Microscopic Investigation of Coupled Mobilization and Blending Behaviors Between Virgin and Reclaimed Aged Asphalt Mastic

Abstract

1. Introduction

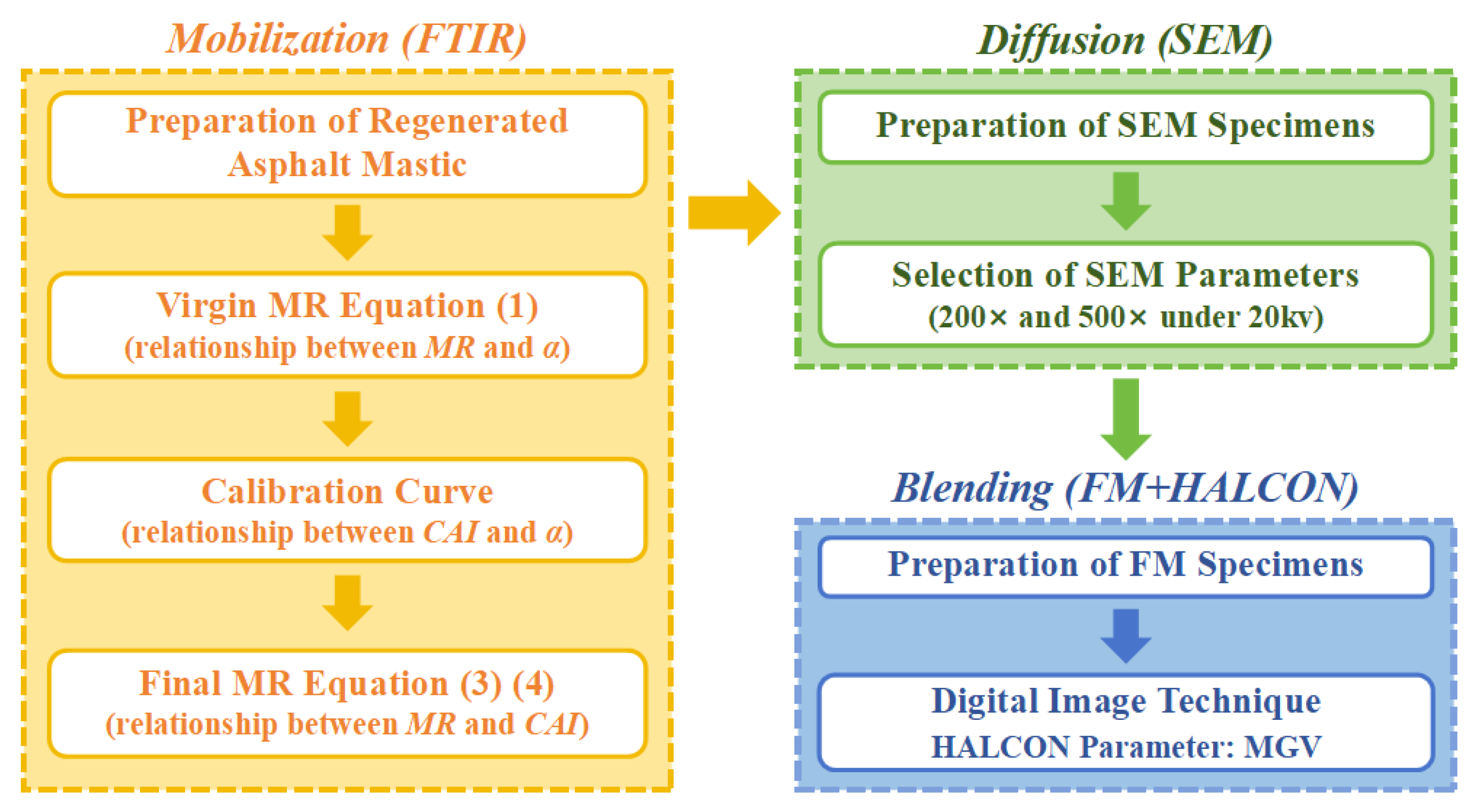

- To investigate the mobilization behavior of aged asphalt mastic on RAP aggregate surfaces under varying mixing conditions, through analysis of chemical functional group evolution using FTIR spectroscopy.

- To characterize the interfacial diffusion and migration processes between virgin and aged asphalt mastic by examining the micro-morphological features of their blended interfaces via SEM.

- To quantify the DoB between virgin and aged asphalt mastic based on fluorescence characteristics, using image-based analysis techniques integrated with FM were performed using OPLENIC Echo-Imager 2.18 software and HALCON machine vision 12.0 software.

- To establish a coupling model that captures the nonlinear effects of mixing conditions on activation and blending performance, aiming to clarify the underlying interaction mechanisms between these two processes.

