Highly Versatile Photonic Integration Platform on an Indium Phosphide Membrane

Abstract

1. Introduction

2. Building Block Functionalities

2.1. Passive Functional Blocks

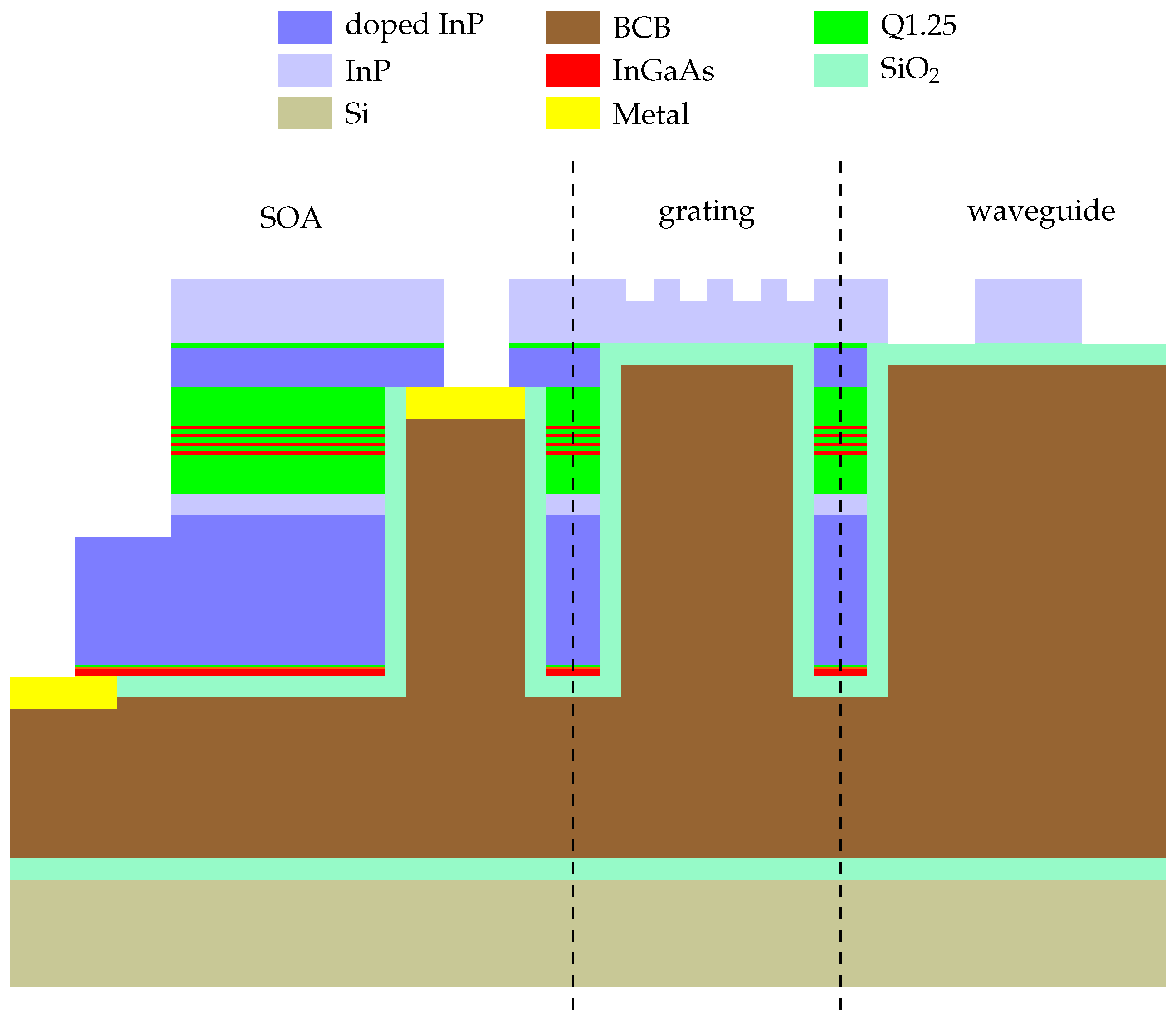

