Abstract

This paper presents a special analysis study about the gas turbine operating line, and an overall description of a gas turbines project, based on experimental data from two particular applications, in order to convert two different types of aero engines into the same engine configuration. The experimental works were carried out with the aim of converting an Ivchenko AI-20K turboprop and a Rolls-Royce Viper 632-41 turbojet into free turbine turboshaft engines, to be used in marine propulsion, and also to obtain an experimental database to be used in other gas turbine applications. In order to carry out the experimental work, the engines were tested in turbojet configuration, to simulate the free turbine load by using jet nozzles with different geometries of the outlet cross-section. Following the engines’ tests, a series of measured data were obtained, through which it was possible to experimentally determine the operating line of some engine components such as the compressor, turbine, and exhaust jet nozzle. This paper is comprehensive and useful through its scientific and technical guidelines, the operation curves coming in handy in the thermodynamic analysis and testing methodology for researchers dealing with similar applications.

1. Introduction

The paper herein is a dissemination part of a complex study regarding experimental research conducted on turboprop and turbojet gas turbines converted into free turbine turboshafts. The project was an internal application project of the Romanian Research and Development Institute for Gas Turbines COMOTI [1]. Using gas turbine engines for industrial power generation, oil, and gas applications or marine propulsion application is a custom practice employed by manufacturers [2,3] and by researchers [4,5,6,7,8] in various engineering projects. Usually, the gas turbines used for marine purposes are aeroderivative engines [9,10], based on models originally designed for aircraft. In some cases, the gas turbines are specially designed for the required applications [11,12]. Depending on the purpose and according to the imposed performance, there are applications employing engines’ configurations that require them to be converted from different types and models of aero engines. Modified engines can be used for various commercial or particular military applications. An engine conversion involves the study of the technical issues regarding the conversion capability, which involves technical modifications and adaptations of the engine assembly, oil systems, and fuel control system. Then, it proceeds to find an adequate technical solution taking into consideration the working and environmental conditions, and then to bring the necessary modifications to the gas turbine in order to apply the new solutions practically.

In most cases, depending on the turbofans and turbojets’ power class, these engines are usually converted into turboshafts [9,10], or into a free turbine turboshaft. Globally, this involves removing the jet nozzle (JN) or the fan, and adding or integrating a power turbine module. There are some works [13,14,15,16] with a potential interest in adapting gas turbines for particular applications and examining the problems that can appear with the conversion process. These works show a particular analysis of operating regimes in different conditions in order to obtain maximum efficiency for aeroderivative engines which can be applied for the aviation or cogeneration industry [13,14,15,16].

Oftentimes, aviation engines that are at the end of their operation resource are transformed to operate in a new configuration for cogeneration, as their functioning can only present risks when used for aircraft propulsion, while some minor faults do not present a significant issue for energy production and research [4,5]. Usually, in similar works [14,15] close to our research, detailed experimental data are not shown; there are only some graphs with certain performance parameters, making the overall understanding and assessment of the application quite narrow, so in this way, the study evaluation of application can be limited [16,17,18]. In this paper, valid experimental data and real values are presented, as well as a series of graphs outlining curves variation of various performance parameters. These allow a more accessible evaluation of the engine operating line or engine working regimes.

2. Engine Presentation

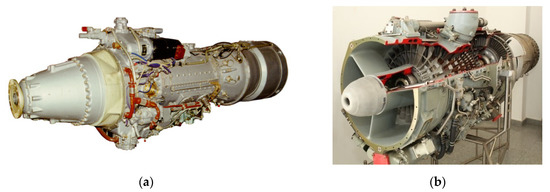

The studies were carried out on two types of aviation engines, a turboprop engine, AI-20K, developed by Ivchenko Progress, and a Viper 632-41 turbojet, manufactured by Rolls-Royce. The AI-20K shown in Figure 1a is a one-spool turboprop axial flow engine, made of ten-stages axial compressor, an annular chamber, a three-stages axial turbine, an exhaust nozzle, a reduction gearbox, and a propeller. At International Standard Atmosphere (ISA) sea level conditions, the engine provides an equivalent power of 4000 eHP, at maximum engine rotational speed of 12,880 rpm, and an overall pressure ratio of 7.6:1, for an air mass flow of 20.7 kg/s, and a specific fuel consumption of 0.264 kg/HP/h [19]. The engine fuel is controlled through a constant speed law. The idle regime corresponding on engine speed of 80.75 + 1.6% ≈ 10,400 + 90 rpm, but for higher working regimes than idle, the engine speed increases to 95.7 + 0.7% ≈ 12,300 + 90 rpm [19]. The maximum turbine inlet temperature is ~1170 K [19].

Figure 1.

(a) Ivchenko AI-20K turboprop engine [20]; (b) Viper 632 turbojet engine [21].

The Viper 632-41 shown in Figure 1b is a one-spool turbojet axial flow engine, consisting of an axial compressor with eight stages, an annular chamber, an axial turbine in two stages, and an exhaust jet nozzle. At ISA sea level conditions, the engine ensures a thrust of 1812 kgf, at a maximum engine rotational speed of 13,760 rpm, and an overall pressure ratio of 5.9:1, for an air mass flow of 26.3 kg/s at a specific fuel consumption of 0.97 kgf/kg/h. The maximum turbine inlet temperature is ~1240 K [22].

