Low-Power, Flexible Sensor Arrays with Solderless Board-to-Board Connectors for Monitoring Soil Deformation and Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Inclination Measurements Using Accelerometers

2.2. Sensor Arrays for Deformation Monitoring

2.3. Electronic Design

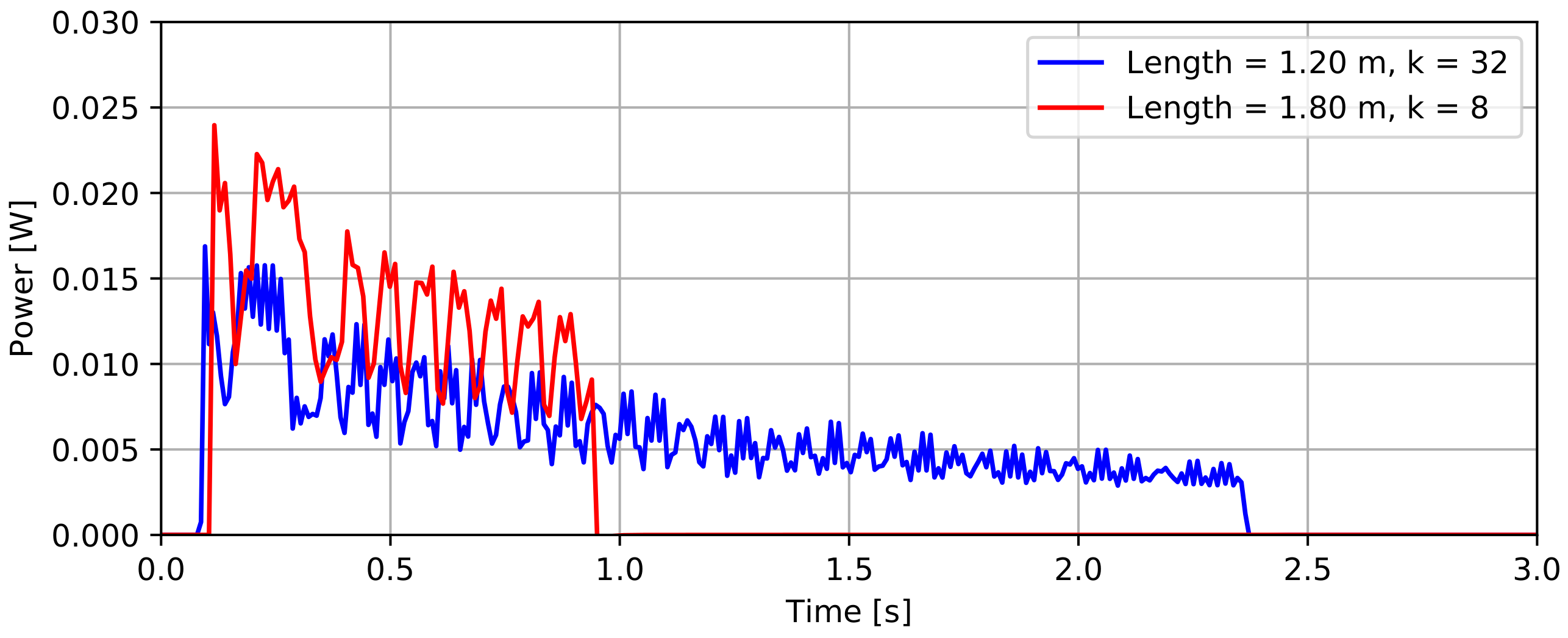

Device Integration and Power Consumption

| Algorithm 1: Probe Measurement |

|

2.4. Electromechanical Design

- Connector–cable–connector setups: This labor intensive, costly, and bulky solution is often found in prototypes and low-volume production devices [44]. Each sensor board has an incoming and outgoing connector soldered onto it, and all boards are connected with cable assemblies. The cost of the connector terminals, cable assemblies, soldering, and manual assembly easily exceeds the actual cost of the sensors.

- Direct PCB-to-PCB soldering: This technique is often found in cascaded LED strips and constitutes PCB edge pads that are aligned and soldered together. This approach is labor intensive, prone to production errors, and often mechanically unreliable, as mechanical stress can result in solder cracks [45].

