Conjugate Study on Thermal–Hydraulic Performance of Topology-Optimized Lattice-Filled Cooling Channel for Thermal Management of Solid-Oxide Fuel Cells

Abstract

1. Introduction

2. Methodology

2.1. Numerical Models

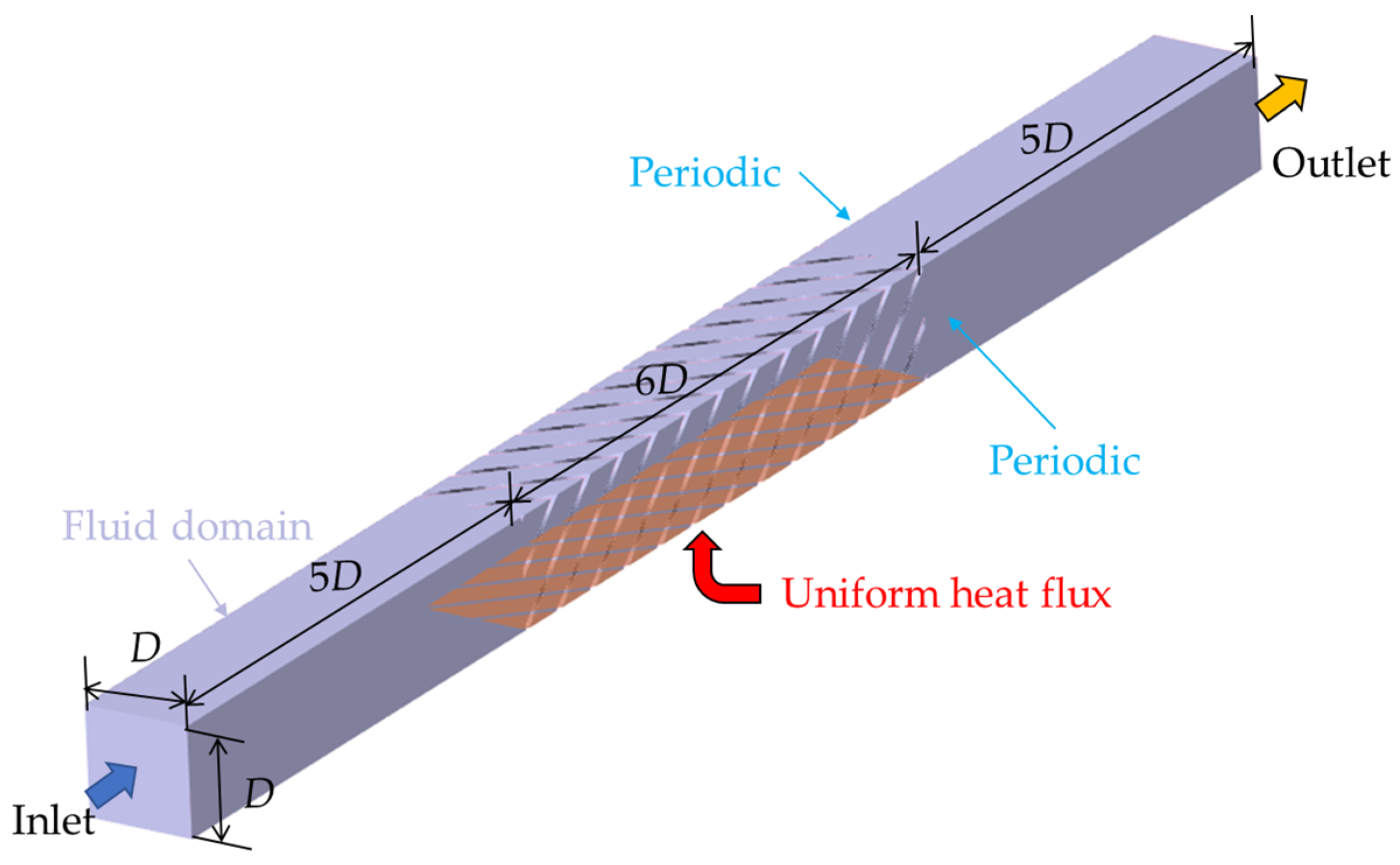

2.2. Computational Domain and Boundary Conditions

2.3. Parameter Definition

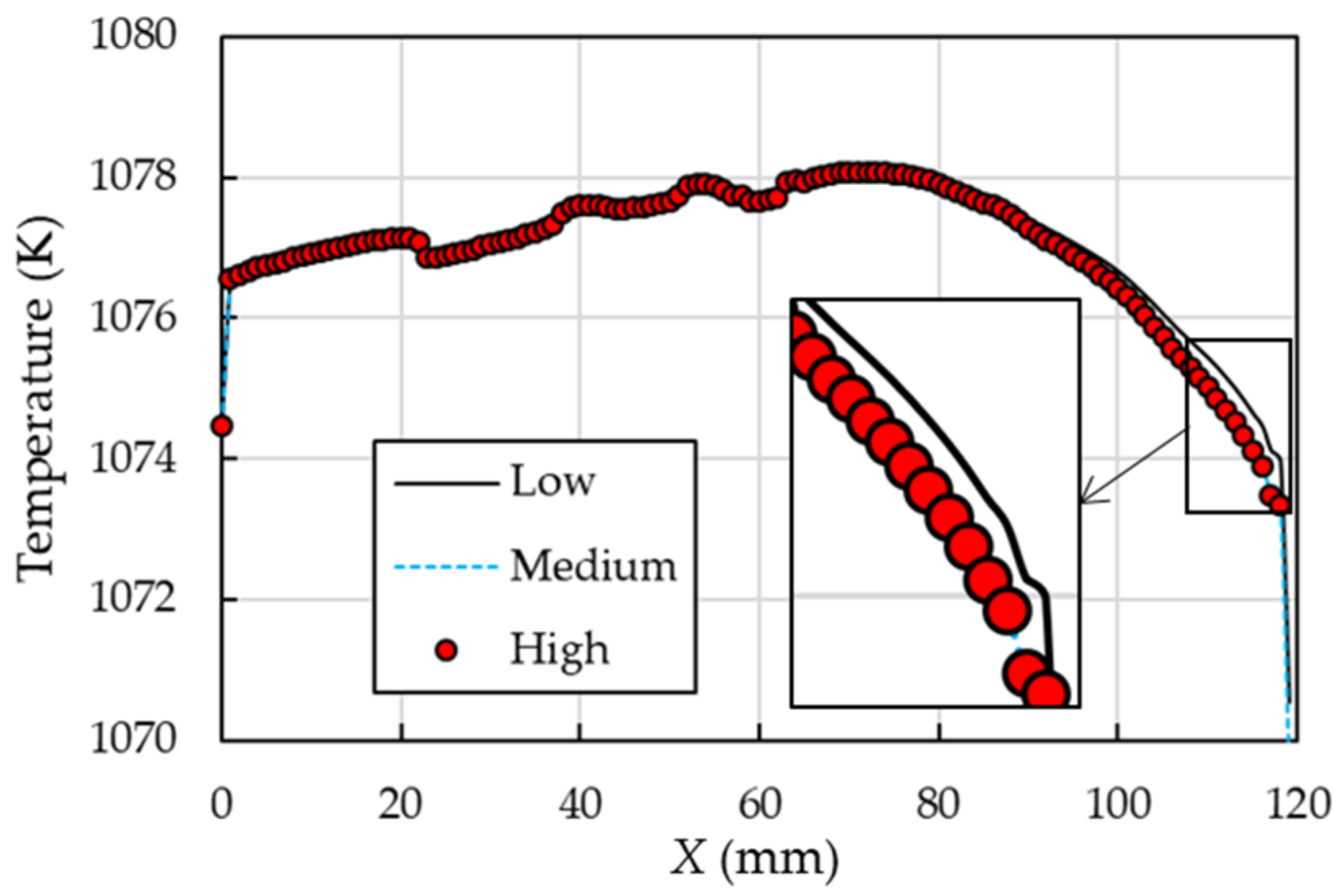

2.4. Mesh Independence Check and Numerical Scheme

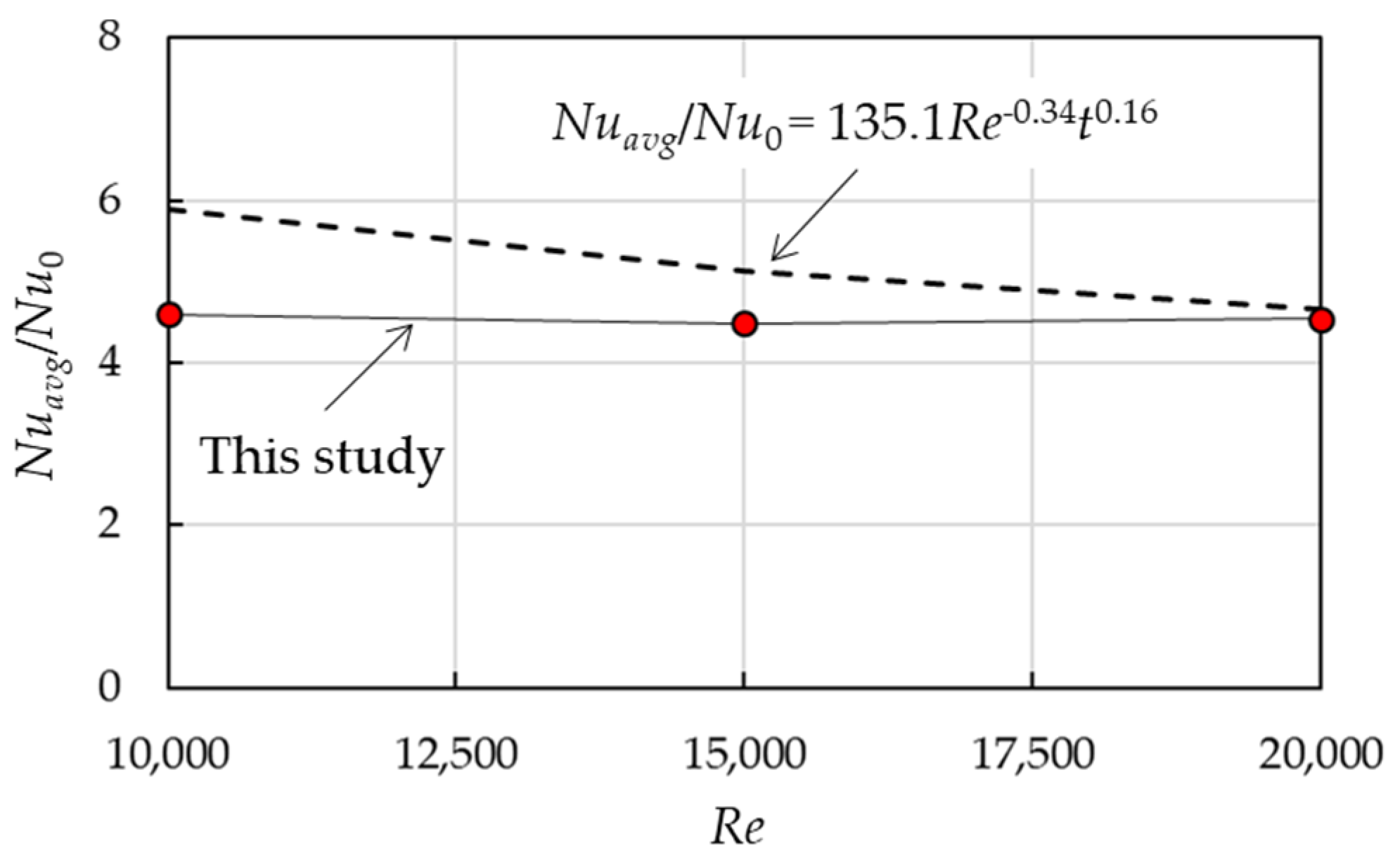

2.5. Validation

3. Results and Discussion

3.1. Influences of Coolant Flow Rate

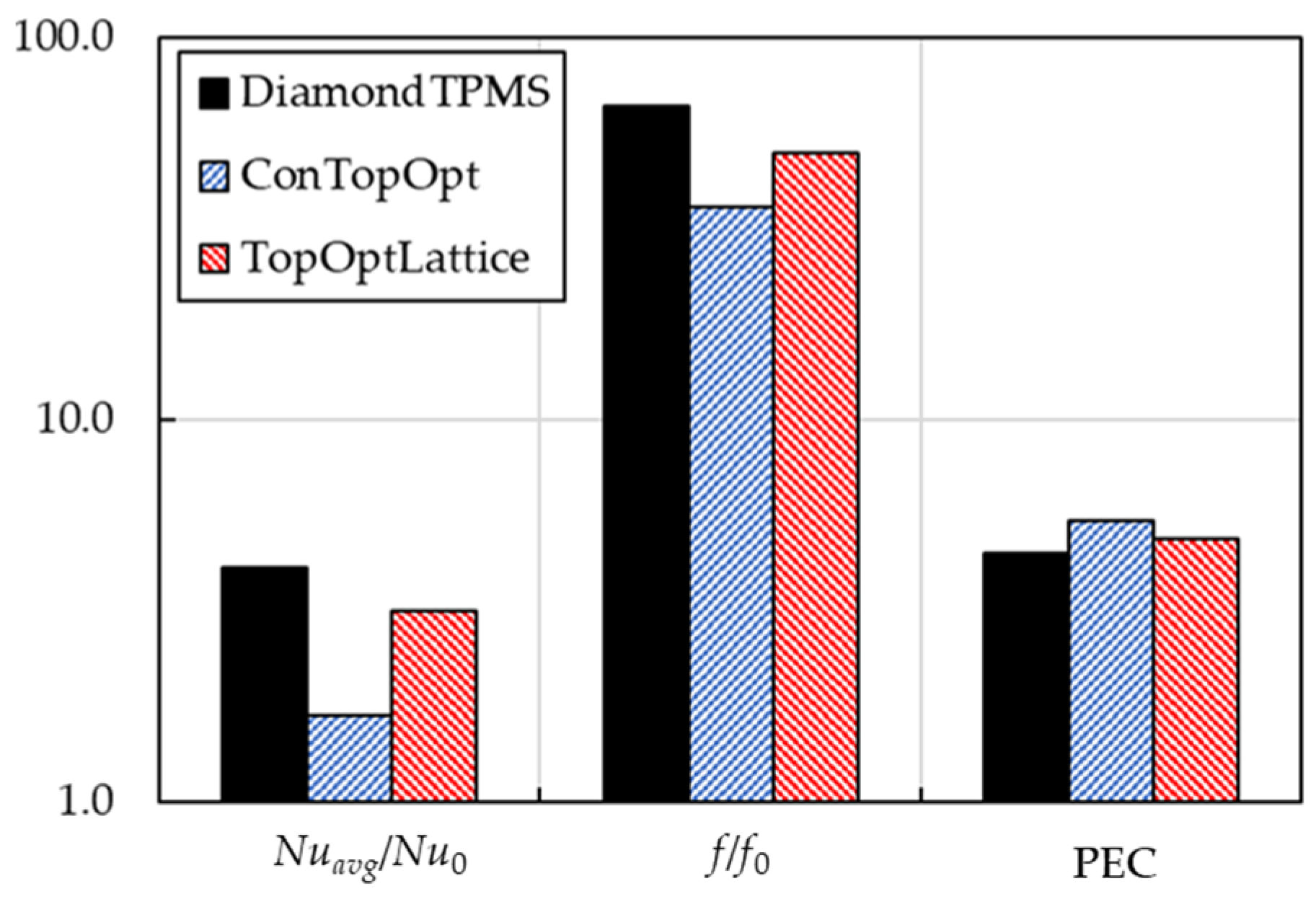

3.1.1. Thermal–Hydraulic Performance

3.1.2. Flow Characteristics

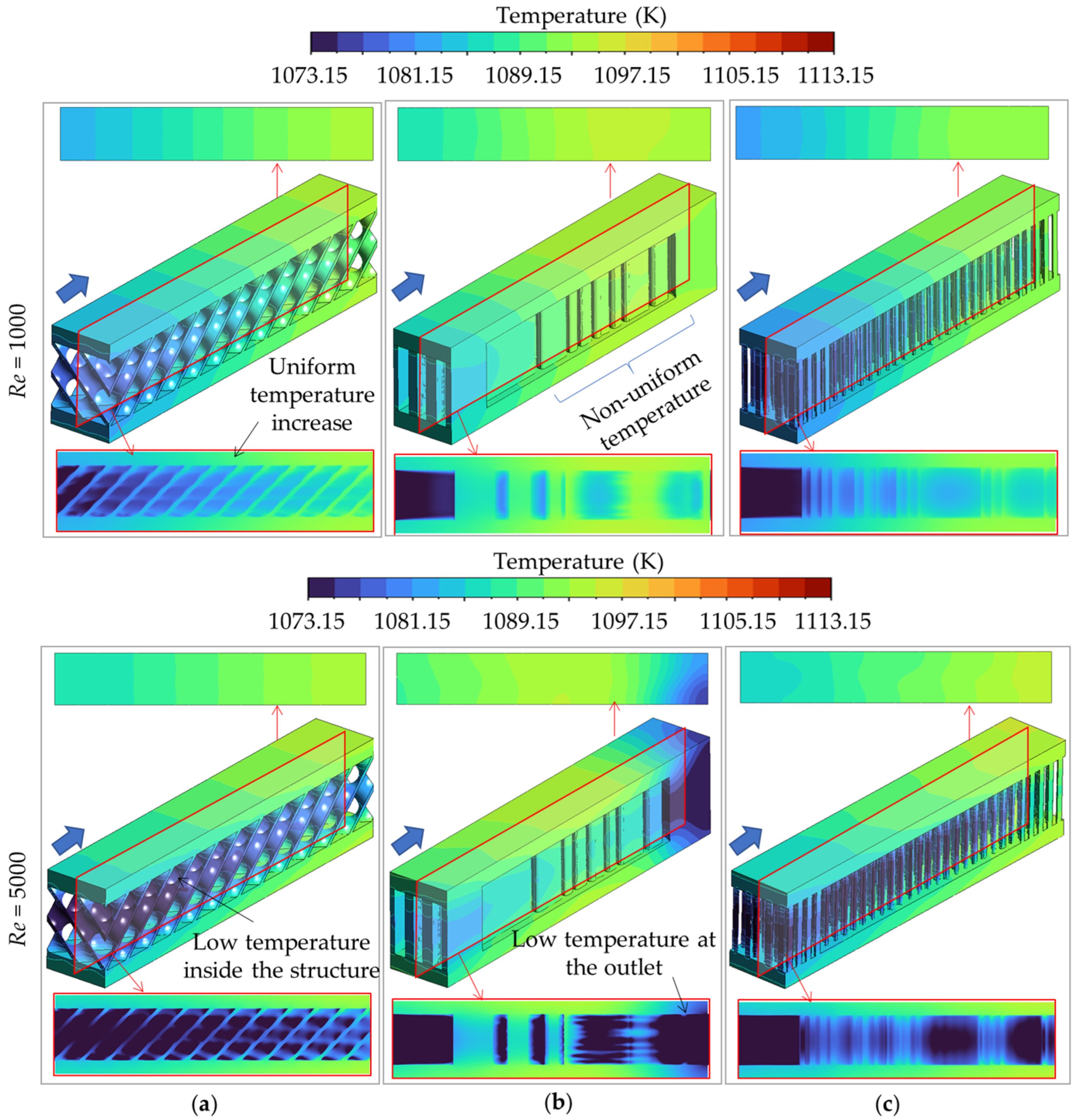

3.1.3. Heat Transfer Distributions

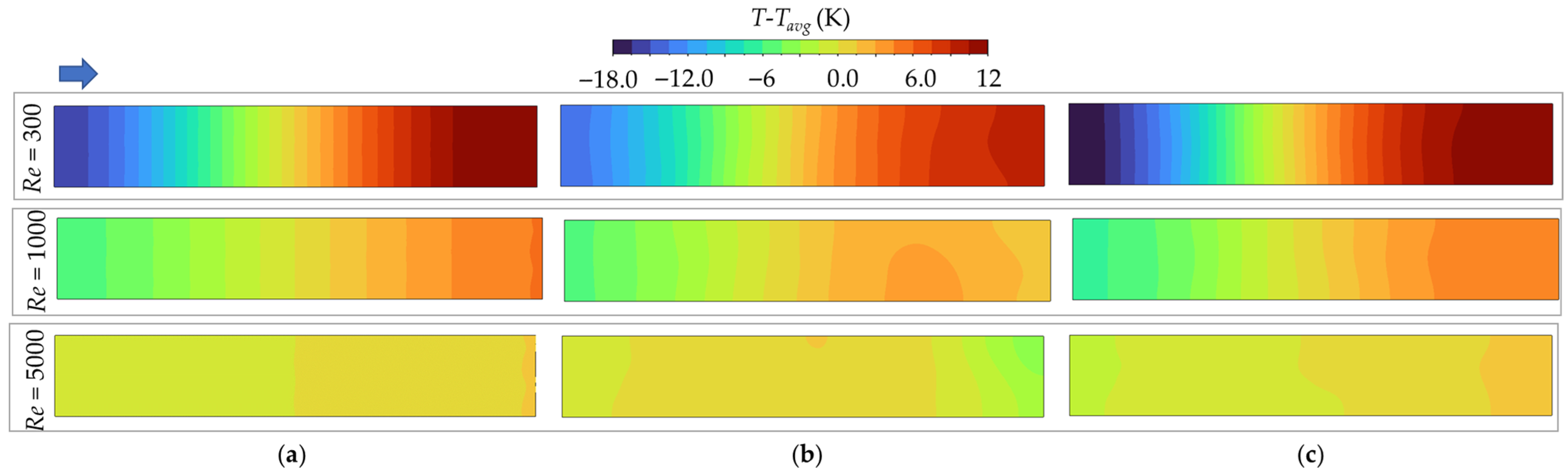

