Measuring and Integrating Risk Management into Green Innovation Practices for Green Manufacturing under the Global Value Chain

Abstract

1. Introduction

2. Literature Review

2.1. Green Innovation in the Manufacturing Industry

2.2. Green Innovation Risk Management

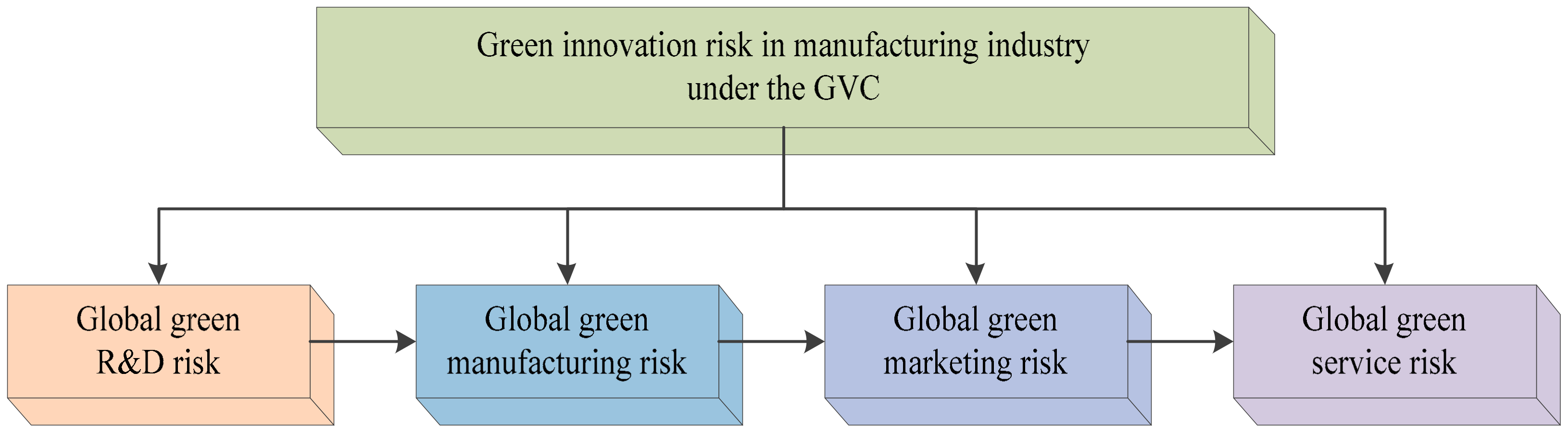

3. Construction of Green Risk Identification System

3.1. Process of Green Innovation Risk Identification

3.2. Criteria System of Green Innovation Risk Identification

3.2.1. Global Green R&D Risk

3.2.2. Global Green Manufacturing Risk

3.2.3. Global Green Marketing Risk

3.2.4. Global Green Service Risk

4. Research Methodology

4.1. Criterion Weight Method

4.2. Criterion Value Method

4.2.1. Fuzzy Value of Qualitative Criterion

4.2.2. Data Acquisition of Quantitative Criteria

4.3. Comprehensive Time Sequence Weight

4.3.1. Time Weight Based on Time Degree and Ideal Solution

4.3.2. Time Weight Based on Time Degree and Information Entropy

4.3.3. Comprehensive Time Weight

4.4. Integration Method

4.4.1. Expert Weighting Method

4.4.2. Deviation Maximization Method

4.4.3. Average Method

5. Empirical Study

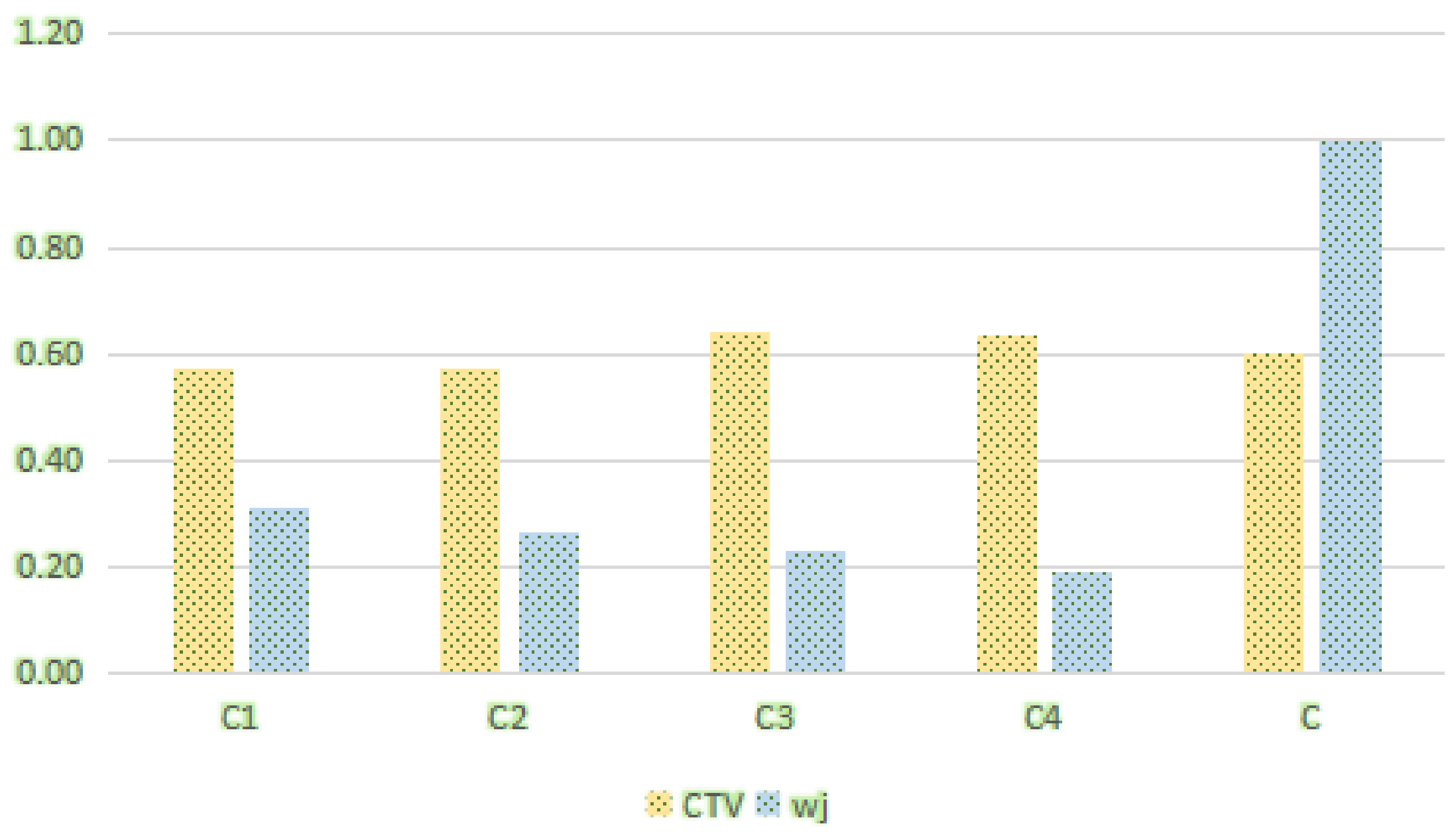

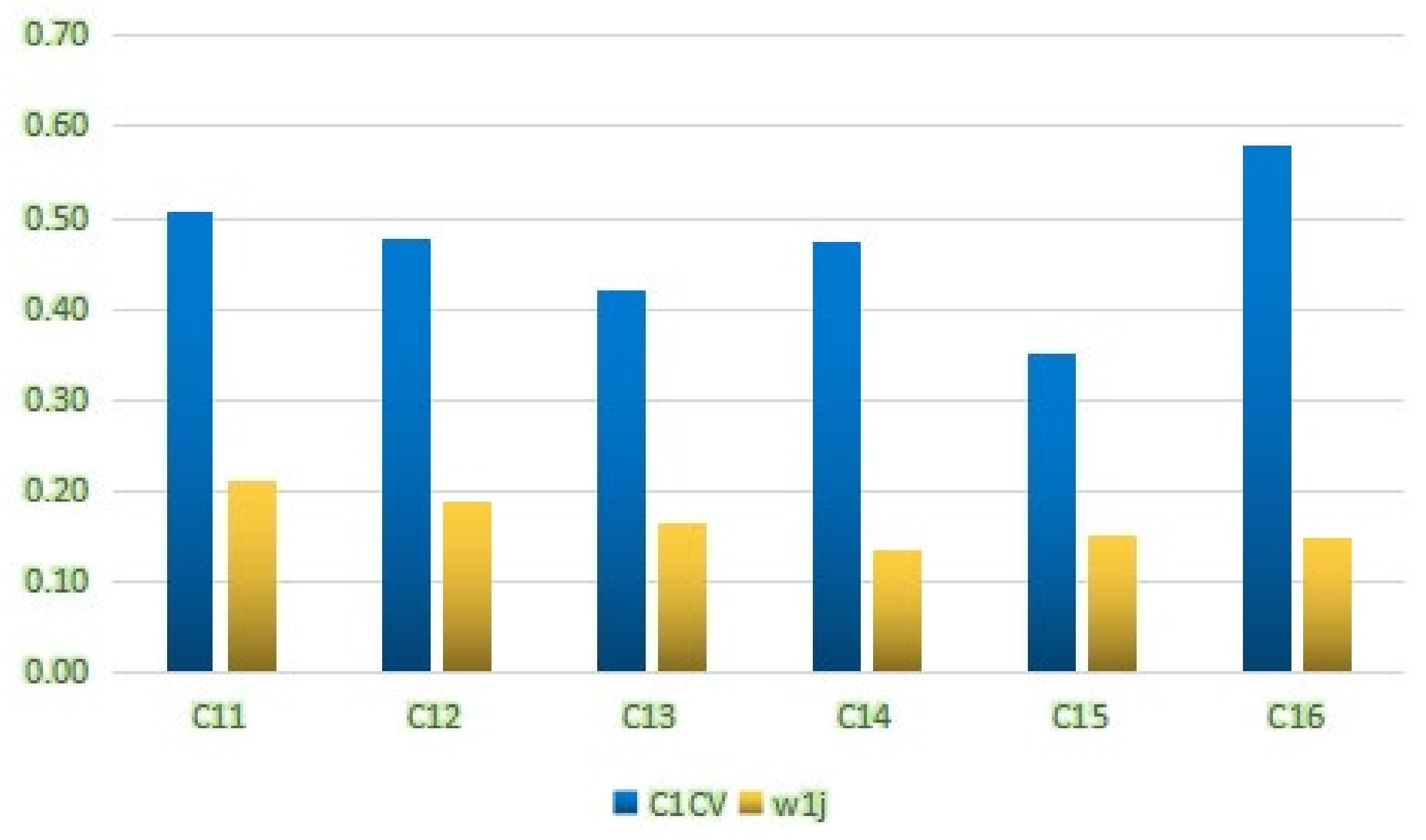

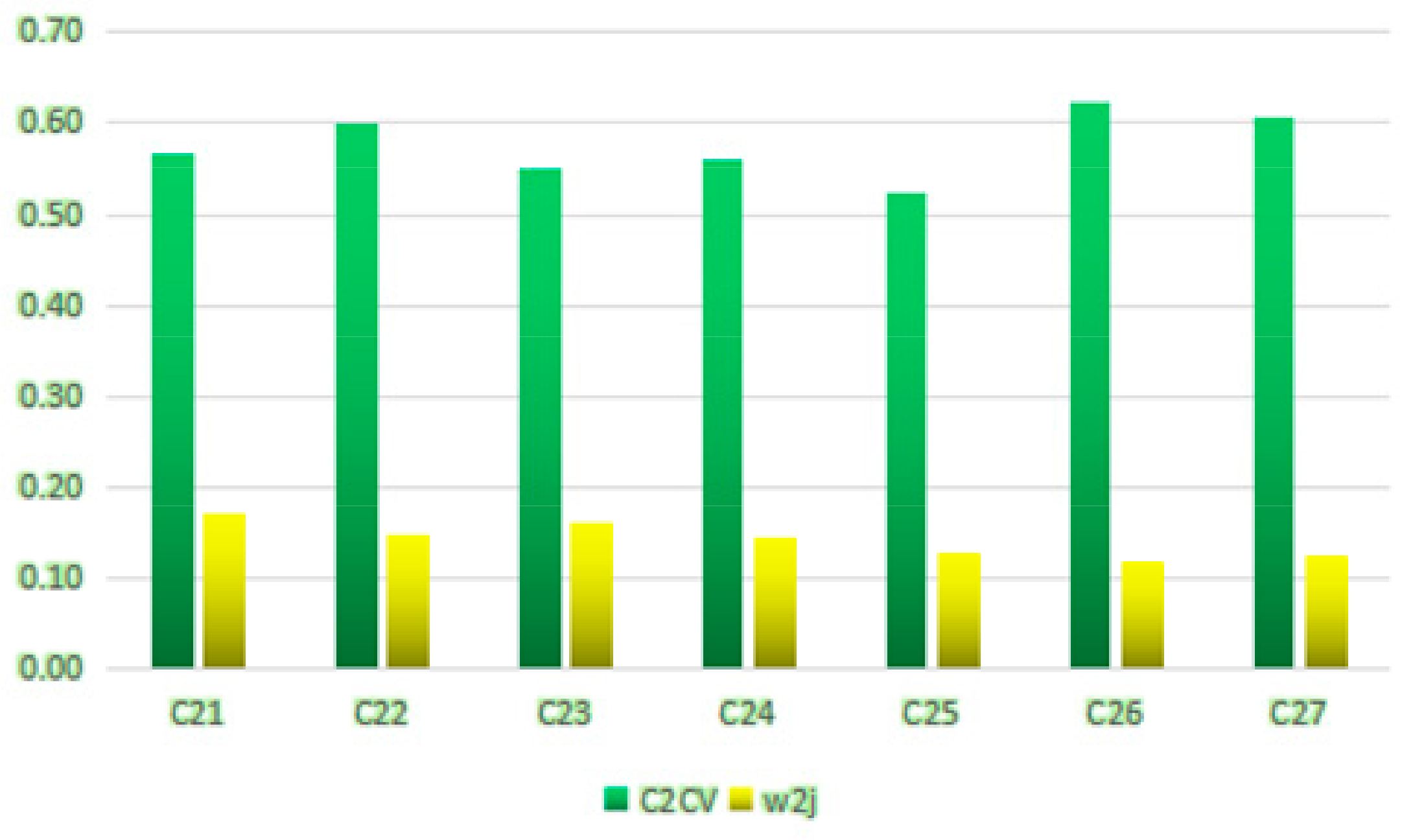

5.1. Determination Weights of Identification Criteria

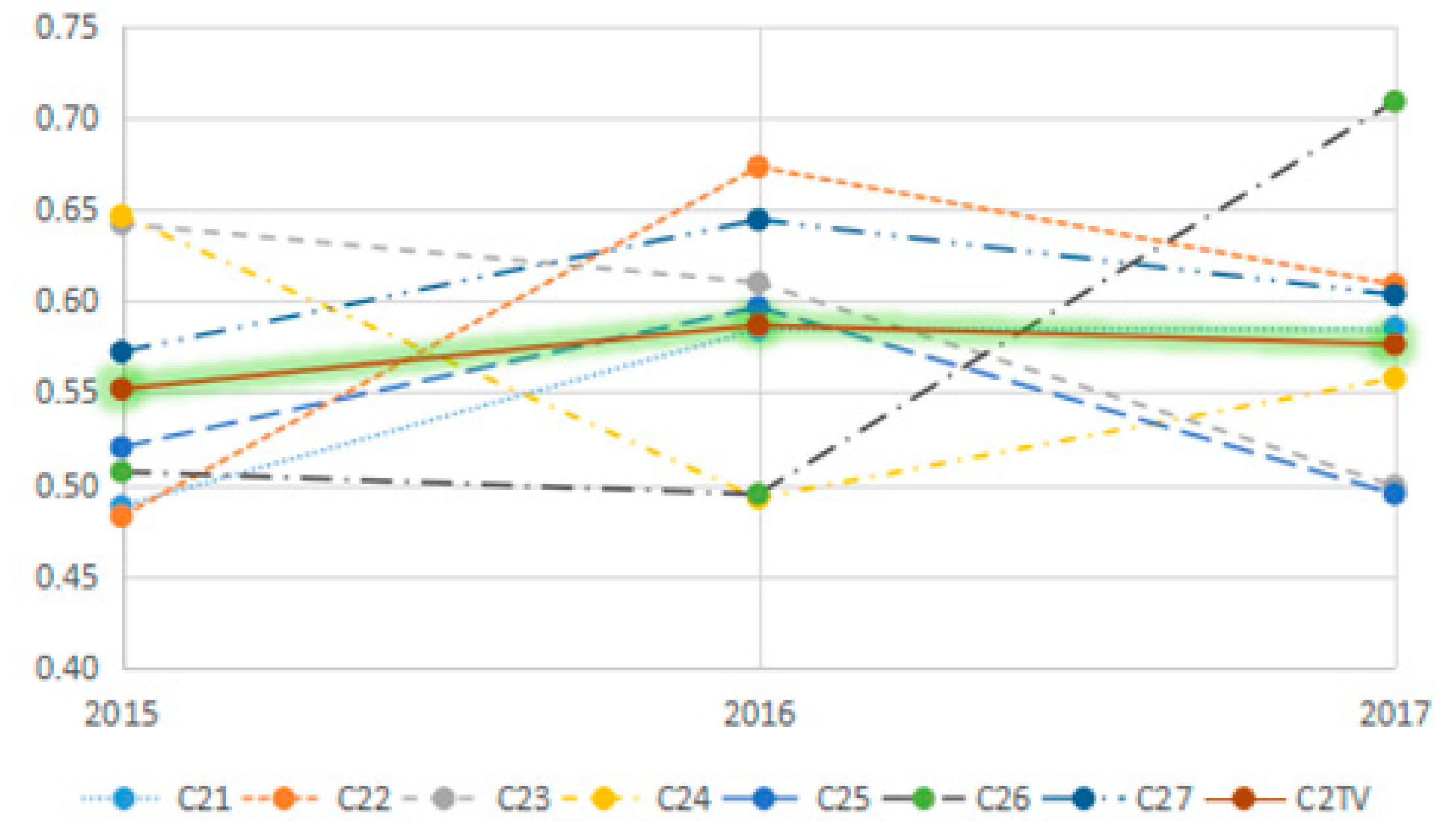

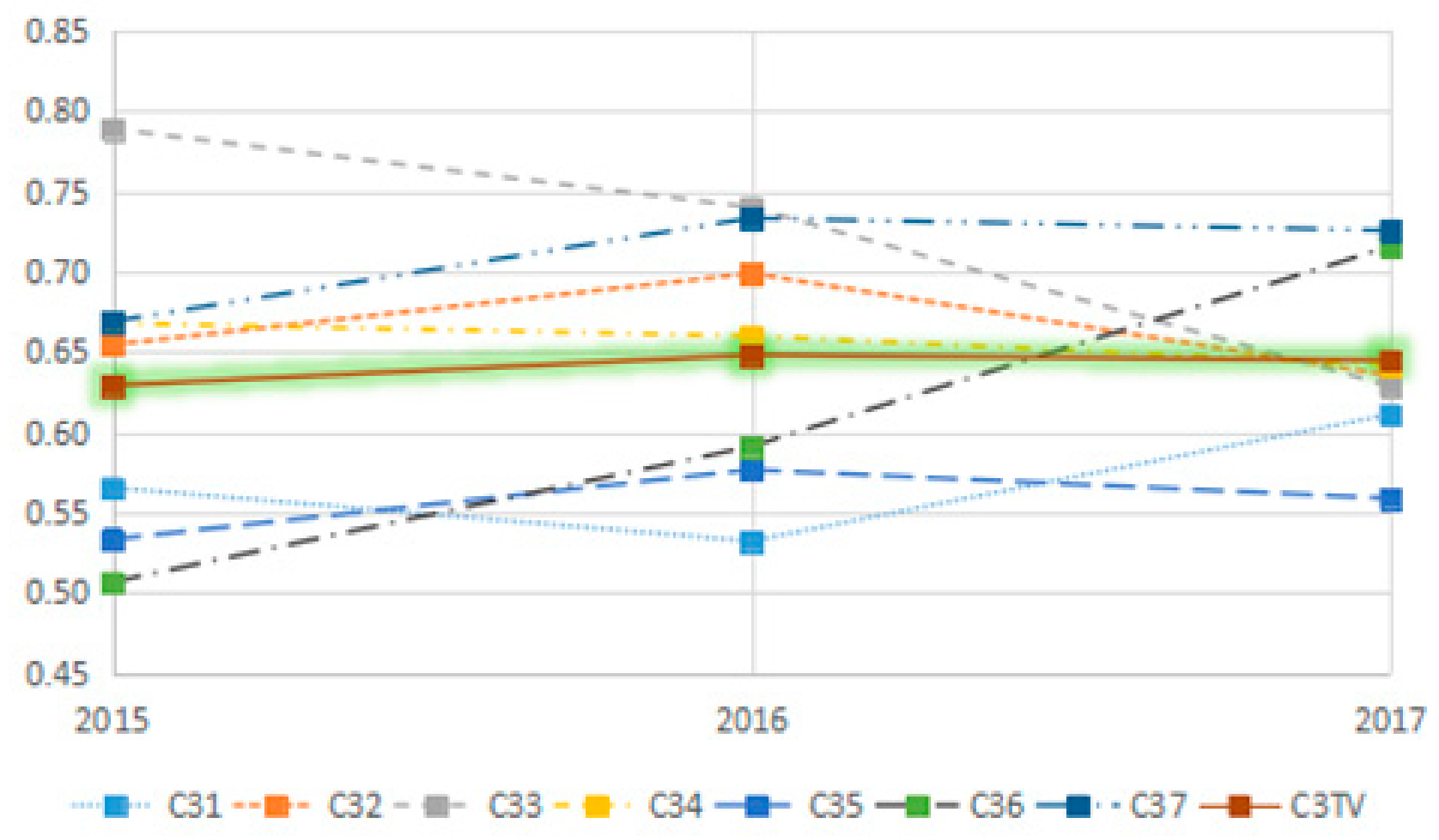

5.2. Determination Value of Identification Criteria

