The analysis of the results is presented mainly in terms of the relative quantities to make the analysis, discussion and results valid, not only for the particular cases considered in the present article, but also to extend the results and conclusions to other cases.

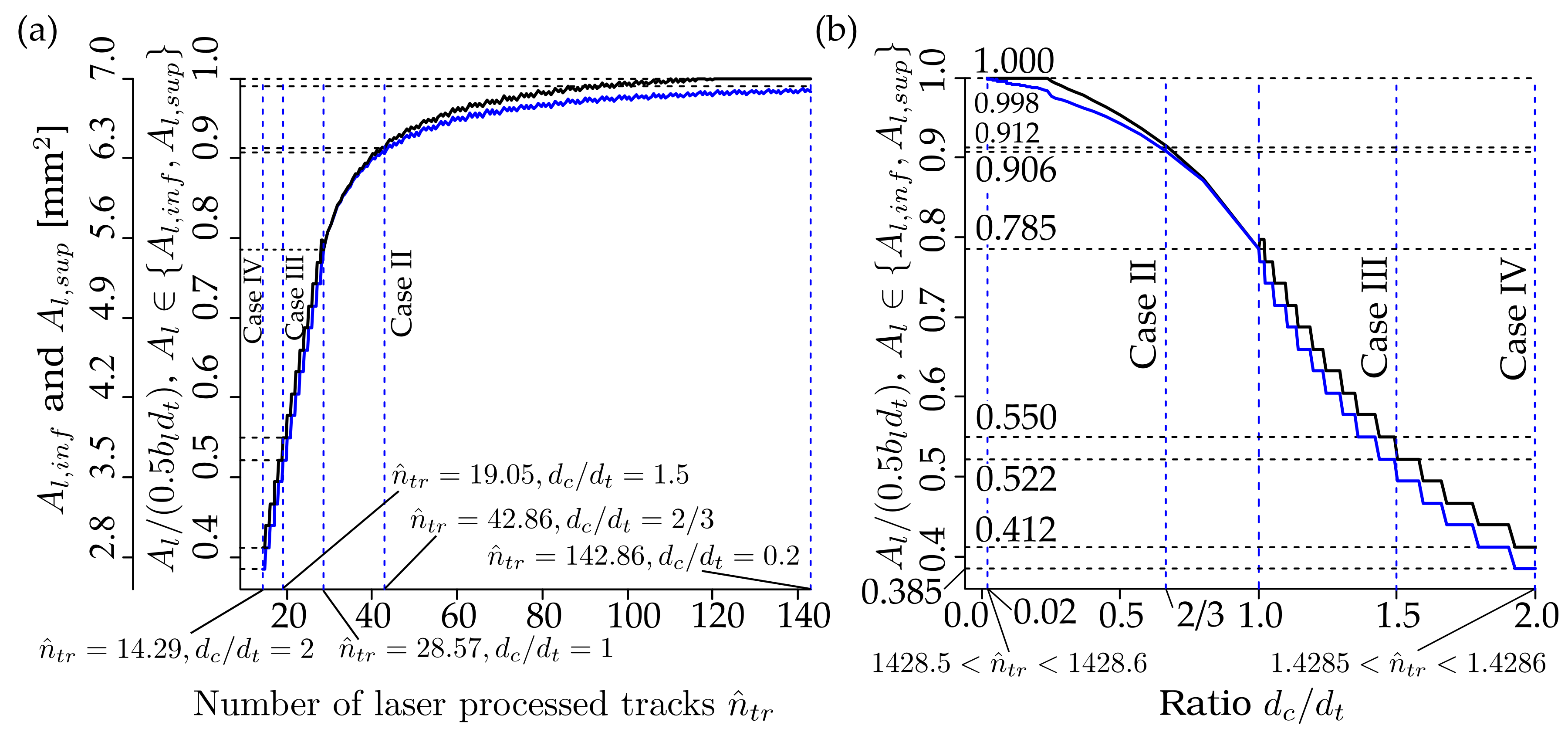

4.4.1. Area

of the Laser-Processed Metal

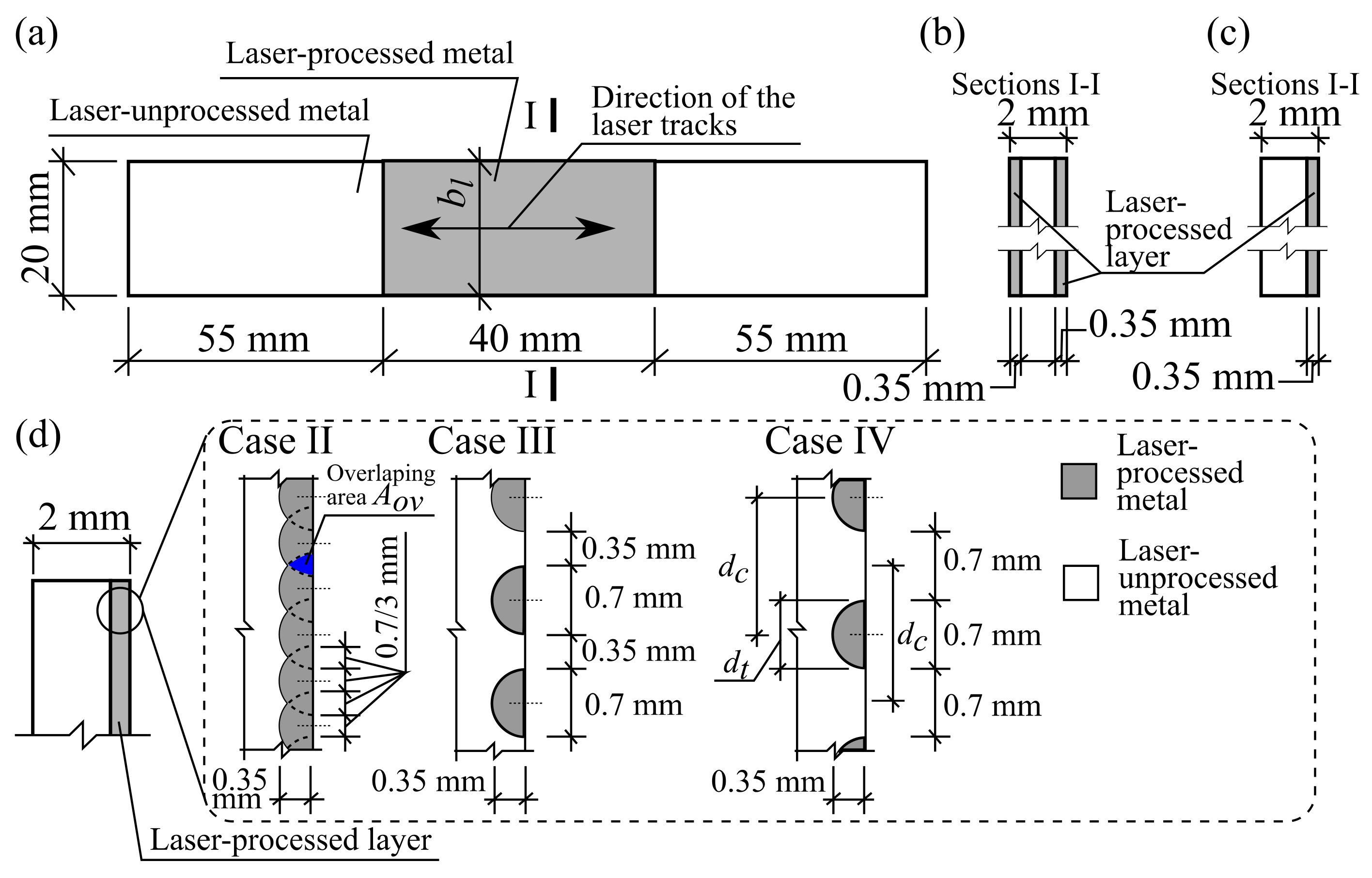

Figure 12 shows the dependencies of the bounds of the cross-sectional area of the laser-processed metal,

and

, as well as their ratios

, where

on the estimated number of the laser-processed tracks,

, calculated by Equations (6) or (10), and on the ratio

. The areas

and

were calculated by Equations (4), (5), (7)–(10) of the plate, shown in

Figure 1, when the width of the laser-processed track

mm and the width of the laser-processed area of the plate under consideration,

m. The vertical dotted lines correspond to the minimum and maximum of

or

and laser-processing cases: case II when

; case III when

; and case IV when

; see

Table 5.

Please note: in the present calculations, the numbers of tracks,

, for cases II–IV were evaluated by Equations (6) or (10), i.e.,

was not taken from

Table 5.

As can be seen from

Figure 12,

approaches

with increasing numbers of laser-processed tracks,

, or with a decrease in the ratio,

or

. Also from

Figure 12, it can be seen that the rate of increase of the areas,

, is practically constant with respect to increasing

within the interval

, corresponding to the interval,

, or when

.

More remarkably, the rate of increase of

even increases with respect to decreasing

within the interval

. However, as shown in

Figure 12, the increase in the areas

becomes slower with increasing

or decreasing

or

at

.

Finally, the increase of practically does not change at a very large . It should be noted that the biggest difference and the () occurs at the largest value of ratio , or at the smallest .