In Table 1 are presented the engine working regimes defined through the percentage values of engine speed, specific fuel consumption, thrust or shaft power, extracted from engine manuals [19,22].

Table 1.

AI-20K and Viper 632-41 specified working regimes.

The functional experimental characteristics of the engine components were achieved by modifying the load after the turbine and testing the engines in the turbojet configuration. In this way, we simulated the free power turbine load, by varying the output section of the reaction nozzle. The engines were tested with different exhaust jet nozzle geometries, observing some engine main parameters (such as speed and gas turbine temperature). For a certain jet nozzle size, at the maximum regime, it was pursued to obtain similar values comparing to the reference data in the engine specifications and operation manuals, as intended in the original aviation configuration.

This paper presents a method of researching, through a series of experimental results, how a free turbine turboshaft can be implemented or developed, while being converted from a turboprop and a turbojet engine. Moreover, this paper assesses the influence of the exhaust jet nozzle geometry on the engines’ main parameters and presents the variation of these parameters from the maximum area of the outlet jet nozzle to the minimum allowed area, at every engine speed regime.

Considering that the engines were tested in a turbojet configuration, this involves some modifications to the engine assembly. In the case of the AI-20K turboprop, the exhaust nozzle and the propeller were removed, and in the case of the Viper 632-41 turbojet, only the extension exhaust tube was removed. Therefore, it was ensured that the engines were made ready to be equipped with the test jet nozzles.

3. Application Description

The current paper is based on two experimental works made in COMOTI from two particular applications of two aero engine types, a turboprop and a turbojet, in order to convert the engines into the same type, more exactly, into a free turbine turboshaft. These experimental works had as the main objective the experimental determination of the engine functional characteristics but also the operating line of the main components, such as the compressor, turbine, and jet nozzle.

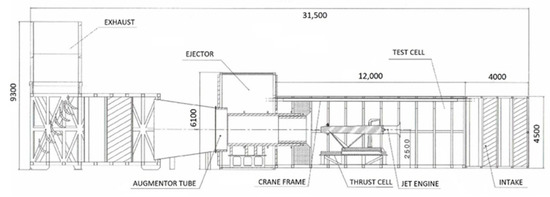

The experimental results were obtained following the engines’ testing on the test bench [23], as shown in Figure 2 and Figure 3, as an internal application of the Romanian Research and Development Institute for Gas Turbines COMOTI.

Figure 2.

COMOTI Turbojet test bench 2D drawing.

Figure 3.

COMOTI Turbojet test bench 3D CAD model.

4. Engine Instrumentation Model

4.1. Instrumentation Configuration

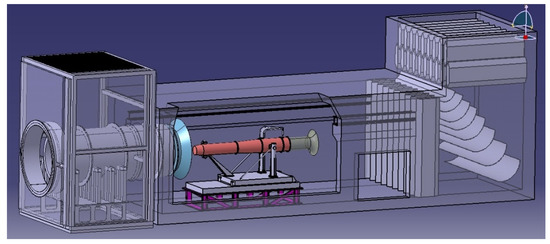

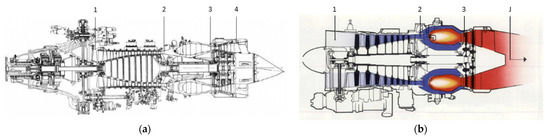

Generally, manufacturers present the engine constructive diagrams, or the engine components, delimited by a series of stations marked with numbers. The stations are the sections which define the inlet and the outlet of the compressor, turbine, and jet nozzle. So, the station 1 is defined as compressor inlet, station 2 is compressor outlet, station 3 is turbine inlet, station 4 is turbine outlet and station j is particular section of the jet nozzle. These stations represent a landmark on the definition of some parameters in case of a supplementary instrumentation of the engines.

Figure 4a below presents the stations of the AI-20K turboprop, according to the engine manual [19], and Figure 4b presents the stations of the Viper 632-41 turbojet, according to the engine manual [22].

Figure 4.

(a) AI-20K engine station [19]; (b) Viper 632-41 engine station [22].

Considering that the engines were tested in a turbojet configuration, this involves some modifications to the engine assembly. In the case of the AI-20K turboprop, the exhaust nozzle and the propeller were removed, and in the case of the Viper 632-41 turbojet, only the extension exhaust tube was removed. Therefore, the engines had been prepared to be equipped with the test jet nozzle.

The paper herein is based on two experimental works made in COMOTI from two particular applications of two aero engine types, a turboprop and a turbojet, in order to convert the engines into the same type, more exactly, into a free turbine turboshaft. These experimental works had as the main objective the experimental determination of the engine functional characteristics but also the operating line of the main components, such as the compressor, turbine, and jet nozzle.

As mentioned, the study of the engine’s operating line was based on datasets from both experimental works, containing a series of measured engine parameters obtained from bench tests. A control and monitoring system of the engines was required, which was realized through an instrumentation model consisting of command lines and parameters’ measuring lines. The instrumentation model involved additional instrumentation with a series of thermodynamic parameters, in the main engine stations, more precisely in the sections that define the inlet and outlet of the compressor, turbine, and exhaust jet nozzle.

