Air-Coupled and Resonant Pulse-Echo Ultrasonic Technique

Abstract

:1. Introduction

2. Materials and Methods

2.1. Methods

2.2. Experimental Methods and Setups

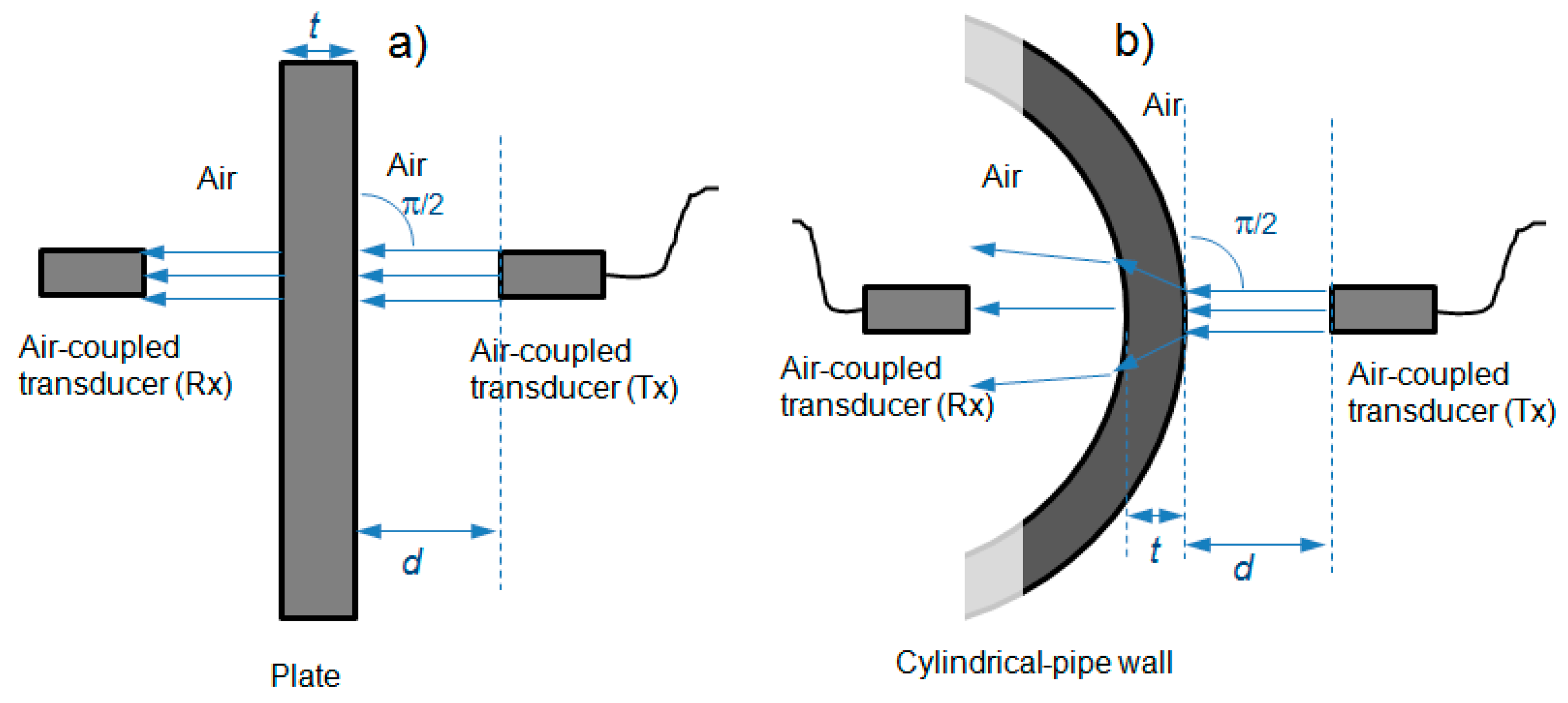

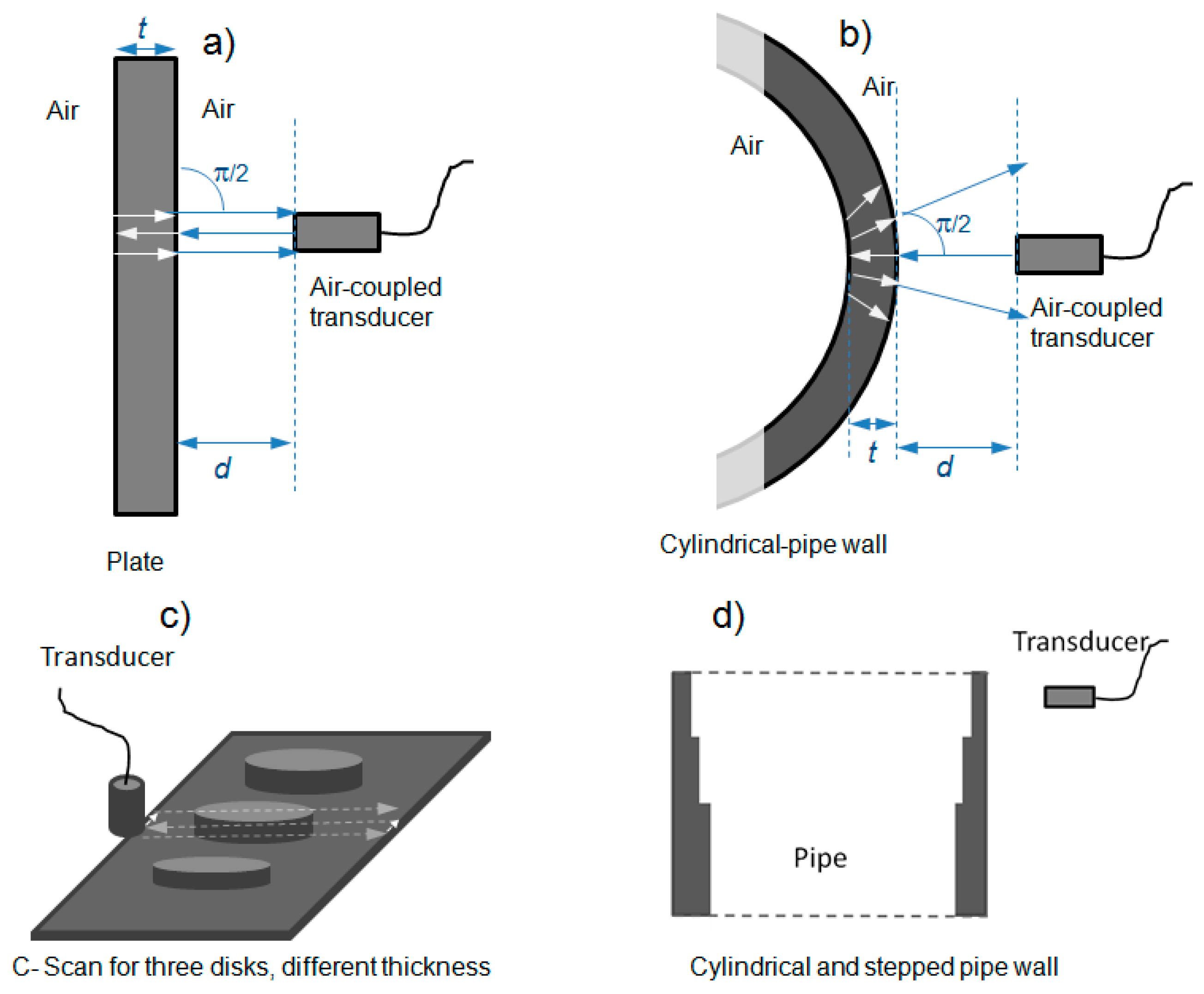

2.2.1. Through-Transmission (TT)

2.2.2. Pulse-Echo (PE)

2.2.3. Resonant PE C-Scan Images

2.3. Materials

3. Results

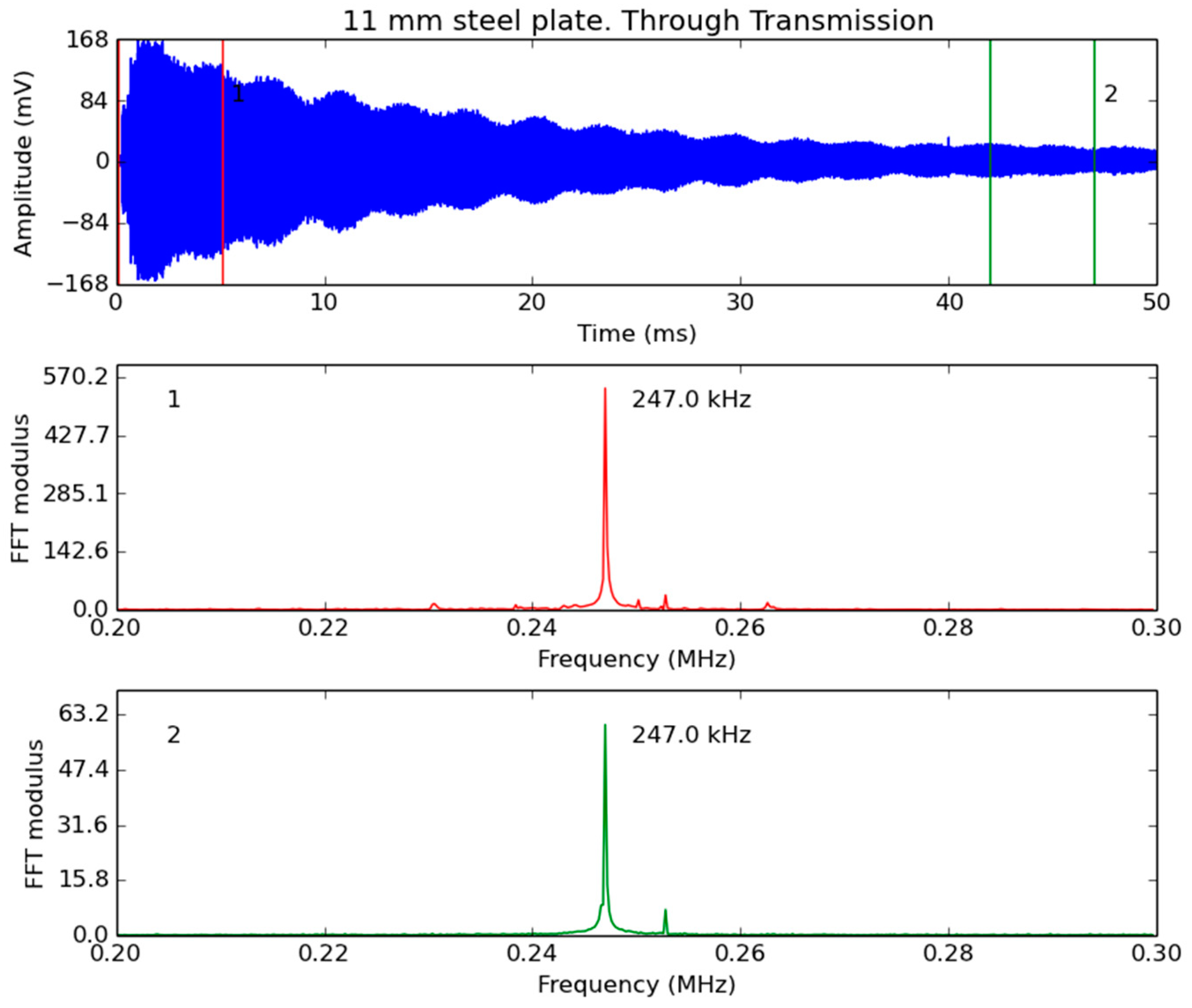