3.1.4. Temperature Uniformity

3.2. Effect of Coolant Type

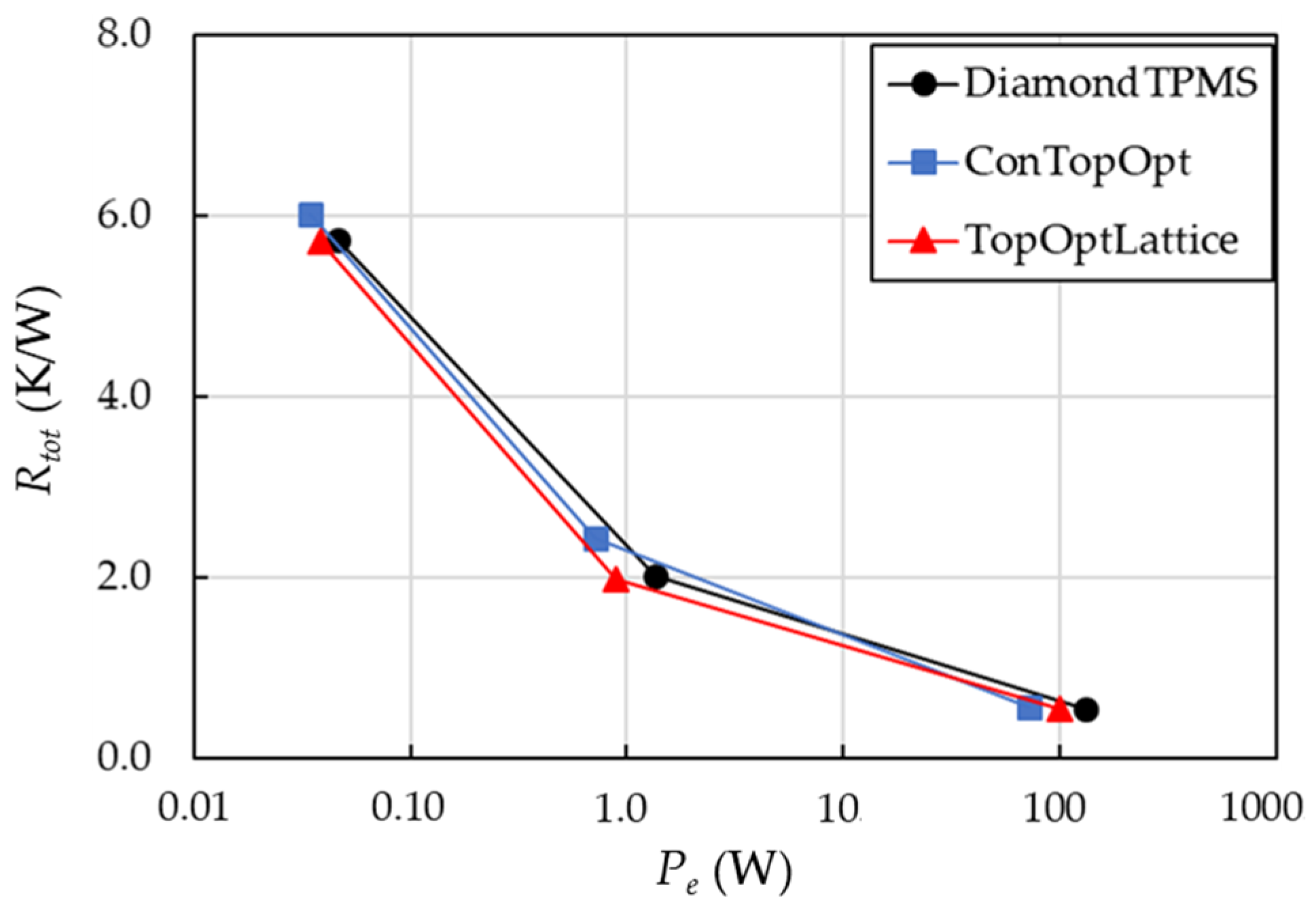

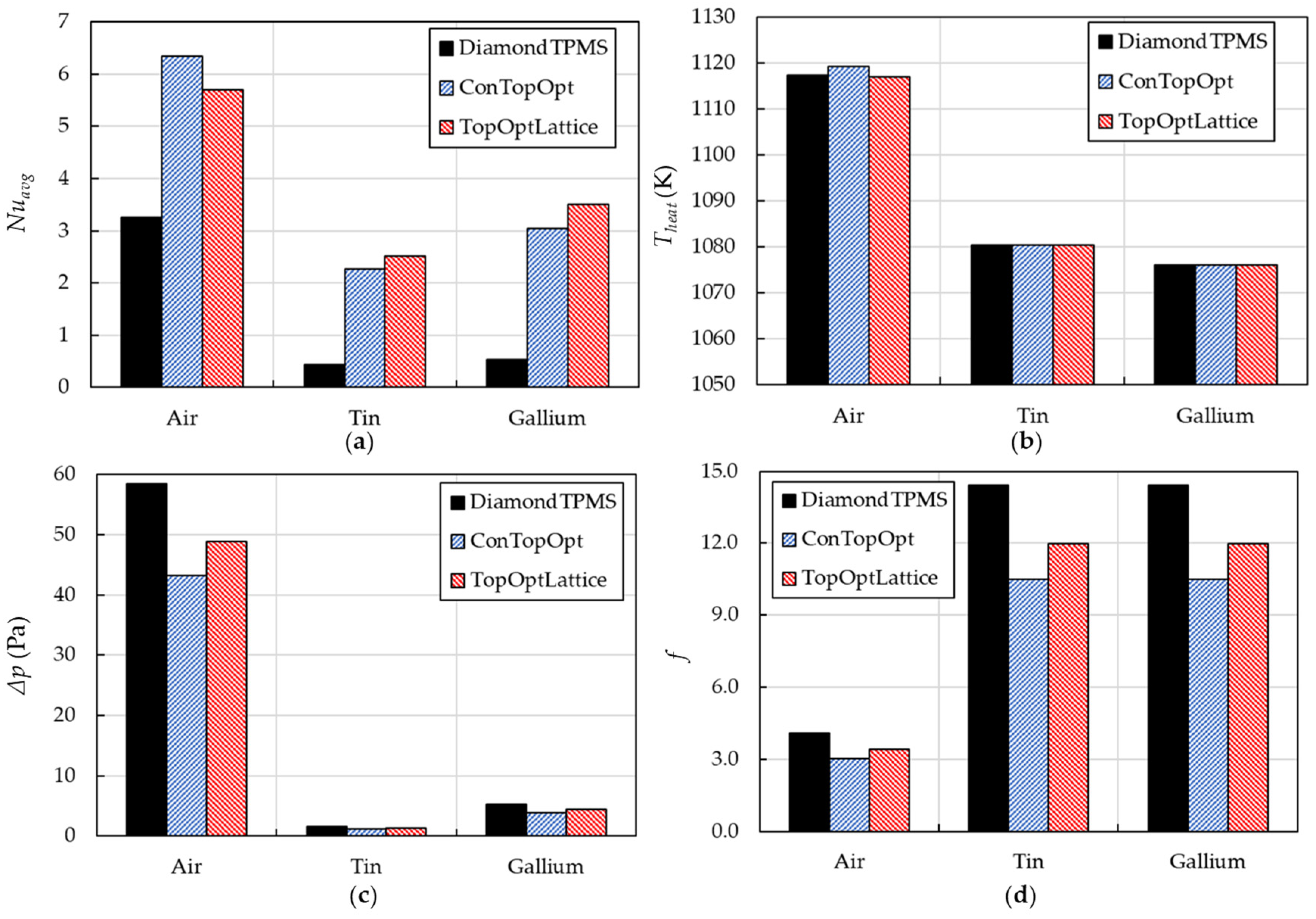

3.2.1. Thermal–Hydraulic Performance

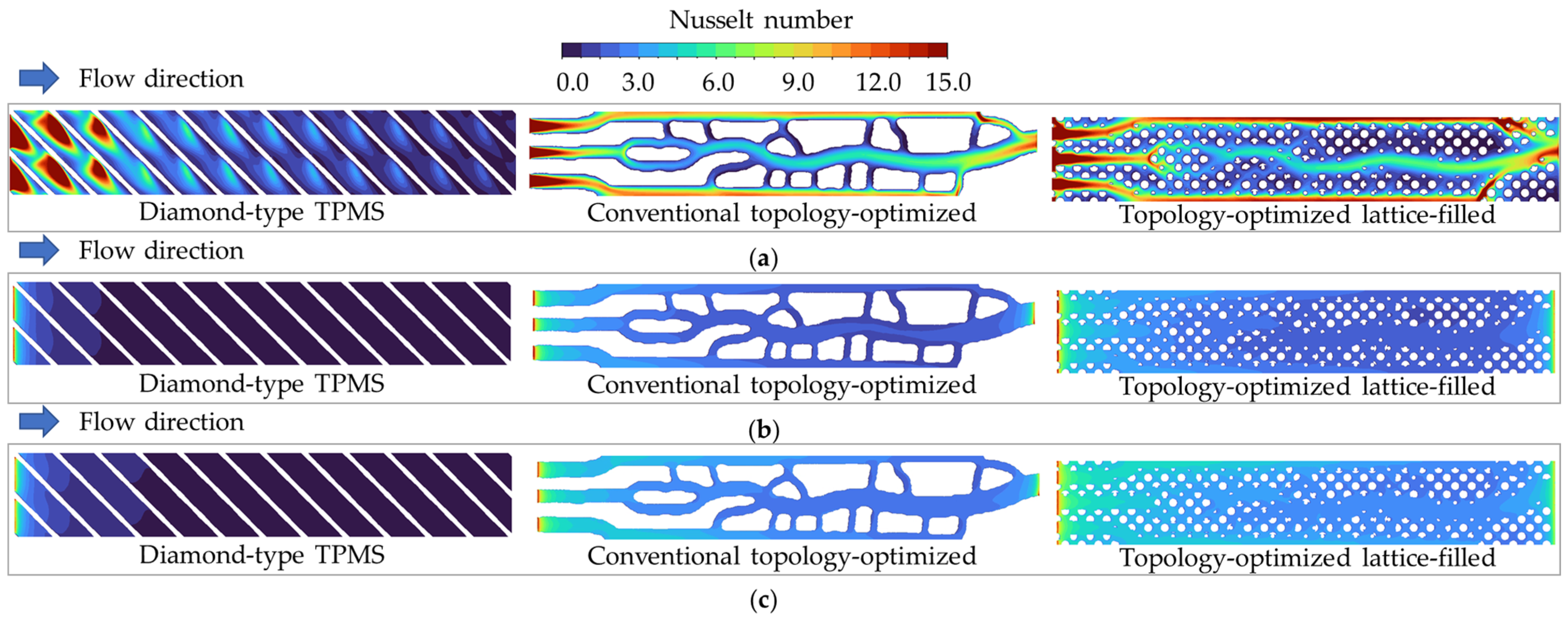

3.2.2. Heat Transfer Distributions

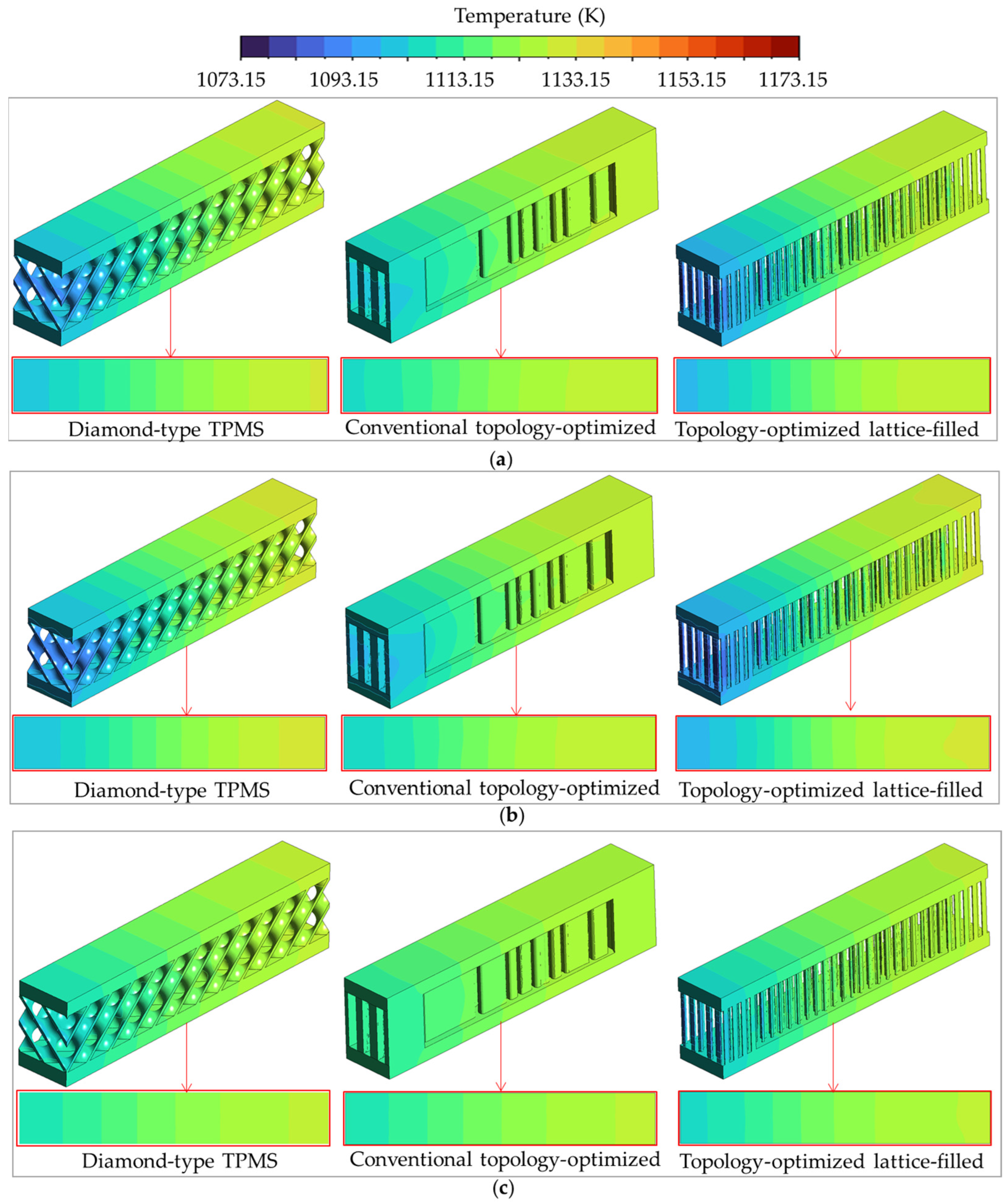

3.2.3. Temperature Uniformity

3.3. Effect of Structural Material

3.3.1. Heat Transfer Performance

3.3.2. Heat Transfer Distributions

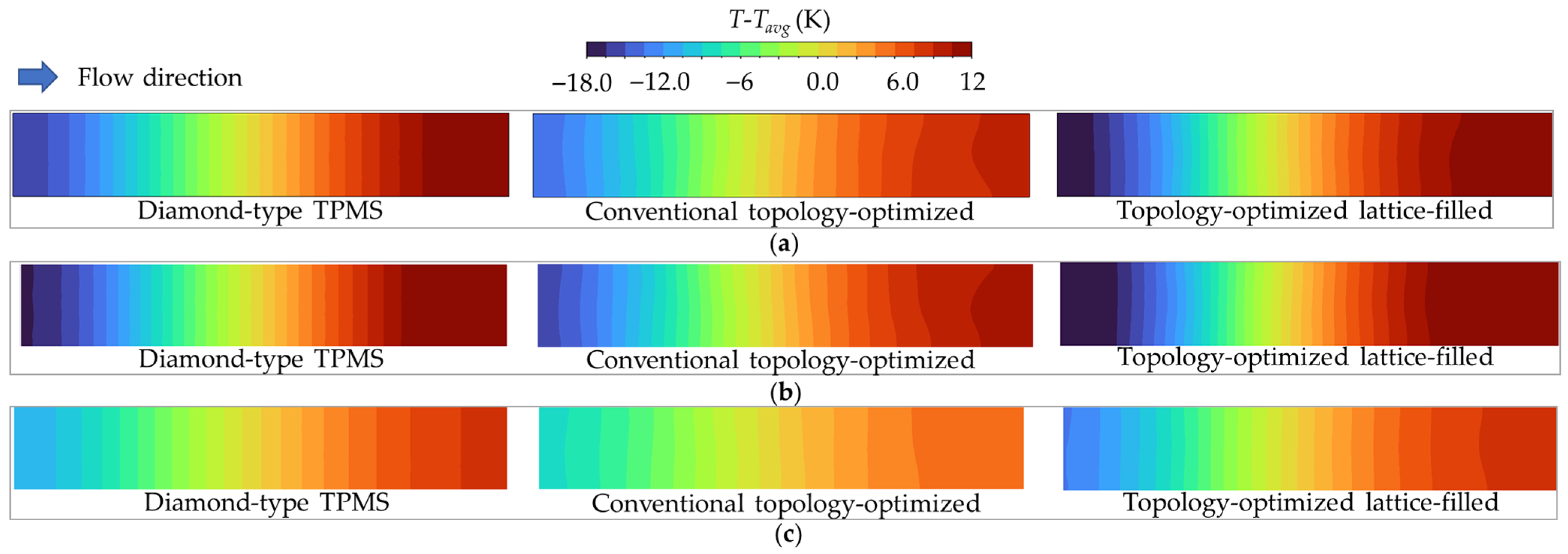

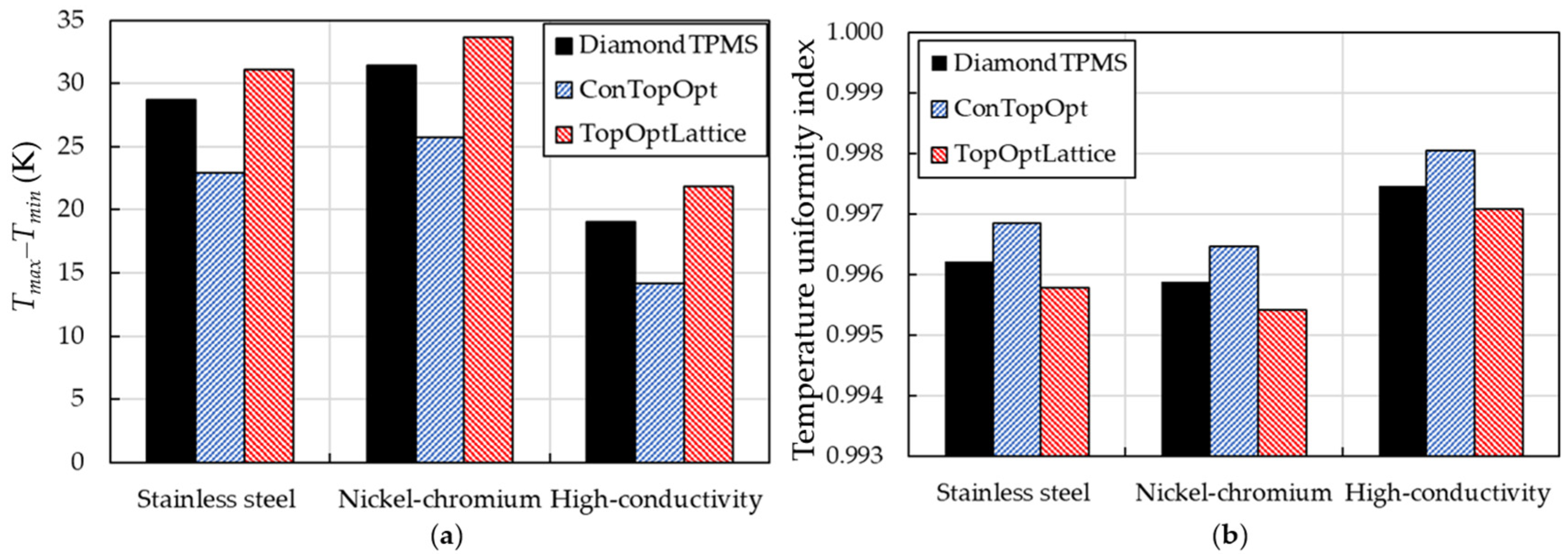

3.3.3. Temperature Uniformity

4. Conclusions

- (1)

- The Diamond TPMS structure provides excellent flow and heat transfer distribution, but causes a significant pressure penalty of 45.6% and 24.6% at Re = 5000, compared to the conventional topology-optimized and lattice-filled