Testing for Abrasion Resistance of WC-Co Composites for Blades Used in Wood-Based Material Processing

Abstract

1. Introduction

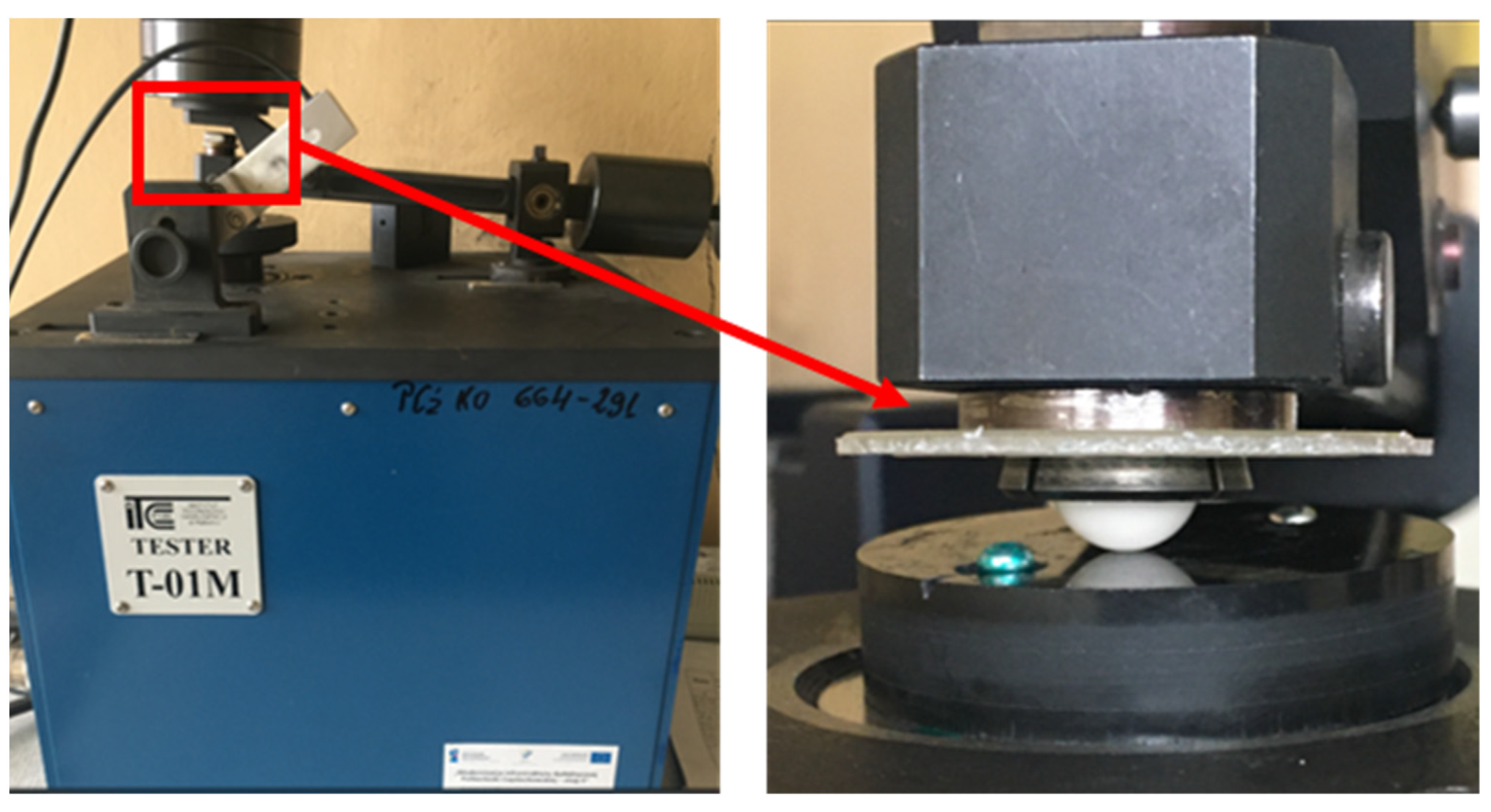

2. Experimental Procedure

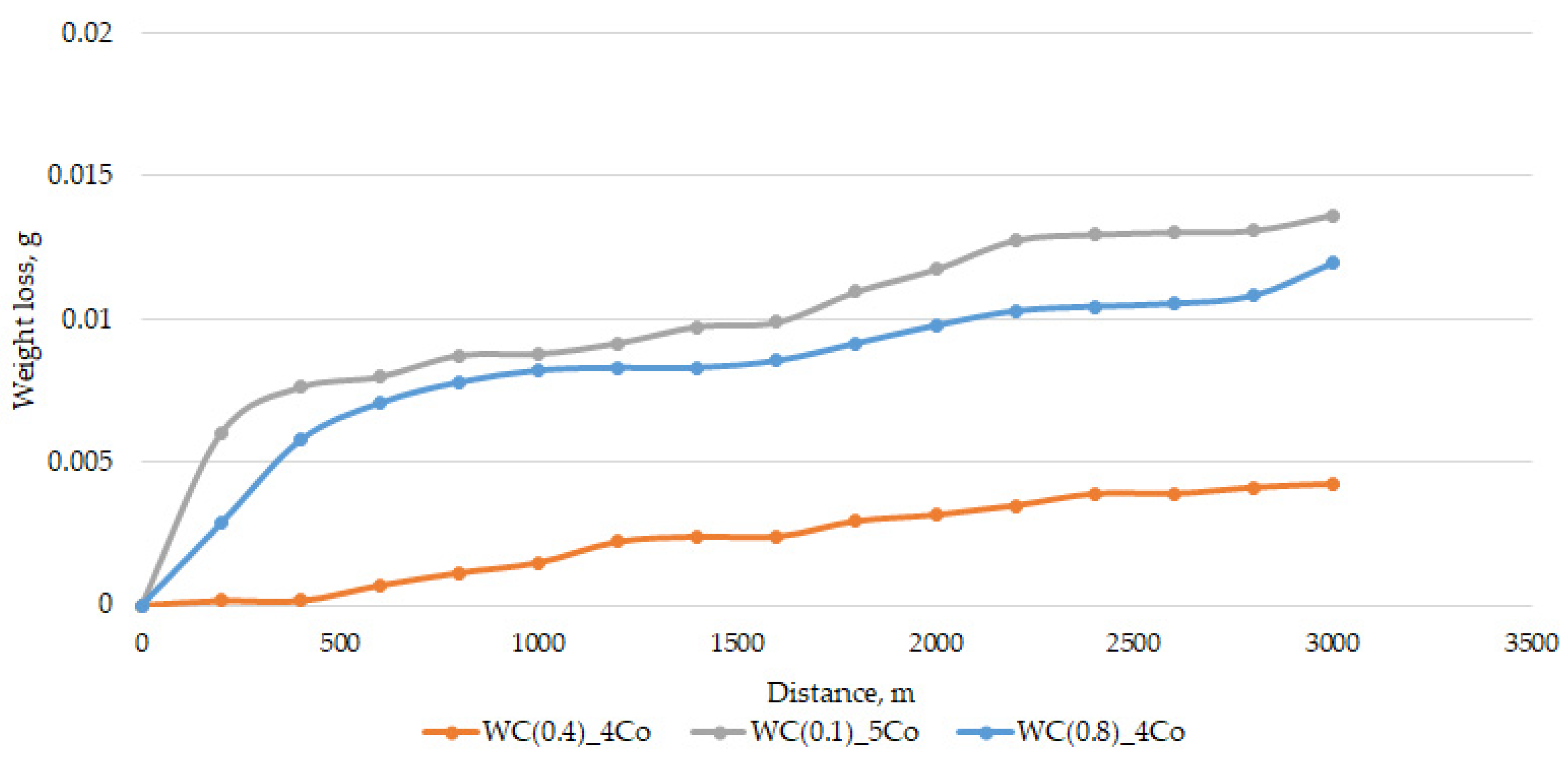

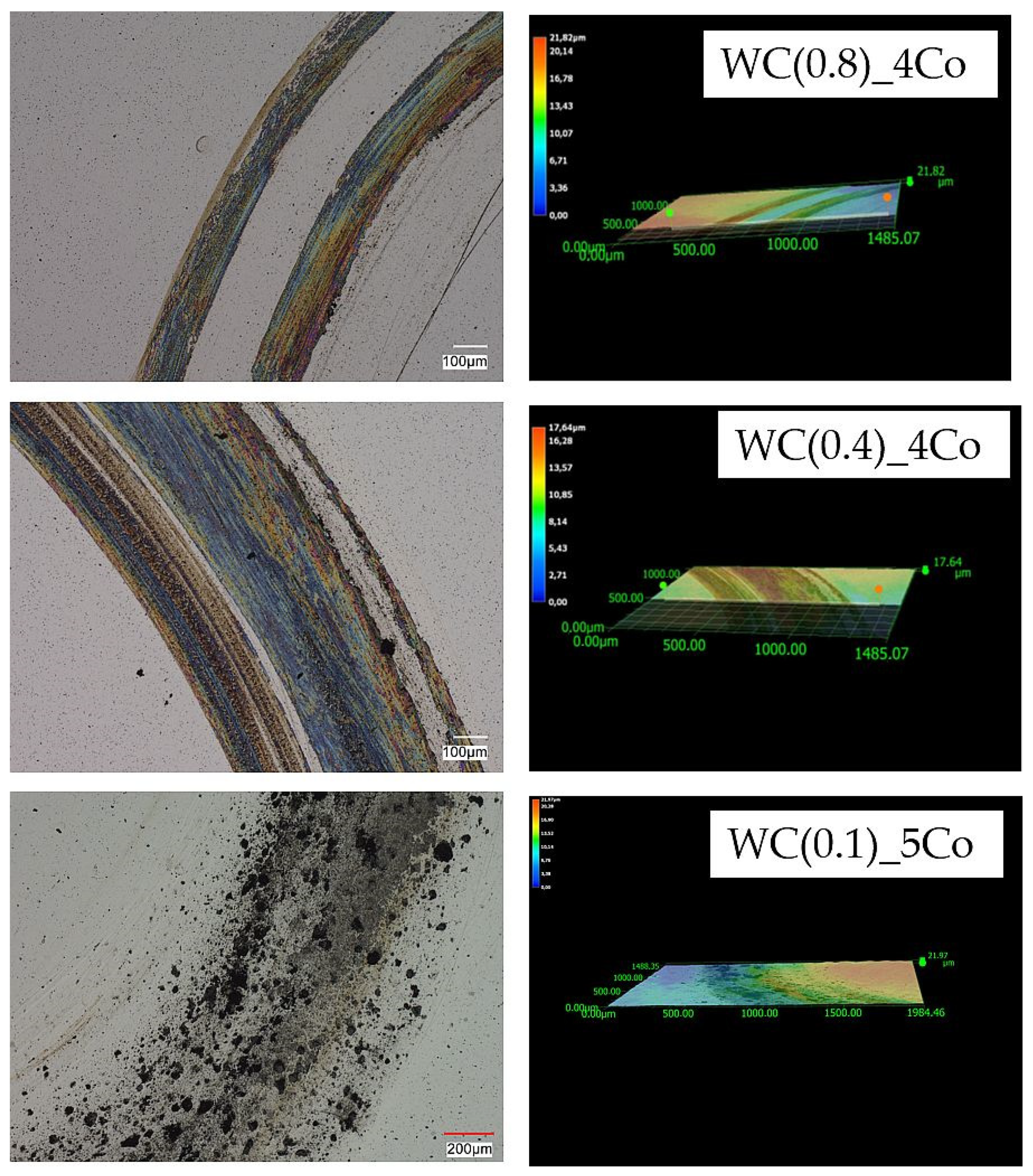

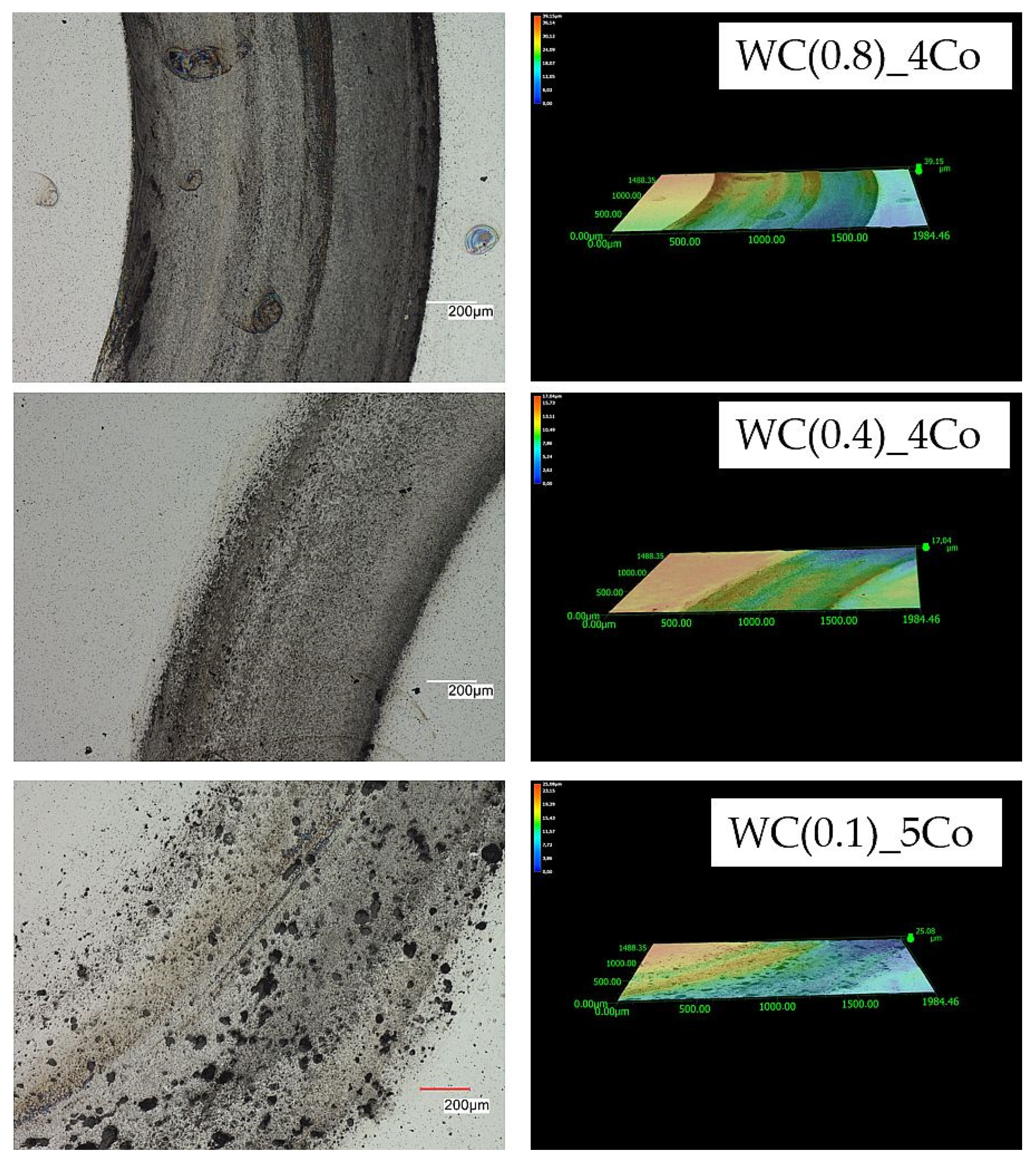