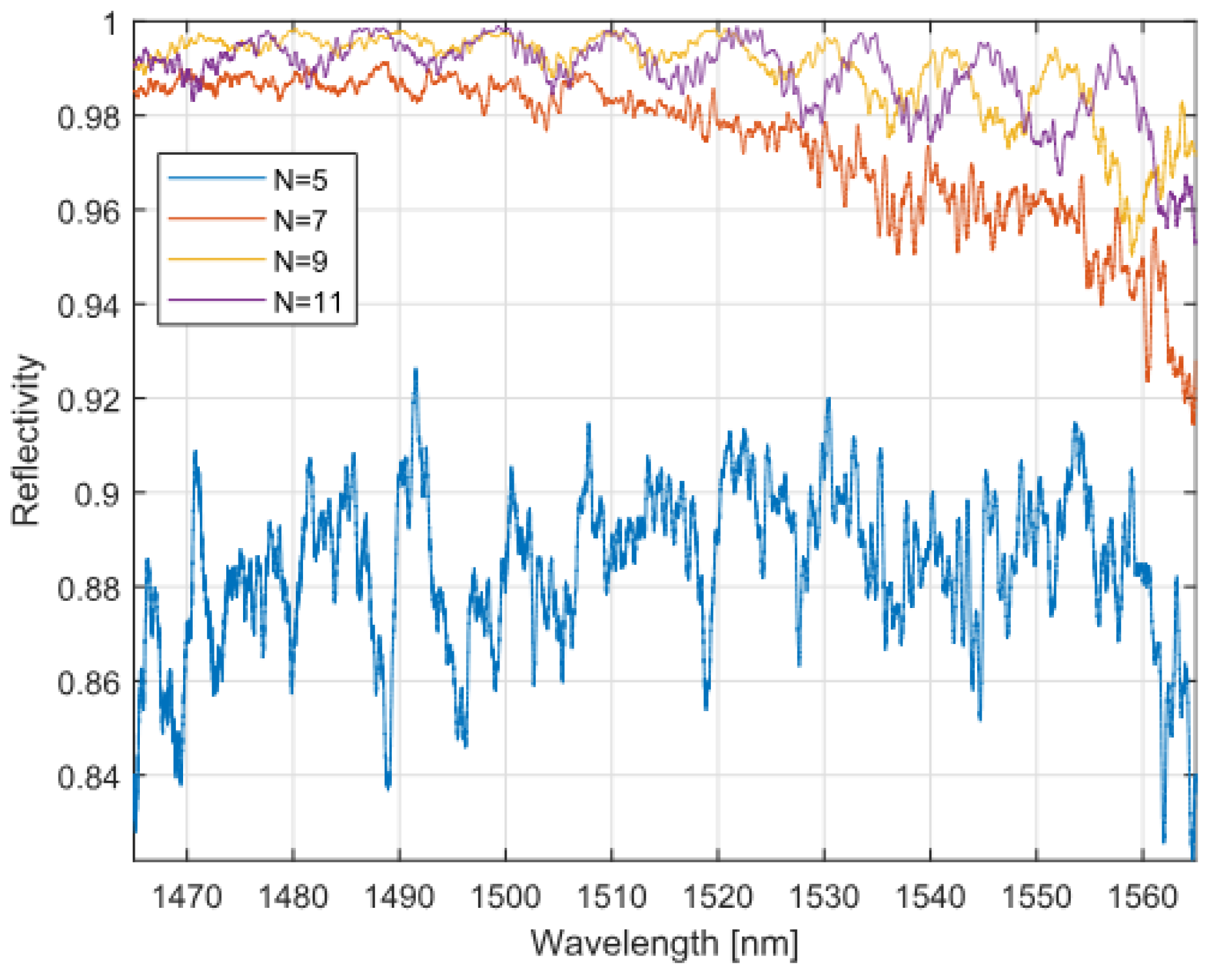

2.1.1. Light Reflection

2.1.2. Polarization Control