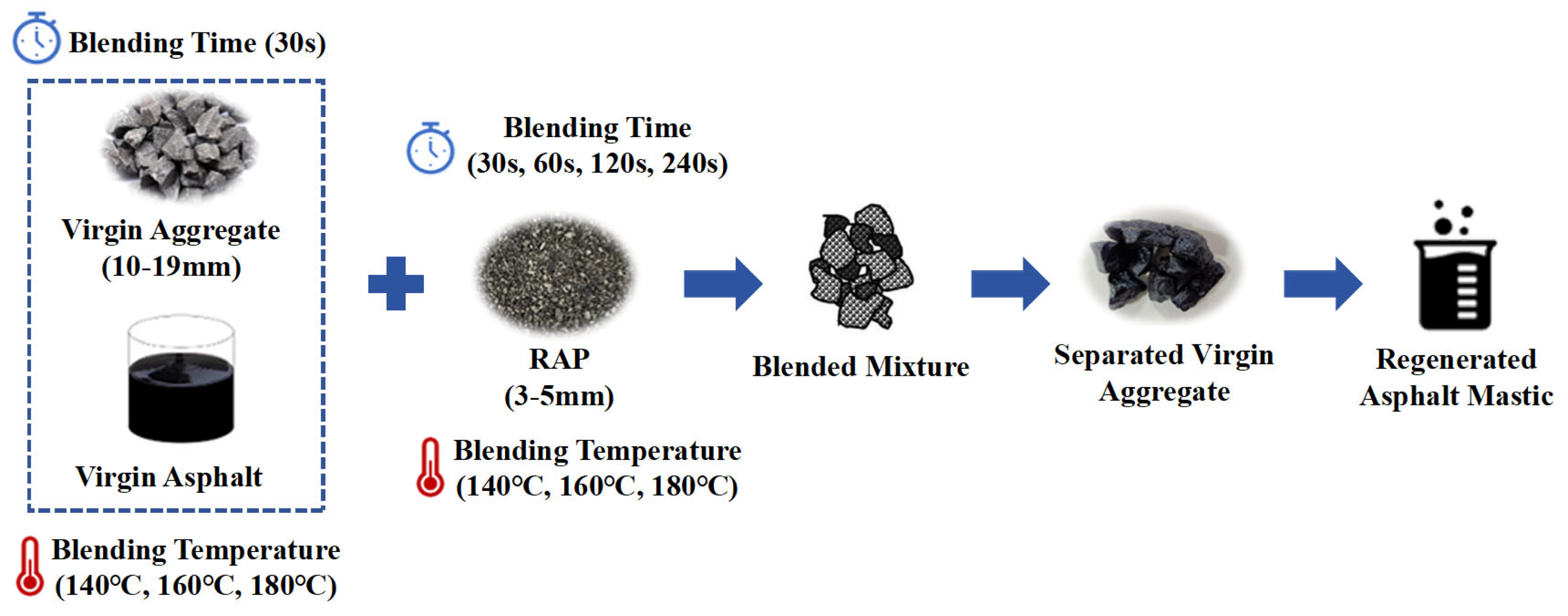

2. Materials and Methods

2.1. Materials

2.1.1. RAP

2.1.2. Asphalt Binder

2.1.3. Aged Asphalt Mastic

2.1.4. Regenerated Asphalt Mastic

2.2. Experimental Methods

2.2.1. FTIR

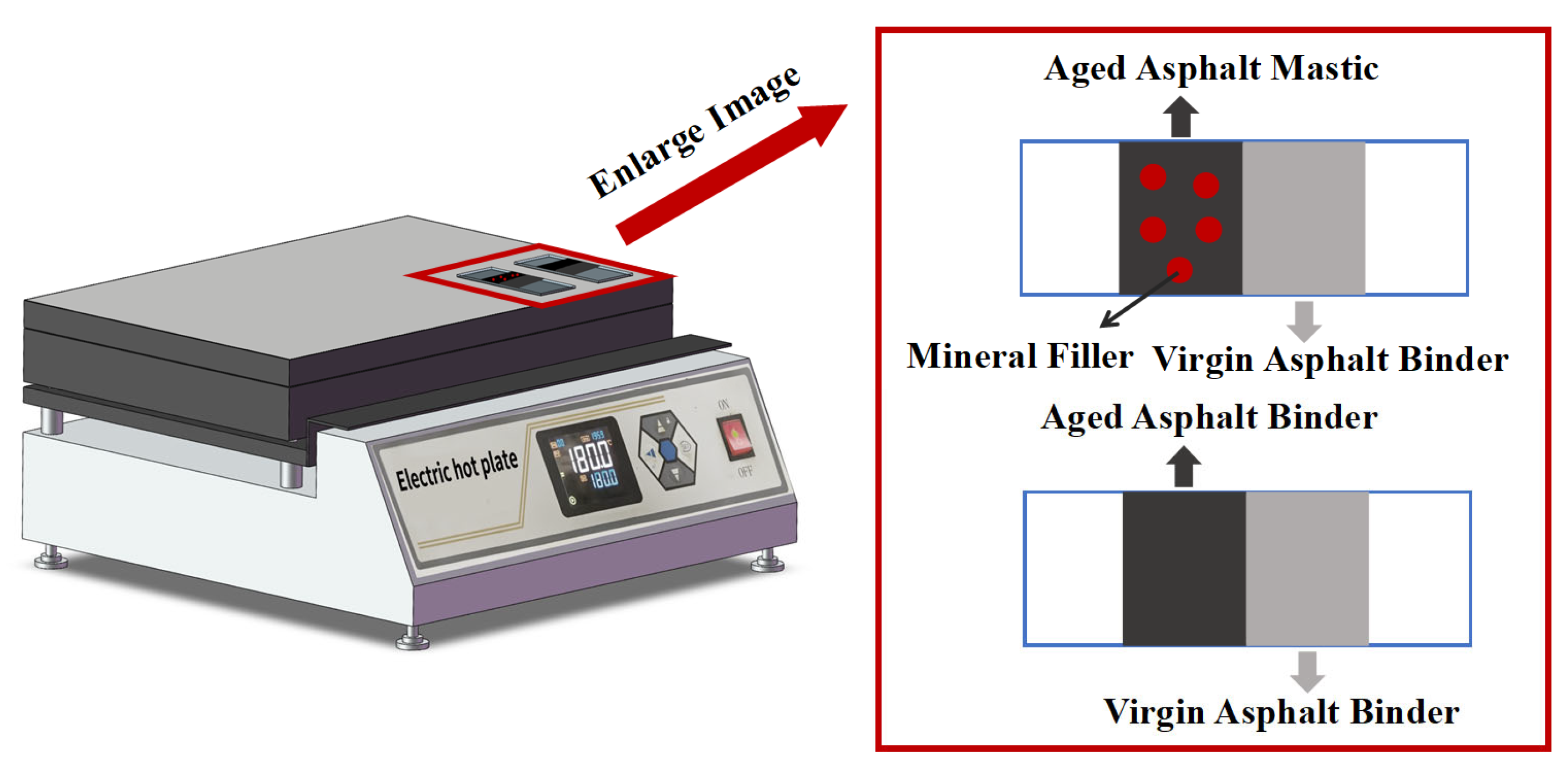

2.2.2. SEM

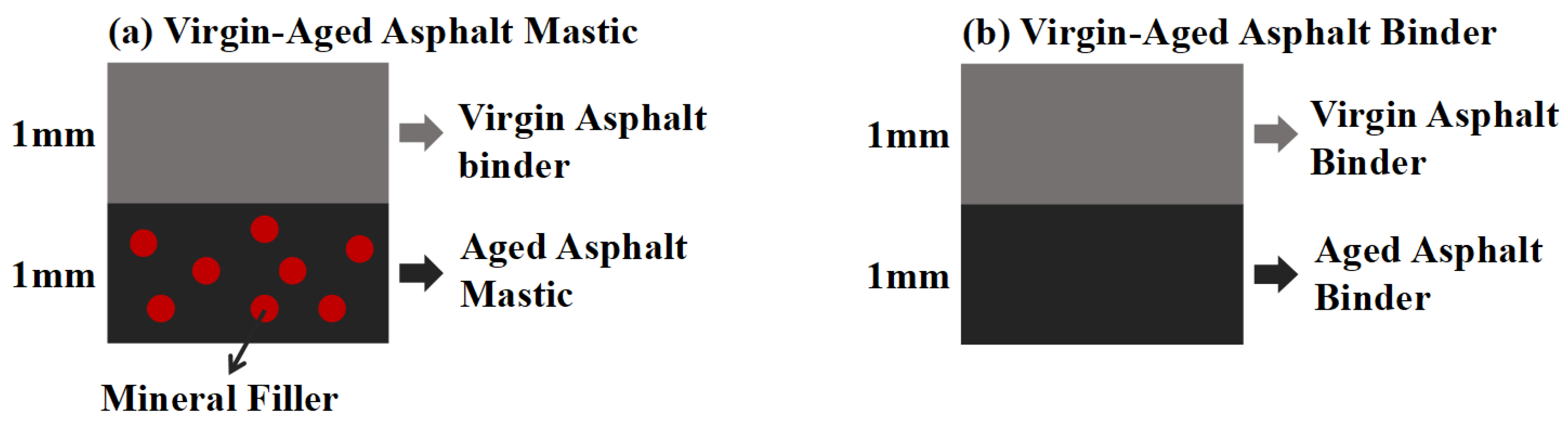

2.2.3. FM

2.2.4. Digital Image Technique

3. Results and Discussion

3.1. Analysis of Activation and Transfer Behaviors

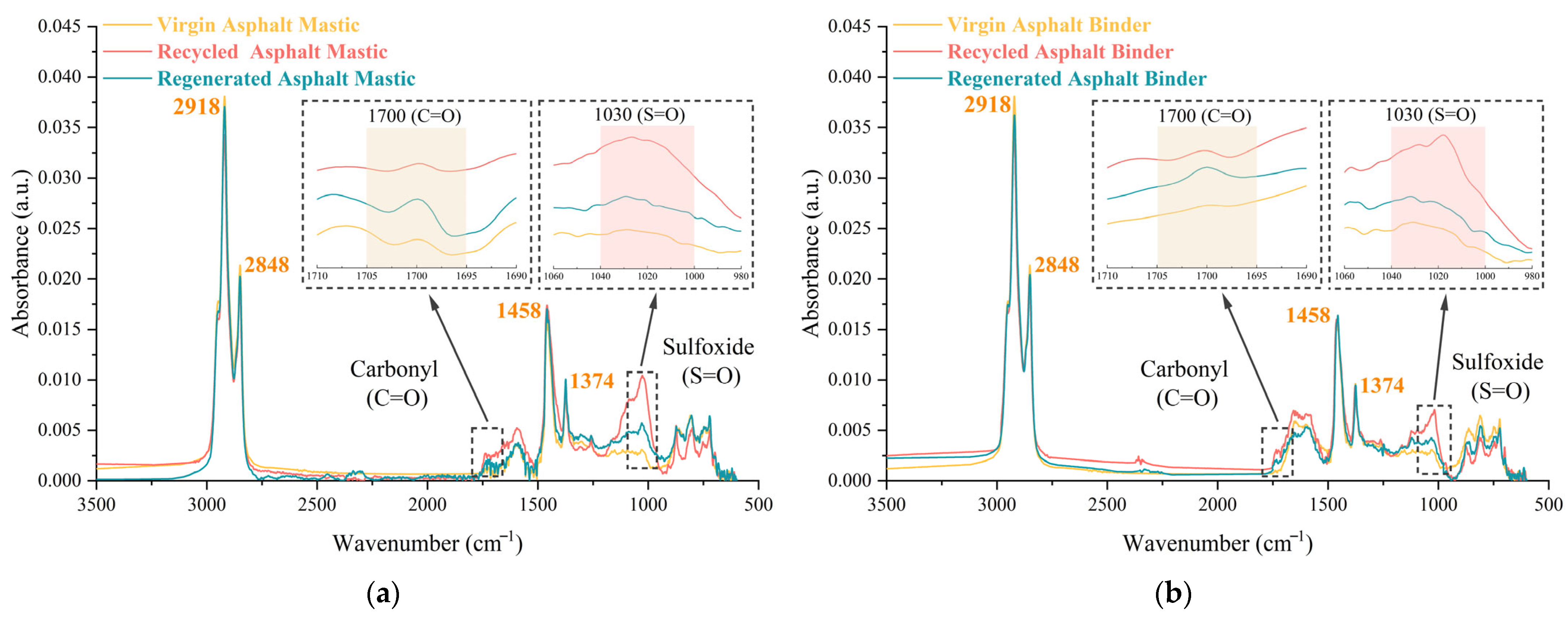

3.1.1. Microstructure Characteristics

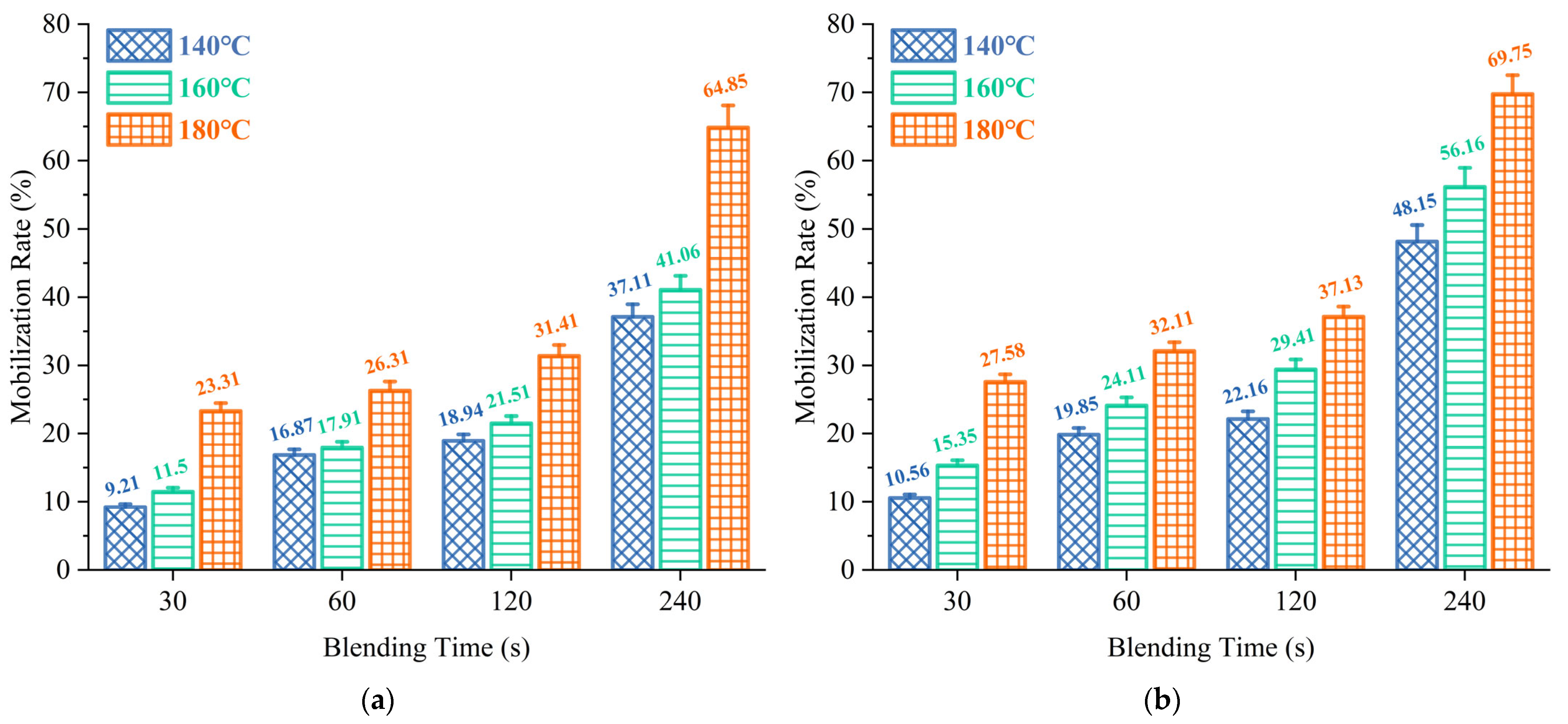

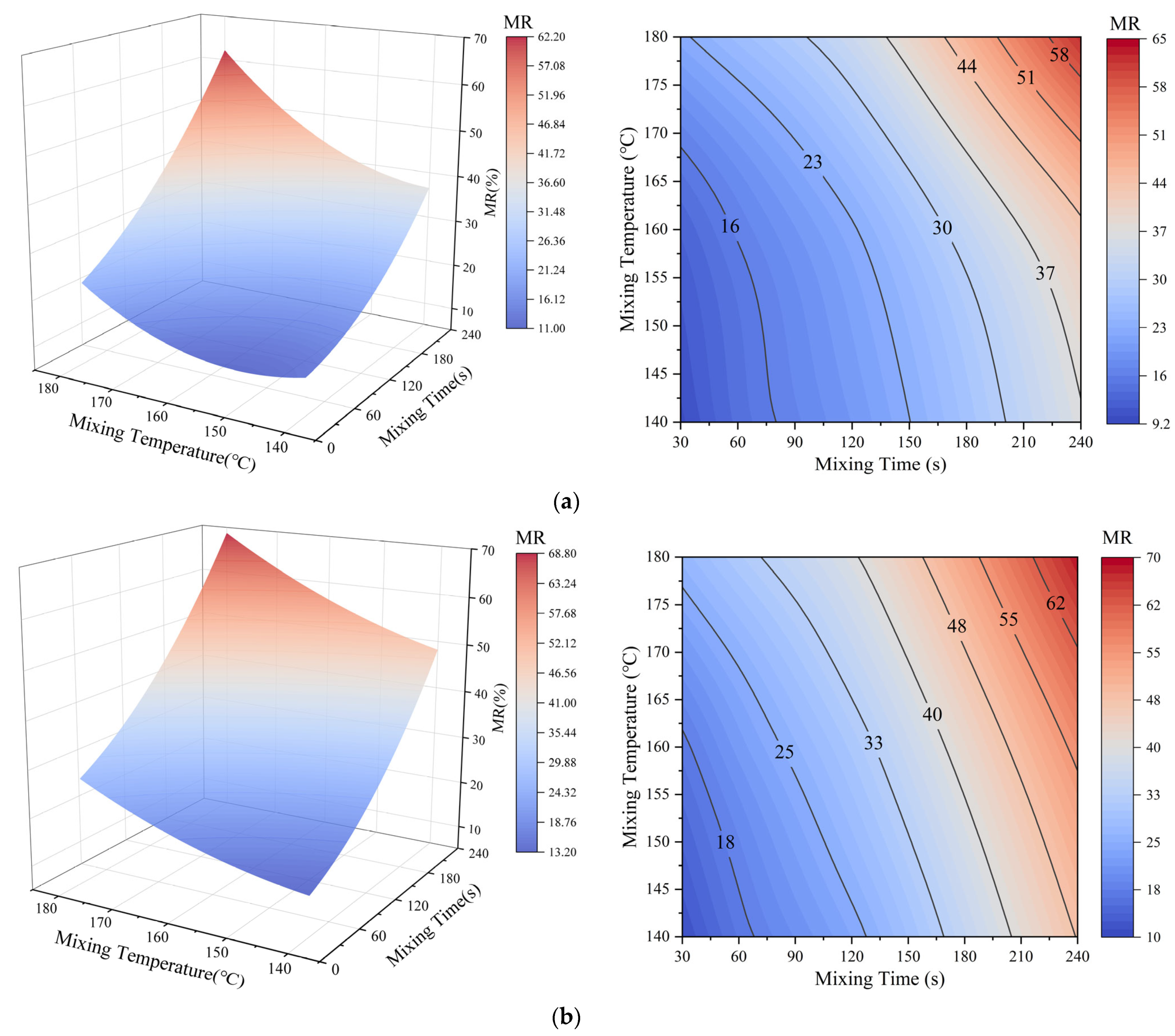

3.1.2. Mobilization Rate

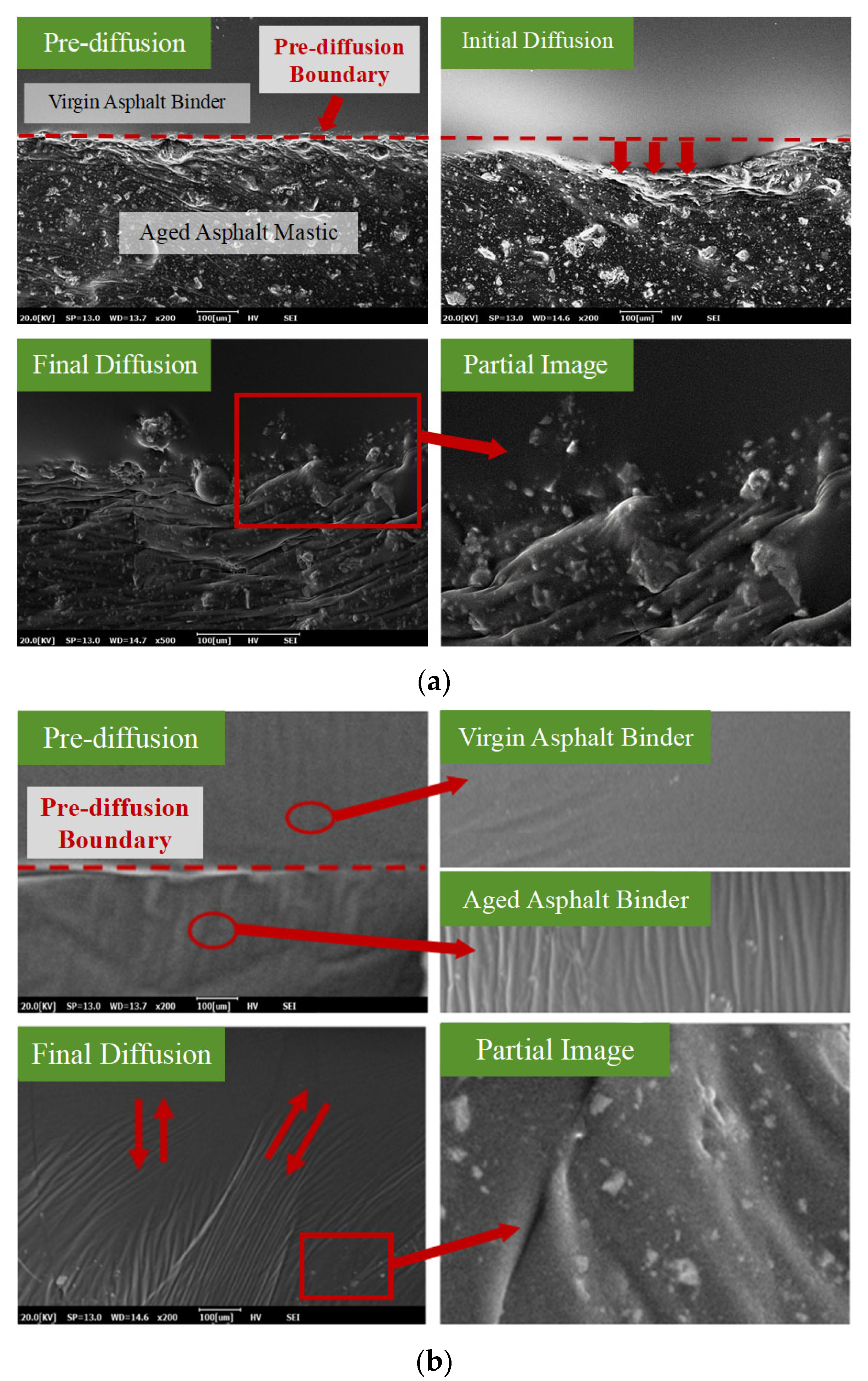

3.2. Analysis of Diffusion Behaviors Based on SEM

3.3. Analysis of the Blending Behavior Based on FM

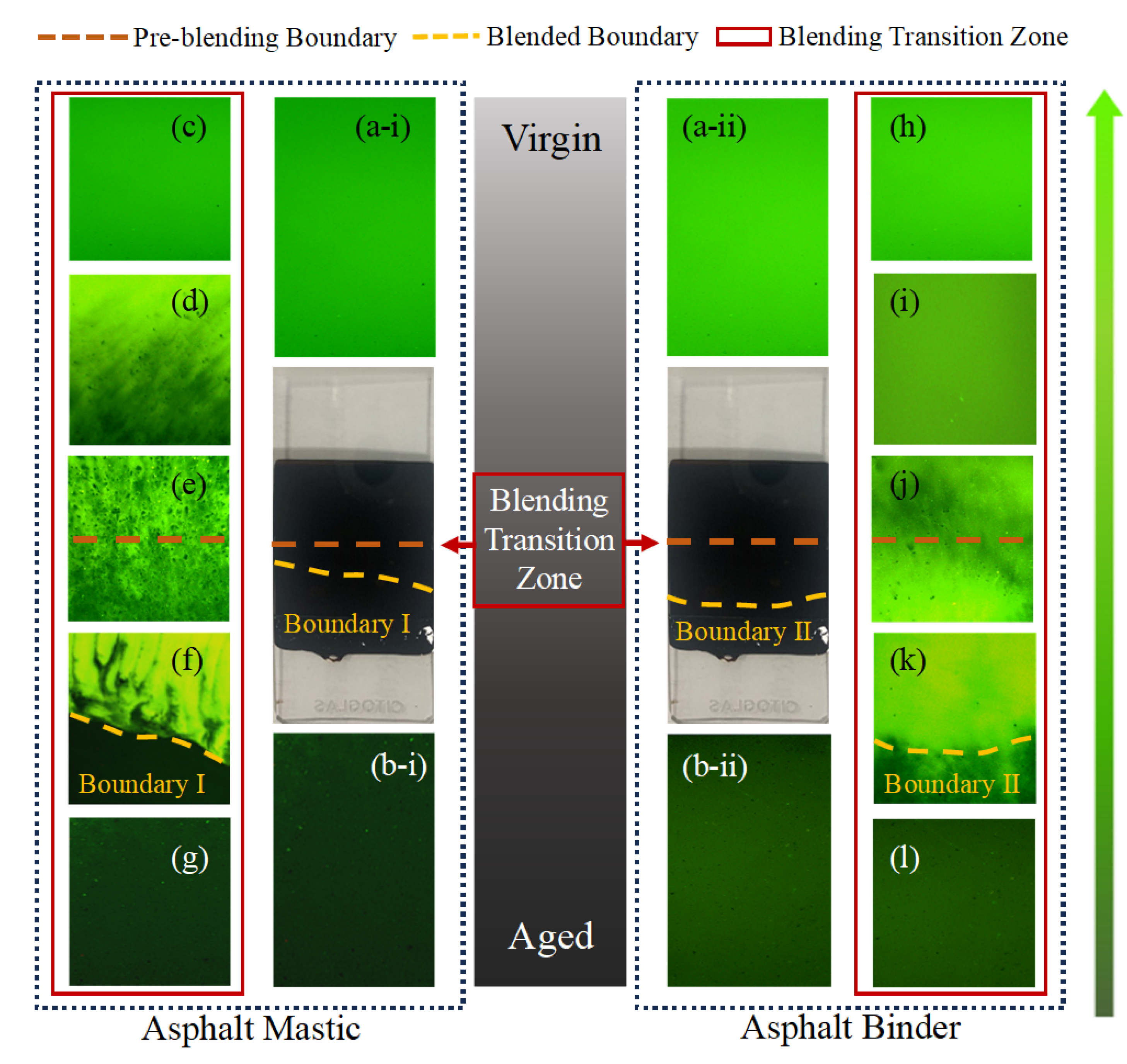

3.3.1. Dynamic Blending Process

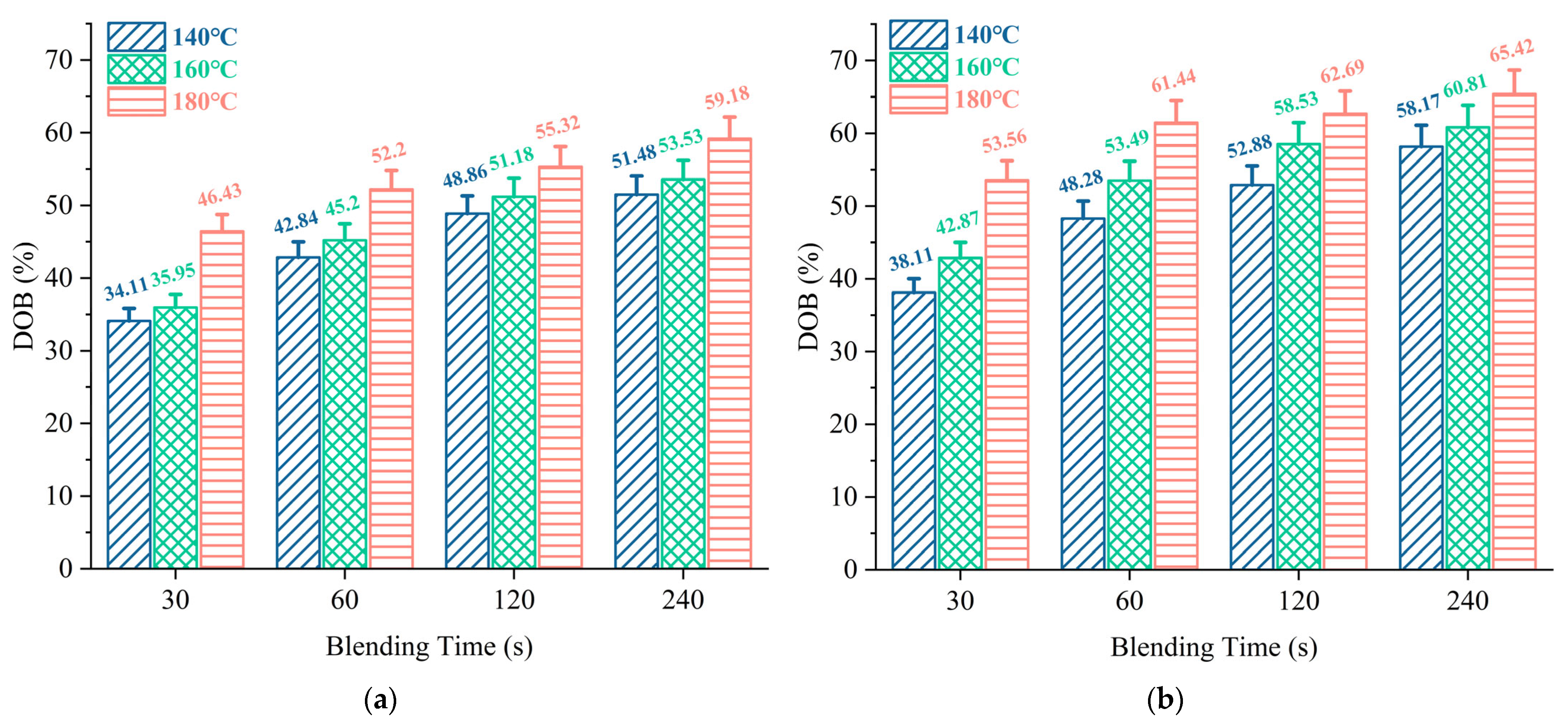

3.3.2. Quantitative Evaluation of Blending Degree

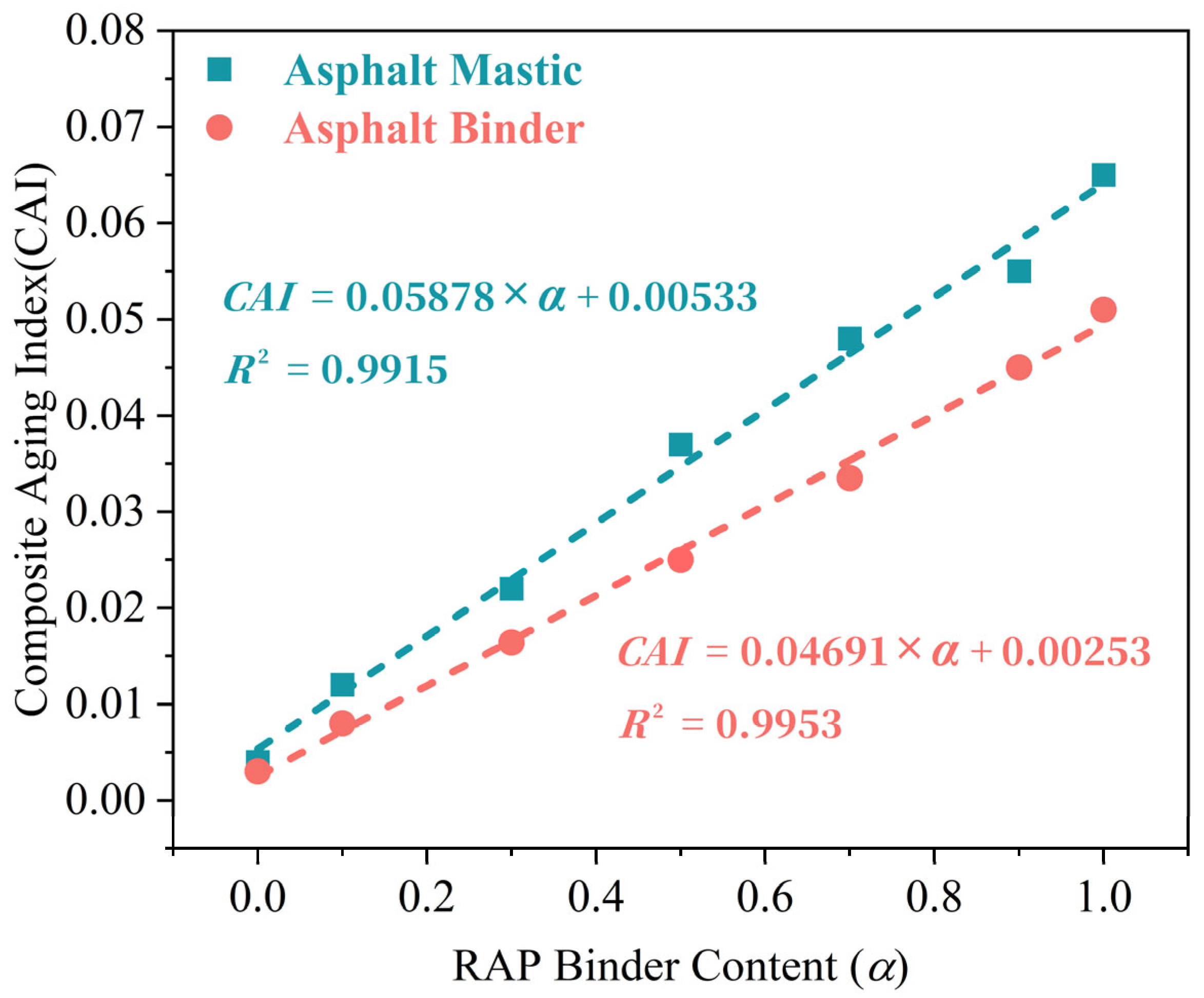

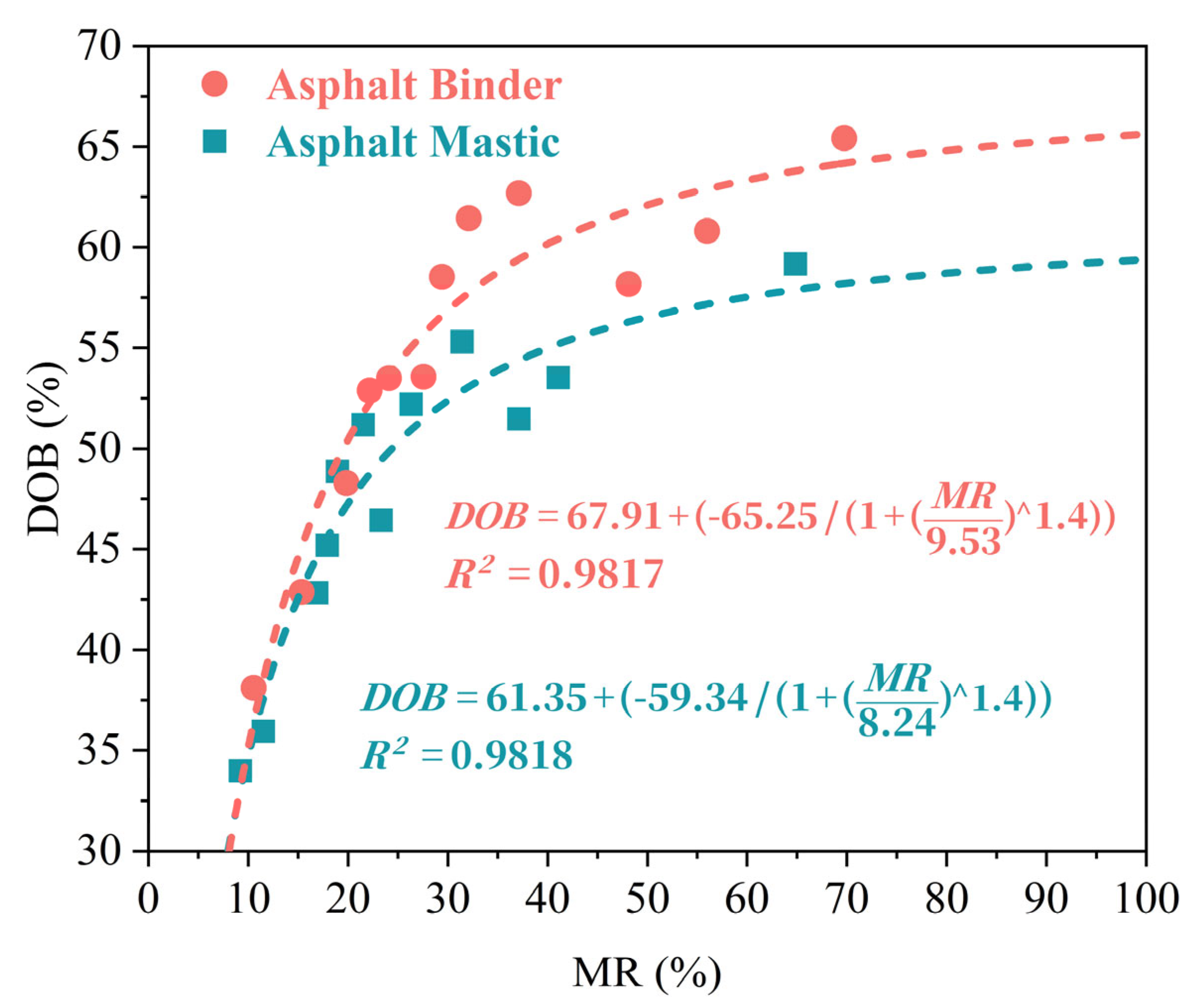

3.4. Correlation Between Mobilization and Blending

4. Conclusions

