Autogenous Fiber Laser Welding of 316L Austenitic and 2304 Lean Duplex Stainless Steels

Abstract

:1. Introduction

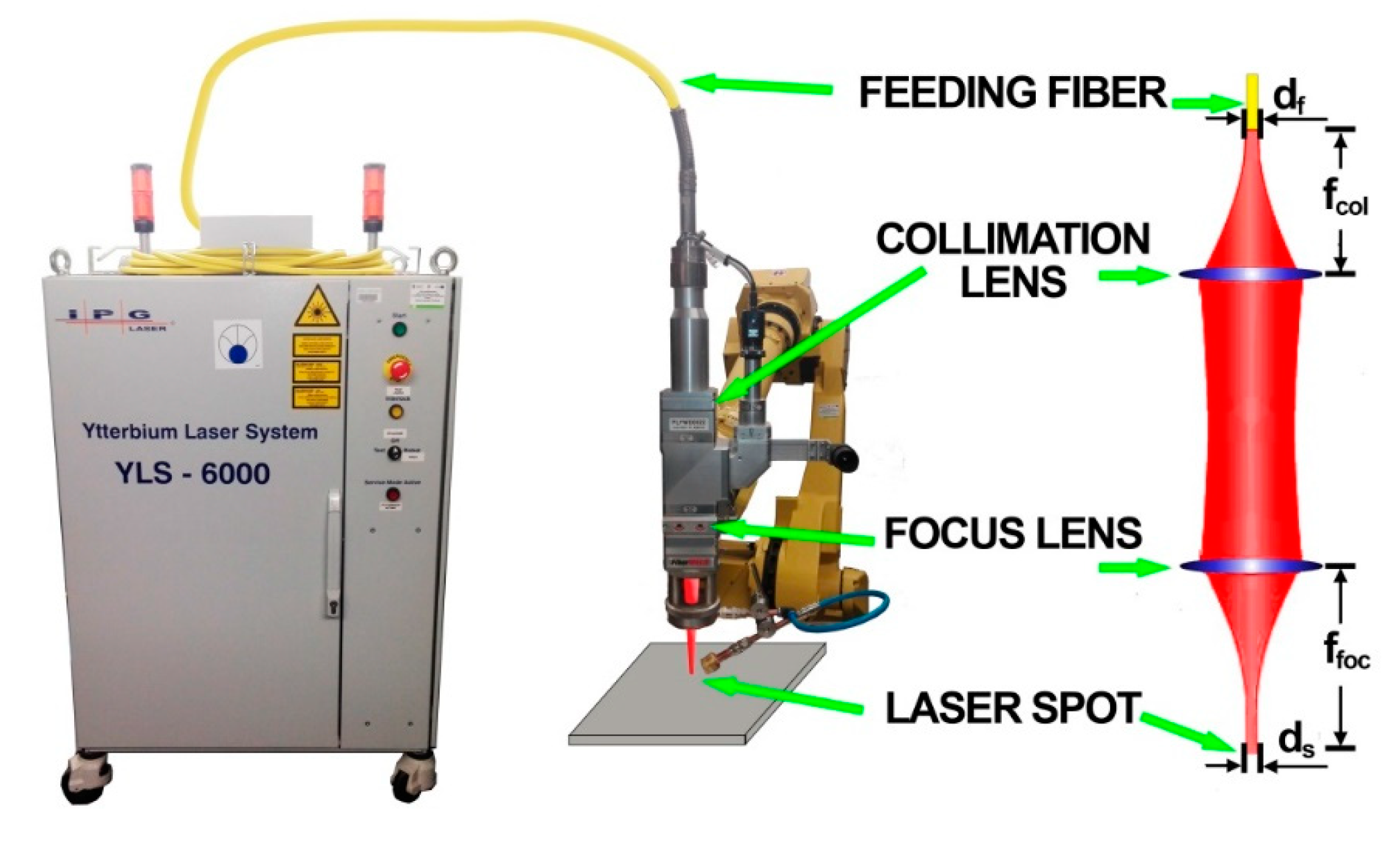

2. Materials and Methods

3. Results and Discussion

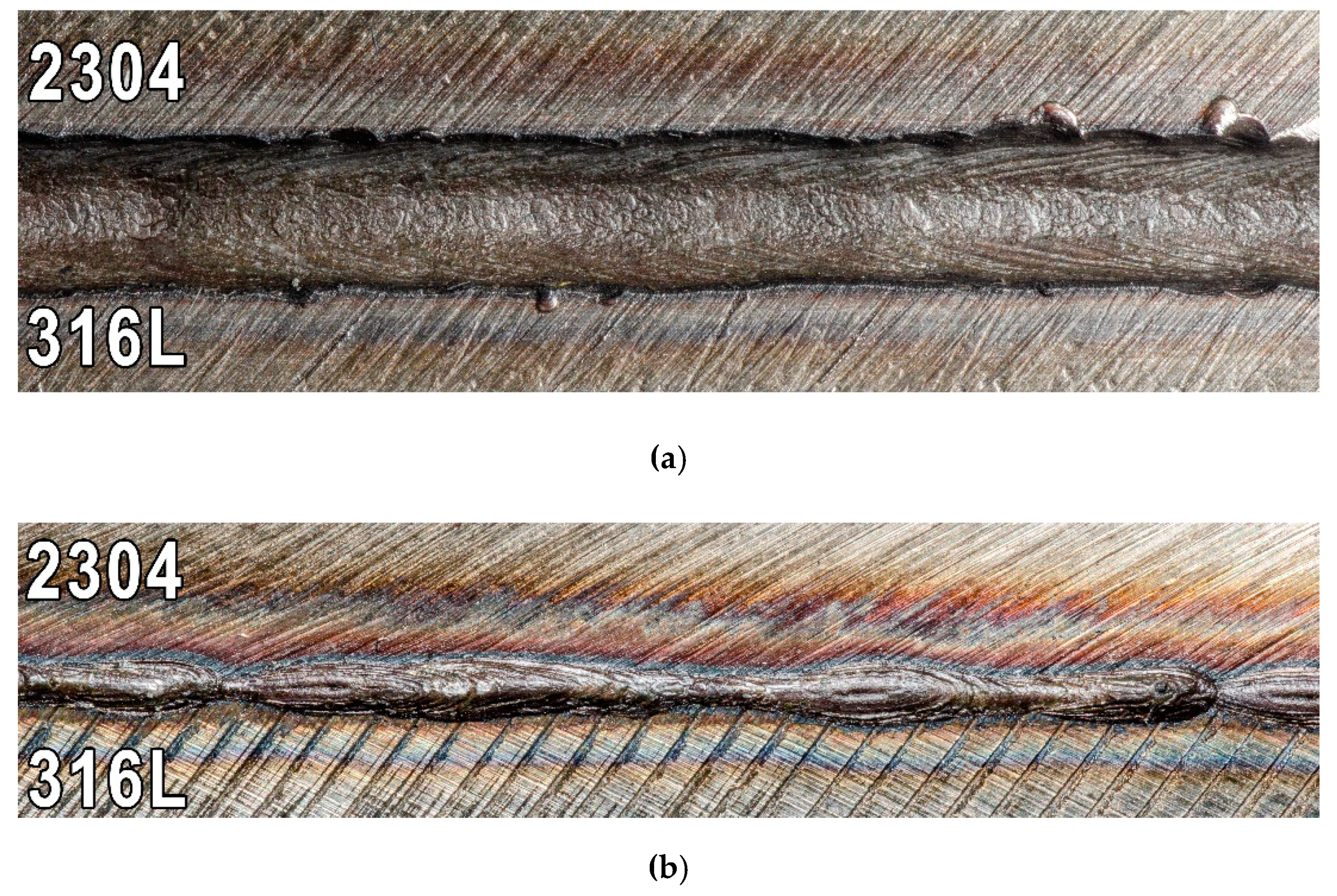

3.1. Non-Destructive Tests

3.2. Destructive Tests

3.2.1. Static Tensile Test

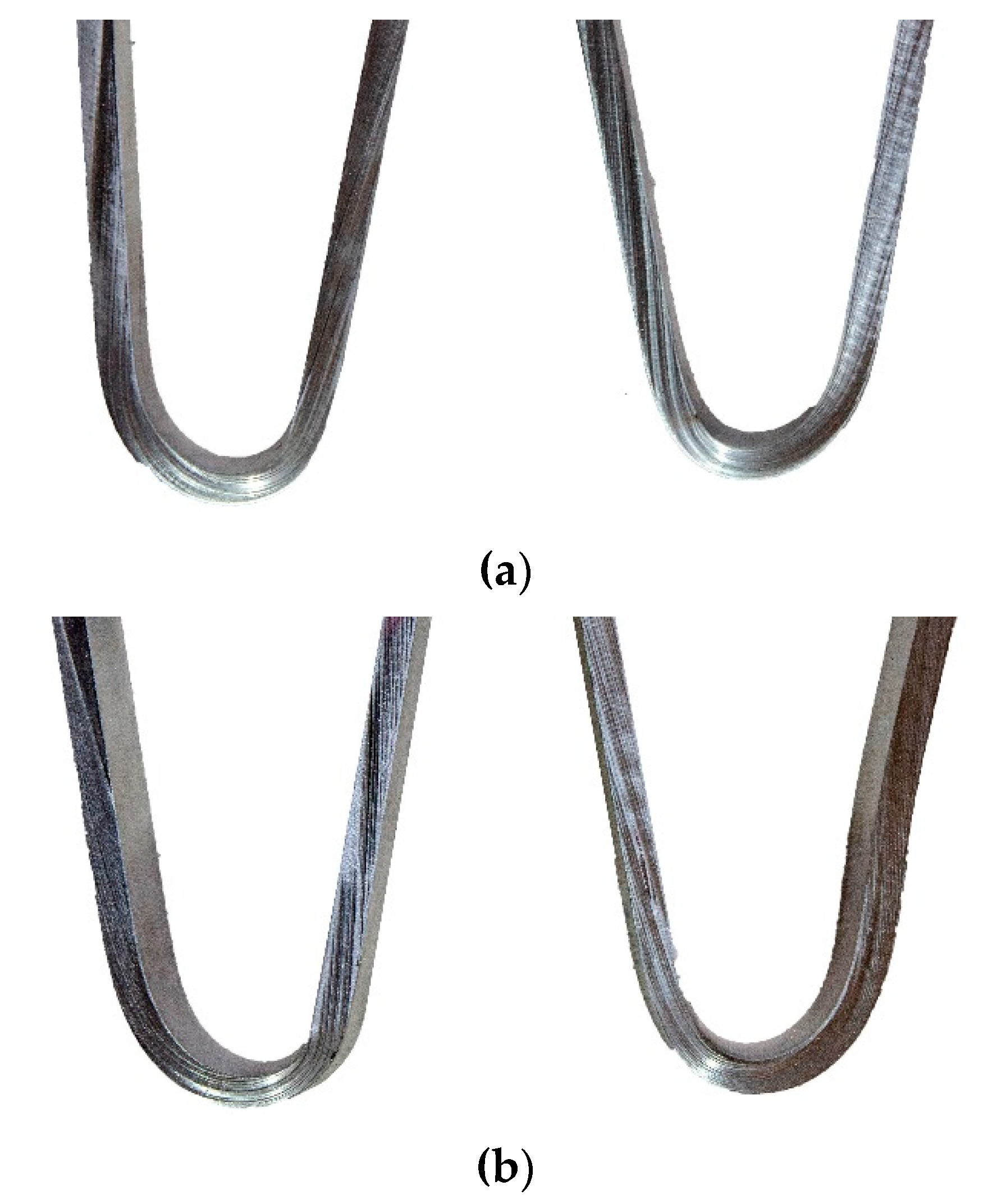

3.2.2. Bending Test

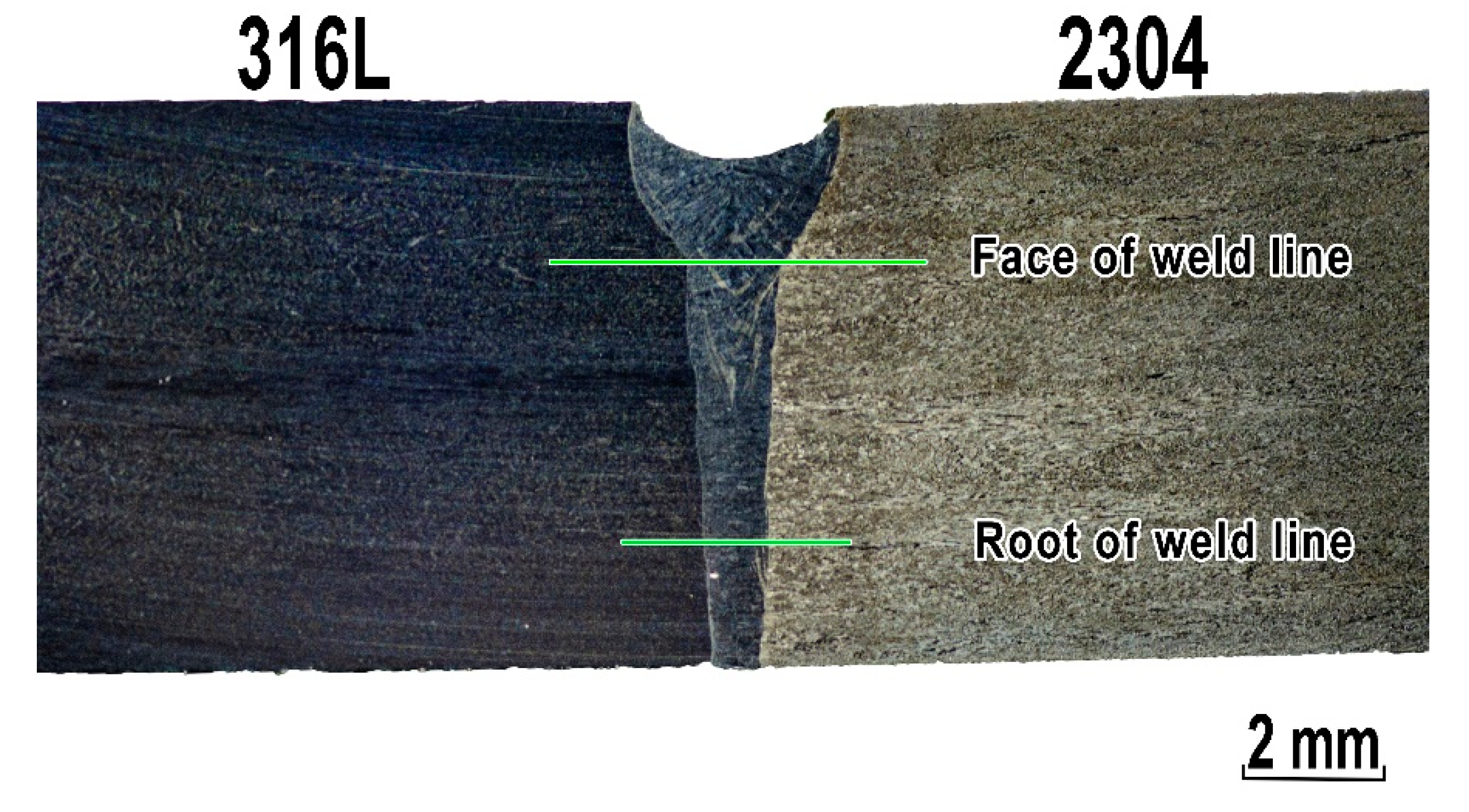

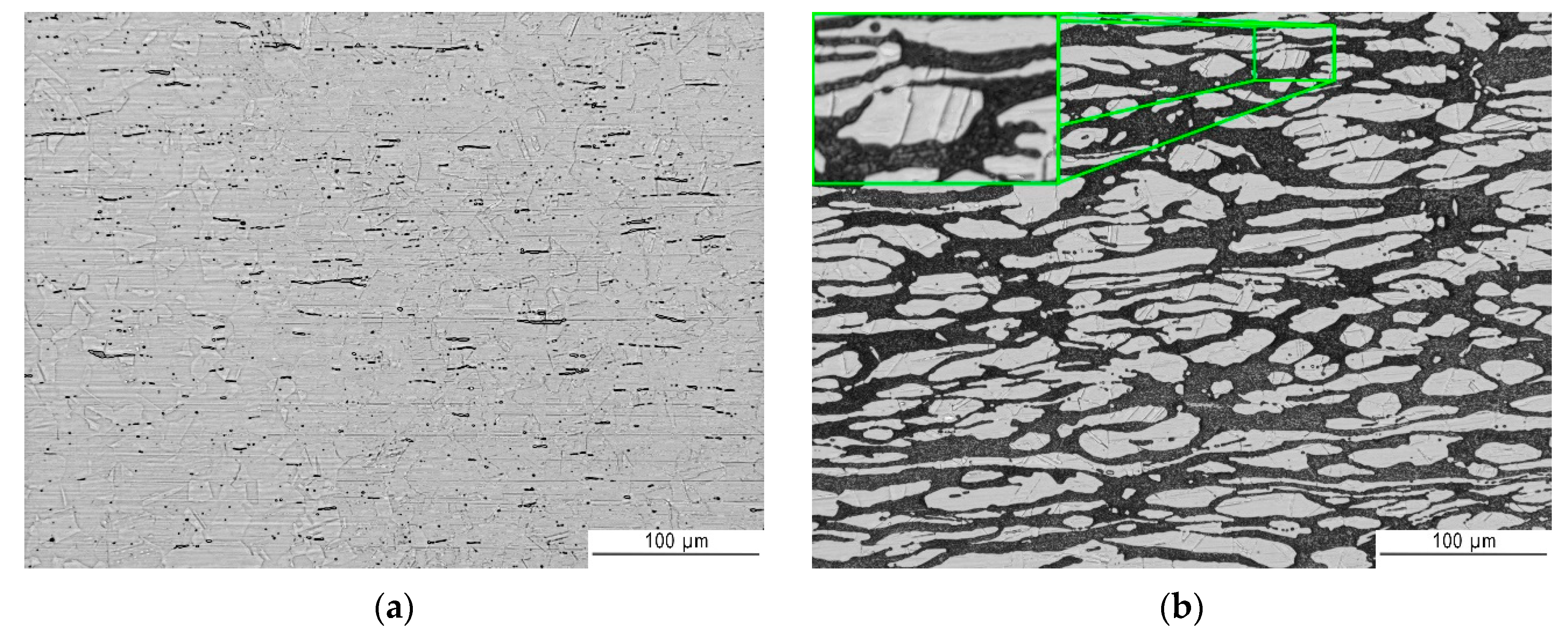

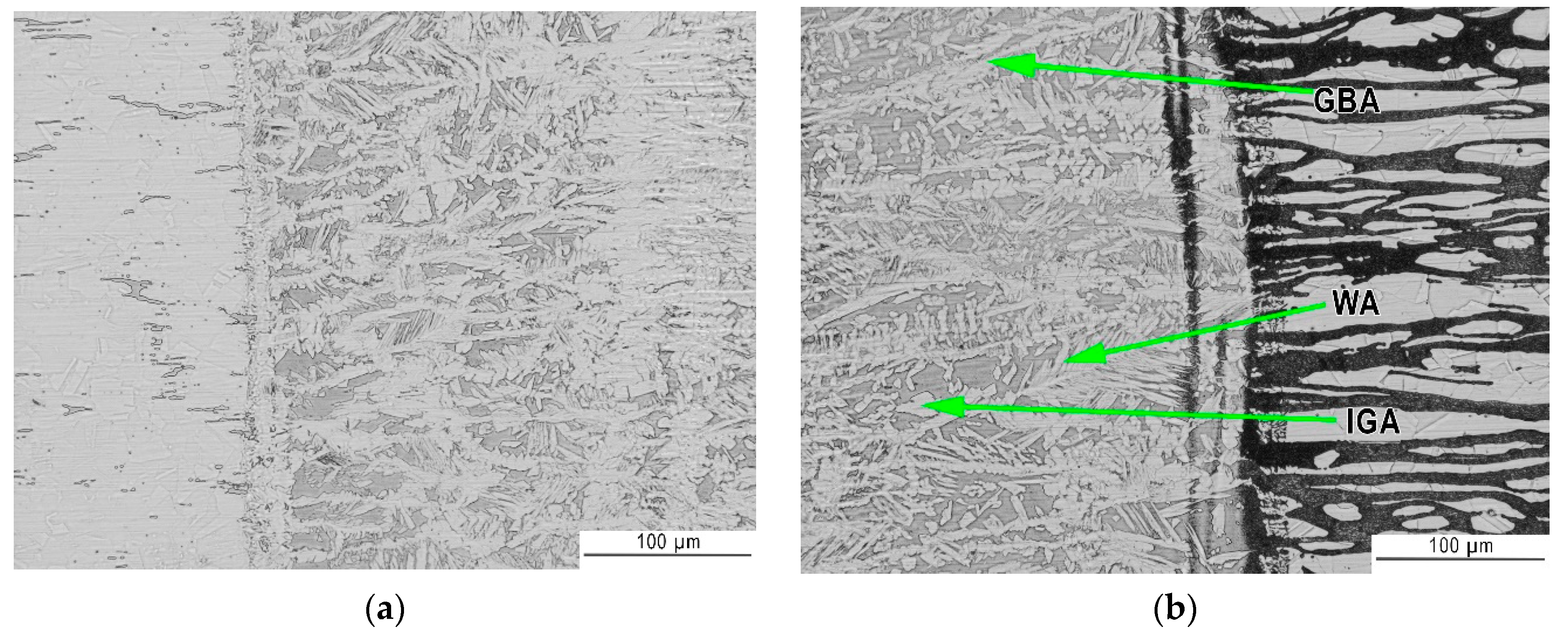

3.2.3. Macro- and Microscopic Examinations

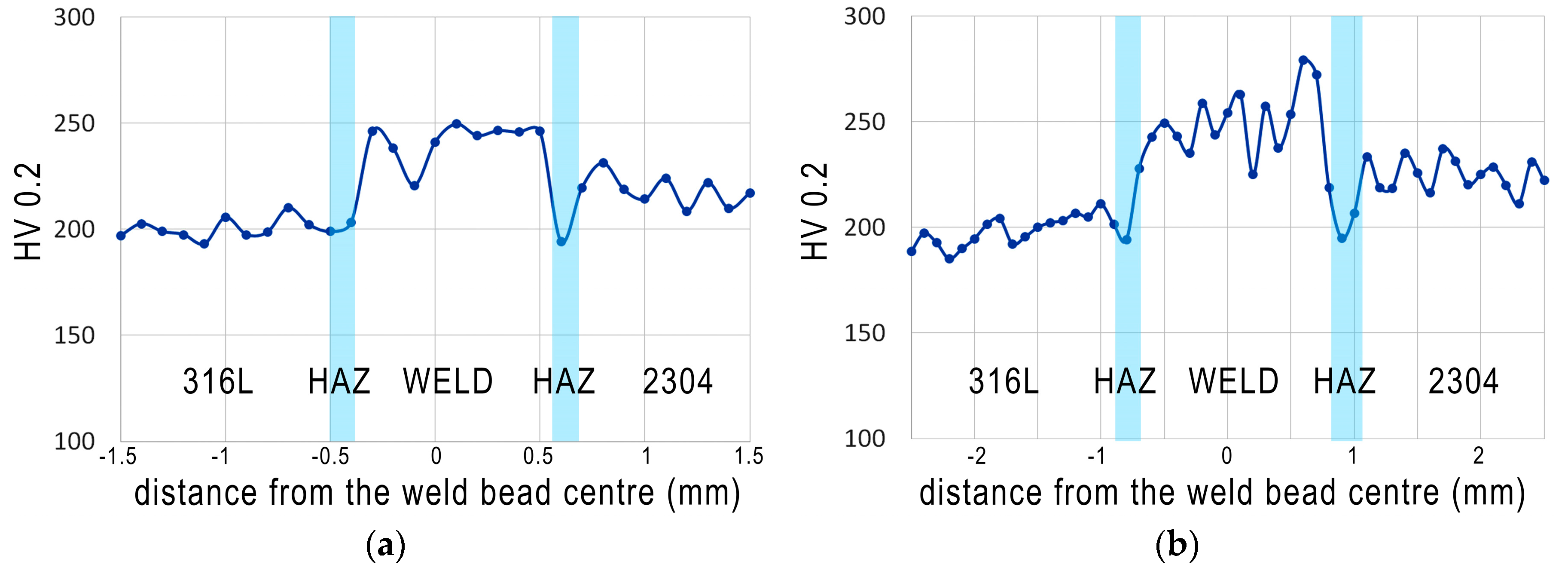

3.2.4. Microhardness Measurements

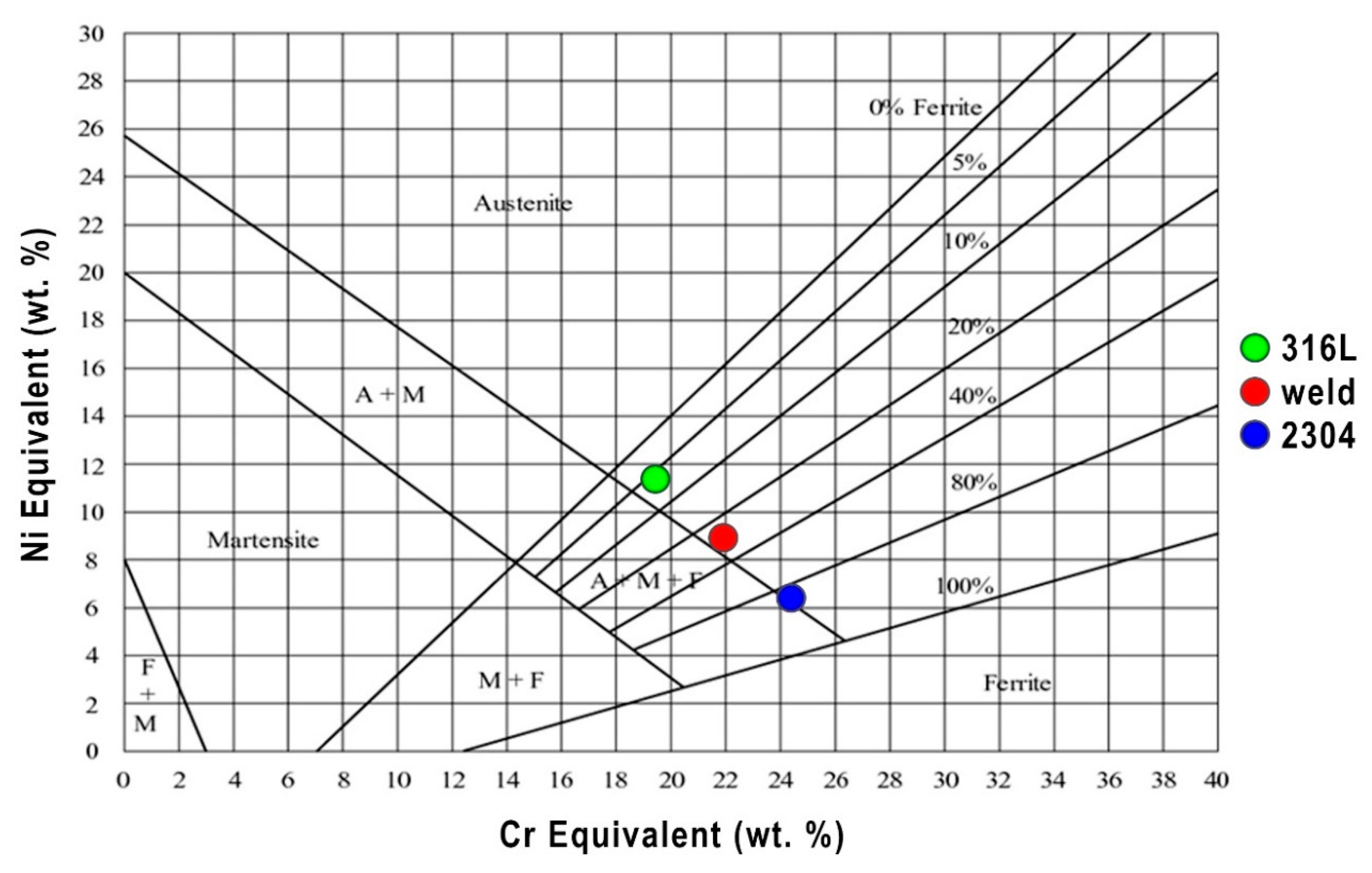

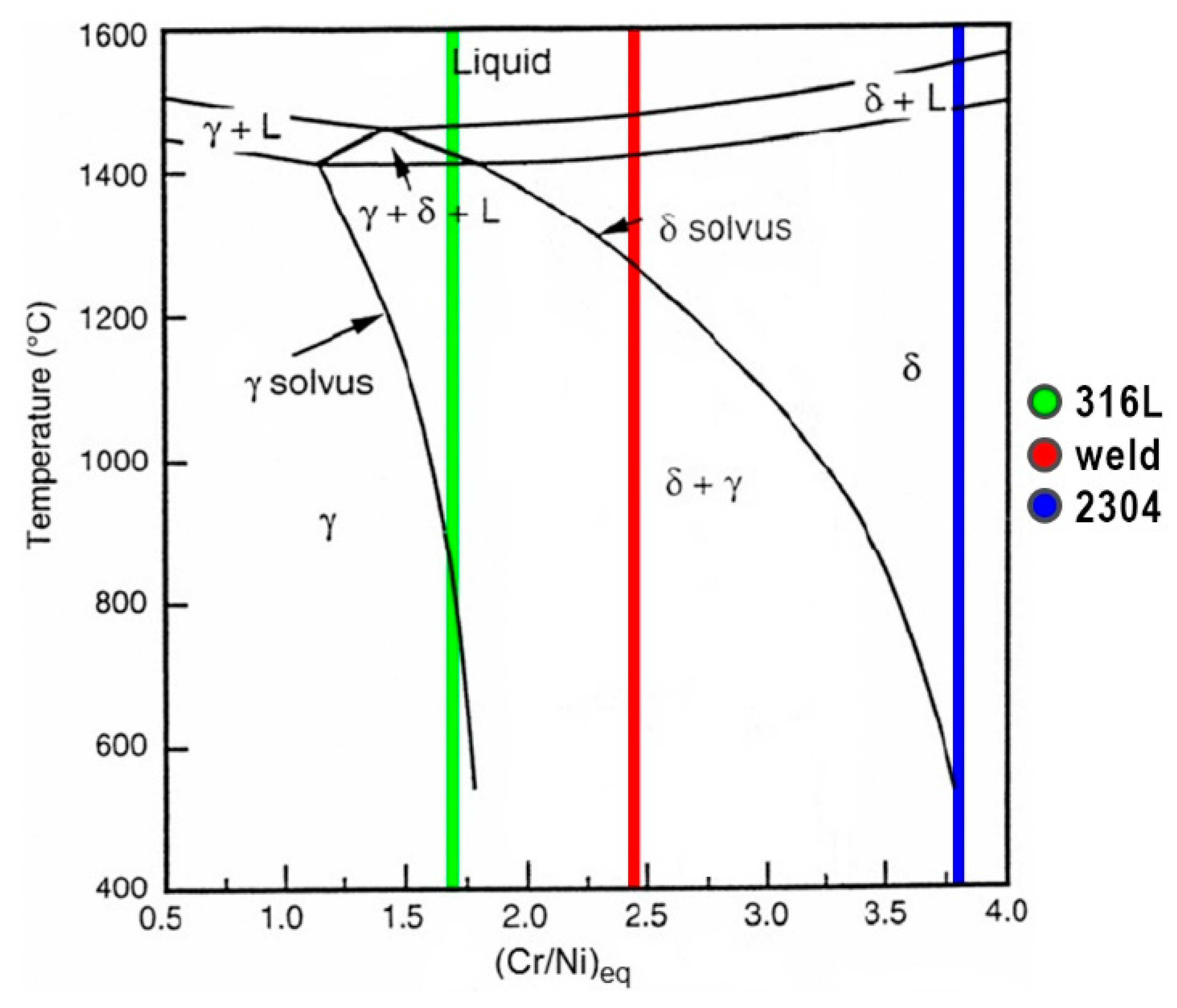

3.2.5. Ferrite Content Measurements and Calculations

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Quazi, M.M.; Ishak, M.; Fazal, M.A.; Arslan, A.; Rubaiee, S.; Aiman, M.H.; Qaban, A.; Yusof, F.; Sultan, T.; Ali, M.M.; et