The instrumentation model is based on the engine availability for installation and mounting instrumentation tests in the requested engine sections. Depending on the cross-section configuration and instrumentation availability, it can be established what types of parameters can be measured and what type of testing instrumentation can be installed. The engines are equipped with a minimum standard instrumentation, generally for providing information regarding the shaft speed, fuel flow, gases temperature, compressor outlet pressure, oil pressure, oil temperature, and vibrations.

In the case of gases temperature, there is no standard rule about where the temperature should be measured. Depending on the engine type, model, and manufacturer, the gases temperature can be measured at the turbine inlet, turbine outlet, as in the case of the AI-20K, or at the entry of the jet nozzle, as in the case of the Viper 632-41. The engines hold a standard instrumentation with a limited number of parameters which are sufficient to monitor the engine working. However, in order to perform studies on the operating line, an extra instrumentation was necessary to provide information about certain parameters. For testing configuration, some of these parameters are measured in two up to six points of the instrumentation.

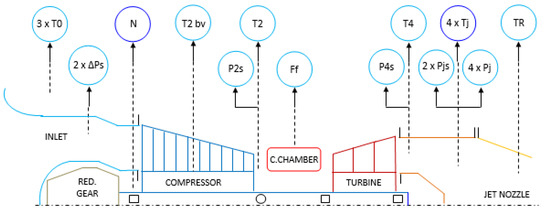

Figure 5 presents the instrumentation scheme of the AI-20K for testing configuration. In the case of the AI-20K, the standard instrumentation parameters are the speed (N), turbine total outlet temperature (T4t), and fuel flow (Ff). Additional parameters for AI-20K engine instrumentation application are the air inlet temperature (T0), inlet differential static pressure (ΔPs) relative to barometric pressure (Pb), compressor outlet static pressure (P2s), compressor outlet total temperature (T2), compressor bleed valve total temperature (T2_bv), turbine outlet static pressure (P4s), jet nozzle inlet total pressure (Tj), jet nozzle inlet static pressure (Pjs), jet nozzle inlet total pressure (Pj), and thrust (TR).

Figure 5.

AI-20K engine model instrumentation.

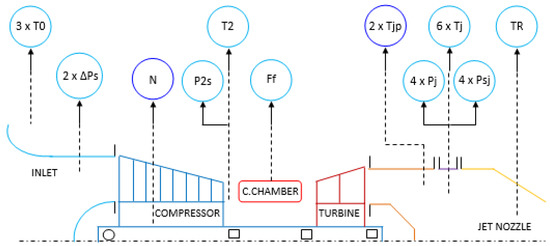

Figure 6 presents the instrumentation scheme of the Viper 632-41 for the testing configuration. In the case of the Viper 632-41, the standard instrumentation parameters are the speed (N), jet nozzle inlet total temperature (Tjp), and fuel flow (Ff). Additional parameters for Viper 632-41 engine instrumentation application are not so different than those of the AI-20K engine, consisting of: air inlet temperature (T0), inlet differential static pressure (ΔPs) relative to barometric pressure (Pb), compressor outlet static pressure (P2s), compressor outlet total temperature (T2), jet nozzle inlet total pressure (Tj), jet nozzle inlet static pressure (Pjs), jet nozzle inlet total pressure (Pj), and thrust (TR).

Figure 6.

Viper 632-41 engine model instrumentation.

4.2. Engine Configurations for Testing

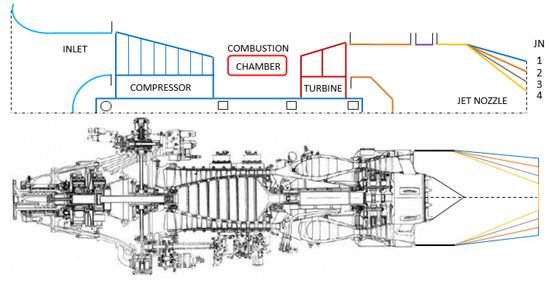

For conducting the experiments, the engine was controlled through a test bench operating system, globally consisting of a control system and a data acquisition system (DAQS). The engines were equipped with several jet nozzles with different outlet geometries. In the case of the AI-20K, the jet nozzles used have the following outlet diameters (D5), JN1 = 429.8 mm, JN2 = 384.7 mm, JN3 = 339.5 mm, JN4 = 320.8 mm, as presented and highlighted by specific colors in Figure 7. For each jet nozzle, the engine was tested from a minimum speed to a maximum speed, approximately at the same speed regime, starting with 60% with a step of 5% until at 100%.

Figure 7.

AI-20K turbojet test configuration scheme.

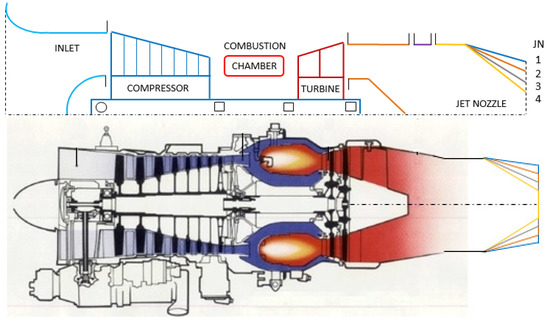

In the case of the Viper 632-41 test, the used jet nozzles (JN) have the next outlet diameters (D5), JN1.C = 430.2 mm, JN2.D = 390.6 mm, JN3.B = 346.0 mm, JN4.E = 340.7 mm, as presented and highlighted by specific colors in Figure 8. Also, for each jet nozzle, the engine was tested from a minimum to a maximum speed, close at the same speed regime, starting with 40% with a step of 5% until at 100%.

