Bio-Based Polyethylene Composites with Natural Fiber: Mechanical, Thermal, and Ageing Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization of Natural Fibers

2.3. Method of Testing

2.3.1. Physic-Mechanical Characterization

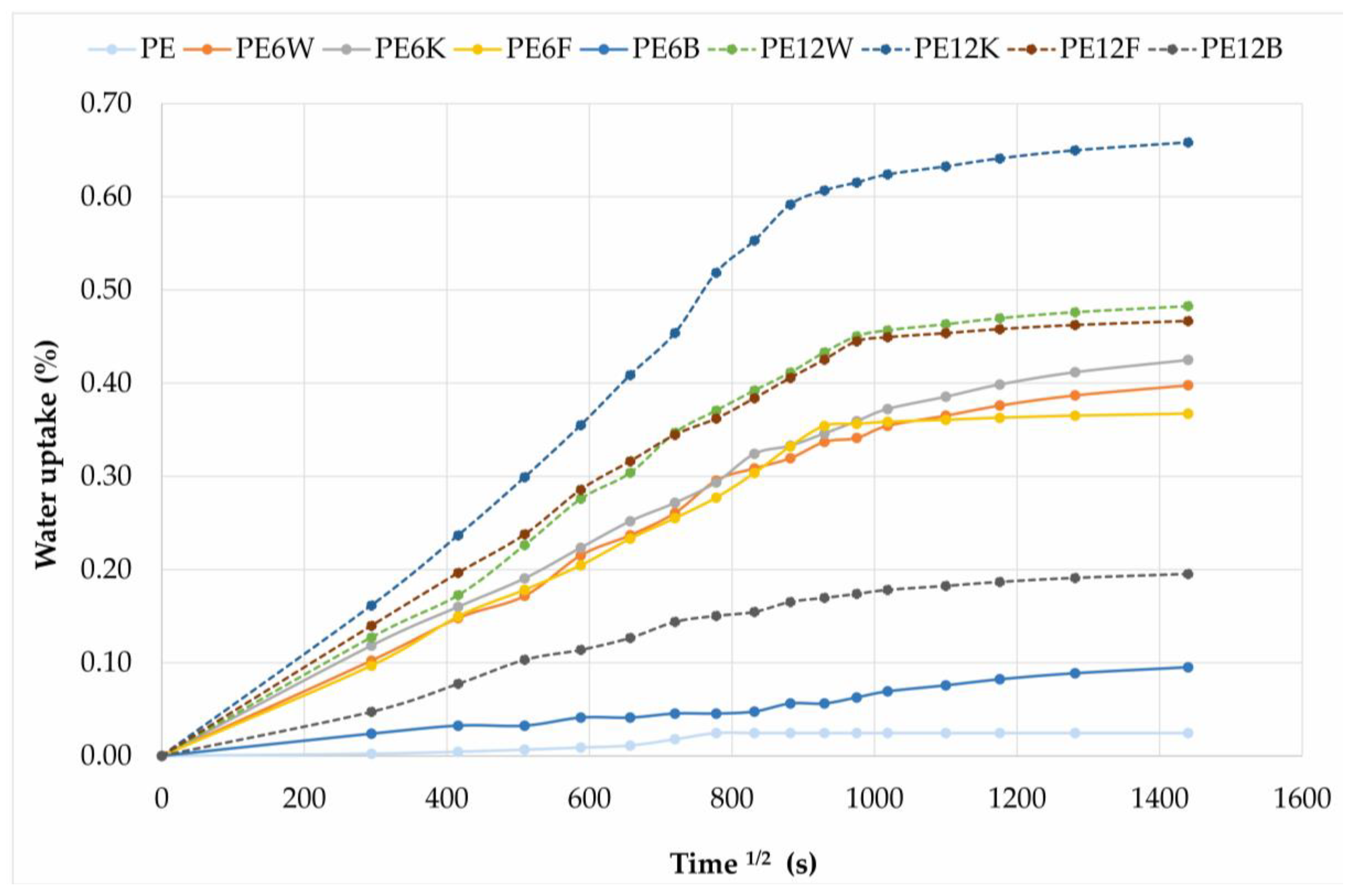

2.3.2. Water Absorption and Water Diffusion Coefficient