al. A comprehensive assessment of laser welding of biomedical devices and implant materials: Recent research, development and applications. Crit. Rev. Solid. State 2020, 4, 1–43. [Google Scholar] [CrossRef]

- Kik, T. Computational techniques in numerical simulations of arc and laser welding processes. Materials 2020, 13, 608. [Google Scholar] [CrossRef] [Green Version]

- Górka, J. Assessment of the effect of laser welding on the properties and structure of TMCP steel butt joints. Materials 2020, 13, 1312. [Google Scholar] [CrossRef] [Green Version]

- Lisiecki, A. Study of optical properties of surface layers produced by laser surface melting and laser surface nitriding of titanium alloy. Materials 2019, 12, 3112. [Google Scholar] [CrossRef] [Green Version]

- Janicki, D.; Górka, J.; Kwaśny, W.; Pakieła, W.; Matus, K. Influence of solidification conditions on the microstructure of laser-surface-melted ductile cast iron. Materials 2020, 13, 1174. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sroka, M.; Jonda, E.; Pakieła, W. Laser surface modification of aluminium alloy AlMg9 with B4C powder. Materials 2020, 13, 402. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Wang, J.; Yin, L.; Hu, H.; Yao, Z. Quantitative correlation between thermal cycling and the microstructures of X100 pipeline steel laser-welded joints. Materials 2020, 13, 121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lisiecki, A.; Kurc-Lisiecka, A. Automated laser welding of AISI 304 stainless steel by disk laser. Arch. Metall. Mater. 2018, 63, 1663–1672. [Google Scholar]

- Tęczar, P.; Majkowska-Marzec, B.; Bartmański, M. The influence of laser alloying of Ti13Nb13Zr on surface topography and properties. Adv. Mater. Sci. 2019, 19, 44–56. [Google Scholar] [CrossRef] [Green Version]