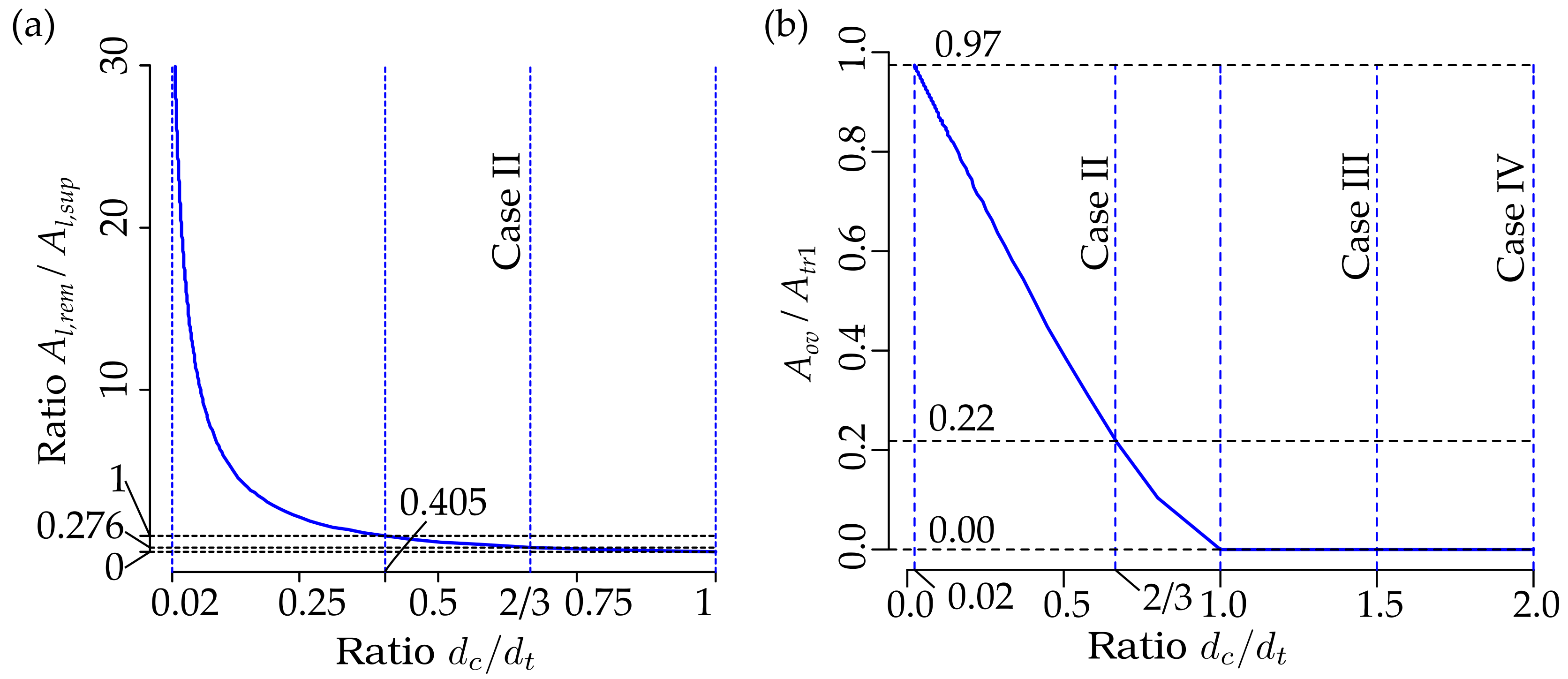

Figure 13 shows the dependency of the ratio of the area of the remelted metal to the supremum bound of the area of the laser-processed metal

(

Figure 13a), and the dependency of the ratio of the overlapping area on the cross-sectional area of the single laser-processed track

on the ratio

of the plate under consideration; see

Figure 1, where the total area of the remelted metal is calculated as follows:

.

It is clear that

as

or

. As we can see from

Figure 13a,b, the rate of the increase of the ratio

on

jumps sharply at

, and this rate is almost constant within the interval

, since

on

depends very similarly to the line. However, the dependence of the ratio of the total area of the remelted metal to the supremum bound of the laser-processed metal

increases very slowly at

, but becomes very steep with a higher ratio of

.

The behavior of with respect to differs from due to the influence of the number of laser-processed tracks, . At relatively large , the number is small. Therefore, the contribution of to is also small. With decreasing the number increases and, hence the contribution of increased to increases also.

As we can see from

Figure 13a, the ratio

as

. Therefore

as

, and the difference

or the ratio

increases very quickly with increasing

. It should be noted that the cross-sectional area of the remelted metal,

can be many times, ten- or even twenty-times, bigger than the supremum bound of the cross-sectional area of the laser-processed metal

at small values of

. Throughout this subchapter, a decrease in

corresponds to increasing the number of laser-processed tracks,

and vice versa, while increasing

corresponds to a decrease in

.

The analysis above allows us to conclude that making a laser-processed layer is very inefficient at small values of

or large values of

, since a very large volume of the metal is melted repeatedly. For practical applications, it is reasonable to take the ratio,

. In this case, as we can see from

Figure 12b,

. This means that the increase in the number of laser-processed tracks

or decrease of the distance between the tracks,

or the ratio

can increase the cross-sectional area of the laser-processed metal only up to

. However, as shown above, the cross-section of the remelted metal, or the ratio

, increases very quickly with decreasing

or increasing

. Hence, the efficiency of laser processing decreases very quickly.