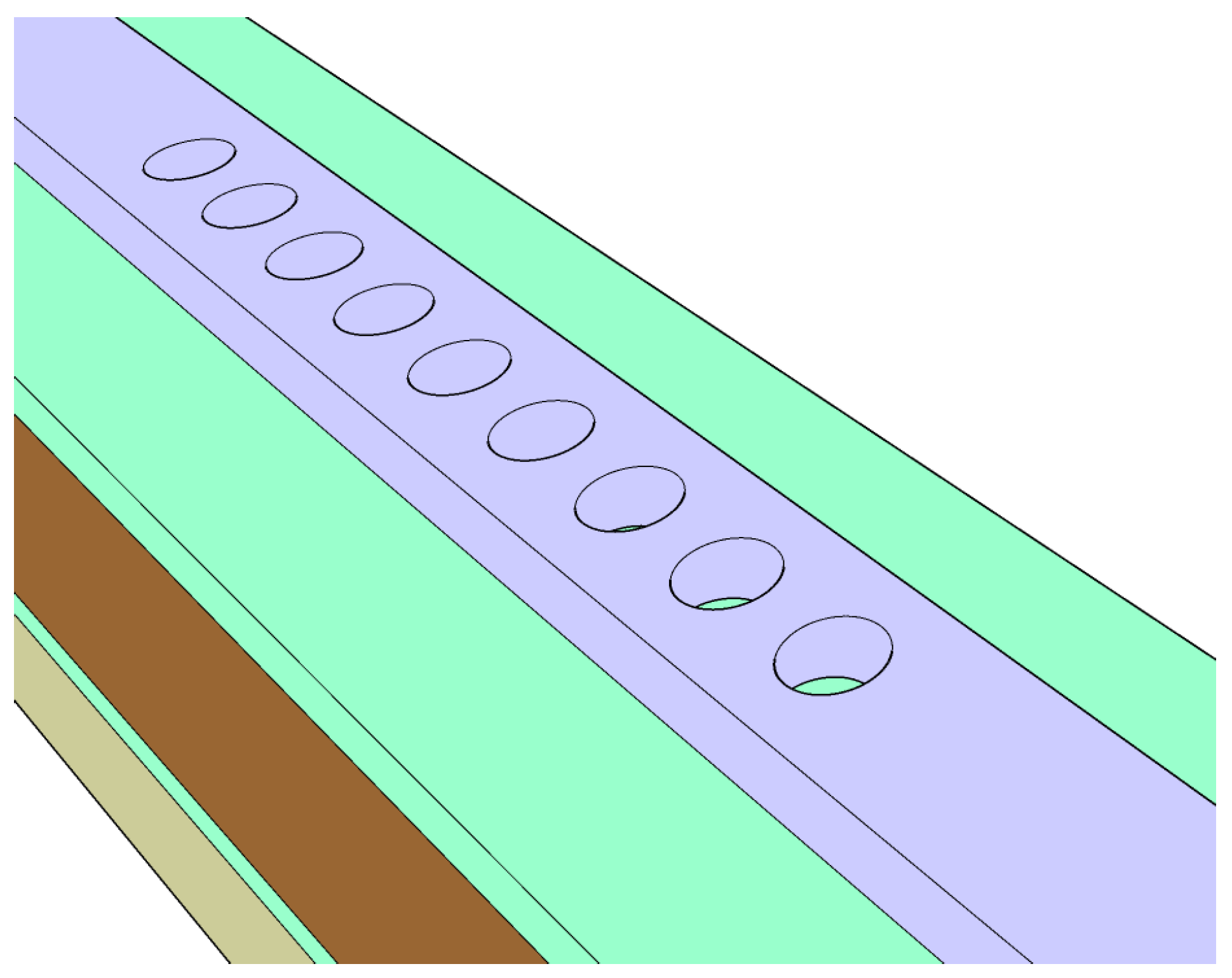

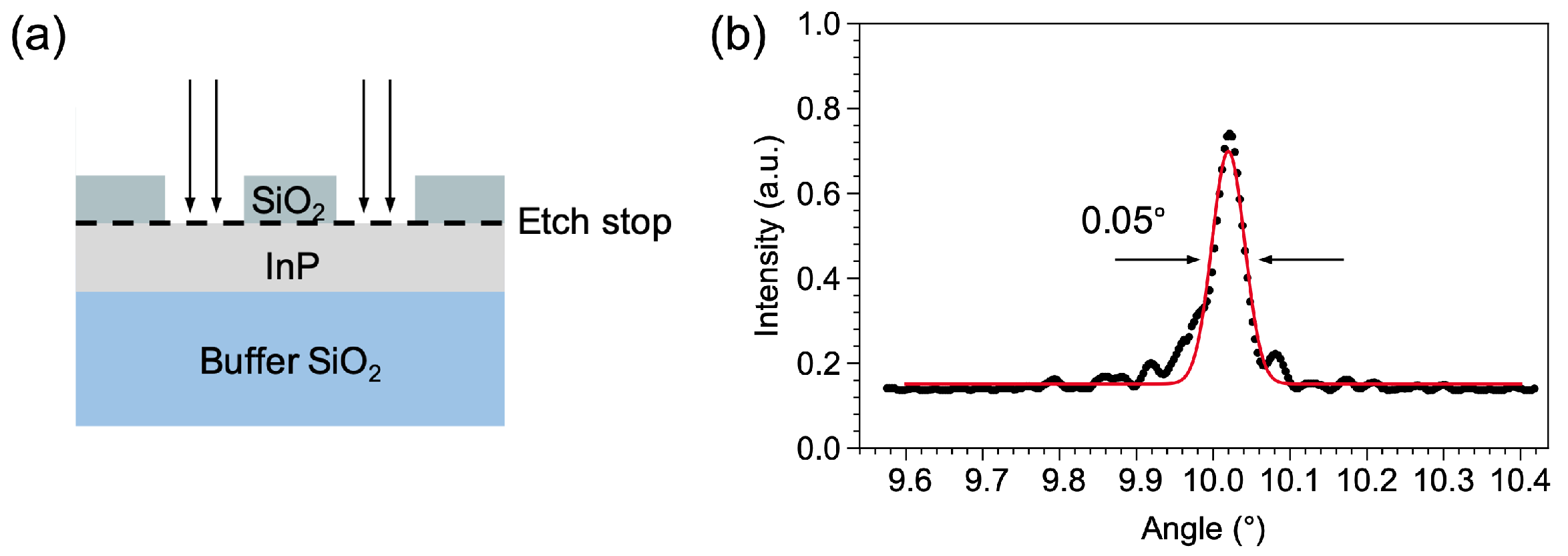