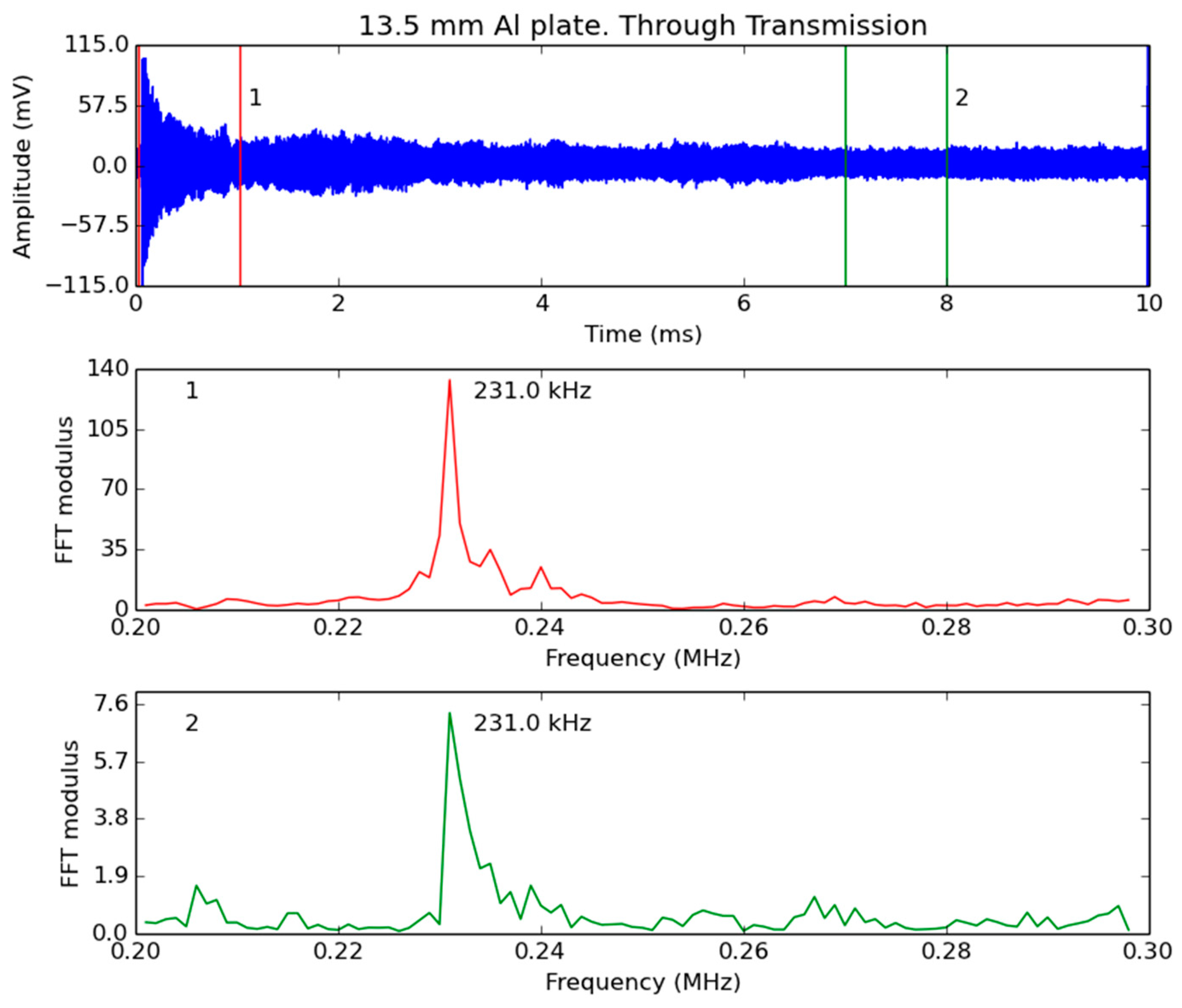

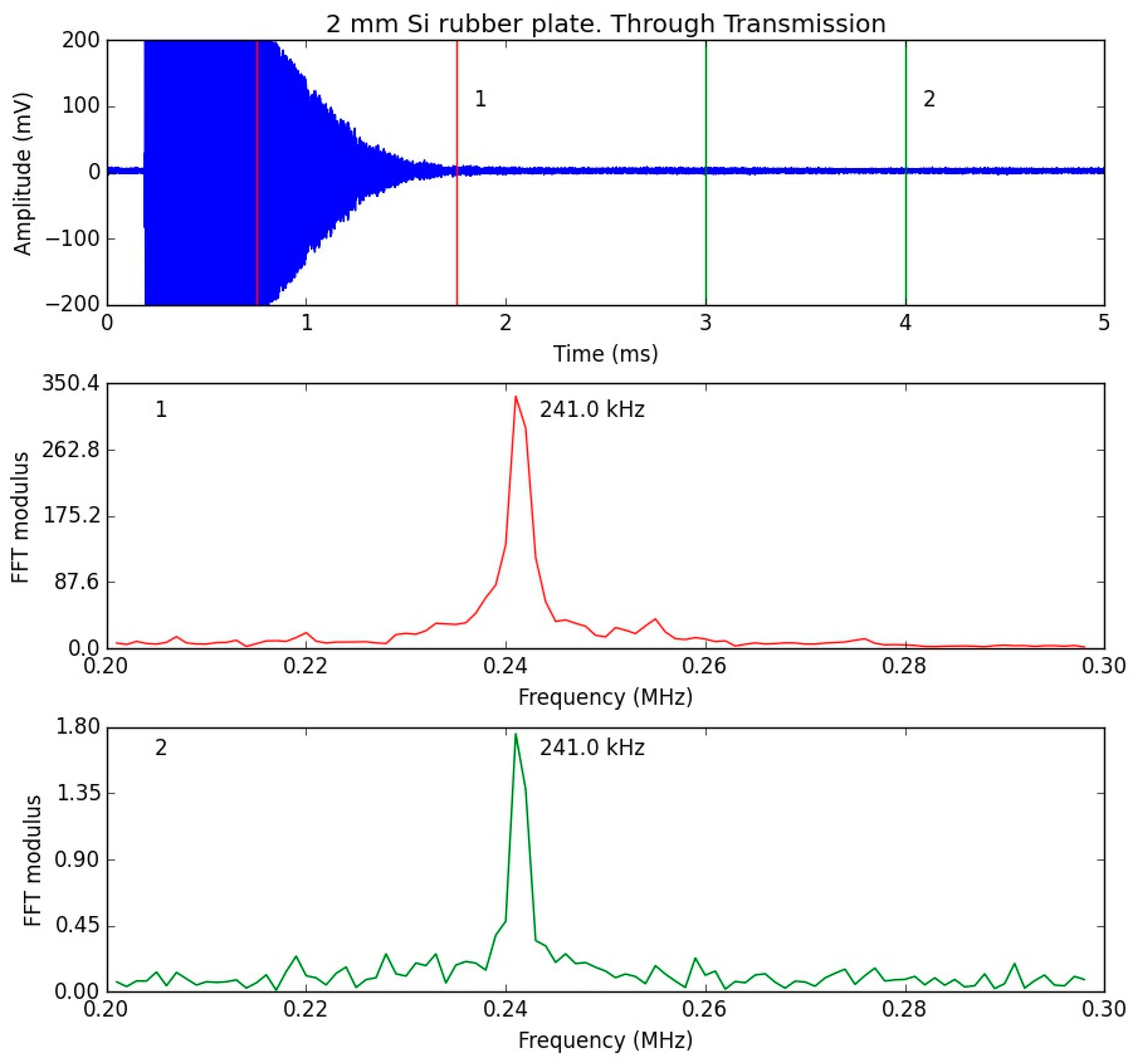

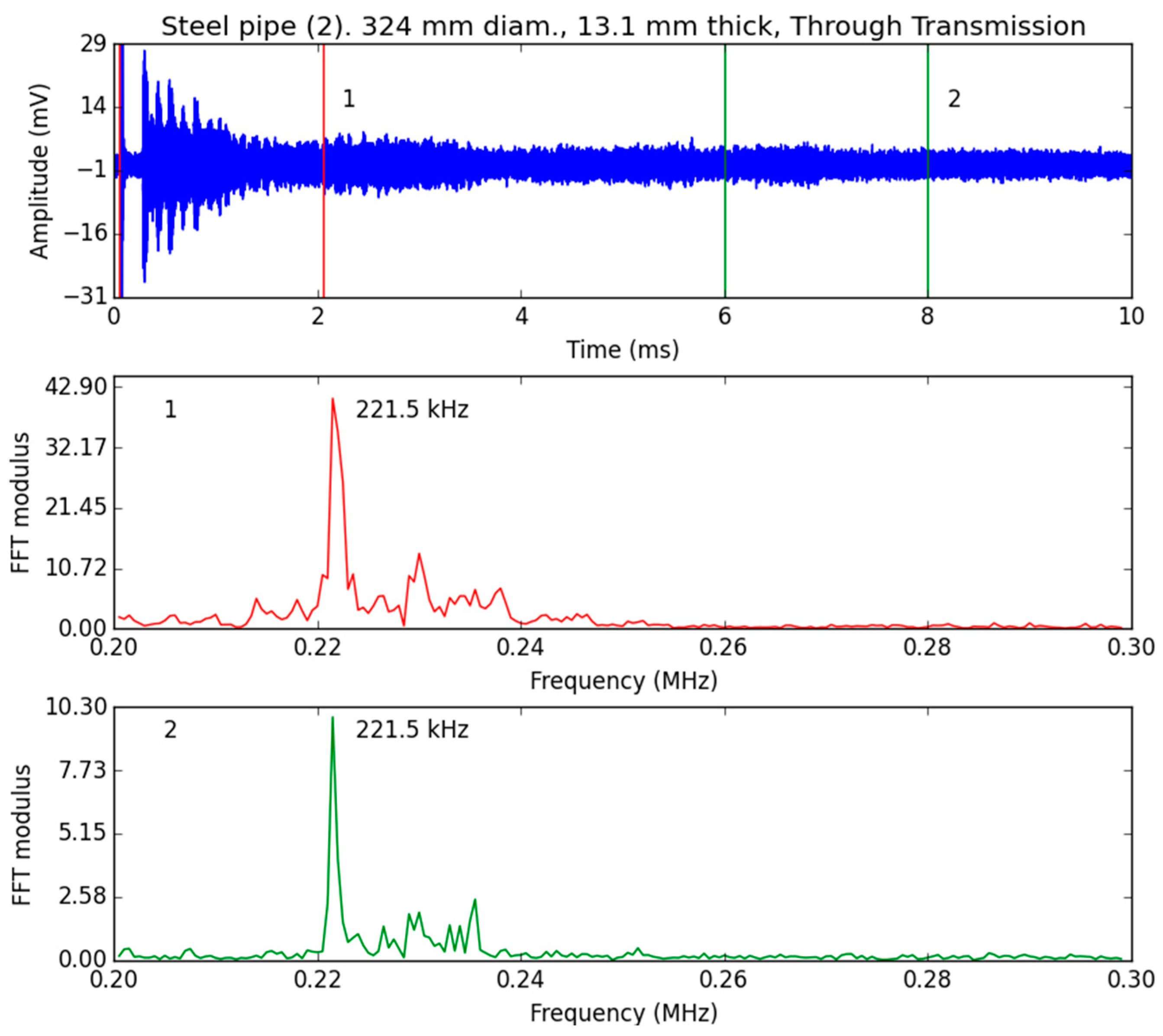

3.1. Through-Transmission

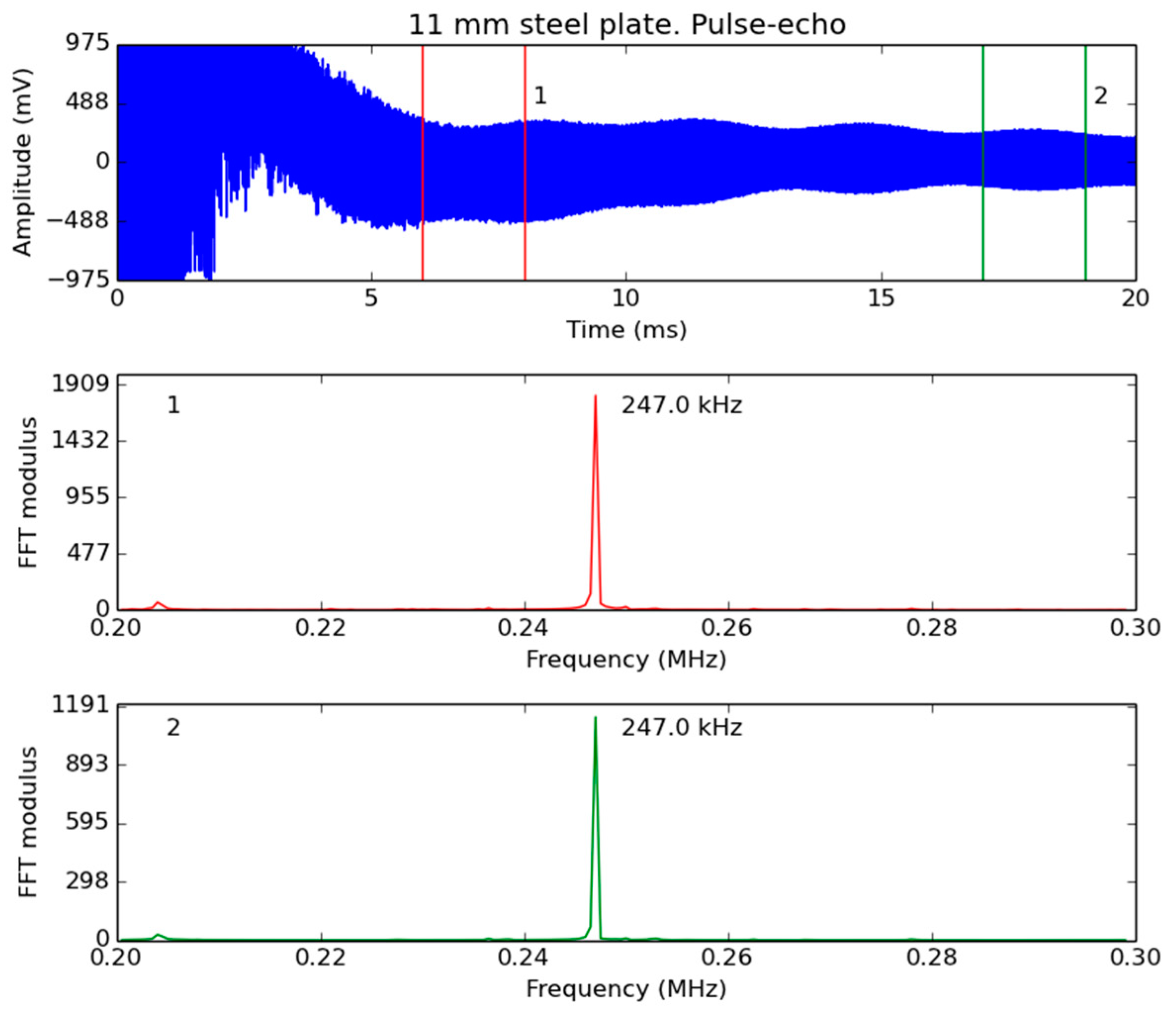

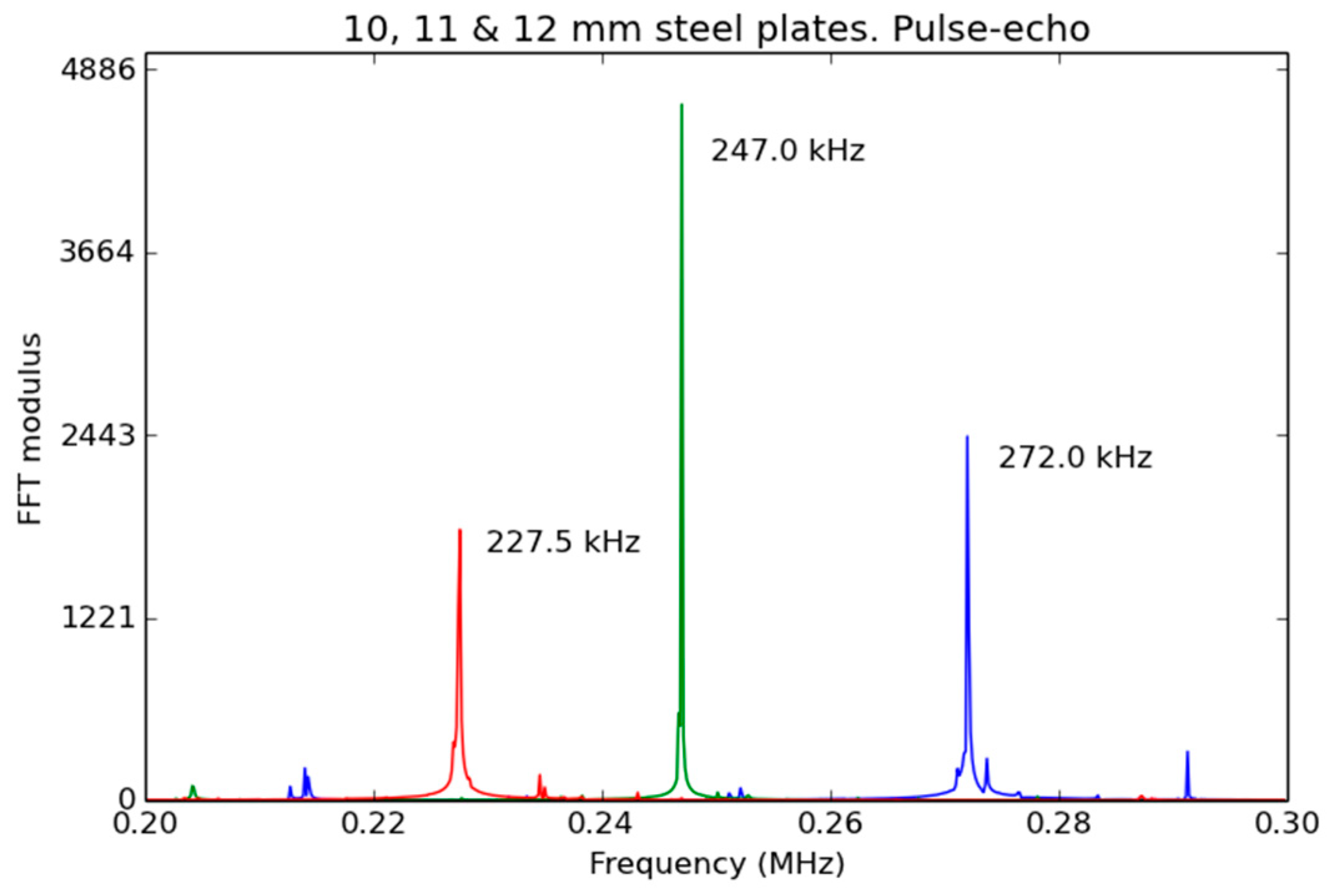

3.2. Pulse-Echo

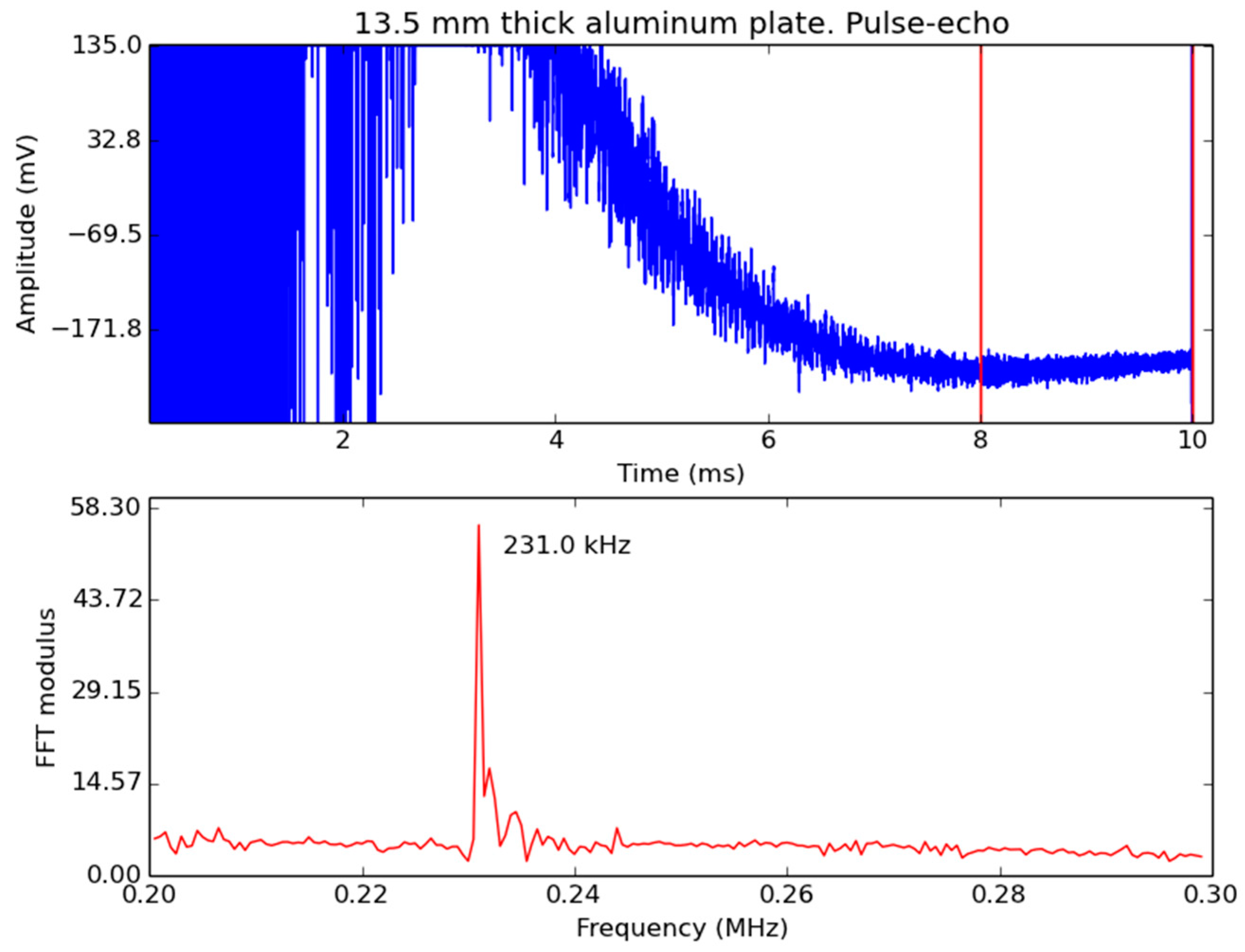

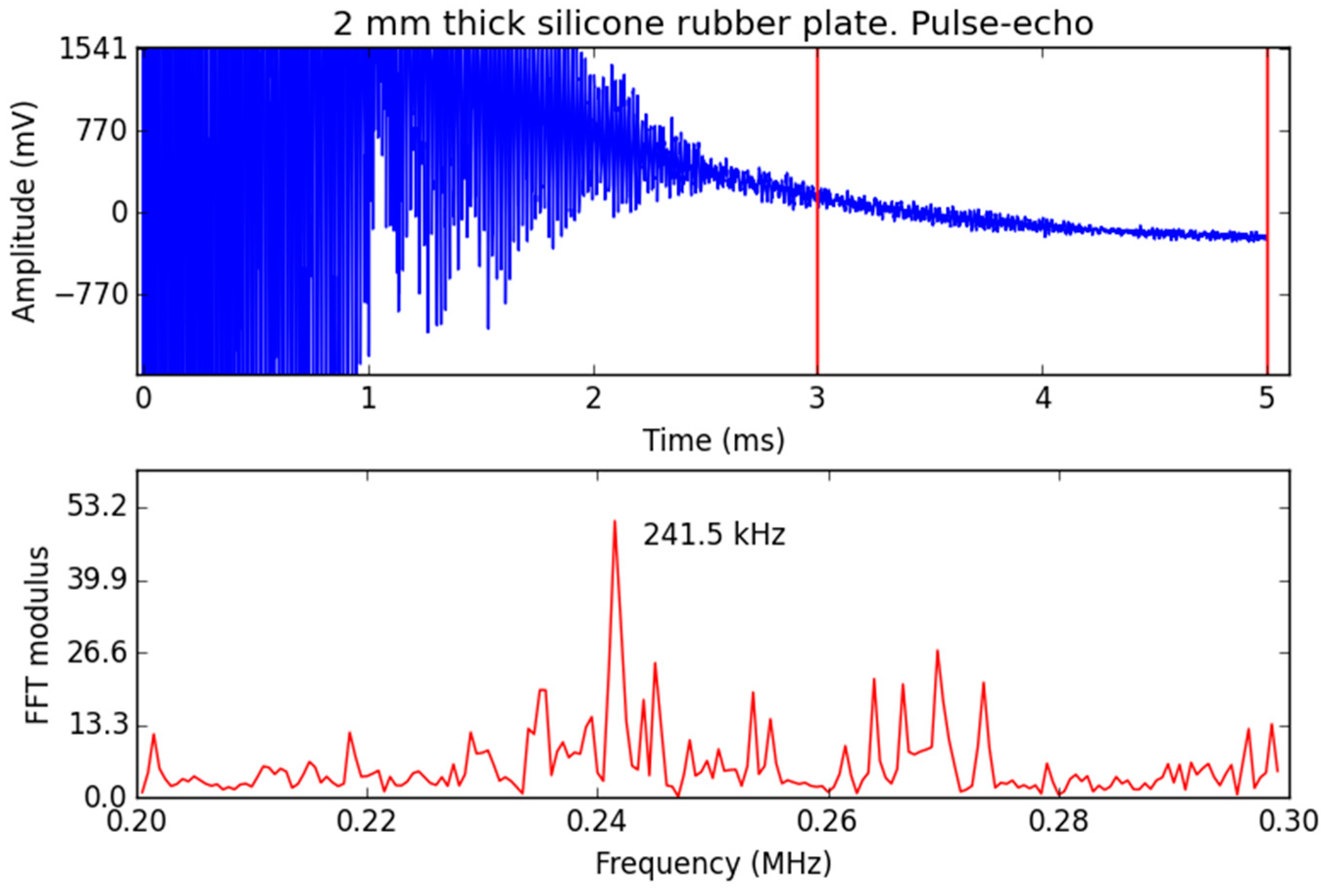

3.2.1. Plates

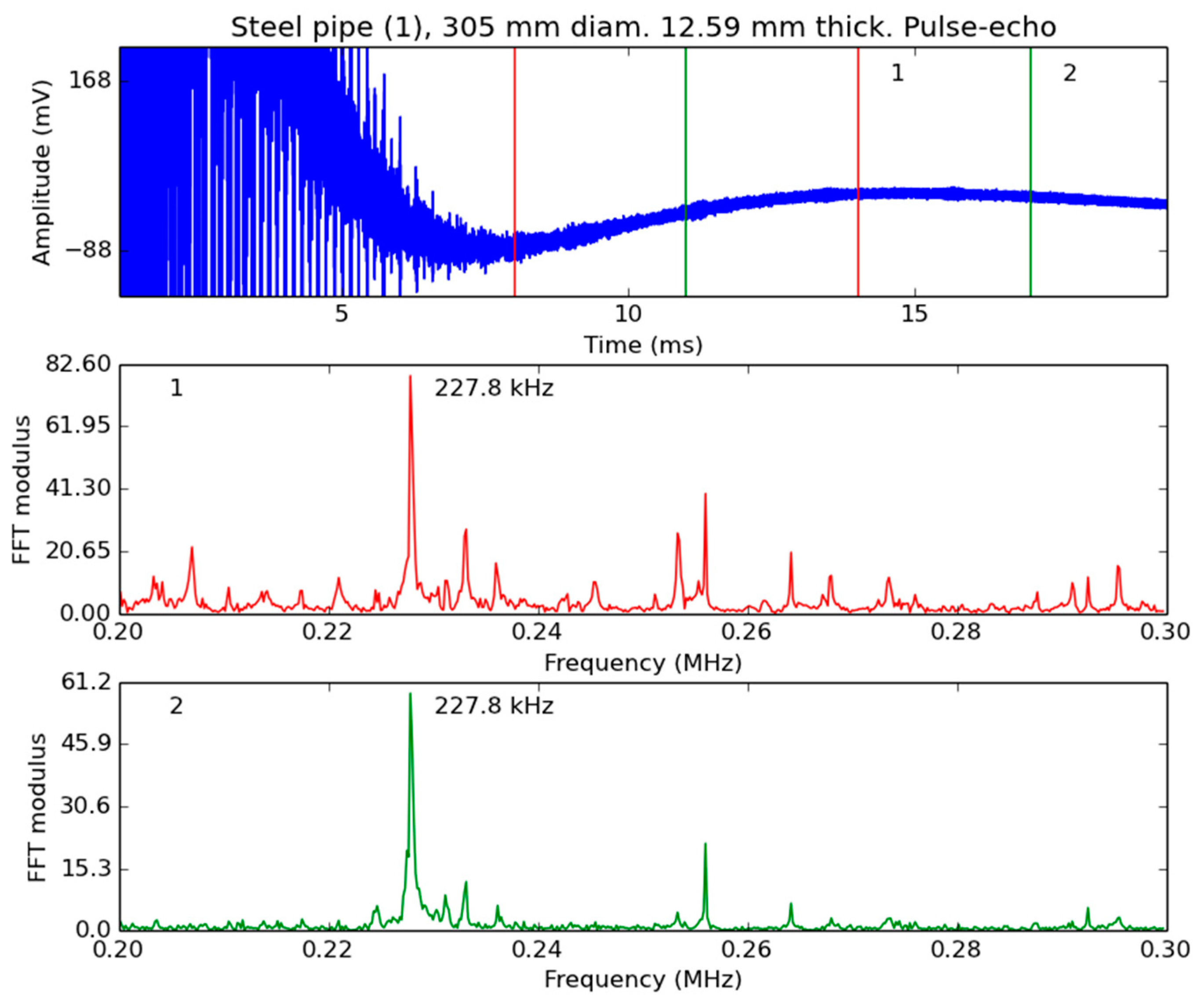

3.2.2. Pipes

