Aluminum Nitride Transition Layer for Power Electronics Applications Grown by Plasma-Enhanced Atomic Layer Deposition

Abstract

1. Introduction

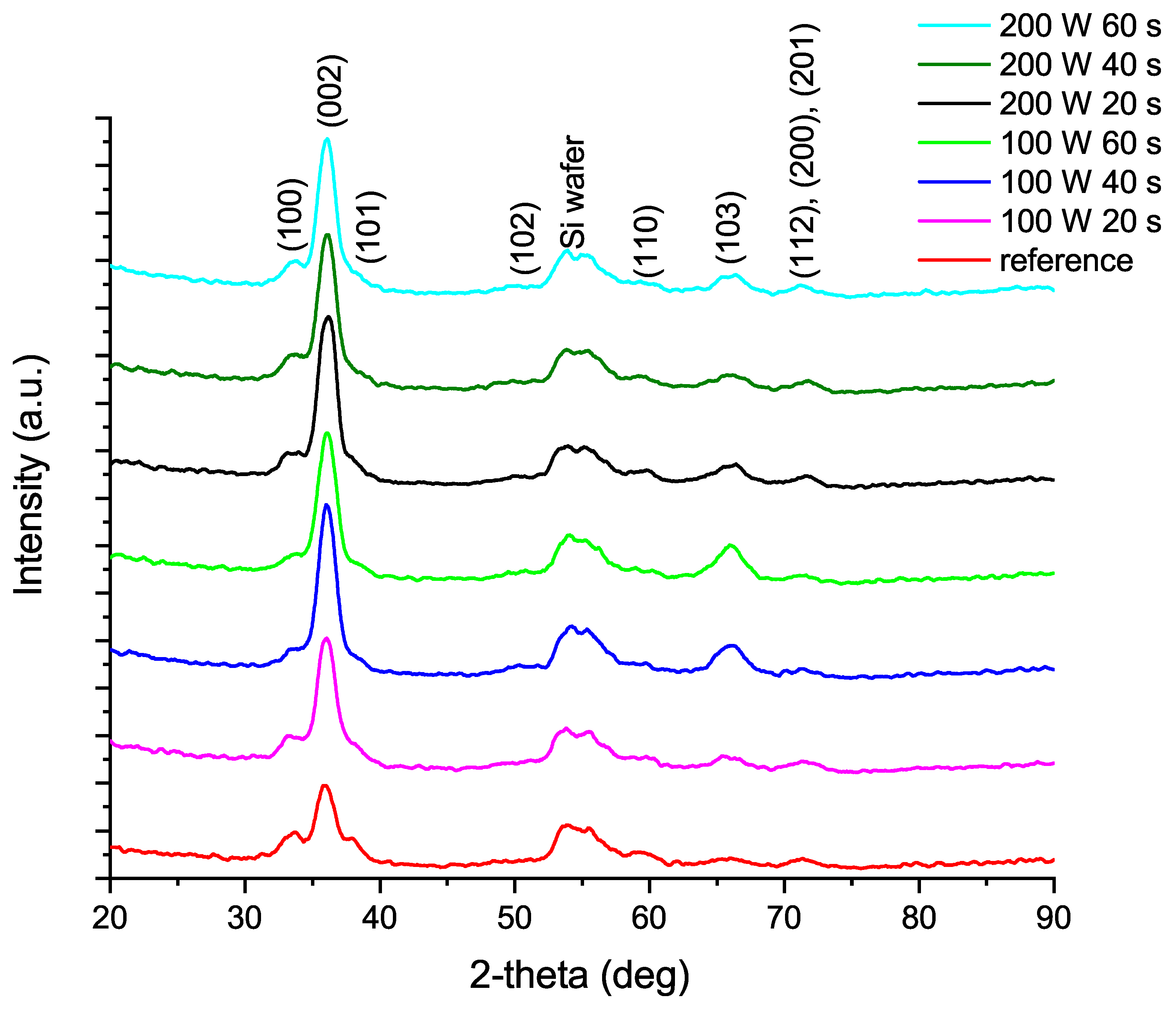

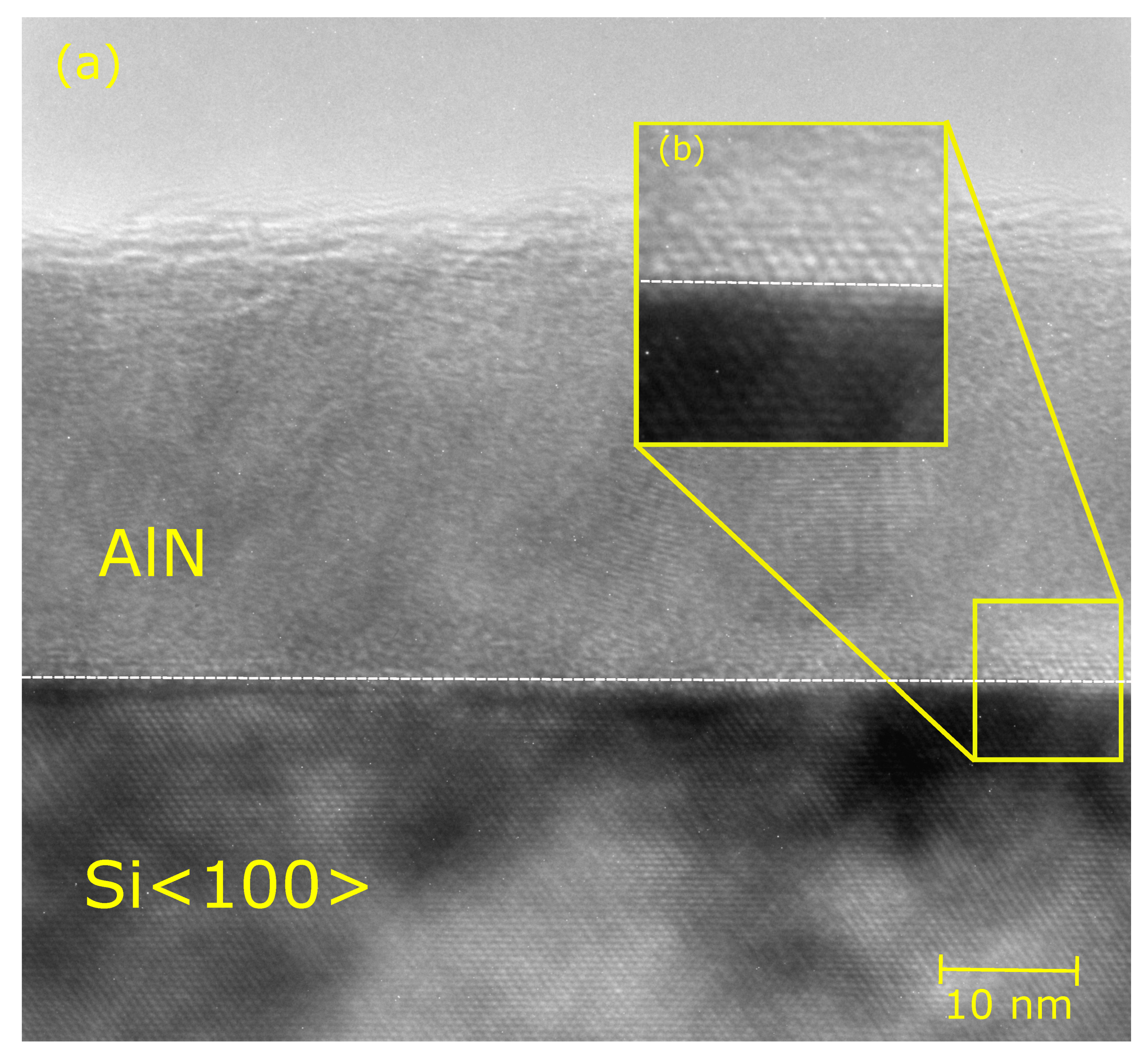

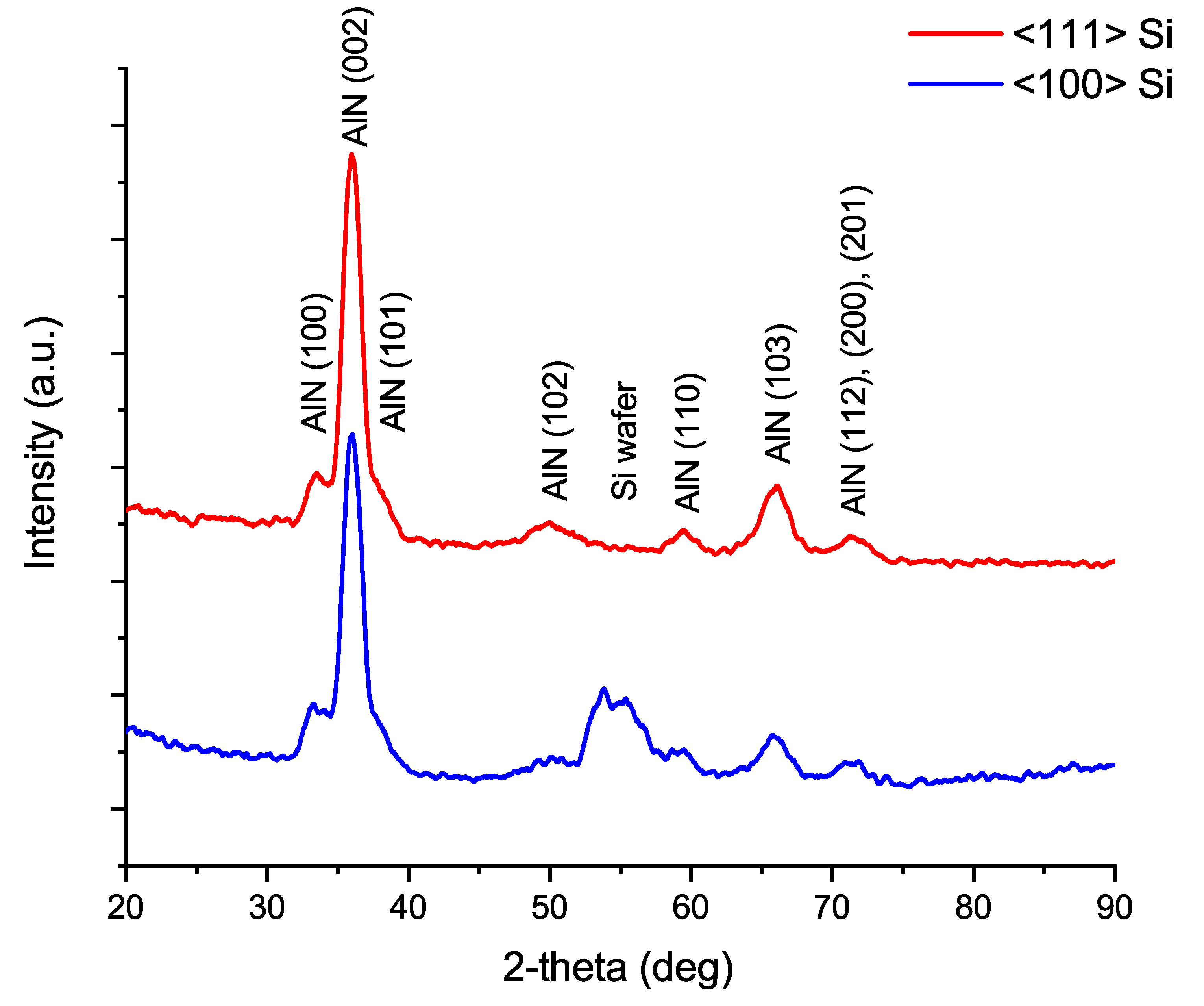

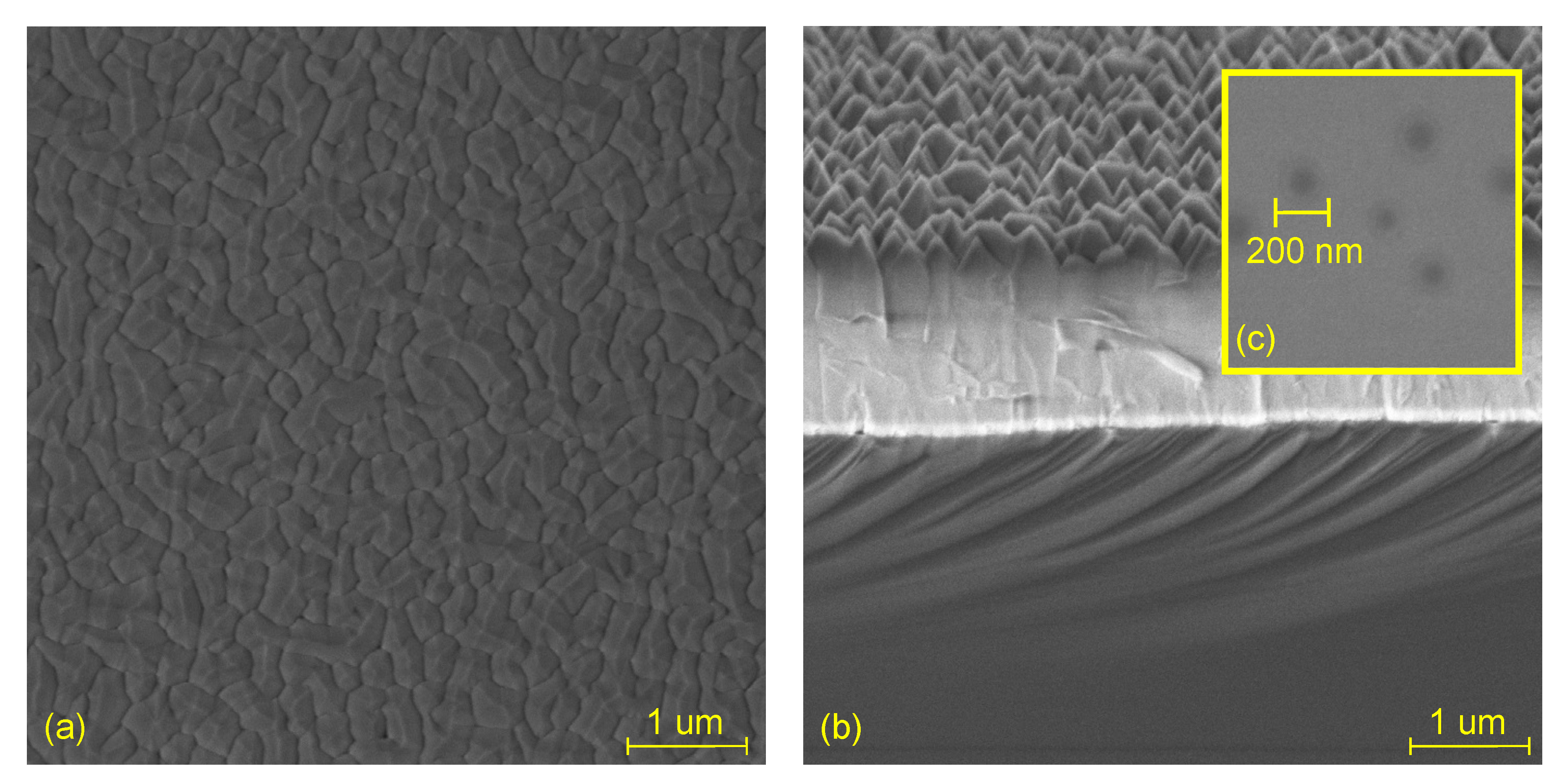

2. Results and Discussion

3. Conclusions

4. Materials and Methods

