Trends in Surgical and Beauty Masks for a Cleaner Environment

Abstract

1. Introduction

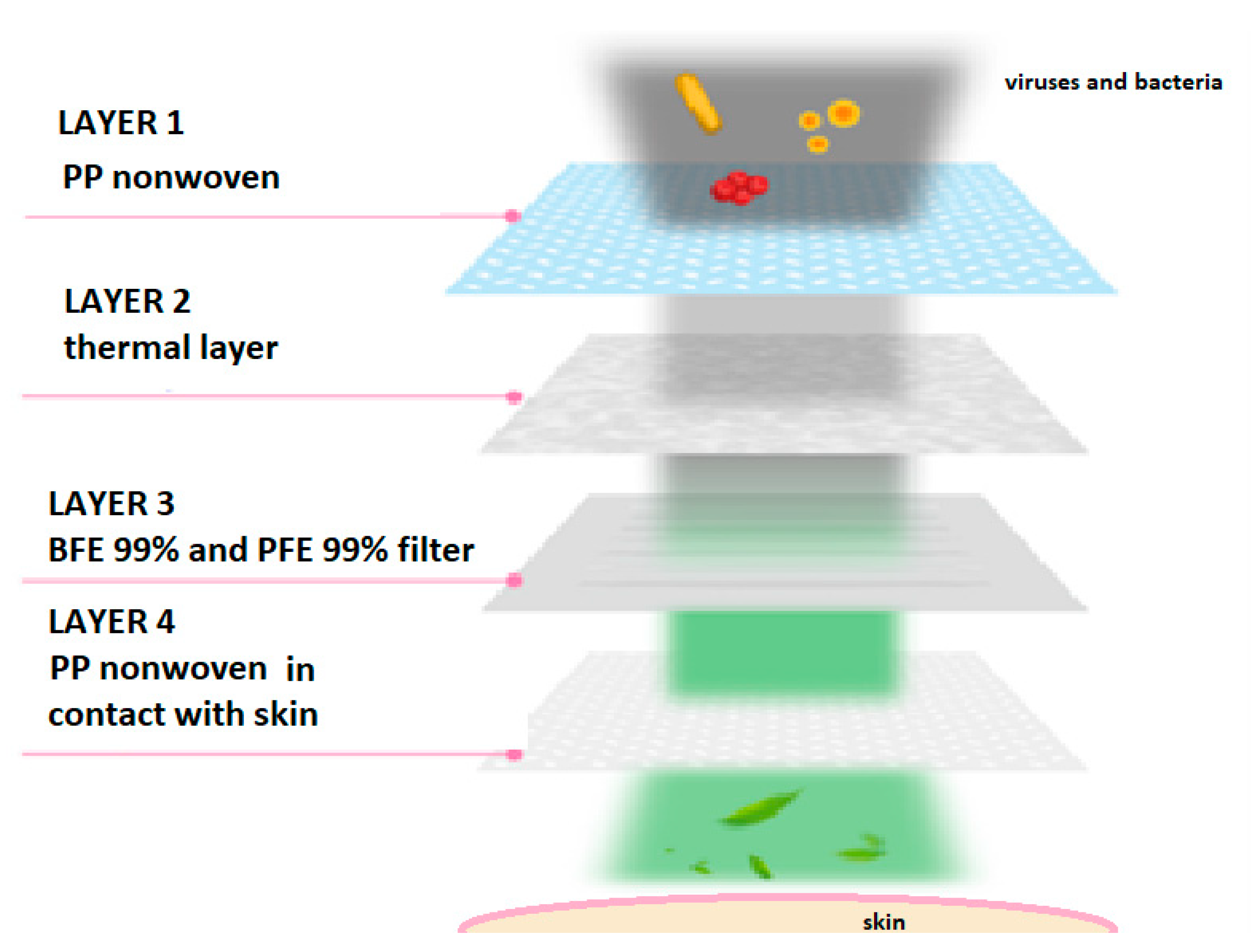

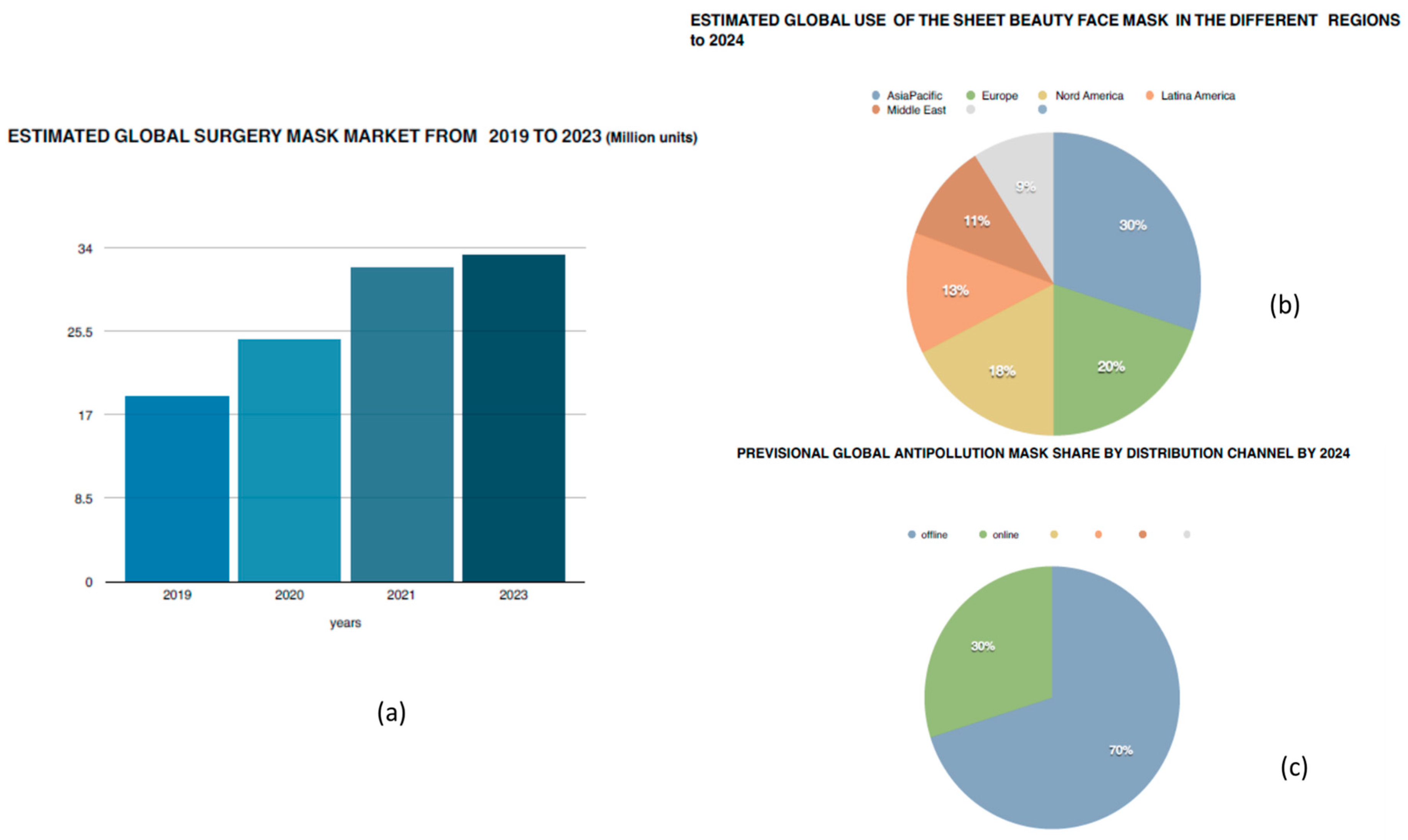

2. Surgical Face Mask Activity and Market

3. Beauty Face Masks (BFMs) Activity and Market

4. Surgery and Beauty Face Masks: The Environment Problem

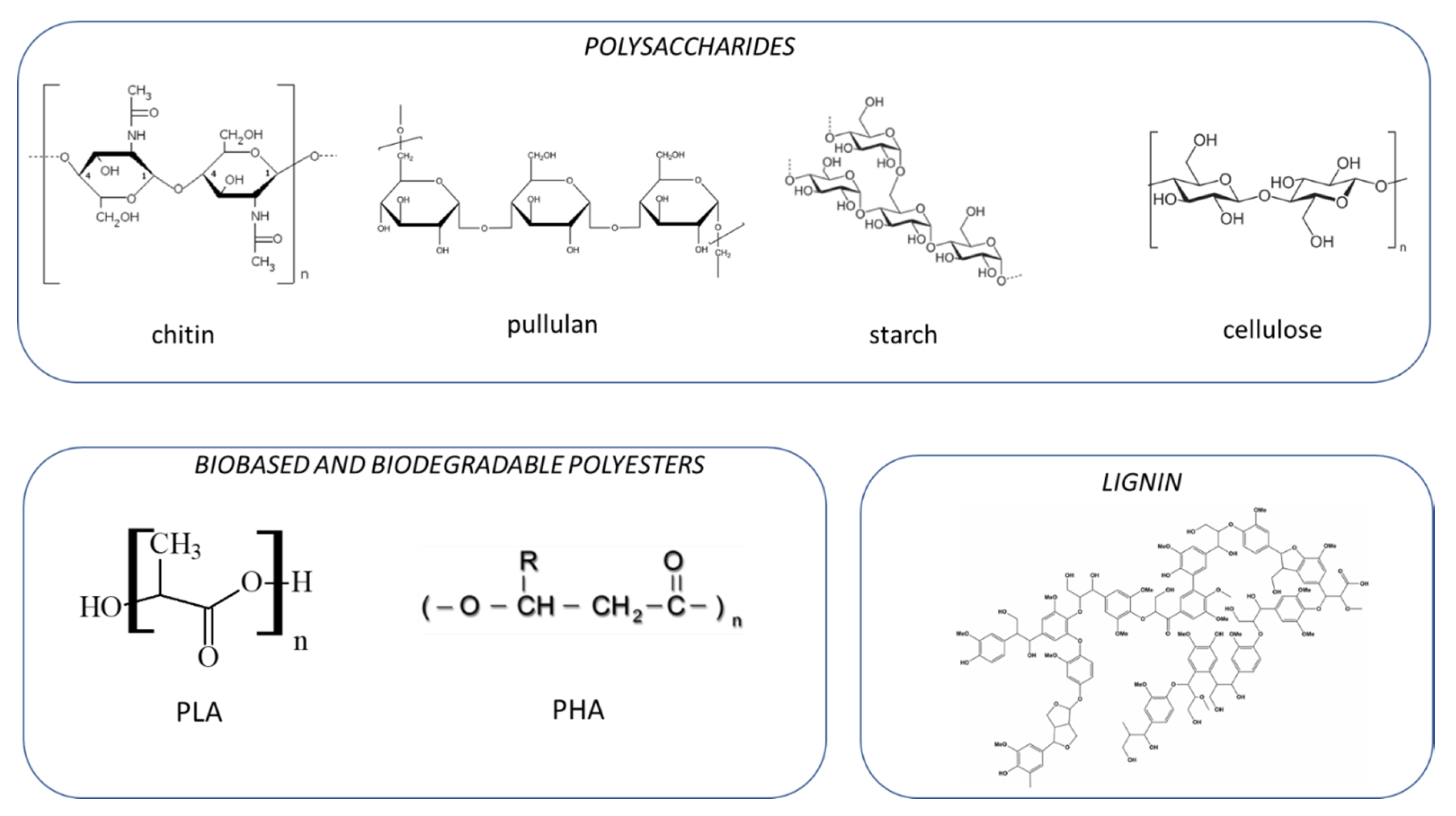

5. Innovative Renewable and Biodegradable Polymers for Non-Woven Tissues

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Baka, A.; Cenciarelli, O.; Duffell, E.; Melidou, A.; Pettinen, P.; Plachous, D. Using Face Masks in the Community. European Centre od Disease Prevention and Control. European Centre for Disease Prevention and Control (ECDC) Technical report. 8 April 2020. Available online: https://www.ecdc.europa.eu/en/publications-data/using-face-masks-community-reducing-covid-19-transmission (accessed on 22 August 2020).