Figure 8.

Viper 632-41 turbojet test configuration scheme.

From the experimental tests, it was determined that the jet nozzle with the smallest outlet cross section or diameter is the reference jet nozzle, since with this nozzle, in time of testing at maximum regime around 98%, the inlet turbine temperature achieves values close to the maximum allowed according to the engine manual or from the engine testing in flight configuration.

5. Mathematical Model

According to the instrumentation scheme and to the data acquisition system, a series of measured parameters can be acquired. Based on the experimentally measured parameters, several main parameters of the engine can be calculated using a computation model [24]. Considering that we have a high volume of experimental data, as the engines were tested with different jet nozzles, at different engine speed regimes, we will only present the relevant data for our study, relying on certain parameters of interest and performances, which have been measured or calculated.

In this paper, the calculated parameters are the mass air flow (Maf), the overall pressure ratio (πC), the compressor overall adiabatic efficiency (ηC), the fuel flow (Ff), the turbine inlet temperature (T3), and the turbine overall adiabatic efficiency (ηT). The mass air flow is calculated using the same method and mathematical model from our previous papers [25,26,27].

The compressor’s overall pressure ratio is determined using a method from a calculation model [25,26,27] which depends on the compressor outlet temperature (T2), pressure (P2s), and cross-sections (A2).

The compressor’s overall adiabatic efficiency is determined using the same method of calculation from [24,25,26].

Considering that the AI-20K is a one-spool engine, which means that the overall specific work of the turbine is equal with the compressor’s total specific actual work, the first step to determine the total adiabatic efficiency of the turbine is to calculate the inlet turbine temperature (T3) as demonstrated in our previous papers [24,25].

The second step is to determine the overall turbine pressure at the outlet or the expansion degree, by using the following parameters and the second method from [25].

In the case of the Viper 632-41, the inlet turbine temperature (T3) is determined from the energy equation of the combustion chamber, as is in the mathematical model in papers [24,25].

Considering the ideal case when there is no total pressure loss from the turbine outlet to the jet nozzle inlet, the pressure in station 4 and in station j are assumed to be approximately equal.

Knowing the entropy conditions from station 3 and station 4.id, and using the information about the total outlet turbine pressure, we can determine the overall ideal temperature at the turbine outlet.

Therefore, we can conclude that in the case of both engines, the turbine overall adiabatic efficiency can be written in the following form as is presented in relation (11):

The free power turbine load is viewed through the jet nozzle power (WJN), which is the product between the gas flow (Gf) and the jet nozzle exhaust gas velocity (VJN)

where the jet nozzle exhaust gas velocity is the ratio between the gas flow () and engine thrust ()

The jet nozzle power () is the available power which can be converted into shaft power.

6. Experimental Result

The measured results and calculated results are shown in a series of tables which present the values of certain engine main parameters or performance, for each engine, at the same working speed regimes and for each jet nozzle geometry defined by the outlet cross-section diameter ().

Table 2 presents the measured and calculated values for each jet nozzle diameter for 76 ± 1% and 80 ± 1% speed regimes of AI-20K engine.

Table 2.

AI-20K engine main data from each jet nozzle diameter at 76 ± 1% and 80 ± 1% speed regimes.

Table 3 presents the measured and calculated values for each jet nozzle diameter for 85 ± 2% and 89.8 ± 0.3% speed regimes of AI-20K engine.

Table 3.

AI-20K engine main data from each jet nozzle diameter at 85 ± 2% and 89.8 ± 0.3% speed regimes.

Table 4 presents the measured and calculated values for each jet nozzle diameter for 94.9 ± 0.2% and 97 ± 1% speed regimes ofAI-20K engine.

Table 4.

AI-20K engine main data from each jet nozzle diameter at 94.9 ± 0.2% and 97 ± 1% speed regimes.

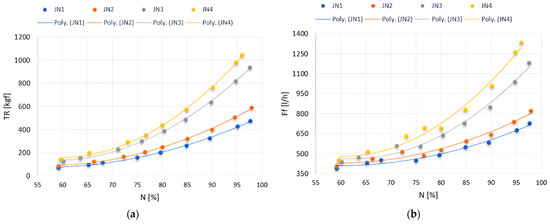

In the following charts, we present the variations of engine main parameters and certain performances of engine components reported to the engine speed. The charts were realized in such a way to have a better view of parameters variation. In the case of the AI-20K tested in a turbojet configuration, we plotted the graphs presented in the figures hereinafter. The variation curve of engine thrust (TR) and fuel flow (Ff) with engine speed (N) of the AI-20K in turbojet configuration are presented in Figure 9a,b for every jet nozzle.

Figure 9.

(a) AI-20K engine thrust function of speed; (b) AI-20K fuel flow function of speed.