For practical applications, the optimal limit of ratio can be 0.405, since at this point and ratios and . Therefore, a further increase in or decrease in can increase the ratios only up to 4%. To increase the cross-sectional area of the laser-processed metal, , it is better to increase the width, and hence the depth, of the laser-processed track than to increase or decrease .

The considerations given above concerning the ratios , , , , and the corresponding cross-section areas , , , , , are also valid for the corresponding ratios of the volumes , , , , and the corresponding volumes , , , , of the laser-processed metal, where stands for the volume of the laser-processed metal and its indexes , , , , , and means the same as the corresponding indexes of the cross-sectional areas denoted by .

Since the above analysis, results, conclusions and recommendations are expressed in relative terms, then these considerations are also valid for other cases of plates, laser-processed areas, their widths , the laser-processed track widths , the distances between the track centers , the number of laser tracks and so on.

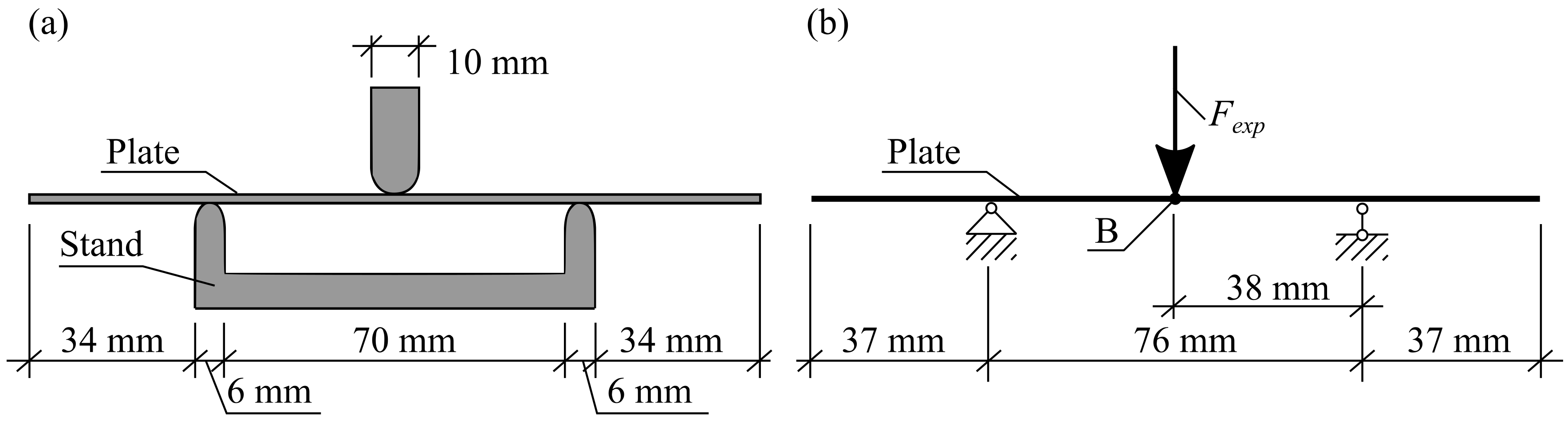

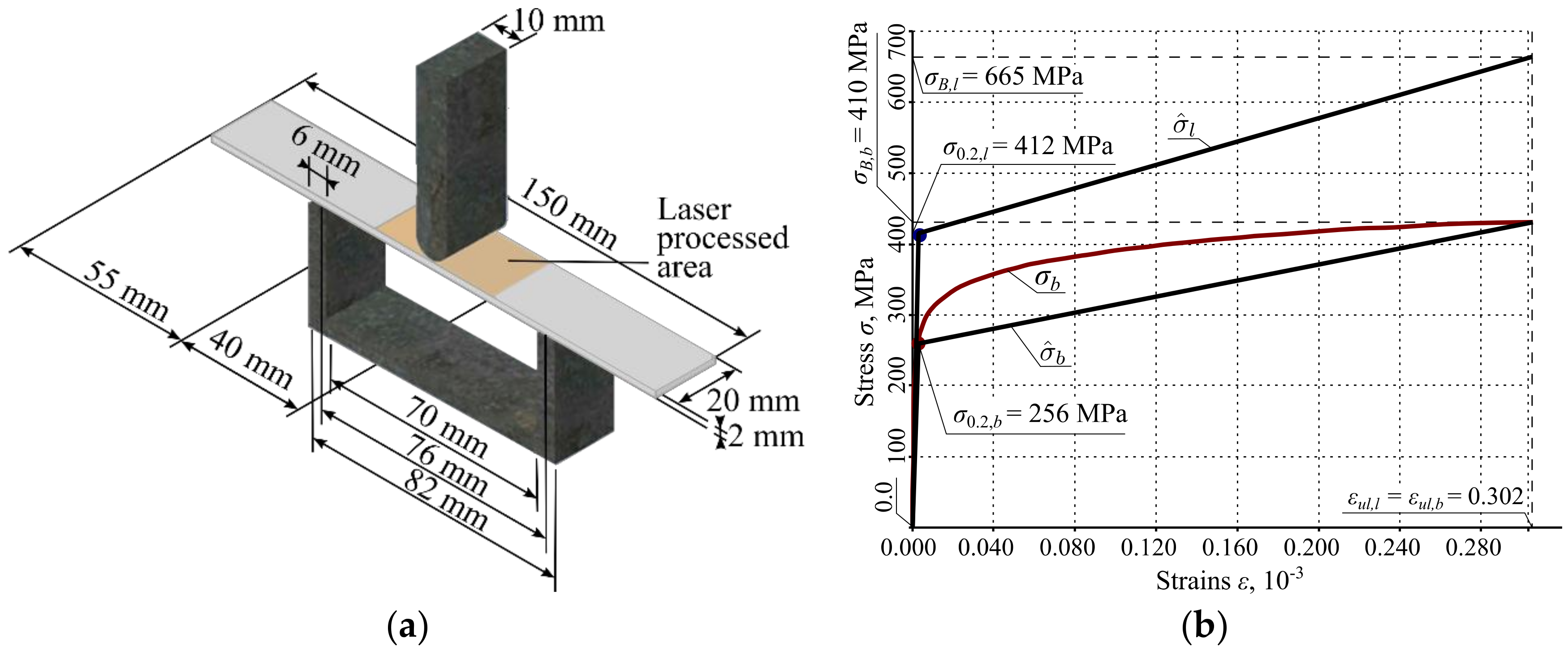

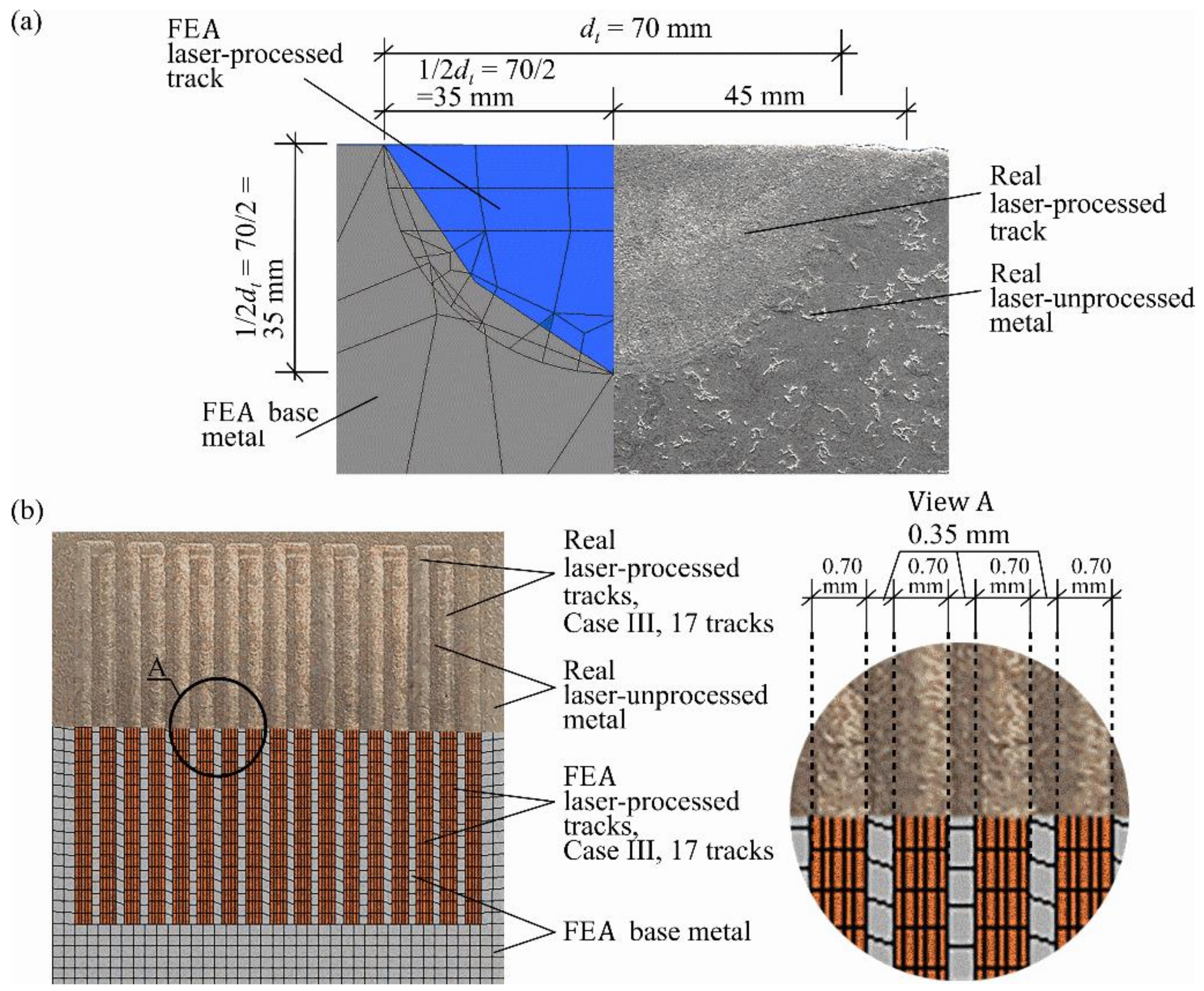

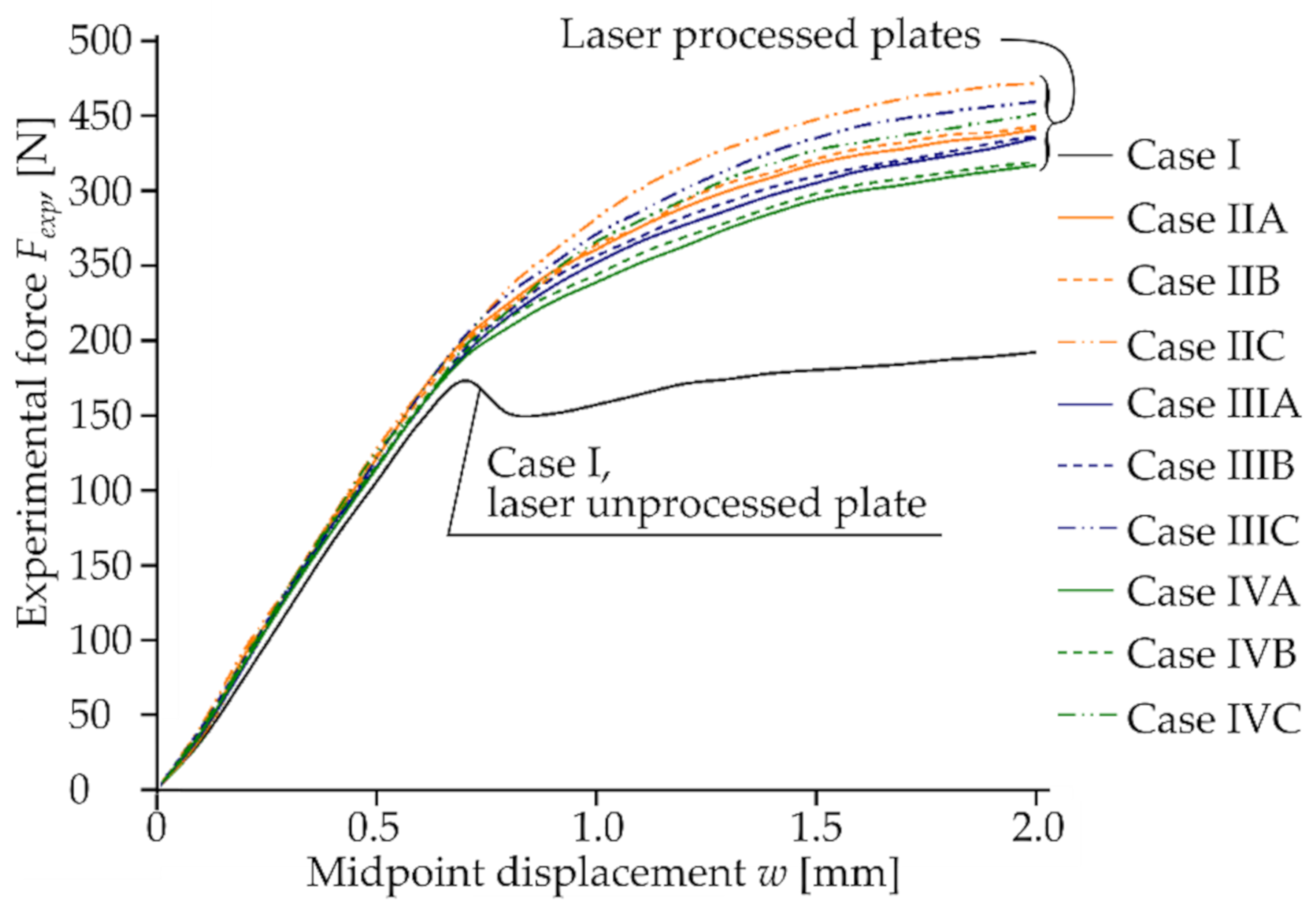

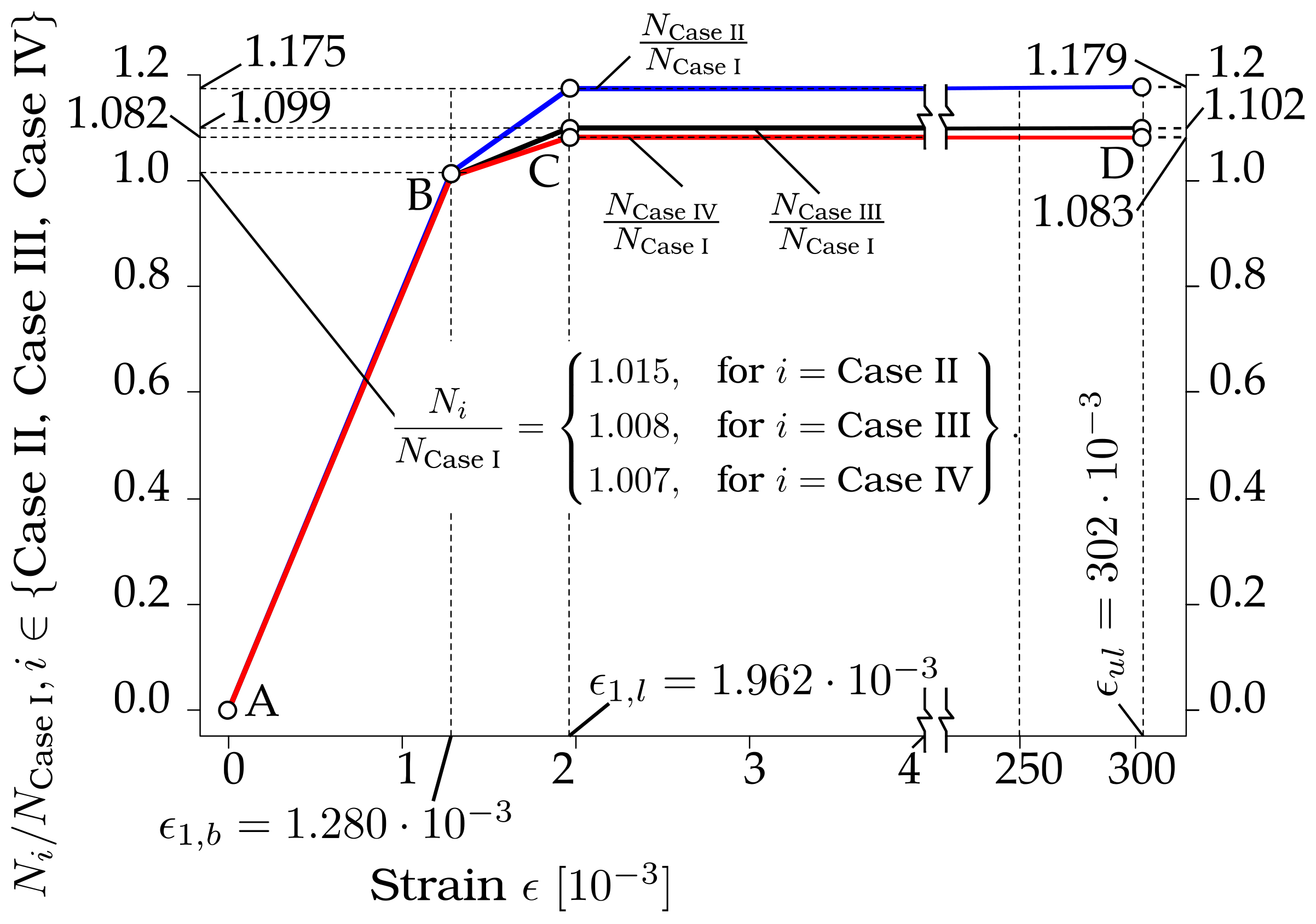

4.4.2. Axial Stiffness and Force—Strain Behavior of the Laser-Processed Plate

The dependencies of the ratios of the axial forces of the laser-processed plates (see

Figure 1, cases II, III and IV) to the unprocessed plate, case I:

,

on strain

are shown in

Figure 14. The axial forces

,

