Abstract

Neuromorphic devices emulating the temperature-sensing capabilities of biological thermoreceptors hold significant promise for neuron-like artificial sensory systems. In this work, Bi2Se3-based threshold-switching memristors were presented in constructing temperature-sensing neuron circuits, leveraging its exceptional attributes, such as high switching ratio (>106), low threshold voltage, and thermoelectric response. The spiking oscillation response of the devices to resistance and temperature variations was analyzed using Hspice simulation of the memristor model based on its resistance in on/off states, threshold voltage (Vth), and hold voltage (Vhold). These results show the great potential of the Bi2Se3-based memristor in enabling biorealistic thermoreception applications.

1. Introduction

As artificial intelligence (AI) computational capabilities surge exponentially in an explosive manner and Moore’s Law moves forward encountering bottlenecks, a discrepancy emerges in the advancement of computational power [1,2,3,4]. Due to the limitations of traditional von Neumann computing architectures, their internal storage units and processors can only interact with each other through logical signals, which results in data redundancy and wasted energy consumption [5,6]. Consequently, the transfer of information via pulsed electrical signals, akin to biological organisms, has garnered significant research attention [7,8]. The construction of traditional bionic systems realizes the simulation of bionic function through the emulation of synaptic characteristics and then the construction of neuronal systems [9,10,11]. As an important self-protection mechanism of organisms, there are fewer artificial sensory systems to realize the function of temperature sensing [12,13,14,15,16]. Among the existing research, the biological neuronal sensory systems exhibit intricate complexities, often entailing challenges inherent to conventional complementary metal–oxide semiconductor (CMOS) device-based implementations [8,17].

Memristive devices, because of their own conductance in relation to the applied stimulus, allow the emulation of synaptic dynamic features at the single device level. In particular, the emerging threshold-switching (TS) behavior of memristors offers a pathway to achieve neuron-like thresholding and excitation behavior within a simplistic circuit structure, necessitating only resistors and capacitors. This efficacy stems from its inherent attributes of resistance switching, simple structure, and low threshold voltage [18,19]. Conventional transition metal–oxide (e.g., HfO2)-based memristors are non-volatile devices that find applications in areas such as neural networks, chaos, and nonlinear circuits [6,20,21,22,23,24]. In contrast, volatile threshold-switching devices are commonly utilized in constructing artificial neurons. For instance, the use of Bi2Se3, a topological insulator material, shows unique thermoelectric sensation and excellent electrical properties (e.g., low leakage current and reduced threshold voltage) [25], facilitating the realization of artificial neuron circuits characterized by minimal power consumption (<1 μW) and rapid switching speeds.

In this work, we outline the preparation of the Bi2Se3 material, known for its thermoelectric properties, as a functional layer for memristive devices. And Bi2Se3-based threshold- switching (TS) memristors were designed and fabricated to construct an artificial neuron circuit with thermoreception. The oscillatory output of the circuit was simulated under various conditions, including resistance and temperature variations. Such devices are poised to advance the development of multifunctional neuromorphic sensory systems.

