Ultra-Highly Efficient Removal of Methylene Blue Based on Graphene Oxide/TiO2/Bentonite Sponge

Abstract

1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of GO Sponge

2.3. Preparation of GO/TiO2 and TiO2/Bent

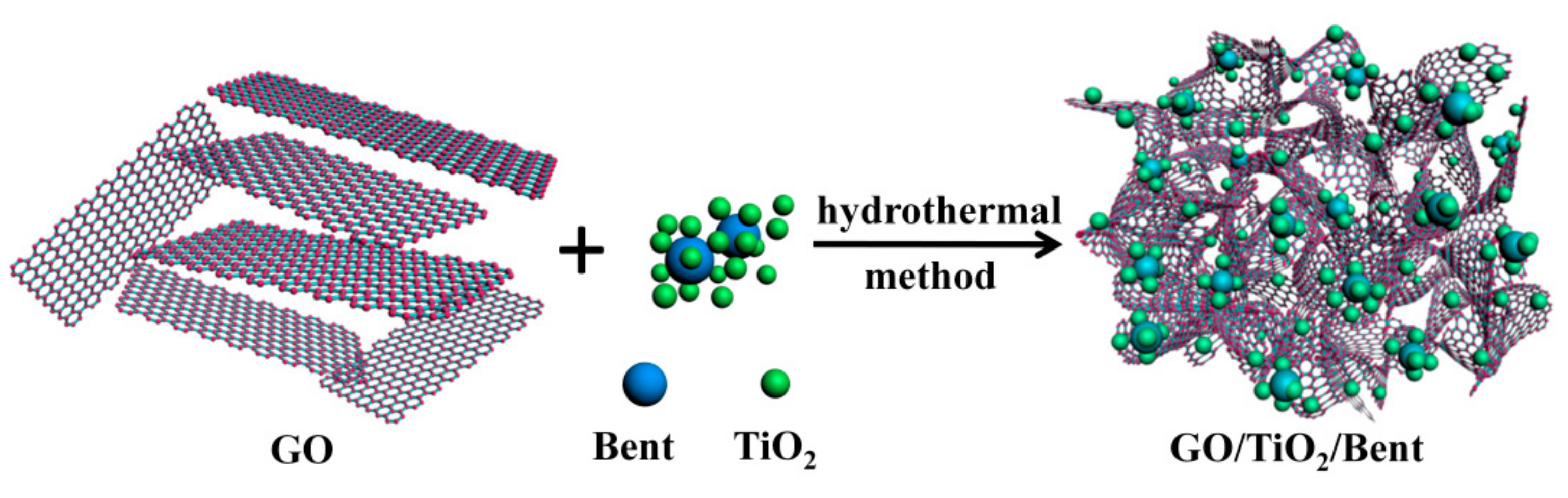

2.4. Preparation of GO/TiO2/Bent Sponge

2.5. Photocatalytic Tests

2.6. Characterization of Materials

3. Results and Discussion

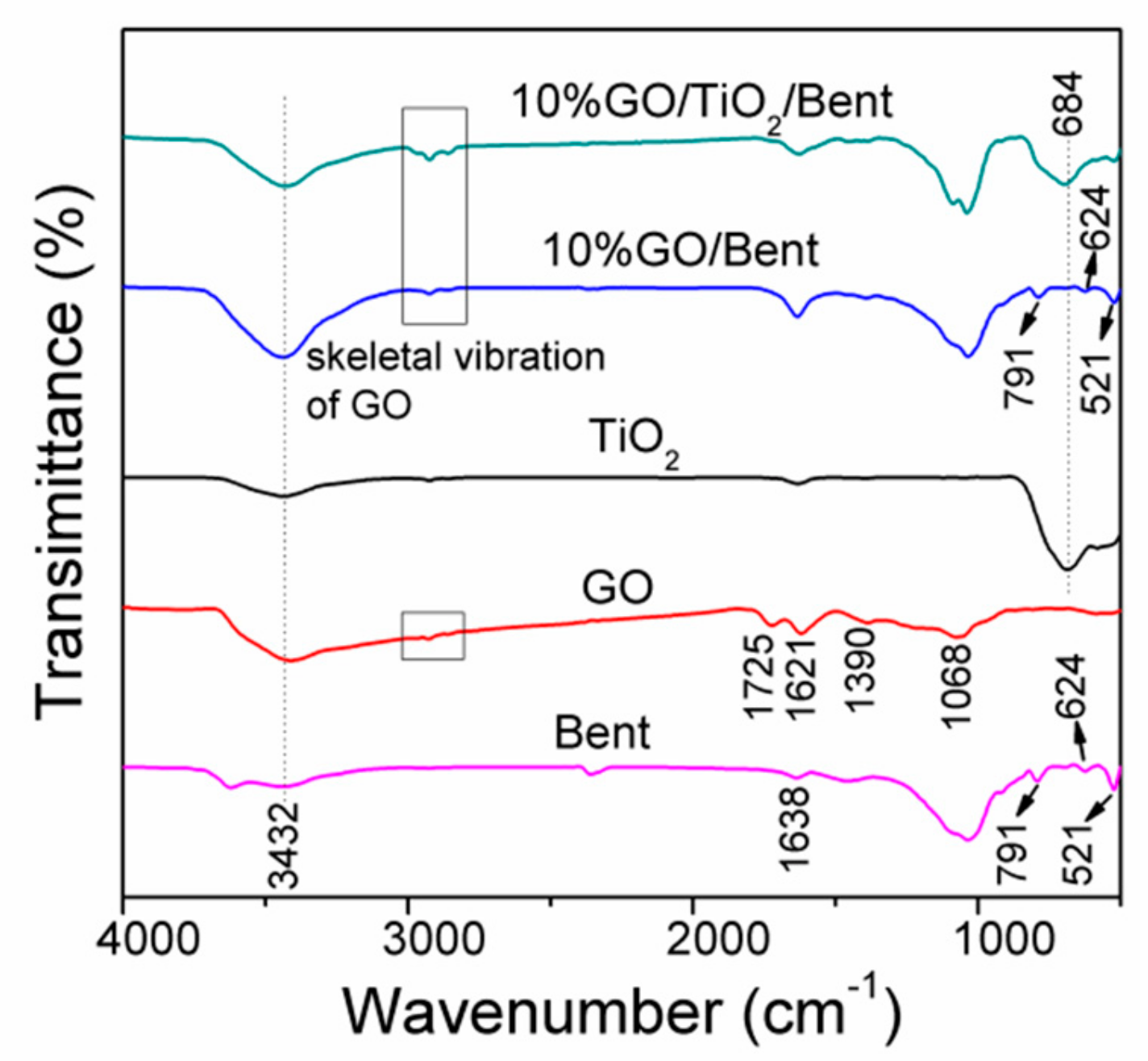

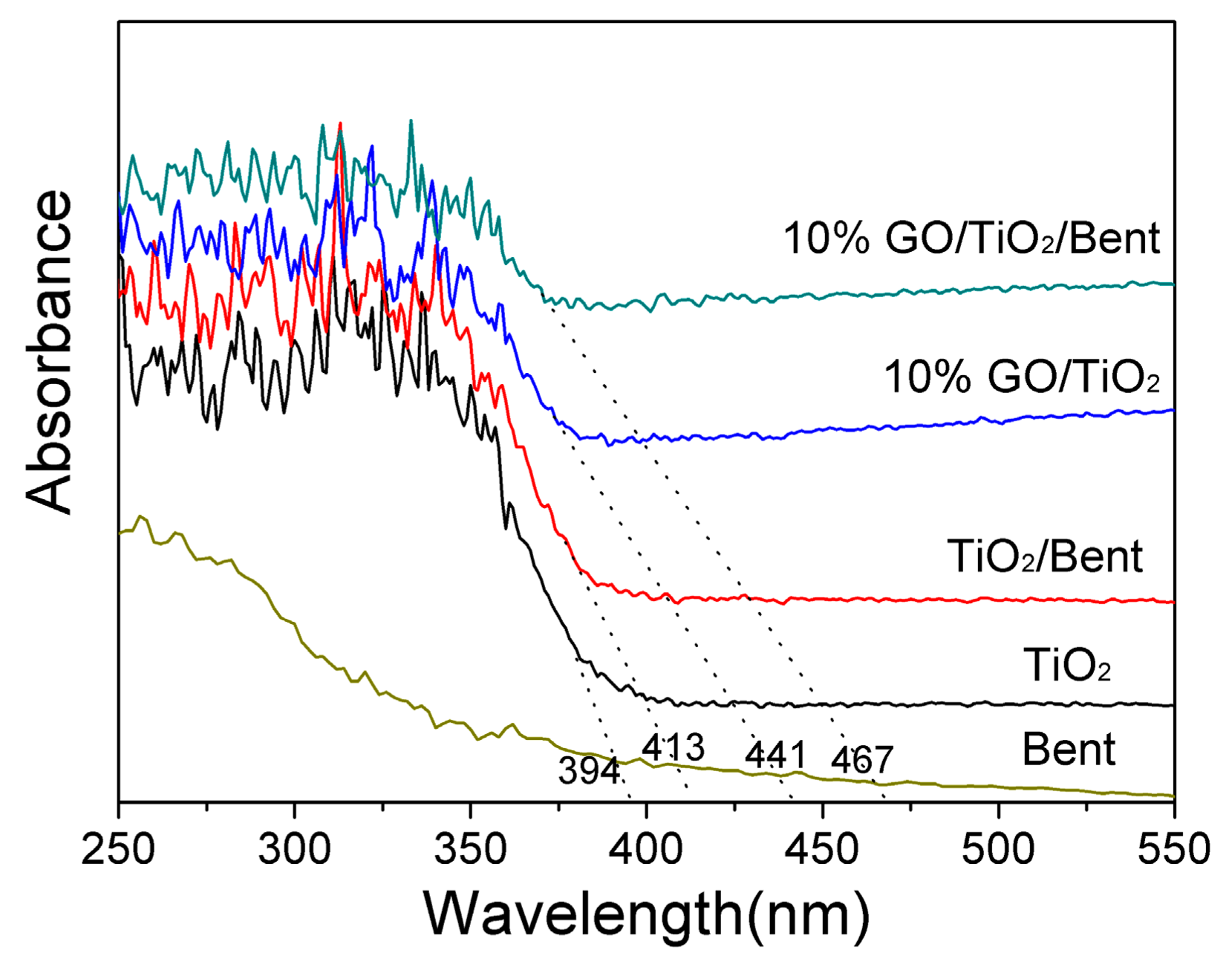

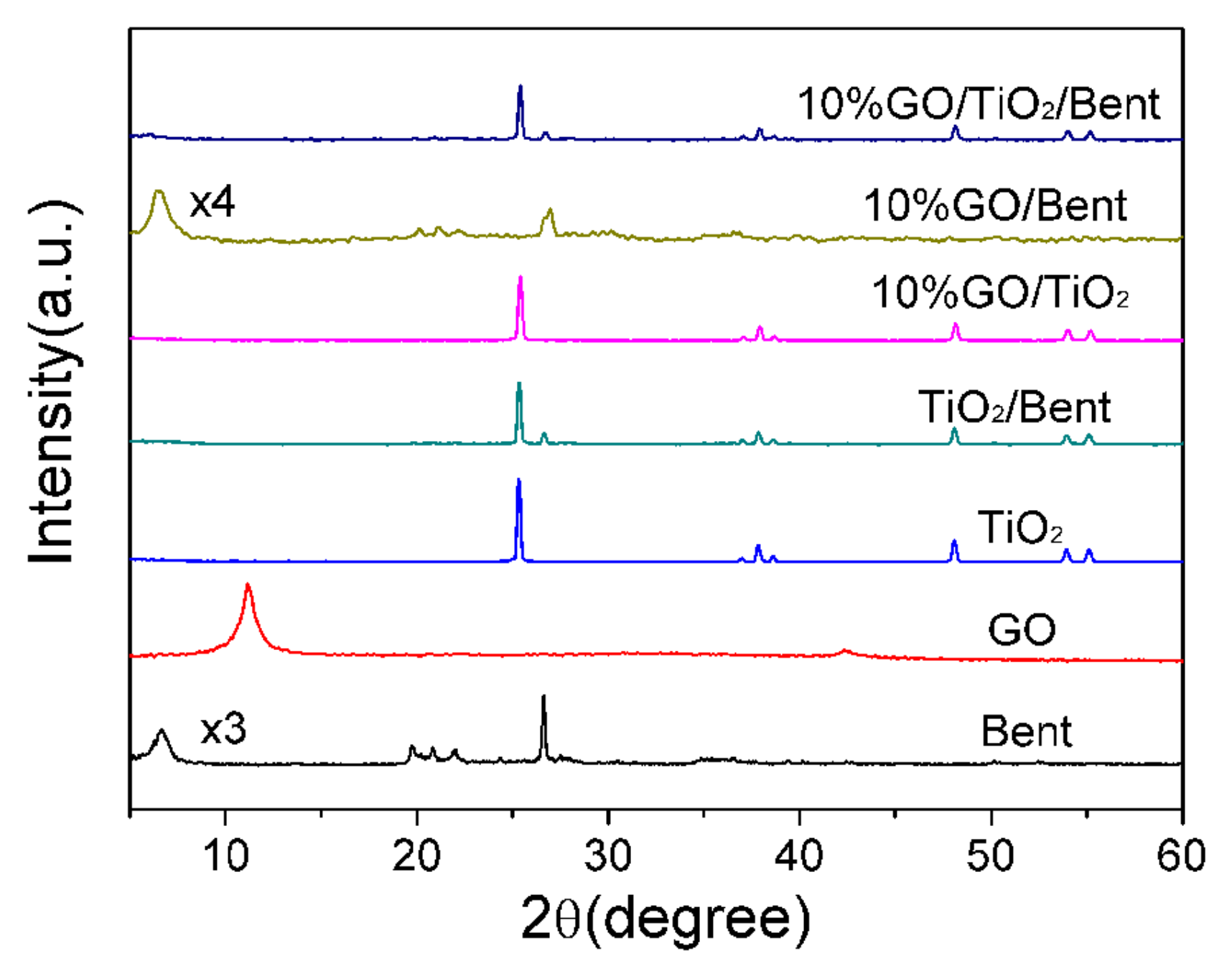