- Nilforoushzadeh, M.A.; Amirkhani, M.A.; Zarrintaj, P.; Moghaddam, A.S.; Mehrabi, T.; Alavi, S. Skin Care and Rejuvenation by Cosmeceutical Facial Mask. J. Cosmet. Derm. 2018, 17, 693–702. [Google Scholar] [CrossRef]

- Chellamani, K.P.; Veerasubramanian, D.; Vignesh Balaji, R.S. Surgical Face Masks: Manufacturing Methods and Classification. J. Acad. Ind. Res. (JAIR) 2013, 2, 320–324. [Google Scholar]

- European Commission. Horizon 2020, Work Programme 2018–2020, Nanotechnology, Advanced Materials, Biotechnology and Advanced manufacturing and Processing. European Commission Decision No1862. 25 March 2020. Available online: https://ec.europa.eu/research/participants/data/ref/h2020/wp/2018-2020/main/h2020-wp1820-leit-nmp_en.pdf (accessed on 15 July 2020).

- Song, R.; Murphy, M.; Li, C.; Soo, C.; Zheng, Z. Current Development of Biodegradable Polymeric Materials for Biomedical Applications. Drug Design Develop. Ther. 2018, 12, 3117–3145. [Google Scholar] [CrossRef]

- Sell, S.A.; Wolfe, P.S.; Garg, K.; McCool, J.M.; Rodriguez, I.A.; Bowling, G.L. The use of Natural Polymes in Tissue Engineering: A Focus on Electrospun Extracellular Matrix Analogues. Polymers 2020, 2, 522. [Google Scholar] [CrossRef]

- Lackner, M. Chapter Bioplastics. Biobased Plastics as Renowable and/or Biodegradable Alternative to Petroplastics. In Encyclopedia of Chemical Technology, 6th ed.; Othmer, K., Ed.; Jhon Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Worldometer—Real Time World Statistics. Available online: https://www.worldometers.info (accessed on 15 July 2020).

- Wong, A.; Wilkinson, A. Surgical Face Masks-Filtering Counterfeit Copies Bird & Bird. 2020. Available online: https://www.twobirds.com/EU/news/articles (accessed on 1 May 2020).

- Merchant Research & Consulting Ltd. (2020) Polypropylene (PP): 2020 World Market Outlook and forecast up to 2029. Available online: https://mcgroup.co.uk/researches/polypropylene-pp (accessed on 15 July 2020).