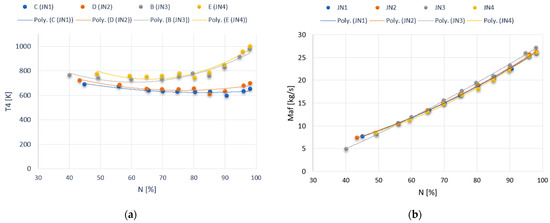

In Figure 10a,b, we have plotted the variation curves of the outlet turbine gas temperature (T4) and mass air flow (Maf) with engine speed (N), for the AI-20K in turbojet configuration for every jet nozzle.

Figure 10.

(a) AI-20K outlet turbine gas temperature function of speed; (b) AI-20K mass air flow function of speed.

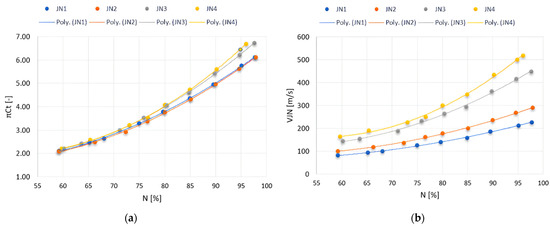

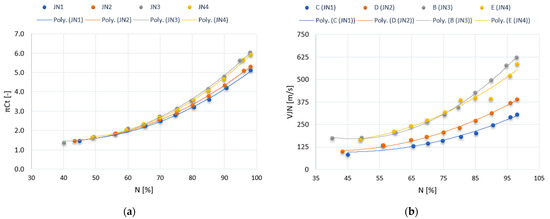

Figure 11a,b shows the variation curves of the overall pressure ratio (πCt) and the exhaust gas velocity (VJN) with engine speed (N), for the AI-20K in turbojet configuration.

Figure 11.

(a) AI-20K overall pressure ratio function of speed; (b) AI-20K exhaust gas velocity function of speed.

The graphs from here onward have been plotted based on experimental data shown in Table 5, Table 6 and Table 7 for the Viper-632 turbojet.

Table 5.

Viper 632-41 main data from each jet nozzle diameter at around 75.1 ± 0.3% and 80.1 ± 0.4% speed regimes.

Table 6.

Viper 632-41 main data from each jet nozzle diameter at 85.1 ± 0.1% and 90.2 ± 0.4% speed regimes.

Table 7.

Viper 632-41 main data from each jet nozzle diameter at 95 ± 1% and 98 +1% speed regimes.

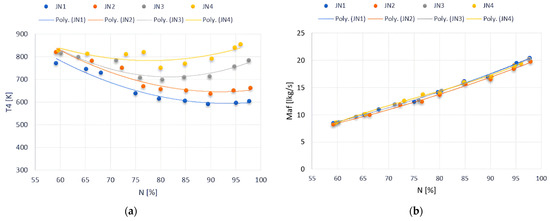

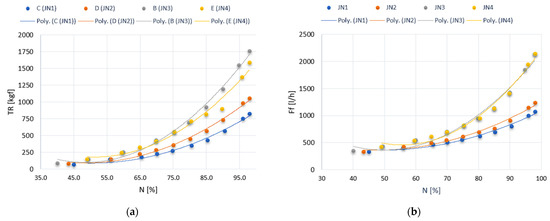

In Figure 12a,b, we plotted the variation curves of the engine thrust (TR) and fuel flow (Ff) with engine speed (N) for the Viper-632 turbojet for every jet nozzle.

Figure 12.

(a) Viper 632-41 engine thrust function of speed; (b) Viper-632-41 fuel flow function of speed.

In Figure 13a,b are presented the variation curves of the outlet turbine gas temperature (T4) and the mass air flow (Maf) with engine speed (N), for the Viper 632-41 turbojet for every jet nozzle.

Figure 13.

(a) Viper 632-41 outlet turbine gas temperature function of speed; (b) Viper 632-41 mass air flow function of speed.

In Figure 14a,b is presented the variation curves of overall pressure ratio (πC,t) and exhaust gas velocity (VJN) with engine speed (N), for Viper 632-41 turbojet with every jet nozzle.

Figure 14.

(a) Viper 632-41 overall pressure ratio function of speed; (b) Viper-632-41 exhaust gas velocity function of speed.

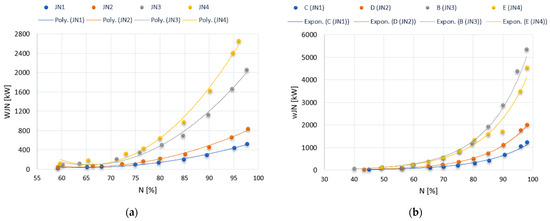

Figure 15a,b shows the variation curves of jet nozzle power (WJN) with engine speed (N), for AI-20K jet nozzles and Viper 632 jet nozzles in turbojet configuration.

Figure 15.

(a) AI-20K jet nozzle power function of speed; (b) Viper 632-41 jet nozzle power function of speed.

7. Discussion

The graphical results presented above demonstrate that when both AI-20K and Viper 632-41 engines are tested in a turbojet configuration, for every speed regime, the thrust (TR), mass air flow (Maf), fuel flow (Ff), overall pressure ratio (πC), turbine temperatures (T3, T4), exhaust gas velocity (VJN), and jet nozzle power (WJN) increase ↗ with the decrease of nozzle outlet diameter (D5) ↘. Only the turbine expansion degree (πT) decreases ↘ with the decreasing of nozzle outlet diameter (D5) ↘.

