Topic Menu

► Topic MenuTopic Editors

Safety, Reliability and Effectiveness of Internal Combustion Engines

Topic Information

Dear Colleagues,

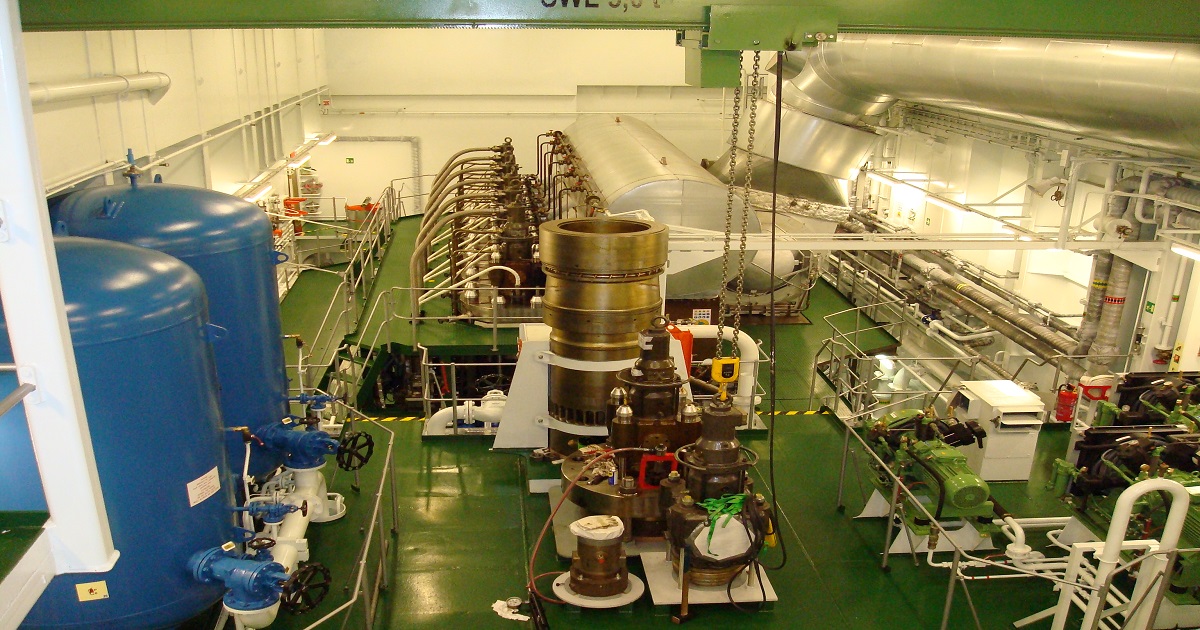

Despite the growth of renewable energy capacities, internal combustion engines (ICE) will probably remain the main source of propulsion in transport and other industries. New technologies are developed to improve and reduce the ICE’s economic and environmental impacts, its construction and operating procedures included. It forces continuous improvement of the ICE’s effectiveness, safety and reliability. This article collection aims at bringing together research on how to identify, rectify and verify the effective, safe and reliable operation of different ICEs types. We welcome original research and review papers. This topic covers, in particular:

• Genesis, assessment and prediction ICE’s effectiveness, safety and reliability;

• Application of new methods, algorithms and heuristics for ICE’s effectiveness, safety and reliability analysis including AI, FEM, CFD, ALT;

• Development of new and improved protection systems for ICEs;

• Mitigation of new risks connected with the application of modern fuels including hydrogen, ammonia and methanol;

• Prevention of failures, breakdowns, fires and explosions;

• Prevention of incidents and accidents including pollution, damages, injuries, poisoning and death;

• Training and education in effective and safe operation;

• Application of procedures for more effective, safer and more reliable operation of ICEs;

• Development of modern condition monitoring systems;

• Root cause analysis of ICE’s failure case studies.

Prof. Dr. Leszek Chybowski

Dr. Jarosław Myśków

Dr. Przemysław Kowalak

Dr. Andrzej Jakubowski

Topic Editors

Keywords

- Internal combustion engine

- diesel engine

- effective, safe and reliable operation

- fault tolerance

- condition monitoring

- accident analysis and modelling

- reliability-centered maintenance

- accident and incident prevention

- risk, safety and reliability assessment

- alternative fuels

- human factor and human-centered design

Participating Journals

| Journal Name | Impact Factor | CiteScore | Launched Year | First Decision (median) | APC |

|---|---|---|---|---|---|

Energies

|

3.2 | 7.3 | 2008 | 16.8 Days | CHF 2600 |

Journal of Marine Science and Engineering

|

2.8 | 5.0 | 2013 | 16.5 Days | CHF 2600 |

Safety

|

1.7 | 3.7 | 2015 | 34 Days | CHF 1800 |

Sensors

|

3.5 | 8.2 | 2001 | 17.8 Days | CHF 2600 |

Processes

|

2.8 | 5.5 | 2013 | 14.9 Days | CHF 2400 |

Preprints.org is a multidisciplinary platform offering a preprint service designed to facilitate the early sharing of your research. It supports and empowers your research journey from the very beginning.

MDPI Topics is collaborating with Preprints.org and has established a direct connection between MDPI journals and the platform. Authors are encouraged to take advantage of this opportunity by posting their preprints at Preprints.org prior to publication:

- Share your research immediately: disseminate your ideas prior to publication and establish priority for your work.

- Safeguard your intellectual contribution: Protect your ideas with a time-stamped preprint that serves as proof of your research timeline.

- Boost visibility and impact: Increase the reach and influence of your research by making it accessible to a global audience.

- Gain early feedback: Receive valuable input and insights from peers before submitting to a journal.

- Ensure broad indexing: Web of Science (Preprint Citation Index), Google Scholar, Crossref, SHARE, PrePubMed, Scilit and Europe PMC.