5.3. Process of Risk Identification

6. Results and Discussion

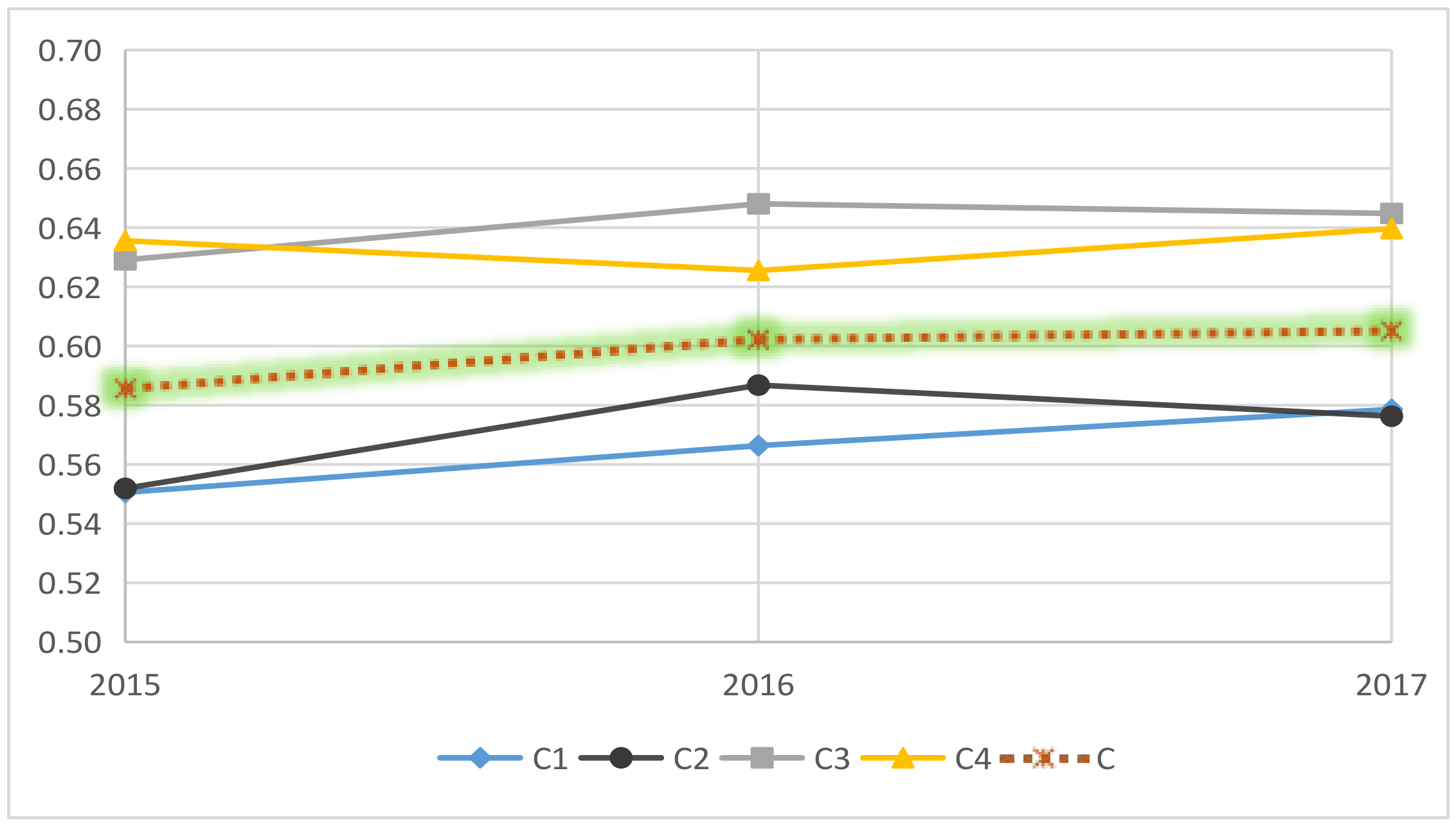

6.1. Analysis of Green Innovation Risk

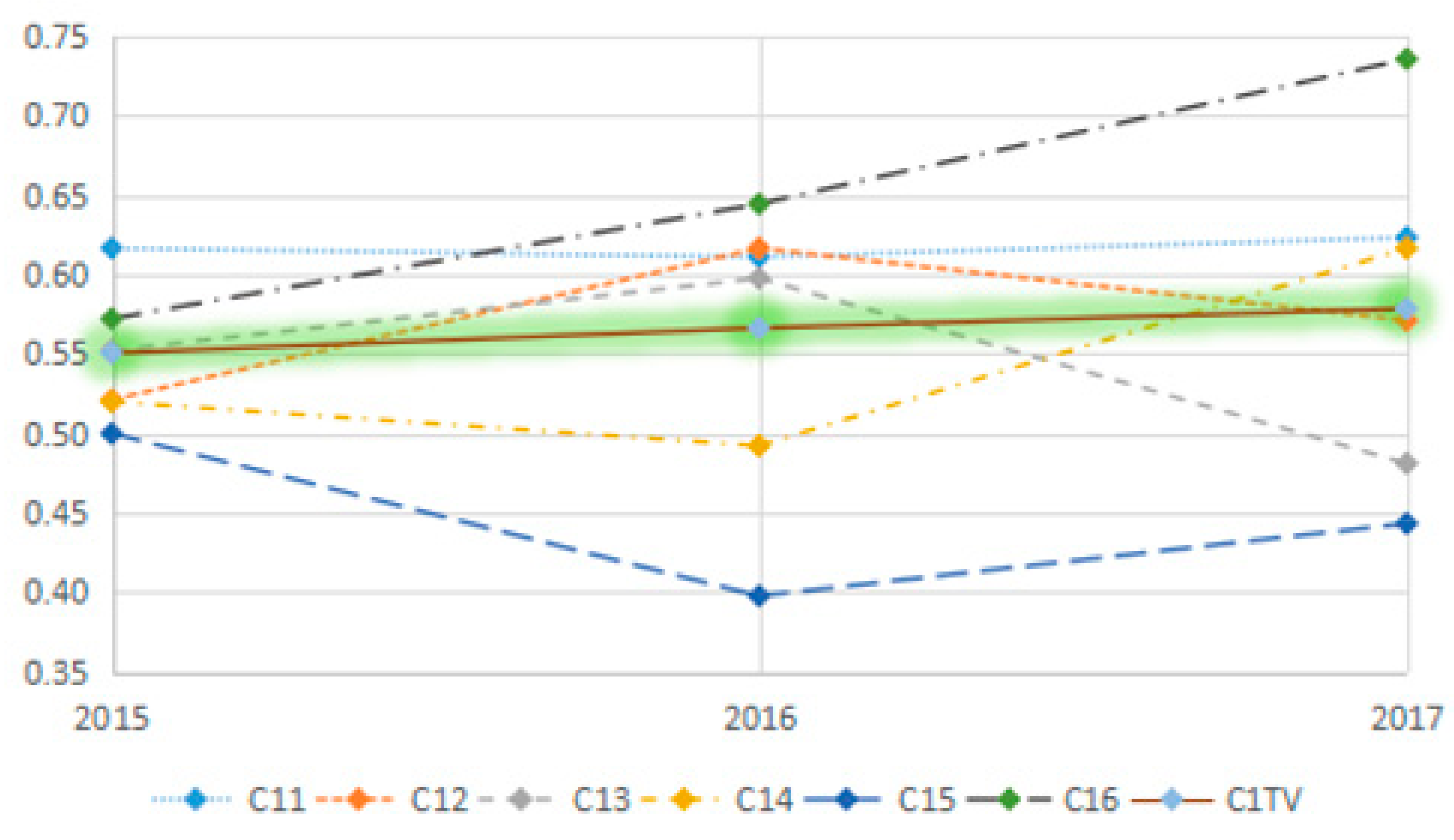

6.2. Analysis of Green R&D Risk

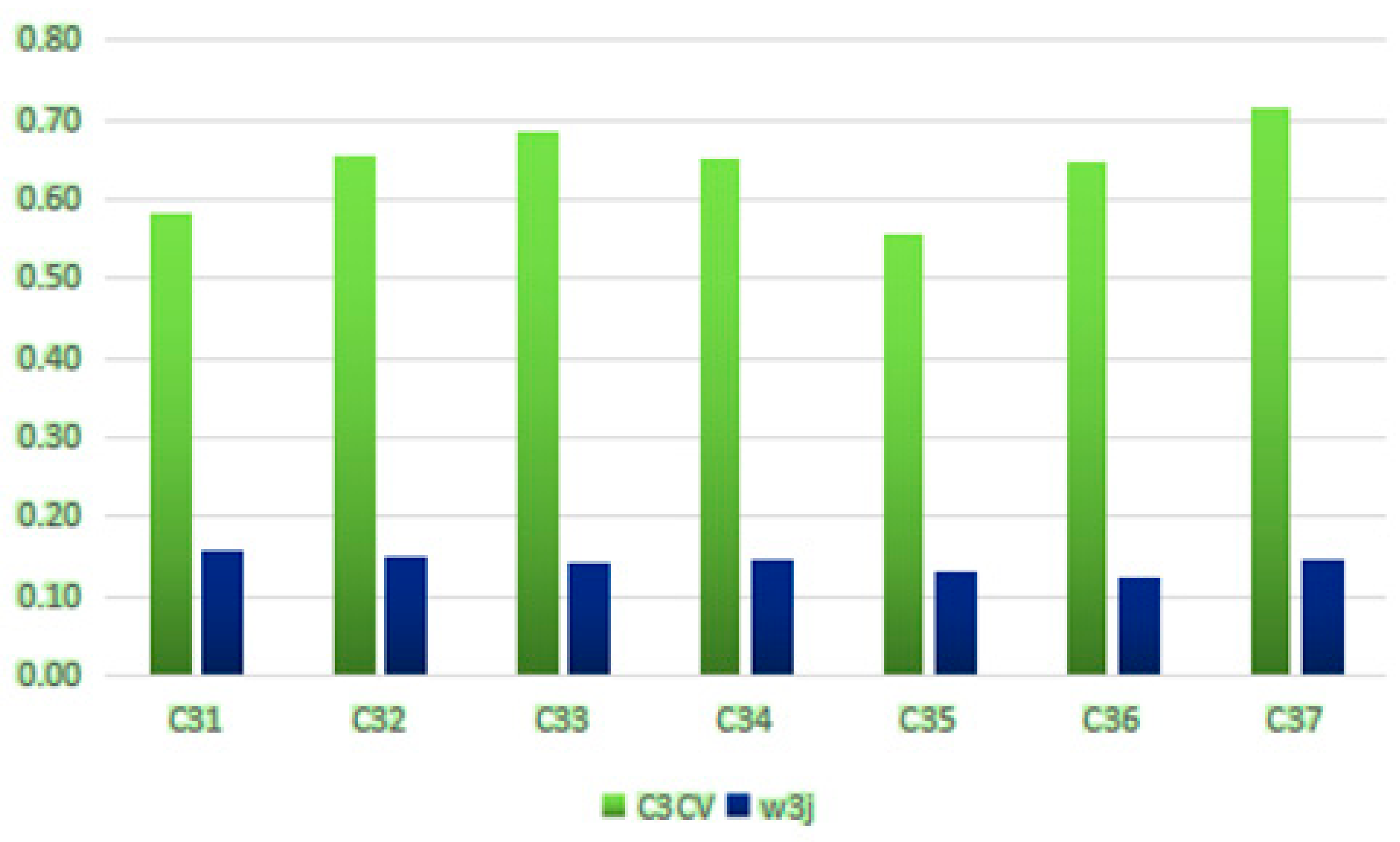

6.3. Analysis of Green Manufacturing Risk

6.4. Analysis of Green Marketing Risk

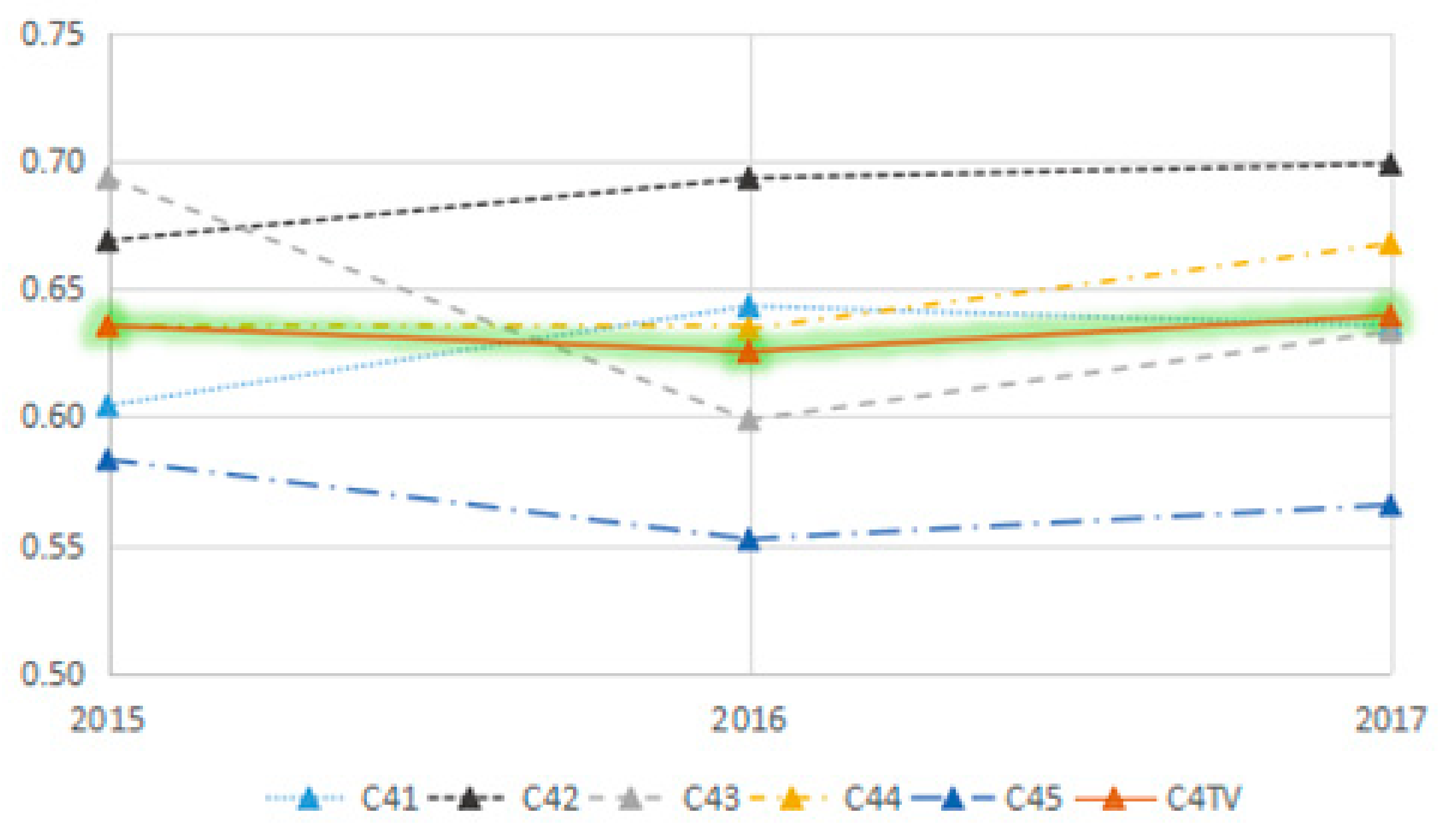

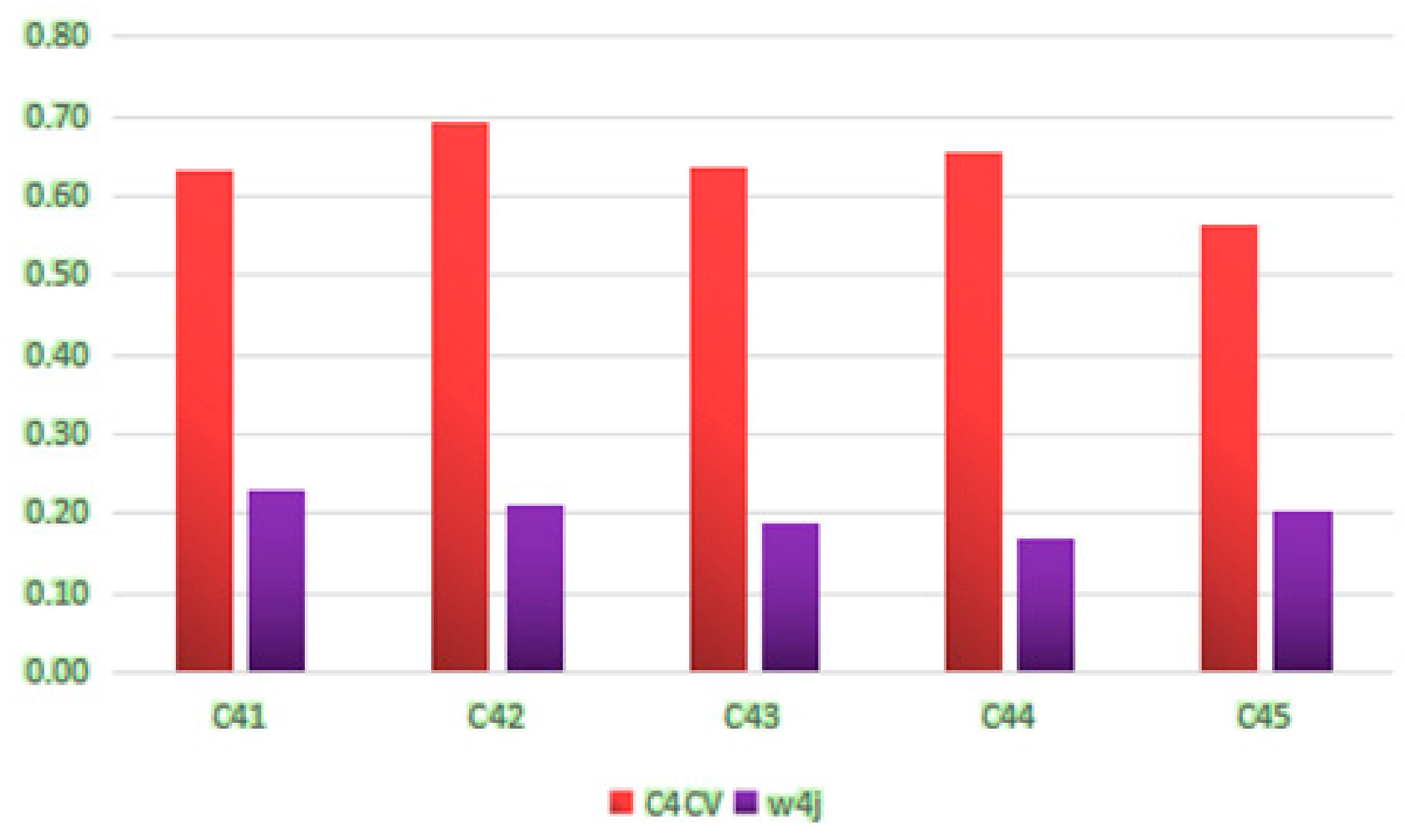

6.5. Analysis of Green Service Risk

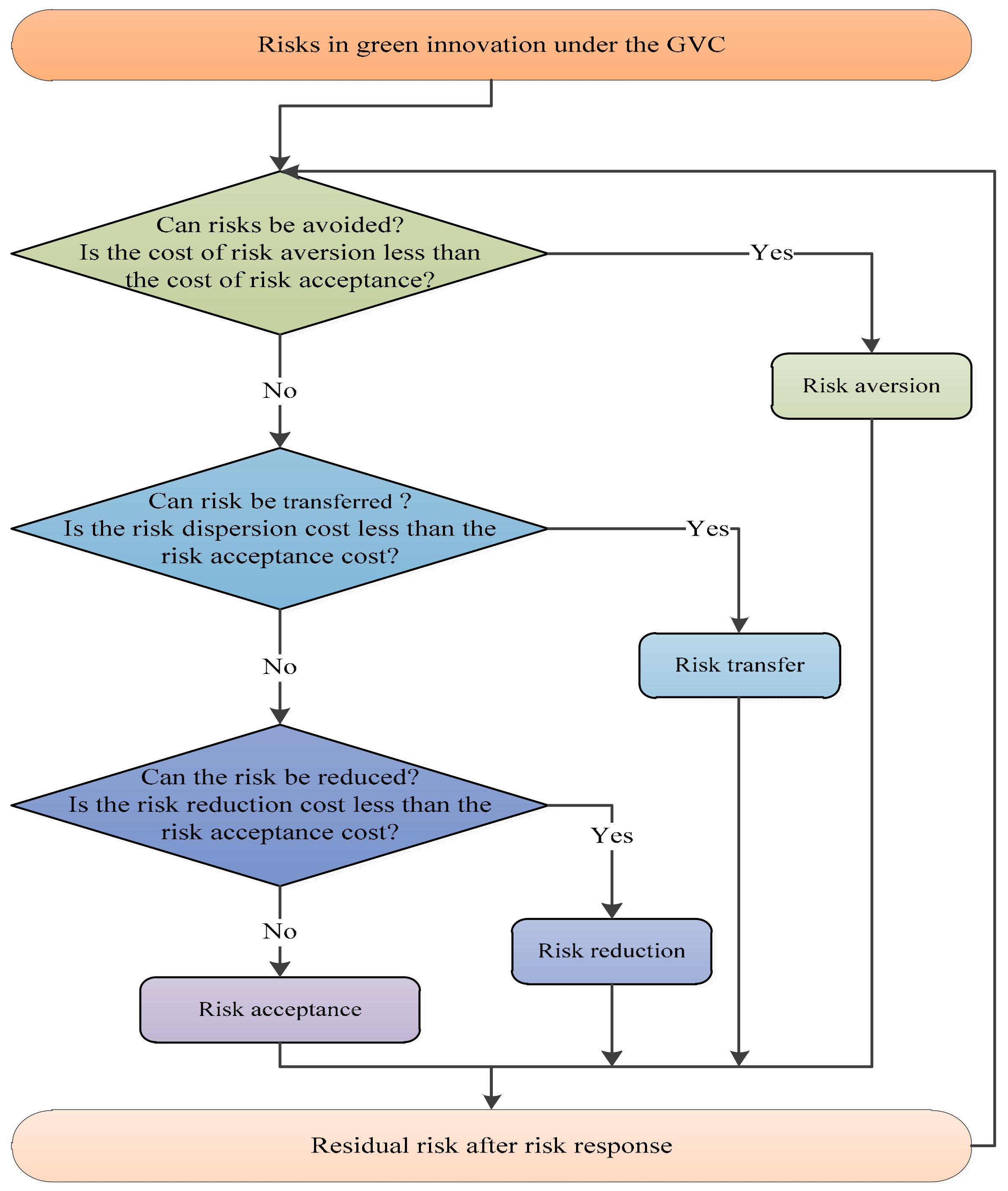

7. Response to Green Innovation Risk

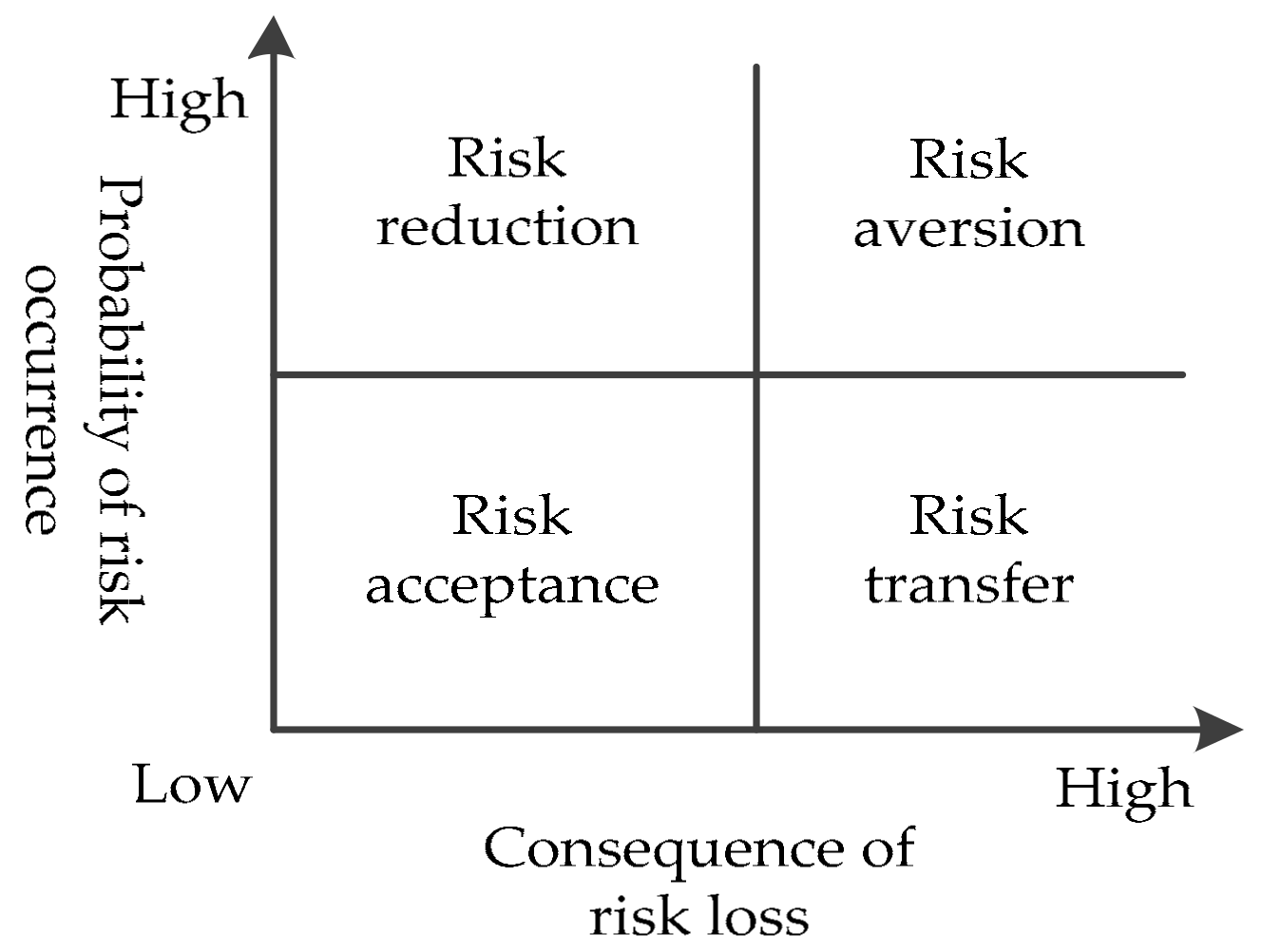

7.1. Response Way to Green Innovation Risk

7.2. Response Procedure to Green Innovation Risk

7.3. Response Strategy to Green Innovation Risk

8. Conclusions and Future Research

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Yin, S.; Li, B.Z.; Xing, Z.Y. The governance mechanism of the building material industry (BMI) in transformation to green BMI: The perspective of green building. Sci. Total Environ. 2019, 677, 19–33. [Google Scholar] [CrossRef] [PubMed]

- Alves, A.; Vojinovic, Z.; Kapelan, Z.; Sanchez, A.; Gersonius, B. Exploring trade-offs among the multiple benefits of green-blue-grey infrastructure for urban flood mitigation. Sci. Total Environ. 2019, 5, 134980. [Google Scholar] [CrossRef] [PubMed]