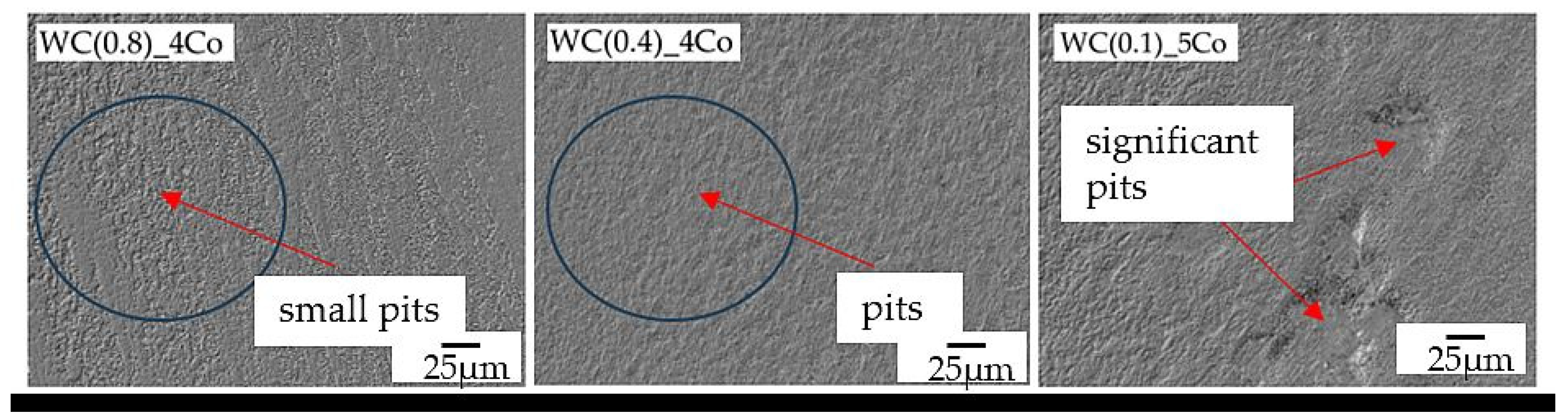

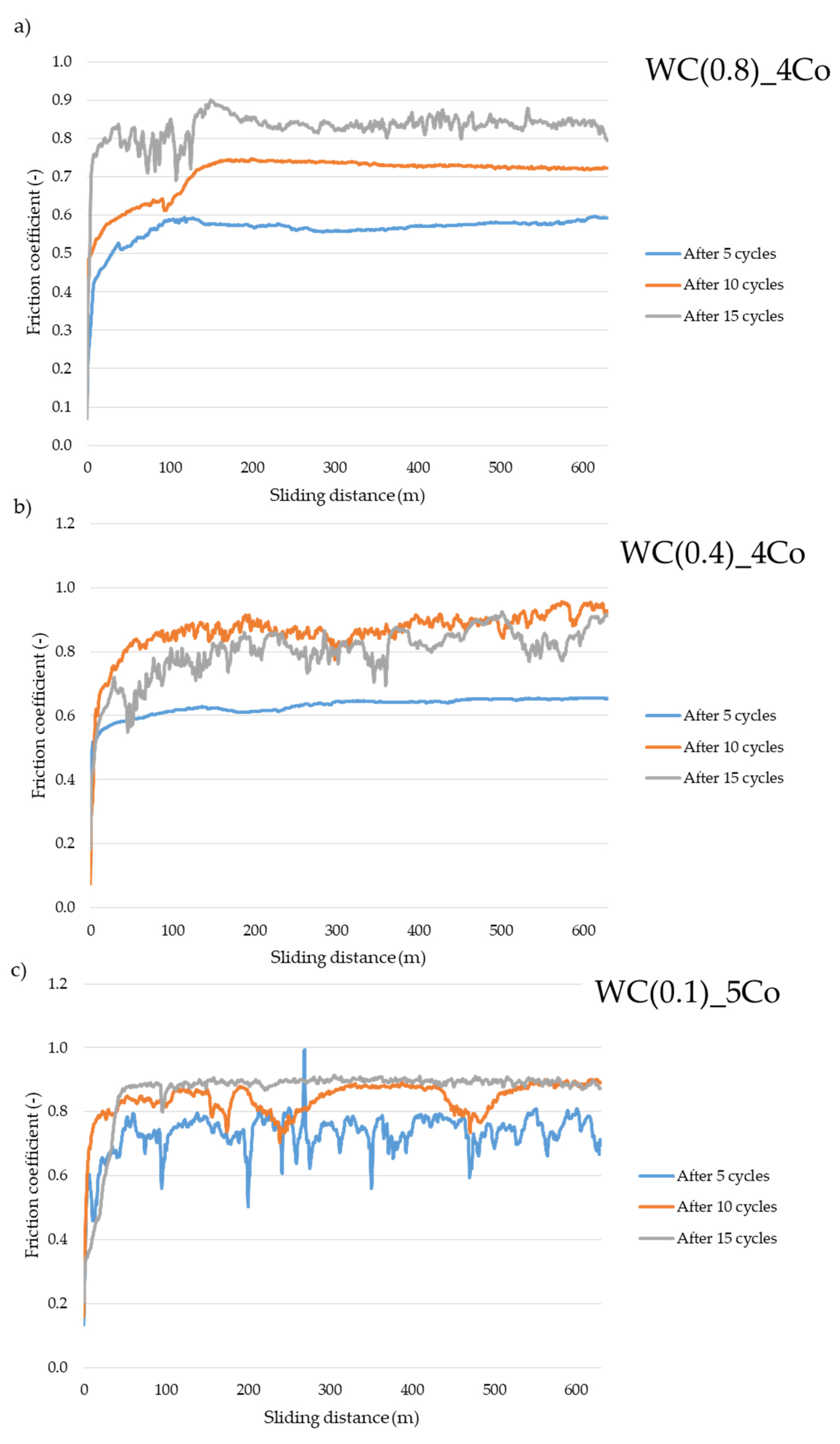

3. Results

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kaplinsky, R.; Memedovic, O.; Morris, M.; Readman, J. The global wood furniture value chain: What prospects for upgrading by developing countries. In UNIDO Sectoral Studies Series Working Paper; UNIDO: Vienna, Austria, 2003. [Google Scholar]

- Rajić, M.N.; Maksimović, R.M.; Milosavljević, P.; Pavlović, D. Energy Management System Application for Sustainable Development in Wood Industry Enterprises. Sustainability 2020, 12, 76. [Google Scholar] [CrossRef]

- Loučanová, E.; Olšiaková, M.; Dzian, M. Suitability of innovative marketing communication forms in the furniture industry. Acta Fac. Xylologiae Zvolen. Publica Slovaca 2018, 60, 159–171. [Google Scholar]

- Ratnasingam, J.; Chin, K.A.; Latib, H.A.; Subramaniam, H.; Khoo, A. Innovation in the Malaysian furniture industry: Drivers and challenges. BioResources 2018, 13, 5254–5270. [Google Scholar] [CrossRef]

- Barbaritano, M.; Bravi, L.; Savelli, E. Sustainability and Quality Management in the Italian Luxury Furniture Sector: A Circular Economy Perspective. Sustainability 2019, 11, 3089. [Google Scholar] [CrossRef]

