1. Introduction

In recent years a large number of silicon based MEMS (micro electro-mechanical systems) sensors and actuators were developed. Besides a high technology readiness level, this success is based on the broad range of different application scenarios covering sensors for e.g., the detection of chemical [

1,

2] or physical quantities [

3,

4], what requests, however, an individual and an application-specific design. But, despite any differences, most approaches make use of either membranes or cantilevers as functional key components. Furthermore, many MEMS devices are operated in resonance by applying either electro-magnetic, electro-thermal [

5,

6], capacitive or piezoelectric actuators for excitation [

7] to increase the sensitivity.

When making use of the latter transducer principle, a typical design consists of a piezoelectric aluminum nitride layer (AlN) sputter deposited on a released silicon (Si) support structure clamped to a substrate [

8]. Although offering only moderate piezoelectric constants [

9], AlN is often preferred compared to zinc oxide (ZnO) or lead zirconate titanate (PZT), as it is compatible with standard complementary metal oxide semiconductor (CMOS) microfabrication processes [

10] and offers a high temperature stability [

11]. Cantilever or membrane-type micro-machined AlN devices are most promising candidates for density and viscosity sensors of liquids [

12,

13], high frequency filters [

14], MEMS scanning mirrors [

15] or vibrational energy harvesters [

16,

17].

Advanced future analyses of complex surfaces require an extensive characterization by measuring a large variety of topography and material-related parameters, which are provided by the sophisticated combination of well-established techniques such as scanning electron microscopy (SEM) and atomic force microscopes (AFM). Doing so provides the possibility to investigate the same area of interest with both SEM and AFM. However, standard AFM cantilevers excited by a piezo-shaker feature a low bandwidth in vacuum due to increased Q-factors as the damping by the surrounding atmosphere is negligible compared to a standard operation in air [

18]. To overcome this drawback, the realization of an electronically adjustable Q-factor is targeted to improve the performance of resonantly operated AFM cantilevers.

A common method for active modification of the Q-factor is the implementation of a feedback on the tapping piezo based on the optical beam deflection [

19]. The improvement of the image quality by mixing a 90° phase shifted signal to the cantilever deflection signal is shown in [

20]. By removing the optical sensor from the feedback loop, an active shunt replaces the deflection measurement with a tip velocity measurement. The piezoelectric layer is driven by a synthetic impedance [

21] and reduces the Q-factor. The use of the electrical cantilever velocity signal for a feedback loop necessitates the compensation of parasitic effects, as shown in [

22]. A tailored differential sensing approach is used to cancel out manufacturing tolerances. By adding various active layers for actuation and sensing purposes, a positive position feedback (PPF) controller and a field-programmable analogue array (FPAA) are implemented as a multimode Q-controller that adjusts the Q-factor within three to four orders of magnitude [

23].

It is the objective of this study to determine the potential of active Q-factor tuning with one piezoelectric element integrated on a MEMS cantilever [

24]. For demonstration purposes, a tailored electrical circuit stimulates the thin film actuator with a frequency-dependent phase shift, thus manipulating the oscillation of the cantilever which in turn is excited by the macroscopic piezoelectric actuator as it is usually done in AFMs. In contrast to other technically demanding techniques, the implementation of a straightforward approach is in the focus of this work by only using standard lab-equipment for the manipulation of the cantilever oscillation. Therefore, the straight-forward transfer to a microprocessor controlled unit is feasible, so that a low-cost add-on electronic system can be realized, which can be placed close to the cantilever for minimizing signal losses.

2. Experimental Details

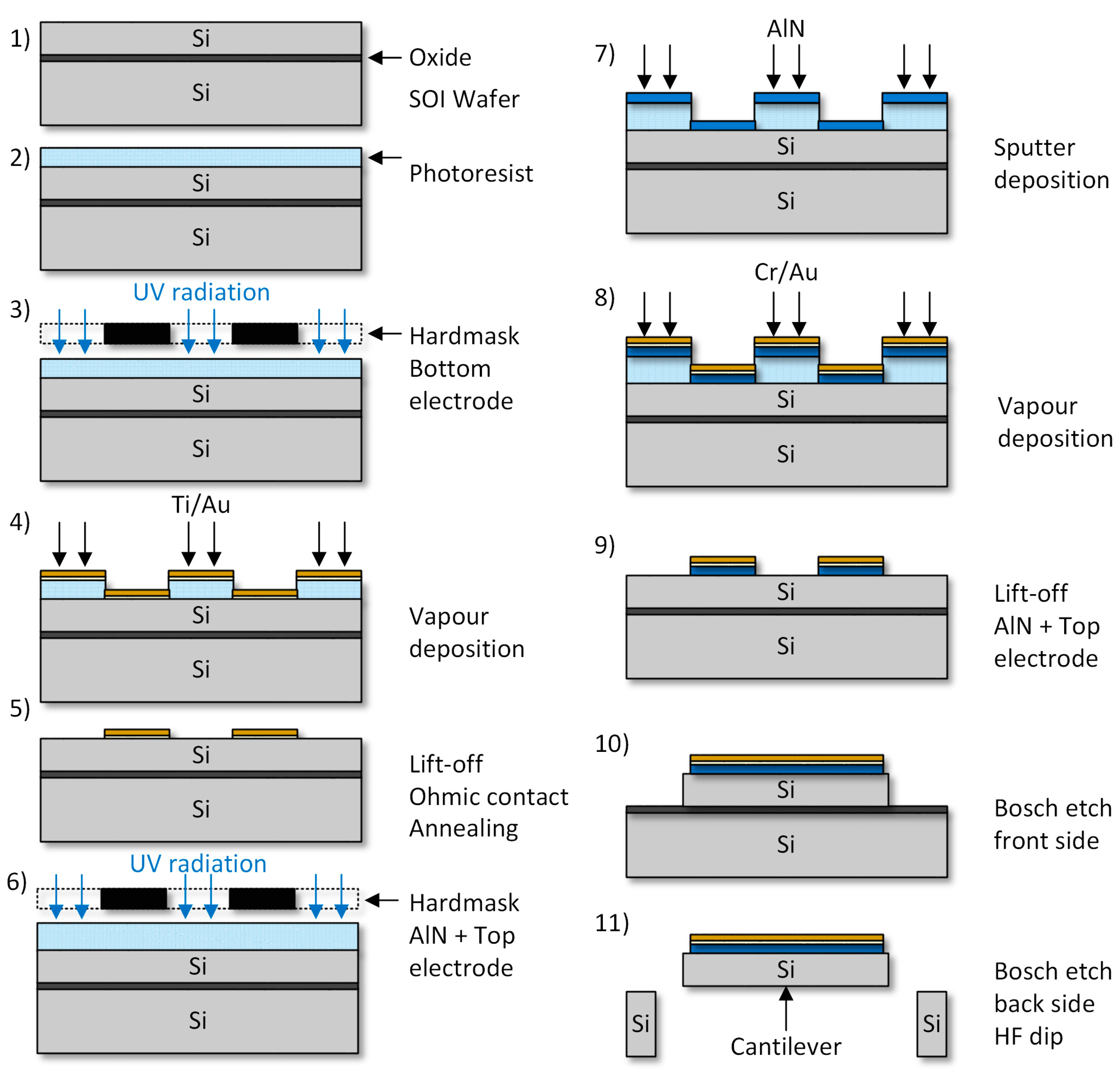

For hardware realization, a fabrication process was developed based on 4-inch silicon-on-insulator (SOI) (0.5 µm buried oxide) wafers, as shown in

Figure 1. The device layer with a thickness

TSub of 20 µm is highly boron p-doped (0.01–0.02 Ω·cm) serving as bottom electrode on the cantilever. The surface is covered with a reactively sputter deposited aluminum nitride (AlN) thin film (AlN thickness Δ = 500 nm), as shown in

Figure 1, steps 1–4. The AlN thin film is deposited with an industry type DC magnetron sputter equipment (Von Ardenne LS730S, Dresden, Germany). During AlN synthetization the wafer is continuously self-heated by the particle bombardment. In order to ensure a low sample temperature (T < 140 °C), thus avoiding the degeneration of the photo-resist and enabling a lift-off process for AlN patterning (

Figure 1, step 5), a tailored clamping fixture for the 4” wafers was used [

25]. After deposition and patterning of the gold (Au) top electrode (top electrode thickness

TTE = 200 nm) the piezoelectric thin film actuator stack is completed, as shown at

Figure 1, steps 6–9. By applying a Bosch etch process at front and back side the cantilever is defined and released (

Figure 1, steps 10 and 11).