- Regenerated asphalt mastic exhibited intermediate C=O and S=O peak intensities between virgin and aged samples, confirming partial dilution of oxidative groups. The absence of new peaks suggests a diffusion-dominated regeneration process. This supports the adoption of physical-compatibility-based strategies over chemical modification in practical recycling.

- Although MR increased with higher temperatures (160–180 °C) and longer mixing times, it remained below 70%, indicating incomplete activation. Thus, time and temperature are necessary but insufficient alone, emphasizing the need for optimized conditions and material pairing to enhance recycling effectiveness.

- A serrated, interlocked interface was observed between virgin and aged mastic, while binder interfaces showed smoother blending. This highlights the adverse role of mineral fillers in hindering interfacial diffusion, guiding the aggregate–mastic balance in mixture design.

- Under FM, aged binders appeared darker due to aromatic loss, and blending boundaries shifted toward the aged side, indicating dominant virgin binder diffusion. The deeper penetration of binder over mastic reflects higher molecular mobility, informing targeted treatment of different asphalt phases in recycling.

- Binder systems exhibited higher DoB than mastic, with temperature and time both promoting blending. Early-stage heating proved especially effective, suggesting that front-loaded thermal input may improve blending efficiency in industrial applications.

- Mixing temperature influenced aged binder mobilization more than mixing time. Although DoB increased rapidly at 10–40% MR, it plateaued thereafter, showing that mobilization alone does not ensure full blending. Therefore, when higher temperature or longer mixing are impractical, adding rejuvenators is key to enhancing compatibility and diffusion between aged and virgin binders.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reyes-Ortiz, O.; Berardinelli, E.; Alvarez, A.E.; Carvajal-Muñoz, J.S.; Fuentes, L.G. Evaluation of Hot Mix Asphalt Mixtures with Replacement of Aggregates by Reclaimed Asphalt Pavement (RAP) Material. Procedia Soc. Behav. Sci. 2012, 53, 379–388. [Google Scholar] [CrossRef]

- Hajj, E.Y.; Sebaaly, P.E.; Kandiah, P. Evaluation of the Use of Reclaimed Asphalt Pavement in Airfield HMA Pavements. J. Transp. Eng. 2010, 136, 181–189. [Google Scholar] [CrossRef]