2. Material and Methods

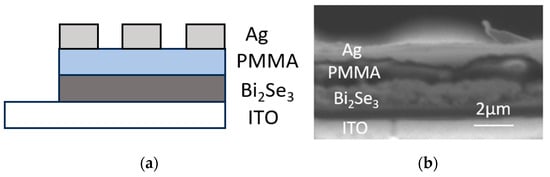

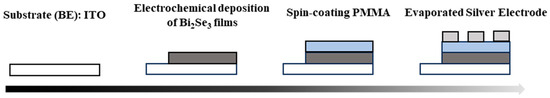

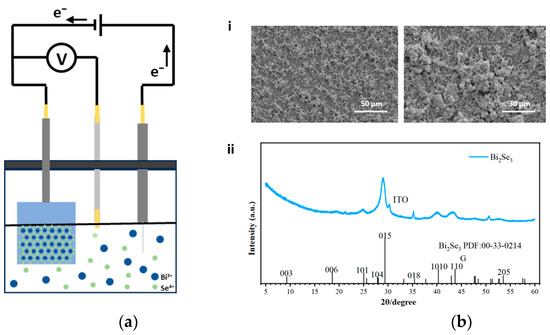

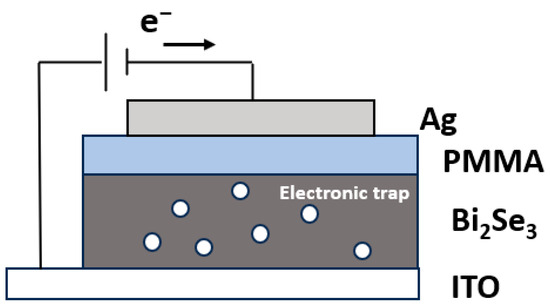

The Bi2Se3-based TS memristor is designed with a stacked structure of ITO/Bi2Se3/PMMA/Ag, as shown in Figure 1a. The cross-sectional scanning electron microscopy (SEM) image (Figure 1b) clearly demonstrates the pronounced multilayer morphologies. The fabrication process flowchart of the Bi2Se3-based TS memristor is illustrated in Figure 2. Initially, the Bi2Se3 thin films were grown on an ITO-film-coated (2.5 × 2.5 cm2) glass substrate using the electrochemical deposition method with a three-electrode configuration, as illustrated in Figure 3a.

Figure 1.

(a) Schematic diagram of structure design of the Bi2Se3-based memristor; (b) cross-sectional SEM image of the Bi2Se3-based memristor.

Figure 2.

The fabrication process flowchart of the Bi2Se3-based memristor.

Figure 3.

Preparation and characterization of Bi2Se3 films: (a) schematic illustration of the electrochemical deposition of Bi2Se3 films; (b) i: SEM images of deposited Bi2Se3 film at different magnifications; ii: X-ray diffraction (XRD) pattern of the as-grown Bi2Se3 film.

A solution system comprising 3 mM Bi(NO3)3∙5H2O + 3 mM SeO2 was employed; before deposition, the prepared electrolyte solution needed to be evacuated to remove deoxygenation from the solution, and the ITO-film-coated glass substrate was cleaned with acetone, absolute ethanol, and deionized water, respectively. After that, a deposition voltage at −0.4 V was applied for 1500 s to obtain Bi2Se3 films on the working electrode at 300 K. Given that the surface of the directly electrochemically deposited Bi2Se3 film is not uniformly smooth, and the material’s low energy level tends to form Ohmic contacts with silver electrodes, a poly methyl methacrylate (PMMA) layer was utilized as a barrier layer. This PMMA layer acts as both an encapsulation to protect the functional layer of Bi2Se3 and a means to smoothen the material’s surface, facilitating the attachment and contact of the top electrode. Specifically, a dimethylformamide (DMF) solution containing dissolved PMMA was spin-coated onto the dried Bi2Se3 film at 1200 r/s three times to obtain a slippery PMMA barrier layer surface. Subsequently, an Ag thin film with a top electrode size of 750 μm was fabricated through an evaporation method, and a single-layer thickness of 120 nm served as the top electrode. Finally, the Bi2Se3-based TS memristor was successfully obtained.

In the electrochemical deposition system, as depicted in Figure 3a, we employed a calomel electrode as the reference electrode, a platinum wire electrode as the counter electrode, and the ITO conductive glass as the working electrode. Subsequently, Bi2Se3 films were deposited by applying external potentials between the working and counter electrodes. To assess the quality of the deposited Bi2Se3 films, the surface morphology and material composition were characterized using scanning electron microscopy (SEM) and X-ray diffraction (XRD), respectively, as illustrated in Figure 3b. The SEM images show that the deposited Bi2Se3 material effectively adheres to the ITO surface. Moreover, the XRD result reveals prominent diffraction peaks, indicating the high crystallinity and sizable grain size of the Bi2Se3 films achievable through electrochemical deposition.

3. Results

3.1. Device Performance

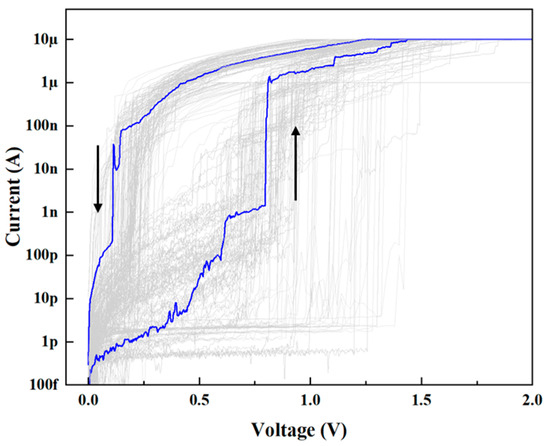

To evaluate the switching performance of the Bi2Se3-based TS memristor, the device was subjected to current–voltage (I–V) sweeping at a compliant current of 10 μA. Figure 4 shows the I–V curves of the device, with the arrows indicating the direction of resistance transition, exhibiting pronounced volatile threshold-switching behavior. Under the current compliance of 10 μA, the device switches from the high resistance state (HRS) to the low resistance state (LRS) at a threshold voltage (Vth) between 0.6 V and 1.5 V, and then, the device switches from the LRS to the HRS when the voltage retraces to a hold voltage (Vhold) of around 0.2 V. Meanwhile, the device is able to maintain its LRS throughout the continuous sweeping process and return to its initial HRS when the applied voltage is removed. Even after more than 100 cycles, the device exhibits stable switching behavior.

