On the Development and Experimental Validation of a Novel and Intuitive Interior Permanent Magnet Synchronous Motor Controller for Electric Vehicle Application

Abstract

1. Introduction

2. Methodology

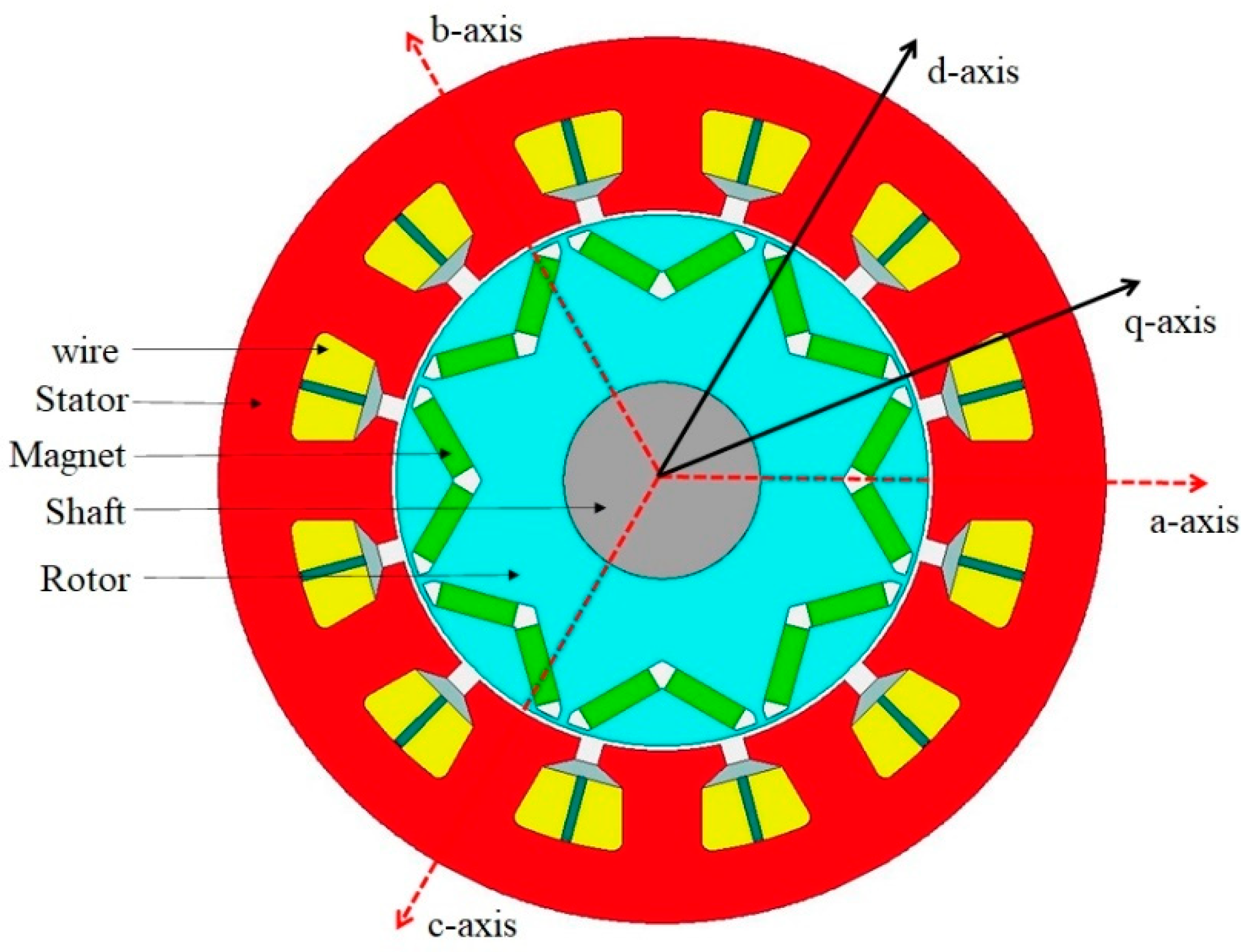

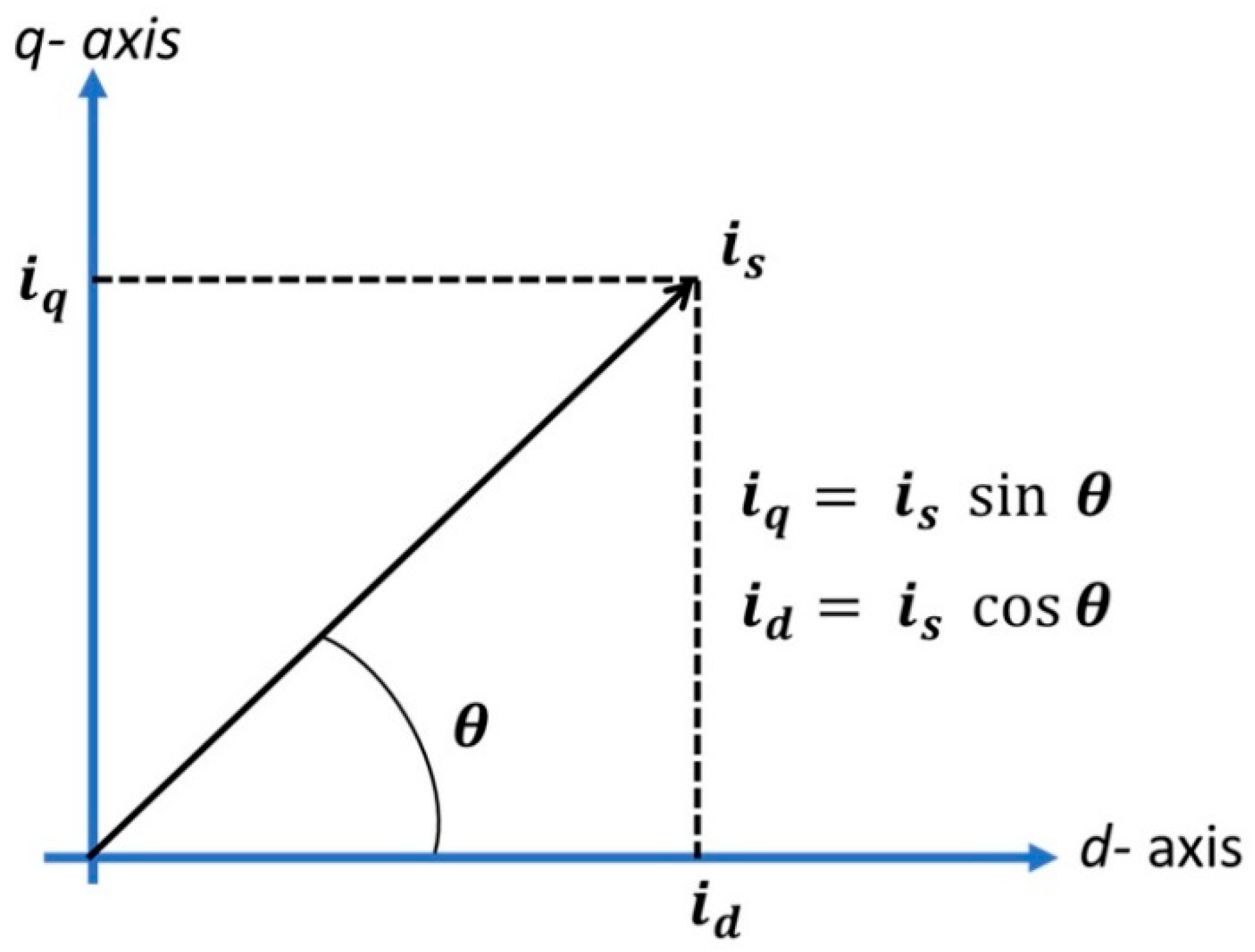

2.1. Basic Mathematical Control Equations of the 3-Phase V-Shaped IPMSM

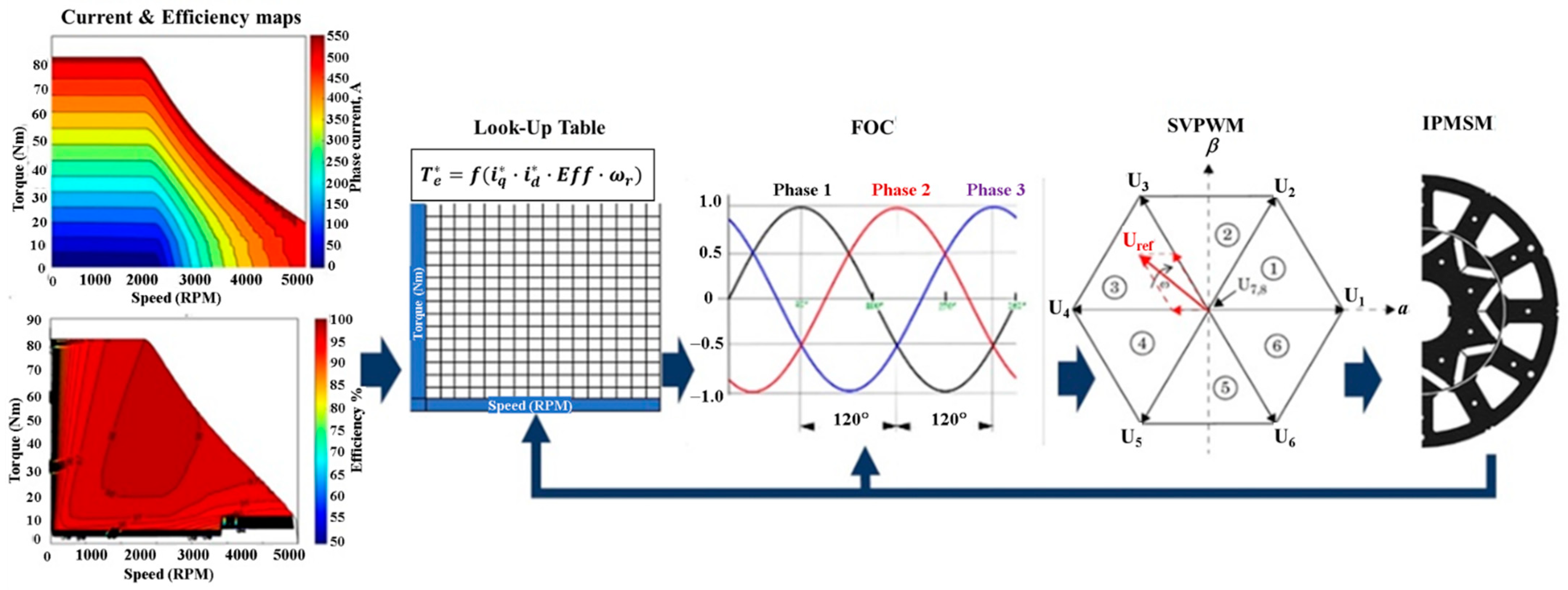

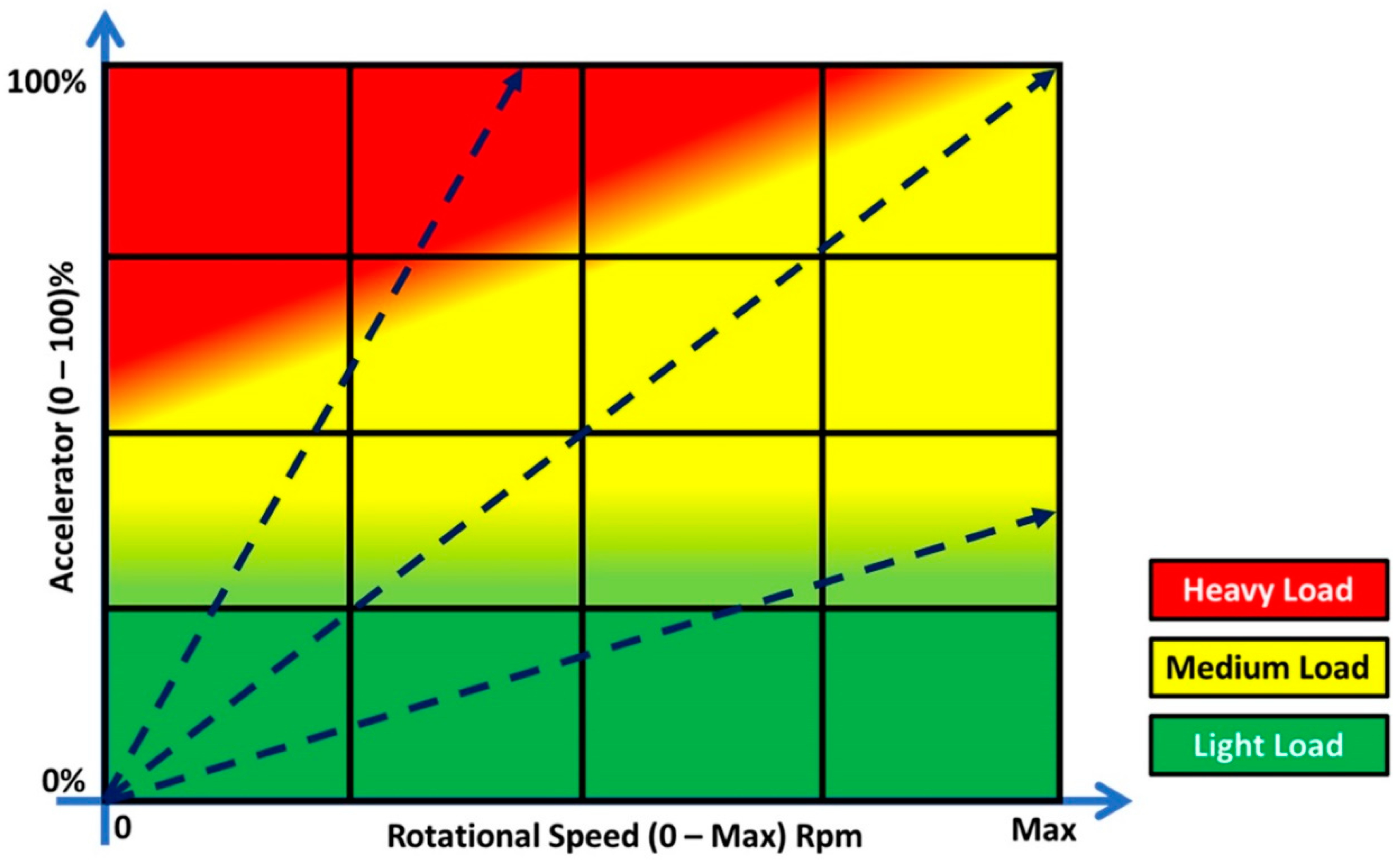

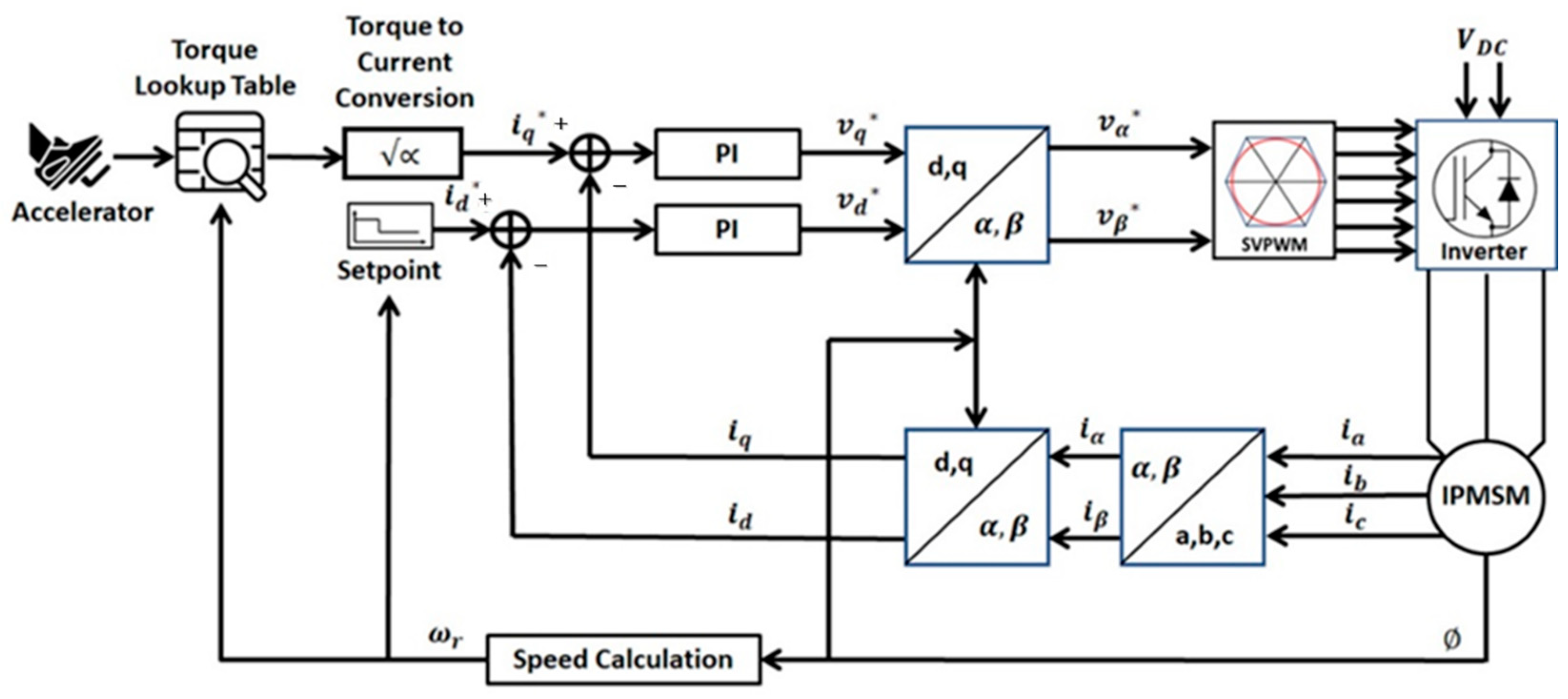

2.2. Proposed Control Algorithm for the IPMSM

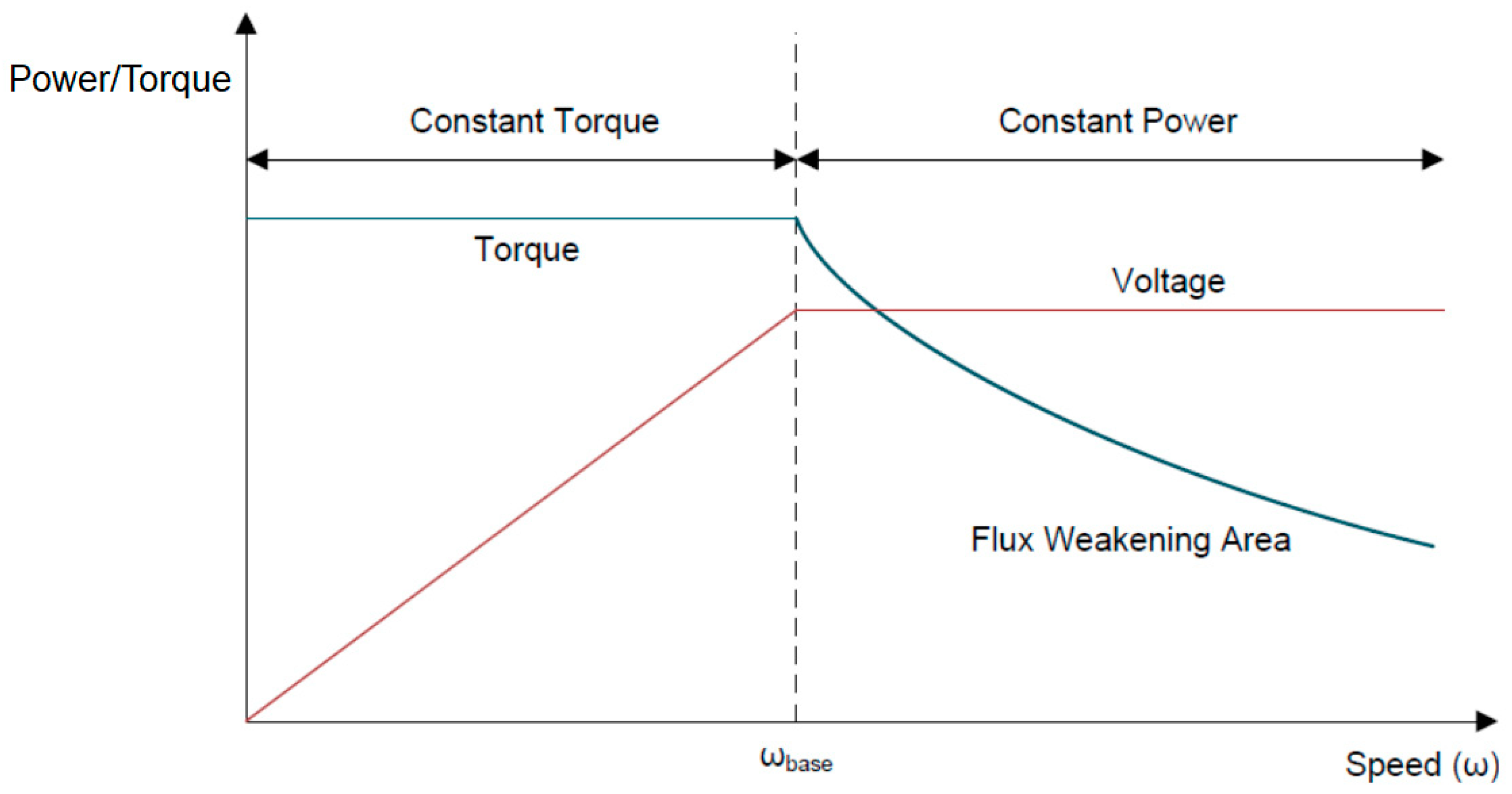

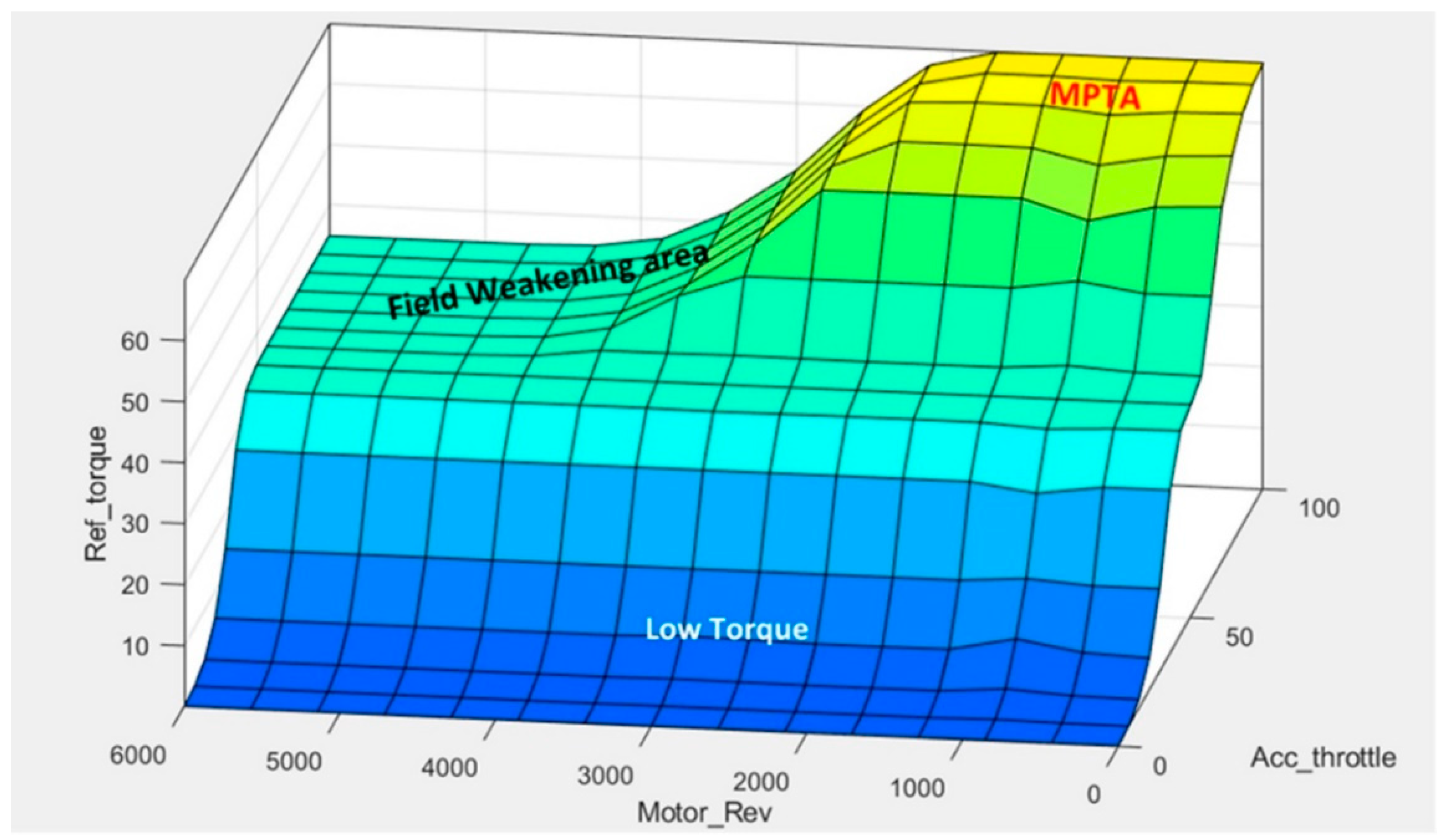

2.3. Constant Torque Region