- Sorociak, W.; Grzesik, B.; Szołtysik, J.; Bzówka, J.; Mieczkowski, P.; Klemens, M. Analysis of Reclaimed Asphalt Pavement Heating with Microwave Radiation. Arab. J. Sci. Eng. 2025, 50, 12813–12826. [Google Scholar] [CrossRef]

- Gao, J.; Yao, Y.; Song, L.; Xu, J.; Yang, J. Determining the Maximum Permissible Content of Recycled Asphalt Pavement Stockpile in Plant Hot-Mix Recycled Asphalt Mixtures Considering Homogeneity: A Case Study in China. Case Stud. Constr. Mater. 2022, 16, e00961. [Google Scholar] [CrossRef]

- Liu, H.; Wang, J.; Lu, W.; Zhang, N. Optimization Design and Mechanical Performances of Plant-Mix Hot Recycled Asphalt Using Response Surface Methodology. Materials 2023, 16, 5863. [Google Scholar] [CrossRef] [PubMed]

- Jiang, L.; Shen, J.; Wang, W. Performance of High-Dose Reclaimed Asphalt Mixtures (RAPs) in Hot In-Place Recycling Based on Balanced Design. Materials 2024, 17, 2096. [Google Scholar] [CrossRef]

- Guo, F.; Pei, J.; Zhang, J.; Xue, B.; Sun, G.; Li, R. Study on the Adhesion Property between Asphalt Binder and Aggregate: A State-of-the-Art Review. Constr. Build. Mater. 2020, 256, 119474. [Google Scholar] [CrossRef]