- Board-to-board connectors: Solder-mounted board-to-board connectors are commonly used in electronic designs and can accommodate the required fixed sensor spacing when mounted at the edge of the board. However, these parts are usually costly, affect production yields and cost, are often unreliable under mechanical stress, and—most importantly—require too much board space, affecting the thickness of the entire probe [44].

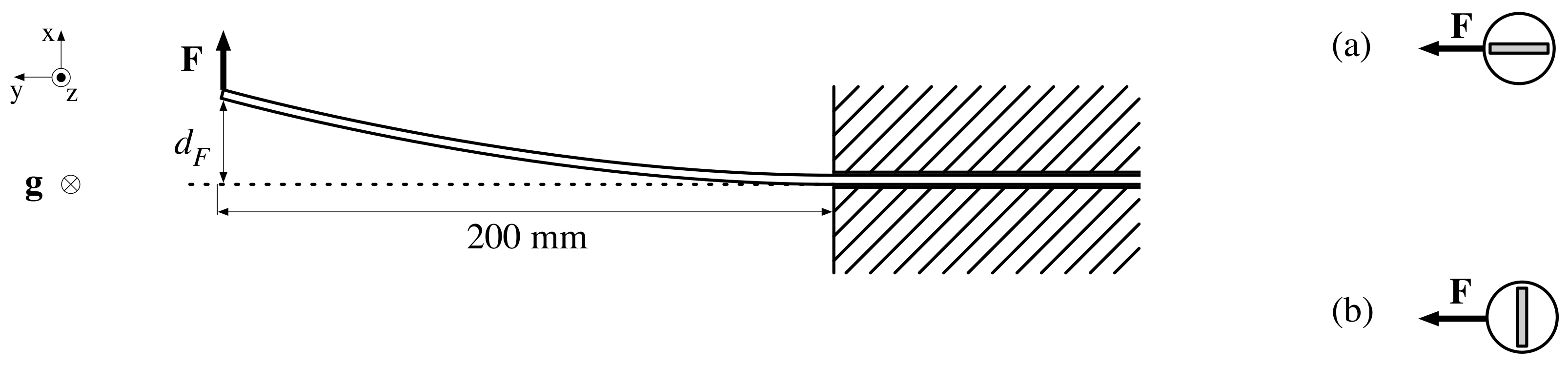

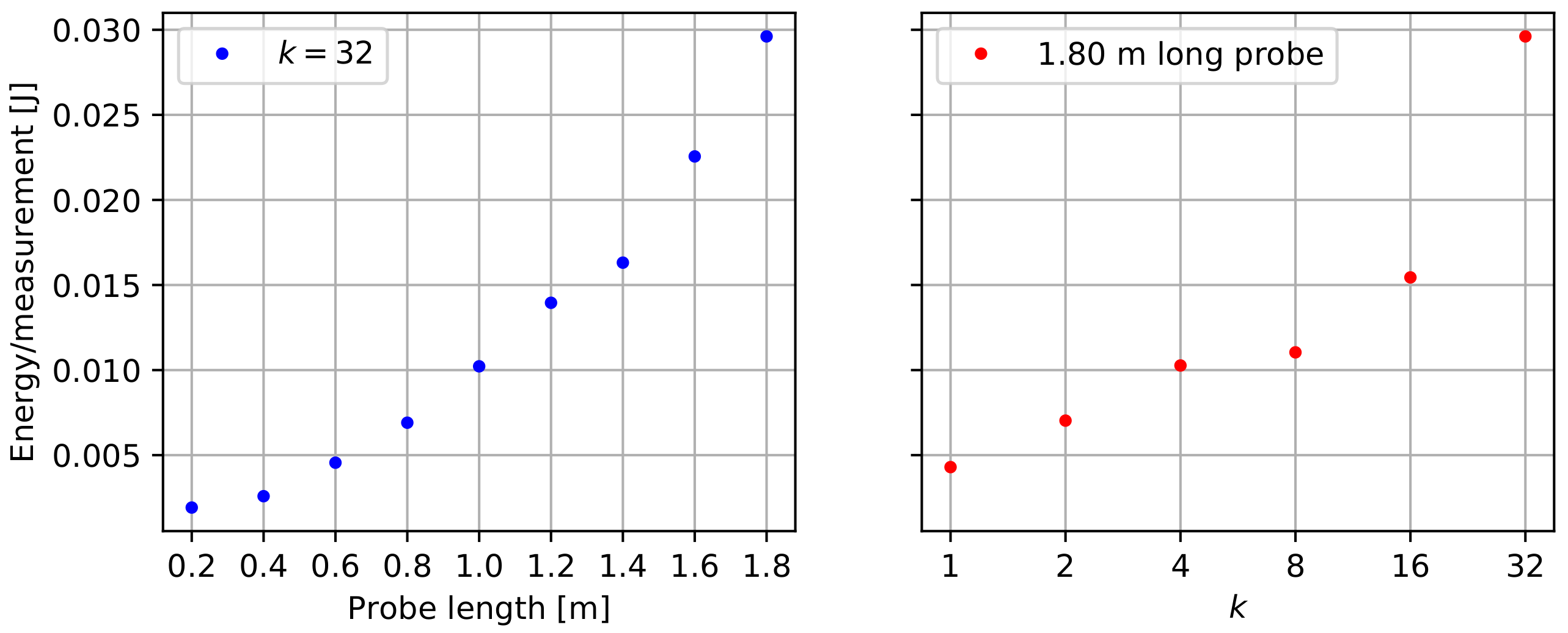

2.4.1. Probe Flexibility Tests

2.4.2. Connector Evaluation

2.5. Functional Probe Evaluation and Accuracy Assessment

3. Results

3.1. Power Consumption

3.2. Probe Flexibility

3.3. Electromechanical Connector Characteristics

3.3.1. Trace Resistance

3.3.2. Thermal Effects and Epoxying

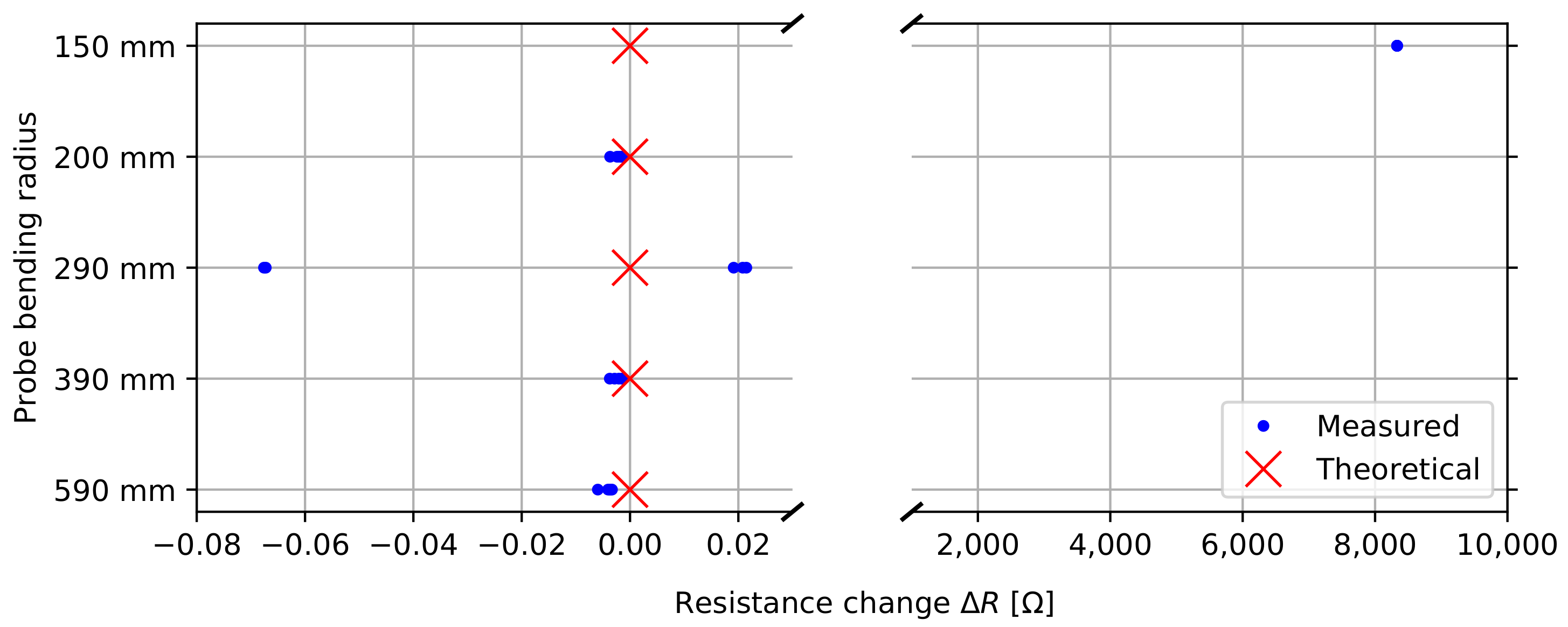

3.3.3. Probe Bending

3.3.4. Trace Resistance over Time

3.4. Accuracy Assessment

3.5. Field Experiment

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Froude, M.J.; Petley, D.N. Global fatal landslide occurrence from 2004 to 2016. Nat. Hazards Earth Syst. Sci. 2018, 18, 2161–2181. [Google Scholar] [CrossRef] [Green Version]