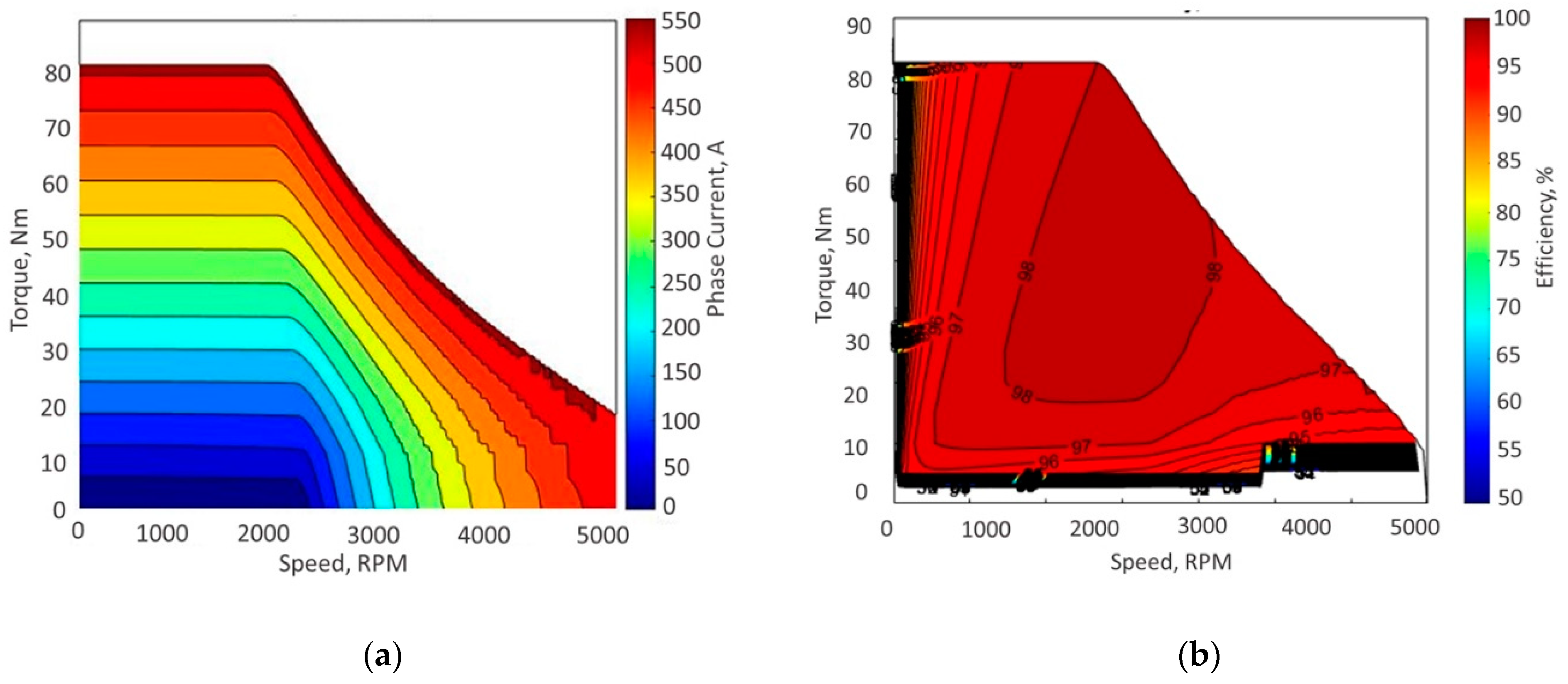

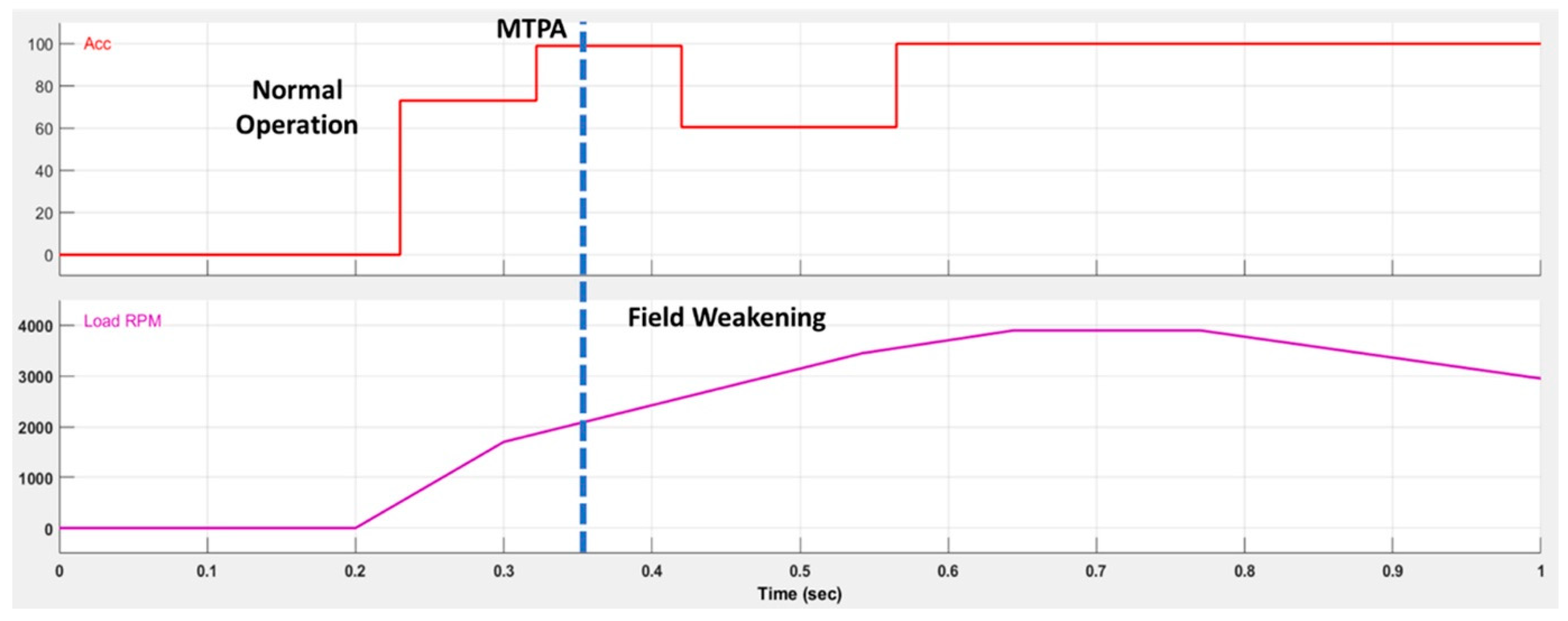

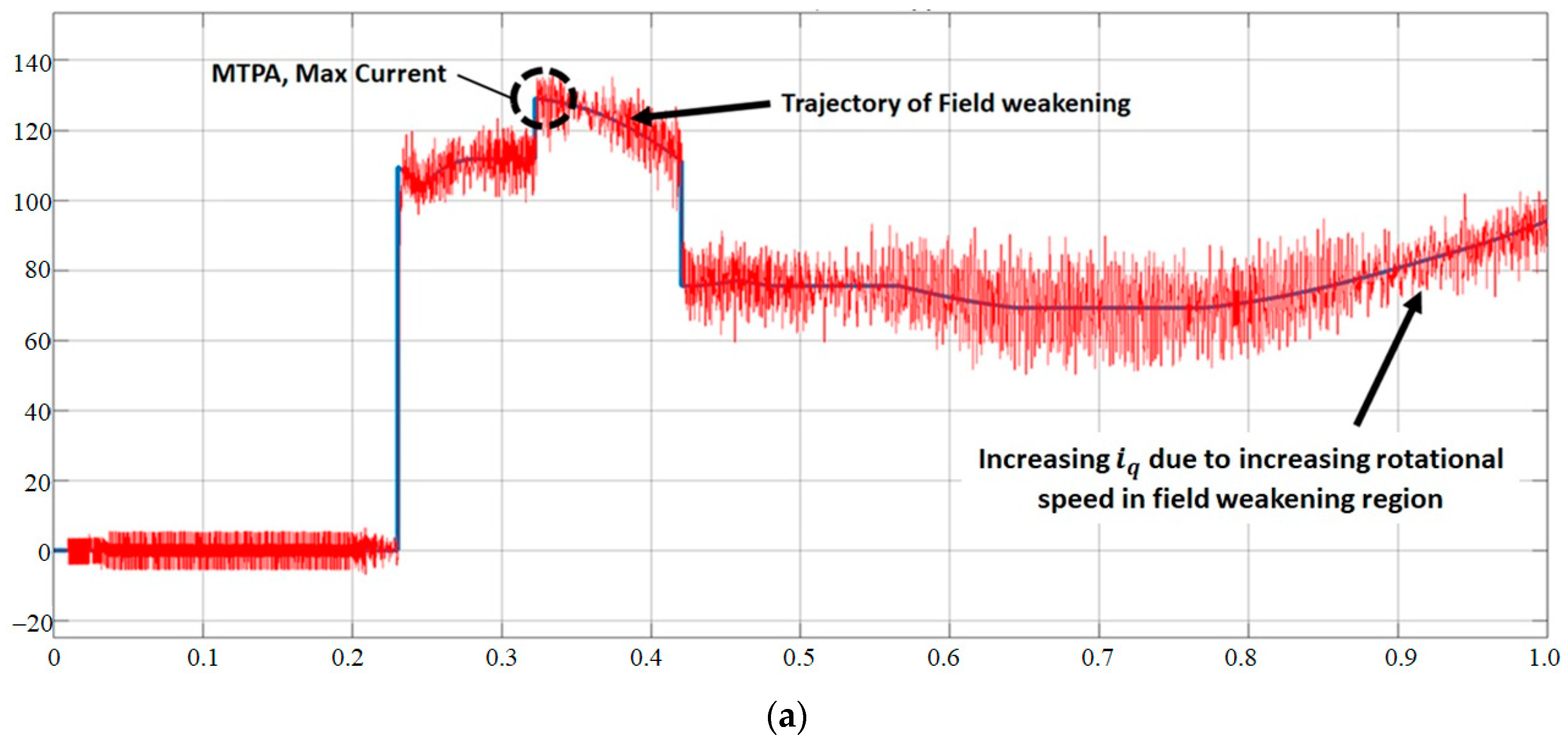

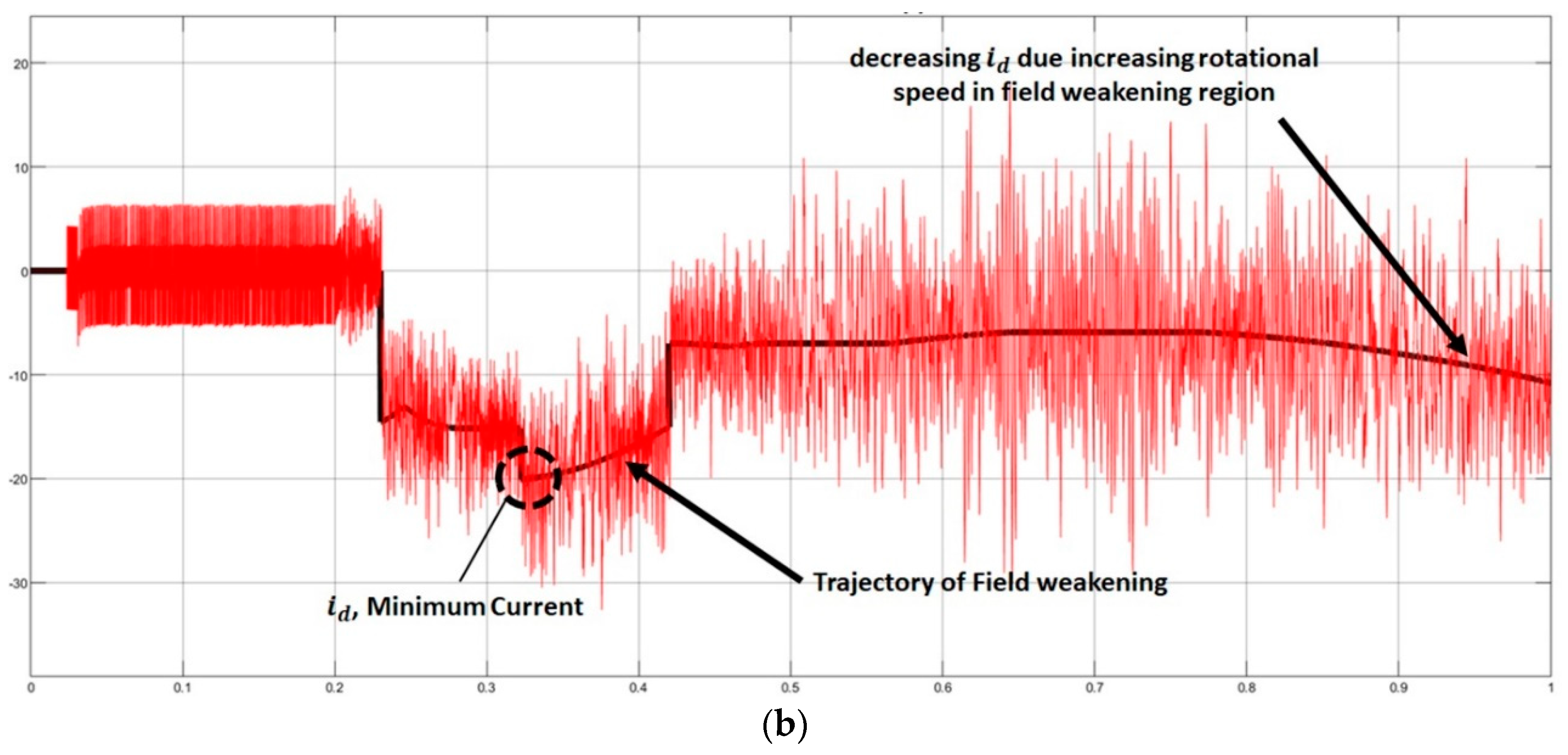

2.4. Constant Power/Flux Weakening Region

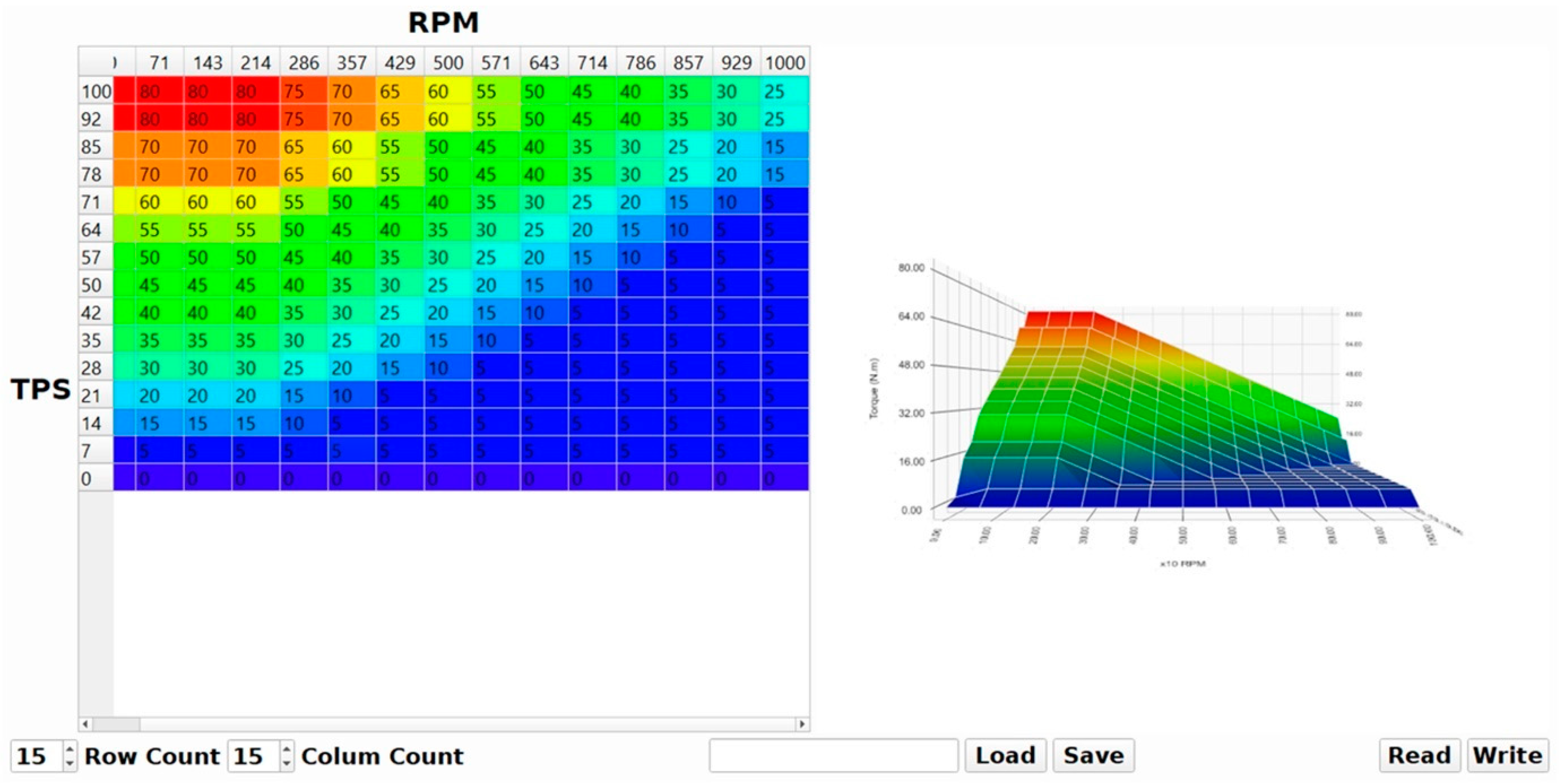

2.5. Lookup Table Development

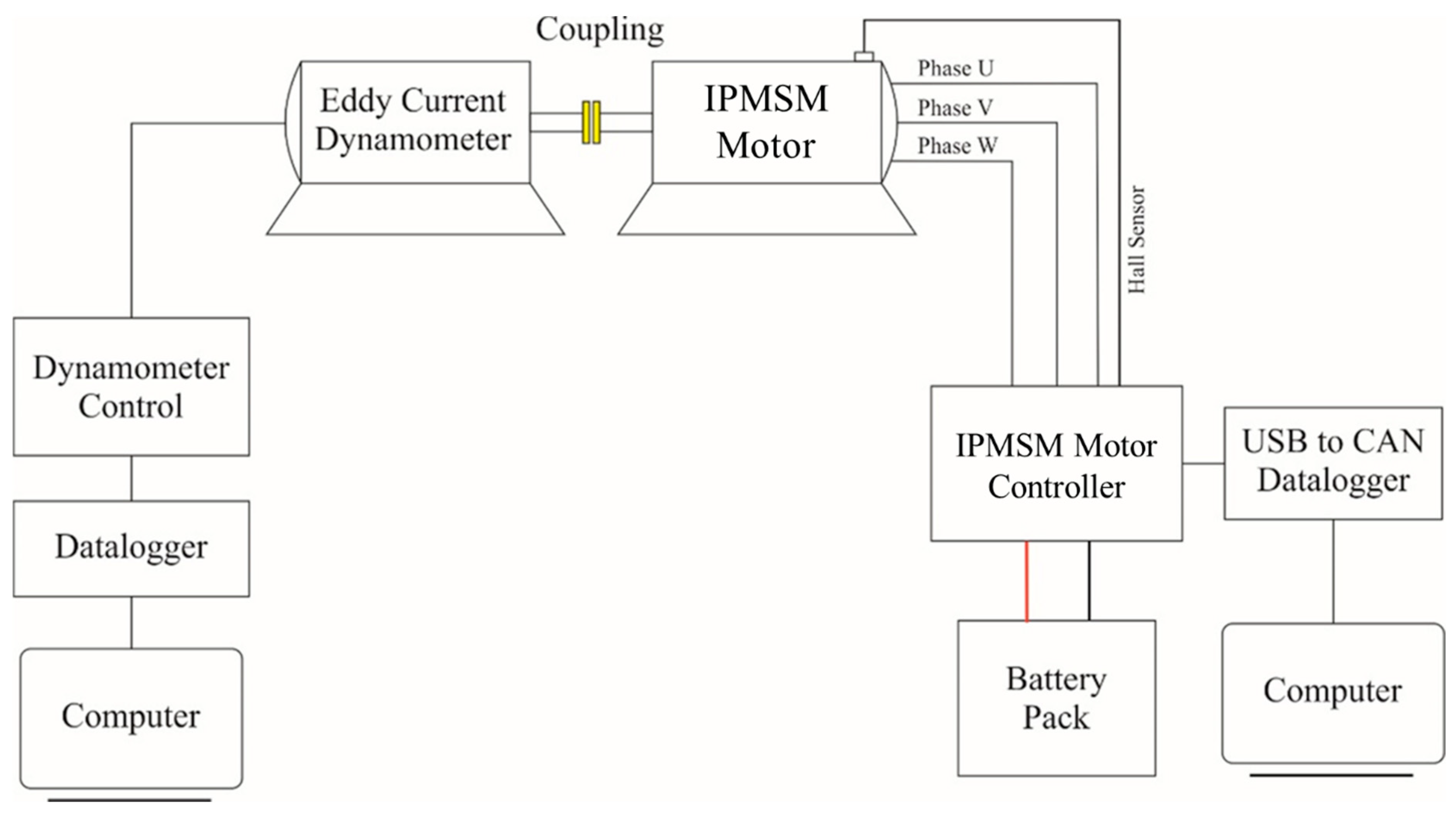

3. Experimental Set-Up of the Proposed PMSM Controller

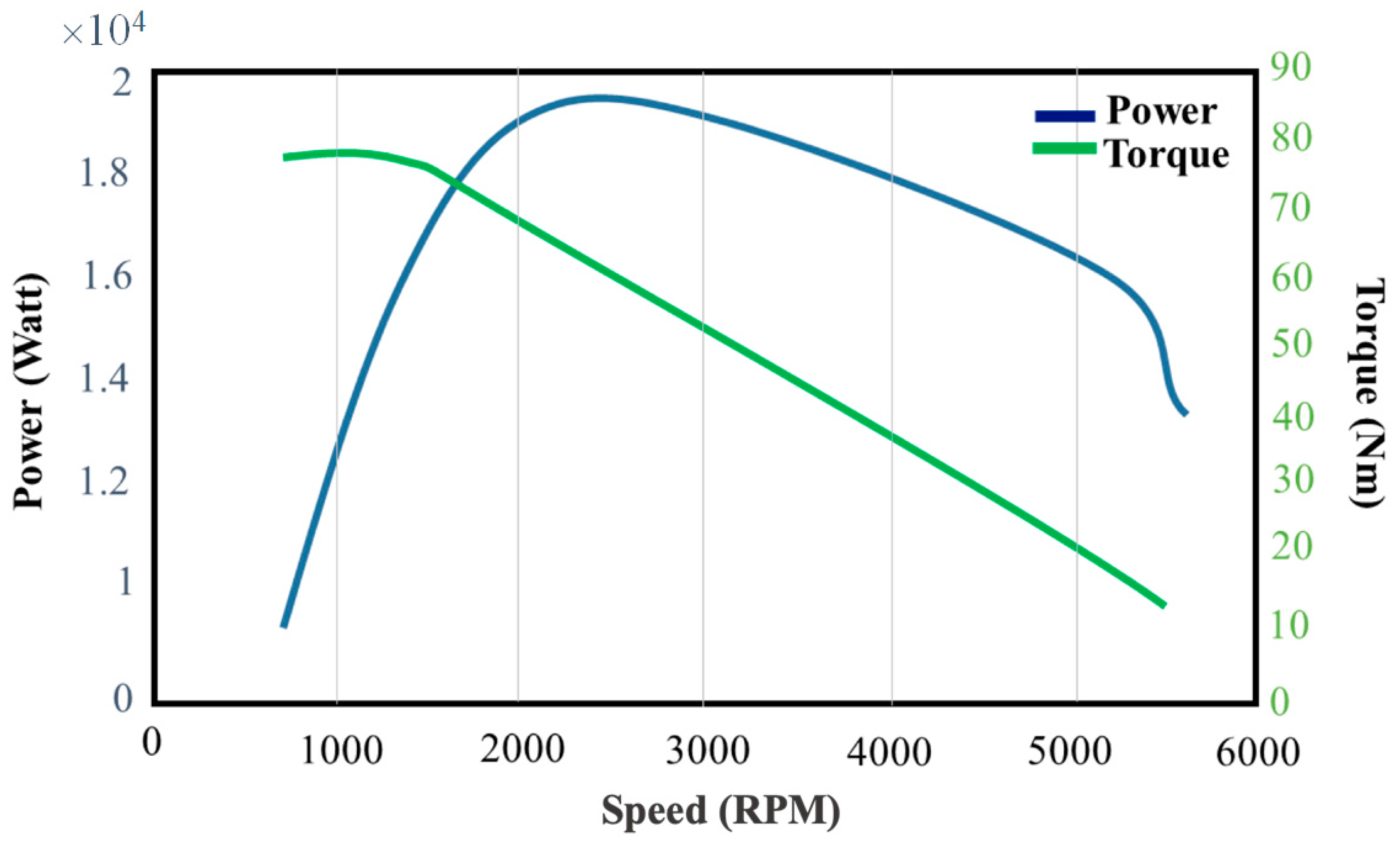

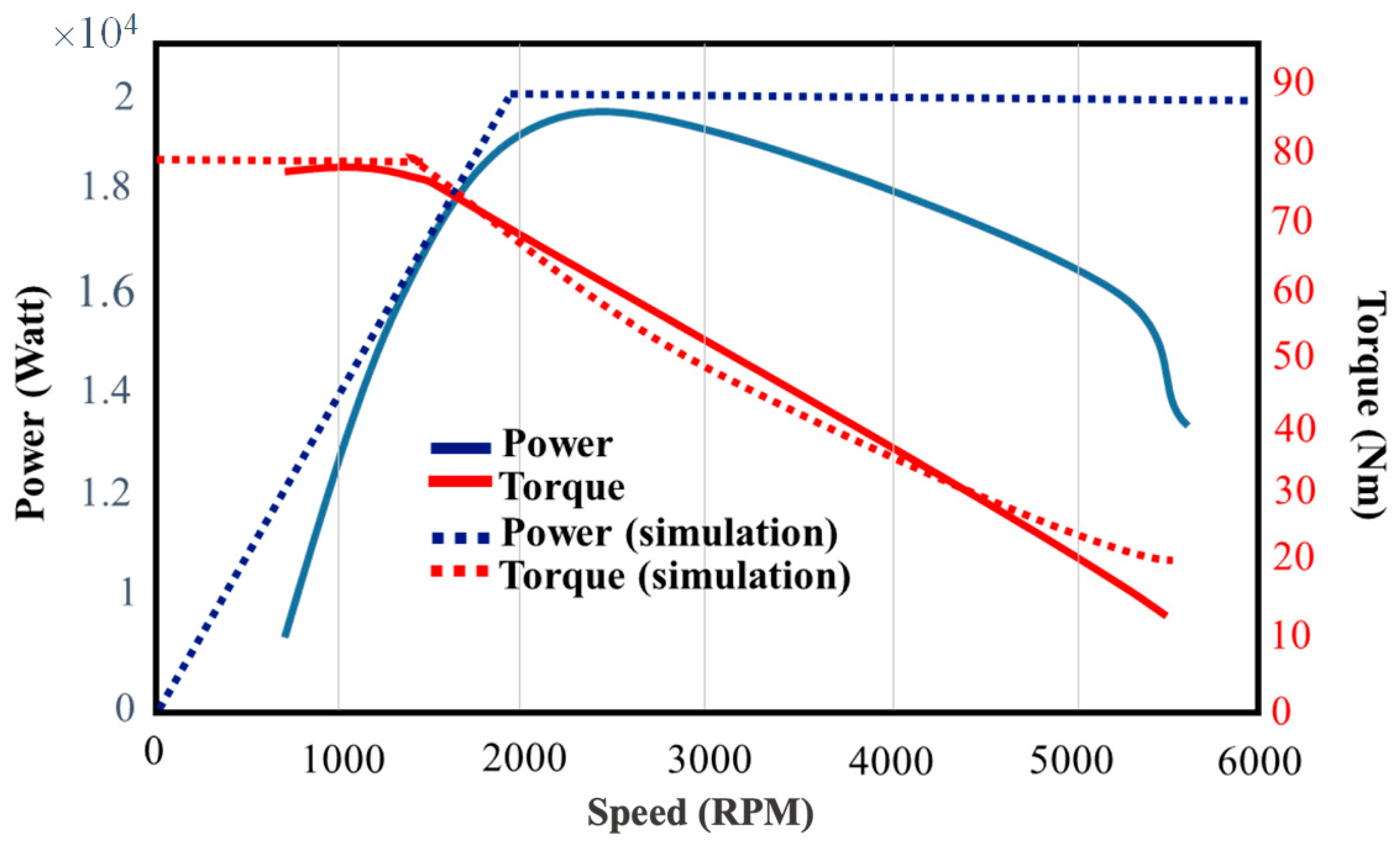

4. Discussions and Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Benchaib, A.; Poullain, S.; Thomas, J.L.; Alacoque, J.C. Discrete-Time Field-Oriented Control for SM-PMSM Including Voltage and Current Constraints. In