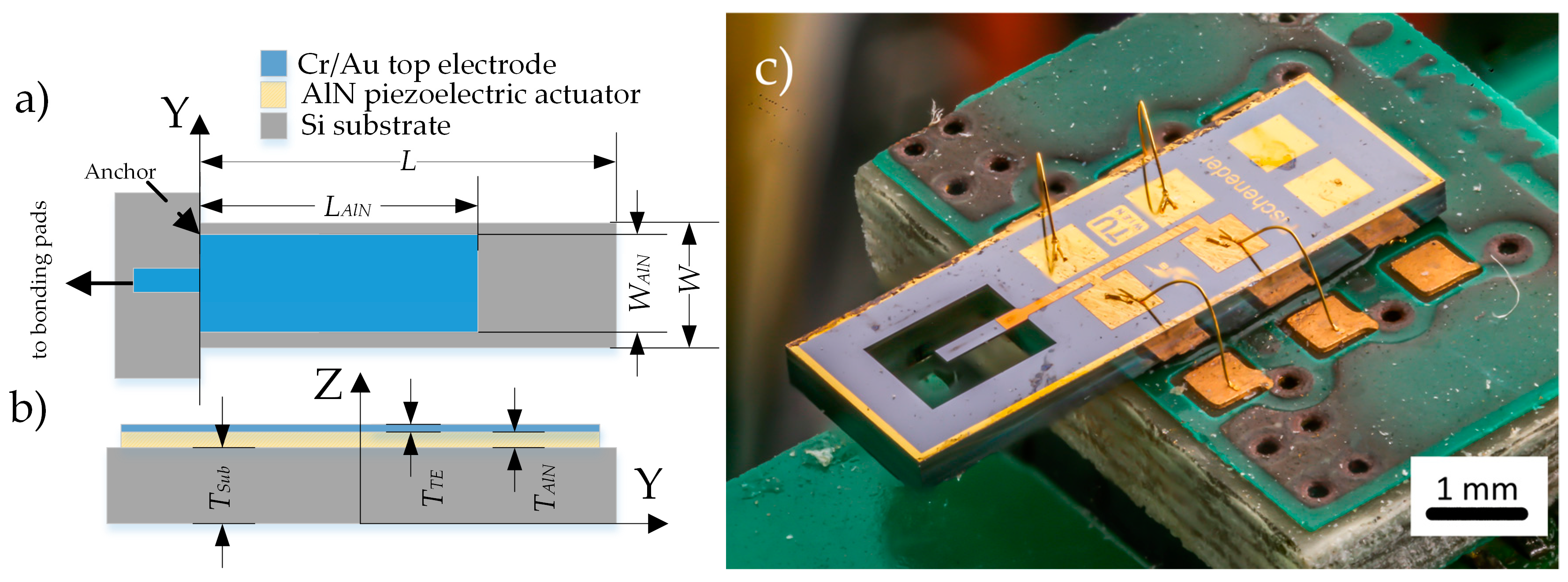

The cantilever in

Figure 2 was designed having a resonance frequency of the first bending mode lower than the critical frequency of the measurement equipment (f < 100 kHz), which is limited by the shaker piezo design. Basically, the cantilever has a length of

W = 750 µm, a width

W = 160 µm and is covered with AlN by a length

LAlN = 200 µm, a width

WAlN = 154 µm resulting in a resonance frequency of 48.5 kHz in air.

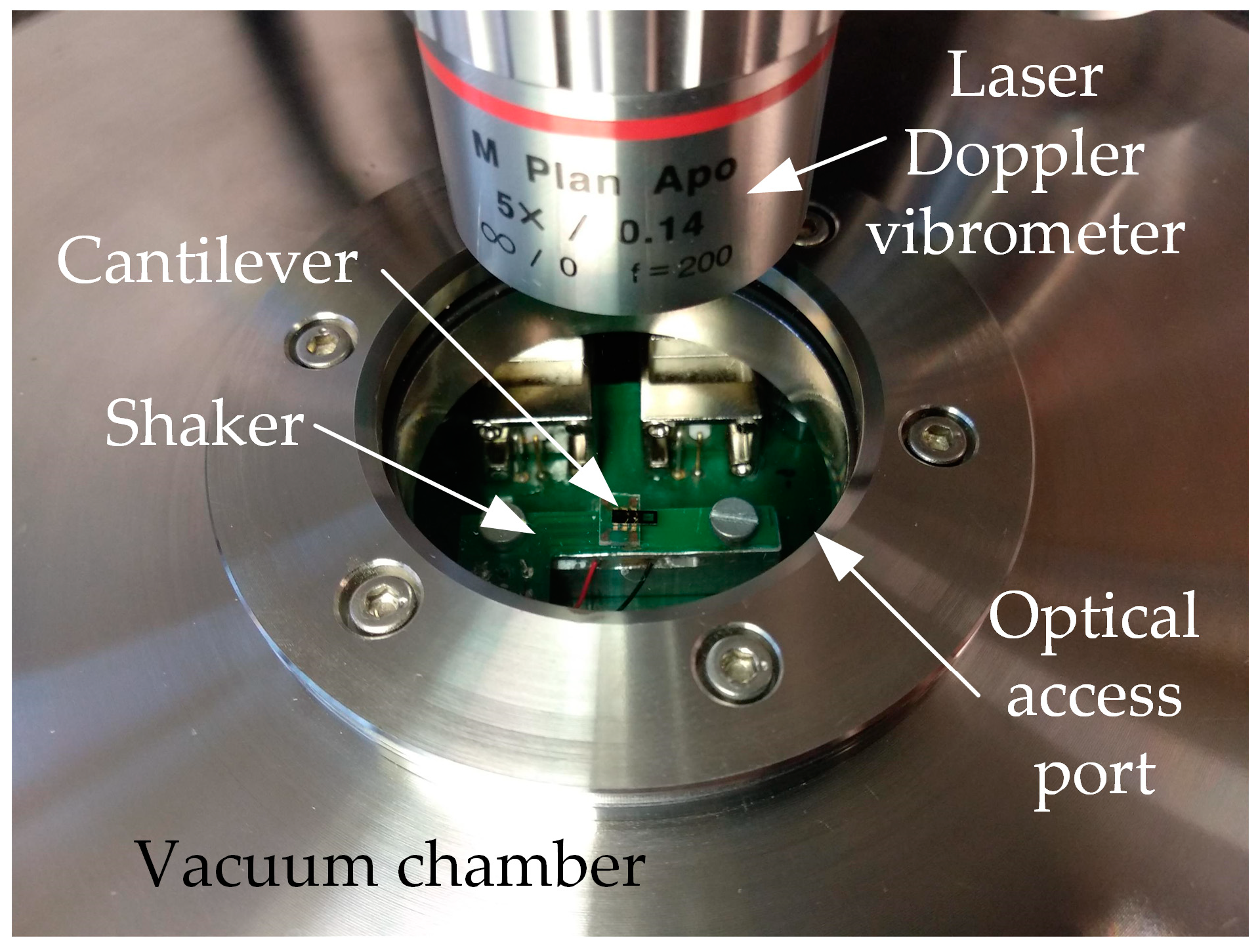

The fabricated cantilever is glued and bonded to a specially designed printed circuit board (PCB) which connects the cantilever electrically to the electrical stimulus and mechanically to the piezo shaker. The optical photograph in