designs. The conventional optimized model minimizes pressure loss but can lead to non-uniform flow and temperature distributions at high flow rates. The topology-optimized lattice-filled structure emerges as an excellent compromise, especially at high Re. By combining the tailored flow paths from topology optimization with the high surface area of a lattice-filled array, this design in the air-cooled system achieves temperature uniformity comparable to that of the Diamond TPMS at Re = 5000, while incurring a significant reduction in pressure loss penalty.

- (2)

- While both topology-optimized designs can improve convective heat transfer, the choice of coolant is found to be the highest dominant factor, governing the thermal–hydraulic performance. The transition coolants from air to liquid metals resulted in a significant reduction in thermal resistance, up to 93%, and a relatively high temperature uniformity index at Re = 300. The liquid gallium, with its superior thermal conductivity, outperformed liquid tin, achieving the most uniform temperature distributions on the heated wall, where the differences between the maximum and minimum temperatures (Tmax–Tmin) are less than 5 K in both topology-optimized designs. However, the excellent cooling performance of liquid metals might come with a higher cost and greater engineering challenges.

- (3)

- A higher thermal conductivity material improves heat spreading within the solid structure, creating a more uniform temperature in all geometries. Under low coolant flow rates and air-cooled conditions, the baffle-like structures in the conventional topology-optimized model exhibit preferable thermal–hydraulic performance, facilitating a smooth flow field, and achieve the lowest temperature range (Tmax–Tmin) of 16 K at Re = 300.

- (4)

- For maximum performance, employing a liquid metal coolant within the optimized-baffle design channel is highly recommended for the precise thermal management of the SOFC. This configuration leverages their balanced thermal–hydraulic performance and the high thermal conductivity of the liquid metals. Additionally, fabricating the channel with a high thermal conductivity material for a conventional topology-optimized design further achieves better temperature uniformity while minimizing parasitic power.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Ai | Local area (m2) |