Figure 4.

Cyclic I–V characteristics of the Bi2Se3-based memristor (The arrow indicates the direction of the I–V sweeping).

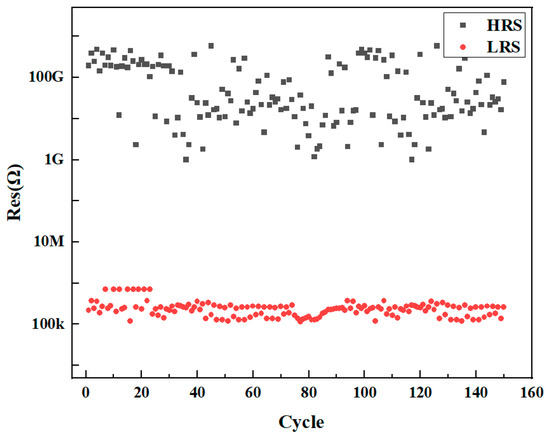

Additionally, 150 electrical pulses were performed on the device; we recorded the resistance values of the device in the form of electrical pulses during a single cycle, and the HRS and LRS values of the device were derived from the switching of 150 cycles. As shown in Figure 5, it can be seen that the device has a uniform distribution of the HRS and the LRS, showing good stability performance.

Figure 5.

Endurance of the Bi2Se3-based memristor at a read voltage of 0.1 V with a compliance current (Icc) of 10 μA.

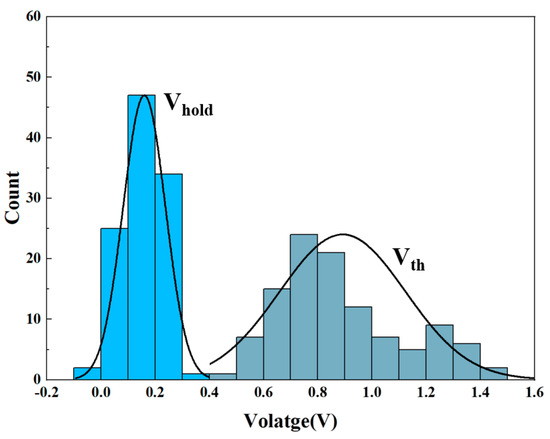

Figure 6 shows the correspondence of device measurement data for a volatile threshold-switching device over 150 forward sweep voltage cycles, including the Vth and Vhold. The Vth and Vhold of the device were statistically analyzed, and it was found that the Vth distribution of the device was more dispersed at 0.9 V, while the Vhold distribution was stable at 0.2 V, but all of them tended to converge with the normal distribution in a range, which demonstrates good cycling stability of the device.

Figure 6.

Probability distribution of Vth and Vhold in the Bi2Se3-based memristor.

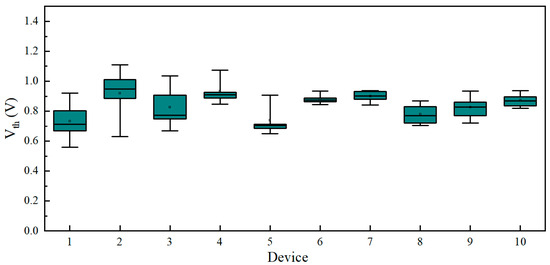

To assess device-to-device variability, we further conducted I–V characteristic tests on ten devices on a single substrate, recording their threshold voltages. Each device was subjected to ten consecutive operations. As illustrated in Figure 7, the Vth of the memristor falls within the range of 0.6 V to 1.2 V, indicating comparable uniformity.

Figure 7.

Statistical distribution of threshold voltages for 10 devices.