- Attahiru, Y.B.; Aziz, M.M.A.; Kassim, K.A.; Shahid, S.; Bakar, W.A.W.A.; NSashruddin, T.F.; Ahamed, M.I. A review on green economy and development of green roads and highways using carbon neutral materials. Renew. Sustain. Energy Rev. 2019, 101, 600–613. [Google Scholar] [CrossRef]

- Han, H.; Zhang, X. Static and dynamic cultivated land use efficiency in China: A minimum distance to strong efficient frontier approach. J. Clean. Prod. 2020, 246, 119002. [Google Scholar] [CrossRef]

- Mishenin, Y.; Koblianska, I.; Medvid, V.; Maistrenko, Y. Sustainable regional development policy formation: Role of industrial ecology and logistics. Entrep. Sustain. Issues 2018, 6, 329–341. [Google Scholar] [CrossRef]

- Strong, D.; Kay, M.; Conner, B.; Wakefield, T.; Manogharan, G. Hybrid manufacturing–integrating traditional manufacturers with additive manufacturing (AM) supply chain. Addit. Manuf. 2018, 21, 159–173. [Google Scholar] [CrossRef]

- Müller, J.M.; Voigt, K.I. Sustainable industrial value creation in SMEs: A comparison between industry 4.0 and made in China 2025. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 659–670. [Google Scholar] [CrossRef]

- Liu, S.X. Innovation design: Made in China 2025. Des. Manag. Rev. 2016, 27, 52–58. [Google Scholar]

- Gupta, H.; Barua, M.K. A grey DEMATEL-based approach for modeling enablers of green innovation in manufacturing organizations. Environ. Sci. Pollut. Res. 2018, 25, 9556–9578. [Google Scholar] [CrossRef]

- Abdullah, M.; Zailani, S.; Iranmanesh, M.; Jayaraman, K. Barriers to green innovation initiatives among manufacturers: The Malaysian case. Rev. Manag. Sci. 2016, 10, 683–709. [Google Scholar] [CrossRef]