2.3.3. Thermal Aging

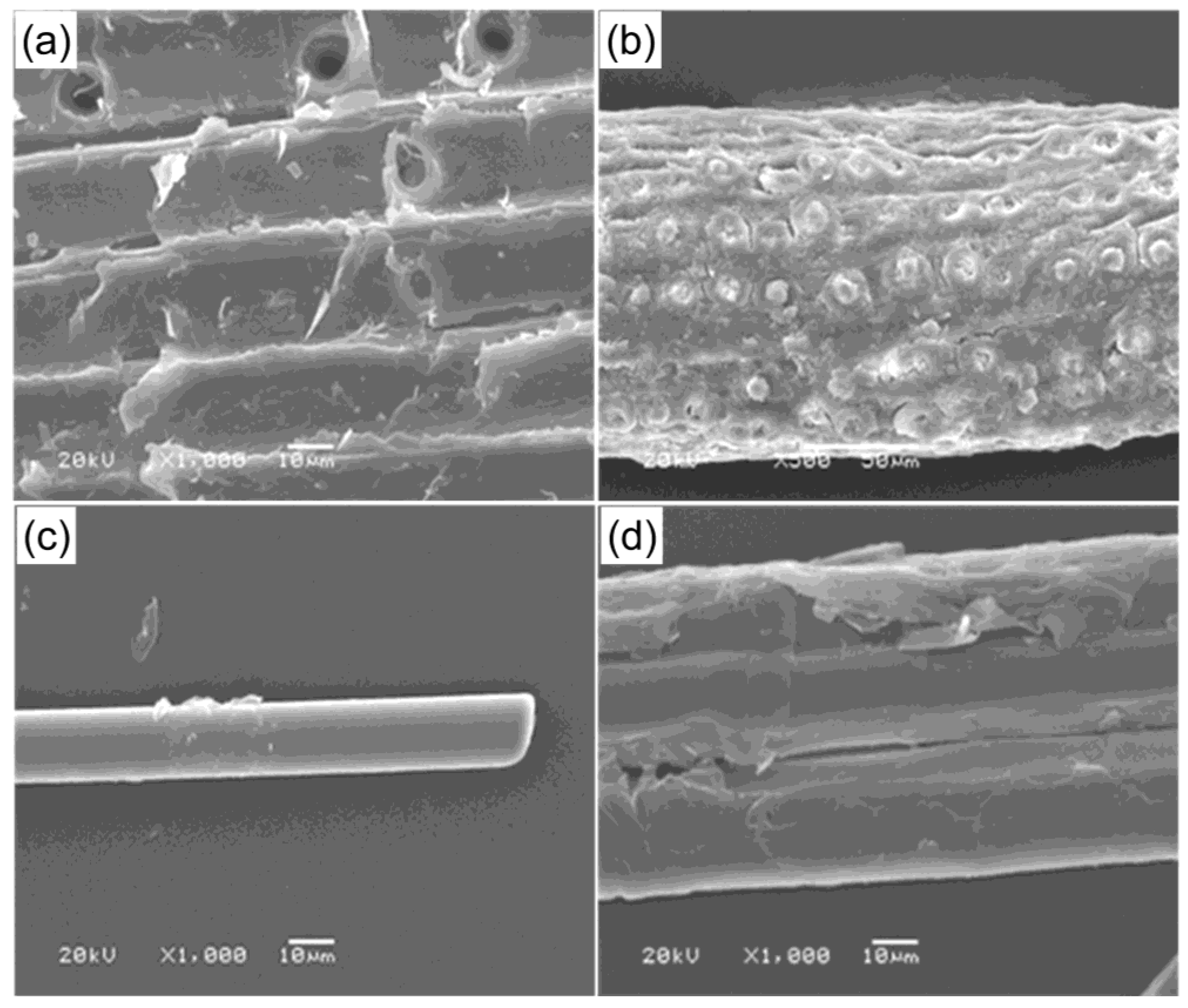

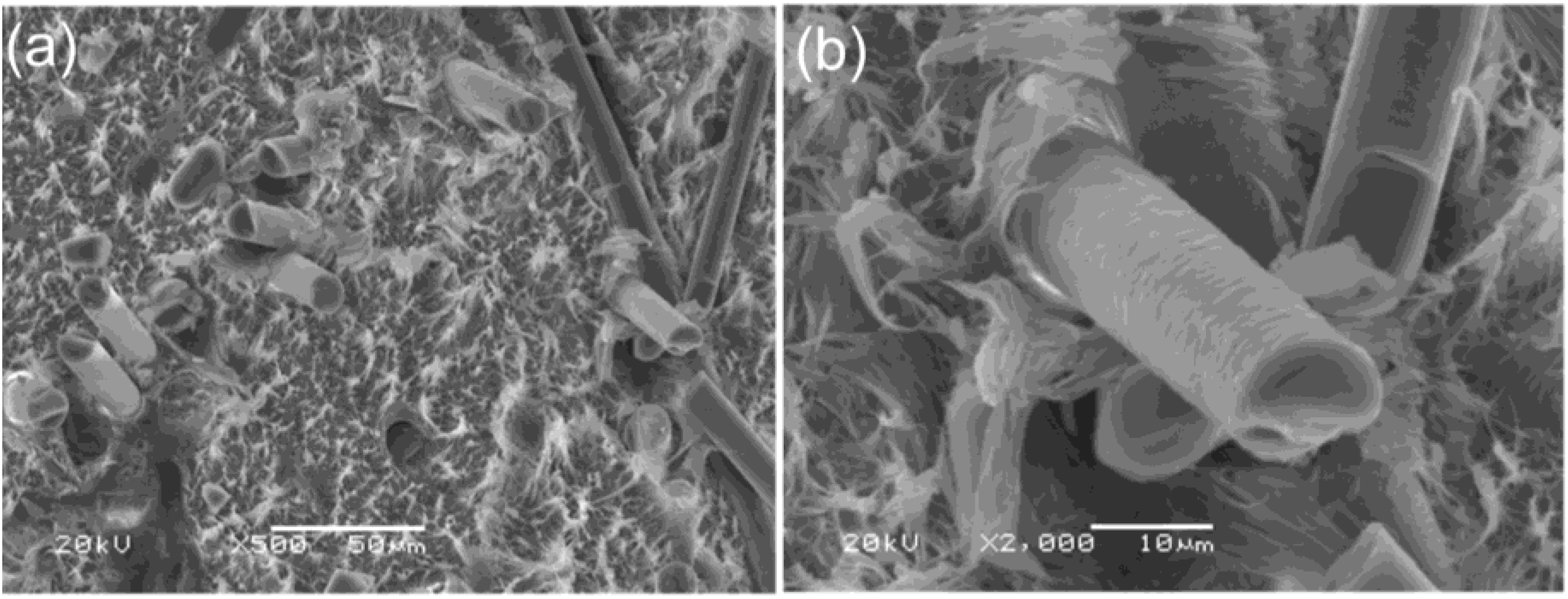

2.3.4. Scanning Electron Microscopy (SEM)

2.3.5. Short-Time Relaxation Test

3. Results and Discussion

3.1. Mechanical Investigation of Composites

3.2. Thermal Aging and Water Immersion Investigation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kalinowski, R. Biotworzywa jako nowe materiały przyjazne środowisku naturalnemu. Inżynieria Ochr. Środowiska 2015, 18, 215–231. [Google Scholar]

- Rabek, J.F. Polimery—Otrzymywanie, Metody Badawcze, Zastosowanie, 1st ed.; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2013; pp. 193–194, 313–319. [Google Scholar]

