Effect of Microstructure and Crystallographic Texture on the Fracture Toughness Anisotropy of LPBF IN718

Abstract

1. Introduction

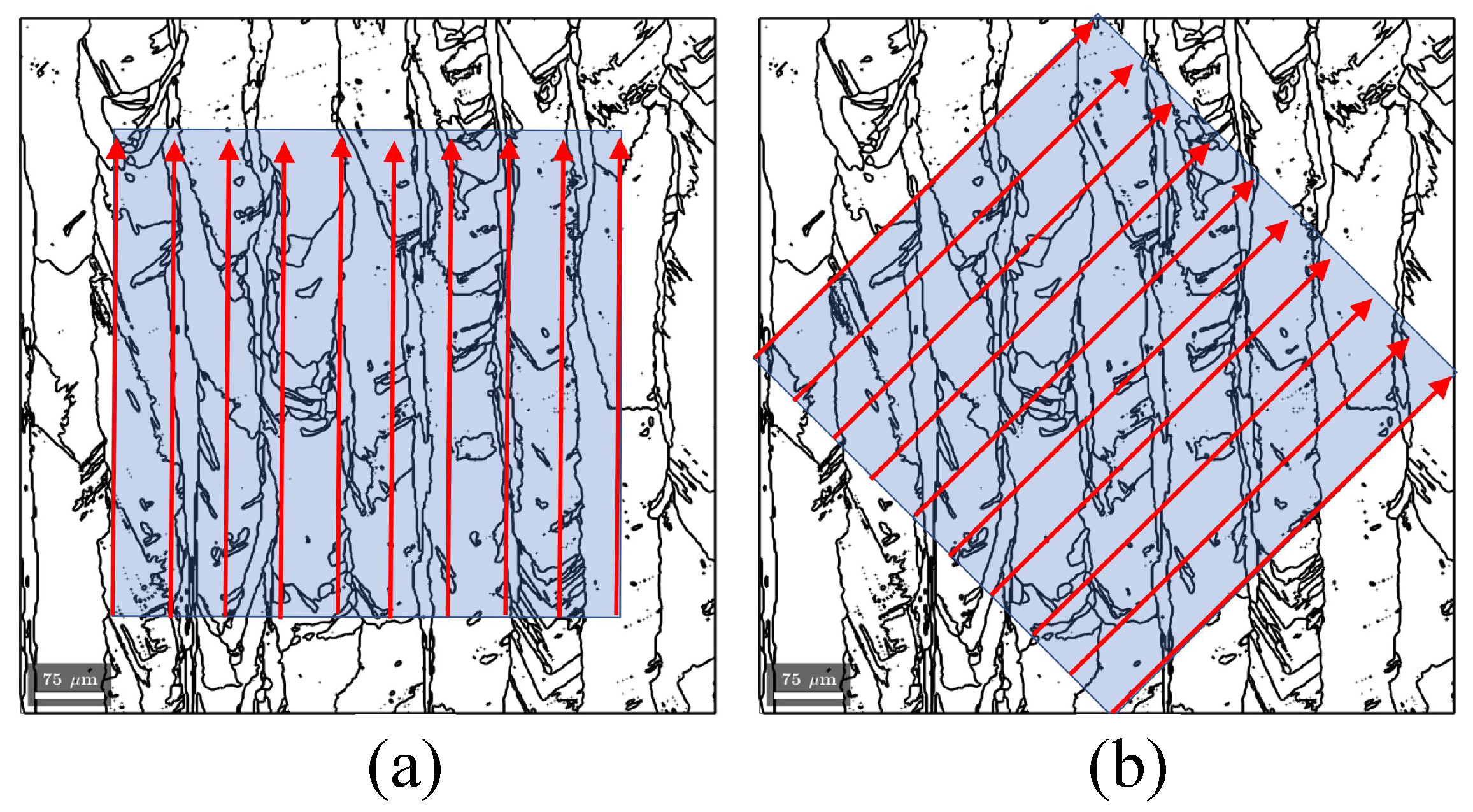

2. Materials and Methods

2.1. Materials and Specimen Preparation

2.2. Fracture Toughness Calculation via J-Integral

2.2.1. Standardized Method (M1): ASTM E1820 for CT Specimens

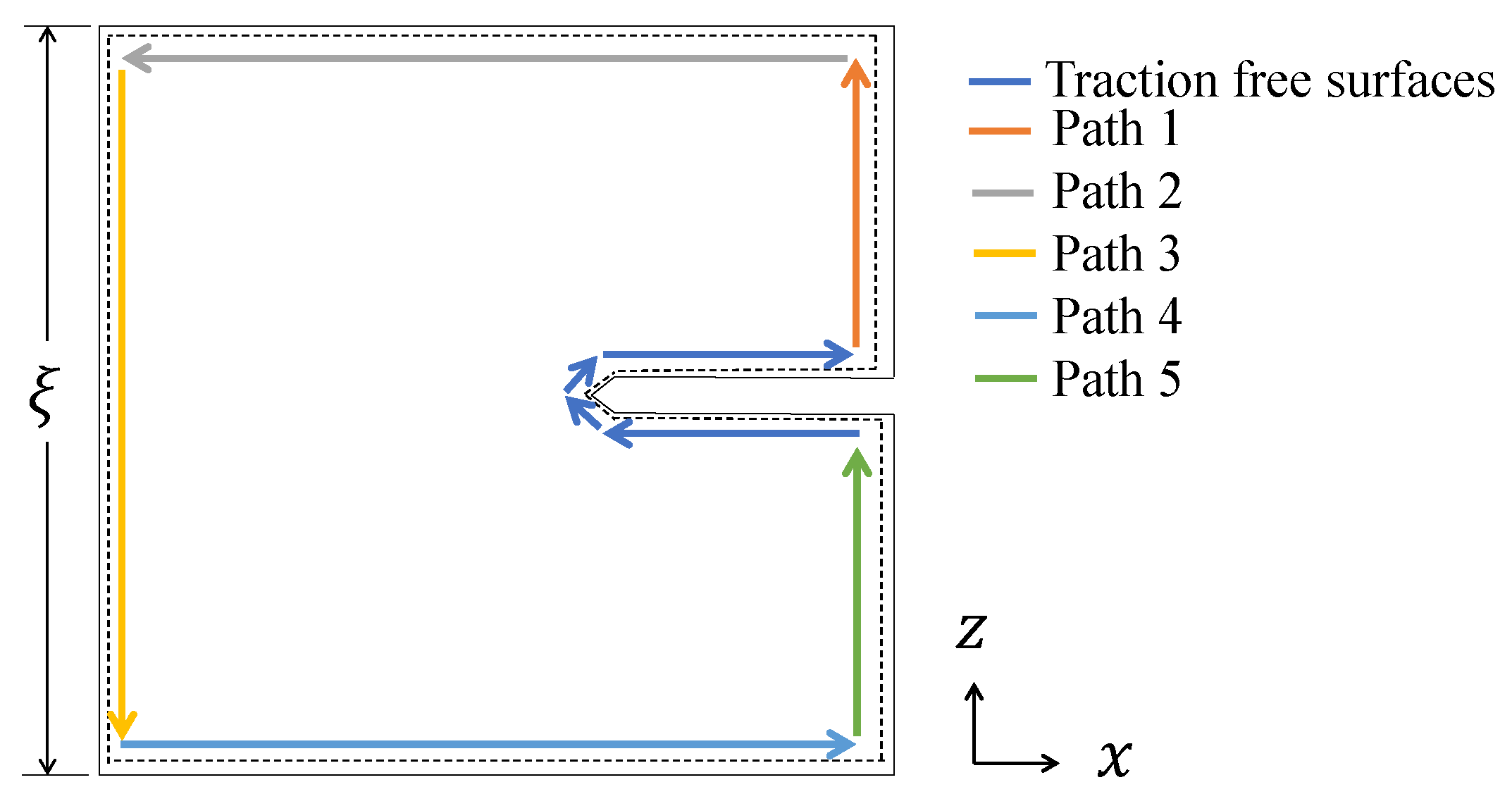

2.2.2. J-Integral Estimation via Simplified Contour Integration (M2): Rice’s Path-Independent Integral

- Along the segments corresponding to the traction free surfaces, it holds that and . Thus, by referring to Figure 3, the total contour integral can be decomposed as:

- For the outer segments, Path 1 and Path 5, direct evaluation of confirms that both the tractions and the strain energy density vanish. As a result, , , and consequently .

- For the crack surfaces, Path 2 and Path 4, the condition remains valid. Additionally, the traction vectors take the form , and the displacement gradients along x are given by ; therefore , yielding .

- Finally, due to the traction-free boundary condition on Path 3, the normal traction vanishes, i.e., .