- Dellermann, D.; Fliaster, A.; Kolloch, M. Innovation risk in digital business models: The German Energy Sector. J. Bus. Strategy 2017, 38, 35–43. [Google Scholar] [CrossRef]

- Meroño-Cerdán, A.L.; López-Nicolás, C.; Molina-Castillo, F.J. Risk aversion, innovation and performance in family firms. Econ. Innov. New Technol. 2018, 27, 189–203. [Google Scholar] [CrossRef]

- Huang, Z.; Liao, G.; Li, Z. Loaning scale and government subsidy for promoting green innovation. Technol. Forecast. Soc. Chang. 2019, 144, 148–156. [Google Scholar] [CrossRef]

- Sastoque Pinilla, L.; Llorente Rodríguez, R.; Toledo Gandarias, N.; López de Lacalle, L.N.; Ramezani Farokhad, M. TRLs 5–7 Advanced Manufacturing Centres, Practical Model to Boost Technology Transfer in Manufacturing. Sustainability 2019, 11, 4890. [Google Scholar] [CrossRef]

- Blühdorn, I.; Deflorian, M. The Collaborative Management of Sustained Unsustainability: On the Performance of Participatory Forms of Environmental Governance. Sustainability 2019, 11, 1189. [Google Scholar] [CrossRef]

- Tu, Z.G.; Hu, T.Y.; Shen, R.J. Evaluating public participation impact on environmental protection and ecological efficiency in China: Evidence from PITI disclosure. China Econ. Rev. 2019, 55, 111–123. [Google Scholar] [CrossRef]