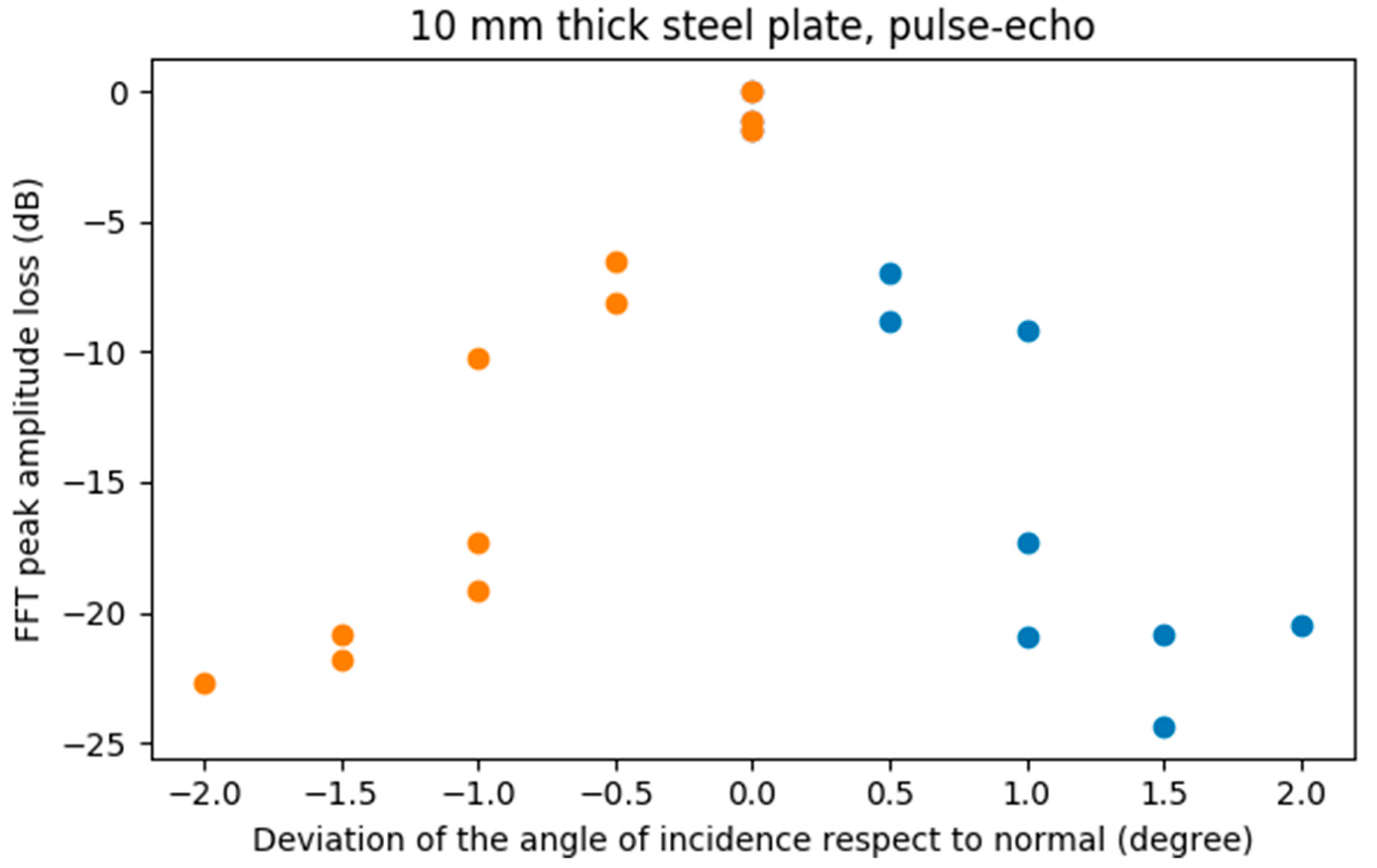

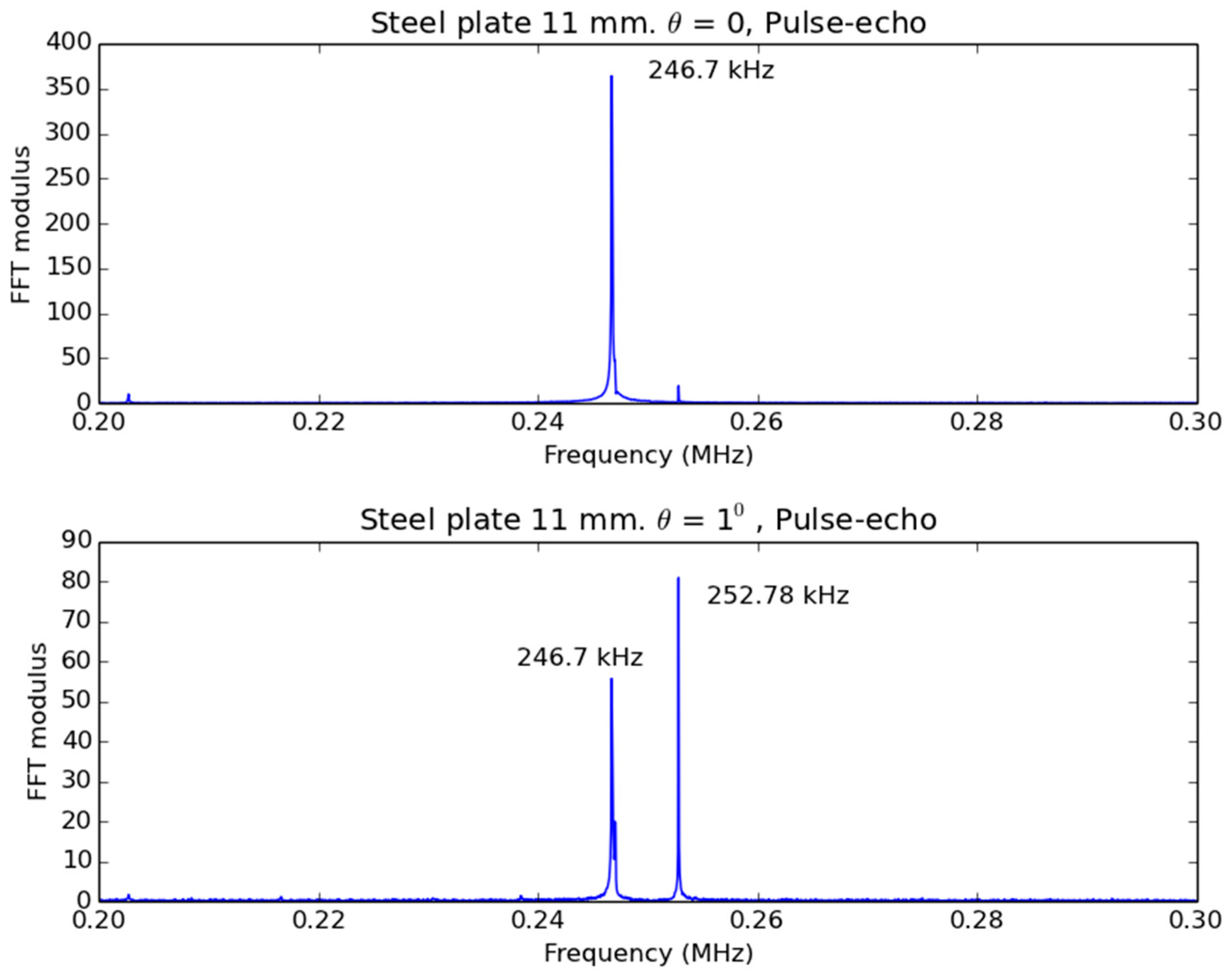

3.2.3. Influence of the Angle of Incidence

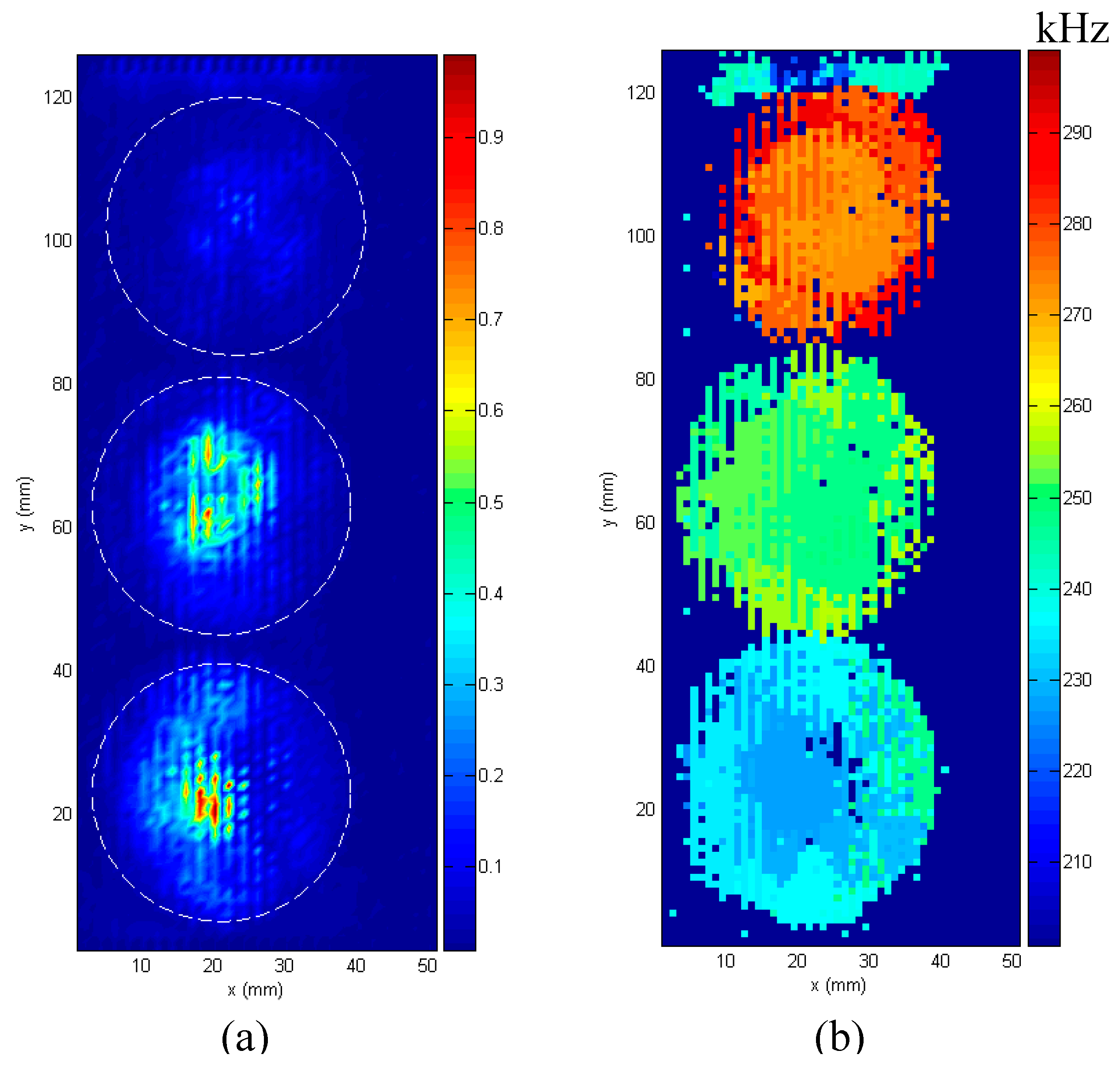

3.3. Pulse-Echo C-Scan

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Grandia, W.A.; Fortunko, C.M. NDE applications of air-coupled ultrasonic transducers. In Proceedings of the 1995 IEEE International Ultrasonics Symposium, Seattle, WA, USA, 7–10 November 1995; pp. 697–709. [Google Scholar]