Figure 3 shows the measurement setup. To demonstrate the loss of the damping, the cantilever and the PCB are exposed to a pressure of 6.5 × 10

−5 mbar in a specific vacuum chamber, so that viscous damping effects of the residual gas atmosphere are negligible [

26].

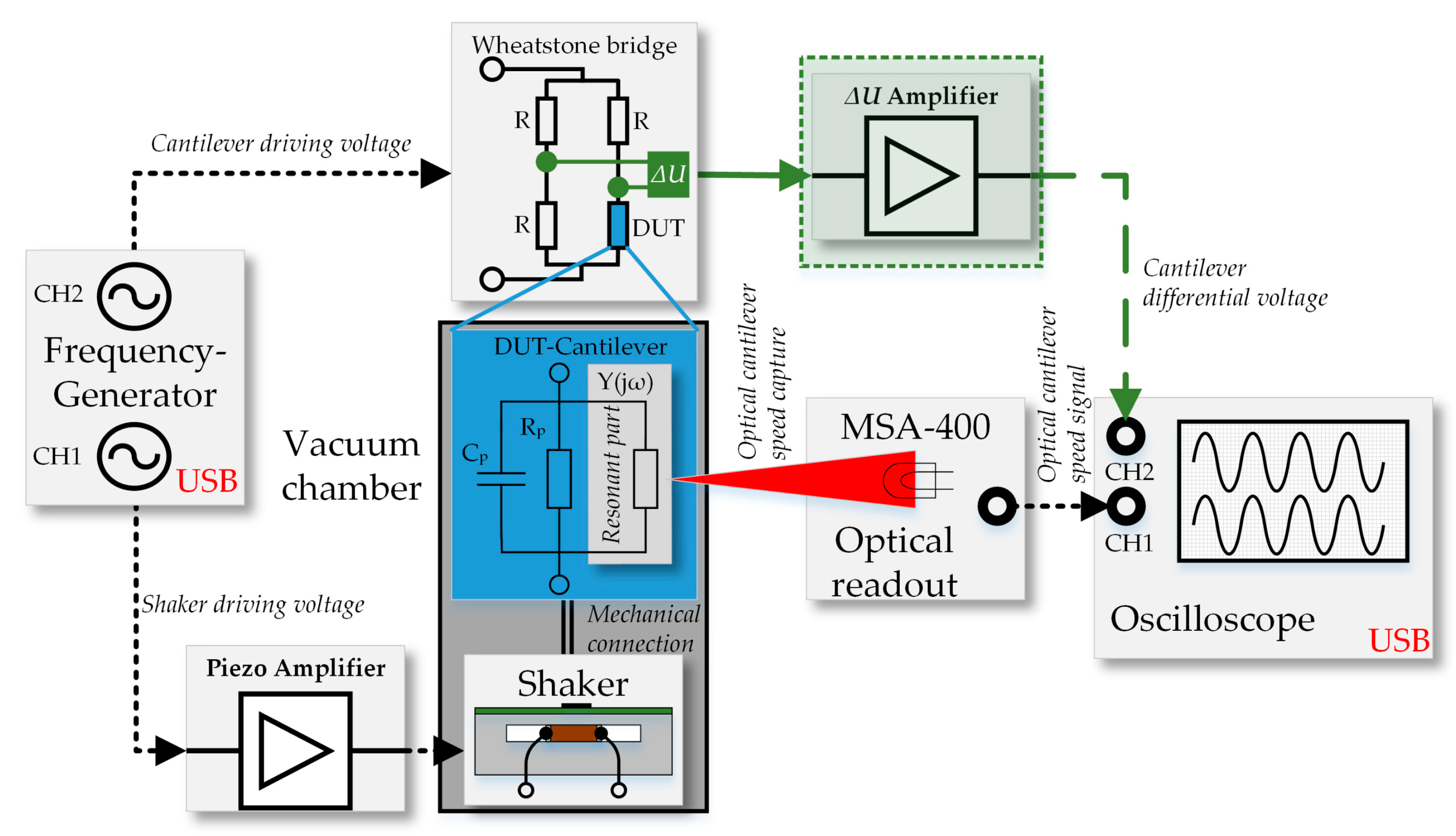

The vacuum chamber has both, an optical access port and electrical feedthroughs which connect the PCB with the cantilever to the driving and measurement equipment. The complete measurement system is illustrated in

Figure 4 and is controlled by a MATLAB script via an USB interface.

A discrete set of sinusoidal frequencies (frequency spectrum) without DC offset is provided at CH1 and CH2 of the frequency generator (FG). The signal of FG–CH1 is boosted by a custom-made piezo amplifier and drives the clamped piezo shaker, which generates the mechanical excitation of the cantilever in resonance. Due to the higher mass of the shaker, the phase of FG–CH1 is chosen as the reference and the phase of FG–CH2 is varied accordingly. The Wheatstone bridge is powered by FG–CH2 where the cantilever acts as device under test (DUT). In literature the piezoelectric sensor is modelled as a high-pass filtered open-circuit voltage, which will be amplified with a high impedance buffer for cantilevers [

27] and membranes [

28]. Beside this, the electrical impedance behavior of resonators with large Q-factors are described with the well-established extended Butterworth Van-Dyke equivalent circuit [

29]. Its magnitude and phase is electrically read out by a differential amplifier (∆

U) and recorded by the oscilloscope (OSC) at OSC–CH2. As verification of the electrical measurements, the oscillation amplitude of the cantilever is measured with a Micro System Analyzer (MSA-400, Waldbronn, Germany) from Polytec and converted to a velocity proportional voltage signal, which is recorded by the oscilloscope at OSC–CH1.