- Wanat, L.; Potkański, T.; Chudobiecki, J.; Mikołajczak, E.; Mydlarz, K. Intersectoral and Intermunicipal Cooperation as a Tool for Supporting Local Economic Development: Prospects for the Forest and Wood-Based Sector in Poland. Forests 2018, 9, 531. [Google Scholar] [CrossRef]

- Wachowicz, J.; Wilkowski, J.; Talarek, S. Influence of cutting parameters on the tool life for WC-Co composites in the machining of wood-based materials. Wood Mater. Sci. Eng. 2023, 1–10. [Google Scholar] [CrossRef]

- Wilkowski, J.; Barlak, M.; Böttger, R.; Werner, Z.; Konarski, P.; Pisarek, M.; Wachowicz, J.; Von Barany, J.; Auriga, A. Effect of nitrogen ion implantation on the life time of WC-Co tools used in particleboard milling. Wood Mater. Sci. Eng. 2022, 17, 521–532. [Google Scholar] [CrossRef]

- Wachowicz, J.; Dembiczak, T.; Stradomski, G.; Bałaga, Z.; Dyner, M.; Wilkowski, J. Properties of WCCo composites produced by the SPS method intended for cutting tools for machining of wood-based materials. Materials 2021, 14, 2618. [Google Scholar] [CrossRef]

- Jurko, J.; Miškiv-Pavlík, M.; Husár, J.; Michalik, P. Turned Surface Monitoring Using a Confocal Sensor and the Tool Wear Process Optimization. Processes 2022, 10, 2599. [Google Scholar] [CrossRef]

- Ganeshkumar, S.; Singh, B.K.; Kumar, S.D.; Gokulkumar, S.; Sharma, S.; Mausam, K.; Li, C.; Zhang, Y.; Tag Eldin, E.M. Study of Wear, Stress and Vibration Characteristics of Silicon Carbide Tool Inserts and Nano Multi-Layered Titanium Nitride-Coated Cutting Tool Inserts in Turning of SS304 Steels. Materials 2022, 15, 7994. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J. A review on wood machining: Characterization, optimization, and monitoring of the sawing process. Wood Mater. Sci. Eng. 2020, 15, 1–16. [Google Scholar] [CrossRef]

- Henke, M.; Lis, B.; Krystofiak, T. Evaluation of Surface Roughness Parameters of HDF for Finishing under Industrial Conditions. Materials 2022, 15, 6359. [Google Scholar] [CrossRef] [PubMed]

- De Deus, P.R.; Alves, M.C.D.S.; Vieira, F.H.A. The quality of MDF workpieces machined in CNC milling machine in cutting speeds, feedrate, and depth of cut. Meccanica 2015, 50, 2899–2906. [Google Scholar] [CrossRef]

- Szwajka, K.; Trzepieciński, T. Effect of tool material on tool wear and delamination during machining of particleboard. J. Wood Sci. 2016, 62, 305–315. [Google Scholar] [CrossRef]

- Pałubicki, B.; Rogoziński, T. Efficiency of chips removal during CNC machining of particleboard. Wood Res. 2016, 61, 811–818. [Google Scholar]

- Fang, Z.; Eason, J.W. Study of nanostructured WC-Co composites. Int. J. Refract. Met. Hard Mater. 1995, 13, 297–303. [Google Scholar] [CrossRef]

- Zhang, F.L.; Wang, C.Y.; Zhu, M. Nanostructured WC/Co composite powder prepared by high energy ball milling. Scr. Mater. 2003, 49, 1123–1128. [Google Scholar] [CrossRef]

- Chen, C.; Huang, B.; Liu, Z.; Li, Y.; Zou, D.; Liu, T.; Chen, L. Additive manufacturing of WC-Co cemented carbides: Process, microstructure, and mechanical properties. Addit. Manuf. 2023, 63, 103410. [Google Scholar] [CrossRef]

- Zhang, H.; Xiong, J.; Guo, Z.; Yang, T.; Liu, J.; Hua, T. Microstructure, mechanical properties, and cutting performances of WC-Co cemented carbides with Ru additions. Ceram. Int. 2021, 47, 26050–26062. [Google Scholar] [CrossRef]

- Ke, Z.; Zheng, Y.; Zhang, G.; Ding, Q.; Zhang, J.; Wu, H.; Zhu, X. Microstructure and mechanical properties of dual-grain structured WC-Co cemented carbides. Ceram. Int. 2019, 45, 21528–21533. [Google Scholar] [CrossRef]

- Wachowicz, J.; Wilkowski, J. Influence of Diamond Grain Size on the Basic Properties of WC-Co/Diamond Composites Used in Tools for Wood-Based Materials Machining. Materials 2022, 15, 3569. [Google Scholar] [CrossRef]