3. Results

3.1. Elastic Components: Stress Intensity Factor and J-Integral

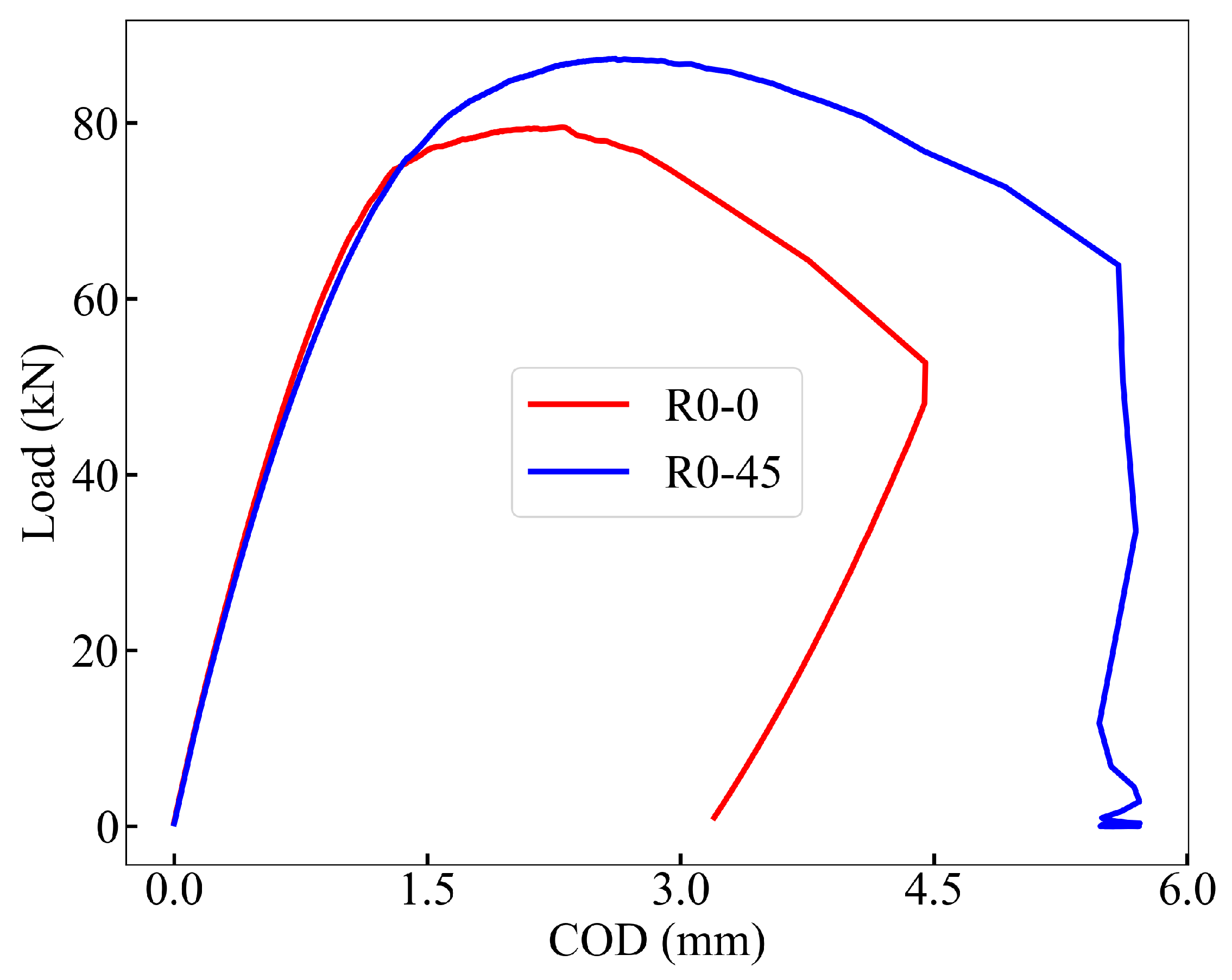

3.2. Fracture Toughness ()

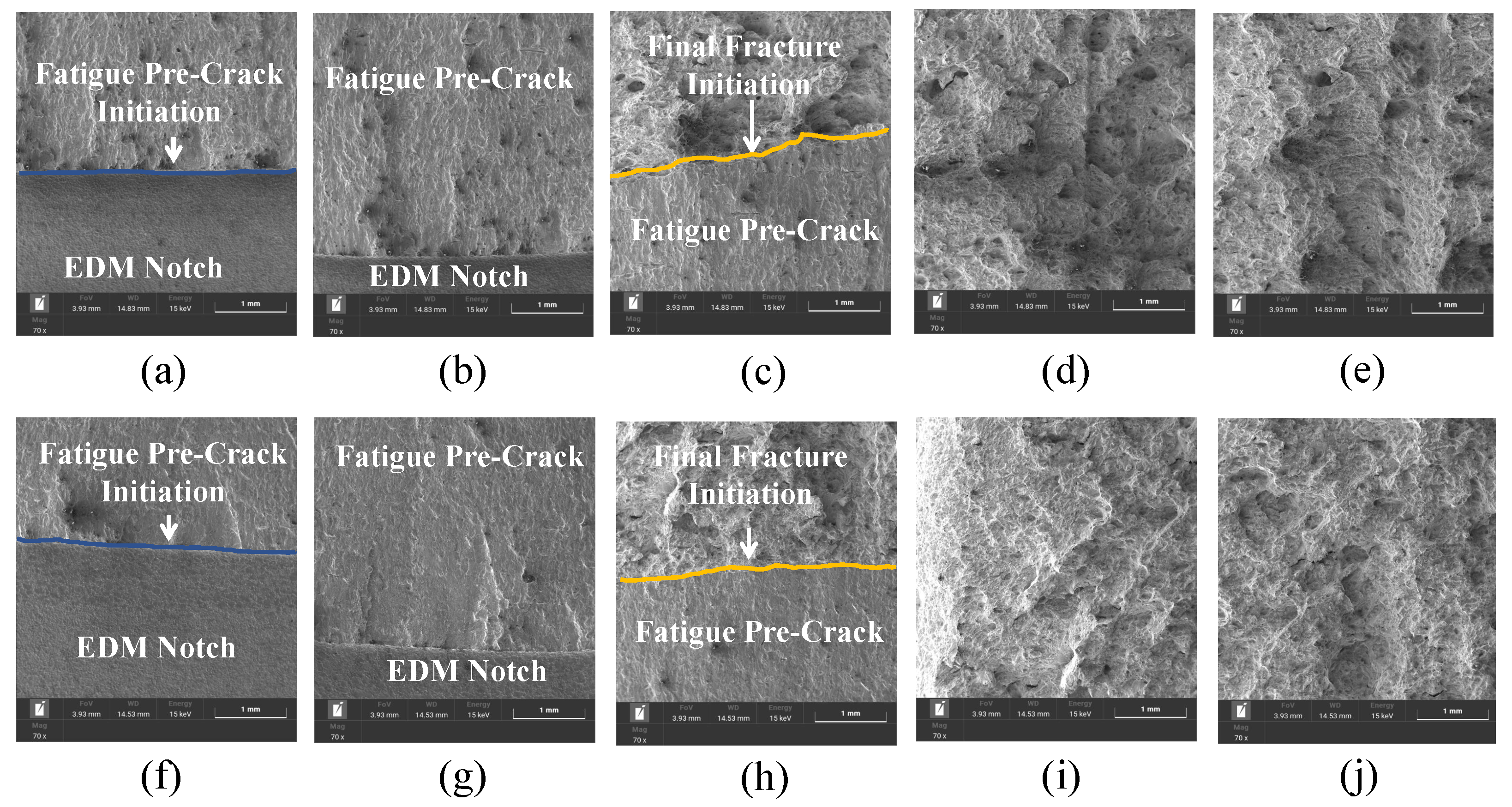

3.3. Fractographic Analysis Based on SEM Observations

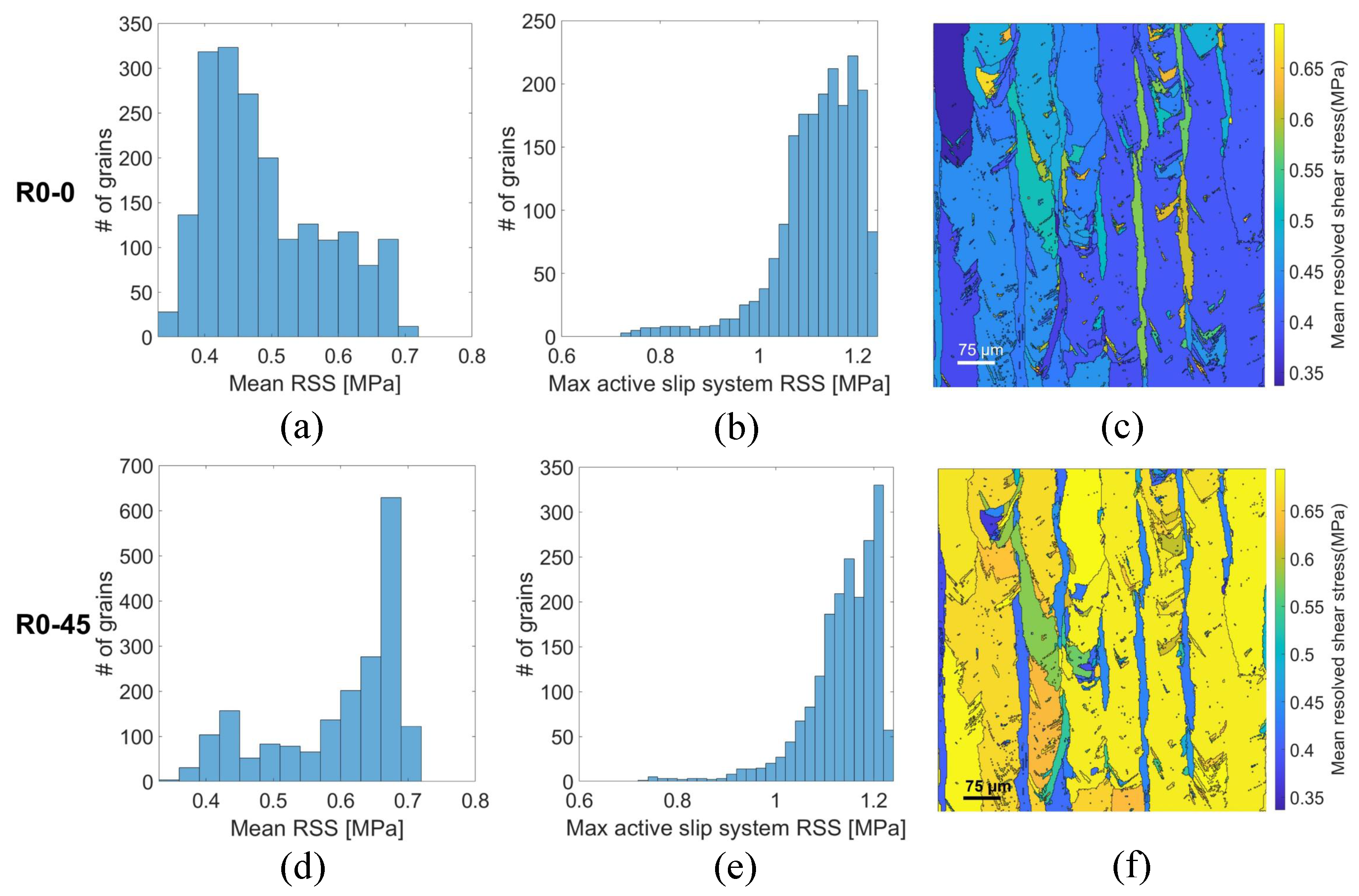

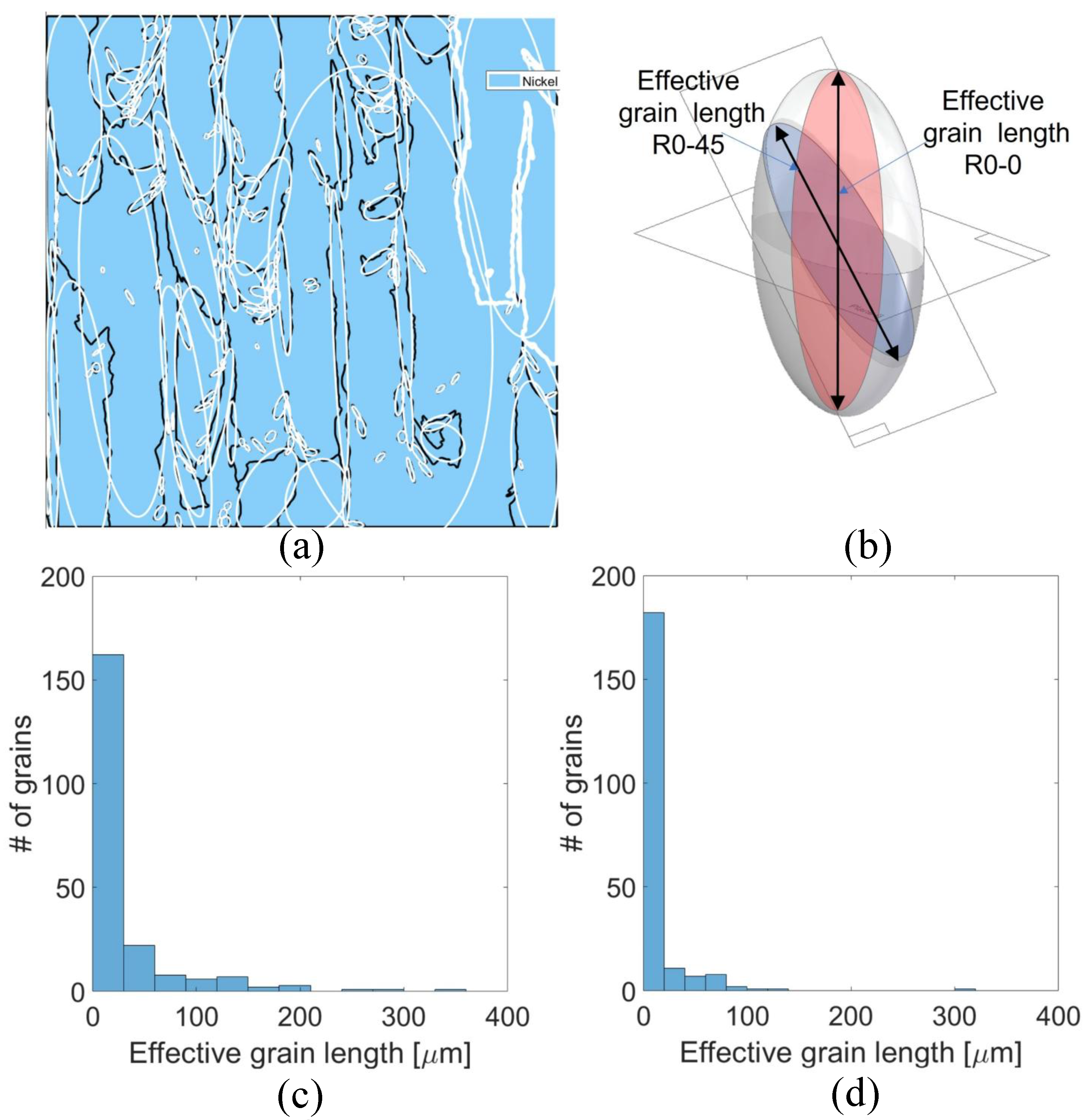

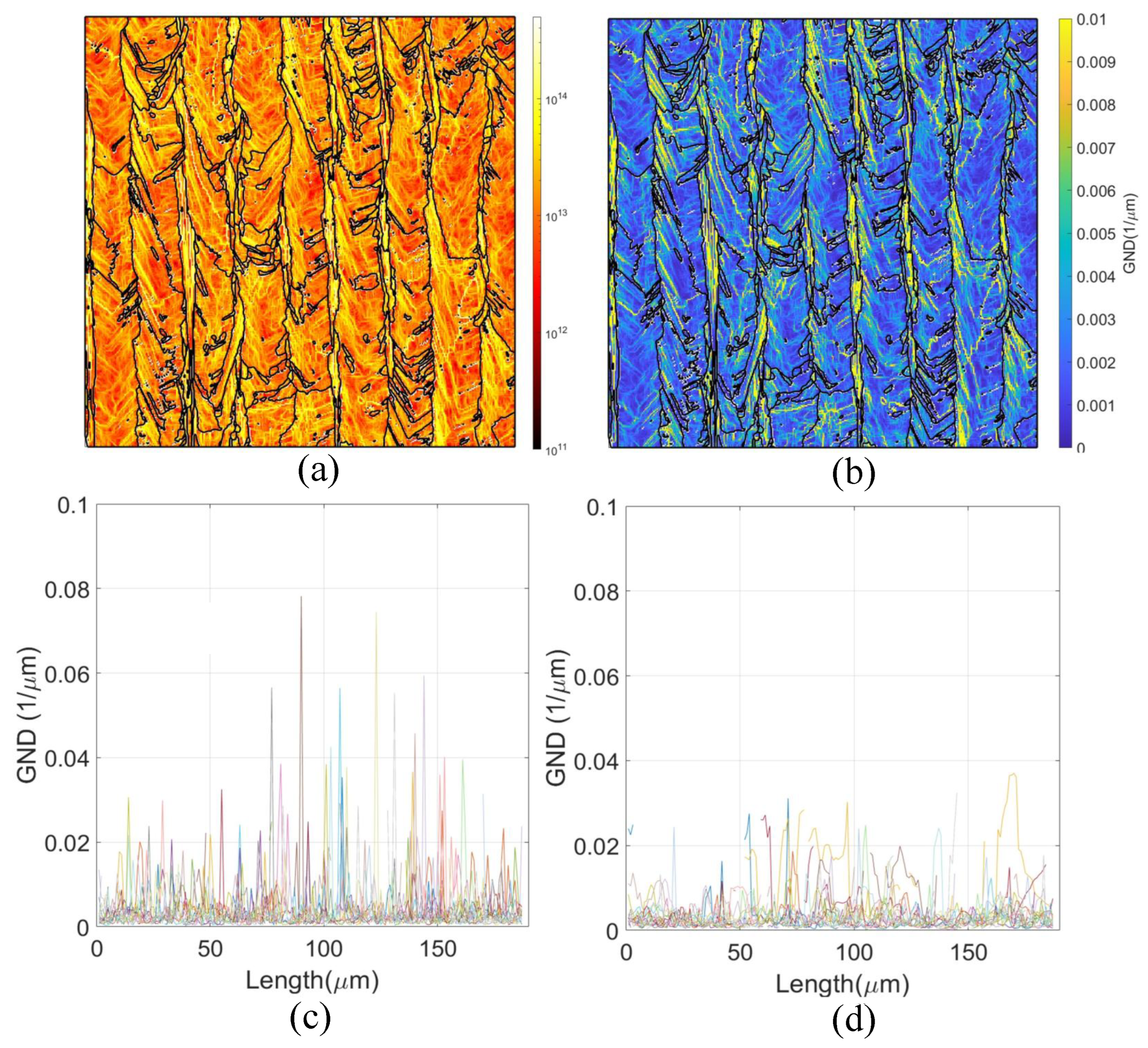

3.4. Orientation-Dependent Fracture Behavior

4. Discussion

5. Conclusions

- Build orientation significantly influences the fracture resistance of LPBF-fabricated IN718. Specimens oriented at R0-45 demonstrated nearly 2.5 times higher values compared to those built at R0-0, indicating superior crack growth resistance.

- The fracture behavior was governed by elastic–plastic deformation, with the plastic component contributing substantially to the total J-integral in both orientations. This confirms the relevance of using elastic–plastic fracture mechanics criteria in AM nickel-based superalloys.