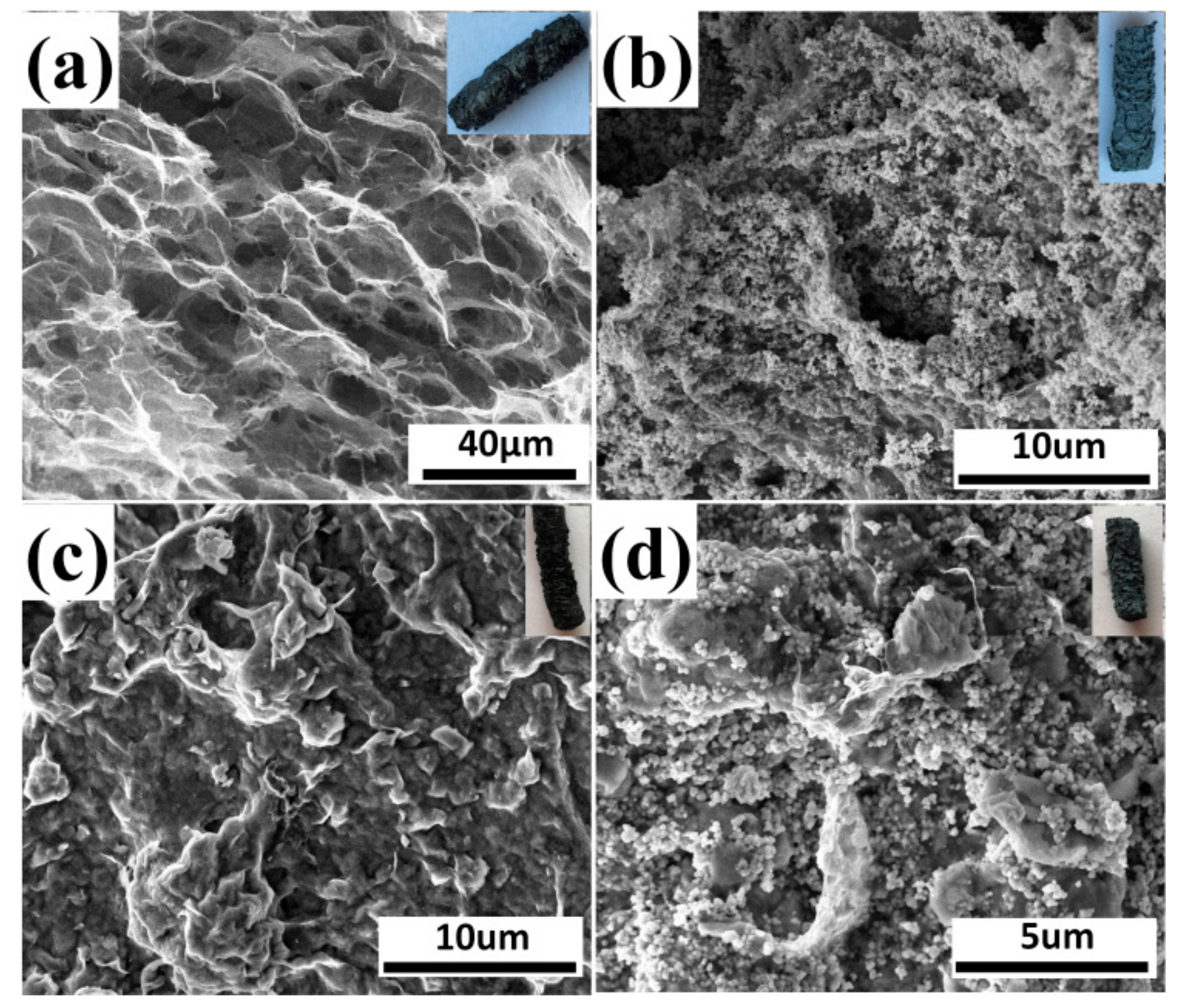

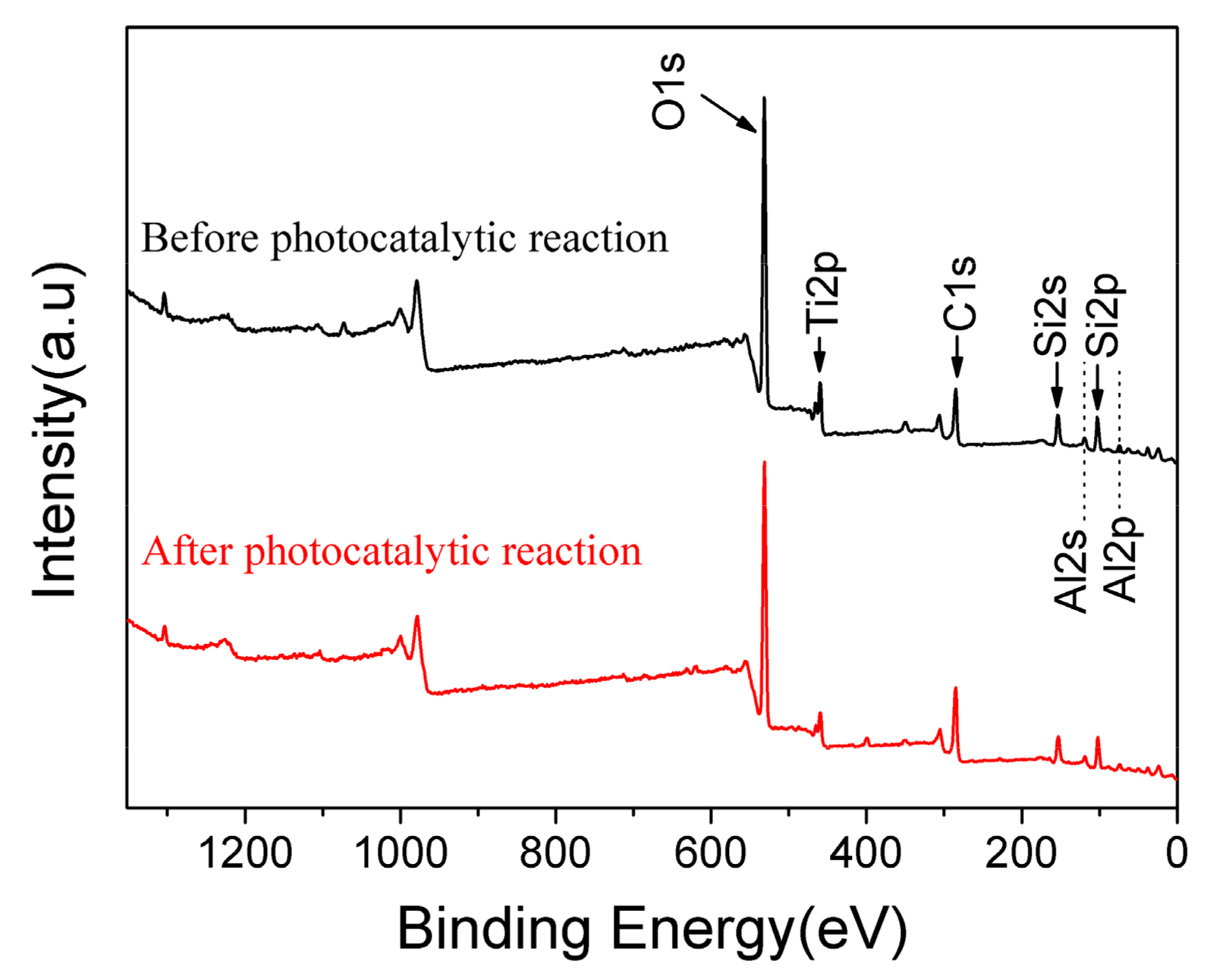

3.1. Characterization of Materials

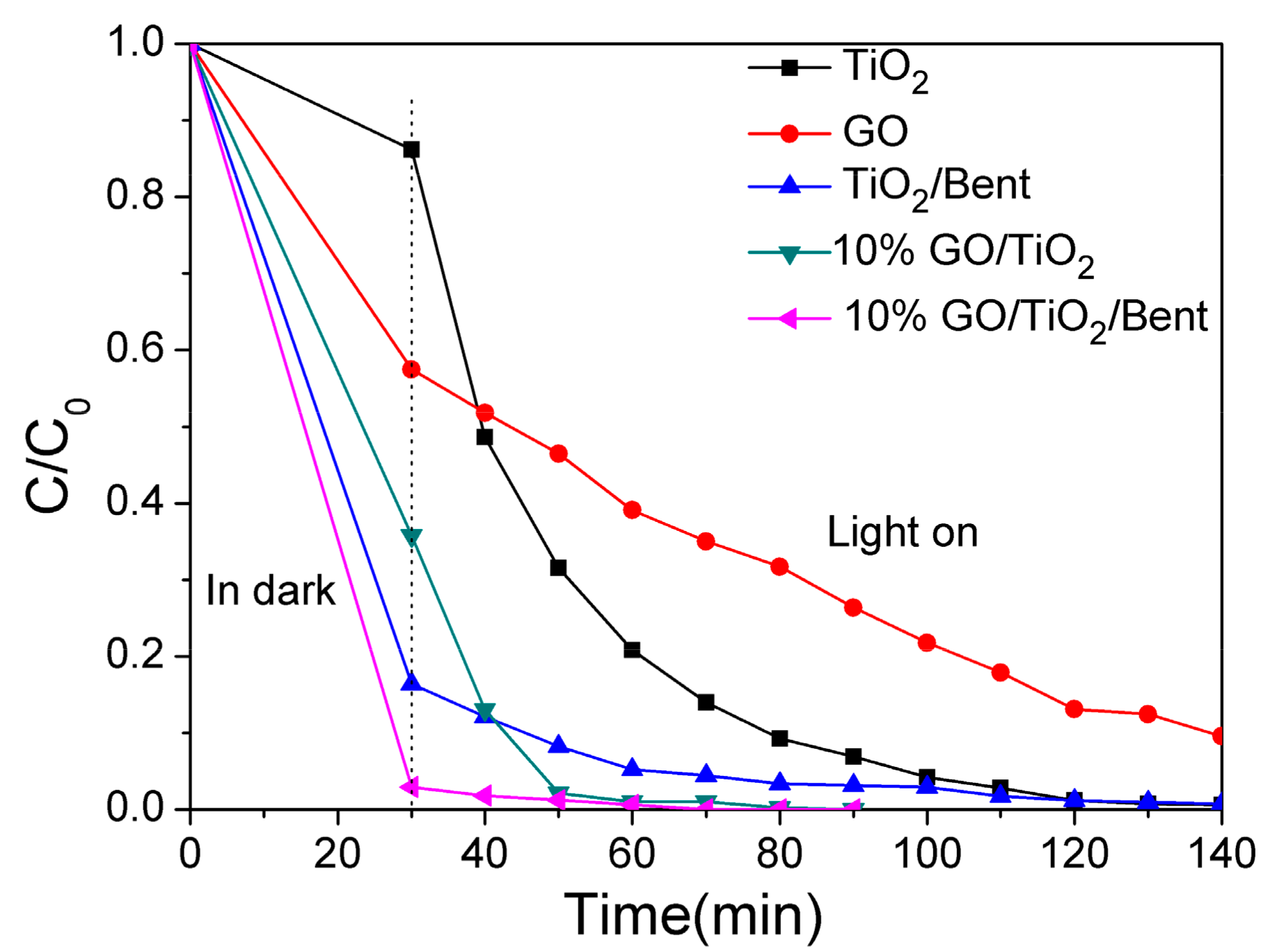

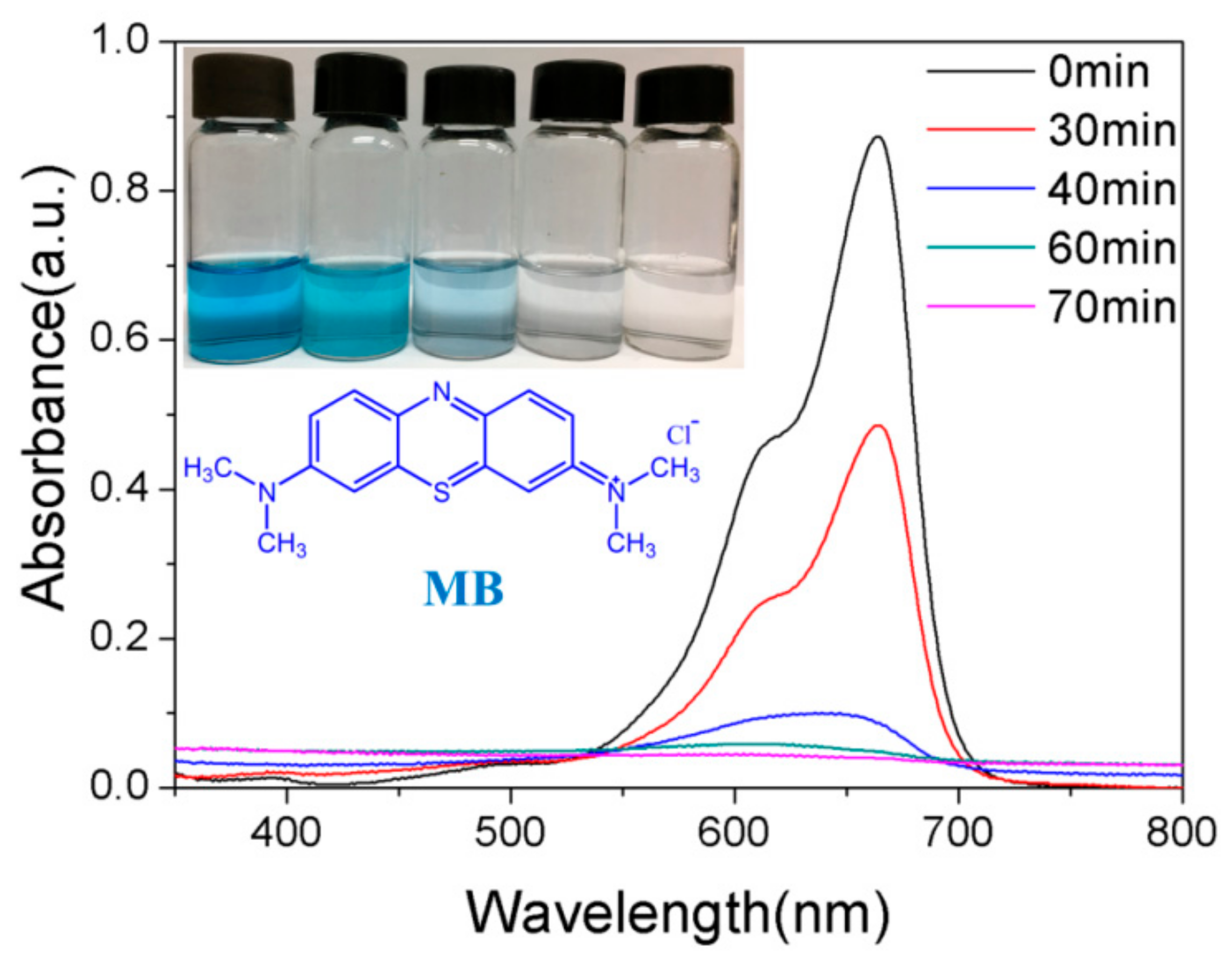

3.2. Photocatalytic Degradation

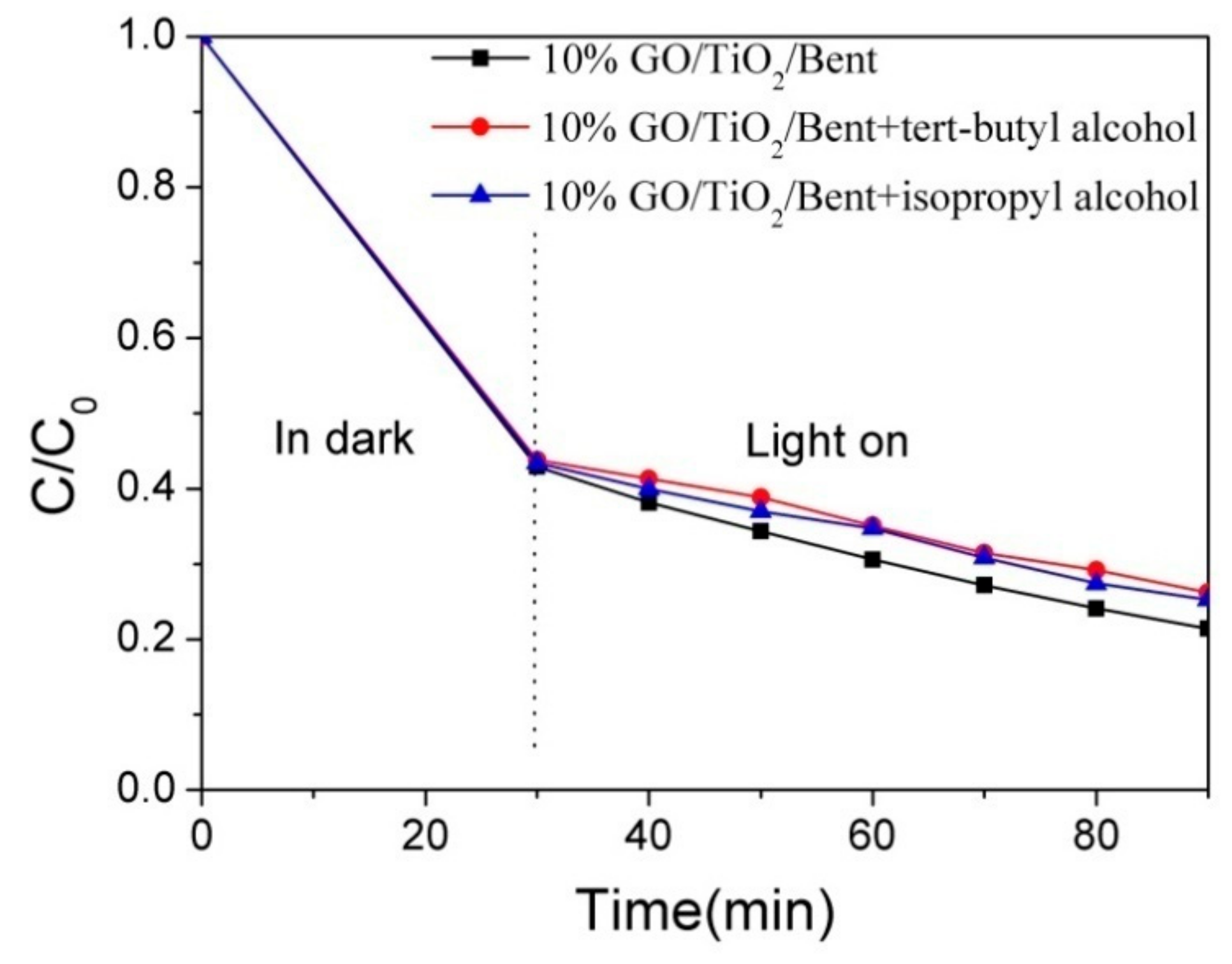

3.3. Photocatalytic Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Ferreira Neto, E.; Ullah, S.; Simões, M.; Perissinotto, A.; De Vicente, F.; Noeske, P.L.; Ribeiro, S.; Rodrigues Filho, U. Solvent-controlled