- Horbach, J.; Rammer, C.; Rennings, K. Determinants of eco-innovations by type of environmental impact—The role of regulatory push/pull, technology push and market pull. Ecol. Econ. 2012, 78, 112–122. [Google Scholar] [CrossRef]

- Cleff, T.; Rennings, K. Determinants of environmental product and process innovation. Eur. Environ. 1999, 9, 191–201. [Google Scholar] [CrossRef]

- Brunnermeier, S.B.; Cohen, M.A. Determinants of environmental innovation in US manufacturing industries. J. Environ. Econ. Manag. 2003, 45, 278–293. [Google Scholar] [CrossRef]

- Ziegler, A.; Rennings, K. Determinants of Environmental Innovations in Germany: Do Organizational Measures Matter; ZEW-Centre for European Economic Research Discussion Paper; ZEW: Mannheim, Germany, 2004. [Google Scholar]

- De Vries, F.P.; Withagen, C. Innovation and Environmental Stringency: The Case of Sulfur Dioxide Abatement; Center Discussion Paper Series No. 2005-18. 2005. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=670158 (accessed on 21 February 2005).

- Hamamoto, M. Environmental regulation and the productivity of Japanese manufacturing industries. Resour. Energy Econ. 2006, 28, 299–312. [Google Scholar] [CrossRef]

- Rehfeld, K.M.; Rennings, K.; Ziegler, A. Integrated product policy and environmental product innovations: An empirical analysis. Ecol. Econ. 2007, 61, 91–100. [Google Scholar] [CrossRef]

- Wagner, M. Empirical influence of environmental management on innovation: Evidence from Europe. Ecol. Econ. 2008, 66, 392–402. [Google Scholar] [CrossRef]