Based on the I–V characteristics of the device and the material properties of Bi2Se3, we employ a charge-trap model to elucidate the electron trapping and releasing process that underlies the resistive switching mechanism of the memristor, as shown in Figure 8. In instances where the device initiates in an intermediate resistance state, the application of a bias voltage would expel trapped electrons, activating a greater number of traps to effectuate the transition to the HRS. Upon the application of the activation voltage, the device reverts to the HRS state. During the subsequent scanning process of applying the forward sweep voltage from 0 V to 2 V, the device undergoes a switching transition from the HRS to the LRS as electrons from the top electrode traverse the PMMA barrier layer, filling up the electron traps. As the electron trap becomes saturated with electrons, the injected carriers gain mobility within the dielectric layer, leading to the device exhibiting a switch from the HRS to the LRS.

Figure 8.

Schematic diagram of the resistance switching mechanism of the Bi2Se3-based memristor.

Throughout the continuous process of applying the forward sweeping voltage, the device remains in the LRS until the applied forward voltage drops below the Vhold, characteristic of a threshold-type switching device. Specifically, the resistance switching behavior manifests as the forward sweep voltage scan decreases from 2 V to 0.2 V, causing the detached electrons from the trap to transition the device back from the LRS to the HRS. Consequently, upon the conclusion of the forward voltage application, the device returns to the HRS. This reversible process, as illustrated in Figure 8, denotes the volatile memristive characteristics.

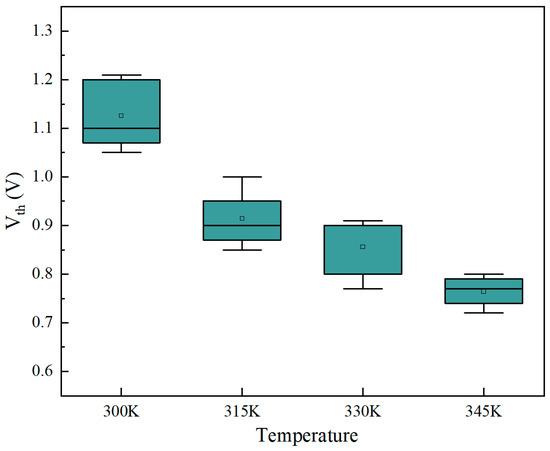

To validate the temperature-sensing capabilities of the Bi2Se3-based memristor, a thermal test platform equipped with a chuck was constructed to analyze the variation in threshold voltage across different temperatures. Initially, the memristor device was configured to the HRS and subjected to a temperature increment from room temperature (300 K) to 345 K. At intervals of 15 K, I–V scans were conducted on the device to monitor its temperature-dependent output response. The output relationship between the device and the temperature response is shown in Figure 9. We conducted tests on the device through five cyclic I–V scans at varying temperatures, ranging from 300 K to 345 K. Observing a decrease of approximately 0.4 V in the device’s threshold voltage with rising temperatures. Subsequently, we incorporated the average values from the box-plot analysis at different temperatures into the device model for circuit simulation, affirming the device’s potential suitability for application in neuromorphic circuits.

Figure 9.

Vth of the Bi2Se3-based memristor under different temperatures (at 300 K, 315 K, 330 K, and 345 K).

In order to provide a comprehensive characterization of the Bi2Se3-based memristor, we have conducted a comparative analysis of the device parameters with findings from previous studies on volatile memristive devices [22,23,24,25]. Table 1 illustrates that the Bi2Se3-based memristor has comparable performance to the typical devices, in terms of operating voltage (Vth), ON/OFF ratio, and energy consumption per switching event (expressed as leakage current (Ioff)). Additionally, when compared to planar devices, the Bi2Se3-based memristor exhibits enhanced cycling stability due to its stacked devices. Functioning as a temperature-sensitive switching threshold device, the Bi2Se3-based memristor developed in this work demonstrates a lower leakage current and a higher ON/OFF ratio. These attributes signify substantial potential for the implementation of memristor-based neurons with temperature-sensing capabilities in an ultralow-power fashion. Subsequently, we intend to delve deeper into the validation of incorporating this device into neuronal circuits through simulation.

Table 1.

Comparison of the ON/OFF ratio, SET voltage (Vth), leakage current (Icc), and functions of the Bi2Se3-based memristor developed in this study with some perceptive planar memristors.