- Taylor, F.E.; Tarolli, P.; Malamud, B.D. Preface: Landslide–transport network interactions. Nat. Hazards Earth Syst. Sci. 2020, 20, 2585–2590. [Google Scholar] [CrossRef]

- Voumard, J.; Derron, M.H.; Jaboyedoff, M. Natural hazard events affecting transportation networks in Switzerland from 2012 to 2016. Nat. Hazards Earth Syst. Sci. 2018, 18, 2093–2109. [Google Scholar] [CrossRef] [Green Version]

- Glendinning, S.; Hughes, P.; Helm, P.; Chambers, J.; Mendes, J.; Gunn, D.; Wilkinson, P.; Uhlemann, S. Construction, management and maintenance of embankments used for road and rail infrastructure: Implications of weather induced pore water pressures. Acta Geotech. 2014, 9, 799–816. [Google Scholar] [CrossRef]

- Smethurst, J.A.; Smith, A.; Uhlemann, S.; Wooff, C.; Chambers, J.; Hughes, P.; Lenart, S.; Saroglou, H.; Springman, S.M.; Löfroth, H.; et al. Current and future role of instrumentation and monitoring in the performance of transport infrastructure slopes. Q. J. Eng. Geol. Hydrogeol. 2017, 50, 271–286. [Google Scholar] [CrossRef] [Green Version]

- Hungr, O.; Leroueil, S.; Picarelli, L. The Varnes classification of landslide types, an update. Landslides 2014, 11, 167–194. [Google Scholar] [CrossRef]

- Uhlemann, S.; Smith, A.; Chambers, J.; Dixon, N.; Dijkstra, T.; Haslam, E.; Meldrum, P.; Merritt, A.; Gunn, D.; Mackay, J. Assessment of ground-based monitoring techniques applied to landslide investigations. Geomorphology 2016, 253, 438–451. [Google Scholar] [CrossRef] [Green Version]

- Ramesh, M.V.; Vasudevan, N. The deployment of deep-earth sensor probes for landslide detection. Landslides 2012, 9, 457–474. [Google Scholar] [CrossRef]

- Holmes, J.; Chambers, J.; Meldrum, P.; Wilkinson, P.; Boyd, J.; Williamson, P.; Huntley, D.; Sattler, K.; Elwood, D.; Sivakumar, V.; et al. Four-dimensional electrical resistivity tomography for continuous, near-real-time monitoring of a landslide affecting transport infrastructure in British Columbia, Canada. Surf. Geophys. 2020, 18, 337–351. [Google Scholar] [CrossRef] [Green Version]