- Demirel, P.; Kesidou, E. Stimulating different types of eco-innovation in the UK: Government policies and firm motivations. Ecol. Econ. 2011, 70, 1546–1557. [Google Scholar] [CrossRef]

- Ustaoğlu, M.; Yıldız, B. Innovative green technology in Turkey: Electric vehicles’ future and forecasting market share. Procedia-Soc. Behav. Sci. 2012, 41, 139–146. [Google Scholar]

- Eaton, D. Technology and innovation for a green economy. Rev. Eur. Comp. Int. Environ. Law 2013, 22, 62–67. [Google Scholar] [CrossRef]

- Meltzer, J. A carbon tax as a driver of green technology innovation and the implications for international trade. Energy LJ 2014, 35, 45. [Google Scholar]

- El-Kassar, A.N.; Singh, S.K. Green innovation and organizational performance: The influence of big data and the moderating role of management commitment and HR practices. Technol. Forecast. Soc. Chang. 2019, 144, 483–498. [Google Scholar] [CrossRef]

- Fernando, Y.; Jabbour, C.J.C.; Wah, W.X. Pursuing green growth in technology firms through the connections between environmental innovation and sustainable business performance: Does service capability matter. Resour. Conserv. Recycl. 2019, 141, 8–20. [Google Scholar] [CrossRef]

- Xie, X.X.; Huo, J.G.; Zou, H.L. Green process innovation, green product innovation, and corporate financial performance: A content analysis method. J. Bus. Res. 2019, 101, 697–706. [Google Scholar] [CrossRef]