Proceedings of the IEEE International Electric Machines and Drives Conference, IEMDC’03, Madison, WI, USA, 1–4 June 2003; Volume 4. [Google Scholar] [CrossRef]

- Feng, C.; Chaoying, X.; Xiaoxin, H. Study on the Losing Control Problem of Direct Torque Control in Permanent Magnet Synchronous Motor Drive. Trans. Inst. Meas. Control 2018, 41, 504–515. [Google Scholar] [CrossRef]

- Kommula, B.N.; Kota, V.R. Journal of King Saud University–Engineering Sciences Direct Instantaneous Torque Control of Brushless DC Motor Using Firefly Algorithm Based Fractional Order PID Controller. J. King Saud Univ.-Eng. Sci. 2018, 32, 133–140. [Google Scholar] [CrossRef]

- Vajsz, T.; Számel, L.; Rácz, G. A Novel Modified DTC-SVM Method with Better Overload-Capability for Permanent Magnet Synchronous Motor Servo Drives. Period. Polytech. Electr. Eng. Comput. Sci. 2017, 61, 253–263. [Google Scholar] [CrossRef]

- Zurbriggen, F.; Ott, T.; Onder, C.H. Fast and Robust Adaptation of Lookup Tables in Internal Combustion Engines: Feedback and Feedforward Controllers Designed Independently. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2015, 230, 723–735. [Google Scholar] [CrossRef]

- Benfriha, E.; Mansouri, A.; Bendiabdellah, A.; Boufadene, M. Engineering Sciences Nonlinear Adaptive Observer for Sensorless Passive Control of Permanent Magnet Synchronous Motor. J. King Saud Univ.