- Kuciel, S.; Liber-Knec, A.; Zajchowski, S. Biocomposites based on thermoplastic starch or polylactide/starch blends as the matrices filled with natural fibers. Polym. Warsaw. 2009, 54, 747–753. [Google Scholar] [CrossRef]

- Kuciel, S.; Mazur, K.; Hebda, M. The Influence of Wood and Basalt Fibres on Mechanical, Thermal and Hydrothermal Properties of PLA Composites. J. Polym. Environ. 2020, 28, 1204–1215. [Google Scholar] [CrossRef]

- Kuciel, S.; Mazur, K.; Jakubowska, P. Novel Biorenewable Composites Based on Poly (3-hydroxybutyrate-co-3-hydroxyvalerate) with Natural Fillers. J. Polym. Environ. 2019, 27, 803–815. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; Taylor & Francis: New York, NY, USA, 2005; pp. 232–255, 262–284. [Google Scholar]

- Min, R.; Ortega, B.; Marques, C. Latest Achievements in Polymer Optical Fiber Gratings: Fabrication and Applications. Photonics 2019, 6, 36. [Google Scholar] [CrossRef]

- Muniyasamy, S.; John, M.J. Biodegradability of Biobased Polymeric Materials in Natural Environments. In Handbook of Composites from Renewable Materials, Biodegradable Materials; Thakur, V.K., Thakur, M.K., Kessler, M.R., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA; Scrivener Publishing: Salem, MA, USA, 2017; Volume 5, pp. 625–649. [Google Scholar] [CrossRef]

- Brito, G.F.; Agrawal, P.; Araujo, E.M.; Tomas, J.A.; De Melo, T.J.A. Polylactide/biopolyethylene bioblends. Polímeros 2012, 22, 427–429. [Google Scholar] [CrossRef]

- Cavallo, D.; Campopiano, A.; Cardinali, G.; Casciardi, S.; De Simone, P.; Kovacs, D.; Perniconi, B.; Spagnoli, G.; Ursini, C.L.; Fanizza, C. Cytotoxic and oxidative effects induced by man-made vitreous fibers (MMVFs) in a human mesothelial cell line. Toxicology 2004, 201, 219–229. [Google Scholar] [CrossRef] [PubMed]

- AL-Oqla, F.M.; Salit, M.S. Materials Selection for Natural Fiber Composites, 1th ed.; Elsevier: London, UK, 2017; pp. 23–31. [Google Scholar]

- Ashori, A. Non-wood fibers—A potential source of raw material in papermaking. Polym. Plast. Technol. Eng. 2006, 45, 1133–1136. [Google Scholar] [CrossRef]

- Ashori, A. Hybrid thermoplastic composites using nonwood plant fibers. In Hybrid Polymer Composite Materials, 1st ed.; Thakur, V.K., Thakur, M.K., Pappu, A., Eds.; Woodhead Publishing Is an Imprint of Elsevier: London, UK, 2017; pp. 39–53. [Google Scholar]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part. B-Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Moudood, A.; Rajman, A.; Ochsner, A.; Islam, M.; Francucci, G. Flax fiber and its composites: An overview of water and moisture absorption impact on their performance. J. Rein. Plast. Comp. 2019, 38, 323–339. [Google Scholar] [CrossRef]

- Assarar, M.; Scida, D.; El Mahi, A.; Poilane, C.; Ayad, R. Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax-fibres and glass-fibres. Mater. Des. 2011, 32, 788–795. [Google Scholar] [CrossRef]

- Cheour, K.; Assarar, M.; Scida, D.; Ayad, R.; Gong, X.-L. Effect of water ageing on the mechanical and damping properties of flax-fibre reinforced composite materials. Compos. Struct. 2016, 152, 259–266. [Google Scholar] [CrossRef]

- Chilali, A.; Zouari, W.; Assarar, M.; Kebir, H.; Ayad, R. Effect of water ageing on the load-unload cyclic behaviour of flax fibre-reinforced thermoplastic and thermosetting composites. Compos. Struct. 2018, 183, 309–319. [Google Scholar] [CrossRef]