deposition of titania on silica spheres for the preparation of SiO2@TiO2 core@shell nanoparticles with enhanced photocatalytic activity. Colloid. Surf. A 2019, 570, 293–305. [Google Scholar] [CrossRef]

- Gan, W.; Shang, X.; Li, X.H.; Zhang, J.; Fu, X. Achieving high adsorption capacity and ultrafast removal of methylene blue and Pb2+ by graphene-like TiO2@C. Colloid. Surf. A 2018, 561, 218–225. [Google Scholar] [CrossRef]

- Field, R. Surface science: Separation by reconfiguration. Nature 2012, 489, 41–42. [Google Scholar] [CrossRef] [PubMed]

- Chu, Z.; Feng, Y.; Seeger, S. Oil/water separation with selective superantiwetting/superwetting surface materials. Angew. Chem. Int. Ed. 2014, 54, 2328–2338. [Google Scholar] [CrossRef]

- Mathieu Denoncourt, J.; Martyniuk, C.; De Solla, S.; Balakrishnan, V.; Langlois, V. Sediment contaminated with the azo dye disperse yellow 7 alters cellular stress and androgen-related transcription in silurana tropicalis larvae. Environ. Sci. Technol. 2014, 48, 2952–2961. [Google Scholar] [CrossRef]

- Li, D.; Li, Q.; Bai, N.; Dong, H.; Mao, D. One-step synthesis of cationic hydrogel for efficient dye adsorption and its second use for emulsified oil separation. ACS Sustain. Chem. Eng. 2017, 5, 5598–5607. [Google Scholar] [CrossRef]

- Qiu, S.; Xu, S.; Li, G.; Yang, J. Synergetic Effect of ultrasound, the heterogeneous fenton reaction and photocatalysis by TiO2 loaded on nickel foam on the degradation of pollutants. Materials 2016, 9, 457. [Google Scholar] [CrossRef]