In order to facilitate a more comprehensive evaluation, the percentages variation (Δprm) and percentage difference variation (dprm) of the parameters and performance are calculated by reporting all values of all three nozzles to the values of the reference jet nozzle (JN.ref), which is the fourth jet nozzle (JN4) in the case of the AI-20K and of the third jet nozzle (JN3) in the case of the Viper 632-41.

At a closer look, it can be observed that the actual variation values are different from a jet nozzle to another, depending on engine speed, and the parameters do not vary in the same way, but the variation percentages of the real parameters obtained from tests, for every nozzle, have quite a similar dependence. The Table 8, Table 9 and Table 10 below displays the percentage variation of the parameters and performance of the fourth jet nozzle (JN4) for the AI-20K engine. Additionally, the table also presents the percentage difference variations for the other nozzles reported to the reference nozzle (JN.ref).

Table 8.

AI-20K thrust, outlet turbine temperature, and mass air flow percentage differences reported to the reference nozzle (JN4).

Table 9.

AI-20K overall pressure ratio, fuel flow, and inlet engine temperature percentages difference reported to the reference nozzle (JN4).

Table 10.

AI-20K exhaust gas velocity and jet nozzle power percentage differences reported to the reference nozzle (JN4).

The Table 11, Table 12 and Table 13 below presents the percentage variation of the parameters and performance of the third jet nozzle (JN3) in the case of the Viper 632-41. Additionally, the table also presents the percentage difference variations for the other nozzles reported to the reference nozzle (JN.ref).

Table 11.

Viper 632-41 thrust, outlet turbine temperature, and mass air flow percentage differences reported to the reference nozzle (JN3).

Table 12.

Viper 632-41 overall pressure ratio, fuel flow, and inlet engine temperature percentage differences reported to the reference nozzle (JN3).

Table 13.

Viper 632-41 exhaust gas velocity and jet nozzle power percentage differences reported to the reference nozzle (JN3).

In order to validate the measured parameters and calculated parameters obtained through the model calculation, a specific assessment is performed by calculating the percentage errors. This approach facilitates a comparison between the experimental results and the data extracted from the engine manual.

The comparison is suitable only at maximum operational regime due to the availability of specific data for additional parameters, such as air mass flow and overall pressure ratio. These values are provided only for the reference nozzle, the fourth jet nozzle (JN4) in the case of the AI-20K and the third jet nozzle (JN3) in the case of the Viper 632-41. In the case of the AI-20K engine, which operates as a turboprop that produces shaft power, the comparison was adapted in parameters for turbojet, as a testing configuration. Therefore, in the case of the AI-20K, if it is considering shaft power equally, jet nozzle power can be calculated with exhaust gas velocity and thrust reference values. In the case of the Viper 632-41 engine, the comparison is based on the same conditions because the engine was tested in the same configuration as the turbojet.

Table 14 presents data and calculated performance for maximum regime extracted from AI-20K engine manual.

Table 14.

AI-20K engine data at maximum regime based on the engine manual.

Table 15 presents measured and calculated parameters for maximum testing regime extracted for JN4 nozzle for AI-20K engine.

Table 15.

AI-20k measured and calculated parameters at maximum testing regime for JN4 nozzle.

Table 16 presents the percentage errors reported to the data manual for AI-20K engine.

Table 16.

AI-20K percentage errors values reported to the data manual.

Table 17 presents data and calculated performance for maximum regime extracted from Viper 632-41 engine manual.

Table 17.

Viper 632-41 engine data at maximum regime based on the engine manual.

Table 18 presents measured and calculated parameters for maximum testing regime extracted for JN3 nozzle for Viper 632-41 engine.

Table 18.

Viper 632-41 measured and calculated parameters at maximum testing regime for JN3 nozzle.

Table 19 presents the percentage errors reported to the data manual for Viper 632-41 engine.

Table 19.

Viper 632-41 percentage errors values reported to the data manual.

It is observed that the biggest difference is 9% only for the jet nozzle power and 6% for the exhaust gas velocity; the rest of the parameters are maximum 3.5%. Also, it can be observed that these differences are negative which means that the experimental values are lower than the data manual. One of the reasons is that the engines were tested at a difference of speed regime around 2% in the case of the AI-20K engine and 3% in the case of the Viper 632-41, and not to the maximum regime indicated in the manual. Therefore, if the engines were tested at the same maximum regime, theoretically, the differences will decrease with 2 ÷ 3%, resulting in a maximum difference of 6%, thus do not exceed by much the acceptable error limit.