- Moudood, A.; Hall, W.; Ochsner, A.; Li, H.; Rajman, A.; Francucci, G. Effect of moisture in flax fibres on the quality of their composites. J. Nat. Fibers 2019, 16, 209–224. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Bennett, N.; Lopez-Arraiza, A.; Vallejo, F.J. Effects of water immersion ageing on the mechanical properties of flax and jute fibre biocomposites evaluated by nanoindentation and flexural testing. J. Compos. Mater. 2014, 48, 1399–1406. [Google Scholar] [CrossRef]

- Stamboulis, A.; Baillie, C.A.; Garkhail, S.K.; Van Melick, H.G.H.; Peijs, T. Environmental durability of flax fibres and their composites based on polypropylene matrix. Appl. Compos. Mater. 2000, 7, 273–294. [Google Scholar] [CrossRef]

- Anupama Sai Priya, N.; Veera Raju, P.; Naveen, P.N.E. Experimental Testing of Polymer Reinforced with Coconut Coir Fiber Composites. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 453–460. [Google Scholar]

- Singh, A.; Singh, S.; Kumar, A. Study of Mechanical Properties and Absorption Behaviour of Coconut Shell Powder-Epoxy Composites. Int. J. Mater. Sci. Appl. 2013, 2, 157–161. [Google Scholar] [CrossRef]

- Balarami Reddy, T. Mechanical Performance of Green Coconut Fiber/HDPE Composites. Int. J. Eng. 2013, 3, 1262–1270. [Google Scholar]

- Siva, I.; Winowlin, J.T.; Sankar, I.; Sandro, A.; Ravindran, D. Effect of Fiber Volume Fraction on The Mechanical Properties Of Coconut Sheath/USP Composite. J. Manuf. Eng. 2013, 8, 60–63. [Google Scholar]

- Onuegbu, T.U.; Umoh, E.T.; Okoroh, N.C. Tensile Behaviour and Hardness of Coconut Fiber-Ortho Unsaturated Polyester Composites. Glob. J. Sci. Front. Res. Chem. 2013, 13, 1. [Google Scholar]

- Huand, H.B.; Du, H.H.; Wang, H.H.; Wang, H.G. Effects of the Size of Wood Flour on Mechanical Properties of Wood-Plastic Composites. Adv. Mater. Res. 2011, 393–395, 76–79. [Google Scholar] [CrossRef]

- Sheshmani, S.; Ashori, A.; Farhani, F. Effects of extractives on the performance properties of wood flour-polypropylene composites. Appl. Polym. Sci. 2012, 123, 1563–1567. [Google Scholar] [CrossRef]

- Ichazo, M.N.; Alban, C.; Gonzalez, J.; Petera, R.; Candal, M.V. Polypropylene/wood flour composites: Treatments and properties. Compos. Struct. 2001, 54, 207–214. [Google Scholar] [CrossRef]

- Hamzeh, Y.; Ashori, A.; Hojati Marvast, E.; Rashedi, K.; Mohammad Olfat, A. A comparative study on the effects of Coriolus versicolor on properties of HDPE/wood flour/paper sludge composites. Compos. Part B Eng. 2012, 43, 2409–2414. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A. Preparation and properties of wood plastic composites made of recycled HDPE. Compos. Mater. 2009, 43, 877–883. [Google Scholar] [CrossRef]

- Singha, K. A Short Review on Basalt Fiber. Int. J. Text. Sci. 2012, 1, 19–28. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part. B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part. B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Tarrés, Q.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Vilaseca, F. Biobased composites from biobased-polyethylene and barley thermomechanical fibers: Micromechanics of composites. Materials 2019, 12, 4182. [Google Scholar] [CrossRef]

- Castro, D.O.; Ruvolo-Filho, A.; Frollini, E. Materials prepared from biopolyethylene and curaua fibers: Composites from biomass. Polym. Test. 2012, 31, 880–888. [Google Scholar] [CrossRef]