-Eng. Sci. 2019, 32, 510–517. [Google Scholar] [CrossRef]

- Carpiuc, S.C.; Lazar, C. Fast Real–Time Constrained Predictive Current Control in Permanent Magnet Synchronous Machine Based Automotive Traction Drives. IEEE Trans. Transp. Electrif. 2015, 1, 326–335. [Google Scholar] [CrossRef]

- Pollex, V.; Feld, T.; Slomka, F.; Margull, U.; Mader, R.; Wirrer, G. Sufficient Real-Time Analysis for an Engine Control Unit with Constant Angular Velocities. In Proceedings of the 2013 Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 18–22 March 2013; pp. 5–8. [Google Scholar] [CrossRef]

- Liang, P.; Pei, Y.; Chai, F.; Zhao, K. Analytical Calculation of D-and Q -Axis Inductance. Energies 2016, 9, 580. [Google Scholar] [CrossRef]

- Chen, Z. Maximum Torque Per Ampere and Flux-Weakening Control for PMSM Based on Curve Fitting. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 3 September 2010; Volume 4, pp. 3–7. [Google Scholar] [CrossRef]

- Jahns, T.M. Flux-Weakening Regime Operation of an Interior Permanent-Magnet Synchronous Motor Drive. IEEE Trans. Ind. Appl. 1987, IA-23, 681–689. [Google Scholar] [CrossRef]

- Sudhoff, S.; Corzine, K.; Hegner, H. A Flux Weakening Strategy for Current Regulated Surface Mounted Permanent Magnet Machine Drives. IEEE Trans. Energy Convers. 1995, 10, 431–437. [Google Scholar] [CrossRef]

- Kwon, Y.; Kim, S.; Sul, S. Voltage Feedback Current Control Scheme for Improved Transient Performance of Permanent Magnet Synchronous Machine Drives. IEEE Trans. Ind. Electron. 2012, 59, 3373–3382. [Google Scholar] [CrossRef]

- Lin, P.; Lai, Y. Voltage Control Technique for the Extension of DC-Link Voltage Utilization of Finite-Speed SPMSM Drives. IEEE Trans. Ind. Electron. 2012, 59, 3392–3402. [Google Scholar] [CrossRef]

- Balashanmugham, A.; Maheswaran, M. Permanent-Magnet Synchronous Machine Drives. 2019. Available online: https://www.intechopen.com/chapters/68961 (accessed on 20 May 2022).