3.2. Neuronal Circuit Simulation

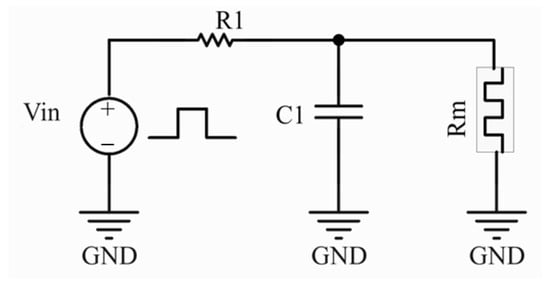

Due to the unavoidable system complexity of neuronal circuits based on CMOS devices, we constructed artificial neuronal circuits with a simple structure based on the memristor neuronal oscillatory function. And the feasibility of the device for neuronal circuits is further investigated through circuit simulations. The TS behavior of the device, transitioning between HRS and LRS, can be roughly equated to a “two-resistor model”, where HRS and LRS are represented as two constant resistors [29]. Based on this, we built a neuronal circuit consisting of multiple passive devices by means of a neuronal-functioning memristive device, in which the memristive device performs a function similar to neuronal leakage integration and excitation. In detail, a memristor model is established based on empirical data. At 300 K, the memristor exhibits a Vth of 1.1 V, Vhold of 0.2 V, HRS at 100 GΩ, and the LRS is 100 kΩ. Subsequently, a neuronal circuit is devised utilizing the memristive device, as shown in Figure 10, comprising an RC oscillator circuit and a voltage divider circuit.

Figure 10.

Schematic diagram of the constructed artificial neuron circuit (i.e., thermoreceptor).

In the RC oscillator circuit, the output voltage frequency can be controlled by changing the resistance value of R1 in the circuit. Firstly, the trise of the output voltage is calculated by the following equation:

trise = ReqC1ln[(Vin/R1 − Vhold/Req)/(Vin/R1 − Vth/Req)]

In Equation (1), Roff stands for the resistance value of the HRS of the memristor, and Vth and Vhold represent the threshold and hold voltages of the memristor, respectively. R1 denotes the resistance value in the oscillator circuit. When Roff ≫ R1, Req = Roff ‖ R1 ≈ R1, Req can be approximated as R1, and f can be regarded as primarily affected by R1.

Above all, the frequency is determined by the following equation:

f ∝ 1/trise ≈ 1/R1C1ln[(Vin − Vhold)/(Vin − Vth)]

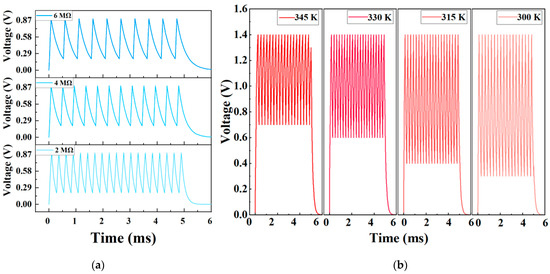

Following the construction of the artificial neuron simulation model, the feasibility of the memristive device for developing artificial neuron circuits is verified by changing the value of R1 and the model parameters of the memristor in the circuit, respectively. By observing the resulting alterations in the output signal of the oscillator circuit, the efficacy of the memristive device in artificial neuron circuitry is confirmed. Initially, we varied the resistor values (R1: 2 MΩ, 4 MΩ, and 6 MΩ) in the RC circuit. In response to the same pulse voltage, as shown in Figure 11a, the output voltage frequency (f) shifted from 4 kHz to 2 kHz with the increasing resistance value of R1, while the peak value remained relatively stable. By substituting R1 with a resistive sensor, the circuit can effectively convey external information via a frequency signal, enabling the neuronal circuitry to sense external environmental signals.

Figure 11.

Impulse simulation response of neuronal circuits: (a) simulated oscillation characteristics of the thermoreceptor in response to various values of R1 in the neuron circuit (2 MΩ, 4 MΩ, and 6 MΩ); (b) simulated oscillation characteristics of the thermoreceptor in response to various Vth (0.8 V, 0.9 V, 1.1 V, and 1.2 V) of Bi2Se3-based memristor under different temperatures.

Subsequently, to further assess the impact of temperature on the output signal of the neuronal circuit, we introduced various Vth values at different temperatures (Figure 9) into the memristor model, as shown in Figure 11b. Upon observing temperature fluctuations (i.e., 300 K, 315 K, 330 K, and 345 K), the peak-to-peak output voltage ranges from 1.1 V to 0.7 V, while the frequency exhibited minimal change. Consequently, the potential application of this neuron circuit in multimodal sensing circuits shows promise in conveying information through the peak and frequency of the output signal. This capability facilitates the realization of artificial thermoreception, which can be leveraged for multimodal spiking-based sensing of the external environment.