- Luukkala, M.; Meriläinen, P. Metal plate testing using airborne ultrasound. Ultrasonics 1973, 11, 218–221. [Google Scholar] [CrossRef]

- Castaings, M.; Cawley, P. The generation, propagation, and detection of Lamb waves in plates using air-coupled ultrasonic transducers. J. Acoust. Soc. Am. 1996, 100, 3070–3077. [Google Scholar] [CrossRef]

- Álvarez-Arenas, T.E.G. Air-coupled ultrasonic transducers. In Ultrasound in Food Processing: Recent Advances; Villamiel, M., García-Pérez, V.J., Montilla, M., Cárcel, A., Benedito, J., Eds.; Wiley & Sons: Chichester, UK, 2016. [Google Scholar]

- Hutchins, D.; Burrascano, P.; Davis, L.; Laureti, S.; Ricci, M. Coded waveforms for optimised air-coupled ultrasonic nondestructive evaluation. Ultrasonics 2014, 54, 1745–1759. [Google Scholar] [CrossRef] [PubMed]

- Svilainis, L.; Aleksandrovas, A. Application of arbitrary pulse width and position trains for the correlation sidelobes reduction for narrowband transducers. Ultrasonics 2013, 53, 1344–1348. [Google Scholar] [CrossRef] [PubMed]

- Chimenti, D.E. Review of air-coupled ultrasonic materials characterization. Ultrasonics 2014, 54, 1804–1816. [Google Scholar] [CrossRef] [PubMed]

- Schindel, D.W. Air-coupled generation and detection of ultrasonic bulk waves in metals using micromachined capacitance transducers. Ultrasonics 1997, 35, 179–181. [Google Scholar] [CrossRef]

- Hutchins, D.A.; Wright, W.M.D. Ultrasonic measurements in polymeric materials using air-coupled capacitance transducers. J. Acoust. Soc. Am. 1994, 96, 1634–1642. [Google Scholar] [CrossRef]