- The adopted methodology, combining compact tension specimens with compliance-based crack length estimation and ASTM E1820 procedures, proved robust for characterizing fracture toughness in LPBF components.

- The findings highlight the importance of build orientation as a critical parameter in the design and qualification of AM parts. The R0-45 orientation offers enhanced damage tolerance and should be prioritized in structural applications.

- These insights provide a foundation for future studies aiming to link microstructure and fracture behavior more explicitly, and to optimize additive manufacturing parameters for high-performance applications.

- The superior fracture toughness observed in the R0-45 sample is closely linked to microstructural and crystallographic features. Enhanced plastic deformation capacity, increased GND density, elevated KAM values, and higher resolved shear stress levels collectively promote crack-tip shielding and energy dissipation. Furthermore, the oblique crack path reduces the effective grain size intersected, leading to Hall–Petch strengthening. These findings underscore the critical role of grain morphology and crystallographic texture in governing fracture resistance in LPBF-fabricated IN718.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hasani, N.; Dharmendra, C.; AlaghmandFard, R.; Keshavarzan, M.; Forooghi, F.; Sanjari, M.; Amirkhiz, B.S.; Ram, G.D.J.; Pirgazi, H.; Kestens, L.; et al. High strain rate compressive behavior of laser powder bed fused Inconel-718. Mater. Sci. Eng. A 2025, 924, 147782. [Google Scholar] [CrossRef]

- Ghorbanpour, S.; Deshmukh, K.; Sahu, S.; Riemslag, T.; Reinton, E.; Borisov, E.; Popovich, A.; Bertolo, V.; Jiang, Q.; Sanchez, M.T.; et al. Additive manufacturing of functionally graded inconel 718: Effect of heat treatment and building orientation on microstructure and fatigue behaviour. J. Mater. Process. Technol. 2022, 306, 117573. [Google Scholar] [CrossRef]

- Pereira, R.B.D.; Pérez-Ruiz, J.D.; Gómez-Escudero, G.; Calleja-Ochoa, A.; Villarrazo-Rubia, N.; Brandão, L.C.; de Lacalle, L.N.L. Helical milling hole finishing of Inconel 718 parts manufactured by laser powder bed fusion. Prog. Addit. Manuf. 2025, 10, 5025–5041. [Google Scholar] [CrossRef]

- Pérez-Ruiz, J.D.; de Lacalle, L.N.L.; Urbikain, G.; Álvarez, H.; Pacheco, J. Instantaneous contact area-based model for shear strength sensitive cutting coefficients characterization of anisotropic parts. Eng. Sci. Technol. Int. J. 2024, 52, 101650. [Google Scholar] [CrossRef]

- Holfelder, P.; Brenner, F.; Rund, M.; Witte, A.; Junghans, S.; Seyfert, C.; Richter, M.; Dell, H.; Koukolikova, M.; Gese, H.; et al. Finite element simulation of plasticity and fracture for Inconel 718 deposited by laser powder bed fusion—Chances, use and challenges. Addit. Manuf. 2022, 56, 102888. [Google Scholar] [CrossRef]