4. Conclusions

In summary, drawing inspiration from the temperature-sensing mechanisms in living organisms [30,31], we successfully fabricated threshold-switching memristors based on Bi2Se3 material through the electrochemical deposition method. The device demonstrates the ability to switch between the HRS and LRS attributed to the function of the PMMA layer barrier layer and the charge trapping and de-trapping function of the Bi2Se3 functional layer. Specifically, we have substantiated the device’s performance, including high switching ratio (>106), low threshold voltage, high endurance, and temperature sensation through I–V cycling tests. A benefit of the thermoelectric properties of the Bi2Se3 material itself, the Bi2Se3-based memristor exhibits temperature-sensing capability. Performance testing at different temperatures (300 K, 315 K, 330 K, and 345 K) further confirms this feature. Leveraging the Bi2Se3-based memristor model at different temperatures in neuronal circuit simulations allows us to unlock the device’s potential for neuronal functionalities such as oscillation and frequency response. The feasibility of neuronal circuits based on Bi2Se3 material for artificial thermoreceptors was further shown. Notably, this work exhibits immense promise for advancing biorealistic thermoreceptors and multimodal neuromorphic sensory systems, and the constructed perceptual neuronal circuits based on Bi2Se3 material could be used in edge devices for human–computer interaction [32,33].

Author Contributions

Conceptualization and methodology, H.L. and Q.H.; validation and formal analysis, H.L. and C.J.; data curation and visualization, H.L.; writing—original draft preparation, H.L. and Q.H.; writing—review and editing and project administration, Q.H. All authors have read and agreed to the published version of this manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (62374018, 62464001, and 61904012), the Guangxi Key Laboratory of Brain-inspired Computing and Intelligent Chips (BCIC-23-K5).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors are thankful for the support from Xiaomi Young Scholars Program, the Fundamental Research Funds for the Central Universities, and the Beijing Institute of Technology Research Fund Program for Young Scholars.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CMOS | Complementary Metal–Oxide Semiconductor |

| TS | Threshold Switching |

| PMMA | Poly Methyl Meth-Acrylate |

| DMF | Dimethylformamide |

| BE | Bottom Electrode |

| TE | Top Electrode |

| SEM | Scanning Electron Microscopy |

| XRD | X-Ray Diffraction |

| ITO | Indium Tin Oxide |

| LRS | Low Resistance State |

| HRS | High Resistance State |

| RC | Resistor Capacitance |

References

- Duan, X.; Cao, Z.; Gao, K.; Yan, W.; Sun, S.; Zhou, G.; Wu, Z.; Ren, F.; Sun, B. Memristor-Based Neuromorphic Chips. Adv. Mater. 2024, 36, 2310704. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Yao, P.; Gao, B.; Liu, Q.; Wu, D.; Zhang, Q.; Li, Y.; Qin, Q.; Li, J.; Zhu, Z.; et al. Edge learning using a fully integrated neuro-inspired memristor chip. Science 2023, 381, 1205–1211. [Google Scholar] [CrossRef] [PubMed]

- Hua, Q.; Gao, G.; Jiang, C.; Yu, J.; Sun, J.; Zhang, T.; Gao, B.; Cheng, W.; Liang, R.; Qian, H.; et al. Atomic Threshold-Switching Enabled MoS2 Transistors towards Ultralow-Power Electronics. Nat. Commun. 2020, 11, 6207. [Google Scholar] [CrossRef]

- Xu, H.; Shang, D.; Luo, Q.; An, J.; Li, Y.; Wu, S.; Yao, Z.; Zhang, W.; Xu, X.; Dou, C.; et al. A low-power vertical dual-gate neurotransistor with short-term memory for high energy-efficient neuromorphic computing. Nat. Commun. 2023, 14, 6385. [Google Scholar] [CrossRef] [PubMed]

- Yi, W.; Tsang, K.K.; Lam, S.K.; Bai, X.; Crowell, J.A.; Flores, E.A. Biological plausibility and stochasticity in scalable VO2 active memristor neurons. Nat. Commun. 2018, 9, 4661. [Google Scholar] [CrossRef]

- Baek, E.; Song, S.; Baek, C.-K.; Rong, Z.; Shi, L.; Cannistraci, C.V. Neuromorphic dendritic network computation with silent synapses for visual motion perception. Nat. Electron. 2024, 7, 454–465. [Google Scholar] [CrossRef]