- Herthoge, M.; De Pelsmaeker, J.; Boone, M.; De Baere, I.; Van Paepegem, W.; Van Vlierberghe, S. Laser welding of carbon fiber filled polytetrafluoroethylene. J. Mater. Proc. Technol. 2020, 282, 116681. [Google Scholar] [CrossRef]

- Liao, H.; Zhu, J.; Chang, S.; Xue, G.; Zhu, H.; Chen, B. Al2O3 loss prediction model of selective laser melting Al2O3–Al composite. Ceram. Int. 2020, 46, 13414–13423. [Google Scholar] [CrossRef]

- Wen, X.; Jin, G.; Cui, X.; Feng, X.; Lu, B.; Cai, Z.; Zhao, Y.; Fang, Y. Underwater wet laser cladding on 316L stainless steel: A protective material assisted method. Opt. Laser Technol. 2019, 111, 814–824. [Google Scholar] [CrossRef]

- Fu, Y.; Guo, N.; Cheng, Q.; Zhang, D.; Feng, J. In-situ formation of laser-cladded layer on Ti-6Al-4 V titanium alloy in underwater environment. Opt. Lasers Eng. 2020, 131, 106104. [Google Scholar] [CrossRef]

- Kik, T.; Górka, J. Numerical simulations of laser and hybrid S700MC T-joint welding. Materials 2019, 12, 516. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, H.; Liu, X.; Liu, L. Research on laser-TIG hybrid welding of 6061-T6 aluminum alloys joint and post heat treatment. Metals 2020, 10, 130. [Google Scholar] [CrossRef] [Green Version]

- Yazdian, N.; Mohammadpour, M.; Razavi, R.; Kovacevic, R. Hybrid laser/arc welding of 304L stainless steel tubes, part 2–Effect of filler wires on microstructure and corrosion behavior. Int. J. Press. Vessel. Pip. 2018, 163, 45–54. [Google Scholar] [CrossRef]

- Mohammed, G.R.; Ishak, M.; Aqida, S.N.; Abdulhadi, H.A. Effects of heat input on microstructure, corrosion and mechanical characteristics of welded austenitic and duplex stainless steels: A review. Metals 2017, 7, 39. [Google Scholar] [CrossRef] [Green Version]

- Kuryntsev, S.V.; Gilmutdinov, A.K. Welding of stainless steel using defocused laser beam. J. Constr. Steel Res. 2015, 114, 305–313. [Google Scholar] [CrossRef]

- Verma, J.; Taiwade, R.V. Effect of welding processes and conditions on the microstructure, mechanical properties and corrosion resistance of duplex stainless steel weldments—A review. J. Manuf. Process. 2017, 25, 134–152. [Google Scholar] [CrossRef]

- Prijanovič, U.; Prijanovič Tonkovič, M.; Trdan, U.; Pleterski, M.; Jezeršek, M.; Klobčar, D. Remote fibre laser welding of advanced high strength martensitic steel. Metals 2020, 10, 533. [Google Scholar] [CrossRef]

- Pańcikiewicz, K.; Radomski, W. Lack of tightness analysis of concealed welded radiators. Eng. Fail. Anal. 2020, 114, 104579. [Google Scholar] [CrossRef]

- Skowrońska, B.; Chmielewski, T.; Pachla, W.; Kulczyk, M.; Skiba, J.; Presz, W. Friction weldability of UFG 316L stainless steel. Arch. Metall. Mater. 2019, 64, 1051–1058. [Google Scholar]

- Krella, A.K.; Krupa, A. Effect of cavitation intensity on degradation of X6CrNiTi18-10 stainless steel. Wear 2018, 408, 180–189. [Google Scholar] [CrossRef]