2.1.3. Free-Space Interfacing

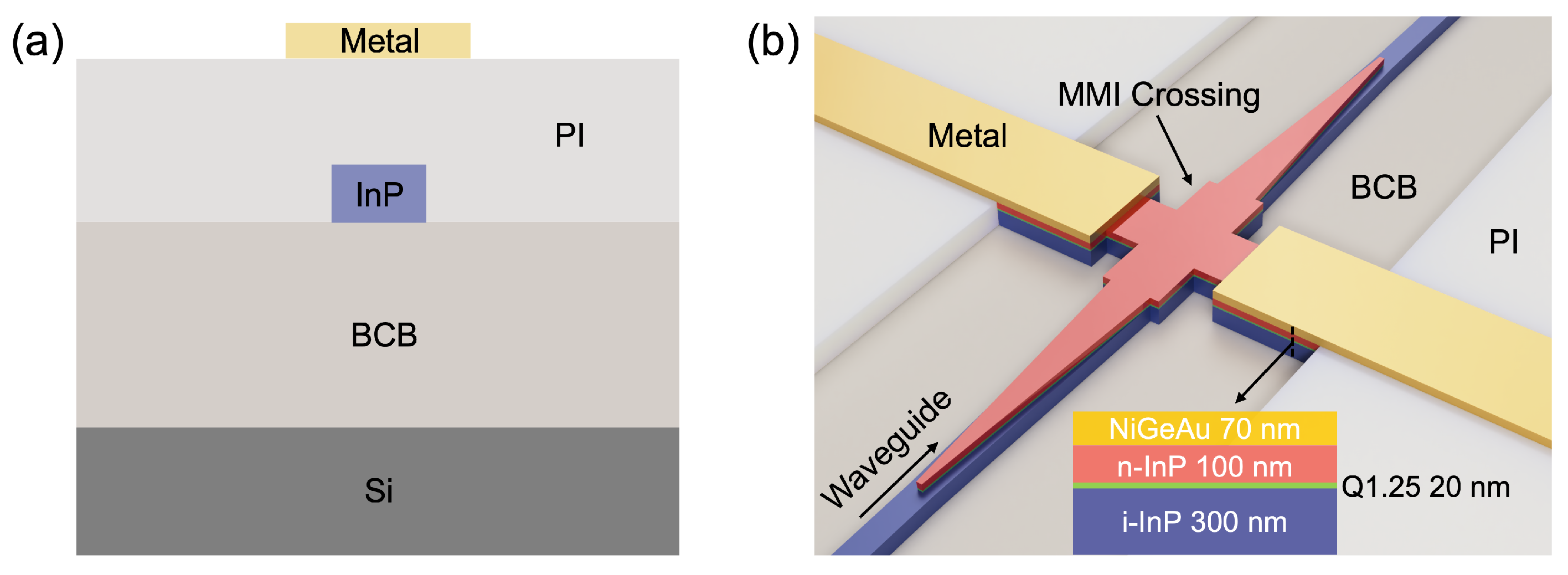

2.2. Active Building Blocks