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- George, T.; Son, K.A.; Powers, R.A.; Del Castillo, L.Y.; Okojie, R. Harsh environment microtechnologies for NASA and terrestrial applications. Proc. IEEE Sens. 2005, 2005, 1253–1258. [Google Scholar] [CrossRef]

- Millan, J.; Godignon, P.; Perpina, X.; Perez-Tomas, A.; Rebollo, J. A Survey of Wide Bandgap Power Semiconductor Devices. IEEE Trans. Power Electron. 2014, 29, 2155–2163. [Google Scholar] [CrossRef]

- Paskova, T.; Hanser, D.A.; Evans, K.R. GaN Substrates for III-Nitride Devices. Proc. IEEE 2010, 98, 1324–1338. [Google Scholar] [CrossRef]

- Baliga, B.J. Gallium nitride devices for power electronic applications. Semicond. Sci. Technol. 2013, 28, 074011. [Google Scholar] [CrossRef]

- Ambacher, O. Growth and applications of Group III-nitrides. J. Phys. D Appl. Phys. 1998, 31, 2653–2710. [Google Scholar] [CrossRef]

- Thompson, A.G. MOCVD technology for semiconductors. Mater. Lett. 1997, 30, 255–263. [Google Scholar] [CrossRef]

- Zhu, D.; Wallis, D.J.; Humphreys, C.J. Prospects of III-nitride optoelectronics grown on Si. Rep. Prog. Phys. 2013, 76, 106501. [Google Scholar] [CrossRef] [PubMed]

