High Hydrostatic Pressure and Co-Fermentation by Lactobacillus rhamnosus and Gluconacetobacter xylinus Improve Flavor of Yacon-Litchi-Longan Juice

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. YLL Juice Preparation

2.3. Preparation of Cultures

2.4. Processing Conditions

2.5. Fermentation Assays

2.6. Microbiological Assay

2.7. Chemical Analysis

2.7.1. Carbohydrate

2.7.2. Organic Acids

2.7.3. Exopolysaccharide (EPS)

2.7.4. Free Amino Acids (FAA)

2.7.5. Volatile Flavor Compounds

2.8. Statistical Analysis

3. Results and Discussion

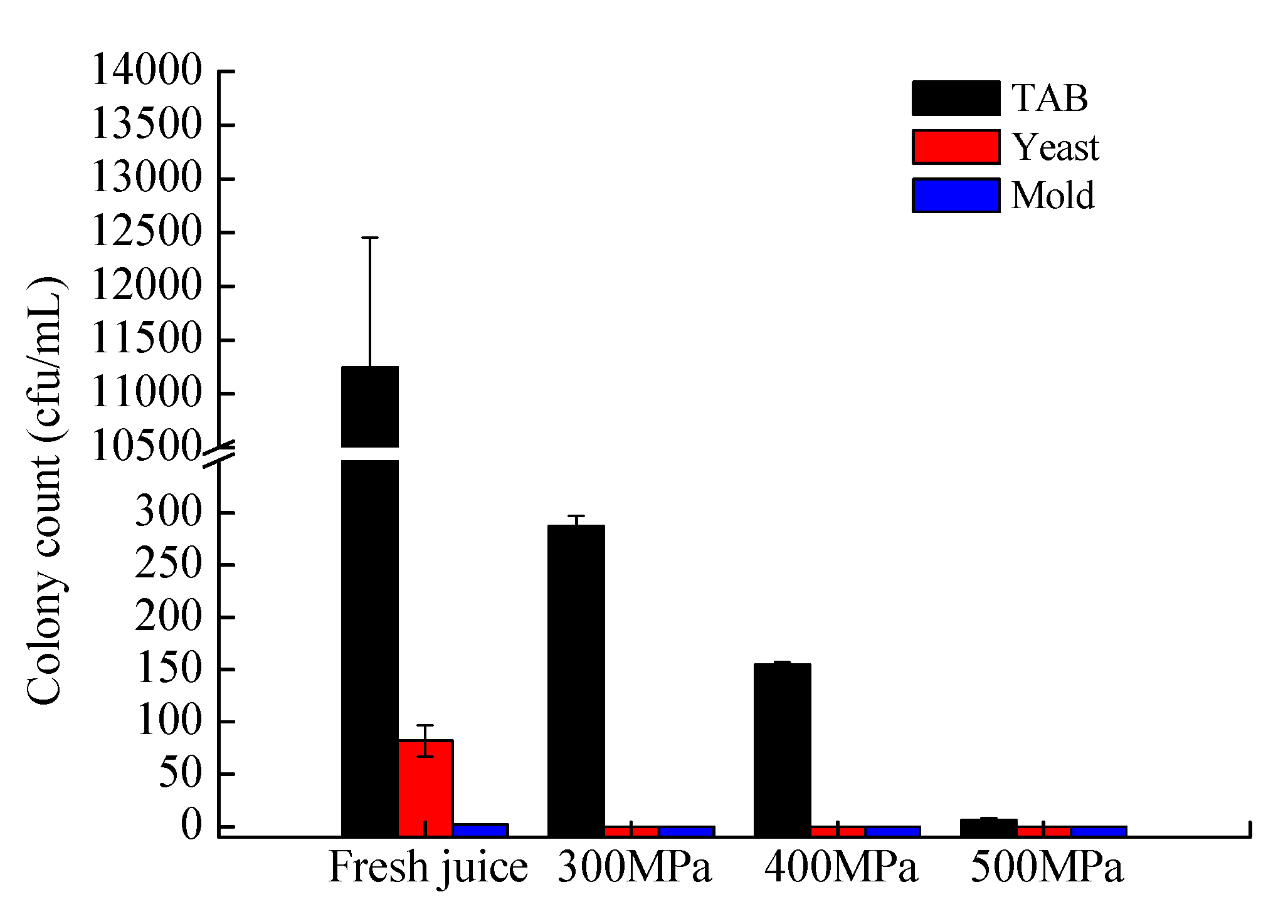

3.1. Effect of HHP Treatment on Inactivation of Total Aerobic Bacteria, Yeast, and Mold in YLL Juice

3.2. Microbial Growth and Substrate Consumption of TP- and HHP-Treated YLL Juice During Co-Fermentation

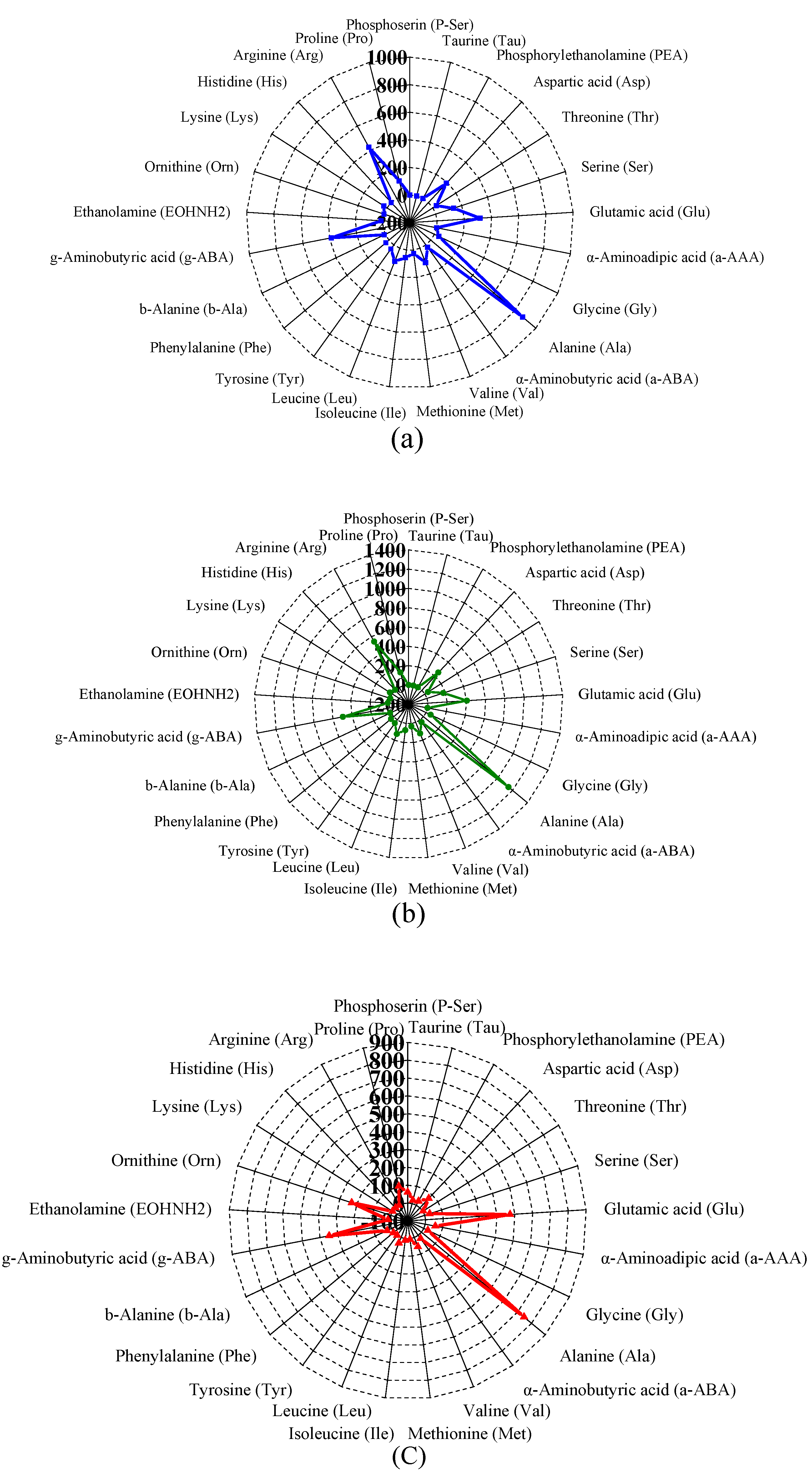

3.3. Changes in FAA Content of TP- and HHP-Treated YLL Juice After Co-Fermentation