8. Conclusions

This paper presents an experimental study conducted on two types of aviation engines, focusing on the working regimes, depending on their application, following the engine testing into the same engine configuration. The two engines, an AI-20K turboprop and a Viper 632-61 turbojet, were tested in turbojet configuration with different exhaust nozzle geometries, in order to evaluate the working parameters, and implicitly the working lines of compressor and turbines. The impact of the outlet nozzle diameter dimensions on values of engine parameters has been assessed. Special attention was paid to turbine parameters, since the main purpose was to modify the engines to operate as free turbine turboshafts. The gas turbines were tested with various customized jet nozzles, in similar transitory regimes, by varying the speed. Subsequently, a series of experimental data have been obtained, which were analyzed and used in the mathematical model, in order to determine the variations of the performance parameters from minimum to a maximum speed for every jet nozzle installed. The experimental research presented herein can be relevant for the evaluation of engine working regimes and engine configurations for similar applications considering thermodynamic analysis and testing configurations.

Author Contributions

Conceptualization, R.M.C.; methodology, R.M.C.; software, R.M.C.; validation, R.M.C.; formal analysis, R.M.C.; investigation, R.M.C.; resources, R.M.C.; data curation, R.M.C.; writing—original draft preparation, R.M.C.; writing—review and editing, G.P.B.; visualization, G.P.B.; supervision, G.P.B.; project administration, R.M.C.; moreover, preparing the engines, instrumentation, the acquisition of parameters and testing, R.M.C. All authors have read and agreed to the published version of the manuscript.

Funding

The Research was carried out under the “Nucleu” Program through The National Plan for Research, Development and Innovation 2022–2027, funded by the Romanian Ministry of Research, Innovation and Digitalization (MCID), Grant no. 31N/2023. The APC was funded by the Romanian Ministry of Research, Innovation and Digitalization (MCID) through project number PN23.12.01.01.

Data Availability Statement

Data are contained within the article and in referenced papers.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

The following parameters and variables are used in this research.

| Parameter [U.M.] | Description |

| N [%] | Percentage Speed |

| TR [Kgf] | Thrust |

| P [HP] | Shaft power |

| eP [eHP] | Equivalent shaft power |

| SFC [kg/HP/h] | Specific fuel consumption |

| eSFC [kg/eHP/h] | Equivalent specific fuel consumption |

| FC [kg/h] | Fuel consumption |

| Ff [l/h] | Fuel flow |

| Maf [kg/s] | Mass air flow |

| Gf [Kg/s] | Gas flow |

| LHVf [J/Kg] | Low heat value |

| [%] | Combustion chamber efficiency |

| A2 [mm2] | Compressor outlet cross section |

| A4 [mm2] | Turbine outlet cross section |

| D5 [mm] | Jet nozzle outlet diameter |

| T0 [K] | Inlet temperature |

| T2_bv [K] | Compressor bleed valve total temperature |

| [K] | Compressor outlet ideal temperature |

| T2 [K] | Compressor outlet total temperature |

| T3 [K] | Turbine inlet temperature |

| T4 [K] | Turbine total outlet temperature |

| [K] | Turbine outlet ideal temperature |

| Tj,p [K] | Jet nozzle inlet total temperature |

| Pb [Pa] | Relative to barometric pressure |

| ΔPs [Pa] | Inlet differential static pressure |

| P2s [Pa] | Compressor outlet static pressure |

| [Pa] | Compressor outlet total pressure |

| P3 [Pa] | Turbine inlet total pressure |

| P4 [Pa] | Turbine outlet total pressure |

| P4s [K] | Turbine outlet static pressure |

| Pjs [Pa] | Jet nozzle inlet static pressure |

| Pj [Pa] | Jet nozzle inlet total pressure |

| πC [-] | Compressor overall pressure ratio |

| ηC [%] | Overall adiabatic efficiency |

| πT [-] | Turbine expansion degree |

| ηT [%] | Turbine overall adiabatic efficiency |

| [J/K] | Compressor inlet entropy |

| [J/K] | Compressor outlet ideal entropy |

| [J/K] | Turbine inlet entropy |

| [J/K] | Turbine outlet ideal entropy |

| [kW] | Jet nozzle power |

| VJN [m/s] | Nozzle exhaust gas velocity |

| JN1-4 | First to fourth jet nozzles |

| JNref | Jet nozzle reference |

| DAQS | Data acquisition system |

| Engine parameter | |

| Percentage variation of parameters | |

| Percentage differences | |

| [%] | Percentage errors of parameters |

| Parameters of jet nozzle reference | |

| Engine parameters from manual |

References

- COMOTI—Romanian Research and Development Institute for Gas Turbines. Comoti.ro. 2022. Available online: http://www.comoti.ro/en/despre_noi.htm (accessed on 25 March 2023).

- Aeroderivative and Heavy-Duty Gas Turbines|GE Gas Power, Gepower-V2. 2022. Available online: https://www.ge.com/gas-power/products/gas-turbines (accessed on 31 March 2023).

- Mitsubishi Power Aero LLC|Products, Mitsubishi Power Aero LLC. 2022. Available online: https://power.mhi.com/group/aero/products (accessed on 3 April 2023).