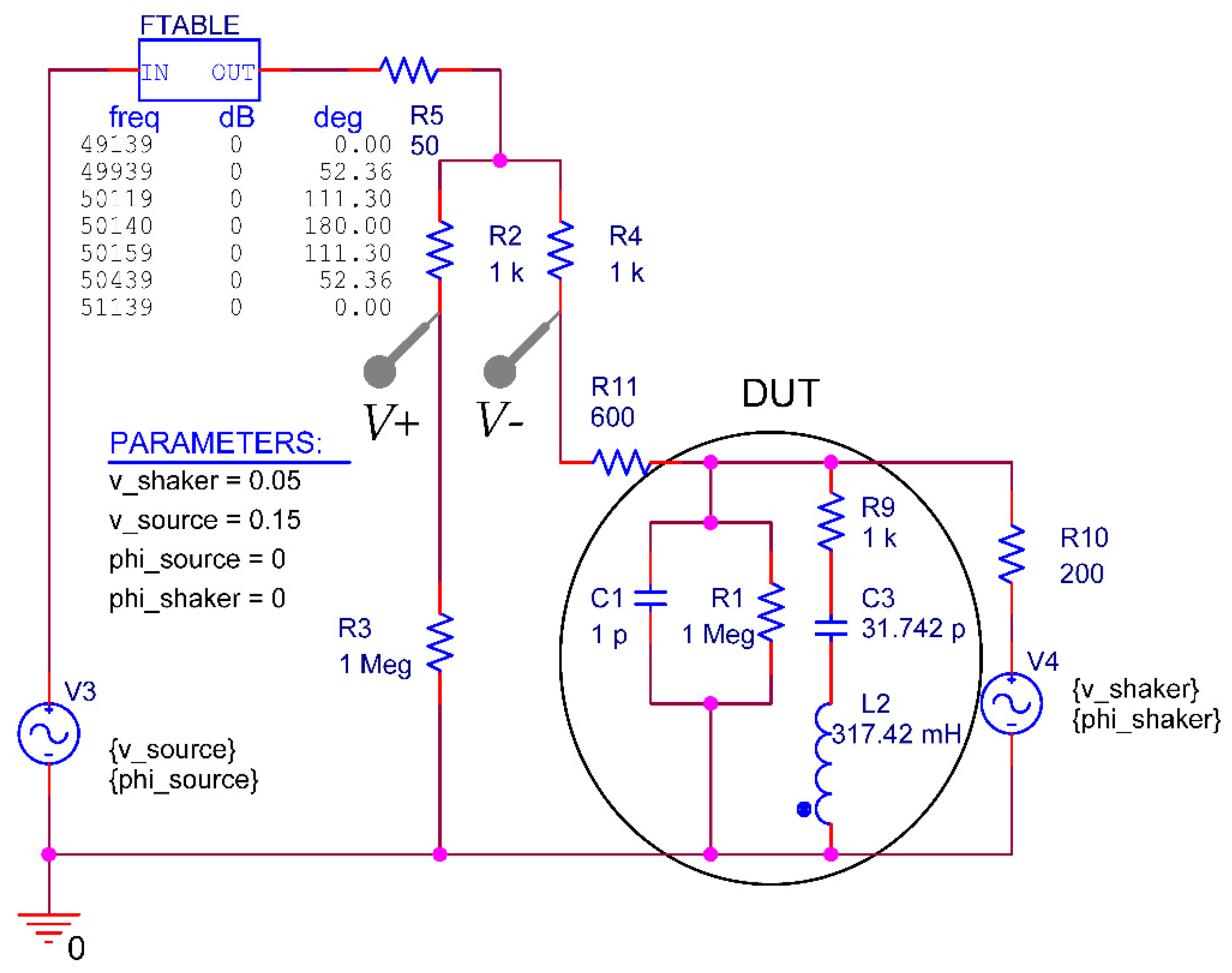

A circuit simulation with PSpice of the electrical circuit is performed to verify the electrical measurements at the oscilloscope (see

Figure 5), which includes the description of the electrical impact of the mechanical shaker on the differential voltage (∆

U = V+ −

V−).

The simulation circuit is powered with two voltage sources (V3 and V4). V3 (internal resistor R5) powers the Wheatstone bridge (WB) which consists of R2, R3, R4 and the DUT. V4 represents the impact of the shaker on ∆U. The variation of the phase lag of V3 is reached by the block FTABLE which generates the frequency-dependent linear interpolated phase shift. The piezoelectric cantilever (DUT) is modelled with parasitic components R1, C1 and a series resonant circuit R9, C3, L2 and the component characteristics are calculated based on the theoretical formulas. Finally, R11 and R10 models the wiring between the WB and the DUT and the impact of the shaker that are determined experimentally by adjusting the voltage baseline and the resonance peak amplitude.

3. Results and Discussion

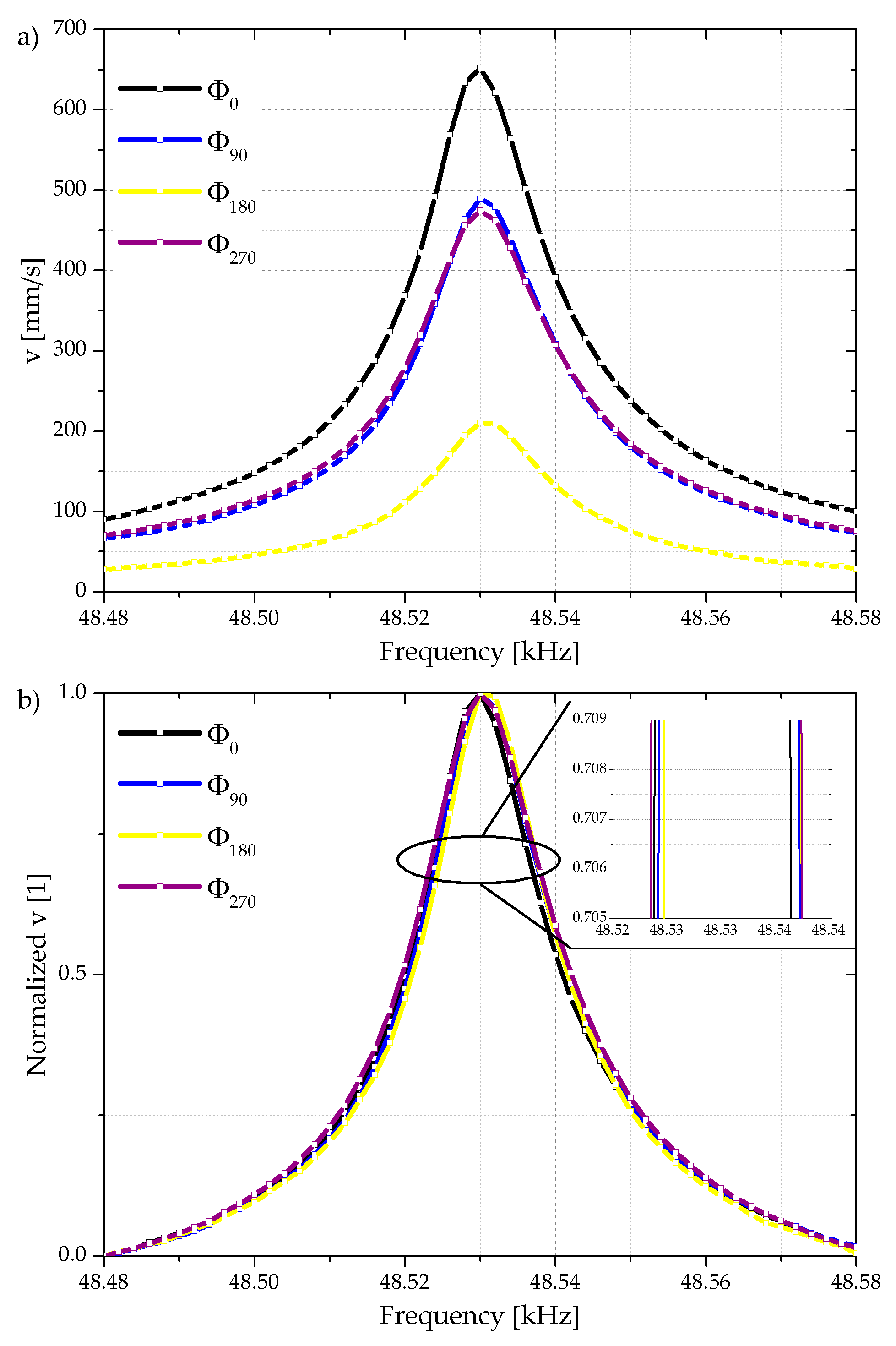

Before using the frequency dependent phase shift approach, the independence of the Q-factor with respect to any frequency independent constant phase shift between cantilever and shaker actuation is verified in air atmosphere. The power supply of the shaker at FG–CH1 acts as the reference phase while the phase of the integrated cantilever actuation is changed in 30° steps from 0° to 330°. The oscillation of the cantilever is recorded optically with a laser Doppler vibrometer (LDV) and electrically by the Wheatstone bridge and the differential voltage amplifier, respectively. Basically, the cantilever oscillation amplitude depends on the cantilever actuation phase and selected phases are shown in