| Ain | Inlet area of the cooling channel (m) |

| D | Characteristic length (m) |

| Dh | Hydraulic diameter of the cooling channel (m), defined in Equation (2) |

| Dp | Diameter of the circular pin-fin structure (m) |

| f | Friction factor, defined in Equation (6) |

| f0 | Blasius correlations, defined in Equation (10) |

| h | Heat transfer coefficient (W/(m2∙K), defined in Equation (4) |

| Tb | Bulk flow temperature (K) |

| Theat | Temperature of the heated wall (K) |

| Tin, Tout | Inlet and outlet coolant temperatures (K) |

| Ti | Local temperature (K) |

| Tmax, Tmin | Maximum and minimum temperature on the heated wall (K) |

| Tw | Endwall temperature(K) |

| L | Length of the cooling structure (m) |

| Lp | Wetted perimeter (m) |

| Nu | Nusselt number, defined in Equation (3) |

| Nuavg | Area-averaged Nusselt number |

| Nu0 | Dittus-Boelter equation, defined in Equation (9) |

| q | Wall heat flux (W/m2) |

| k | Thermal conductivity of the fluid (W/m·K) |

| Pe | Pumping power (W), defined in Equation (7) |

| pin | Coolant inlet pressure (Pa) |

| Re | Reynolds number, defined in Equation (1) |

| Rtot | Total thermal resistance (K/W), defined in Equation (5) |

| Sv | Specific area surface (m2/m3) |

| Vin | Velocity at the inlet (m/s) |

| X, Y, Z | Cartesian coordinate |

| Greek letter | |

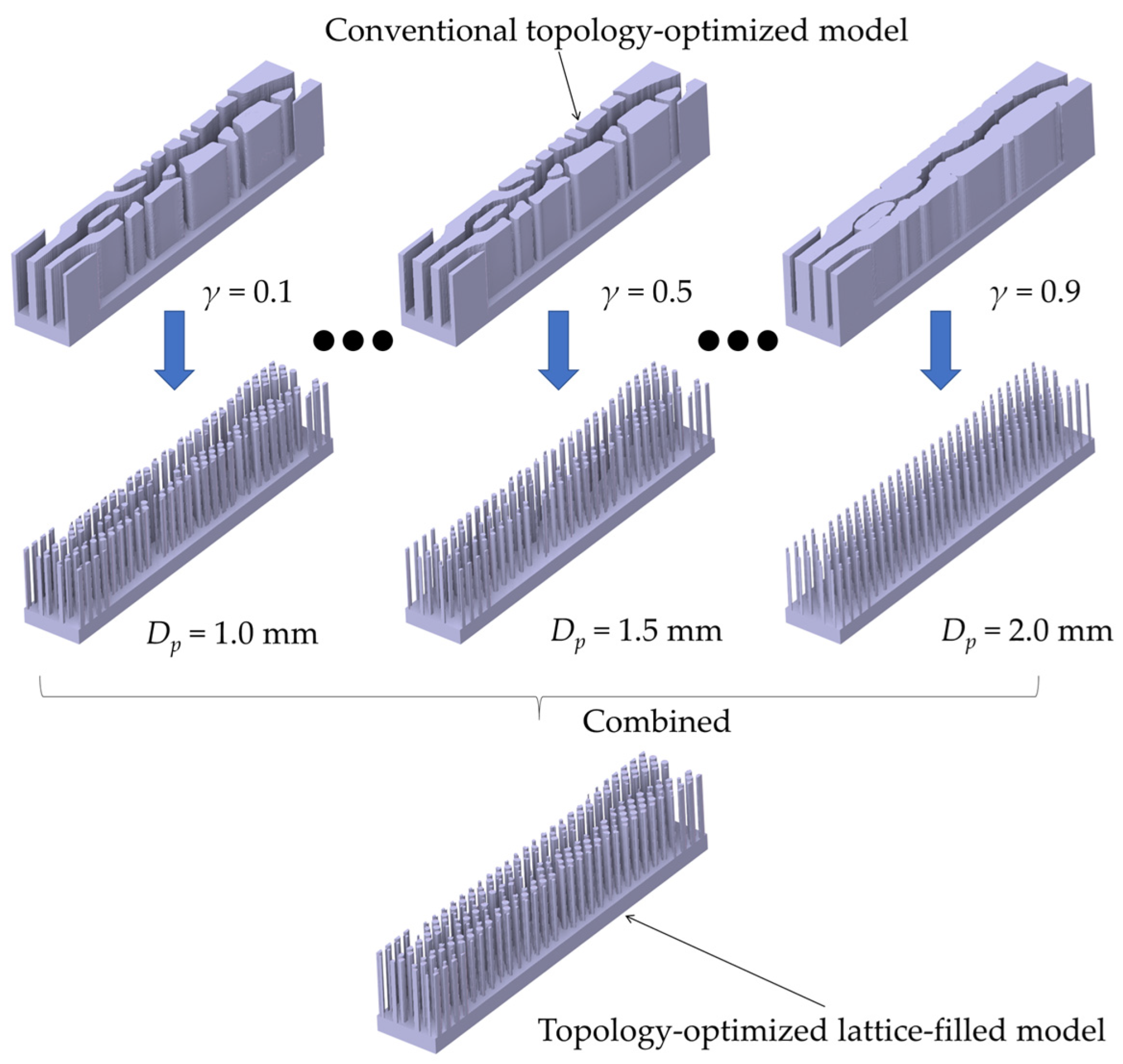

| γ | Density field in the topology optimization |

| μ | Dynamic viscosity of the coolant (Pa∙s) |

| ρ | Density of the coolant (kg/m3) |

| ∆p | Different pressure between the inlet and outlet boundaries (Pa) |

| Гin | Inlet boundary |

| ψ | Porosity (%) |

| Abbreviations | |

| CHT | Conjugate heat transfer |

| PEC | Performance evaluation criterion, defined in Equation (8) |

| PEMFCs | Proton-exchange membrane fuel cells |

| PEN | Positive electrode-electrolyte-negative electrode |

| TLC | Transient liquid crystal thermography |

| TPMS | Triply periodic minimal surface |

| TUI | Temperature uniformity index, defined in Equation (11) |

| SOFC | Solid-oxide fuel cell |

Appendix A

| Geometry | Diamond TPMS Model | Conventional Topology-Optimized Model | Topology-Optimized Lattice-Filled Model |

|---|---|---|---|

| Hydraulic diameter (mm) | 6.65 | 5.55 | 5.3 |

References

- Lin, C.; Kerscher, F.; Spliethoff, H. Thermal Gradient Management in Solid Oxide Fuel Cells: Mechanisms, Strategies, and Future Directions. J. Power Sources 2025, 656, 238017. [Google Scholar] [CrossRef]

- Veza, I. Fuel-Cell Thermal Management Strategies for Enhanced Performance: Review of Fuel-Cell Thermal Management in Proton-Exchange Membrane Fuel Cells (PEMFCs) and Solid-Oxide Fuel Cells (SOFCs). Hydrogen 2025, 6, 65. [Google Scholar] [CrossRef]

- Zeng, Z.; Qian, Y.; Zhang, Y.; Hao, C.; Dan, D.; Zhuge, W. A Review of Heat Transfer and Thermal Management Methods for Temperature Gradient Reduction in Solid Oxide Fuel Cell (SOFC) Stacks. Appl. Energy 2020, 280, 115899. [Google Scholar] [CrossRef]

- Aguiar, P.; Adjiman, C.S.; Brandon, N.P. Anode-Supported Intermediate-Temperature Direct Internal Reforming Solid Oxide Fuel Cell: II. Model-Based Dynamic Performance and Control. J. Power Sources 2005, 147, 136–147. [Google Scholar] [CrossRef]

- Manglik, R.M.; Magar, Y.N. Heat and Mass Transfer in Planar Anode-Supported Solid Oxide Fuel Cells: Effects of Interconnect Fuel/Oxidant Channel Flow Cross Section. J. Therm. Sci. Eng. Appl. 2015, 7, 041003. [Google Scholar] [CrossRef]