- Schindel, D.W.; Hutchins, D.A. Through-thickness characterization of solids by wideband air-coupled ultrasound. Ultrasonics 1995, 33, 11–17. [Google Scholar] [CrossRef]

- Waag, G.; Hoff, L.; Norli, P. Air-coupled thickness measurements of stainless steel. arXiv 2012, arXiv:1210.0428. [Google Scholar]

- Álvarez-Arenas, T.E.G.; Montero, F.; Moner-Girona, M.; Rodríguez, E.; Roig, A.; Molins, E. Viscoelasticity of silica aerogels at ultrasonic frequencies. Appl. Phys. Lett. 2002, 81, 1198. [Google Scholar] [CrossRef]

- Fariñas, M.D.; Sancho-Knapik, D.; Peguero-Pina, J.J.; Gil-Pelegrín, E.; Álvarez-Arenas, T.E.G. Shear waves in vegetal tissues at ultrasonic frequencies. Appl. Phys. Lett. 2013, 102, 103702. [Google Scholar] [CrossRef]

- Álvarez-Arenas, T.E.G. Simultaneous determination of the ultrasound velocity and the thickness of solid plates from the analysis of thickness resonances using air-coupled ultrasound. Ultrasonics 2010, 50, 104–109. [Google Scholar] [CrossRef] [PubMed]

- Livings, R. Flaw detection in Multi-layer, Multi-material Composites by Resonance Imaging: Utilizing Air-coupled Ultrasonics and Finite Element Modeling. Master Thesis, Iowa State University, Ames, IA, USA, 2011. [Google Scholar]

- Yano, T.; Tone, M.; Fukumoto, A. Range finding and surface characterization using high-frequency air transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 1987, 34, 232–236. [Google Scholar] [CrossRef] [PubMed]

- Schindel, D.W. Ultrasonic imaging of solid surfaces using a focused air-coupled capacitance transducer. Ultrasonics 1998, 35, 587–594. [Google Scholar] [CrossRef]

- Álvarez-Arenas, T.E.G.; Montero, F.; Pozas, A.P. Air-coupled ultrasonic scanner for Braille. In Proceedings of the IEEE Ultrasonics Symposium, Atlanta, GA, USA, 7–10 October 2001; pp. 591–594. [Google Scholar]

- Bantz, W.J. Inspection of the internal portion of objects using ultrasonics. US Patent No. 4594879, 17 June 1986. [Google Scholar]

- Fortunko, C.M.; Schramm, R.E.; Teller, C.M.; Light, G.M.; McColskey, J.D.; Dube, W.P.; Renken, M.C. Gas coupled, pulse-echo ultrasonic crack detection and thickness gaging. In Review of Progress in Quantitative Nondestructive Evaluation; Thompson, D.O., Chimenti, D.E., Eds.; Plenum Press: New York, NY, USA, 1995; pp. 951–958. [Google Scholar]

- Kommareddy, V.K. Air-coupled ultrasonic measurements in composites. PhD Thesis, Iowa State University, Ames, IA, USA, 2003. [Google Scholar]

- Waag, G.; Hoff, L.; Norli, P. Feasibility of pulse-echo thickness measurements in air with a laterally displaced receiver. In Proceedings of the International Ultrasonics Symposium, Chicago, IL, USA, 3–6 September 2014; pp. 1029–1032. [Google Scholar]

- Álvarez-Arenas, T.E.G. Acoustic impedance matching of piezoelectric transducers to the air. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2004, 51, 624–633. [Google Scholar] [CrossRef]

- Brekhovskikh, L. Waves in Layered Media; Academis Press: New York, NY, USA, 1960. [Google Scholar]

- Rack, H.J. Physical and Mechanical Properties of Cast 17-4 PH Stainless Steel; Energy Report, Ref: SANDS0-2302, TTC-0161; Sandia National Laboratories: Albuquerque, NM, USA, 1981. [Google Scholar]

- Poisson’s Ratio. Available online: Wikipedia: https://en.wikipedia.org/wiki/Poisson%27s_ratio (accessed on 20 March 2019).

- Gao, Z.; Zhang, X.; Wang, Y.; Yang, R.; Wang, G.; Wang, Z. Measurements of the Poisson’s ratio of materials based on the bending mode of the cantilever plate. Bioresources 2016, 11, 5703–5721. [Google Scholar] [CrossRef]

| Material | Thickness (mm) | Diameter (mm) |

|---|---|---|

| Stainless steel | 10.0 ± 0.05 | 36 |

| 11.0 ± 0.05 | 36 | |

| 12.0 ± 0.05 | 36 | |

| Aluminum | 13.5 ± 0.05 | 55 |

| Silicone rubber | 2.0 ± 0.02 | 40 |

| Material | Diameter/Wall Thickness (mm) |

|---|---|

| Steel (1) | 305/10.30 ± 0.2 |

| 305/11.16 ± 0.3 | |

| 305/11.86 ± 0.4 | |

| 305/12.59 ± 0.4 | |

| Steel (2) | 324/13.10 ± 0.2 |

| Sample | Material | Thickness (mm) | Resonant Frequency (kHz) |

|---|---|---|---|

| Plate | Stainless Steel | 10.0 ± 0.05 | 272.0 |

| 11.0 ± 0.05 | 247.0 | ||

| 12.0 ± 0.05 | 227.1 | ||

| Aluminum | 12.5 ± 0.05 | 231.0 | |

| Silicone rubber | 2.0 ± 0.02 | 241.0 | |

| Steel Pipe | (1) | 10.3 ± 0.2 1 | 276 |

| 11.16 ± 0.3 1 | 257 | ||

| 11.86 ± 0.4 1 | 243 | ||

| 12.59 ± 0.4 | 227.5 | ||

| (2) | 13.1 ± 0.2 | 221.5 |

| Sample | Material | Thickness (mm) | Resonant Frequency 2 (kHz) | Peak Value of the Modulus of the FFT 2 |

|---|---|---|---|---|

| Plate | Stainless Steel | 10.0 ± 0.05 | 272.0 | 1197 |

| 11.0 ± 0.05 | 247.0 | 1830 | ||

| 12.0 ± 0.05 | 227.1 | 910 | ||

| Aluminum | 12.5 ± 0.05 | 231.0 | 56.1 | |

| Silicone rubber | 2.0 ± 0.02 | 241.5 | 53.2 | |

| Pipe | Steel (1) | 10.3 ± 0.2 1 | -- | -- |

| 11.16± 0.3 1 | 257.1 | 17.0 | ||

| 11.86 ± 0.4 1 | 242.3 | 16.0 | ||

| 12.59 ± 0.4 | 227.5 | 40.5 | ||

| Steel (2) | 13.1 ± 0.2 | 221.7 | 14.0 |

| Disc Thickness (mm) | Average Resonant Frequency (kHz) | Average Resonant Frequency at Center (r < 9 mm) (kHz) |

|---|---|---|

| 10.0 ± 0.05 | 277.6 ± 6.9 | 272.9 ± 2.5 |

| 11.0 ± 0.05 | 249.9 ± 3.5 | 248.5 ± 2.4 |

| 12.0 ± 0.05 | 233.8 ± 6.1 | 229.2 ± 3.5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez-Arenas, T.G.; Camacho, J. Air-Coupled and Resonant Pulse-Echo Ultrasonic Technique. Sensors 2019, 19, 2221. https://doi.org/10.3390/s19102221

Álvarez-Arenas TG, Camacho J. Air-Coupled and Resonant Pulse-Echo Ultrasonic Technique. Sensors. 2019; 19(10):2221. https://doi.org/10.3390/s19102221

Chicago/Turabian StyleÁlvarez-Arenas, Tomás Gómez, and Jorge Camacho. 2019. "Air-Coupled and Resonant Pulse-Echo Ultrasonic Technique" Sensors 19, no. 10: 2221. https://doi.org/10.3390/s19102221

APA StyleÁlvarez-Arenas, T. G., & Camacho, J. (2019). Air-Coupled and Resonant Pulse-Echo Ultrasonic Technique. Sensors, 19(10), 2221. https://doi.org/10.3390/s19102221