Figure 6a. When increasing the phase shift the amplitude of the cantilever oscillation is reduced reaching its lowest value at 180° due to destructive interference. Considering the Q-factor, the normalized cantilever velocity is presented in

Figure 6b, indicating due to equal curve shapes an almost constant Q-factor in the range of 3460 to 3860 independent of the phase shift applied to the integrated piezoelectric thin film actuator.

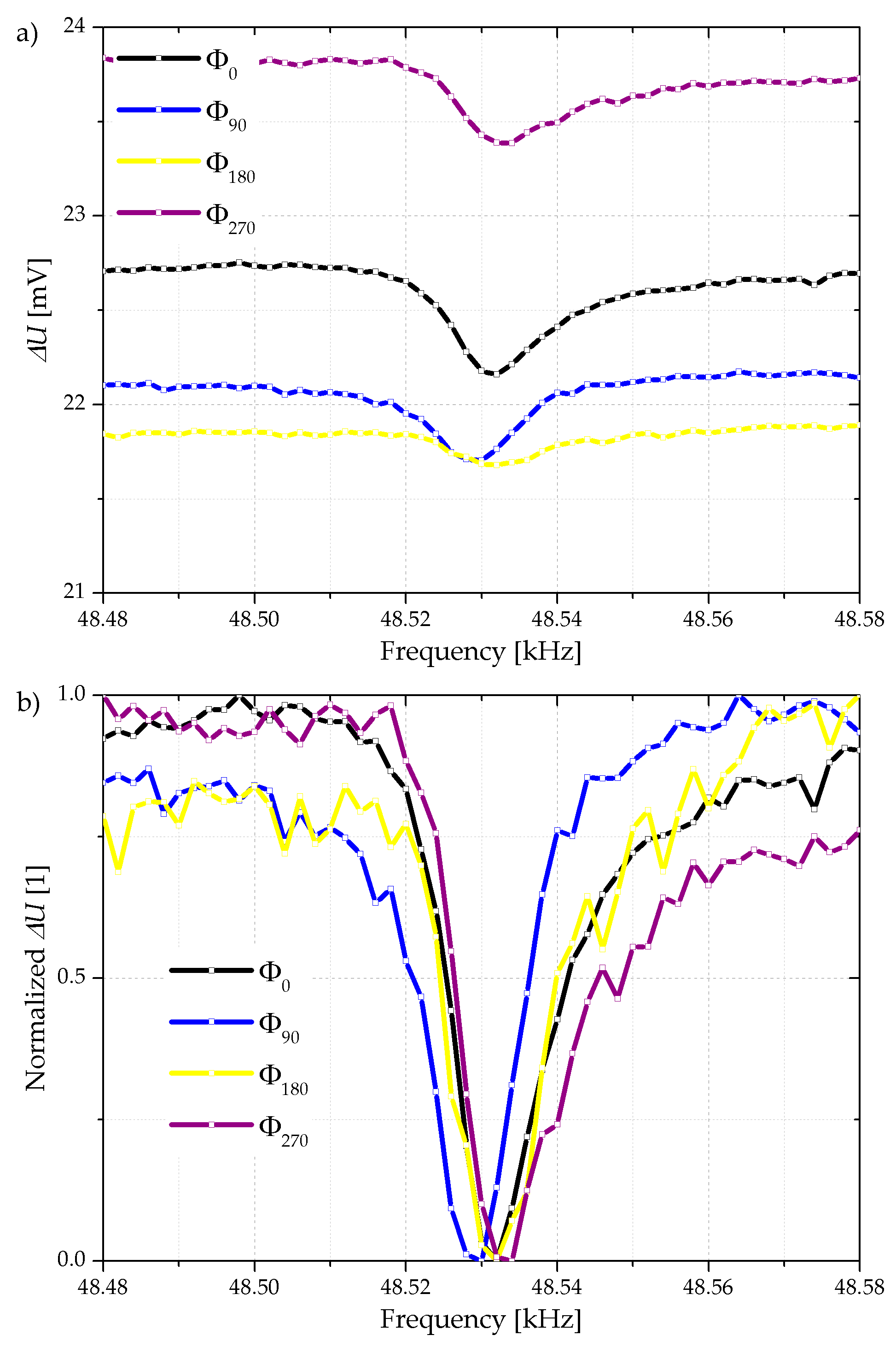

At the same time the electrical measurements of ∆

U at the Wheatstone bridge show a cantilever resonance signal as illustrated in

Figure 7a. Here the phase shift has the same effect on the amplitude of the cantilever oscillation, which results in a lower electrical amplitude of ∆

U at resonance frequency. If these curves are normalized where minimal values are set to 0 and the resulting curves normalized to 1 as shown

Figure 7b, a straightforward comparability of the electrically measured Q-factors which are ranging between 3300 and 5300 is possible.

The large noise of the electrical output signal is due to the non-shielded wiring circuit and due to the DC-related fraction of the electrical signal which prevents the oscilloscope to make use of the entire measurement range. The Q-factors are determined by

(optical measurement) or

(electrical measurement), where

,

B0.707 and

B0.293 represent the resonance frequency and amplitude bandwidths for both LDV and electrical measurements, respectively. As shown in