- Velilla-Díaz, W.; Pinzón, R.; Guillén-Rujano, R.; Pérez-Ruiz, J.D.; de Lacalle, L.N.L.; Palencia, A.; Maury, H.; Zambrano, H.R. Fatigue Life Estimation Model of Repaired Components with the Expanded Stop-Hole Technique. Metals 2024, 14, 182. [Google Scholar] [CrossRef]

- Lee, D.; Park, S.; Lee, C.H.; Hong, H.U.; Oh, J.; So, T.Y.; Kim, W.S.; Seo, D.; Han, J.; Ko, S.H.; et al. Correlation between microstructure and mechanical properties in additively manufactured Inconel 718 superalloys with low and high electron beam currents. J. Mater. Res. Technol. 2024, 28, 2410–2419. [Google Scholar] [CrossRef]

- Meng, G.; Gong, Y.; Zhang, J.; Jiang, Z.; Ren, Q.; Zhao, J. Microstructure and mechanical properties of Inconel 718 thin walls prepared by laser direct energy deposition and selective laser melting. Thin-Walled Struct. 2023, 193, 111284. [Google Scholar] [CrossRef]

- Gómez, I.G.; Lorca, Y.E.; Velilla-Díaz, W.; Pacheco-Sanjuán, A. Elastic constants and material stability analysis of orthotropic titanium-based metal foams. Int. J. Mech. Sci. 2025, 299, 110431. [Google Scholar] [CrossRef]

- Cruzado, A.; LLorca, J.; Segurado, J. Modeling cyclic deformation of inconel 718 superalloy by means of crystal plasticity and computational homogenization. Int. J. Solids Struct. 2017, 122, 148–161. [Google Scholar] [CrossRef]

- Cruzado, A.; Lucarini, S.; LLorca, J.; Segurado, J. Crystal plasticity simulation of the effect of grain size on the fatigue behavior of polycrystalline Inconel 718. Int. J. Fatigue 2018, 113, 236–245. [Google Scholar] [CrossRef]

- Tran, H.T.; Liang, X.; To, A.C. Efficient prediction of cracking at solid-lattice support interface during laser powder bed fusion via global-local J-integral analysis based on modified inherent strain method and lattice support homogenization. Addit. Manuf. 2020, 36, 101590. [Google Scholar] [CrossRef]

- Wan, M.; Liu, C.; Ren, Y.Y.; Wen, D.Y. Determination of fracture toughness and yield strength of Inconel 718 by milling operation. J. Manuf. Process. 2023, 101, 770–783. [Google Scholar] [CrossRef]

- Vieille, B.; Keller, C.; Mokhtari, M.; Briatta, H.; Breteau, T.; Nguejio, J.; Barbe, F.; Azzouna, M.B.; Baustert, E. Investigations on the fracture behavior of Inconel 718 superalloys obtained from cast and additive manufacturing processes. Mater. Sci. Eng. A 2020, 790, 139666. [Google Scholar] [CrossRef]

- Velilla-Díaz, W.; Pacheco-Sanjuan, A.; Zambrano, H.R. The role of the grain boundary in the fracture toughness of aluminum bicrystal. Comput. Mater. Sci. 2019, 167, 34–41. [Google Scholar] [CrossRef]

- Velilla-Díaz, W.; Zambrano, H.R. Effects of Grain Boundary Misorientation Angle on the Mechanical Behavior of Al Bicrystals. Nanomaterials 2023, 13, 3031. [Google Scholar] [CrossRef] [PubMed]

- Velilla-Díaz, W.; Zambrano, H.R. Effect of the grain boundary on the fatigue crack growth for aluminum bi-crystals. Procedia Struct. Integr. 2024, 57, 461–468. [Google Scholar] [CrossRef]

- Pérez-Ruiz, J.D.; López de Lacalle, L.N.; Velilla-Díaz, W.; Mesa, J.A.; Gómez, G.; Maury, H.; Urbikain, G.; Gonzalez, H. Evaluating the feasibility of using crystalline patterns induced by PBF-LB to predict strength enhancing orientations. Mater. Des. 2025, 254, 114006. [Google Scholar] [CrossRef]

- Saju, T.; Velu, M. Fracture toughness and fatigue crack growth rate studies on rotary friction weldments of nickel-based superalloys. Mater. Lett. 2022, 327, 133027. [Google Scholar] [CrossRef]

- Monkova, K.; Papadopoulou, S.; Bouzouni, M.; Toulfatzis, A.; Pantazopoulos, G. The effect of 3D printing orientation on tensile behaviour and fracture mechanisms of Inconel 718. Eng. Fail. Anal. 2024, 166, 108920. [Google Scholar] [CrossRef]

- Muhammad, M.; Lee, S.; Frye, P.; Simsiriwong, J.; Shao, S.; Shamsaei, N. High cycle and very high cycle fatigue behavior of additively manufactured Inconel 718: Effects of stress-relieving, surface texture, part orientation, and test frequency. Eng. Fail. Anal. 2025, 169, 109227. [Google Scholar] [CrossRef]

- Chowdhury, H.T.; Morishige, A.; Palleda, T.N.; Kakuta, N.; Kakehi, K.; Miyakita, A. Effect of process parameters on grain morphology and high-temperature mechanical properties of Inconel 718 manufactured by EB-PBF. Mater. Sci. Eng. A 2025, 931, 148185. [Google Scholar] [CrossRef]