- Figge, S.; Kröncke, H.; Hommel, D.; Epelbaum, B.M. Temperature dependence of the thermal expansion of AlN. Appl. Phys. Lett. 2009, 94, 101915. [Google Scholar] [CrossRef]

- Kadir, A.; Srivastava, S.; Li, Z.; Lee, K.E.K.; Sasangka, W.A.; Gradecak, S.; Chua, S.J.; Fitzgerald, E.A. Influence of substrate nitridation on the threading dislocation density of GaN grown on 200 mm Si (111) substrate. Thin Solid Films 2018, 663, 73–78. [Google Scholar] [CrossRef]

- Lemettinen, J.; Kauppinen, C.; Rudzinski, M.; Haapalinna, A.; Tuomi, T.O.; Suihkonen, S. MOVPE growth of GaN on 6-inch SOI-substrates: Effect of substrate parameters on layer quality and strain. Semicond. Sci. Technol. 2017, 32. [Google Scholar] [CrossRef]

- Zolotukhin, D.; Nechaev, D.; Kuznetsova, N.; Ratnikov, V.; Rouvimov, S.; Jmerik, V.; Ivanov, S. Control of stress and threading dislocation density in the thick GaN/AlN buffer layers grown on Si (111) substrates by low- temperature MBE. J. Phys. Conf. Ser. 2016, 741, 012025. [Google Scholar] [CrossRef]

- Amano, H.; Sawaki, N.; Akasaki, I.; Toyoda, Y. Metalorganic vapor phase epitaxial growth of a high quality GaN film using an AlN buffer layer. Appl. Phys. Lett. 1986, 48, 353–355. [Google Scholar] [CrossRef]

- Lang, T.; Odnoblyudov, M.; Bougrov, V.; Suihkonen, S.; Sopanen, M.; Lipsanen, H. Morphology optimization of MOCVD-grown GaN nucleation layers by the multistep technique. J. Cryst. Growth 2006, 292, 26–32. [Google Scholar] [CrossRef]

- Lang, T.; Odnoblyudov, M.A.; Bougrov, V.E.; Suihkonen, S.; Svensk, O.; Törmä, P.T.; Sopanen, M.; Lipsanen, H. Reduction of threading dislocation density in Al0.12Ga0.88N epilayers by a multistep technique. J. Cryst. Growth 2007, 298, 276–280. [Google Scholar] [CrossRef]

- Yang, Y.; Xiang, P.; Liu, M.; Chen, W.; He, Z.; Han, X.; Ni, Y.; Yang, F.; Yao, Y.; Wu, Z.; et al. Effect of compositionally graded AlGaN buffer layer grown by different functions of trimethylaluminum flow rates on the properties of GaN on Si (111) substrates. J. Cryst. Growth 2013, 376, 23–27. [Google Scholar] [CrossRef]

- Lemettinen, J.; Okumura, H.; Kim, I.; Rudzinski, M.; Grzonka, J.; Palacios, T.; Suihkonen, S. MOVPE growth of nitrogen- and aluminum-polar AlN on 4H-SiC. J. Cryst. Growth 2018, 487, 50–56. [Google Scholar] [CrossRef]

- Pan, L.; Dong, X.; Li, Z.; Luo, W.; Ni, J. Influence of the AlN nucleation layer on the properties of AlGaN/GaN heterostructure on Si (1 1 1) substrates. Appl. Surf. Sci. 2018, 447, 512–517. [Google Scholar] [CrossRef]

- Le Louarn, A.; Vézian, S.; Semond, F.; Massies, J. AlN buffer layer growth for GaN epitaxy on (111) Si: Al or N first? J. Cryst. Growth 2009, 311, 3278–3284. [Google Scholar] [CrossRef]

- Davis, R.; Einfeldt, S.; Preble, E.; Roskowski, A.; Reitmeier, Z.; Miraglia, P. Gallium nitride and related materials: Challenges in materials processing. Acta Mater. 2003, 51, 5961–5979. [Google Scholar] [CrossRef]

- Liu, X.; Ramanathan, S.; Lee, E.; Seidel, T.E. Atomic Layer Deposition of Aluminum Nitride Thin films from Trimethyl Aluminum (TMA) and Ammonia. MRS Proc. 2004, 811. [Google Scholar] [CrossRef]

- Bosund, M.; Sajavaara, T.; Laitinen, M.; Huhtio, T.; Putkonen, M.; Airaksinen, V.M.; Lipsanen, H. Properties of AlN grown by plasma enhanced atomic layer deposition. Appl. Surf. Sci. 2011, 257, 7827–7830. [Google Scholar] [CrossRef]