- Gonçalves, J.F.; Sá, L.F.N.; Lopes, T.; Meneghini, J.R.; Silva, E.C.N. Design of Solid Oxide Fuel Cell (SOFC) Channel Layout Using the Topology Optimization Method with a Design Variable Propagation Approach. Struct. Multidiscip. Optim. 2024, 67, 216. [Google Scholar] [CrossRef]

- Ren, K.; Su, Y.; Zhong, Z.; Jiao, Z. Microstructure-Insight Topology Optimization for Efficient Interconnect Flow Channels in Solid Oxide Fuel Cells. Int. J. Heat Mass Transf. 2025, 242, 126823. [Google Scholar] [CrossRef]

- Lee, W.; Lang, M.; Costa, R.; Lee, I.S.; Lee, Y.S.; Hong, J. Enhancing Uniformity and Performance in Solid Oxide Fuel Cells with Double Symmetry Interconnect Design. Appl. Energy 2025, 381, 125178. [Google Scholar] [CrossRef]

- Gong, C.; Luo, X.; Tu, Z.; Chan, S.H. A Novel Flow Channel Design to Achieve High Temperature Homogenization in Solid Oxide Fuel Cell. Int. J. Hydrogen Energy 2024, 52, 442–453. [Google Scholar] [CrossRef]

- Dillig, M.; Plankenbühler, T.; Karl, J. Thermal Effects of Planar High Temperature Heat Pipes in Solid Oxide Cell Stacks Operated with Internal Methane Reforming. J. Power Sources 2018, 373, 139–149. [Google Scholar] [CrossRef]

- Dillig, M.; Meyer, T.; Karl, J. Integration of Planar Heat Pipes to Solid Oxide Cell Short Stacks. Fuel Cells 2015, 15, 742–748. [Google Scholar] [CrossRef]

- Dokmaingam, P.; Irvine, J.T.S.; Assabumrungrat, S.; Charojrochkul, S.; Laosiripojana, N. Modeling of IT-SOFC with Indirect Internal Reforming Operation Fueled by Methane: Effect of Oxygen Adding as Autothermal Reforming. Int. J. Hydrogen Energy 2010, 35, 13271–13279. [Google Scholar] [CrossRef]

- Dillig, M.; Leimert, J.; Karl, J. Planar High Temperature Heat Pipes for SOFC/SOEC Stack Applications. Fuel Cells 2014, 14, 479–488. [Google Scholar] [CrossRef]

- Li, C.; Cheng, K.; Li, B.; Liu, H.; Qin, J.; Wei, L. Feasibility Study on Supercritical Fuel Cooled Solid Oxide Fuel Cell Stack with Internal Reforming. Int. J. Hydrogen Energy 2024, 50, 312–322. [Google Scholar] [CrossRef]

- Fan, J.; Wang, Y.; Tian, R.; Shi, J.; Shi, Y.; Cao, H.; Cai, N. Thermal Management of Solid Oxide Fuel Cells with Liquid Metal. Int. J. Hydrogen Energy 2023, 48, 10659–10670. [Google Scholar] [CrossRef]

- Promsen, M.; Komatsu, Y.; Sciazko, A.; Kaneko, S.; Shikazono, N. Feasibility Study on Saturated Water Cooled Solid Oxide Fuel Cell Stack. Appl. Energy 2020, 279, 115803. [Google Scholar] [CrossRef]

- Wang, M.; Wang, K.; Wang, Y.; Chen, J.; An, B.; Tu, S. Effect of Operation Parameters on the Thermal Characteristics in a Planar Solid Oxide Fuel Cell. J. Therm. Sci. 2024, 33, 1974–1989. [Google Scholar] [CrossRef]

- Peters, R.; Blum, L.; Deja, R.; Hoven, I.; Tiedemann, W.; Küpper, S.; Stolten, D. Operation Experience with a 20 KW SOFC System. Fuel Cells 2014, 14, 489–499. [Google Scholar] [CrossRef]

- Hasbi, S.; Amber, I.; Hossain, M.; Leong, K.Y.; Saharudin, M.S. Feasibility Study of Liquid Metal-Based Thermal Management for Solid Oxide Electrolyzer Cell (SOEC). Int. J. Green Energy 2025, 1–22. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, C.; Liu, W.; Liu, Z.; Bian, H.; Zhang, K. Advances in Triply Periodic Minimal Surface Structures for Thermal Management Systems: A Comprehensive Review. Appl. Therm. Eng. 2025, 279, 127481. [Google Scholar] [CrossRef]