- Castro, D.O.; Passador, F.; Ruvolo-Filho, A.; Frollini, E. Use of castor and canola oils in “biopolyethylene” curauá fiber composites. Compos. Part. A Appl. Sci. Manuf. 2017, 95, 22–30. [Google Scholar] [CrossRef]

- Kuciel, S.; Jakubowska, P.; Kuźniar, P. A study on the mechanical properties and the influence of water uptake and temperature on biocomposites based on polyethylene from renewable sources. Compos. Part. B Eng. 2014, 64, 72–77. [Google Scholar] [CrossRef]

- Tarrés, Q.; Melbø, J.K.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Chinga-Carrasco, G. Bio-polyethylene reinforced with thermomechanical pulp fibers: Mechanical and micromechanical characterization and its application in 3D-printing by fused deposition modelling. Compos. Part. B Eng. 2018, 153, 70–77. [Google Scholar] [CrossRef]

- Technical Date Sheet of Coconut Shell Fibers. Procotex SA Corporation NV. Available online: https://en.procotex.com (accessed on 6 June 2020).

- Technical Data Sheet of Flax Fibers. Procotex SA Corporation NV. Available online: https://en.procotex.com (accessed on 6 June 2020).

- Technical Date Sheet of Wood Flour. J. Rettenmaier & Söhne Company. Available online: https://www.jrs.eu/jrs_en (accessed on 6 June 2020).

- Technical Date Sheet of Basalt Fiber. Kemenny Vek. Available online: https://basfiber.com (accessed on 6 June 2020).

- Clemons, C.M. Wood Flour. In Functional Fillers for Plastics, 1st ed.; Xanthos, M., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2006; pp. 263–273. [Google Scholar]

- Ramesh, M. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Oksman, K.; Sain, M. Wood-Polymer Composites; Woodhead Publishing Limited: Cambridge, UK, 2008; pp. 100–102. [Google Scholar]

- Porębska, R.; Mazurkiewicz, S. Energia dyssypacji w kompozytach polimerowych. Tech. Transction 2009, 3, 245–248. [Google Scholar]

- Broniewski, T.; Iwasiewicz, A.; Kapko, J.; Płaczek, W. Metody Badań i Ocena Tworzyw Sztucznych; Wydawnictwo Naukowo-Techniczne: Warszawa, Poland, 1970; pp. 327–395. [Google Scholar]

- Gardette, M.; Perthue, A.; Gardette, J.-L.; Janecska, T.; Pukánszky, B.; Their, S. Photo- and thermal-oxidation of polyethylene: Comparison of mechanisms and influence of unsaturation content. Polym. Degrad. Stabil. 2013, 98, 2383–2390. [Google Scholar] [CrossRef]

| Index | Description |

|---|---|

| PE | 100 wt.% Green PE SHC7260 Braskem (Bio-PE) |

| PE6W | 92 wt.% of Bio-PE + 6 wt.% wood flour + 2 wt.% Scona TPPP 9112 FA |

| PE6K | 92 wt.% of Bio-PE + 6 wt.% coconut shell fibers + 2 wt.% Scona TPPP 9112 FA |

| PE6F | 92 wt.% of Bio-PE + 6 wt.% flax fibers + 2 wt.% Scona TPPP 9112 FA |

| PE6B | 92 wt.% of Bio-PE + 6 wt.% basalt fibers + 2 wt.% Scona TPPP 9112 FA |

| PE12W | 86 wt.% of Bio-PE + 12 wt.% wood flour + 2 wt.% Scona TPPP 9112 FA |

| PE12K | 86 wt.% of Bio-PE + 12 wt.% coconut shell fibers + 2 wt.% Scona TPPP 9112 FA |

| PE12F | 86 wt.% of Bio-PE + 12 wt.% flax fibers + 2 wt.% Scona TPPP 9112 FA |

| PE12B | 86 wt.% of Bio-PE + 12 wt.% basalt fibers + 2 wt.% Scona TPPP 9112 FA |