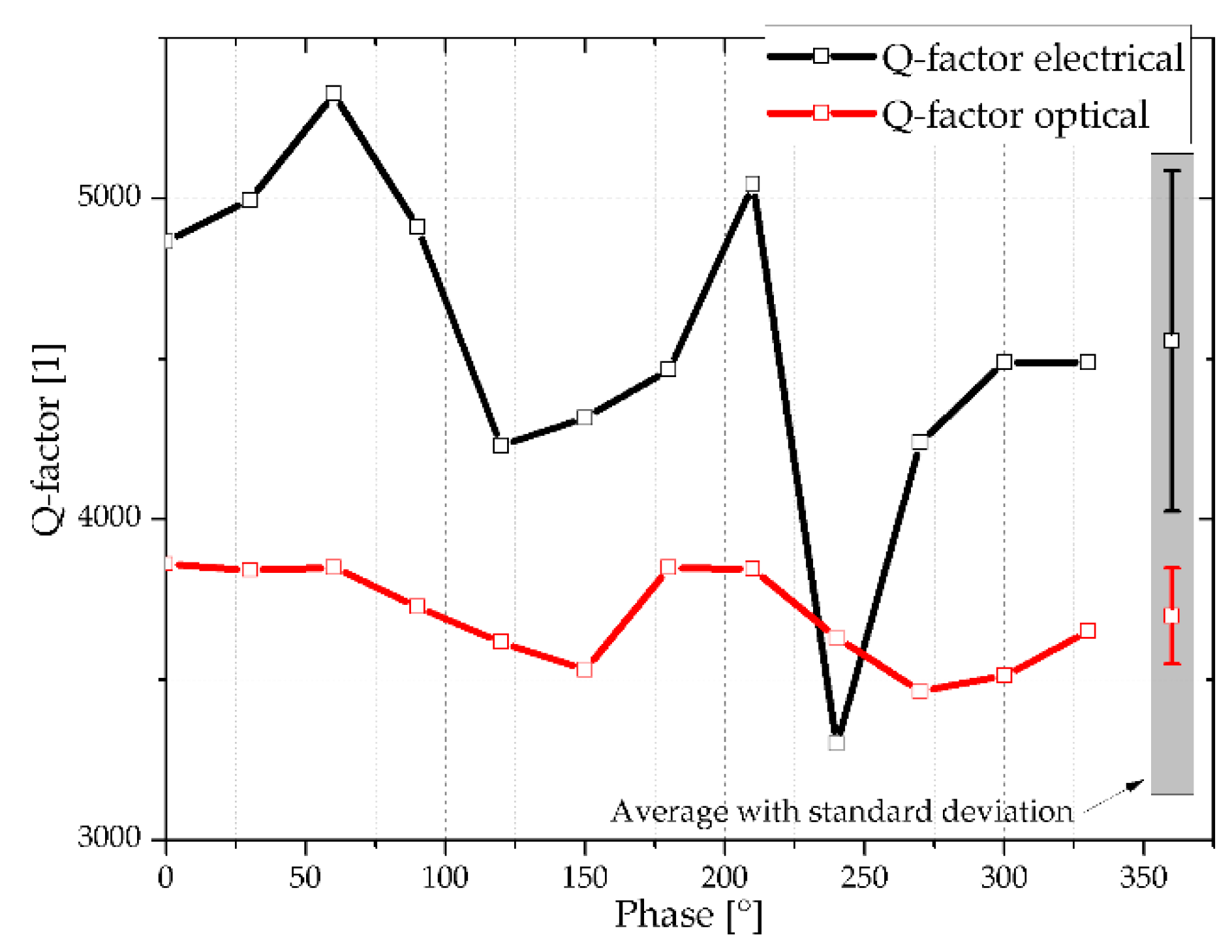

Figure 8, the Q-factors determined by LDV are constant within the measurement accuracy of about ±6%, but those deduced from the electrical measurements show a substantially higher noise due to the poor peak characteristics in resonance. The constant Q-factor arises from the fact that the absolute oscillating amplitude depends on the phase between shaker and cantilever actuation, but the relative change of the oscillating amplitude remains the same, hence the constructive or destructive superimposition has no influence on the Q-factor.

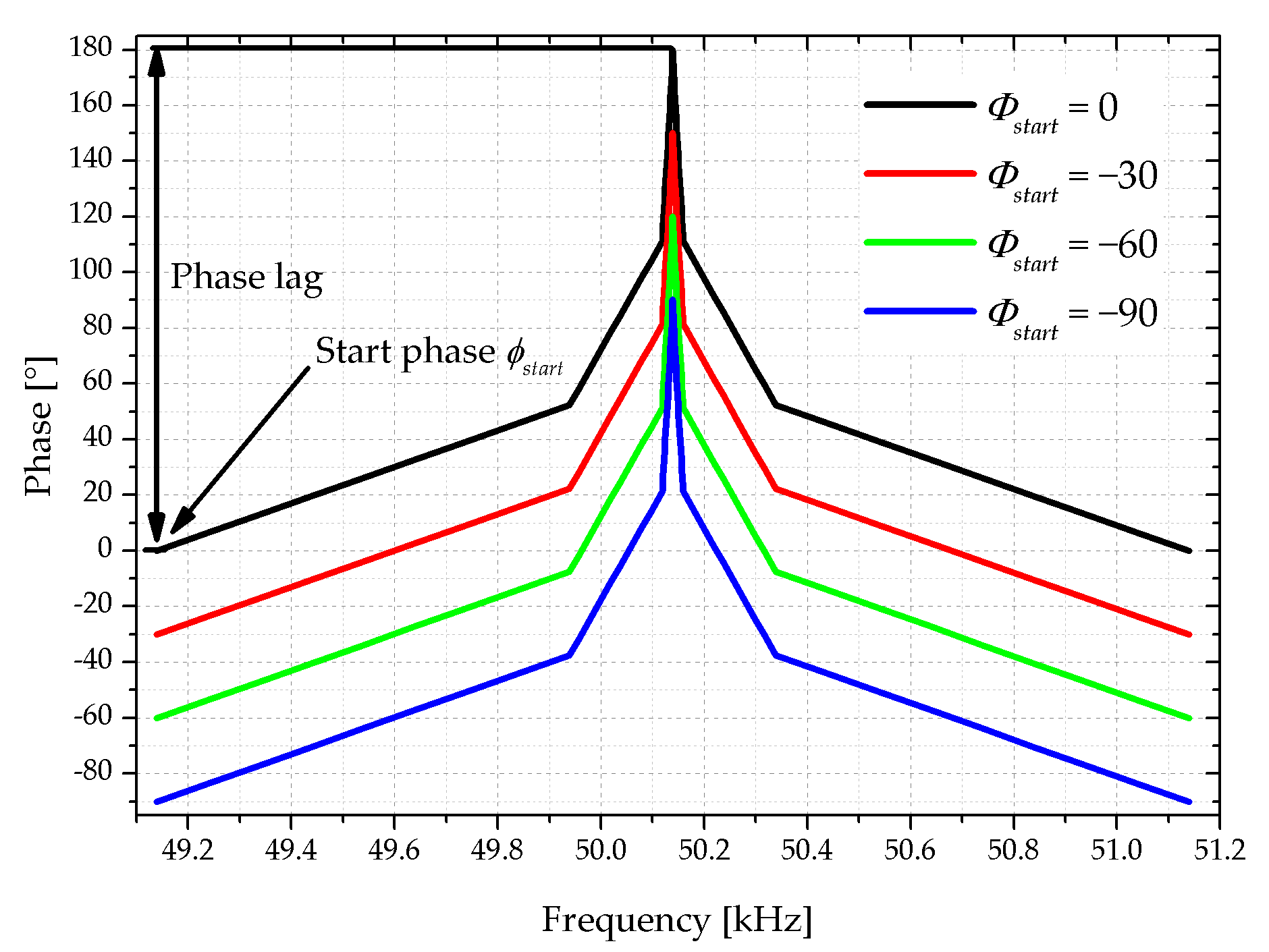

Based on the previous result, where any constant phase shift does not affect the Q-factor, an active Q-factor adjustment with two parameters is defined, namely the phase lag and the start phase

φstart. Here the frequency dependent phase shift approach is introduced. The proposed phase profile is symmetric around the resonance frequency, while the phase at resonance is increased to the maximum phase lag of 180°. The phase is chosen such that it approximates a typical impedance spectrum of a piezoelectric MEMS cantilever resonating in the first bending mode (see

Figure 9). The second parameter is varied from −90° to 0°, which shifts the whole frequency-dependent curve, but does not change its shape.