- Wang, K.; Endo Kimura, M.; Belchi, R.; Zhang, D.; Habert, A.; Bouclé, J.; Ohtani, B.; Kowalska, E.; Herlin Boime, N. Carbon/Graphene-modified titania with enhanced photocatalytic activity under uv and vis irradiation. Materials 2019, 12, 4158. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, K.S.; Sorcar, S.; Razzaq, A.; Grimes, C.A.; In, S.I. Wastewater treatment and electricity generation from a sunlight-powered single chamber microbial fuel cell. J. Photochem. Photobiol. A Chem. 2018, 358, 432–440. [Google Scholar] [CrossRef]

- Saurav, S.; Thompson, J.F.; Hwang, Y.; Park, Y.H.; Majima, T.; Grimes, C.A.; Durrant, J.R.; In, S. High-rate solar-light photo conversion of CO2 to fuel: Controllable transformation from C1 to C2 products. Energy Environ. Sci. 2018, 11, 3183–3193. [Google Scholar]

- Malato, S.; Fernandez Ibanez, P.; Maldonado, M.; Blanco, J.; Gernjak, W. Decontamination and disinfection of water by solar photocatalysis: Recent overview and trends. Catal. Today 2009, 147, 1–59. [Google Scholar] [CrossRef]

- Ullah, R.; Sun, H.; Wang, S.; Ang, H.; Tadé, M. Wet-Chemical synthesis of InTaO4 for photocatalytic decomposition of organic contaminants in air and water with UV-vis light. Ind. Eng. Chem. Res. 2012, 51, 1563–1569. [Google Scholar] [CrossRef]

- Yu, J.; Ho, W.; Yu, J.; Yip, H.; Wong, P.K.; Zhao, J. Efficient visible-light-induced photocatalytic disinfection on sulfur-doped nanocrystalline titania. Environ. Sci. Technol. 2005, 39, 1175–1179. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Jiang, Z.; Geng, J.; Wang, Q.; Yang, D. Carbon and nitrogen co-doped TiO2 with enhanced visible-light photocatalytic Activity. Ind. Eng. Chem. Res. 2007, 46, 2741–2746. [Google Scholar] [CrossRef]

- Cong, Y.; Zhang, J.; Chen, F.; Anpo, M.; He, D. Preparation, photocatalytic activity, and mechanism of nano-TiO2 co-doped with nitrogen and iron (III). J. Phys. Chem. C 2007, 111, 10618–10623. [Google Scholar] [CrossRef]

- Hu, C.; Hu, X.; Wang, L.; Qu, J.; Wang, A. Visible-light-induced photocatalytic degradation of azodyes in aqueous AgI/TiO2 dispersion. Environ. Sci. Technol. 2006, 40, 7903–7907. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Choi, W. Visible-light-induced photocatalytic degradation of 4-chlorophenol and phenolic compounds in aqueous suspension of pure titania: Demonstrating the existence of a surface-complex-mediated path. J. Phys. Chem. B 2005, 109, 5143–5149. [Google Scholar] [CrossRef]

- Ma, Z.; Hu, L.; Li, X.; Deng, L.; Fan, G.; He, Y. A novel nano-sized MoS2 decorated Bi2O3 heterojunction with enhanced photocatalytic performance for methylene blue and tetracycline degradation. Ceram. Int. 2019, 45, 15824–15833. [Google Scholar] [CrossRef]

- Carreño Lizcano, M.I.; Gualdrón Reyes, A.F.; Rodríguez González, V.; Pedraza Avella, J.A.; Niño Gómez, M.E. Photoelectrocatalytic phenol oxidation employing nitrogen doped TiO2-rGO films as photoanodes. Catal. Today 2020, 341, 96–103. [Google Scholar] [CrossRef]

- Zhang, G.; Ding, X.; He, F.; Yu, X.; Zhou, J.; Hu, Y.; Xie, J. Low-temperature synthesis and photocatalytic activity of TiO2 pillared montmorillonite. Langmuir 2008, 24, 1026–1030. [Google Scholar] [CrossRef]

- Ma, Z.; Zeng, C.; Hu, L.; Zhao, Q.; Yang, Q.; Niu, J.; Yao, B.; He, Y. A high-performance photocatalyst of ZnTCPP sensitized porous graphitic carbon nitride for antibiotic degradation under visible light irradiation. Appl. Surf. Sci. 2019, 484, 489–500. [Google Scholar] [CrossRef]

- Xiang, Q.; Yu, J.; Jaroniec, M. Synergetic Effect of MoS2 and graphene as cocatalysts for enhanced photocatalytic H2 production activity of TiO2 nanoparticles. J. Am. Chem. Soc. 2012, 134, 6575–6578. [Google Scholar] [CrossRef] [PubMed]

- Anandan, S.; Rao, T.N.; Sathish, M.; Rangappa, D.; Honma, I.; Miyauchi, M. Superhydrophilic graphene-loaded TiO2 thin film for self-cleaning applications. ACS Appl. Mater. Interfaces 2013, 5, 207–212. [Google Scholar] [CrossRef] [PubMed]

- Pastrana Martínez, L.M.; Morales Torres, S.; Likodimos, V.; Figueiredo, J.L.; Faria, J.L.; Falaras, P.; Silva, A.M.T. Advanced nanostructured photocatalysts based on reduced graphene oxide-TiO2 composites for degradation of diphenhydramine pharmaceutical and methyl orange dye. Appl. Catal. B Environ. 2012, 123–124, 241–256. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, K. Reduced graphene oxide-TiO2 nanocomposite with high photocatalystic activity for the degradation of rhodamine B. J. Mol. Catal. A Chem. 2011, 345, 101–107. [Google Scholar] [CrossRef]

- Liu, S.; Sun, H.; Liu, S.; Wang, S. Graphene facilitated visible light photodegradation of methylene blue over titanium dioxide photocatalysts. Chem. Eng. J. 2013, 214, 298–303. [Google Scholar] [CrossRef]

- Zhang, H.; Lv, X.; Li, Y.; Wang, Y.; Li, J. P25-graphene composite as a high performance photocatalyst. ACS Nano 2010, 4, 380–386. [Google Scholar] [CrossRef]

- Pan, X.; Zhao, Y.; Liu, S.; Korzeniewski, C.L.; Wang, S.; Fan, Z. Comparing graphene-TiO2 nanowire and graphene-TiO2 nanoparticle composite photocatalysts. ACS Appl. Mater. Interfaces 2012, 4, 3944–3950. [Google Scholar] [CrossRef]

- Liu, M.; Yang, H. Large surface area mesoporous Al2O3 from kaolin: Methodology and characterization. Appl. Clay Sci. 2010, 50, 554–559. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, J.; Liang, C.H.; Xie, Q.; Wang, Y.N.; Zhang, S.; Qiao, X.; Li, X. Quantum chemical investigation on the mechanism and kinetics of PBDE photo oxidation by center dot oh: A case study for bde-15. Environ. Sci. Technol. 2011, 45, 4839–4845. [Google Scholar] [CrossRef]