- Shi, J.; Qian, N.; Sun, S.; Kaynak, Y.; Das, R.; Fu, Y.; Su, H. Effect of process parameters on microstructure and properties of Inconel-718 superalloy fabricated by wire-arc direct energy deposition technique. J. Mater. Res. Technol. 2025, 37, 173–185. [Google Scholar] [CrossRef]

- Poulin, J.R.; Kreitcberg, A.; Terriault, P.; Brailovski, V. Long fatigue crack propagation behavior of laser powder bed-fused inconel 625 with intentionally-seeded porosity. Int. J. Fatigue 2019, 127, 144–156. [Google Scholar] [CrossRef]

- Rodríguez, V.M.; González, C.R.; García, S.F.; Garcidueñas, H.C.; Morelos, V.H.L.; Ruiz, A. Analysis of the effects of isothermal aging and Laser Shock Peening on the flow properties, fatigue crack growth, and fracture toughness of Inconel 718. Opt. Laser Technol. 2023, 162, 109288. [Google Scholar] [CrossRef]

- Pérez-Ruiz, J.D.; Galbusera, F.; Caprio, L.; Previtali, B.; de Lacalle, L.N.L.; Lamikiz, A.; Demir, A.G. Laser beam shaping facilitates tailoring the mechanical properties of IN718 during powder bed fusion. J. Mater. Process. Technol. 2024, 328, 118393. [Google Scholar] [CrossRef]

- ASTM E399; Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM E1820; Standard Test Method for Measurement of Fracture Toughness. ASTM: West Conshohocken, PA, USA, 2018.

- Liu, F.; Lyu, F.; Liu, F.; Lin, X.; Huang, C. Laves phase control of inconel 718 superalloy fabricated by laser direct energy deposition via δ aging and solution treatment. J. Mater. Res. Technol. 2020, 9, 9753–9765. [Google Scholar] [CrossRef]

- Rice, J.R. A Path Independent Integral and the Approximate Analysis of Strain Concentration by Notches and Cracks. J. Appl. Mech. 1968, 35, 379–386. [Google Scholar] [CrossRef]

| wt.% | Al | C | Cr | Fe | Mo | N | Nb + Ta | Ni | O | Ti | Other |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal | 0.48 | 0.03 | 19.04 | 18.20 | 2.98 | 0.01 | 5.16 | 52.99 | 0.02 | 0.97 | 0.12 |

| Measured | 0.80 | ND | 20.28 | 18.10 | 2.73 | ND | 5.45 | 51.78 | ND | 0.86 | ND |

| Parameter | Value |

|---|---|

| Material | IN718 |

| Hatch distance, , (m) | 90 |

| Layer thickness, z, (m) | 60 |

| Laser power, , (W) | 200 |

| Scan speed, v, (mm/s) | 1000 |

| Scanning strategy, | R0 |

| Parameter | R0-0 | R0-45 |

|---|---|---|

| P (MN) | 0.07954 | 0.08711 |

| B (m) | 0.025 | 0.025 |

| (m) | 0.025 | 0.025 |

| (m) | 0.312 | 0.312 |

| W (m) | 0.05 | 0.05 |

| a (m) | 0.017625 | 0.017625 |

| 0.3525 | 0.3525 | |

| 6.4331 | 6.4331 | |

| 0.33 | 0.33 | |

| E (MPa) | 200,000 | 200,000 |

| (MPa) | 224,441.70 | 224,441.70 |

| Orientation | K [MPa] | [MJ/m2] |

|---|---|---|

| 0° | 91.5305 | 0.03732 |

| 45° | 100.249 | 0.04477 |

| R | [MNm] | [MJ/m2] | [m] | [MJ/m2] | [MJ/m2] |

|---|---|---|---|---|---|

| 0° | 0.00017301 | 0.49977 | 0.0615 | 0.5370 | 0.4213 |

| 45° | 0.00043639 | 1.26059 | 0.0620 | 1.3053 | 1.0714 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perez-Ruiz, J.D.; Velilla-Díaz, W.; Abasolo, M.; Gómez Escudero, G.; López de Lacalle, L.N. Effect of Microstructure and Crystallographic Texture on the Fracture Toughness Anisotropy of LPBF IN718. Materials 2025, 18, 3737. https://doi.org/10.3390/ma18163737

Perez-Ruiz JD, Velilla-Díaz W, Abasolo M, Gómez Escudero G, López de Lacalle LN. Effect of Microstructure and Crystallographic Texture on the Fracture Toughness Anisotropy of LPBF IN718. Materials. 2025; 18(16):3737. https://doi.org/10.3390/ma18163737

Chicago/Turabian StylePerez-Ruiz, José David, Wilmer Velilla-Díaz, Mikel Abasolo, Gaizka Gómez Escudero, and Luis Norberto López de Lacalle. 2025. "Effect of Microstructure and Crystallographic Texture on the Fracture Toughness Anisotropy of LPBF IN718" Materials 18, no. 16: 3737. https://doi.org/10.3390/ma18163737

APA StylePerez-Ruiz, J. D., Velilla-Díaz, W., Abasolo, M., Gómez Escudero, G., & López de Lacalle, L. N. (2025). Effect of Microstructure and Crystallographic Texture on the Fracture Toughness Anisotropy of LPBF IN718. Materials, 18(16), 3737. https://doi.org/10.3390/ma18163737