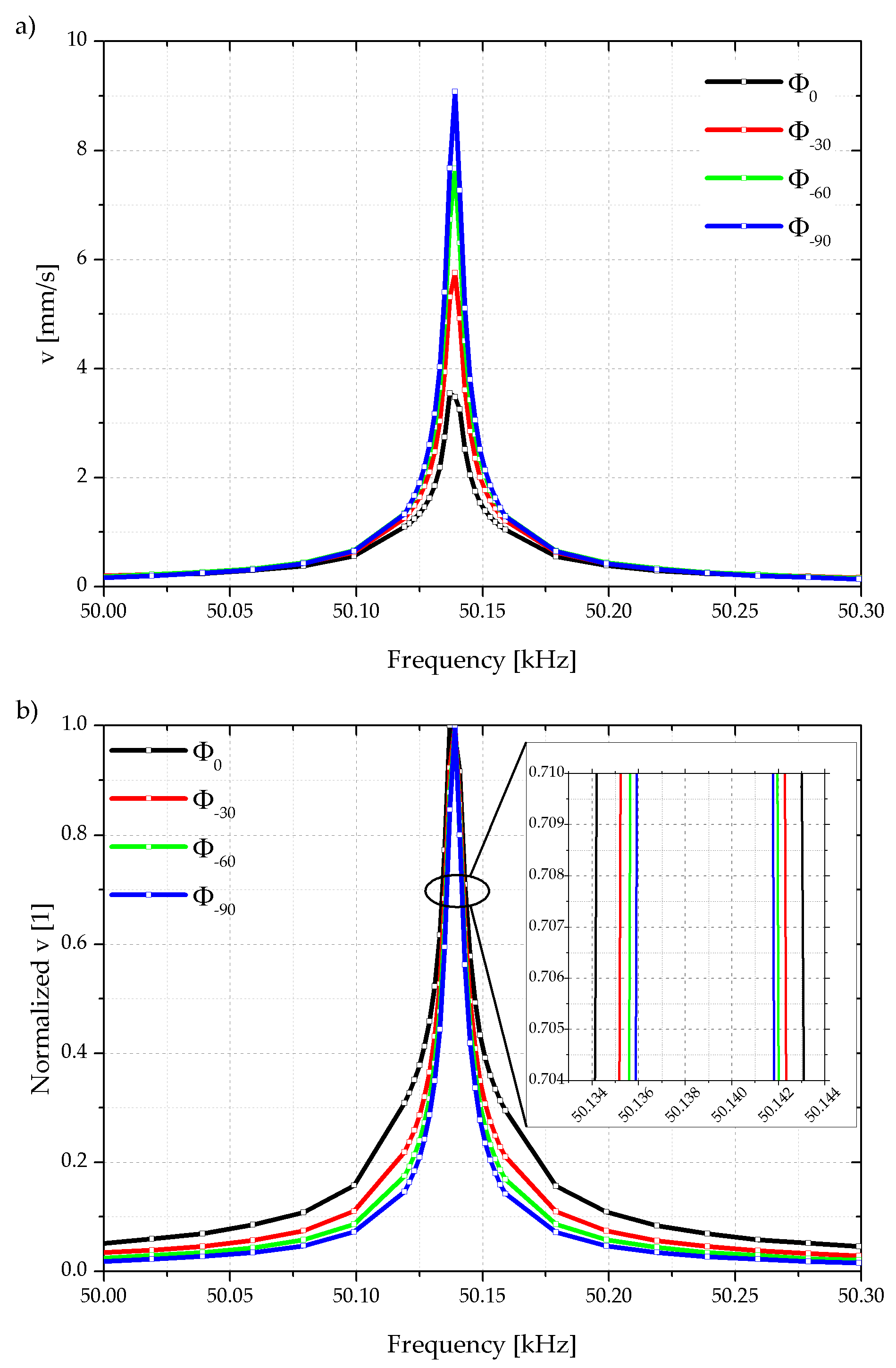

While the phase of the shaker actuation voltage at FG–CH1 retains at 0°, a MATLAB script constantly adjusts the phase shift at each individual frequency value of the integrated piezoelectric actuator, which is driven by FG–CH2. The oscilloscope OSC–CH1 records the cantilever tip oscillation measured with the laser Doppler vibrometer as shown in

Figure 10a. The corresponding normalized oscillation amplitudes of the cantilever tip are shown in

Figure 10b. Due to the change of

φstart from −90° to 0° the cantilever oscillation amplitude responded with a broader normalized resonance peak which is shown in a more detailed view as insert in the figure.

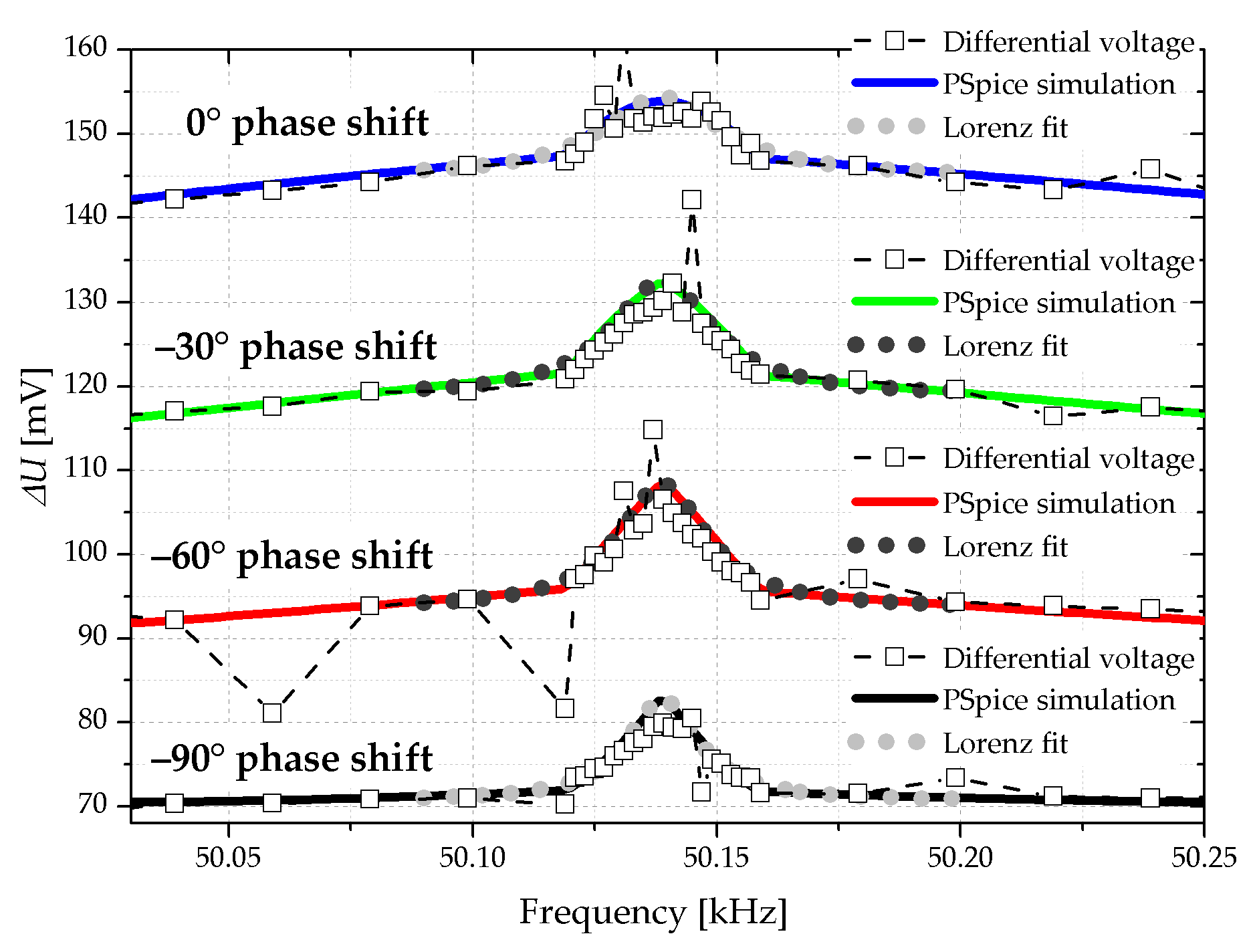

Simultaneously the oscilloscope records the amplified electrical differential voltage at the Wheatstone bridge at OSC–CH2 and the frequency spectrum is shown in

Figure 11. The figure shows the measured and the simulated values, whereas the latter are based on the equivalent circuit from

Figure 5 and inserted with colored lines.