- Fujii, H.; Managi, S. Decomposition analysis of sustainable green technology inventions in China. Technol. Forecast. Soc. Chang. 2019, 139, 10–16. [Google Scholar] [CrossRef]

- LeBlanc, R.; Tranchant, C.; Gagnon, Y.; Côté, R. Potential for eco-industrial park development in Moncton, New Brunswick (Canada): A comparative analysis. Sustainability 2016, 8, 472. [Google Scholar] [CrossRef]

- Deif, A.M. A system model for green manufacturing. J. Clean. Prod. 2011, 19, 1553–1559. [Google Scholar] [CrossRef]

- Lanoie, P.; Laurent-Lucchetti, J.; Johnstone, N.; Ambec, S. Environmental policy, innovation and performance: New insights on the Porter hypothesis. J. Econ. Manag. Strategy 2011, 20, 803–842. [Google Scholar] [CrossRef]

- Wong, C.W.; Lai, K.H.; Shang, K.C.; Lu, C.S.; Leung, T.K.P. Green operations and the moderating role of environmental management capability of suppliers on manufacturing firm performance. Int. J. Prod. Econ. 2012, 140, 283–294. [Google Scholar] [CrossRef]

- Wong, S.K.S. Environmental requirements, knowledge sharing and green innovation: Empirical evidence from the electronics industry in China. Bus. Strategy Environ. 2013, 22, 321–338. [Google Scholar] [CrossRef]

- Ghisetti, C.; Rennings, K. Environmental innovations and profitability: How does it pay to be green? An empirical analysis on the German innovation survey. J. Clean. Prod. 2014, 75, 106–117. [Google Scholar] [CrossRef]

- Ren, Y.J.; Wang, C.X. Research on the regional difference and spatial effect of green innovation efficiency of industrial enterprises in China. Rev. Ibérica Sist. Tecnol. Inf. 2016, E10, 373–384. [Google Scholar]

- Guo, X.F.; Yang, H.T. A combination of EFG-SBM and a temporally-piecewise adaptive algorithm to solve viscoelastic problems. Eng. Anal. Bound. Elem. 2016, 67, 43–52. [Google Scholar] [CrossRef]

- Liu, J.; Liu, H.; Yao, X.L.; Liu, Y. Evaluating the sustainability impact of consolidation policy in China’s coal mining industry: A data envelopment analysis. J. Clean. Prod. 2016, 112, 2969–2976. [Google Scholar] [CrossRef]

- Rumanti, A.A.; Samadhi, T.A.; Wiratmadja, I.I.; Reynaldo, R. Conceptual model of green innovation toward knowledge sharing and open innovation in Indonesian SME. In Proceedings of the 2017 4th IEEE International Conference on Industrial Engineering and Applications (ICIEA), Nagoya, Japan, 21–23 April 2017; pp. 182–186. [Google Scholar]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2015, 98, 66–83. [Google Scholar] [CrossRef]

- Yin, S.; Li, B.Z. Transferring green building technologies from academic research institutes to building enterprises in the development of urban green building: A stochastic differential game approach. Sustain. Cities Soc. 2018, 39, 631–638. [Google Scholar] [CrossRef]

- Lin, S.; Sun, J.; Marinova, D.; Zhao, D. Evaluation of the green technology innovation efficiency of China’s manufacturing industries: DEA window analysis with ideal window width. Technol. Anal. Strateg. Manag. 2018, 30, 1166–1181. [Google Scholar] [CrossRef]

- Yin, S.; Li, B.Z.; Zhang, X.Y.; Zhang, M.L. How to improve the quality and speed of green new product development? Processes 2019, 7, 443. [Google Scholar] [CrossRef]

- Ho, G.T.S.; Lau, H.C.W.; Lee, C.K.M.; Ip, A.W.H.; Pun, K.F. An intelligent production workflow mining system for continual quality enhancement. Int. J. Adv. Manuf. Technol. 2006, 28, 792–809. [Google Scholar] [CrossRef]

- Balachandra, R.; Friar, J.H. Factors for success in R&D projects and new product innovation: A contextual framework. IEEE Trans. Eng. Manag. 1997, 44, 276–287. [Google Scholar]

- Visser, J.K.; Malan, H.T. Identification of risk associated with process automation systems. Int. J. Econ. Manag. Eng. 2019, 13, 1044–1051. [Google Scholar]

- Nie, S.; Li, Y.P.; Liu, J.; Huang, C.Z. Risk management of energy system for identifying optimal power mix with financial-cost minimization and environmental-impact mitigation under uncertainty. Energy Econ. 2017, 61, 313–329. [Google Scholar] [CrossRef]

- Hsieh, N.C.; Chang, C.Y.; Lee, K.C.; Chen, J.C.; Chan, C.H. Technology in the development of cardiovascular clinical information systems. J. Med. Syst. 2012, 36, 965–978. [Google Scholar] [CrossRef]

- Ciabuschi, F.; Lindahl, O.; Barbieri, P.; Fratocchi, L. Manufacturing reshoring: A strategy to manage risk and commitment in the logic of the internationalization process model. Eur. Bus. Rev. 2019, 31, 139–159. [Google Scholar] [CrossRef]

- Guo, Y. Research on innovation risk management based on Bayesian risk decision-making. Int. J. Bus. Adm. 2012, 3, 21. [Google Scholar] [CrossRef][Green Version]

- Akande, J.O.; Kwenda, F.; Ehalaiye, D. Competition and commercial banks risk-taking: Evidence from Sub-Saharan Africa region. Appl. Econ. 2018, 50, 4774–4787. [Google Scholar] [CrossRef]

- Mu, J.; Peng, G.; MacLachlan, D.L. Effect of risk management strategy on NPD performance. Technovation 2009, 29, 170–180. [Google Scholar] [CrossRef]

- Rostamzadeh, R.; Ghorabaee, M.K.; Govindan, K.; Esmaeili, A.; Nobar, H.B.K. Evaluation of sustainable supply chain risk management using an integrated fuzzy TOPSIS-CRITIC approach. J. Clean. Prod. 2018, 175, 651–669. [Google Scholar] [CrossRef]

- Wu, D.D.; Chen, Y.; Liu, J.; Xie, K.F. Risk in integrated leapfrogging mode of technology. Kybernetes 2012, 41, 1423–1439. [Google Scholar]

- De Assis, C.A.; Iglesias, M.C.; Bilodeau, M.; Johnson, D.; Phillips, R.; Peresin, M.S.; Gonzalez, R. Cellulose micro-and nanofibrils (CMNF) manufacturing-financial and risk assessment. Biofuelsbioprod. Biorefin. 2018, 12, 251–264. [Google Scholar] [CrossRef]

- Wu, J.; Wu, Z. Integrated risk management and product innovation in China: The moderating role of board of directors. Technovation 2014, 34, 466–476. [Google Scholar] [CrossRef]

- Mishra, A.K.; Kumar, A.; Joshi, P.K.; D’souza, A. Production risk, risk preference and contract farming: Impact on food security in India. Appl. Econ. Perspect. Policy 2018, 40, 353–378. [Google Scholar] [CrossRef]

- Schewe, G. Successful innovation management: An integrative perspective. J. Eng. Technol. Manag. 1994, 11, 25–53. [Google Scholar] [CrossRef]

- Singh, K.; Sur, D. Analysing company-specific components of business risk in selected manufacturing firms in Indian corporate sector. Int. J. Risk Assess. Manag. 2018, 21, 359–373. [Google Scholar] [CrossRef]

- Truong, H.Q.; Hara, Y. Supply chain risk management: Manufacturing-and service-oriented firms. J. Manuf. Technol. Manag. 2018, 29, 218–239. [Google Scholar]

- Wu, D.D.; Kefan, X.; Hua, L.; Shi, Z.; Olson, D.L. Modeling technology risk of an entrepreneurial team using system dynamics: An agent-based perspective. Technol. Forecast. Soc. Chang. 2010, 77, 857–869. [Google Scholar] [CrossRef]

- ISO, ISO31000. Risk Management–Principles and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- Luko, S.N. Risk management principles and guidelines. Qual. Eng. 2013, 25, 451–454. [Google Scholar] [CrossRef]

- Tiganoaia, B.; Niculescu, A.; Negoita, O.; Popescu, M. A new sustainable model for risk management—RIMM. Sustainability 2019, 11, 1178. [Google Scholar] [CrossRef]

- Spross, J.; Olsson, L.; Stille, H. The Swedish Geotechnical Society’s methodology for risk management: A tool for engineers in their everyday work. Georisk Assess. Manag. Risk Eng. Syst. Geohazards 2018, 12, 183–189. [Google Scholar] [CrossRef]

- Baryannis, G.; Validi, S.; Dani, S.; Antoniou, G. Supply chain risk management and artificial intelligence: State of the art and future research directions. Int. J. Prod. Res. 2019, 57, 2179–2202. [Google Scholar] [CrossRef]

- Miorando, R.F.; Ribeiro, J.L.D.; Cortimiglia, M.N. An economic–probabilistic model for risk analysis in technology projects. Technovation 2014, 34, 485–498. [Google Scholar] [CrossRef]

- Nazam, M.; Xu, J.; Tao, Z.; Ahmad, J.; Hashim, M. A fuzzy AHP-TOPSIS framework for the risk assessment of green supply chain implementation in the textile industry. Int. J. Supply Oper. Manag. 2015, 2, 548. [Google Scholar]