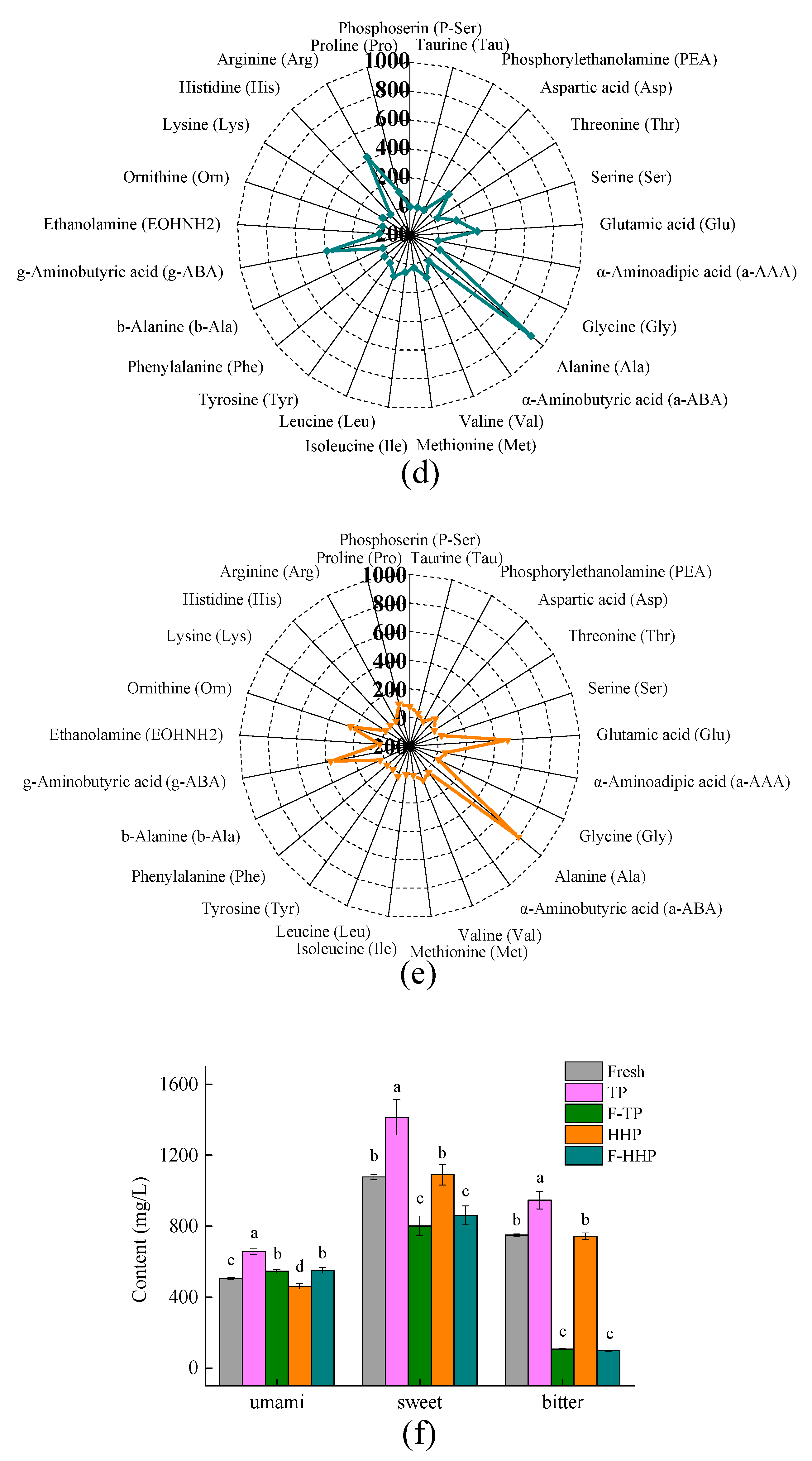

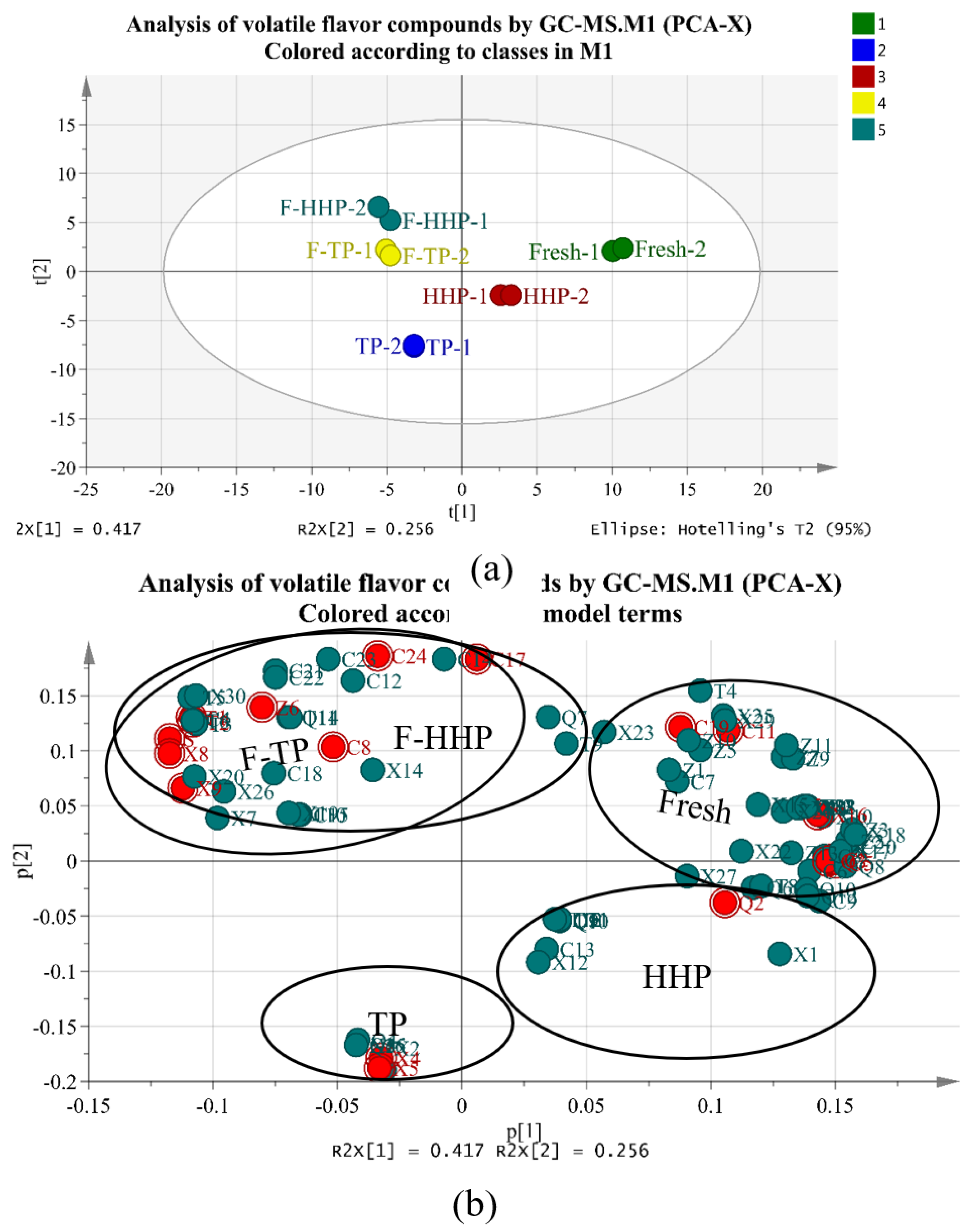

3.4. Effect of HHP and Co-Fermentation on Volatile Flavor Compounds in YLL Juice

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Ankolekar, C.; Pinto, M.; Greene, D.; Shetty, K. In vitro bioassay based screening of antihyperglycemia and antihypertensive activities of Lactobacillus acidophilus fermented pear juice. Innov. Food Sci. Emerg. Technol. 2012, 13, 221–230. [Google Scholar] [CrossRef]

- Granato, D.; Branco, G.F.; Nazzaro, F.; Cruz, A.G.; Faria, J.A. Functional Foods and Nondairy Probiotic Food Development: Trends, Concepts, and Products. Compr. Rev. Food Sci. Food Saf. 2010, 9, 292–302. [Google Scholar] [CrossRef]

- Genta, S.; Cabrera, W.; Habib, N.; Pons, J.; Carillo, I.M.; Grau, A.; Sanchez, S. Yacon syrup: Beneficial effects on obesity and insulin resistance in humans. Clin. Nutr. 2009, 28, 182–187. [Google Scholar] [CrossRef] [PubMed]