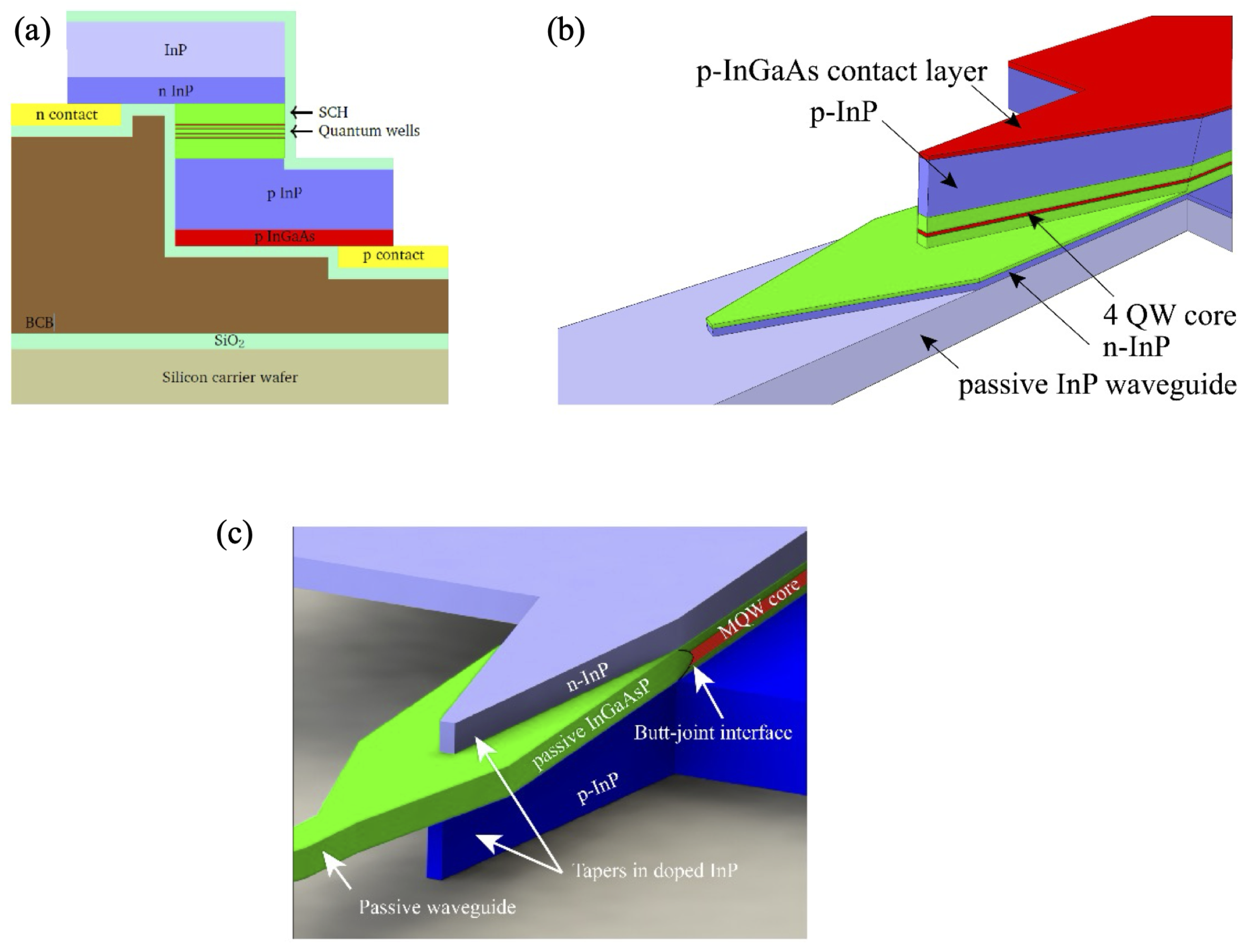

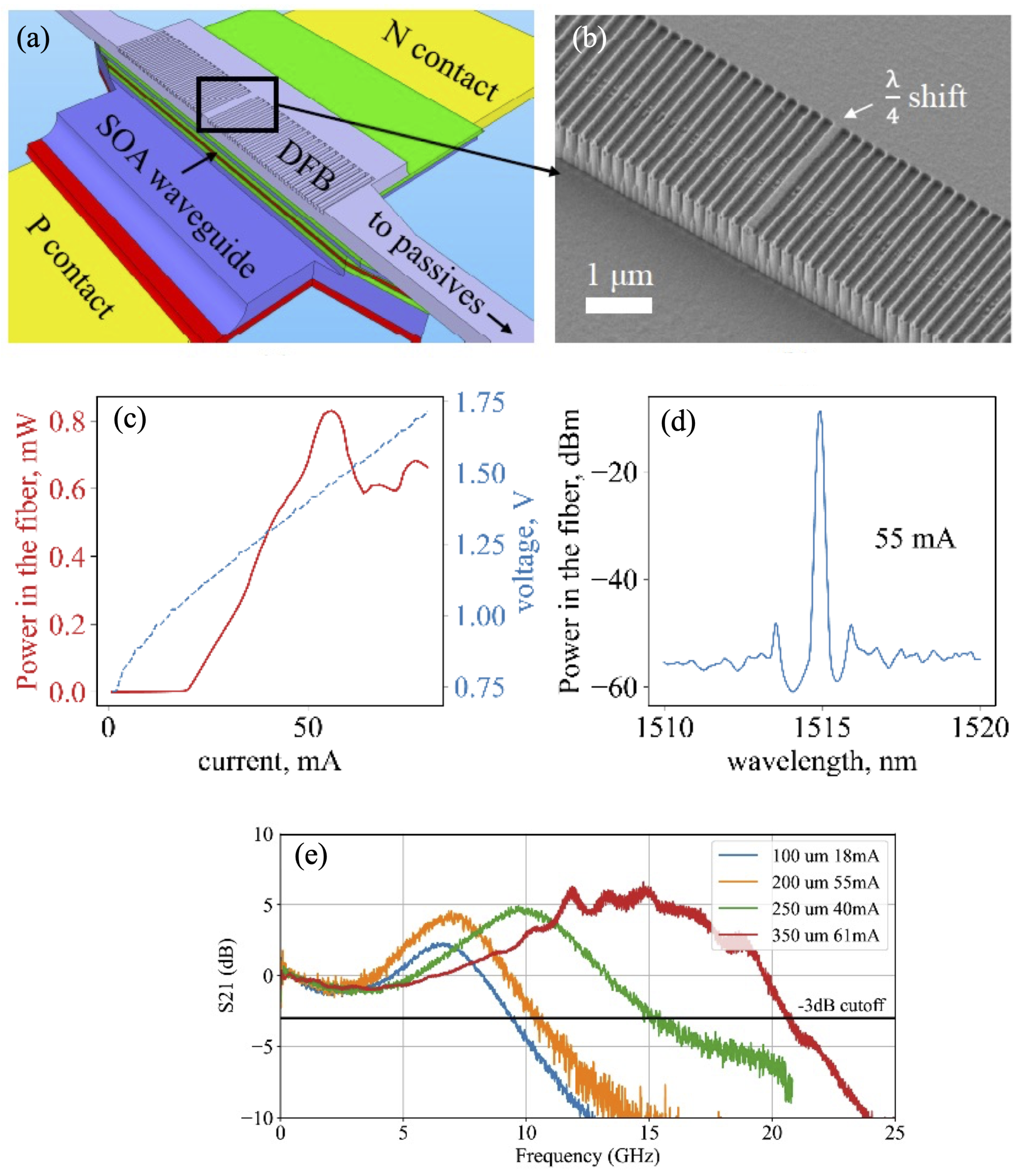

2.2.1. Light Generation