- Tang, Y.; Fu, Z.; Raos, G.; Ma, F.; Zhao, P.; Hou, Y. Molecular Dynamics Simulation of Adhesion at the Asphalt-Aggregate Interface: A Review. Surf. Interfaces 2024, 44, 103706. [Google Scholar] [CrossRef]

- Oliviero Rossi, C.; Teltayev, B.; Angelico, R. Adhesion Promoters in Bituminous Road Materials: A Review. Appl. Sci. 2017, 7, 524. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M.E. Quantitative Evaluation of Blending and Diffusion in High RAP and RAS Mixtures. Mater. Des. 2016, 89, 1161–1170. [Google Scholar] [CrossRef]

- Li, N.; Tang, W.; Yu, X.; Zhan, H.; Wang, X.; Wang, Z. Laboratory Investigation on Blending Process of Reclaimed Asphalt Mixture. Constr. Build. Mater. 2022, 325, 126793. [Google Scholar] [CrossRef]

- Gao, J.; Yao, Y.; Yang, J.; Song, L.; Xu, J.; He, L.; Tao, W. Migration Behavior of Reclaimed Asphalt Pavement Mastic during Hot Mixing. J. Clean. Prod. 2022, 376, 134123. [Google Scholar] [CrossRef]

- Orešković, M.; Menegusso Pires, G.; Bressi, S.; Vasconcelos, K.; Lo Presti, D. Quantitative Assessment of the Parameters Linked to the Blending between Reclaimed Asphalt Binder and Recycling Agent: A Literature Review. Constr. Build. Mater. 2020, 234, 117323. [Google Scholar] [CrossRef]