were calculated according to Equations (1) and (2), using the properties of the base and laser-processed metals given in

Table 7. The cross-sectional areas of the laser-processed metal of plate

were calculated by the proposed Equations, (3), (7) and (11) when the number of the laser-processed sides

and the number of the laser-processed tracks of one side of the plate, corresponding to cases I, II, III and IV

is given in

Table 5. The following cross-sectional areas were obtained:

for case I,

m

2 for case II,

m

2 for case III,

m

2 for case IV. The cross-sectional areas of the base metal of the plate corresponding to cases I–IV,

, where

m

2 is the cross-sectional area of the plate; see

Figure 1b.

As we can see from

Figure 14, the influence of laser processing is almost infinitesimal when

; see section AB in

Figure 14. The maximum ratio,

. If the axial stiffness of the cross-section of the plate is

, then we can say that laser processing does not have any influence on the axial stiffness of the plate when

. However, the influence of laser processing on the ratio of the axial forces

increases with increasing strain within the interval

and remains constant when

, where hereafter

; see sections BC and CD in

Figure 13.

As shown in

Figure 14, laser processing increases the axial forces

and hence the axial stiffness

,

, about 17.5% for case II, 9.9% for case III, and 8.2% for case IV. For practical structural calculations, it is reasonable to assume that the plate’s bearing capacity corresponds to the axial force

at

, since the increase of the ratio

within the interval

is very low:

for case II;

for case III; and

for case IV.