- Wachowicz, J.; Michalski, A. Synthesis and properties of WCCo/diamond composite for uses as tool material for wood-based material machining. Compos. Interfaces 2021, 28, 735–747. [Google Scholar] [CrossRef]

- Jach, K.; Figiel, P.; Biedunkiewicz, A. Application of U-FAST Technology in Sintering of Titanium Biomaterials. Biomed. J. Sci. Tech. Res. 2019, 23, 17441–17444. [Google Scholar]

- Figiel, P.; Biedunkiewicz, A.; Jach, K.; Obrosov, A.; Garbiec, D.; Bik, M.; Weiß, S. Ti-Mo-xTiC composites manufactured by U-FAST reactive sintering. Int. J. Refract. Met. Hard Mater. 2022, 108, 105960. [Google Scholar]

- Schembri, J.; Kaur, S.; Oskouei, R.H.; Rosinski, M.; Ghomashchi, R.; Rumman, R. Understanding the Potential of U-FAST Sintering Process–An Overview. Asp. Min. Miner. Sci. 2019, 3, 367–372. [Google Scholar]

- Szablewski, P.; Legutko, S.; Mróz, A.; Garbiec, D.; Czajka, R.; Smak, K.; Krawczyk, B. Surface Topography Description after Turning Inconel 718 with a Conventional, Wiper and Special Insert Made by the SPS Technique. Materials 2023, 16, 949. [Google Scholar] [CrossRef] [PubMed]

- Wachowicz, J.; Kruzel, R.; Bałaga, Z.; Ostrowska, A.; Dembiczak, T. Application of U-FAST Technology in Sintering of Submicron WC-Co Carbides. Materials 2023, 16, 2450. [Google Scholar] [CrossRef]

- Le Godec, Y.; Le Floch, S. Recent Developments of High-Pressure Spark Plasma Sintering: An Overview of Current Applications, Challenges and Future Directions. Materials 2023, 16, 997. [Google Scholar]

- Kuprin, A.S.; Ovcharenko, V.D.; Gilewicz, A.; Tolmachova, G.N.; Kolodiy, I.V.; Vasilenko, R.L.; Warcholinski, B. Structural, mechanical and tribological properties of Cr-VN coatings deposited by cathodic arc evaporation. Tribol. Int. 2022, 165, 107246. [Google Scholar]

- Wyżga, P.; Laszkiewicz-Łukasik, J.; Jaworska, L. Badania odporności na zużycie ścierne potencjalnych materiałów narzędziowych. Mechanik 2016, 89, 109–112. [Google Scholar] [CrossRef][Green Version]

- Sulima, I. Tribological properties of steel/TiB2 composites prepared by spark plasma sintering. Arch. Metall. Mater. 2014, 59, 1263–1268. [Google Scholar] [CrossRef]

- Puchý, V.; Kováčik, J.; Kovalčíková, A.; Sedlák, R.; Džunda, R.; Dusza, J.; Hvizdoš, P. Mechanical and tribological properties of TiB 2-Ti composites prepared by spark plasma sintering. Met. Mater. 2019, 57, 435–442. [Google Scholar]

- Kalandyk, B.; Zapała, R.; Madej, M.; Kasińska, J.; Piotrowska, K. Influence of Pre-Hardened Gx120mn13 Cast Steel on the Tribological Properties under Technically Dry Friction. Tribologia 2022, 301, 17–24. [Google Scholar]

- Walnik, B.; Marcisz, J.; Iwaniak, A.; Wieczorek, J. Badania zużycia ściernego nanostrukturalnej stali bainitycznej. Pr. Inst. Metal. Żelaza 2017, 69, 55–60. [Google Scholar]

- Zhang, X.; Zhang, J.; Ding, J. Effect of the additive graphene oxide on tribological properties of WC-Co cemented carbide. Int. J. Refract. Met. Hard Mater. 2022, 109, 105962. [Google Scholar]

- Bonny, K.; De Baets, P.; Quintelier, J.; Vleugels, J.; Jiang, D.; Van der Biest, O.; Liu, W. Surface finishing: Impact on tribological characteristics of WC–Co hardmetals. Tribol. Int. 2010, 43, 40–54. [Google Scholar]

- Piekoszewski, W. Wpływ na powierzchniową trwałość zmęczeniową wybranych materiałów i technologii konstytuowania warstw powierzchniowych elementów węzła tocznego. Tribologia 2009, 3, 185–196. [Google Scholar]

- Jia, K.; Fischer, T.E. Abrasion resistance of nanostructured and conventional cemented carbides. Wear 1996, 200, 206–214. [Google Scholar] [CrossRef]