- WHO. Advice on the Use of Masks in the Contest of COVID-19; World Health Organization: Geneva, Switzerland, 2020. [Google Scholar]

- McKornick. COVID-19 Airway Protection on PPE Overview; Report McKornick & Company: New York, NY, USA, 2020. [Google Scholar]

- Sivri, C. Improvement of protective and comfort properties of face masks using superabsorbent polymer containing nanofibers. Int. J. Chot. Sci. Technol. 2018, 30, 668–686. [Google Scholar] [CrossRef]

- European Union. Manual on Borderline and Classification in the Community Regulatory Framework for Medical Device, version 1.22 (May 2019); European Union: Bruxelles, Belgium, 2019. [Google Scholar]

- WHO. Medical Devices: Managing the Mismatch—An Outcome of the Priority Medical Devices Project; World Health Organization: Geneve, Switzerland, 2010; ISBN 978 92 4 156404 5. [Google Scholar]

- Globe Newswire. Face Market to Surpass USD Billion by 2026; Market Study Report: Selbyville, DE, USA, 2020; Available online: https://www.globenewawire.com (accessed on 5 May 2020).

- Market Watch. Industry Analysis, Growth, Trends, Key Players and Forecast 2020–2026. Available online: https://www.marketwatch.com (accessed on 5 May 2020).

- Gran View Research. Disposable Face Mask Market Size, Share & Trends Analysis Report by Product, by Application and Segment Forecasts, 2020–2027. 2020. Available online: https://www.grandreviewresearch.com (accessed on 6 May 2020).

- Moelling, K.; Broecker, F. Air Microbiome and Pollution:Composition and Potential Effects of Human Health, Including SARS Coronavirus Infection. J. Environ. Pub. Health 2020, ID1646943, 14P. [Google Scholar] [CrossRef]

- Technavio Web-Site. Available online: https://www.technavio.com (accessed on 15 July 2020).

- Spiritelli, C. Cosmetic Industry: An Analysis of Marketing and Mass Communication Strategies. Master’s Thesis, Lecterature Depart, Padoa University, Padoa, Italy, 2019. [Google Scholar]

- Morganti, P.; Morganti, G.; Chen, H.-D.; Gagliardini, A. Beauty Mask: Market and Environment. J. Clin. Cosmet. Dermatol. 2019, 3, 1–10. [Google Scholar] [CrossRef]

- Statista. Beauty & Personal Care Report 2019. Statista Consumer Market Outlook, Market Report. May 2019. Available online: https://www.statista.com (accessed on 6 May 2020).

- Bhadallar, S. Sheet Face Masks Market by Product Type, Price Point and Distribution Channel: Global Opportunity Analysis and Industry Forecast, 2018–2026, Allied Market Research. 2019. Available online: https://www.alliedmarketresearch.com (accessed on 6 May 2020).

- Zhang, L.; Adique, A.; Sarkar, P.; Shenai, V.; Sampath, M.; Lai, R. The Impact of Routine SkinCare on The Quality of Life. Cosmetics 2020, 7, 59. [Google Scholar] [CrossRef]

- Gran View Research. Sheet Face Mask Market Size, Share & Trends Analysis Report by Product Type (Cotton, non-woven, hydro gel, biocellulose) by Region and Segment Forecast 2019–2025. 2020. Available online: https://www.granviewresearch.com/industry-analysis/sheet-face-maskmarket (accessed on 6 May 2020).

- Kwek, S.; Mintel, G.N.P.D. Global New Products Database: Tracked, Analyzed, Explained. Mintel Group Ltd.. Available online: https://www.mintel.com/global-new-products-database (accessed on 7 May 2020).

- Ritchie, H.; Roser, M. Plastic Pollution. Available online: https://www.ourworldindafa.org/plasticpollution (accessed on 7 May 2020).

- Ritchie, H. The Carbon Footprint of Foods: Are Differences Explained by the Impacts of Methane? Available online: https://www.ourworldindata.org/carbonfootprint-food-methane (accessed on 7 May 2020).

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Perryman, M.; Andrady, A. Plastic Waste Inputs from Land into the Ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Statista. Plastic Waste Worldwide-Statistics & Facts. Available online: https://www.statista.com (accessed on 13 May 2020).

- Sensoneo. Global Waste Index 2019. Available online: https://www.sensoneo.com/references/ (accessed on 7 May 2020).

- IMF. Global Wellnes Economy Monitor, Global Economy Outlook Data Base, Global Wellness Institute. April 2018. Available online: https://www.imf.org/external/pubs/ft/Wei/2018/01/welfare/index.aspx (accessed on 15 July 2020).

- Ellen Mac Arthur Foundation. From Linear to Circular Economy. A global learning Programme. Ellen Mac Arthur Foundation. 15 April 2020. Available online: https://www.ellenmacarthurfoundation.org (accessed on 15 July 2020).