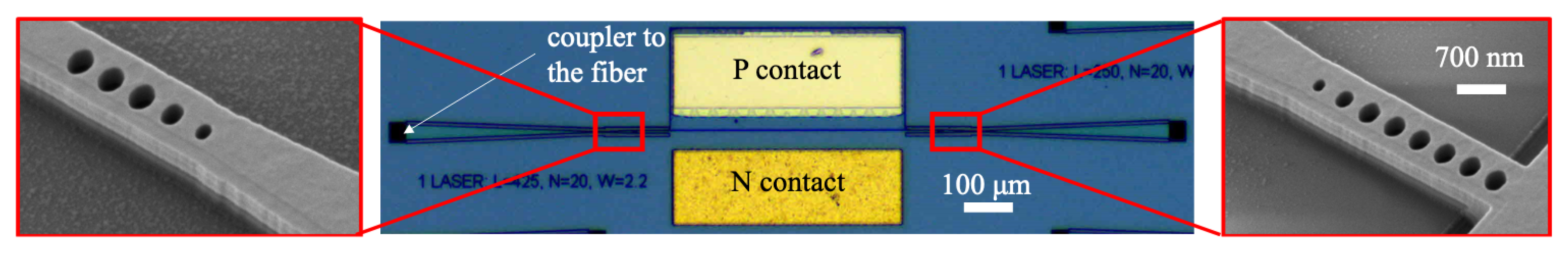

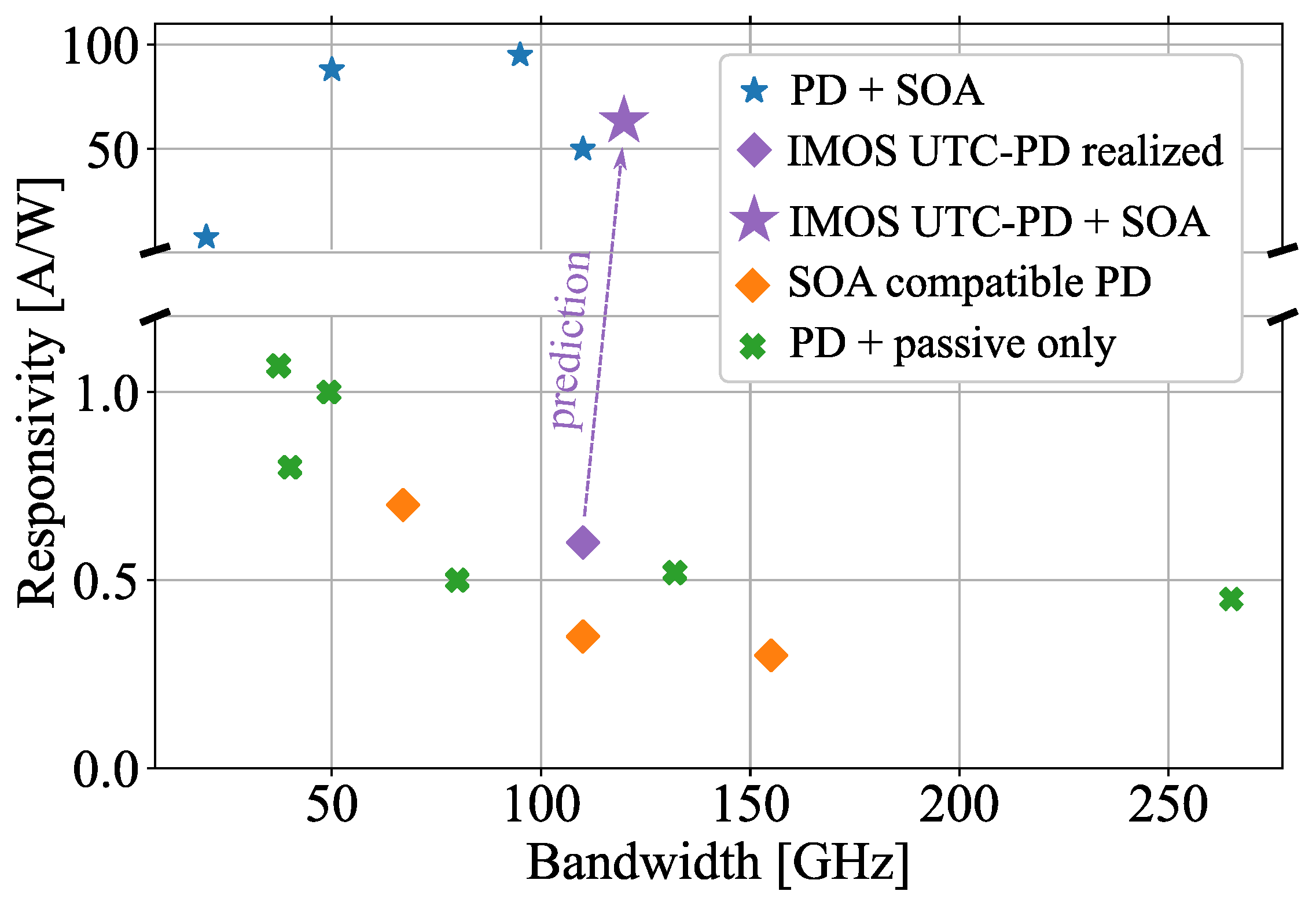

2.2.2. Light Detection