| Wood Flour (wt.%) | Coconut Shell (wt.%) | Flax Fibers (wt.%) | Basalt Fibers (%) |

|---|---|---|---|

| Cellulose: 40–50 | Cellulose: 26.5 | Cellulose: 71 | SiO2: 51.6–59.3 |

| Hemicellulose: 15–25 | Pentosans: 27.7 | Hemicellulose: 18–20 | AL2O3: 14.6–18.3 |

| Lignin: 15–30 | Lignin: 29.4 | Lignin: 2.2 | CaO: 5.9–9.4 |

| Moisture: 8–16 | Moisture: 8 | Moisture: 10 | MgO: 3.0–5.3 |

| - | Solvent extractives: 4.2 | Pectin: 2.3 | FeO + Fe2O3: 9–14 |

| - | Uronic anhydrides: 3.5 | Wax: 1.7 | TiO2: 0.8–2.25 |

| - | Ash: 0.6 | - | Na2O + K2O: 0.09–0.13 |

| Fibers | Density (g/cm3) | Diameter (µm) | Length (mm) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Strain at Break (%) |

|---|---|---|---|---|---|---|

| Wood flour | 1.3–2.2 | 300–500 | - | 44–90 | 6–13 | 2.0–3.0 |

| Coconut shell | 1.1–1.3 | 100 | 2.0 | 130–250 | 4–15 | 2.0–4.0 |

| Basalt | 2.7 | 13–22 | 3.2 | 2800–2900 | 70–110 | 2.5–3.5 |

| Flax | 1.40–1.45 | 50–70 | 1–65 | 400–1200 | 40–70 | 1.8–3.2 |

| Index | Density, g/cm3 | Tensile Strength, MPa | Tensile Modulus, MPa | Strain at Break, % | Flexural Strength, MPa | Flexural Modulus, MPa | Impact Strength, kJ/m2 |

|---|---|---|---|---|---|---|---|

| PE | 0.961 ± 0.002 | 18.1 ± 0.3 | 1062 ± 26 | >200 | 19.3 ± 0.5 | 809 ± 21 | unbroken |

| PE6W | 0.976 ± 0.001 | 18.7 ± 0.5 | 1974 ± 21 | 5.6 ± 0.6 | 23.4 ± 0.6 | 995 ± 25 | 13.5 ± 0.1 |

| PE6K | 0.968 ± 0.004 | 18.5 ± 0.6 | 1596 ± 12 | 5.1 ± 0.4 | 24.9 ± 1.1 | 978 ± 54 | 16.6 ± 1.6 |

| PE6F | 0.969 ± 0.001 | 19.2 ± 0.8 | 1508 ± 36 | 7.0 ± 0.5 | 24.4 ± 1.5 | 1065 ± 14 | 31.7 ± 2.4 |

| PE6B | 0.988 ± 0.002 | 24.7 ± 1.2 | 2280 ± 15 | 4.1 ± 0.9 | 30.1 ± 1.2 | 1316 ± 16 | 16.6 ± 0.2 |

| PE12W | 1.001 ± 0.002 | 19.3 ± 0.4 | 1695 ± 25 | 5.3 ± 0.7 | 29.9 ± 0.9 | 1465 ± 26 | 13.5 ± 1.1 |

| PE12K | 0.988 ± 0.003 | 18.9 ± 1.1 | 1389 ± 14 | 5.4 ± 0.5 | 30.2 ± 0.7 | 1190 ± 24 | 13.0 ± 0.1 |

| PE12F | 0.991 ± 0.002 | 21.3 ± 0.7 | 2311 ± 34 | 2.8 ± 0.5 | 33.6 ± 1.8 | 1633 ± 15 | 15.9 ± 0.3 |

| PE12B | 1.011 ± 0.001 | 34.0 ± 1.4 | 2484 ± 18 | 4.0 ± 0.7 | 44.9 ± 2.3 | 2160 ± 31 | 17.1 ± 0.1 |

| Index | Properties after Water Incubation | Properties after Thermal Ageing | ||||