- Ocean Crusaders. Plastic Statistics. Plastic Ain’t so Fantastic, Ocean Crusaders Foundation Ltd. Available online: https://www.oceancrusaders.org (accessed on 13 May 2020).

- Kwek, S. Face Masks Fuel Post-Covid-19 Beauty Opportunie. Mintel UK. 2020. Available online: https://www.mintel.com/blog/beauty-market-news/face-masks-fuelpost-covid-19-beauty-opportunities (accessed on 7 May 2020).

- Angus, A. How is COVID-19 affecting the Top 10 Global Consumer Trends 2020? Euromonitor International. 2020. Available online: https://go.euromonitor.com/webinar-ec-2020-covid-19-impact-on-gct.html (accessed on 15 July 2020).

- Angus, A.; Westbrook, G. Top 10 Global Consumer Trends; Euromonitor International: London, UK, 2019; Available online: https://go.euromonitor.com/white-paper-EC-2019-Top-10-Global-Consumer-Trends.html (accessed on 15 July 2020).

- Jindal, S.; Kwek, S.; McDougall, A. Global Beauty and Personal Care Trends 2030; Mintel: London, UK, 2020; Available online: https://www.mintel.com/beauty-trends (accessed on 15 July 2020).

- Morganti, P.; Morganti, G.; Coltelli, M.B. Chitin Nanomaterials and Nanocosmetics for Tissue Repair. In Marine-Derived Biomaterials for Tissue Engineering; Choi, A.H., Ben-Nissan, B., Eds.; Spring: Singapore, 2019; pp. 523–544. [Google Scholar]

- Tuin, A.; Pourdeyhimi, B.; Loboa, E.G. Creating Tissues from Textiles: Scalable Nonwoven Manufacturing Techniques for Fabrication of Tissue Engineering Scaffolds. Biomed. Mater. 2016, 11, 015017. [Google Scholar] [CrossRef]

- Aires, C.E.; Sheehan Jha, B.; Sell, S.A.; Bowin, G.L.; Simpson, D.G. Nanotechnology in the design of Self Tissue scaffolds: Innovation in structure and function. WIREs Nanomed. Nanobiotechnol. 2010, 2, 20–34. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, S.; Wendorff, J.H.; Greiner, A. Use of electrospinning technique for biomedical applications. Polymer 2008, 49, 5603–5621. [Google Scholar] [CrossRef]

- Fuller, K.; Pandit, A.; Zeugolis, D.I. The multifaceted Potential of Electrospinnig in Regenerative Medicine. Pharm. Nanotechnol. 2014, 2, 23–34. [Google Scholar] [CrossRef]

- Parham, S.; Kharazi, A.Z.; Bakhsheshi-Rad, H.R.; Ghayour, H.; Ismail, A.F.; Nur, H.; Berto, F. Electrospun Nano-Fibers for Biomedical and Tissue Engineering Applications: A Comprehensive Review. Materials 2020, 13, 2153. [Google Scholar] [CrossRef]

- Morganti, P. Chitin Nanofibrils: Tuning Fishery’s Waste into Goods. J. Clin. Rev. Case Rep. 2018, 3, 1–3. [Google Scholar]

- Morganti, P.; Chen, H.D.; Gao, X.; Morganti, G.; Febo, D. Chitin & Lignin:Tuning Food Waste into Cosmeceuticals. J. Clin. Cosmet. Dermatol. 2018, 3, 1–10. [Google Scholar] [CrossRef]

- Morganti, P.; Febo, P. Innovative tissue engineering for an enlarged Market. J. Clin. Cosmet. Derm. 2017, 2, 119. [Google Scholar] [CrossRef]

- Morganti, P.; Coltelli, M.B.; Danti, S. Biobased tissues for Innovative Cosmetic products: PolyBioSkin as an EU Resarch Project. Glob. J. Nano Case Rep. 2018, 3, 555620. [Google Scholar] [CrossRef]

- Morganti, P.; Coltelli, M.B. A New Carrier for Advanced Cosmeceuticals. Cosmetics 2019, 6, 10. [Google Scholar] [CrossRef]

- Morganti, P.; Del Ciotto, P.; Stoller, M.; Chianese, A. Antibacterial and Antiinflammatory Green Nanocomposites. Chem. Eng. Trans. 2016, 47, 6–66. [Google Scholar] [CrossRef]

- Morganti, P.; Fusco, A.; Paoletti, I.; Perfetto, B.; Del Ciotto, P.; Palombo, M.; Chianese, A.; Baroni, A.; Donnarumma, G. Anti-Inflammatory, Immunomodulatory, and Tissue Repair Activity on Human Keratinocytes by Green Innovative Nanocomposites. Materials 2017, 10, 843. [Google Scholar] [CrossRef] [PubMed]

- Morganti, P.; Stoller, M. Chitin Natural Ingredients from Waste Materials to Make Innovative and Heakthy Products for Humans and plant. Chem. Eng. Trans. 2017, 48, 319–324. [Google Scholar] [CrossRef]