- Kuryntsev, S.V. Effect of heat treatment on the phase composition and corrosion resistance of 321 SS welded joints produced by a defocused laser beam. Materials 2019, 12, 3720. [Google Scholar] [CrossRef] [Green Version]

- Świerczyńska, A.; Fydrych, D.; Landowski, M.; Rogalski, G.; Łabanowski, J. Hydrogen embrittlement of X2CRNiMoCuN25-6-2 super duplex stainless steel welded joints under cathodic protection. Constr. Build. Mater. 2020, 238, 117697. [Google Scholar] [CrossRef]

- Varbai, B.; Májlinger, K. Optimal etching sequence for austenite to ferrite ratio evaluation of two lean duplex stainless steel weldments. Measurement 2019, 147, 106832. [Google Scholar] [CrossRef]

- Ouali, N.; Khenfer, K.; Belkessa, B.; Fajoui, J.; Cheniti, B.; Idir, B.; Branchu, S. Effect of heat input on microstructure, residual stress, and corrosion resistance of UNS 32101 lean duplex stainless steel weld joints. J. Mater. Eng. Perform. 2019, 28, 4252–4264. [Google Scholar] [CrossRef]

- Verma, J.; Taiwade, R.V. Dissimilar welding behavior of 22% Cr series stainless steel with 316L and its corrosion resistance in modified aggressive environment. J. Manuf. Proc. 2016, 24, 1–10. [Google Scholar] [CrossRef]

- Świerczyńska, A.; Łabanowski, J.; Michalska, J.; Fydrych, D. Corrosion behavior of hydrogen charged super duplex stainless steel welded joints. Mater. Corros. 2017, 68, 1037–1045. [Google Scholar] [CrossRef]

- Varbai, B.; Májlinger, K. Physical and theoretical modeling of the nitrogen content of duplex stainless steel weld metal: Shielding gas composition and heat input effects. Metals 2019, 9, 762. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Guo, Y.; Liu, Y.; Li, J.; Jiang, Y. The microstructure and pitting resistance of 2002 lean duplex stainless steel after the simulated welding thermal cycle process. Materials 2019, 12, 70. [Google Scholar] [CrossRef] [Green Version]

- Łabanowski, J.; Fydrych, D.; Rogalski, G.; Samson, K. Underwater welding of duplex stainless steel. Solid State Phenom. 2012, 183, 101–106. [Google Scholar] [CrossRef]

- Silva Leite, C.G.; da Cruz Junior, E.J.; Lago, M.; Zambon, A.; Calliari, I.; Ventrella, V.A. Nd: YAG pulsed laser dissimilar welding of UNS S32750 duplex with 316L austenitic stainless steel. Materials 2019, 12, 2906. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fydrych, D.; Łabanowski, J.; Tomków, J.; Rogalski, G. Cold cracking of underwater wet welded S355G10+N high strength steel. Adv. Mater. Sci. 2015, 15, 48–56. [Google Scholar] [CrossRef] [Green Version]

- Rogalski, G.; Świerczyńska, A.; Landowski, M.; Fydrych, D. Mechanical and microstructural characterization of TIG welded dissimilar joints between 304L austenitic stainless steel and Incoloy 800HT nickel alloy. Metals 2020, 10, 559. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G. Dissimilar underwater wet welding of HSLA steels. Int. J. Adv. Manuf. Tech. 2020, in press. [Google Scholar]

- Wang, W.; Hu, Y.; Zhang, M.; Zhao, H. Microstructure and mechanical properties of dissimilar friction stir welds in austenitic-duplex stainless steels. Mater. Sci. Eng. A 2020, 787, 139499. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Singh, A.; Raghuvanshi, S.; Bajpai, A.; Solanki, T.; Arivarasu, M.; Arivazhagan, N.; Narayanan, S. Metallurgical and mechanical characterization of dissimilar welds of austenitic stainless steel and super-duplex stainless steel–a comparative study. J. Manuf. Process. 2015, 19, 212–232. [Google Scholar] [CrossRef]

- Yıldızlı, K. Investigation on the microstructure and toughness properties of austenitic and duplex stainless steels weldments under cryogenic conditions. Mater. Des. 2015, 201577, 83–94. [Google Scholar] [CrossRef]

- Başyiğit, A.B.; Kurt, A. Investigation of the weld properties of dissimilar S32205 duplex stainless steel with AISI 304 steel joints produced by arc stud welding. Metals 2017, 7, 77. [Google Scholar] [CrossRef] [Green Version]

- Abdollahi, A.; Shamanian, M.; Golozar, M.A. Comparison of pulsed and continuous current gas tungsten arc welding in dissimilar welding between UNS S32750 and AISI 321 in optimized condition. Int. J. Adv. Manuf. Tech. 2018, 97, 687–696. [Google Scholar] [CrossRef]

- Theodoro, M.C.; Pereira, V.F.; Mei, P.R.; Ramirez, A.J. Dissimilar friction stir welding between UNS S31603 austenitic stainless steel and UNS S32750 superduplex stainless steel. Metall. Mater. Trans. B 2015, 46, 1440–1447. [Google Scholar] [CrossRef]

- Neissi, R.; Shamanian, M.; Hajihashemi, M. The effect of constant and pulsed current gas tungsten arc welding on joint properties of 2205 duplex stainless steel to 316L austenitic stainless steel. J. Mater. Eng. Perform. 2016, 25, 2017–2028. [Google Scholar] [CrossRef]

- Szala, M.; Łukasik, D. Pitting corrosion of the resistance welding joints of stainless steel ventilation grille operated in swimming pool environment. Int. J. Corros. 2018, 2018, 1–7. [Google Scholar] [CrossRef]

- Vicente, T.A.; Oliveira, L.A.; Correa, E.O.; Barbosa, R.P.; Macanhan, V.B.P.; Alcântara, N.G. Stress corrosion cracking behaviour of dissimilar welding of AISI 310S austenitic stainless steel to 2304 duplex stainless steel. Metals 2018, 8, 195. [Google Scholar]

- Rahmani, M.; Eghlimi, A.; Shamanian, M. Evaluation of microstructure and mechanical properties in dissimilar austenitic/super duplex stainless steel joint. J. Mater. Eng. Perform. 2014, 23, 3745–3753. [Google Scholar] [CrossRef]