- Glendinning, S.; Helm, P.R.; Rouainia, M.; Stirling, R.A.; Asquith, J.D.; Hughes, P.N.; Toll, D.G.; Clarke, D.; Powrie, W.; Smethurst, J.; et al. Research-informed design, management and maintenance of infrastructure slopes: Development of a multi-scalar approach. IOP Conf. Ser. Earth Environ. Sci. 2015, 26, 012005. [Google Scholar] [CrossRef] [Green Version]

- Özer, I.E.; van Leijen, F.J.; Jonkman, S.N.; Hanssen, R.F. Applicability of satellite radar imaging to monitor the conditions of levees. J. Flood Risk Manag. 2019, 12, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Sharma, P.; Jones, C.E.; Dudas, J.; Bawden, G.W.; Deverel, S. Monitoring of subsidence with UAVSAR on Sherman Island in California’s Sacramento–San Joaquin Delta. Remote Sens. Environ. 2016, 181, 218–236. [Google Scholar] [CrossRef] [Green Version]

- Schenato, L. A Review of Distributed Fibre Optic Sensors for Geo-Hydrological Applications. Appl. Sci. 2017, 7, 896. [Google Scholar] [CrossRef]

- Ajo-Franklin, J.B.; Dou, S.; Lindsey, N.J.; Monga, I.; Tracy, C.; Robertson, M.; Rodriguez Tribaldos, V.; Ulrich, C.; Freifeld, B.; Daley, T.; et al. Distributed Acoustic Sensing Using Dark Fiber for Near-Surface Characterization and Broadband Seismic Event Detection. Sci. Rep. 2019, 9, 1328. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thoen, B.; Callebaut, G.; Leenders, G.; Wielandt, S. A Deployable LPWAN Platform for Low-Cost and Energy-Constrained IoT Applications. Sensors 2019, 19, 585. [Google Scholar] [CrossRef] [Green Version]

- Ramesh, M.V. Design, development, and deployment of a wireless sensor network for detection of landslides. Ad Hoc Netw. 2014, 13, 2–18. [Google Scholar] [CrossRef]

- Intrieri, E.; Gigli, G.; Mugnai, F.; Fanti, R.; Casagli, N. Design and implementation of a landslide early warning system. Eng. Geol. 2012, 147–148, 124–136. [Google Scholar] [CrossRef] [Green Version]

- Wielandt, S.; Dafflon, B. A Local LoRa Based Network Protocol with Low Power Redundant Base Stations Enabling Remote Environmental Monitoring. In Proceedings of the 2020 54th Asilomar Conference on Signals, Systems, and Computers, Pacific Grove, CA, USA, 1–5 November 2020; pp. 520–523. [Google Scholar] [CrossRef]

- Callebaut, G.; Leenders, G.; Van Mulders, J.; Ottoy, G.; De Strycker, L.; Van der Perre, L. The Art of Designing Remote IoT Devices—Technologies and Strategies for a Long Battery Life. Sensors 2021, 21, 913. [Google Scholar] [CrossRef]

- Abdoun, T.; Bennett, V.; Desrosiers, T.; Simm, J.; Barendse, M. Asset Management and Safety Assessment of Levees and Earthen Dams Through Comprehensive Real-Time Field Monitoring. Geotech. Geol. Eng. 2013, 31, 833–843. [Google Scholar] [CrossRef]

- Ruzza, G.; Guerriero, L.; Revellino, P.; Guadagno, F.M. A Multi-Module Fixed Inclinometer for Continuous Monitoring of Landslides: Design, Development, and Laboratory Testing. Sensors 2020, 20, 3318. [Google Scholar] [CrossRef]

- Wielandt, S.; Dafflon, B. Minimizing Power Consumption in Networks of Environmental Sensor Arrays using TDD LoRa and Delta Encoding. In Proceedings of the 2021 55th Asilomar Conference on Signals, Systems, and Computers, Pacific Grove, CA, USA, 31 October–3 November 2021; pp. 318–323. [Google Scholar] [CrossRef]