- Szarek, A.; Stradomski, G.; Łukomska-Szarek, J.; Rydz, D.; Wolański, W.; Joszko, K. Wear Morphology on the Surfaces of CoCrMo Unicompartmental Knee Joint Endoprostheses as Elements of Metal–Metal Friction Nodes. Materials 2020, 13, 2689. [Google Scholar]

- Lin, N.; He, Y.; Wu, C.; Zhang, Q.; Zou, J.; Zhao, Z. Fabrication of tungsten carbide–vanadium carbide core–shell structure powders and their application as an inhibitor for the sintering of cemented carbides. Scr. Mater. 2012, 67, 826–829. [Google Scholar]

- Wei, C.; Song, X.; Zhao, S.; Zhang, L.; Liu, W. In-situ synthesis of WC–Co composite powder and densification by sinter-HIP. Int. J. Refract. Met. Hard Mater. 2010, 28, 567–571. [Google Scholar]

- Zhao, S.; Song, X.; Wei, C.; Zhang, L.; Liu, X.; Zhang, J. Effects of WC particle size on densification and properties of spark plasma sintered WC–Co cermet. Int. J. Refract. Met. Hard Mater. 2009, 27, 1014–1018. [Google Scholar] [CrossRef]

- Zhu, Y.C.; Yukimura, K.; Ding, C.X.; Zhang, P.Y. Tribological properties of nanostructured and conventional WC–Co coatings deposited by plasma spraying. Thin Solid Film. 2001, 388, 277–282. [Google Scholar]

- Sheng, L.; Xiao, Y.; Jiao, C.; Du, B.; Li, Y.; Wu, Z.; Shao, L. Influence of layer number on microstructure, mechanical properties and wear behavior of the TiN/Ti multilayer coatings fabricated by high-power magnetron sputtering deposition. J. Manuf. Process. 2021, 70, 529–542. [Google Scholar]

| Sample | WC Grain Size (µm) | Cobalt Content (% wt.) | Hardness (HV30) | KIC (MPa m1/2) | Technology | Literature |

|---|---|---|---|---|---|---|

| WC(0.4)_4Co | 0.4 | 4 | 2270 | 8.33 | U-FAST | [28] |

| WC(0.8)_4Co | 0.8 | 4 | 2085 | 8.36 | U-FAST | [28] |

| WC(0.1)_5Co | 0.1 | 5 | 2192 | 9.27 | U-FAST | This work |

| Compound (unit) | Contents |

|---|---|

| Al2O3 (%) | 99.8 |

| Na2O (ppm) | 500 |

| CaO (ppm) | 200 |

| MgO (ppm) | 500 |

| SiO2 (ppm) | 350 |

| Fe2O3 (ppm) | 180 |

| Material | Cycle Number | Roughness Parameters | ||

|---|---|---|---|---|

| Ra (µm) | Rt (µm) | Rz (µm) | ||

| WC(0.8)_4Co | 5 | 2.23 | 11.42 | 11.44 |

| 10 | 2.77 | 10.03 | 10.03 | |

| 15 | 5.24 | 18.96 | 18.97 | |

| WC(0.4)_4Co | 5 | 1.30 | 7.90 | 7.90 |

| 10 | 1.48 | 6.10 | 6.10 | |

| 15 | 1.58 | 5.84 | 5.84 | |

| WC(0.1)_5Co | 5 | 2.46 | 12.61 | 12.61 |

| 10 | 2.77 | 10.03 | 10.03 | |

| 15 | 5.24 | 18.96 | 18.96 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wachowicz, J.; Fik, J.; Bałaga, Z.; Stradomski, G. Testing for Abrasion Resistance of WC-Co Composites for Blades Used in Wood-Based Material Processing. Materials 2023, 16, 5836. https://doi.org/10.3390/ma16175836

Wachowicz J, Fik J, Bałaga Z, Stradomski G. Testing for Abrasion Resistance of WC-Co Composites for Blades Used in Wood-Based Material Processing. Materials. 2023; 16(17):5836. https://doi.org/10.3390/ma16175836

Chicago/Turabian StyleWachowicz, Joanna, Joanna Fik, Zbigniew Bałaga, and Grzegorz Stradomski. 2023. "Testing for Abrasion Resistance of WC-Co Composites for Blades Used in Wood-Based Material Processing" Materials 16, no. 17: 5836. https://doi.org/10.3390/ma16175836

APA StyleWachowicz, J., Fik, J., Bałaga, Z., & Stradomski, G. (2023). Testing for Abrasion Resistance of WC-Co Composites for Blades Used in Wood-Based Material Processing. Materials, 16(17), 5836. https://doi.org/10.3390/ma16175836