- Paul, B.; Martens, W.N.; Frost, R.L. Immobilised anatase on clay mineral particles as a photocatalyst for herbicides degradation. Appl. Clay Sci. 2012, 57, 49–54. [Google Scholar] [CrossRef]

- Navalon, S.; Alvaro, M.; Garcia, H. Heterogeneous Fenton catalysts based on clays, silicas and zeolites. Appl. Catal. B Environ. 2010, 99, 1–26. [Google Scholar] [CrossRef]

- Bujdák, J. Effect of the layer charge of clay minerals on optical properties of organic dyes. A review. Appl. Clay Sci. 2006, 34, 58–73. [Google Scholar] [CrossRef]

- Zhou, C.H. An overview on strategies towards clay-based designer catalysts for green and sustainable catalysis. Appl. Clay Sci. 2011, 53, 87–96. [Google Scholar] [CrossRef]

- Ng, S.; Plank, J. Interaction mechanisms between Na montmorillonite clay and MPEG-based polycarboxylate superplasticizers. Cem. Concr. Res. 2012, 42, 847–854. [Google Scholar] [CrossRef]

- Mohsin, N.; Waheed, M.; Jiseon, J.; Dae, S. One-step hydrothermal synthesis of porous 3D reduced graphene oxide/TiO2 aerogel for carbamazepine photodegradation in aqueous solution. Appl. Catal. B Environ. 2017, 203, 85–89. [Google Scholar]

- Zhang, Y.; Cui, W.; An, W.; Liu, L.; Liang, Y.; Zhu, Y. Combination of photoelectrocatalysis and adsorption for removal of bisphenol a over TiO2-graphene hydrogel with 3D network structure. Appl. Catal. B Environ. 2018, 221, 36–46. [Google Scholar] [CrossRef]

- Xue, N.; Wang, L.; Pei, M.; He, Y.; Du, Y.; Guo, W. Preparation and characterization of sodium polyacrylate-grafted bentonite and its performance removing Pb2+ from aqueous solutions. RSC Adv. 2016, 6, 98945–98951. [Google Scholar] [CrossRef]

- Wang, P.; Wang, L.; Ding, M.; Pei, M.; Guo, W. Ultrasensitive electrochemical detection of ochratoxin A based on signal amplification by one-pot synthesized flower-like PEDOT-AuNFs supported on graphene oxide sponge. Analyst 2019, 144, 5866–5874. [Google Scholar] [CrossRef]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Anirudhan, T.S.; Ramachandran, M. Synthesis and Characterization of amidoximated polyacrylonitrile/organobentonite composite for Cu(II), Zn(II), and Cd(II) adsorption from aqueous solutions and industry wastewaters. Ind. Eng. Chem. Res. 2008, 47, 6175–6184. [Google Scholar] [CrossRef]

- Nguyen Phan, T.D.; Pham, V.H.; Shin, E.W.; Pham, H.D.; Kim, S.; Chung, J.S.; Kim, E.J.; Hur, S.H. The role of graphene oxide content on the adsorption-enhanced photocatalysis of titanium dioxide/graphene oxide composites. Chem. Eng. J. 2011, 170, 226–232. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Li, H.P.; Cui, X.L.; Lin, Y. Graphene/TiO2 nanocomposites: Synthesis, characterization and application in hydrogen evolution from water photocatalytic splitting. J. Mater. Chem. 2010, 20, 2801–2806. [Google Scholar] [CrossRef]

- Xu, Y.J.; Zhuang, Y.; Fu, X. New insight for enhanced photocatalytic activity of TiO2 by doping carbon nanotubes: A case study on degradation of benzene and methyl orange. J. Phys. Chem. C 2010, 114, 2669–2676. [Google Scholar] [CrossRef]

- Magalhães, P.; Ângelo, J.; Sousa, V.M.; Nunes, O.C.; Andrade, L.; Mendes, A. Synthesis and assessment of a graphene-based composite photocatalyst. Biochem. Eng. J. 2015, 104, 20–26. [Google Scholar] [CrossRef]

- Sun, S.; Jiang, Y.; Yu, L.; Li, F.; Yang, Z.; Hou, T.; Hu, D.; Xia, M. Enhanced photocatalytic activity of microwave treated TiO2 pillared montmorillonite. Mater. Chem. Phys. 2006, 98, 377–381. [Google Scholar] [CrossRef]

- Miao, S.; Liu, Z.; Han, B.; Zhang, J.; Yu, X.; Du, J.; Sun, Z. Synthesis and characterization of TiO2-montmorillonite nano composites and their application for removal of methylene blue. J. Mater. Chem. 2006, 16, 579–584. [Google Scholar] [CrossRef]

- Chen, Z.; Ma, J.; Yang, K.; Feng, S.; Tan, W.; Tao, Y.; Mao, H.; Kong, Y. Preparation of S-doped TiO2-three dimensional graphene aerogels as a highly efficient photocatalyst. Synth. Met. 2017, 231, 51–57. [Google Scholar] [CrossRef]

- Singh, A.; Khare, P.; Verma, S.; Bhati, A.; Sonker, A.K.; Tripathi, K.M.; Sonkar, S.K. Pollutant soot for pollutant dye degradation: Soluble graphene nanosheets for visible light induced photodegradation of methylene blue. ACS Sustain. Chem. Eng. 2017, 5, 8860–8869. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, Y.; Liu, A.; Wei, Z.; Liu, S. Construction of three-dimensional hemin-functionalized graphene hydrogel with high mechanical stability and adsorption capacity for enhancing photodegradation of methylene blue. ACS Appl. Mater. Interfaces 2017, 9, 4006–4014. [Google Scholar] [CrossRef]

- Breault, T.M.; Bartlett, B.M. Lowering the band gap of anatase-structured TiO2 by coalloying with nb and n: Electronic structure and photocatalytic degradation of methylene blue dye. J. Phys. Chem. C 2012, 116, 5986–5994. [Google Scholar] [CrossRef]

- DePuccio, D.P.; Botella, P.; O’Rourke, B.; Landry, C.C. Degradation of methylene blue using porous WO3, SiO2-WO3, and their au-loaded analogs: Adsorption and photocatalytic studies. ACS Appl. Mater. Interfaces 2015, 7, 1987–1996. [Google Scholar] [CrossRef] [PubMed]

- Gan, L.; Xu, L.; Shang, S.; Zhou, X.; Meng, L. Visible light induced methylene blue dye degradation photo-catalyzed by WO3/graphene nanocomposites and the mechanism. Ceram. Int. 2016, 42, 15235–15241. [Google Scholar] [CrossRef]

- Shanmugam, M.; Alsalme, A.; Alghamdi, A.; Jayavel, R. Enhanced photocatalytic performance of the graphene-V2O5 nanocomposite in the degradation of methylene blue dye under direct sunlight. ACS Appl. Mater. Interfaces 2015, 7, 14905–14911. [Google Scholar] [CrossRef] [PubMed]

- Gan, Z.; Wu, X.; Meng, M.; Zhu, X.; Yang, L.; Chu, P. Photothermal contribution to enhanced photocatalytic performance of graphene-based nanocomposites. ACS Nano 2014, 8, 9304–9310. [Google Scholar] [CrossRef] [PubMed]