- Léger, E.; Dafflon, B.; Robert, Y.; Ulrich, C.; Peterson, J.E.; Biraud, S.C.; Romanovsky, V.E.; Hubbard, S.S. A distributed temperature profiling method for assessing spatial variability in ground temperatures in a discontinuous permafrost region of Alaska. Cryosphere 2019, 13, 2853–2867. [Google Scholar] [CrossRef] [Green Version]

- Vogt, T.; Schneider, P.; Hahn-Woernle, L.; Cirpka, O.A. Estimation of seepage rates in a losing stream by means of fiber-optic high-resolution vertical temperature profiling. J. Hydrol. 2010, 380, 154–164. [Google Scholar] [CrossRef]

- Darrow, M.M.; Daanen, R.P.; Gong, W. Predicting movement using internal deformation dynamics of a landslide in permafrost. Cold Reg. Sci. Technol. 2017, 143, 93–104. [Google Scholar] [CrossRef]

- Bogaard, T.A.; Greco, R. Landslide hydrology: From hydrology to pore pressure. Wiley Interdiscip. Rev. Water 2015, 3, 439–459. [Google Scholar] [CrossRef]

- Steele-Dunne, S.C.; Rutten, M.M.; Krzeminska, D.M.; Hausner, M.; Tyler, S.W.; Selker, J.; Bogaard, T.A.; van de Giesen, N.C. Feasibility of soil moisture estimation using passive distributed temperature sensing. Water Resour. Res. 2010, 46, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Tran, A.P.; Dafflon, B.; Hubbard, S.S. Coupled land surface–subsurface hydrogeophysical inverse modeling to estimate soil organic carbon content and explore associated hydrological and thermal dynamics in the Arctic tundra. Cryosphere 2017, 11, 2089–2109. [Google Scholar] [CrossRef] [Green Version]

- Brunetti, C.; Lamb, J.; Wielandt, S.; Uhlemann, S.; Shirley, I.; McClure, P.; Dafflon, B. Estimation of depth-resolved profiles of soil thermal diffusivity from temperature time series and uncertainty quantification. Earth Surf. Dyn. Discuss. 2021, 2021, 1–25. [Google Scholar] [CrossRef]

- Nicolsky, D.; Romanovsky, V.; Panteleev, G. Estimation of soil thermal properties using in-situ temperature measurements in the active layer and permafrost. Cold Reg. Sci. Technol. 2009, 55, 120–129. [Google Scholar] [CrossRef]

- Swanson, D.K. Permafrost thaw-related slope failures in Alaska’s Arctic National Parks, c. 1980–2019. Permafr. Periglac. Process. 2021, 32, 392–406. [Google Scholar] [CrossRef]

- Dafflon, B.; Wielandt, S.; Lamb, J.; McClure, P.; Shirley, I.; Uhlemann, S.; Wang, C.; Fiolleau, S.; Brunetti, C.; Akins, F.H.; et al. A distributed temperature profiling system for vertically and laterally dense acquisition of soil and snow temperature. Cryosphere 2022, 16, 719–736. [Google Scholar] [CrossRef]

- Wielandt, S.; Dafflon, B. Sensor Probes Including Boards Having Solderless Interconnects. U.S. Patent 17/543,032, 3 December 2021. [Google Scholar]

- Yang, H.; Rao, Y.; Li, L.; Liang, H.; Luo, T.; Luo, B. Dynamic Measurement of Well Inclination Based on UKF and Correlation Extraction. IEEE Sens. J. 2021, 21, 4887–4899. [Google Scholar] [CrossRef]

- Fisher, C.J. Using an Accelerometer for Inclination Sensing; Application Note AN-1057; Analog Devices: Norwood, MA, USA, 2010. [Google Scholar]

- Murphy, C. Choosing the Most Suitable MEMS Accelerometer for Your Application–Part 1; Application Note; Analog Devices: Norwood, MA, USA, 2017. [Google Scholar]

- Analog Devices. 3-Axis, ±2 g/±4 g/±8 g/±16 g Digital Accelerometer—ADXL345 Rev. E.; Data Sheet; Analog Devices: Norwood, MA, USA, 2015. [Google Scholar]