- Borzea, M.; Fetea, G.; Codoban, R. Implementation and Operation of a Cogeneration Plant for Steam Injection in Oil Field. In Volume 7: Education; Industrial and Cogeneration; Marine; Oil and Gas Applications, Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; ASME: New York, NY, USA, 2008. [Google Scholar] [CrossRef]

- Hocko, M.; Polaček, M. Modifications of the turboprop engine AI-24 for alternative energy application use. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2018. [Google Scholar] [CrossRef]

- Effiom, S.; Abam, F.; Nwankwojike, B. Performance evaluation of aeroderivative gas turbine models derived from a high bypass turbofan for industrial power generation. Cogent Eng. 2017, 4, 1301235. [Google Scholar] [CrossRef]

- Fatsis, A. Design point analysis of two-shaft gas turbine engines topped by four-port wave rotors for power generation systems. Propuls. Power Res. 2019, 8, 183–193. [Google Scholar] [CrossRef]

- Isaiah, T.; Dabbashi, S.; Bosak, D.; Sampath, S.; Di Lorenzo, G.; Pilidis, P. Life cycle evaluation of an intercooled gas turbine plant used in conjunction with renewable energy. Propuls. Power Res. 2016, 5, 184–193. [Google Scholar] [CrossRef]

- Propulsion Hub & Engine Product|GE Aviation, Geaviation.Com. 2022. Available online: https://www.geaviation.com/propulsion/marine (accessed on 7 April 2023).

- Gas Turbines, Rolls-Royce.Com. 2022. Available online: https://www.rolls-royce.com/products-and-services/defence/naval/gas-turbines.aspx (accessed on 7 April 2023).

- MAN Energy Solutions gas turbines, MAN Energy Solutions. 2022. Available online: https://www.man-es.com/oil-gas/products/gas-turbines (accessed on 15 April 2023).

- Reliable Gas Turbines. 2022. Available online: https://www.siemens-energy.com/global/en/offerings/power-generation/gas-turbines.html (accessed on 10 May 2023).

- Boyce, M.; Meher-Homji, C.; Wooldridge, B. Condition Monitoring of Aeroderivative Gas Turbines. In Volume 5: Manufacturing Materials and Metallurgy; Ceramics; Structures and Dynamics; Controls, Diagnostics and Instrumentation; Education, Proceedings of the ASME 1989 International Gas Turbine and Aeroengine Congress and Exposition, Toronto, ON, Canada, 4–8 June 1989; ASME: New York, NY, USA, 2015. [Google Scholar]

- Nkoi, B.; Pilidis, P.; Nikolaidis, T. Performance of small-scale aero-derivative industrial gas turbines derived from helicopter engines. Propuls. Power Res. 2013, 2, 243–253. [Google Scholar] [CrossRef]

- Nkoi, B.; Pilidis, P.; Nikolaidis, T. Performance assessment of simple and modified cycle turboshaft gas turbines. Propuls. Power Res. 2013, 2, 96–106. [Google Scholar] [CrossRef][Green Version]

- Najjar, Y.S.; Balawneh, I.A. Optimization of gas turbines for sustainable turbojet propulsion. Propuls. Power Res. 2015, 4, 114–121. [Google Scholar] [CrossRef]

- Dobromirescu, C.; Vilag, V. Energy conversion and efficiency in turboshaft engines. E3S Web Conf. 2019, 85, 01001. [Google Scholar] [CrossRef]

- Catana, R.M.; Cican, G.; Dediu, G. Gas Turbine Engine Starting Applicated on TV2-117 Turboshaft. Eng. Technol. Appl. Sci. Res. 2017, 7, 2005–2009. [Google Scholar] [CrossRef]

- Manual on Soviet AI-20 Turboprop Engine; IL 18-D1-123/7, Technical Documentation; Department of the Czechoslovak Airlines: Czech Republic, 1974.

- AI-20, Motorsich.Com.Ua. 2022. Available online: http://motorsich.com.ua/AI-20 (accessed on 24 May 2023).

- Istoric—Turbomecanica. Turbomecanica. 2022. Available online: https://turbomecanica.ro/despre-noi/istoric/#inceputuriBucharestRomania (accessed on 28 May 2023).

- Viper 632-41 Engine Manual; Aero Engine School of Rolls-Royce Limited, Bristol Engine Division: Bristol, UK, 1971.

- EERIS: Gas Turbines Test Bed, Comoti—National R&D Institute For Gas Turbines. Eeris.eu. 2022. Available online: https://eeris.eu/ERIF-2000-000Z-0574 (accessed on 30 May 2023).

- Strušnik, D.; Avsec, J. Exergoeconomic machine-learning method of integrating a thermochemical Cu–Cl cycle in a multigeneration combined cycle gas turbine for hydrogen production. Int. J. Hydrogen Energy 2022, 47, 17121–17149. [Google Scholar] [CrossRef]

- Catană, R.; Dediu, G.; Tărăbîc, C.; Șerbescu, H. Performance Calculations of Gas Turbine Engine Components Based on Particular Instrumentation Methods. Appl. Sci. 2021, 11, 4492. [Google Scholar] [CrossRef]

- Catană, R.; Dediu, G.; Tărăbîc, C. Studies and Experimental Research in the Evaluation of TV2-117A Turboshaft Engine Working Regimes. Appl. Sci. 2022, 12, 3703. [Google Scholar] [CrossRef]

- Catana, R.M. Thesis, Studies and Experimental Research in the Evaluation of Gas Turbine Engines Operating Regimes by Testing on the Test Bench after a Supplementary Instrumentation and Processing of the Measured Data. Ph.D. Thesis, Politehnica University of Bucharest, Bucharest, Romania, 2019. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).