- Bonagiri, A.; Das, S.K.; Marquez, C.V.; Rúa, A.; Puyoo, E.; Nath, S.K.; Albertini, D.; Baboux, N.; Uenuma, M.; Elliman, R.G.; et al. Biorealistic Neuronal Temperature-Sensitive Dynamics within Threshold Switching Memristors: Toward Neuromorphic Thermosensation. ACS Appl. Mater. Interfaces 2024, 16, 31283–31293. [Google Scholar] [CrossRef]

- Rahman, M.A.; Walia, S.; Naznee, S.; Taha, M.; Nirantar, S.; Rahman, F.; Bhaskaran, M.; Sriram, S. Artificial Somatosensors: Feedback Receptors for Electronic Skins. Adv. Intell. Syst. 2020, 2, 2000094. [Google Scholar] [CrossRef]

- Duan, Q.; Zhang, T.; Liu, C.; Yuan, R.; Li, G.; Tiw, P.J.; Yang, K.; Ge, C.; Yang, Y.; Huang, R. Artificial Multisensory Neurons with Fused Haptic and Temperature Perception for Multimodal In-Sensor Computing. Adv. Intell. Syst. 2022, 4, 2200039. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, X.; Wang, R.; Wang, M.; Chen, P.; Cheng, L.; Wu, Z.; Wang, Y.; Liu, Q.; Liu, M. A Heterogeneously Integrated Spiking Neuron Array for Multimode-Fused Perception and Object Classification. Adv. Mater. 2022, 34, 2200481. [Google Scholar] [CrossRef]

- Wang, B.; Shi, Y.; Li, H.; Hua, Q.; Ji, K.; Dong, Z.; Cui, Z.; Huang, T.; Chen, Z.; Wei, R.; et al. Body-Integrated Ultrasensitive All-Textile Pressure Sensors for Skin-Inspired Artificial Sensory Systems. Small Sci. 2024, 4, 2400026. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, B.; Zhou, X.; Hua, Q.; Gong, J.; Liu, T.; Cui, X.; Zhu, J.; Guo, W.; Jing, L.; et al. Strain-controlled Power Devices as Inspired by Human Reflex. Nat. Commun. 2020, 11, 326. [Google Scholar] [CrossRef] [PubMed]

- Yoon, J.H.; Wang, Z.; Kim, K.M.; Wu, H.; Ravichandran, V.; Xia, Q.; Hwang, C.S.; Yang, J.J. An artificial nociceptor based on a diffusive memristor. Nat. Commun. 2018, 9, 417. [Google Scholar] [CrossRef]

- Yadlapalli, S.; Jiang, C.; Bahle, A.; Reddy, P.; Meyhofer, E.; Shafer, O.T. Circadian clock neurons constantly monitor environmental temperature to set sleep timing. Nature 2018, 555, 98–102. [Google Scholar] [CrossRef]

- Rouyer, F.; Chatterjee, A. A receptor for subtle temperature changes. Nature 2015, 527, 449–451. [Google Scholar] [CrossRef]

- Bian, H.; Goh, Y.Y.; Liu, Y.; Ling, H.; Xie, L.; Liu, X. Power-efficient neural network with artificial dendrites. Nat. Nanotechnol. 2020, 15, 776–782. [Google Scholar]

- Bian, H.; Goh, Y.Y.; Liu, Y.; Ling, H.; Xie, L.; Liu, X. Stimuli-Responsive Memristive Material for Artificial Synapses and Neuromorphic Computing. Adv. Mater. 2021, 33, 2006469. [Google Scholar] [CrossRef] [PubMed]

- Hua, Q.; Wu, H.; Gao, B.; Zhang, Q.; Wu, W.; Li, Y.; Wang, X.; Hu, W.; Qian, H. Low-Voltage Oscillatory Neurons for Memristor-Based Neuromorphic Systems. Glob. Chall. 2019, 3, 1900015. [Google Scholar] [CrossRef]

- Dai, X.; Hua, Q.; Jiang, C.; Long, Y.; Dong, Z.; Shi, Y.; Huang, T.; Li, H.; Meng, H.; Yang, Y.; et al. Artificial synapse based on a tri-layer AlN/AlScN/AlN stacked memristor for neuromorphic computing. Nano Energy 2024, 124, 2211–2855. [Google Scholar]

- Deng, Q.; Wang, C.; Sun, J.; Sun, Y.; Jiang, J.; Lin, H.; Deng, Z. Nonvolatile CMOS Memristor, Reconfigurable Array, and Its Application in Power Load Forecasting. IEEE Trans. Ind. Inform. 2023, 20, 6130–6141. [Google Scholar] [CrossRef]