- Ojansivu, I.; Ferreira, C.L.; Salminen, S. Yacon, a new source of prebiotic oligosaccharides with a history of safe use. Trends Food Sci. Technol. 2011, 22, 40–46. [Google Scholar] [CrossRef]

- Angelov, A.; Gotcheva, V.; Kuncheva, R.; Hristozova, T. Development of a new oat-based probiotic drink. Int. J. Food Microbiol. 2006, 112, 75–80. [Google Scholar] [CrossRef] [PubMed]

- Mikkelsen, D.; Flanagan, B.M.; Dykes, G.A.; Gidley, M.J. Influence of different carbon sources on bacterial cellulose production by Gluconacetobacter xylinus strain ATCC 53524. J. Appl. Microbiol. 2010, 107, 576–583. [Google Scholar] [CrossRef] [PubMed]

- Jagannath, A.; Raju, P.; Bawa, A. Comparative evaluation of bacterial cellulose (nata) as a cryoprotectant and carrier support during the freeze drying process of probiotic lactic acid bacteria. LWT 2010, 43, 1197–1203. [Google Scholar] [CrossRef]

- Rodriguez, H.; Curiel, J.A.; Landete, J.M.; Rivas, B.D.L.; De Felipe, F.L.; Gómez-Cordovés, C.; Mancheño, J.M.; Muñoz, R. Food phenolics and lactic acid bacteria. Int. J. Food Microbiol. 2009, 132, 79–90. [Google Scholar] [CrossRef] [Green Version]

- Prado, F.C.; Parada, J.L.; Pandey, A.; Soccol, C.R. Trends in non-dairy probiotic beverages. Food Res. Int. 2008, 41, 111–123. [Google Scholar] [CrossRef]

- Barba, F.J.; Esteve, M.J.; Frígola, A. High Pressure Treatment Effect on Physicochemical and Nutritional Properties of Fluid Foods during Storage: A Review. Compr. Rev. Food Sci. Food Saf. 2012, 11, 307–322. [Google Scholar] [CrossRef]

- Li, X.; Farid, M. A review on recent development in non-conventional food sterilization technologies. J. Food Eng. 2016, 182, 33–45. [Google Scholar] [CrossRef]

- Yang, Y.; Xia, Y.; Wang, G.; Yu, J.; Ai, L. Effect of mixed yeast starter on volatile flavor compounds in Chinese rice wine during different brewing stages. LWT 2017, 78, 373–381. [Google Scholar] [CrossRef]

- GB 4789.2-2016 National Food Safety Standard. China: Food Microbiological Examination: Aerobic Plate Count. 2016. Available online: http://tradechina.dairyaustralia.com.au/wp-content/uploads/2018/08/GB-4789.2-2016-Safety-Standard-Food-Microbiological-Examination-Aerobic-Plate-Count-.pdf (accessed on 30 July 2019).

- GB 4789.35-2016 National Food Safety Standard. China: Food Microbiological Examination: Lactic Acid Bacteria Plate Count. 2016. Available online: http://www.svscr.cz/wp-content/files/zivocisne-produkty/GB4789._35_2010_food_microbiological_examination_lactic_acid_bacteria.pdf (accessed on 30 July 2019).

- Yu, Y.; Xiao, G.; Xu, Y.; Wu, J.; Fu, M.; Wen, J. Slight Fermentation with Lactobacillus fermentium Improves the Taste (Sugar:Acid Ratio) of Citrus (Citrus reticulata cv. chachiensis) Juice. J. Food Sci. 2015, 80, M2543–M2547. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Cui, S.W.; Tang, J.; Gu, X. Optimization of extraction process of crude polysaccharides from boat-fruited sterculia seeds by response surface methodology. Food Chem. 2007, 105, 1599–1605. [Google Scholar] [CrossRef]

- Ibegbulem, C.; Igwe, C.; Okwu, G.; Ujowundu, C.; Onyeike, E.; Ayalogu, E. Total amino acid profiles of heat-processed fresh Elaeis guineensis and Raphia hookeri wines. Food Chem. 2013, 138, 1616–1620. [Google Scholar] [CrossRef]

- Kaplan, H.; Hutkins, R.W. Fermentation of Fructooligosaccharides by Lactic Acid Bacteria and Bifidobacteria. Appl. Environ. Microbiol. 2000, 66, 2682–2684. [Google Scholar] [CrossRef] [Green Version]