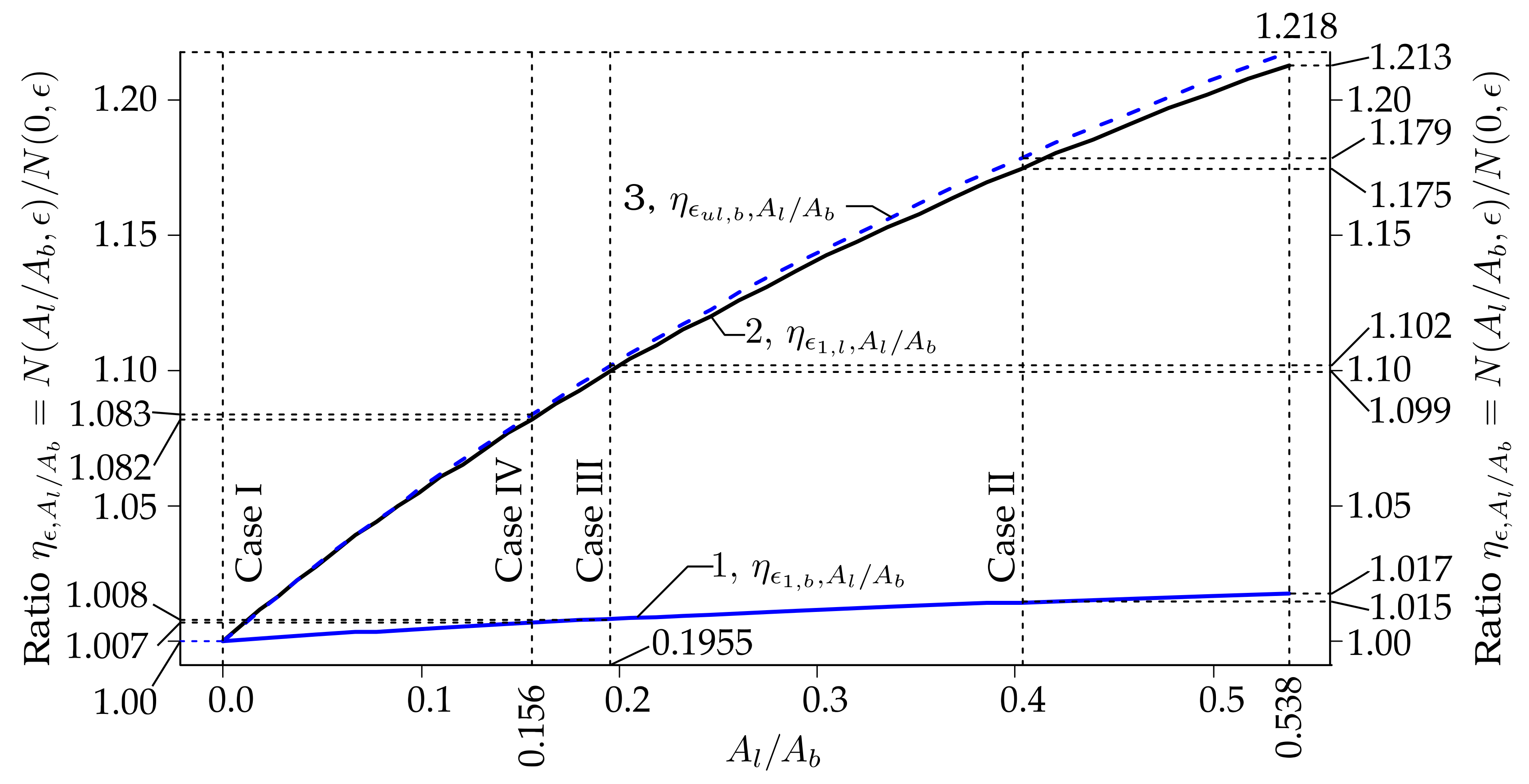

The dependencies of the ratios of the axial forces

at

with respect to the ratio of the cross-sectional areas of the laser-processed and base metals

of the plate shown in

Figure 1 are shown in

Figure 15. In the situation when

, since

also corresponds to the laser-unprocessed plate, i.e., case I, then

. In these calculations, it was assumed that the cross-sectional area of the laser-processed metal attains values from the interval:

. Since

, where

, then

. Thus,

corresponds to the upper bound of the cross-sectional area of the laser-processed metal when

of the two-side laser-processed plate; see

Figure 1b. Other parameters used to draw

Figure 15 were the same as in

Figure 14; see the explanations given at the beginning of the present subchapter.

As we can see from

Figure 15, the ratios

on

do not change according to the linear law, as in the case of the dependence of the

on

when

is constant, according to Equation (2). This happens since the cross-sectional area of the base metal

, i.e.,

also changes when

changes. Also, it is clearly visible that the ratio

affects the ratios

, especially when

Thus, when

, then the relative difference

, while when

, then

; and when

, then

. When the strain increases from

to

and

, then the relative difference

. From

Figure 15, we can see that the biggest possible increase of the axial force is when

is

.