- Stimilli, A.; Virgili, A.; Canestrari, F. New Method to Estimate the “Re-Activated” Binder Amount in Recycled Hot-Mix Asphalt. Road Mater. Pavement Des. 2015, 16, 442–459. [Google Scholar] [CrossRef]

- Ding, Y.; Huang, B.; Shu, X. Blending Efficiency Evaluation of Plant Asphalt Mixtures Using Fluorescence Microscopy. Constr. Build. Mater. 2018, 161, 461–467. [Google Scholar] [CrossRef]

- Vassaux, S.; Gaudefroy, V.; Boulangé, L.; Soro, L.J.; Pévère, A.; Michelet, A.; Barragan-Montero, V.; Mouillet, V. Study of Remobilization Phenomena at Reclaimed Asphalt Binder/Virgin Binder Interphases for Recycled Asphalt Mixtures Using Novel Microscopic Methodologies. Constr. Build. Mater. 2018, 165, 846–858. [Google Scholar] [CrossRef]

- Abd, D.M.; Al-Khalid, H.; Akhtar, R. Novel Methodology to Investigate and Obtain a Complete Blend between RAP and Virgin Materials. J. Mater. Civ. Eng. 2018, 30, 04018060. [Google Scholar] [CrossRef]

- Liphardt, A.; Radziszewski, P.; Król, J. Binder Blending Estimation Method in Hot Mix Asphalt with Reclaimed Asphalt. Procedia Eng. 2015, 111, 502–509. [Google Scholar] [CrossRef]

- Lo Presti, D.; Vasconcelos, K.; Orešković, M.; Menegusso Pires, G.; Bressi, S. On the degree of binder activity of reclaimed asphalt and degree of blending with recycling agents. Road Mater. Pavement Des. 2019, 20, 2071–2090. [Google Scholar] [CrossRef]

- Wen, H.; Zhang, K. Investigation of Blending Mechanisms for Reclaimed Asphalt Pavement Binder and Virgin Binder in Laboratory-Produced Reclaimed Asphalt Pavement Mixtures. Transp. Res. Rec. 2016, 2575, 187–195. [Google Scholar] [CrossRef]

- Bressi, S.; Cavalli, M.C.; Partl, M.N.; Tebaldi, G.; Dumont, A.G.; Poulikakos, L.D. Particle Clustering Phenomena in Hot Asphalt Mixtures with High Content of Reclaimed Asphalt Pavements. Constr. Build. Mater. 2015, 100, 207–217. [Google Scholar] [CrossRef]

- Bowers, B.F.; Huang, B.; Shu, X.; Miller, B.C. Investigation of Reclaimed Asphalt Pavement Blending Efficiency through GPC and FTIR. Constr. Build. Mater. 2014, 50, 517–523. [Google Scholar] [CrossRef]

- Sreeram, A.; Leng, Z.; Zhang, Y.; Padhan, R.K. Evaluation of RAP Binder Mobilisation and Blending Efficiency in Bituminous Mixtures: An Approach Using ATR-FTIR and Artificial Aggregate. Constr. Build. Mater. 2018, 179, 245–253. [Google Scholar] [CrossRef]

- Huang, S.-C.; Pauli, A.T.; Grimes, R.W.; Turner, F. Ageing characteristics of RAP binder blends—what types of RAP binders are suitable for multiple recycling? Road Mater. Pavement Des. 2014, 15, 113–145. [Google Scholar] [CrossRef]

- Coffey, S.; DuBois, E.; Mehta, Y.; Nolan, A.; Purdy, C. Determining the Impact of Degree of Blending and Quality of Reclaimed Asphalt Pavement on Predicted Pavement Performance Using Pavement ME Design. Constr. Build. Mater. 2013, 48, 473–478. [Google Scholar] [CrossRef]

- Rinaldini, E.; Schuetz, P.; Partl, M.N.; Tebaldi, G.; Poulikakos, L.D. Investigating the Blending of Reclaimed Asphalt with Virgin Materials Using Rheology, Electron Microscopy and Computer Tomography. Compos. Part B Eng. 2014, 67, 579–587. [Google Scholar] [CrossRef]

- Shirodkar, P.; Mehta, Y.; Nolan, A.; Sonpal, K.; Norton, A.; Tomlinson, C.; Dubois, E.; Sullivan, P.; Sauber, R. A Study to Determine the Degree of Partial Blending of Reclaimed Asphalt Pavement (RAP) Binder for High RAP Hot Mix Asphalt. Constr. Build. Mater. 2011, 25, 150–155. [Google Scholar] [CrossRef]

- Bowers, B.F.; Moore, J.; Huang, B.; Shu, X. Blending Efficiency of Reclaimed Asphalt Pavement: An Approach Utilizing Rheological Properties and Molecular Weight Distributions. Fuel 2014, 135, 63–68. [Google Scholar] [CrossRef]

- Ding, Y.; Huang, B.; Shu, X. Characterizing Blending Efficiency of Plant Produced Asphalt Paving Mixtures Containing High RAP. Constr. Build. Mater. 2016, 126, 172–178. [Google Scholar] [CrossRef]

- Navaro, J.; Bruneau, D.; Drouadaine, I.; Colin, J.; Dony, A.; Cournet, J. Observation and Evaluation of the Degree of Blending of Reclaimed Asphalt Concretes Using Microscopy Image Analysis. Constr. Build. Mater. 2012, 37, 135–143. [Google Scholar] [CrossRef]

- Xu, J.; Hao, P.; Zhang, D.; Yuan, G. Investigation of Reclaimed Asphalt Pavement Blending Efficiency Based on Micro-Mechanical Properties of Layered Asphalt Binders. Constr. Build. Mater. 2018, 163, 390–401. [Google Scholar] [CrossRef]

- Mogawer, W.S.; Booshehrian, A.; Vahidi, S.; Austerman, A.J. Evaluating the Effect of Rejuvenators on the Degree of Blending and Performance of High RAP, RAS, and RAP/RAS Mixtures. Road Mater. Pavement Des. 2013, 14, 193–213. [Google Scholar] [CrossRef]

- Mogawer, W.; Bennert, T.; Daniel, J.S.; Bonaquist, R.; Austerman, A.; Booshehrian, A. Performance Characteristics of Plant Produced High RAP Mixtures. Road Mater. Pavement Des. 2012, 13, 183–208. [Google Scholar] [CrossRef]

- Gundla, A.; Underwood, S. Evaluation of in situ RAP binder interaction in asphalt mastics using micromechanical models. Int. J. Pavement Eng. 2015, 18, 798–810. [Google Scholar] [CrossRef]

- Hou, X.; Lv, S.; Chen, Z.; Xiao, F. Applications of Fourier Transform Infrared Spectroscopy Technologies on Asphalt Materials. Measurement 2018, 121, 304–316. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Mills-Beale, J. Asphalt Binders Blended with a High Percentage of Biobinders: Aging Mechanism Using FTIR and Rheology. J. Mater. Civ. Eng. 2015, 27, 04014157. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, F.; Zhang, J.; Hu, D.; Minelli, M.; Pei, J.; Sangiorgi, C. Contributions of Fourier-Transform Infrared Spectroscopy Technologies to the Research of Asphalt Materials: A Comprehensive Review. Fuel 2024, 371, 132078. [Google Scholar] [CrossRef]

- Zhang, R.; You, Z.; Wang, H.; Ye, M.; Yap, Y.K.; Si, C. The Impact of Bio-Oil as Rejuvenator for Aged Asphalt Binder. Constr. Build. Mater. 2019, 196, 134–143. [Google Scholar] [CrossRef]

- Li, M.; Xu, O.; Min, Z.; Wang, Q. Engineering Performance and Activation Mechanism of Asphalt Binder Modified by Microwave and Diesel Pre-Processed Waste Crumb Rubber. Mater. Struct. 2023, 56, 117. [Google Scholar] [CrossRef]

- Sreeram, A.; Leng, Z. Variability of Rap Binder Mobilisation in Hot Mix Asphalt Mixtures. Constr. Build. Mater. 2019, 201, 502–509. [Google Scholar] [CrossRef]

- Wu, Q.; Wu, S.; Sun, X.; Su, X.; Shan, J. Improvement of RAP binder mobilization and blending efficiency using microwave induction. J. Mater. Civ. Eng. 2023, 35, 04023348. [Google Scholar] [CrossRef]