- Xu, X.G.; Gao, X.H.; Chen, H.D.; Morganti, P. Chitin Nanocomposite Scaffolds for Advanced Medications. In Bionanotechnolgy to Save the Environment. Plant and Fishery’s Biomass as Alternative to Petrol; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 260–271. [Google Scholar]

- Morganti, P.; Tishchenko, G.; Palombo, M.; Kelnar, I.; Brozova, L.; Spirkova, M. Chitin Nanofibrils for Biomimetic Products: Nanoparticles and Nanocomposites Chitosan Films in Health Care. In Marine Biomaterials. characterization Isolation and Applications; Kim, S.K., Ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 681–716. [Google Scholar]

- Tishchenko, G.; Morganti, P.; Stoller, M.; Kelnar, I.; Mikesova, J.; Kovarova, J. Chitin Nanofibrils-Chitosan Composite Films: Characterization and Properties. In Bionanotechnolgy to Save The Environment. Plant and Fishery’s Biomass as Alternative to Petrol; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 191–226. [Google Scholar]

- Danti, S.; Trombi, L.; Fusco, A.; Azimi, B.; Lazzeri, A.; Morganti, P.; Coltelli, M.B.; Donnarumma, G. Chitin Nanofibrils and Nanolignin as Functional Agents in Skin Regeneration. Int. J. Mol. Sci. 2019, 20, 2669. [Google Scholar] [CrossRef] [PubMed]

- Hamad, K.; Kanseem, M.; Yang, H.W.; Deri, F.; Ko, Y.G. Properties and medical Applications of polylactic acid: A review. Express Polym. Lett. 2015, 9, 435–455. [Google Scholar] [CrossRef]

- de Andrade, M.F.C.; Souza, P.M.S.; Cavalett, O. Life Cycle Assessment of Poly (Lactic Acid) (PLA): Comparison Between Chemical Recycling, Mechanical Recycling and Composting. J. Polym. Environ. 2016, 24, 372–384. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Della Maggiore, I.; Bertoldo, M.; Bronco, S.; Signori, F.; Ciardelli, F. Poly (lactic acid) (PLA) properties as a consequence of poly (butylene adipate-co-terephtahlate) (PBAT) blending and acetyl tributyl citrate (ATBC) plasticization. J. Appl. Polym. Sci. 2008, 110, 1250–1262. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Bronco, S.; Chinea, C. Effect of free radical reactions onto Structure and properties of poly (lactic acid) (PLA) based blends. Polym. Degr. Stab. 2010, 95, 332–341. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Toncelli, C.; Ciardelli, F.; Bronco, S. Compatible blends of biorelated polyesters through catalytic transesterification in the melt. Polym. Degr. Stab. 2011, 96, 982–990. [Google Scholar] [CrossRef]

- Gigante, V.; Coltelli, M.B.; Vannozzi, A.; Panariello, L.; Fusco, A.; Trombi, L.; Donnarumma, G.; Danti, S.; Lazzeri, A. Flat Die Extruded Biocompatible Poly (Lactic Acid) (PLA)/Poly (Butylene Succinate) (PBS) Based Films. Polymers 2019, 11, 1857. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Cinelli, P.; Gigante, V.; Aliotta, L.; Morganti, P.; Panariello, L.; Lazzeri, A. Chitin Nanofibrils in Poly (Lactic Acid) (PLA) Nanocomposites: Dispersion and Thermo-Mechanical Properties. Int. J. Mol. Sci. 2019, 20, 504. [Google Scholar] [CrossRef]

- Castiello, S.; Coltelli, M.-B.; Conzatti, L.; Bronco, S. Comparative study about preparation of poly (lactide) (PLA)/organophilic montmorillonites nanocomposites through melt blending or ring opening polymerization methods. J. Appl. Polym. Sci. 2012, 125, 413–428. [Google Scholar] [CrossRef]

- Scatto, M.; Salmini, E.; Castiello, S.; Coltelli, M.B.; Conzatti, L.; Stagnaro, P.; Andreotti, L.; Bronco, S. Plasticized and nanofilled Poly (Lactic Acid)-based cast films: Effect of plasticizer and organoclay on processability and final properties. J. Appl. Polym. Sci. 2013, 127, 4947–4956. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Aliotta, L.; Vannozzi, A.; Morganti, P.; Panariello, L.; Danti, S.; Neri, S.; Fernandez-Avila, C.; Fusco, A.; Donnarumma, G.; et al. Properties and Skin Compatibility of Films Based on Poly (Lactic Acid) (PLA) Bionanocomposites Incorporating Chitin Nanofibrils (CN). J. Funct. Biomater. 2020, 11, 21. [Google Scholar] [CrossRef] [PubMed]