- Reuss, R.; Stratton, J.; Smith, D.; Read, P.; Cuppett, S.; Parkhurst, A. Malolactic Fermentation as a Technique for the Deacidification of Hard Apple Cider. J. Food Sci. 2010, 75, C74–C78. [Google Scholar] [CrossRef]

- Marsellés, A.R. Effects of thermal and non-thermal processing treatments on fatty acids and free amino acids of grape juice. Food Control. 2007, 18, 473–479. [Google Scholar]

- Blandino, A.; Al-Aseeri, M.; Pandiella, S.; Cantero, D.; Webb, C. Cereal-based fermented foods and beverages. Food Res. Int. 2003, 36, 527–543. [Google Scholar] [CrossRef]

- Komata, Y. The taste and constituents of foods. Nippon Shokuhin Kogyo Gakkaishi 1969, 3, 26. [Google Scholar]

- Viljanen, K.; Lille, M.; Heiniö, R.-L.; Buchert, J. Effect of high-pressure processing on volatile composition and odour of cherry tomato purée. Food Chem. 2011, 129, 1759–1765. [Google Scholar] [CrossRef]

- Deng, Y.; Zhong, Y.; Yu, W.; Yue, J.; Liu, Z.; Zheng, Y.; Zhao, Y. Effect of hydrostatic high pressure pretreatment on flavor volatile profile of cooked rice. J. Cereal Sci. 2013, 58, 479–487. [Google Scholar] [CrossRef]

- Di Cagno, R.; Filannino, P.; Gobbetti, M. Lactic acid fermentation drives the optimal volatile flavor-aroma profile of pomegranate juice. Int. J. Food Microbiol. 2017, 248, 56–62. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, J.; Chatterjee, S.; Gamre, S.; Chattopadhyay, S.; Variyar, P.S.; Sharma, A. Analysis of free and bound aroma compounds of pomegranate (Punica granatum L.). LWT 2014, 59, 461–466. [Google Scholar] [CrossRef]

- Perez-Cacho, P.R.; Rouseff, R. Processing and Storage Effects on Orange Juice Aroma: A Review. J. Agric. Food Chem. 2008, 56, 9785–9796. [Google Scholar] [CrossRef] [PubMed]

- Jyoti, B.; Suresh, A.; Venkatesh, K. Effect of preculturing conditions on growth of Lactobacillus rhamnosus on medium containing glucose and citrate. Microbiol. Res. 2004, 159, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Kaack, K.; Christensen, L.P.; Hughes, M.; Eder, R. The relationship between sensory quality and volatile compounds in raw juice processed from elderberries (Sambucus nigra L.). Eur. Food Res. Technol. 2005, 221, 244–254. [Google Scholar] [CrossRef]

- Bryant, R.J.; McClung, A.M. Volatile profiles of aromatic and non-aromatic rice cultivars using SPME/GC-MS. Food Chem. 2010, 124, 501–513. [Google Scholar] [CrossRef]

- Di Cagno, R.; Surico, R.F.; Paradiso, A.; De Angelis, M.; Salmon, J.-C.; Buchin, S.; De Gara, L.; Gobbetti, M. Effect of autochthonous lactic acid bacteria starters on health-promoting and sensory properties of tomato juices. Int. J. Food Microbiol. 2009, 128, 473–483. [Google Scholar] [CrossRef]

- Servili, M. Relationships between the volatile compounds evaluated by solid phase microextraction and the thermal treatment of tomato juice: Optimization of the blanching parameters. Food Chem. 2000, 71, 407–415. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.; Hao, G.; Yu, H.; Tian, H.; Zhao, G. Role of lactic acid bacteria on the yogurt flavour: A review. Int. J. Food Prop. 2017, 20, S316–S330. [Google Scholar] [CrossRef] [Green Version]

- Borade, S.N.; Deshmukh, R.R. Comparative Study of Principal Component Analysis and Independent Component Analysis. Int. J. Comput Appl. 2014, 92, 45–49. [Google Scholar]