- Texas Instruments. SN74LVC1G175 Single D-Type Flip-Flop with Asynchronous Clear; Data Sheet; Texas Instruments: Dallas, TX, USA, 2015. [Google Scholar]

- Texas Instruments. TMP117 High-Accuracy, Low-Power, Digital Temperature Sensor with SMBus and I2C-Compatible Interface; Data Sheet; Texas Instruments: Dallas, TX, USA, 2021. [Google Scholar]

- Crell, C. Product Data Sheet—Energizer L91 Ultimate Lithium (L91GL1218); Data Sheet; Energizer: St. Louis, MO, USA, 2018. [Google Scholar]

- Callebaut, G.; Van der Perre, L. Characterization of LoRa Point-to-Point Path Loss: Measurement Campaigns and Modeling Considering Censored Data. IEEE Internet Things J. 2020, 7, 1910–1918. [Google Scholar] [CrossRef]

- Tong, C. Advanced Materials for Printed Flexible Electronics; Springer: Bolingbrook, IL, USA, 2022. [Google Scholar]

- Engel, P.A. Structural Analysis of Printed Circuit Board Systems; Springer: New York, NY, USA, 1993. [Google Scholar]

- Kyeong, S.; Pecht, M.G. Electrical Connectors: Design, Manufacture, Test, and Selection; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Ganesan, S.; Pecht, M.G. Lead-Free Electronics; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Japan Solderless Terminal. SH Connector: 1.0 mm Pitch/Disconnectable Crimp Style Connectors; Data Sheet; Japan Solderless Terminal: Osaka, Japan, 2021. [Google Scholar]

- Hinojosa, M.; Rodríguez, C.A.; Aldaco, J.A.; Morales-Castillo, J.; Leal, A.E.; Salinas, V. Study of the Thermomechanical Performance of FR-4 Laminates During the Reflow Process. J. Mater. Eng. Perform. 2019, 28, 6761–6770. [Google Scholar] [CrossRef]

- Epoxies Inc. Unfilled Low Durometer Clear Urethane Elastomers; Data Sheet; Epoxies Inc.: Cranston, RI, USA, 2012. [Google Scholar]

- Aarts, A.; Neves, H.P.; Puers, R.P.; van Hoof, C. Interconnect for Out-of-Plane Mems Assembly. In Proceedings of the 2008 International Interconnect Technology Conference, Burlingame, CA, USA, 1–4 June 2008; pp. 132–134. [Google Scholar] [CrossRef]

- Das, B.M.; Sobhan, K. Principles of Geotechnical Engineering Eighth Edition, SI; Cengage Learning: Stamford, CT, USA, 2012. [Google Scholar]

- Matula, R.A. Electrical resistivity of copper, gold, palladium, and silver. J. Phys. Chem. Ref. Data 1979, 8, 1147–1298. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wielandt, S.; Uhlemann, S.; Fiolleau, S.; Dafflon, B. Low-Power, Flexible Sensor Arrays with Solderless Board-to-Board Connectors for Monitoring Soil Deformation and Temperature. Sensors 2022, 22, 2814. https://doi.org/10.3390/s22072814

Wielandt S, Uhlemann S, Fiolleau S, Dafflon B. Low-Power, Flexible Sensor Arrays with Solderless Board-to-Board Connectors for Monitoring Soil Deformation and Temperature. Sensors. 2022; 22(7):2814. https://doi.org/10.3390/s22072814

Chicago/Turabian StyleWielandt, Stijn, Sebastian Uhlemann, Sylvain Fiolleau, and Baptiste Dafflon. 2022. "Low-Power, Flexible Sensor Arrays with Solderless Board-to-Board Connectors for Monitoring Soil Deformation and Temperature" Sensors 22, no. 7: 2814. https://doi.org/10.3390/s22072814

APA StyleWielandt, S., Uhlemann, S., Fiolleau, S., & Dafflon, B. (2022). Low-Power, Flexible Sensor Arrays with Solderless Board-to-Board Connectors for Monitoring Soil Deformation and Temperature. Sensors, 22(7), 2814. https://doi.org/10.3390/s22072814