- Liu, Y.; Li, H. Risk assessment of government purchased pension services based on AHP-FCE. In Proceedings of the Fifth International Forum on Decision Sciences; Springer: Singapore, 2018; pp. 111–123. [Google Scholar]

- Prewett, K.; Terry, A. COSO’s updated enterprise risk management framework—A quest for depth and clarity. J. Corp. Account. Financ. 2018, 29, 16–23. [Google Scholar] [CrossRef]

- Bates, K.; Filippini, R.; Lai, I.K.; Lau, H.C. A hybrid risk management model: A case study of the textile industry. J. Manuf. Technol. Manag. 2012, 23, 665–680. [Google Scholar]

- Fan, M.; Lin, N.P.; Sheu, C. Choosing a project risk-handling strategy: An analytical model. Int. J. Prod. Econ. 2008, 112, 700–713. [Google Scholar] [CrossRef]

- Gösmann, J.; Ziggel, D. An innovative risk management methodology for trading equity indices based on change points. J. Asset Manag. 2018, 19, 99–109. [Google Scholar] [CrossRef]

- Zhang, F.; Gallagher, K.S. Innovation and technology transfer through global value chains: Evidence from China;s PV industry. Energy Policy 2016, 94, 191–203. [Google Scholar] [CrossRef]

- Lema, R.; Quadros, R.; Schmitz, H. Reorganising global value chains and building innovation capabilities in Brazil and India. Res. Policy 2015, 44, 1376–1386. [Google Scholar] [CrossRef]

- Song, M.; Fisher, R.; Kwoh, Y. Technological challenges of green innovation and sustainable resource management with large scale data. Technol. Forecast. Soc. Chang. 2019, 144, 361–368. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Yin, S.; Li, B.Z. Academic research institutes-construction enterprises linkages for the development of urban green building: Selecting management of green building technologies innovation partner. Sustain. Cities Soc. 2019, 48, 101555. [Google Scholar] [CrossRef]

- Ma, T.; Xiao, F. An improved method to transform triangular fuzzy number into basic belief assignment in evidence theory. IEEE Access 2019, 7, 25308–25322. [Google Scholar] [CrossRef]

| Risk Classification | Risk Factor | Reference Source |

|---|---|---|

| Risk sources | Manage risk and cost-related risk as well as environmental, technical, and market risk | [48,49,50] |

| Environmental risk, technology risk, management risk, and market risk | [51,52] | |

| Technology risk, market risk, transportation capacity, competition risk, and policy risk | [53,54] | |

| Risk characteristics | Technology risk, management risk, and marketing risk | [55,56] |

| Technology risk, manufacturing risk, market risk, management risk, and financial risk | [57,58] | |

| Technology risk, market risk, cooperative risk, financial risk, and institutional risk | [59,60] | |

| Risk processes | Development risk, manufacturing risk, and marketing risk | [61,62] |

| Research risk, manufacturing risk, and market service risk | [63] | |

| Development risk, manufacturing risk, and market risk | [64] |

| Criteria | Main Criteria | Subcriteria | Abbreviations |

|---|---|---|---|

| Risk identification of green innovation in the manufacturing industry under the GVC | Global green R&D risk: C1 | Proportion of global green R&D personnel investment | C11 |

| Proportion of global green R&D funds investment | C12 | ||

| Stability of global green technology R&D | C13 | ||

| Stability of global green technology application | C14 | ||

| The ease of international transfer of green technology | C15 | ||

| International Protection of green technology patents | C16 | ||

| Global green manufacturing risk: C2 | Proportion of global green manufacturing personnel investment | C21 | |

| Proportion of global green manufacturing investment | C22 | ||

| Global green manufacturing product production scale | C23 | ||

| Quality and performance level of global green manufacturing products | C24 | ||

| Global outsourcing scale of green products | C25 | ||

| Global green manufacturing technology transformation degree | C26 | ||

| Increase of global green manufacturing cost | C27 | ||

| Global green marketing risk: C3 | Proportion of global green marketers | C31 | |

| Proportion of global green marketing investment | C32 | ||

| International demand level of green products | C33 | ||

| International competition intensity of green products | C34 | ||

| International marketing channel share of green products | C35 | ||

| Commercialization and internationalization of green technology | C36 | ||

| Intensity of green technical barriers to trade in the international community | C37 | ||

| Global green service risk: C4 | Proportion of global green service personnel investment | C41 | |

| Proportion of global green service investment | C42 | ||

| Global green service network coverage of the manufacturing industry | C43 | ||

| Global level of green product supply chain | C44 | ||

| Global after sales technical service capacity of green products | C45 |

| Linguistic Variables | Abbreviations | TFNs |

|---|---|---|

| Very low risk | VP | (0.0, 0.0, 0.1) |

| Low risk | P | (0.0, 0.1, 0.3) |

| Medium low risk | MP | (0.1, 0.3, 0.5) |

| Medium risk | M | (0.3, 0.5, 0.7) |

| Medium high risk | MG | (0.5, 0.7, 0.9) |

| High risk | G | (0.7, 0.9, 1.0) |

| Very high risk | VG | (0.9, 1.0, 1.0) |

| WC1 = 0.310 | C11 | C12 | C13 | C14 | C15 | C16 | |

| Hierarchy weights | 0.210 | 0.189 | 0.164 | 0.136 | 0.152 | 0.149 | |

| Combination weights | 0.065 | 0.059 | 0.051 | 0.042 | 0.047 | 0.046 | |

| WC2 = 0.265 | C21 | C22 | C23 | C24 | C25 | C26 | C27 |

| Hierarchy weights | 0.173 | 0.149 | 0.162 | 0.145 | 0.127 | 0.119 | 0.125 |

| Combination weights | 0.046 | 0.039 | 0.043 | 0.038 | 0.034 | 0.032 | 0.033 |

| WC3 = 0.234 | C31 | C32 | C33 | C34 | C35 | C36 | C37 |

| Hierarchy weights | 0.159 | 0.150 | 0.142 | 0.147 | 0.131 | 0.125 | 0.146 |

| Combination weights | 0.037 | 0.035 | 0.033 | 0.034 | 0.031 | 0.029 | 0.034 |

| WC4 = 0.191 | C41 | C42 | C43 | C44 | C45 | ||

| Hierarchy weights | 0.231 | 0.210 | 0.187 | 0.169 | 0.203 | ||

| Combination weights | 0.044 | 0.040 | 0.036 | 0.032 | 0.039 | ||

| C1 | C2 | C3 | C4 | C | |

|---|---|---|---|---|---|

| VT1 | 0.5505 | 0.5519 | 0.6291 | 0.6356 | 0.5855 |

| VT2 | 0.5664 | 0.5868 | 0.6480 | 0.6255 | 0.6022 |

| VT3 | 0.5786 | 0.5763 | 0.6448 | 0.6397 | 0.6051 |

| CV | 0.5706 | 0.5743 | 0.6427 | 0.6356 | 0.6009 |

| WCi | 0.3100 | 0.2650 | 0.2340 | 0.1910 | 1.0000 |

| Risk Categories | Risk Factors | Response Strategy to Green Innovation Risk | |||

|---|---|---|---|---|---|

| Risk Aversion | Risk Transfer | Risk Reduction | Risk Acceptance | ||

| Global green R&D risk | Green R&D personnel factor | ○ | ○ | ||

| Green R&D funding factor | ○ | ||||

| Green technology R&D factor | ○ | ○ | ○ | ||

| Green technology application factor | ○ | ||||

| International transfer of green technology factor | ○ | ||||

| International protection factors for green technology patents factor | ○ | ○ | |||

| Global green manufacturing risk | Green manufacturing personnel factor | ○ | |||

| Green manufacturing capital factor | ○ | ||||

| Green manufacturing product production factor | ○ | ||||

| Green manufacturing product quality factor | ○ | ○ | |||

| Global outsourcing of green products factor | ○ | ||||

| Green manufacturing technology transformation factor | ○ | ||||

| Green manufacturing cost factor | ○ | ○ | ○ | ||

| Global green marketing risk | The green marketer factor | ○ | |||

| Green marketing funding factor | ○ | ||||

| International demand for green products factor | ○ | ○ | |||

| Green product international competition factor | ○ | ||||

| Green product international marketing channel factor | ○ | ○ | |||

| The commercialization and internationalization of green technology factor | ○ | ||||

| International community green technical trade factor | ○ | ○ | |||

| Global green service risk | Green service personnel factor | ○ | |||

| Green service funding factor | ○ | ||||

| Green service point factor | ○ | ○ | |||

| Globalization of green product supply chain factor | ○ | ○ | |||

| Green product global after-sales service factor | ○ | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Bi, K.; Yin, S. Measuring and Integrating Risk Management into Green Innovation Practices for Green Manufacturing under the Global Value Chain. Sustainability 2020, 12, 545. https://doi.org/10.3390/su12020545

Sun Y, Bi K, Yin S. Measuring and Integrating Risk Management into Green Innovation Practices for Green Manufacturing under the Global Value Chain. Sustainability. 2020; 12(2):545. https://doi.org/10.3390/su12020545

Chicago/Turabian StyleSun, Yingying, Kexin Bi, and Shi Yin. 2020. "Measuring and Integrating Risk Management into Green Innovation Practices for Green Manufacturing under the Global Value Chain" Sustainability 12, no. 2: 545. https://doi.org/10.3390/su12020545

APA StyleSun, Y., Bi, K., & Yin, S. (2020). Measuring and Integrating Risk Management into Green Innovation Practices for Green Manufacturing under the Global Value Chain. Sustainability, 12(2), 545. https://doi.org/10.3390/su12020545