- Park, S.-E.; Yoo, S.-A.; Seo, S.-H.; Lee, K.-I.; Na, C.-S.; Son, H.-S. GC–MS based metabolomics approach of Kimchi for the understanding of Lactobacillus plantarum fermentation characteristics. LWT 2016, 68, 313–321. [Google Scholar] [CrossRef]

| Fresh | TP | F-TP | HHP | F-HHP | |

|---|---|---|---|---|---|

| Carbohydrates (g/L) | 97.00 ± 0.06 d | 117.89 ± 0.15 a | 101.61 ± 0.11 b | 97.80 ± 0.06c | 85.64 ± 0.22 e |

| Glucose | 20.78 ± 0.03 b | 25.14 ± 0.13 a | 16.86 ± 0.12 c | 21.11 ± 0.16 b | 15.71 ± 0.18 d |

| Fructose | 23.99 ± 0.06 c | 29.33 ± 0.14 a | 24.31 ± 0.03 b | 24.36 ± 0.03 b | 22.24 ± 0.02 d |

| Sucrose | 42.89 ± 0.00 c | 52.59 ± 0.26 a | 49.96 ± 0.28 b | 42.92 ± 0.06c | 38.54 ± 0.25 d |

| 1-Kestose | 3.97 ± 0.09 c | 4.72 ± 0.06 a | 4.46 ± 0.02 b | 3.88 ± 0.02 c | 3.60 ± 0.01 d |

| Nystose | 3.14 ± 0.01 cd | 3.73 ± 0.03 a | 3.63 ± 0.01 b | 3.21 ± 0.03 c | 3.13 ± 0.03 d |

| 1F-Fructofuranosylnystose | 2.24 ± 0.02 c | 2.43 ± 0.02 a | 2.41 ± 0.09 b | 2.24 ± 0.00 c | 2.19 ± 0.01 c |

| EPS (mg/L) | 34.81 ± 074 d | 48.25 ± 7.59 c | 56.71 ± 3.43 b | 34..46 ± 0.92 d | 67.02 ± 4.14 a |

| Organic acids (g/L) | |||||

| Oxalic acid | 0.30 ± 0.00 c | 0.35 ± 0.00 a | 0.16 ± 0.00 e | 0.34 ± 0.00 b | 0.17 ± 0.00 d |

| Acetic acid | 0.31 ± 0.01 c | 0.38 ± 0.01 c | 1.00 ± 0.05 a | 0.32 ± 0.01 c | 0.77 ± 0.07 b |

| Citric acid | 5.43 ± 0.03 c | 6.41 ± 0.00 a | 0.09 ± 0.00 d | 5.47 ± 0.01 b | 0.08 ± 0.00 d |

| Lactic acid | 0.26 ± 0.01 c | 0.40 ± 0.01 c | 4.26 ± 0.21 a | 0.41 ± 0.01 c | 2.89 ± 0.18 b |

| Malic acid | 0.51 ± 0.00 c | 0.70 ± 0.01 a | 0.18 ± 0.01 d | 0.55 ± 0.01 b | 0.19 ± 0.01 d |

| Ascorbic acid | 0.51 ± 0.01 b | 0.58 ± 0.01 a | 0.26 ± 0.00 d | 0.44 ± 0.01 c | 0.14 ± 0.00 e |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Xiao, G.; Xu, Y.; Yu, Y.; Wu, J.; Zou, B. High Hydrostatic Pressure and Co-Fermentation by Lactobacillus rhamnosus and Gluconacetobacter xylinus Improve Flavor of Yacon-Litchi-Longan Juice. Foods 2019, 8, 308. https://doi.org/10.3390/foods8080308

Chen H, Xiao G, Xu Y, Yu Y, Wu J, Zou B. High Hydrostatic Pressure and Co-Fermentation by Lactobacillus rhamnosus and Gluconacetobacter xylinus Improve Flavor of Yacon-Litchi-Longan Juice. Foods. 2019; 8(8):308. https://doi.org/10.3390/foods8080308

Chicago/Turabian StyleChen, Huali, Gengsheng Xiao, Yujuan Xu, Yuanshan Yu, Jijun Wu, and Bo Zou. 2019. "High Hydrostatic Pressure and Co-Fermentation by Lactobacillus rhamnosus and Gluconacetobacter xylinus Improve Flavor of Yacon-Litchi-Longan Juice" Foods 8, no. 8: 308. https://doi.org/10.3390/foods8080308

APA StyleChen, H., Xiao, G., Xu, Y., Yu, Y., Wu, J., & Zou, B. (2019). High Hydrostatic Pressure and Co-Fermentation by Lactobacillus rhamnosus and Gluconacetobacter xylinus Improve Flavor of Yacon-Litchi-Longan Juice. Foods, 8(8), 308. https://doi.org/10.3390/foods8080308