- Yeranee, K.; Rao, Y. A Review of Recent Investigations on Flow and Heat Transfer Enhancement in Cooling Channels Embedded with Triply Periodic Minimal Surfaces (TPMS). Energies 2022, 15, 8994. [Google Scholar] [CrossRef]

- Cheng, L.; Liu, J.; Liang, X.; To, A.C. Coupling Lattice Structure Topology Optimization with Design-Dependent Feature Evolution for Additive Manufactured Heat Conduction Design. Comput. Methods Appl. Mech. Eng. 2018, 332, 408–439. [Google Scholar] [CrossRef]

- Jiang, Y.; Hu, J.; Wang, S.; Lei, N.; Luo, Z.; Liu, L. Meshless Optimization of Triply Periodic Minimal Surface Based Two-Fluid Heat Exchanger. CAD Comput. Aided Des. 2023, 162, 103554. [Google Scholar] [CrossRef]

- Yeranee, K.; Xu, C.; Rao, Y.; Zhang, Y. Experimental and Numerical Study of Improving Flow and Heat Transfer in a Serpentine Cooling Channel with Topology-Optimized TPMS Porous Structures. Int. J. Heat Mass Transf. 2024, 231, 125873. [Google Scholar] [CrossRef]

- Xu, C.; Rao, Y.; Yeranee, K. Experiments and Numerical Analysis of Turbulent Flow Heat Transfer and Pressure Loss of a Channel with Triply Periodic Minimal Surface Structures. Int. J. Therm. Sci. 2026, 220, 110334. [Google Scholar] [CrossRef]

- Li, H.; Ding, X.; Jing, D.; Xiong, M.; Meng, F. Experimental and Numerical Investigation of Liquid-Cooled Heat Sinks Designed by Topology Optimization. Int. J. Therm. Sci. 2019, 146, 106065. [Google Scholar] [CrossRef]

- Matsumori, T.; Kondoh, T.; Kawamoto, A.; Nomura, T. Topology Optimization for Fluid-Thermal Interaction Problems under Constant Input Power. Struct. Multidiscip. Optim. 2013, 47, 571–581. [Google Scholar] [CrossRef]

- Baek, S.M.; Yu, S.H.; Nam, J.H.; Kim, C.J. A Numerical Study on Uniform Cooling of Large-Scale PEMFCs with Different Coolant Flow Field Designs. Appl. Therm. Eng. 2011, 31, 1427–1434. [Google Scholar] [CrossRef]

- Shahsavari, S.; Desouza, A.; Bahrami, M.; Kjeang, E. Thermal Analysis of Air-Cooled PEM Fuel Cells. Int. J. Hydrogen Energy 2012, 37, 18261–18271. [Google Scholar] [CrossRef]

- Fergus, J.W. Metallic Interconnects for Solid Oxide Fuel Cells. Mater. Sci. Eng. A 2005, 397, 271–283. [Google Scholar] [CrossRef]

- Ghorbani, B.; Vijayaraghavan, K. 3D and Simplified Pseudo-2D Modeling of Single Cell of a High Temperature Solid Oxide Fuel Cell to Be Used for Online Control Strategies. Int. J. Hydrogen Energy 2018, 43, 9733–9748. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, J.; Zhang, D.; Kuai, Z. Modeling and Performance Analysis of Solid Oxide Fuel Cell Power Generation System for Hypersonic Vehicles. Aerospace 2024, 11, 846. [Google Scholar] [CrossRef]

- Haertel, J.; Engelbrecht, K.; Lazarov, B.; Sigmund, O. Topology Optimization of a Pseudo 3D Thermofluid Heat Sink Model. Int. J. Heat Mass Transf. 2018, 121, 1073–1088. [Google Scholar] [CrossRef]

- Zeng, S.; Lee, P. Topology Optimization of Liquid-Cooled Microchannel Heat Sinks: An Experimental and Numerical Study. Int. J. Heat Mass Transf. 2019, 142, 118401. [Google Scholar] [CrossRef]

- Zeng, S.; Kanargi, B.; Lee, P. Experimental and Numerical Investigation of a Mini Channel Forced Air Heat Sink Designed by Topology Optimization. Int. J. Heat Mass Transf. 2018, 121, 663–679. [Google Scholar] [CrossRef]

- Zeng, S.; Sun, Q.; Lee, P.S. Thermohydraulic Analysis of a New Fin Pattern Derived from Topology Optimized Heat Sink Structures. Int. J. Heat Mass Transf. 2020, 147, 118909. [Google Scholar] [CrossRef]

- Marshall, S.D.; Lee, P.S. 3D Topology Optimisation of Liquid-Cooled Microchannel Heat Sinks. Therm. Sci. Eng. Prog. 2022, 33, 101377. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, E.; Ni, M.; Zheng, K.; Ouyang, M.; Hu, H.; Wang, H.; Lu, L.; Ren, D.; Chen, Y. A Numerical Analysis of Metal-Supported Solid Oxide Fuel Cell with a Focus on Temperature Field. Heliyon 2024, 10, e37271. [Google Scholar] [CrossRef] [PubMed]

| Models | Details | Surface Area (mm2) | Porosity (%) |

|---|---|---|---|

| Diamond TPMS | The unit cell size of 20 mm is arranged in the channel, and the wall thickness of TPMS is 1 mm | 23,082.2 | 80 |

| Conventional topology-optimized | The final optimized structure is directly extracted from the density field with a threshold value of 0.5 | 17,310.2 | 50 |

| Topology-optimized lattice-filled | Arrays of circular pin-fin structures with a Dp of 2 mm are filled in the density field of 0.1, and the Dp decreases consistently to 0.5 mm in the density field of 0.9. | 28,958.9 | 80 |

| Materials | Dnesity (kg/m3) | Specific Heat Capacity (J/kg∙K) | Thermal Conductivity (W/m∙K) | Viscosity (Pa∙s) | |

|---|---|---|---|---|---|

| Fluid | Air | Compressible | Linear interpolation | Linear interpolation | Linear interpolation |

| Liquid tin [15] | 6330 | 240 | 33.8 | 0.00101 | |

| Liquid gallium [19] | 5600 | 374 | 61.67 | 0.00175 | |

| Solid | Ferritic stainless steel [15] | 8900 | 444 | 30 | - |

| High-thermal-conductivity metal [19,31] | 8900 | 450 | 72 | - | |

| Nickel–chromium superalloy [32] | 8330 | 640 | 22.8 | - | |

| Study Case | Reynolds Number | Coolant | Structure |

|---|---|---|---|

| Coolant flow rate | 300, 1000, and 5000 | Air | Ferritic stainless steel |

| Coolant type | 300 | Air, liquid tin, and liquid gallium | Ferritic stainless steel |

| Structural material | 300 | Air | Ferritic stainless steel, high-thermal-conductivity metal, and nickel–chromium superalloy |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeranee, K.; Cheng, Y.; Rao, Y. Conjugate Study on Thermal–Hydraulic Performance of Topology-Optimized Lattice-Filled Cooling Channel for Thermal Management of Solid-Oxide Fuel Cells. Energies 2025, 18, 6001. https://doi.org/10.3390/en18226001

Yeranee K, Cheng Y, Rao Y. Conjugate Study on Thermal–Hydraulic Performance of Topology-Optimized Lattice-Filled Cooling Channel for Thermal Management of Solid-Oxide Fuel Cells. Energies. 2025; 18(22):6001. https://doi.org/10.3390/en18226001

Chicago/Turabian StyleYeranee, Kirttayoth, Yuli Cheng, and Yu Rao. 2025. "Conjugate Study on Thermal–Hydraulic Performance of Topology-Optimized Lattice-Filled Cooling Channel for Thermal Management of Solid-Oxide Fuel Cells" Energies 18, no. 22: 6001. https://doi.org/10.3390/en18226001

APA StyleYeranee, K., Cheng, Y., & Rao, Y. (2025). Conjugate Study on Thermal–Hydraulic Performance of Topology-Optimized Lattice-Filled Cooling Channel for Thermal Management of Solid-Oxide Fuel Cells. Energies, 18(22), 6001. https://doi.org/10.3390/en18226001