- Luo, G.; Zhang, R.; Chen, Z.; Tu, W.; Zhang, S.; Kennel, R.; Member, S. A Novel Nonlinear Modeling Method for Permanent Magnet Synchronous Motors. IEEE Trans. Ind. Electron. 2016, 46, 6490–6498. [Google Scholar] [CrossRef]

- Nanfang, Y.; Guangzhao, L.U.O.; Weiguo, L.I.U.; Kang, W. Interior Permanent Magnet Synchronous Motor Control for Electric Vehicle Using Look-up Table. In Proceedings of the 7th International Power Electronics and Motion Control Conference, Harbin, China, 2–5 June 2012; Volume 3, pp. 1015–1019. [Google Scholar] [CrossRef]

- Hu, D.; Xu, L. Characterizing the Torque Lookup Table of an IPM Machine for Automotive Application. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014. [Google Scholar] [CrossRef]

- Ji, Y.B.; Lee, J.H. Feedforward Interpolation Error Compensation Method for Field Weakening Operation Region of PMSM Drive. Electronics 2019, 8, 1052. [Google Scholar] [CrossRef]

- Kim, D.Y.; Lee, J.H. Compensation of Interpolation Error for Look-up Table-Based Pmsm Control Method in Maximum Power Control. Energies 2021, 14, 5526. [Google Scholar] [CrossRef]

- Yuniarto, M.N.; Nugraha, Y.U.; Negara, I.M.Y.; Asfani, D.A.; Sidharta, I. Designing and Performance Investigation of Permanent Magnet Motor Prototype for UTV Electric Drive Train Application. Int. J. Power Electron. Drive Syst. 2021, 12, 2018–2029. [Google Scholar] [CrossRef]

- Thike, R.; Member, S.; Pillay, P. Mathematical Model of an Interior PMSM with Aligned Magnet and Reluctance Torques. IEEE Trans. Transp. Electrif. 2020, 6, 647–658. [Google Scholar] [CrossRef]

- Barcaro, M.; Bianchi, N. Interior PM Machines Using Ferrite to Substitute Rare–Earth Surface PM Machines. In Proceedings of the 2012 XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 1339–1345. [Google Scholar] [CrossRef]

- Bilgin, B.; Member, S.; Liang, J.; Terzic, M.V.; Dong, J.; Member, S.; Trickett, E.; Emadi, A. Modeling and Analysis of Electric Motors: State-of-the-Art Review. IEEE Trans. Transp. Electrif. 2019, 5, 602–617. [Google Scholar] [CrossRef]

- Lee, H. Characteristic Analysis of a V-Shape Interior Permanent Magnet Synchronous Motor According to Design Parameter. In Proceedings of the 2018 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Korea, 7–10 October 2018; pp. 505–509. [Google Scholar] [CrossRef]

- Qi, G.; Chen, J.T.; Zhu, Z.Q.; Howe, D.; Zhou, L.B.; Gu, C.L. Influence of Skew and Cross-Coupling on Flux-Weakening Performance of Permanent-Magnet Brushless AC Machines. IEEE Trans. Magn. 2009, 45, 2110–2117. [Google Scholar] [CrossRef]

- Vagati, A.; Boazzo, B.; Guglielmi, P. Design of Ferrite-Assisted Synchronous Reluctance Machines Robust Toward Demagnetization. IEEE Trans. Ind. Appl. 2014, 50, 1768–1779. [Google Scholar] [CrossRef]

- Zhang, H.; Dou, M.; Deng, J. Loss-Minimization Strategy of Non-Sinusoidal Back-EMF PMSM in Multiple Synchronous Reference Frames. IEEE Trans. Power Electron. 2019, 35, 8335–8346. [Google Scholar] [CrossRef]

- Deng, T.; Su, Z.; Li, J.; Tang, P.; Chen, X.; Liu, P. Advanced Angle Field Weakening Control Strategy of Permanent Magnet Synchronous Motor. IEEE Trans. Veh. Technol. 2019, 9545, 3424–3435. [Google Scholar] [CrossRef]

- Pan, C.; Sue, S. A Linear Maximum Torque Per Ampere Control for IPMSM Drives Over Full-Speed Range. IEEE Trans. Energy Convers. 2005, 20, 359–366. [Google Scholar] [CrossRef]

- Wang, J.; Jing, M.; Fan, H.; Liu, H.; Shi, B. Study on Unbalance Magnetic Pull of the Motorized Spindle under Different Rotor Eccentricities. In Proceedings of the 13th International Conference on Ubiquitous Robots and Ambient Intelligence (URAl), Xi’an, China, 19–22 August 2016; pp. 781–785. [Google Scholar] [CrossRef]

- Zhang, K.; Li, G.J.; Zhu, Z.Q.; Jewell, G.W. Investigation on Contribution of Inductance Harmonics to Torque Production in Multiphase Doubly Salient Synchronous Reluctance Machines. IEEE Trans. Magn. 2019, 55, 1–10. [Google Scholar] [CrossRef]

- Fadel, M.; Sepulchre, L.; David, M.; Porte, G. MTPV Flux Weakening Strategy for PMSM. IEEE Trans. Ind. Appl. 2018, 54, 6081–6089. [Google Scholar] [CrossRef]

- Miguel-espinar, C.; Heredero-peris, D.; Gross, G.; Llonch-masachs, M.; Montesinos-miracle, D.; Member, F. Maximum Torque per Voltage Flux-Weakening Strategy with Speed Limiter for PMSM Drives. IEEE Trans. Ind. Electron. 2020, 68, 9254–9264. [Google Scholar] [CrossRef]

- Inoue, T.; Inoue, Y.; Morimoto, S.; Sanada, M. Mathematical Model for MTPA Control of Permanent-Magnet Synchronous Motor in Stator Flux Linkage Synchronous Frame. IEEE Trans. Ind. Appl. 2015, 9994, 3620–3628. [Google Scholar] [CrossRef]

- Bose, B.K. Power Electronics and Variable Frequency Drives, 1st ed.; Knoville, Ed.; IEEE Press: New York, NY, USA, 1997. [Google Scholar]

- PMSM Field-Weakening Control. Available online: https://www.mathworks.com/help/physmod/sps/ug/pmsm-field-weakening-control.html#d123e41959 (accessed on 13 May 2022).

| Parameter | Value | Unit |

|---|---|---|

| Stator outer/inner diameters | 180 | mm |

| Rotor outer/inner diameters | 108 | mm |

| Tooth width | 15.9 | mm |

| Tooth depth | 22 | mm |

| Stack length | 90 | mm |

| Magnet type/thickness | N42H/5 | mm |

| Magnet width | 90 | mm |

| Magnet angle | 43 | Deg (°) |

| Slots/poles (SP) | 12/8 | |

| Air-gap | 1 | mm |

| Rated power | 20 | kW |

| Rated speed | 6000 | RPM |

| Rated torque | 82 | Nm |

| Phase | 3 | Phase |

| Direct current (DC) link voltage | 100 | V |

| Peak current | 550 | A |

| RMS current | 389 | A |

| Inertia | 0.007629 | Kgm2 |

| Resistance | 0.002405 | Ohms |

| D-axis inductance | 0.00002939 | H |

| Q-axis inductance | 0.00004914 | H |

| D-axis reactance | 0.0714 | Ohms |

| Q-axis reactance | 0.1194 | Ohms |

| Flux linkage D (Q-axis current) | 20.2085 | mVs |

| Flux linkage Q (Q-axis current) | 14.6478 | mVs |

| Flux linkage D (on load) | 10.8567 | mVs |

| Flux linkage Q (on load) | 15.6358 | mVs |

| Phase (elec deg) | 45 | Deg (°) |

| Drive mode | Sine | |

| Winding connection | Star/Wye | |

| Magnetization | Radial |

| Kp | Ki | |

|---|---|---|

| 1.0744 | 1061.5 | |

| 0.8779 | 710.3004 |

| Constant Torque Region | Field-Weakening Region | |||

|---|---|---|---|---|

| Torque (Nm) | Base Speed (RPM) | Power (kW) | Max. Speed (RPM) | |

| Simulation | 75 | 2000 | 20 | 6000 |

| Experimental | 80 | 1500 | 19 | 5500 |

| Difference | 7% | −25% | −5% | −8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuniarto, M.N.; Sidharta, I.; Yohanes, Y.; Nugraha, Y.U. On the Development and Experimental Validation of a Novel and Intuitive Interior Permanent Magnet Synchronous Motor Controller for Electric Vehicle Application. World Electr. Veh. J. 2022, 13, 107. https://doi.org/10.3390/wevj13060107

Yuniarto MN, Sidharta I, Yohanes Y, Nugraha YU. On the Development and Experimental Validation of a Novel and Intuitive Interior Permanent Magnet Synchronous Motor Controller for Electric Vehicle Application. World Electric Vehicle Journal. 2022; 13(6):107. https://doi.org/10.3390/wevj13060107

Chicago/Turabian StyleYuniarto, Muhammad Nur, Indra Sidharta, Yohanes Yohanes, and Yoga Uta Nugraha. 2022. "On the Development and Experimental Validation of a Novel and Intuitive Interior Permanent Magnet Synchronous Motor Controller for Electric Vehicle Application" World Electric Vehicle Journal 13, no. 6: 107. https://doi.org/10.3390/wevj13060107

APA StyleYuniarto, M. N., Sidharta, I., Yohanes, Y., & Nugraha, Y. U. (2022). On the Development and Experimental Validation of a Novel and Intuitive Interior Permanent Magnet Synchronous Motor Controller for Electric Vehicle Application. World Electric Vehicle Journal, 13(6), 107. https://doi.org/10.3390/wevj13060107