- Lei, Y.; Zhang, C.; Ni, X.; Gao, J.; Chen, G.; Guo, Y. Transfer of RAP Binder and Its Influence on Recycled HMA under Three Mixing Techniques. Road Mater. Pavement Des. 2023, 24, 1273–1289. [Google Scholar] [CrossRef]

- Li, D.; Leng, Z.; Zhang, S.; Jiang, J.; Yu, H.; Wellner, F.; Leischner, S. Blending Efficiency of Reclaimed Asphalt Rubber Pavement Mixture and Its Correlation with Cracking Resistance. Resour. Conserv. Recycl. 2022, 185, 106506. [Google Scholar] [CrossRef]

- Ding, Y.; Huang, B.; Shu, X. Utilizing Fluorescence Microscopy for Quantifying Mobilization Rate of Aged Asphalt Binder. J. Mater. Civ. Eng. 2017, 29, 04017243. [Google Scholar] [CrossRef]

- Ding, Y.; Cao, X.; Gong, H.; Huang, B.; Guo, P. Evaluating Recycling Efficiency of Plant-Asphalt Mixtures Containing RAP/RAS. J. Mater. Civ. Eng. 2020, 32, 04020316. [Google Scholar] [CrossRef]

- Zou, G.; Zhang, J.; Li, Y.; Lin, Z. Quantitative Characterize Binder Blending and Diffusion in Recycled Asphalt Mixture: An Environmental-Friendly Solution Using Wooden Cube and 3D Fluorescence Image Technology. J. Clean. Prod. 2021, 293, 126204. [Google Scholar] [CrossRef]

- Tao, Z.; Shen, S.; Yu, H.; Zou, Y.; Wen, L. Evaluating Surfactant-Foamed Warm Reclaimed Asphalt and Its Blending Efficiency. J. Mater. Civ. Eng. 2024, 36, 04024219. [Google Scholar] [CrossRef]

- Jiang, Y.; Gu, X.; Zhou, Z.; Ni, F.; Dong, Q. Laboratory Observation and Evaluation of Asphalt Blends of Reclaimed Asphalt Pavement Binder with Virgin Binder Using SEM/EDS. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 69–78. [Google Scholar] [CrossRef]

- Abdalfattah, I.A.; Mogawer, W.S.; Stuart, K. Quantification of the Degree of Blending in Hot-Mix Asphalt (HMA) with Reclaimed Asphalt Pavement (RAP) Using Energy Dispersive X-Ray Spectroscopy (EDX) Analysis. J. Clean. Prod. 2021, 294, 126261. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X. Investigation on Binder Homogeneity of RAP/RAS Mixtures through Staged Extraction. Constr. Build. Mater. 2015, 82, 184–191. [Google Scholar] [CrossRef]

- ASTM D5-06; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM D36-06; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM D113-17; Standard Test Method for Ductility of Asphalt Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4402-06; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2006.

- Hospodka, M.; Hofko, B.; Blab, R. Impact of Distillation Temperature on the Solvent Residue and Viscoelastic Properties of Asphalt Binders. Road Mater. Pavement Des. 2018, 19, 1275–1287. [Google Scholar] [CrossRef]

- Xu, W.; Qiu, X.; Xiao, S.; Hong, H.; Wang, F.; Yuan, J. Characteristics and Mechanisms of Asphalt–Filler Interactions from a Multi-Scale Perspective. Materials 2020, 13, 2744. [Google Scholar] [CrossRef] [PubMed]

- Hettiarachchi, C.; Hou, X.; Xiang, Q.; Yong, D.; Xiao, F. A Blending Efficiency Model for Virgin and Aged Binders in Recycled Asphalt Mixtures Based on Blending Temperature and Duration. Resour. Conserv. Recycl. 2020, 161, 104957. [Google Scholar] [CrossRef]

- ASTM D7906-14; Standard Practice for Recovery of Asphalt from Solution Using Toluene and Rotary Evaporator. ASTM International: West Conshohocken, PA, USA, 2014.

- Ma, Y.; Polaczyk, P.; Hu, W.; Zhang, M.; Huang, B. Quantifying the Effective Mobilized RAP Content during Hot In-Place Recycling Techniques. J. Clean. Prod. 2021, 314, 127953. [Google Scholar] [CrossRef]

- Lin, M.; Shuai, J.; Li, P.; Kang, X.; Lei, Y. Analysis of Rheological Properties and Micro-Mechanism of Aged and Reclaimed Asphalt Based on Multi-Scales. Constr. Build. Mater. 2022, 321, 126290. [Google Scholar] [CrossRef]

- Hou, X.; Xiao, F.; Wang, J.; Amirkhanian, S. Identification of Asphalt Aging Characterization by Spectrophotometry Technique. Fuel 2018, 226, 230–239. [Google Scholar] [CrossRef]

- Zhang, F.; Li, H.; Zou, X.; Cui, C.; Shi, Y.; Wang, H.; Yang, F. Performance and Simulation Study of Aged Asphalt Regenerated from Waste Engine Oil. Coatings 2022, 12, 1121. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M.E. Quantitative Characterization of Binder Blending: How Much Recycled Binder Is Mobilized During Mixing? Transp. Res. Rec. J. Transp. Res. Board 2015, 2506, 72–80. [Google Scholar] [CrossRef]

- Handle, F.; Harir, M.; Füssl, J.; Koyun, A.N.; Grossegger, D.; Hertkorn, N.; Eberhardsteiner, L.; Hofko, B.; Hospodka, M.; Blab, R.; et al. Tracking aging of bitumen and its saturate, aromatic, resin, and asphaltene fractions using high-field Fourier transform ion cyclotron resonance mass spectrometry. Energy Fuels 2017, 31, 4771–4779. [Google Scholar] [CrossRef]

| Property | Test Result | Standard Specification | |

|---|---|---|---|

| Virgin Asphalt Binder | Aged Asphalt Binder | ||

| Penetration (25 °C, 0.1 mm) | 66.20 | 35.00 | ASTM D5 [51] |

| Softening Point (°C) | 48.55 | 68.00 | ASTM D36 [52] |

| Ductility (15 °C, cm) | 146.00 | 25.20 | ASTM D113 [53] |

| Viscosity (135 °C, Pa∙s) | 0.46 | 1.31 | ASTM D4402 [54] |

| Virgin Aggregate | RAP | Virgin Binder | RAP Binder | Total Binder |

|---|---|---|---|---|

| 45.5% | 50.0% | 1.6% | 2.9% | 4.5% |

| Parameter | Value | |

|---|---|---|

| Asphalt Mastic | Asphalt Binder | |

| Z0 | 453 | 221 |

| a | −0.38 | −0.06 |

| b | −4.22 | −1.42 |

| c | 2.1 | 2.5 |

| d | 0.01 | 15 |

| f | 12 | 1 |

| R2 | 0.9757 | 0.9839 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Qiu, X.; Fu, Q.; Shen, Z.; Huang, X.; Chen, H. Microscopic Investigation of Coupled Mobilization and Blending Behaviors Between Virgin and Reclaimed Aged Asphalt Mastic. Materials 2025, 18, 3739. https://doi.org/10.3390/ma18163739

Zhang J, Qiu X, Fu Q, Shen Z, Huang X, Chen H. Microscopic Investigation of Coupled Mobilization and Blending Behaviors Between Virgin and Reclaimed Aged Asphalt Mastic. Materials. 2025; 18(16):3739. https://doi.org/10.3390/ma18163739

Chicago/Turabian StyleZhang, Jiaying, Xin Qiu, Qinghong Fu, Zheyu Shen, Xuanqi Huang, and Haoran Chen. 2025. "Microscopic Investigation of Coupled Mobilization and Blending Behaviors Between Virgin and Reclaimed Aged Asphalt Mastic" Materials 18, no. 16: 3739. https://doi.org/10.3390/ma18163739

APA StyleZhang, J., Qiu, X., Fu, Q., Shen, Z., Huang, X., & Chen, H. (2025). Microscopic Investigation of Coupled Mobilization and Blending Behaviors Between Virgin and Reclaimed Aged Asphalt Mastic. Materials, 18(16), 3739. https://doi.org/10.3390/ma18163739