To demonstrate the impact of

φstart on the Q-factor the values are extracted from

Figure 10 and

Figure 11 with a Lorenz fit and presented in

Table 1.

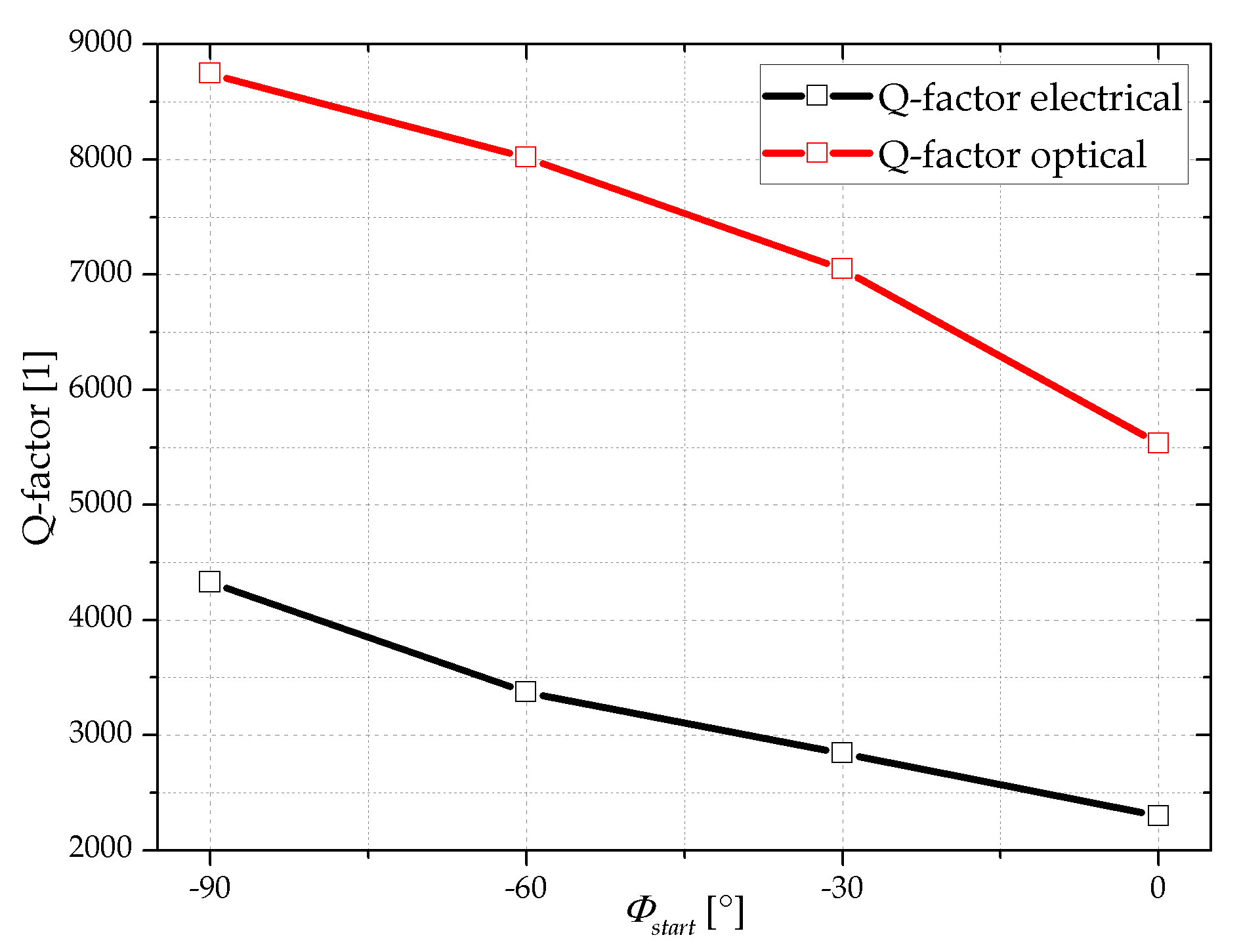

The optically measured Q-factors change from 8746 at

φstart = −90° to 5533 at

φstart = 0° which is a reduction by a factor of about 1.6. The evaluation of the electrical spectrum reveals a Q-factor reduction from 4328 to 2299 which is a factor of about 1.9. The Q-factor values determined electrically or optically as a function of starting phase are shown in

Figure 12.

Basically, the Q-factors determined electrically have less than half the value of those measured optically, independent of the stating phase value. This systematic deviation in Q-factors is attributed to the different measurement methods as the electrically measured Q-factor is influenced by the electrical circuit. In a small signal approximation the piezoelectric layer or the Wheatstone bridge may get short-circuited by the crosstalk through parasitic elements such as the piezoelectric layer and electrical wiring (see

Figure 5).

The manipulation of the Q-factor arises from the adjustment of the phase lag between the shaker and cantilever in the observed frequency spectrum. That method enables a frequency dependent cantilever oscillation amplitude adjustment, where the amplitude far away from the resonance frequency is enlarged, whereas in resonance, it is decreased. Thereby the resonance peak is broadened, resulting in a lower Q-factor. Beneficial for a potential implementation is the variability of the phase characteristics of the stimulating voltage due to a large range of possible phase profiles.

4. Conclusions

In this study, an electronically tuneable reduction in Q-factor of MEMS cantilevers vibrating in the first bending mode is demonstrated by using an integrated piezoelectric thin film actuator. Based on a mechanical stimulation similar to those applied to excite standard AFM cantilevers, this approach for Q-factor tuning offers an easy-to-implement extension to existing AFM equipment. By electrically implementing the piezoelectric thin film actuator into a Wheatstone bridge configuration, the possibility is offered both for active manipulation and for measurement of the cantilever oscillation. When applying a frequency independent phase shift between the two actuators (i.e., shaker and on the cantilever), no impact on the Q-factor is observed within the measurement accuracy. As a consequence, a frequency dependent phase shift approach is introduced where the resonance behavior of a piezoelectric cantilever is mimicked. Based on the optical measurements a reduction of the Q-factor from 8746 down to 5533 is determined by changing the starting phase from −90° to 0°, which is a reduction by a factor of about 1.6. An electrical circuit simulation verifies the electrical readout of the Wheatstone bridge and demonstrates an electrical Q-factor manipulation of 4328 down to 2299, which represents a decrease by a factor of 1.9. The limited impact of this approach on the Q-factor compared to other damping techniques based on feedback controllers and automatically approximated phase shift is due to the straightforward detection principle. All in all, it is demonstrated that damping can be achieved in resonating MEMS devices with a tailored variation of the actuation phase requesting only standard, low-cost electronic equipment. In the near future, the integration of an on-chip compensation structure will reduce the parasitic effects of the resonance structure and enhance the Q-factor reduction when applying the phase shifted damping mode.