- Gigante, V.; Aliotta, L.; Phuong, T.V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Effects of waviness on fiber-length distribution and interfacial shear strength of natural fibers reinforced composites. Compos. Sci. Technol. 2017, 152, 129–138. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Evaluation of Mechanical and Interfacial Properties of Bio-Composites Based on Poly (Lactic Acid) with Natural Cellulose Fibers. Int. J. Mol. Sci. 2019, 20, 960. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Danti, S.; Trombi, L.; Morganti, P.; Donnarumma, G.; Baroni, A.; Fusco, A.; Lazzeri, A. Preparation of Innovative Skin Compatible Films to Release Polysaccharides for Biobased Beauty Masks. Cosmetics 2018, 5, 70. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Panariello, L.; Morganti, P.; Danti, S.; Baroni, A.; Lazzeri, A.; Fusco, A.; Donnarumma, G. Skin-Compatible Biobased Beauty Masks Prepared by Extrusion. J. Funct. Biomater. 2020, 11, 23. [Google Scholar] [CrossRef]

- Miletić, A.; Ristić, I.; Coltelli, M.-B.; Pilić, B. Modification of PLA-Based Films by Grafting or Coating. J. Funct. Biomater. 2020, 11, 30. [Google Scholar] [CrossRef]

- Sashiwa, H.; Fukuda, R.; Okura, T.; Sato, S.; Nakayama, A. Microbial Degradation Behavior in Seawater of Polyester Blends Containing Poly(3-hydroxybutyrateco-3-hydroxyhexanoate) (PHBHHx). Mar. Drugs 2018, 16, 34. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Danti, S.; De Clerck, K.; Lazzeri, A.; Morganti, P. Pullulan for Advanced Sustainable Body and Skin-Contact Applications. J. Funct. Biomater. 2020, 11, 20. [Google Scholar] [CrossRef]

- Panariello, L.; Coltelli, M.B.; Buchignani, M.; Lazzeri, A. Chitosan and nano-structured chitin for biobased anti-microbial treatments onto cellulose based materials. Eur. Polym. J. 2019, 113, 328–339. [Google Scholar] [CrossRef]

- Yudin, V.E.; Dobrovolskaya, I.P.; Neelov, I.M.; Dresvianina, E.N.; Popryadukhin, P.V.; Ivankova, E.M.; Elokhovskii, V.Y.; Kasatkin, I.A.; Okrugin, B.M.; Morganti, P. Wet spinning of fibers made of chitosan and chitin nanofibrils. Carbohydaste Polym. 2014, 108, 176–182. [Google Scholar] [CrossRef] [PubMed]

- Cinelli, P.; Coltelli, M.B.; Mallegni, N.; Morganti, P.; Lazzeri, A. Degradability and Sustainability of Nanocomposites Based on Polylactic acid and Chitin Nanofibrils. Chem. Eng. Trans. 2017, 48, 115–120. [Google Scholar] [CrossRef]

- Biagini, G.; Zizzi, F.; Giantomassi, F.; Orlando, F.; Lucarini, G.; Mattioli-Belmonte, M.; Tucci, M.G.; Morganti, P. Cutaneous Absorption of Nanostructured Chitin Associated with Natural Synergistic molecules (Lutein). J. Appl. Cosmetol. 2008, 26, 69–80. [Google Scholar]

- Shabunin, A.S.; Yudin, V.E.; Dobrovolskaya, I.P.; Zinovyev, E.V.; Zubov, V.; Ivankova, E.; Morganti, P. Composite wound dressing based on Chitin/Chitosan nanofibrils: Processing and biomedical applications. Cosmetics 2019, 6, 16. [Google Scholar] [CrossRef]

- Smirnova, N.V.; Kolbe, K.A.; Dresvyanina, E.N.; Grebennikov, S.F.; Dobrovolskaya, I.P.; Luxbacher, T.; Morganti, P. Effect of Chitin Nanofibril on Biocompatibility and Biodiversity of the Chitosan-based Composite Film Matrix Intended for Tissue Engineering. Materials 2019, 12, 1874. [Google Scholar] [CrossRef]

- Maevskaia, E.N.; Kirichuk, O.P.; Kuznetzov, S.I.; Dresvyanina, E.N.; Yudin, V.V.; Morganti, P. Hemocompatible Chitin-Chitosan Composite Fibers. Cosmetics 2020, 7, 28. [Google Scholar] [CrossRef]

- Azuma, K.; Koizumi, R.; Izawa, H.; Morimoto, M.; Osaka, T.; Saimoto, H.; Ito, N.; Yamashita, M.; Tsuka, T.; Imagawa, T.; et al. Hair Growth-Promoting Activities of Chitosan and Surface-deacetylated Chitin Nanofibrils: Processing and Biomedical Applications. Int. J. Biol. Macromol. 2018, 126, 11–17. [Google Scholar] [CrossRef]

- Jui, Y.Y.; Chin, T.L.; Ing, T.S.; Cardillo, M.; Morganti, P. Cross-Sectional Study Design and Data Analysis of the Effect of Chitin Nanofibriks-Lignin Micro/Nano Particles on Nakaysua’s Subject with Disorders. J. Clin. Cosmet. Derm. 2019, 3, 1–6. [Google Scholar] [CrossRef]