- Deng, Z.; Wang, C.; Lin, H.; Deng, Q.; Sun, Y. Memristor-Based attention Network for Online Real-Time Object Tracking. IEEE Trans. Comput. Aided Des. Integr. Circuits Syst. 2025, 44, 684–695. [Google Scholar] [CrossRef]

- Li, Z.; Tang, W.; Yao, J.; Dou, Z.; Gong, J.; Li, Y.; Zhang, B.; Dong, Y.; Xia, J.; Sun, L. Crossmodal sensory neurons based on high-performance flexible memristors for human-machine in-sensor computing system. Nat. Commun. 2024, 15, 7275. [Google Scholar] [CrossRef]

- Wang, W.; Pedretti, G.; Milo, V.; Carboni, R.; Calderoni, A.; Ramaswamy, N.; Spinelli, A.S.; Ielmini, D. Computing of temporal information in spiking neural networks with ReRAM synapses. Faraday Discuss 2019, 213, 453–469. [Google Scholar] [CrossRef] [PubMed]

- Deng, Q.; Wang, C.; Sun, Y.; Deng, Z.; Yang, G. Memristive tabu learning neuron generated multi-wing attractor with FPGA implementation and application in encryption. IEEE Trans. Circuits Syst. I Regul. Pap. 2025, 72, 300–311. [Google Scholar] [CrossRef]

- Shi, Y.; Hua, Q.; Dong, Z.; Wang, B.; Dai, X.; Niu, J.; Cui, Z.; Huang, T.; Wang, Z.L.; Hu, W. Neuro-inspired thermoresponsive nociceptor for intelligent sensory systems. Nano Energy 2023, 113, 2211–2855. [Google Scholar] [CrossRef]

- Lv, Z.; Zhu, S.; Wang, Y.; Ren, Y.; Luo, M.; Wang, H.; Zhang, G.; Zhai, Y.; Zhao, S.; Zhou, Y.; et al. Development of Bio-Voltage Operated Humidity-Sensory Neurons Comprising Self-Assembled Peptide Memristors. Adv. Mater. 2024, 36, 2405145. [Google Scholar] [CrossRef]

- Milano, G.; Luebben, M.; Ma, Z.; Dunin-Borkowski, R.; Boarino, L.; Pirri, C.F.; Waser, R.; Ricciardi, C.; Valov, I. Self-limited single nanowire systems combining all-in-one memristive and neuromorphic functionalities. Nat. Commun. 2018, 9, 5151. [Google Scholar] [CrossRef]

- Yang, C.; Wang, H.; Zhou, G.; Zhao, H.; Hou, W.; Zhu, S.; Zhao, Y.; Sun, B. A Multimodal Perception-Enabled Flexible Memristor with Combined Sensing-Storage-Memory Functions for Enhanced Artificial Injury Recognition. Small 2024, 20, e2402588. [Google Scholar] [CrossRef]

- Hua, Q.; Jiang, C.; Hu, W. Ag/HfO2-based Threshold Switching Memristor as an Oscillatory Neuron. In Proceedings of the IEEE Electron Devices Technology and Manufacturing Conference (EDTM), Chengdu, China, 8–11 April 2021. [Google Scholar]

- Wang, S.; Yang, T.; Zhang, D.; Hua, Q.; Zhao, Y. Unveiling Gating Behavior in Piezoionic Effect: Toward Neuromimetic Tactile Sensing. Adv. Mater. 2024, 36, e2405391. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, Z.; Kim, B.J.; Zhou, Y.; Wang, Z.; Wan, T.; Yan, J.; Kang, J.; Ahn, J.-H.; Chai, Y. Optoelectronic graded neurons for bioinspired in-sensor motion perception. Nat. Nanotechnol. 2023, 18, 882–888. [Google Scholar] [CrossRef]

- Hua, Q.; Shen, G. Low-dimensional nanostructures for monolithic 3D-integrated flexible and stretchable electronics. Chem. Soc. Rev. 2024, 53, 1316–1353. [Google Scholar] [CrossRef] [PubMed]

- Pei, M.; Zhu, Y.; Liu, S.; Cui, H.; Li, Y.; Yan, Y.; Li, Y.; Wan, C.; Wan, Q. Power-Efficient Multisensory Reservoir Computing Based on Zr-Doped HfO2 Memcapacitive Synapse Arrays. Adv. Mater. 2023, 35, 2305609. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).