- Shih, H.Y.; Lee, W.H.; Kao, W.C.; Chuang, Y.C.; Lin, R.M.; Lin, H.C.; Shiojiri, M.; Chen, M.J. Low-temperature atomic layer epitaxy of AlN ultrathin films by layer-by-layer, in-situ atomic layer annealing. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Rontu, V.; Sippola, P.; Broas, M.; Ross, G.; Sajavaara, T.; Lipsanen, H.; Paulasto-Kröckel, M.; Franssila, S. Atomic layer deposition of AlN from AlCl3 using NH3 and Ar/NH3 plasma. J. Vacuum Sci. Technol. A 2018, 36, 021508. [Google Scholar] [CrossRef]

- Liu, S.; Peng, M.; Hou, C.; He, Y.; Li, M.; Zheng, X. PEALD-Grown Crystalline AlN Films on Si (100) with Sharp Interface and Good Uniformity. Nanoscale Res. Lett. 2017, 12, 279. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.H.; Wu, H.S.; Zhang, C.J.; Jin, Z.H. Morphological properties of AlN piezoelectric thin films deposited by DC reactive magnetron sputtering. Thin Solid Films 2001, 388, 62–67. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, H.; Chen, Y.Z.; Uddin, A.; Yuan, S.; Geng, S.J.; Zhang, S. Growth of AlN films on Si (100) and Si (111) substrates by reactive magnetron sputtering. Surf. Coat. Technol. 2005, 198, 68–73. [Google Scholar] [CrossRef]

- Slack, G. Nonmetallic crystals with high thermal conductivity. Surf. Coat. Technol. 1973, 34, 321–335. [Google Scholar] [CrossRef]

- Windover, D.; Gil, D.L.; Azuma, Y.; Fujimoto, T. Determining sample alignment in X-ray reflectometry using thickness and density from GaAs/AlAs multilayer certified reference materials. Meas. Sci. Technol. 2014, 25, 105007. [Google Scholar] [CrossRef]

- Broas, M.; Jiang, H.; Graff, A.; Sajavaara, T.; Vuorinen, V.; Paulasto-Kröckel, M. Blistering mechanisms of atomic-layer-deposited AlN and Al2O3 films. Appl. Phys. Lett. 2017, 111. [Google Scholar] [CrossRef]

| Sample | Thickness (nm) | Density (g/cm) | Roughness (nm) |

|---|---|---|---|

| 100 W 20 s | 28.3 | 3.0 | 1.5 |

| 100 W 40 s | 28.3 | 3.0 | 1.5 |

| 100 W 60 s | 26.6 | 3.0 | 1.3 |

| 200 W 20 s | 28.8 | 3.1 | 1.5 |

| 200 W 40 s | 28.6 | 3.1 | 1.6 |

| 200 W 60 s | 27.8 | 3.0 | 1.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seppänen, H.; Kim, I.; Etula, J.; Ubyivovk, E.; Bouravleuv, A.; Lipsanen, H. Aluminum Nitride Transition Layer for Power Electronics Applications Grown by Plasma-Enhanced Atomic Layer Deposition. Materials 2019, 12, 406. https://doi.org/10.3390/ma12030406

Seppänen H, Kim I, Etula J, Ubyivovk E, Bouravleuv A, Lipsanen H. Aluminum Nitride Transition Layer for Power Electronics Applications Grown by Plasma-Enhanced Atomic Layer Deposition. Materials. 2019; 12(3):406. https://doi.org/10.3390/ma12030406

Chicago/Turabian StyleSeppänen, Heli, Iurii Kim, Jarkko Etula, Evgeniy Ubyivovk, Alexei Bouravleuv, and Harri Lipsanen. 2019. "Aluminum Nitride Transition Layer for Power Electronics Applications Grown by Plasma-Enhanced Atomic Layer Deposition" Materials 12, no. 3: 406. https://doi.org/10.3390/ma12030406

APA StyleSeppänen, H., Kim, I., Etula, J., Ubyivovk, E., Bouravleuv, A., & Lipsanen, H. (2019). Aluminum Nitride Transition Layer for Power Electronics Applications Grown by Plasma-Enhanced Atomic Layer Deposition. Materials, 12(3), 406. https://doi.org/10.3390/ma12030406