- Qu, J.; Shi, L.; He, C.; Gao, F.; Li, B.; Zhou, Q.; Hu, H.; Shao, G.; Wang, X.; Qiu, J. Highly efficient synthesis of graphene/MnO2 hybrids and their application for ultrafast oxidative decomposition of methylene blue. Carbon 2014, 66, 485–492. [Google Scholar] [CrossRef]

- Lu, Q.; Zhang, Y.; Liu, S. Graphene quantum dots enhanced photocatalytic activity of zinc porphyrin toward the degradation of methyl blue under visible-light irradiation. J. Mater. Chem. A 2015, 3, 8552–8558. [Google Scholar] [CrossRef]

- Guo, R.; Yin, G.; Sha, X.; Wei, L.; Zhao, Q. Effect of surface modification on the adhesion enhancement of electrolessly deposited Ag-PTFE antibacterial composite coatings to polymer substrates. Mater. Lett. 2015, 143, 256–260. [Google Scholar] [CrossRef]

- Yang, N.; Liu, Y.; Wen, H.; Tang, Z.; Zhao, H.; Li, Y.; Wang, D. Photocatalytic properties of graphdiyne and graphene modified TiO2: From theory to experiment. ACS Nano 2013, 7, 1504–1512. [Google Scholar] [CrossRef]

- Feilizadeh, M.; Vossoughi, M.; Zakeri, S.M.E.; Rahimi, M. Enhancement of efficient Ag-S/TiO2 nanophotocatalyst for photocatalytic degradation under visible light. Ind. Eng. Chem. Res. 2014, 53, 9578–9586. [Google Scholar] [CrossRef]

- Khare, P.; Singh, A.; Verma, S.; Bhati, A.; Sonker, A.; Tripathi, K.; Sonkar, S. Sunlight-induced selective photocatalytic degradation of methylene blue in bacterial culture by pollutant soot derived nontoxic graphene nanosheets. ACS. Sustain. Chem. Eng. 2018, 6, 579–589. [Google Scholar] [CrossRef]

- Lee, C.G.; Zhang, D.; Kim, J.H.; Westerhoff, P.; Li, Q.; Alvarez, P. Porous Electrospun fibers embedding TiO2 for Adsorption and photocatalytic degradation of water pollutants. Environ. Sci. Technol. 2018, 52, 4285–4293. [Google Scholar] [CrossRef] [PubMed]

- Sharma, K.; Vyas, R.K.; Dalai, A.K. Thermodynamic and kinetic studies of methylene blue degradation using reactive adsorption and its comparison with adsorption. J. Chem. Eng. Data 2017, 62, 3651–3662. [Google Scholar] [CrossRef]

- Yu, C.; Wei, L.; Chen, J.; Xie, Y.; Zhou, W.; Fan, Q. Enhancing the photocatalytic performance of commercial TiO2 crystals by coupling with trace narrow-band-gap Ag2CO3. Ind. Eng. Chem. Res. 2014, 53, 5759–5766. [Google Scholar] [CrossRef]

- Jiang, H.Y.; Liu, G.; Li, M.; Liu, J.; Sun, W.; Ye, J.; Lin, J. Efficient organic degradation under visible light by α-Bi2O3 with a CuOx-assistant electron transfer process. Appl. Catal. B Environ. 2015, 163, 267–276. [Google Scholar] [CrossRef]

- López, T.; Bosch, P.; Tzompantzi, F.; Gómez, R.; Navarrete, J.; López Salinas, E.; Llanos, M.E. Effect of sulfation methods on TiO2-SiO2 sol-gel catalyst acidity. Appl. Catal. A Gen. 2000, 197, 107–117. [Google Scholar] [CrossRef]

- Lin, Y.L.; Wang, T.J.; Jin, Y. Surface characteristics of hydrous silica-coated TiO2 particles. Powder Technol. 2002, 123, 194–198. [Google Scholar] [CrossRef]

- Zhou, X.; Li, X.; Gao, Q.; Yuan, J.; Wen, J.; Fang, Y.; Liu, W.; Zhang, S.; Liu, Y. Metal-free carbon nanotube-SiC nanowire heterostructures with enhanced photocatalytic H2 evolution under visible light irradiation. Catal. Sci. Technol. 2015, 5, 2798–2806. [Google Scholar] [CrossRef]

| Number | Sample | Removal Rate (%) | Removal Time (min) | Reference |

|---|---|---|---|---|

| 1 | wsGNS | 96a 99.9b | 90a 120b | [47] |

| 2 | Hemin-functionalized graphenehydrogel (Hem/GH) | 96 | 180 | [48] |

| 3 | TiO2-Nb/N | 93 | 120 | [49] |

| 4 | SiO2-WO3 | 100 | 120 | [50] |

| 5 | WO3/grapheme nanocomposite (WO3-G) | 99 | 480 | [51] |

| 6 | graphene-V2O5nanocomposite (GO-V2O5) | 99 | 90 | [52] |

| 7 | P25-GO | >99 | 240 | [53] |

| 8 | TiO2-GO | >80 | 300 | [54] |

| 9 | reduced graphene/manganese oxide (rGO/MnO2 hybrid) | 66 | 5 | [45] |

| 10 | zinc porphyrin functionalized graphene quantum dots (GQDs/ZnPor) | 95 | 60 | [55] |

| 11 | Mn3O4 decorated graphene oxide | 99 | 200 | [56] |

| 12 | TiO2-graphene | 90 | 150 | [57] |

| 13 | Ag-S/PEG/TiO2 | 77.51 | 120 | [58] |

| 14 | water-soluble grapheme nanosheets (wsGNS) | 98 | 75 | [59] |

| 15 | electrospun porous fibers EPF(2/1)-TiO2 | 100 | 120 | [60] |

| 16 | granular activated carbon doped with iron (Fe-GAC) | 94 | 200 | [61] |

| 17 | hybrid-MFC | 82.79 | 210 | [62] |

| 18 | GO/TiO2/Bent | 100 | 70 | present study |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wang, L.; Xue, N.; Wang, P.; Pei, M.; Guo, W. Ultra-Highly Efficient Removal of Methylene Blue Based on Graphene Oxide/TiO2/Bentonite Sponge. Materials 2020, 13, 824. https://doi.org/10.3390/ma13040824

Liu Y, Wang L, Xue N, Wang P, Pei M, Guo W. Ultra-Highly Efficient Removal of Methylene Blue Based on Graphene Oxide/TiO2/Bentonite Sponge. Materials. 2020; 13(4):824. https://doi.org/10.3390/ma13040824

Chicago/Turabian StyleLiu, Yuan, Luyan Wang, Ni Xue, Pengxiang Wang, Meishan Pei, and Wenjuan Guo. 2020. "Ultra-Highly Efficient Removal of Methylene Blue Based on Graphene Oxide/TiO2/Bentonite Sponge" Materials 13, no. 4: 824. https://doi.org/10.3390/ma13040824

APA StyleLiu, Y., Wang, L., Xue, N., Wang, P., Pei, M., & Guo, W. (2020). Ultra-Highly Efficient Removal of Methylene Blue Based on Graphene Oxide/TiO2/Bentonite Sponge. Materials, 13(4), 824. https://doi.org/10.3390/ma13040824