biofiltration in modern mariculture. Aquaculture 2004, 231, 361–391. [Google Scholar] [CrossRef]

- Plechkova, N.V.; Seddon, K.R. Applications of ionic liquids in the chemical industry. Chem. Soc. Rev. 2008, 37, 123–150. [Google Scholar] [CrossRef]

- Sanchez-Iborra, R.; Cano, M.-D. State of the Art in LP-WAN Solutions for Industrial IoT Services. Sensors 2016, 16, 708. [Google Scholar] [CrossRef]

- Spath, S.; Drescher, P.; Seitz, H. Impact of Particle Size of Ceramic Granule Blends on Mechanical Strength and Porosity of 3D Printed Scaffolds. Materials 2015, 8, 4720–4732. [Google Scholar] [CrossRef]

- Lee, E.A. The Past, Present and Future of Cyber-Physical Systems: A Focus on Models. Sensors 2015, 15, 4837–4869. [Google Scholar] [CrossRef]

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging Digital Twin Technology in Model-Based Systems Engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef]

- Carlini, N.; Wagner, D. Towards Evaluating the Robustness of Neural Networks. In Proceedings of the 2017 IEEE Symposium on Security and Privacy (SP); IEEE: San Jose, CA, USA, 2017; pp. 39–57. [Google Scholar]

- Goodchild, A.; Toy, J. Delivery by drone: An evaluation of unmanned aerial vehicle technology in reducing CO 2 emissions in the delivery service industry. Transp. Res. Part D Transp. Environ. 2018, 61, 58–67. [Google Scholar] [CrossRef]

- Ding, K.; Avrutin, V.; Izyumskaya, N.; Özgür, Ü.; Morkoç, H. Micro-LEDs, a Manufacturability Perspective. Appl. Sci. 2019, 9, 1206. [Google Scholar] [CrossRef]

- Evangelista, P.; Santoro, L.; Thomas, A. Environmental Sustainability in Third-Party Logistics Service Providers: A Systematic Literature Review from 2000–2016. Sustainability 2018, 10, 1627. [Google Scholar] [CrossRef]

- Guo, Z.X.; Ngai, E.W.T.; Yang, C.; Liang, X. An RFID-based intelligent decision support system architecture for production monitoring and scheduling in a distributed manufacturing environment. Int. J. Prod. Econ. 2015, 159, 16–28. [Google Scholar] [CrossRef]

- He, B.-J.; Zhao, D.-X.; Zhu, J.; Darko, A.; Gou, Z.-H. Promoting and implementing urban sustainability in China: An integration of sustainable initiatives at different urban scales. Habitat Int. 2018, 82, 83–93. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Chou, P.-C.; Chiang, C.-M.; Lin, C.-F. Sun Tracking Systems: A Review. Sensors 2009, 9, 3875–3890. [Google Scholar] [CrossRef]

- Müller, F.A.; Kunz, C.; Gräf, S. Bio-Inspired Functional Surfaces Based on Laser-Induced Periodic Surface Structures. Materials 2016, 9, 476. [Google Scholar] [CrossRef]

- Kahru, A.; Dubourguier, H.-C.; Blinova, I.; Ivask, A.; Kasemets, K. Biotests and Biosensors for Ecotoxicology of Metal Oxide Nanoparticles: A Minireview. Sensors 2008, 8, 5153–5170. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández-Valdivielso, A.; López de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Fernández-Abia, A.I.; Barreiro, J.; Fernández-Larrinoa, J.; de Lacalle, L.N.L.; Fernández-Valdivielso, A.; Pereira, O.M. Behaviour of PVD Coatings in the Turning of Austenitic Stainless Steels. Procedia Eng. 2013, 63, 133–141. [Google Scholar] [CrossRef]

- Asiimwe, M.M.; de Kock, I.H. An Analysis of the Extent to Which Industry 4.0 has been considered in sustainability or socio-technical transitions. S. Afr. J. Ind. Eng. 2019, 30, 41–51. [Google Scholar] [CrossRef]

- Bonilla, S.H.; Silva, H.R.O.; da Silva, M.T.; Goncalves, R.F.; Sacomano, J.B. Industry 4.0 and Sustainability Implications: A Scenario-Based Analysis of the Impacts and Challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef]

- Beier, G.; Ullrich, A.; Niehoff, S.; Reissig, M.; Habich, M. Industry 4.0: How it is defined from a sociotechnical perspective and how much sustainability it includes-A literature review. J. Clean Prod. 2020, 259. [Google Scholar] [CrossRef]

- Sartal, A.; Bellas, R.; Mejias, A.M.; Garcia-Collado, A. The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review. Adv. Mech. Eng. 2020, 12. [Google Scholar] [CrossRef]

- Tirabeni, L.; De Bernardi, P.; Forliano, C.; Franco, M. How Can Organisations and Business Models Lead to a More Sustainable Society? A Framework from a Systematic Review of the Industry 4.0. Sustainability 2019, 11, 6363. [Google Scholar] [CrossRef]

- Porter, M.E. The Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: New York, NY, USA, 1998. [Google Scholar]

- Trianni, A.; Cagno, E.; Neri, A.; Howard, M. Measuring industrial sustainability performance: Empirical evidence from Italian and German manufacturing small and medium enterprises. J. Clean Prod. 2019, 229, 1355–1376. [Google Scholar] [CrossRef]

- Sangwan, S.R.; Bhatia, M.P.S. Sustainable Development in Industry 4.0. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Anand, N., Akshi, K., Eds.; Advances in Science, Technology & Innovation; Springer: Cham, Switzerland, 2020; pp. 39–56. [Google Scholar]

- Varela, L.; Araujo, A.; Avila, P.; Castro, H.; Putnik, G. Evaluation of the Relation between Lean Manufacturing, Industry 4.0, and Sustainability. Sustainability 2019, 11, 1439. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P.; Ribeiro da Silva, E.H.D. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Brozzi, R.; Forti, D.; Rauch, E.; Matt, D.T. The Advantages of Industry 4.0 Applications for Sustainability: Results from a Sample of Manufacturing Companies. Sustainability 2020, 12, 3647. [Google Scholar] [CrossRef]

| Topic | Industry 4.0 | Green Processes | Sustainability |

|---|---|---|---|

| Web of Science | 5035 | 1436 | 122,097 |

| Scopus | 9387 | 1890 | 167,629 |

| Context (How?) | Interventions (Which?) | Outcomes (What?) | |

|---|---|---|---|

| Topic | Industry 4.0 | Green Processes | Sustainability |

| Synonyms | Fourth industrial revolution | Environmental processes | Ecological |

| Smart factory | Eco/ecological processes | Environmental | |

| Smart production | Clean processes | Social | |

| Smart manufacturing | Low carbon processes | Economical | |

| Keywords | Internet of things | Nanoparticles | Management |