- Morganti, P.; Anniboletti, T.; Pollastrini, C.; Morganti, G. Natural Polymers for Body Care to Save the Environment. Biomed. J. Sci. Tech. Res. 2019, 17, 12570–12574. [Google Scholar] [CrossRef]

- Donnarumma, G.; Fusco, A.; Morganti, P.; Palombo, M.; Anniboletti, T.; Del Ciotto, P.; Baroni, A.; Chianese, A. Advances Medications made by Green Nanocomposites. Int. J. Res. Nano Sci. 2018, 5, 261–270. [Google Scholar]

- Anniboletti, T.; Palombo, M.; Maroni, S.; Bruno, A.; Palombo, P.; Morganti, P. Clinical Activity of Innovative Polymeric Nanoparticles and Non-woven Tissues. In Bionanotechnology to Save the Environment. Plant and Fishery’s Bioamass as Alternative to Petrol; Morganti, P., Ed.; MDPI: Basel, Switzerland, 2019; pp. 340–360. [Google Scholar]

- Morganti, P.; Palombo, M.; Tishchenko, G.; Yudin, V.E.; Guarneri, F.; Cardillo, M.; Del Ciotto, P.; Carezzi, F.; Morganti, G.; Fabrizi, G. Chitin-Hyaluronan Nanoparticles: A Multifunctional Carrier to Deliver Anti-Aging Active Ingredients through the Skin. Cosmetics 2014, 1, 149–158. [Google Scholar] [CrossRef]

- Morganti, P.; Morganti, G.; Coltelli, M.B. Skin and Pollution: The Smart Nano-Based Cosmeceutical-Tissue to Save the Planet Ecosystem. In Nanocosmetics: Fundamentals, Applications and Toxicity; Nanda, A., Nanda, S., Nguyen, T.A., Rajendran, S., Slimani, Y., Eds.; Elsevier: Amsterdam, The Netherland, 2020; pp. 287–304. [Google Scholar]

- Morganti, P.; Chen, H.D.; Morganti, P. Nanocosmetics: Future Perspective. In Nanocosmetics: Fundamentals, Applications and Toxicity; Nanda, A., Nanda, S., Nguyen, T.A., Rajendran, S., Slimani, Y., Eds.; Elsevier: Amsterdam, The Netherland, 2020; pp. 455–481. [Google Scholar]

- Sakamoto, K.; Lochhead, R.Y.; Maybach, H.I.; Yamashita, Y. Cosmetic Science and Technology Principles and Applications; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Morganti, P. Bionanotechnology to Save the Environment. Plant and Fishery’s Biomass as Alternative to Petrol; MDPI: Basel, Switzerland, 2019; pp. 1–21. [Google Scholar]

| Mask | CN-LN | PLA | PHA | PULLULAN or STARCH | CELLULOSE |

|---|---|---|---|---|---|

| SFM | X | X | X | X | |

| Advantages | -Compostable -Easily processable by electrospinning -Antimicrobial -Antioxidant | -Easily processable -Recyclable -Compostable -Slightly antimicrobial -Cheap | -Recyclable -Compostable in marine environment | -Easily processable -Cheap | |

| Disadvantages | none | Compostable only in Composting Plant | -Not easily processable | -Soluble or swelling in Water | -Low resistance to Water Vapor |

| BFM | X | X | X | X | X |

| Advantages | -Compostable -Easily processable by electrospinning -Antimicrobial, -Antioxidant -Regenerative for skin cells | -Cheap and compostable | -Compostable in marine environment | -Efficient release of actives -Compostable -Easily processable by electrospinning -Removal with water (no solid waste) | -Easily processable -Cheap |

| Disadvantages | none | -Hydrophobic -It needs adding actives | -Not easily processable -It needs adding actives | -It needs adding actives | It needs adding actives |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morganti, P.; Yudin, V.E.; Morganti, G.; Coltelli, M.-B. Trends in Surgical and Beauty Masks for a Cleaner Environment. Cosmetics 2020, 7, 68. https://doi.org/10.3390/cosmetics7030068

Morganti P, Yudin VE, Morganti G, Coltelli M-B. Trends in Surgical and Beauty Masks for a Cleaner Environment. Cosmetics. 2020; 7(3):68. https://doi.org/10.3390/cosmetics7030068

Chicago/Turabian StyleMorganti, Pierfrancesco, Vladimir E. Yudin, Gianluca Morganti, and Maria-Beatrice Coltelli. 2020. "Trends in Surgical and Beauty Masks for a Cleaner Environment" Cosmetics 7, no. 3: 68. https://doi.org/10.3390/cosmetics7030068

APA StyleMorganti, P., Yudin, V. E., Morganti, G., & Coltelli, M.-B. (2020). Trends in Surgical and Beauty Masks for a Cleaner Environment. Cosmetics, 7(3), 68. https://doi.org/10.3390/cosmetics7030068