- Moteshakker, A.; Danaee, I. Microstructure and corrosion resistance of dissimilar weld-joints between duplex stainless steel 2205 and austenitic stainless steel 316L. J. Mater. Sci. Technol. 2016, 32, 282–290. [Google Scholar] [CrossRef]

- Moteshakker, A.; Danaee, I.; Moeinifar, S.; Ashrafi, A. Hardness and tensile properties of dissimilar welds joints between SAF 2205 and AISI 316L. Sci. Technol. Weld. Join. 2016, 21, 1–10. [Google Scholar] [CrossRef]

- Taheri, A.; Beidokhti, B.; Boroujeny, B.S.; Valizadeh, A. Characterizations of dissimilar S32205/316L welds using austenitic, super-austenitic and super-duplex filler metals. Int. J. Min. Metall. Mater. 2020, 27, 119–127. [Google Scholar] [CrossRef]

- Fei, Z.; Pan, Z.; Cuiuri, D.; Li, H.; Van Duin, S.; Yu, Z. Microstructural characterization and mechanical properties of K-TIG welded SAF2205/AISI316L dissimilar joint. J. Manuf. Process. 2019, 45, 340–355. [Google Scholar] [CrossRef]

- Ramkumar, K.D.; Bajpai, A.; Raghuvanshi, S.; Singh, A.; Chandrasekhar, A.; Arivarasu, M.; Arivazhagan, N. Investigations on structure–property relationships of activated flux TIG weldments of super-duplex/austenitic stainless steels. Mater. Sci. Eng. A 2015, 638, 60–68. [Google Scholar] [CrossRef]

- Ridha Mohammed, G.; Ishak, M.; Ahmad, S.N.A.S.; Abdulhadi, H.A. Fiber laser welding of dissimilar 2205/304 stainless steel plates. Metals 2017, 7, 546. [Google Scholar] [CrossRef] [Green Version]

- Chun, E.J.; Lee, J.H.; Kang, N. Unmixing behaviour in dissimilar laser welds for duplex and austenitic stainless steels. Sci. Technol. Weld. Join. 2019, 24, 263–275. [Google Scholar] [CrossRef]

- Saravanan, S.; Raghukandan, K.; Sivagurumanikandan, N. Studies on metallurgical and mechanical properties of laser welded dissimilar grade steels. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 3491–3498. [Google Scholar] [CrossRef]

- Cao, F.; Zhang, Y.; Shen, Y.; Jin, Y.; Li, J.; Hou, W. Effects of beam offset on the macro defects, microstructure and mechanical behaviors in dissimilar laser beam welds of SDSS2507 and Q235. J. Manuf. Process. 2020, 55, 335–347. [Google Scholar] [CrossRef]

- Landowski, M. Influence of parameters of laser beam welding on structure of 2205 duplex stainless steel. Adv. Mater. Sci. 2019, 19, 21–31. [Google Scholar] [CrossRef] [Green Version]

| Material | Value | C | Si | Mn | Ni | Cr | Mo | Cu | N | S | P | Creq | Nieq |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 316L | min | 0.000 | 0.00 | 0.0 | 10.00 | 16.50 | 2.00 | - | 0.000 | 0.000 | 0.000 | ||

| max | 0.030 | 0.75 | 2.0 | 13.00 | 18.00 | 2.50 | - | 0.100 | 0.015 | 0.045 | |||

| analysis | 0.024 | 0.43 | 1.3 | 10.02 | 16.74 | 2.04 | - | 0.026 | 0.003 | 0.028 | 19.43 | 11.39 | |

| 2304 | min | 0.000 | 0.0 | 0.0 | 3.5 | 22.0 | 0.10 | 0.10 | 0.05 | 0.000 | 0.000 | ||

| max | 0.030 | 1.0 | 2.0 | 5.5 | 24.0 | 0.60 | 0.60 | 0.20 | 0.015 | 0.035 | |||

| analysis | 0.027 | 0.4 | 1.4 | 4.9 | 23.4 | 0.39 | 0.32 | 0.14 | 0.001 | 0.029 | 24.39 | 6.41 |

| Material | Value | Rp0.2 (MPa) | Rm (MPa) | A50 (%) | λ (W/(m·K)) |

|---|---|---|---|---|---|

| 316L | min | 220 | 530 | 40 | 16.2 |

| max | 680 | ||||

| 2304 | min | 400 | 630 | 25 | 14.3 |

| max | 800 |

| No Specimen | Cross-Section Area (mm2) | Maximum Loading Force (kN) | Tensile Strength, Rm (MPa) | Place of Fracture |

|---|---|---|---|---|

| 1 | 170.7 | 104 | 609 | Base material 316L |

| 2 | 170.7 | 101 | 592 | Base material 316L |

| Place of Measure | Ferrite Content (%) | Average Value | Standard Deviation | |||||

|---|---|---|---|---|---|---|---|---|

| 316L | 0.23 | 0.24 | 0.23 | 0.26 | 0.25 | 0.24 | 0.24 | 0.01 |

| 2304 | 43.4 | 45.6 | 45.4 | 44.3 | 45.3 | 49.7 | 45.62 | 2.17 |

| Weld face | 13.9 | 12.6 | 13.0 | 14.9 | 11.3 | 12.0 | 12.95 | 1.30 |

| Weld root | 19.1 | 18.3 | 23.5 | 19.4 | 23.2 | 22.0 | 20.92 | 2.26 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Landowski, M.; Świerczyńska, A.; Rogalski, G.; Fydrych, D. Autogenous Fiber Laser Welding of 316L Austenitic and 2304 Lean Duplex Stainless Steels. Materials 2020, 13, 2930. https://doi.org/10.3390/ma13132930

Landowski M, Świerczyńska A, Rogalski G, Fydrych D. Autogenous Fiber Laser Welding of 316L Austenitic and 2304 Lean Duplex Stainless Steels. Materials. 2020; 13(13):2930. https://doi.org/10.3390/ma13132930

Chicago/Turabian StyleLandowski, Michał, Aleksandra Świerczyńska, Grzegorz Rogalski, and Dariusz Fydrych. 2020. "Autogenous Fiber Laser Welding of 316L Austenitic and 2304 Lean Duplex Stainless Steels" Materials 13, no. 13: 2930. https://doi.org/10.3390/ma13132930

APA StyleLandowski, M., Świerczyńska, A., Rogalski, G., & Fydrych, D. (2020). Autogenous Fiber Laser Welding of 316L Austenitic and 2304 Lean Duplex Stainless Steels. Materials, 13(13), 2930. https://doi.org/10.3390/ma13132930