|---|---|---|---|---|---|---|

| Tensile Strength, MPa | Tensile Modulus, MPa | Strain at Break, % | Tensile Strength, MPa | Tensile Modulus, MPa | Strain at Break, % | |

| PE | 21.3 ± 0.1 | 1210 ± 27 | >100 | 18.7 ± 0.9 | 1315 ± 26 | 4.0 ± 0.6 |

| PE6W | 21.4 ± 0.1 | 1818 ± 106 | 5.3 ± 0.3 | 15.2 ± 0.1 | 1644 ± 21 | 2.3 ± 0.1 |

| PE6K | 21.0 ± 0.1 | 1727 ± 203 | 5.1 ± 0.7 | 13.2 ± 0.1 | 1621 ± 86 | 1.8 ± 0.1 |

| PE6F | 19.3 ± 0.1 | 1527 ± 19 | 4.7 ± 0.1 | 16.6 ± 0.8 | 1439 ± 23 | 3.4 ± 0.4 |

| PE6B | 27.8 ± 1.2 | 2134 ± 97 | 4.0 ± 0.2 | 20.6 ± 1.2 | 2745 ± 162 | 1.8 ± 0.3 |

| PE12W | 20.4 ± 0.1 | 2055 ± 16 | 3.8 ± 0.5 | 14.6 ± 1.0 | 2024 ± 24 | 2.0 ± 0.3 |

| PE12K | 19.9 ± 0.4 | 1504 ± 36 | 4.5 ± 0.1 | 11.8 ± 0.5 | 1391 ± 25 | 1.9 ± 0.7 |

| PE12F | 21.6 ± 0.3 | 1935 ± 8 | 3.7 ± 0.4 | 16.1 ± 0.6 | 1813 ± 14 | 2.6 ± 0.9 |

| PE12B | 35.0 ± 1.1 | 3231 ± 19 | 2.6 ± 0.1 | 23.1 ± 0.7 | 3175 ± 35 | 3.8 ± 0.4 |

| Samples ID | D (m2/s) | Parameter k | Parameter n |

|---|---|---|---|

| PE | 4.0 × 10−12 | 0.00003 | 1.0000 |

| PE6W | 3.2 × 10−12 | 0.0004 | 0.4792 |

| PE6K | 2.5 × 10−12 | 0.0004 | 0.4342 |

| PE6F | 3.2 × 10−12 | 0.0004 | 0.5633 |

| PE6B | 7.8 × 10−13 | 0.00004 | 0.3001 |

| PE12W | 3.5 × 10−12 | 0.0005 | 0.5155 |

| PE12K | 3.2 × 10−12 | 0.0007 | 0.5606 |

| PE12F | 3.1 × 10−12 | 0.0005 | 0.4854 |

| PE12B | 5.8 × 10−12 | 0.0003 | 0.7102 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bazan, P.; Mierzwiński, D.; Bogucki, R.; Kuciel, S. Bio-Based Polyethylene Composites with Natural Fiber: Mechanical, Thermal, and Ageing Properties. Materials 2020, 13, 2595. https://doi.org/10.3390/ma13112595

Bazan P, Mierzwiński D, Bogucki R, Kuciel S. Bio-Based Polyethylene Composites with Natural Fiber: Mechanical, Thermal, and Ageing Properties. Materials. 2020; 13(11):2595. https://doi.org/10.3390/ma13112595

Chicago/Turabian StyleBazan, Patrycja, Dariusz Mierzwiński, Rafał Bogucki, and Stanisław Kuciel. 2020. "Bio-Based Polyethylene Composites with Natural Fiber: Mechanical, Thermal, and Ageing Properties" Materials 13, no. 11: 2595. https://doi.org/10.3390/ma13112595

APA StyleBazan, P., Mierzwiński, D., Bogucki, R., & Kuciel, S. (2020). Bio-Based Polyethylene Composites with Natural Fiber: Mechanical, Thermal, and Ageing Properties. Materials, 13(11), 2595. https://doi.org/10.3390/ma13112595