2.2.3. Phase Control

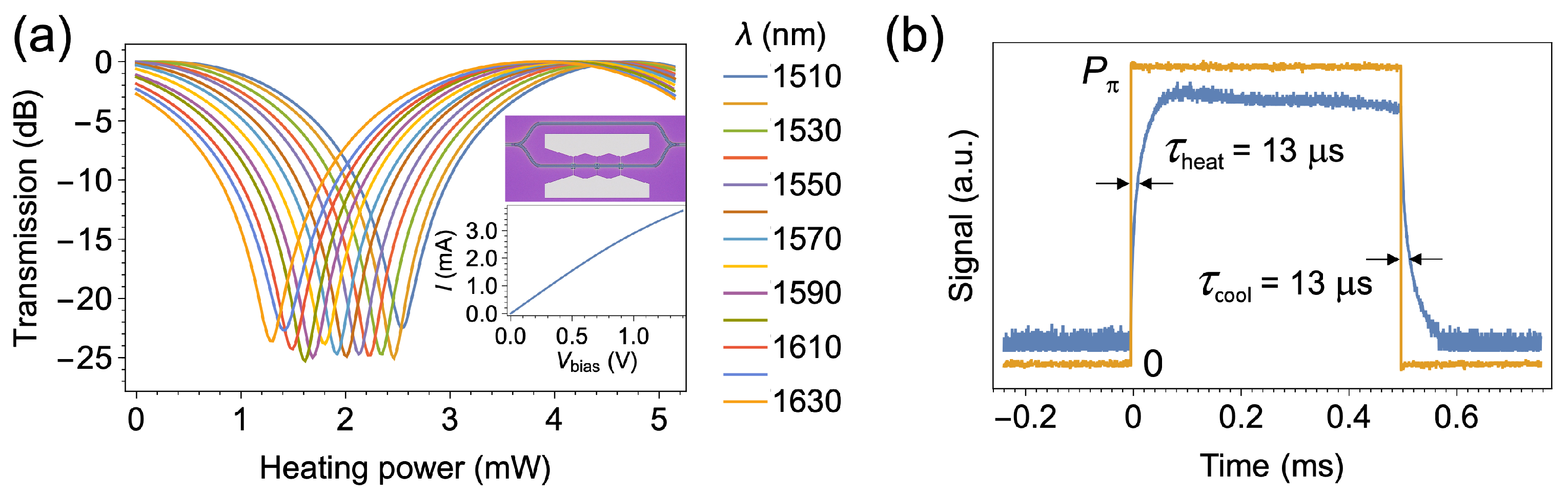

Low-Energy Thermo-Optic Tuning

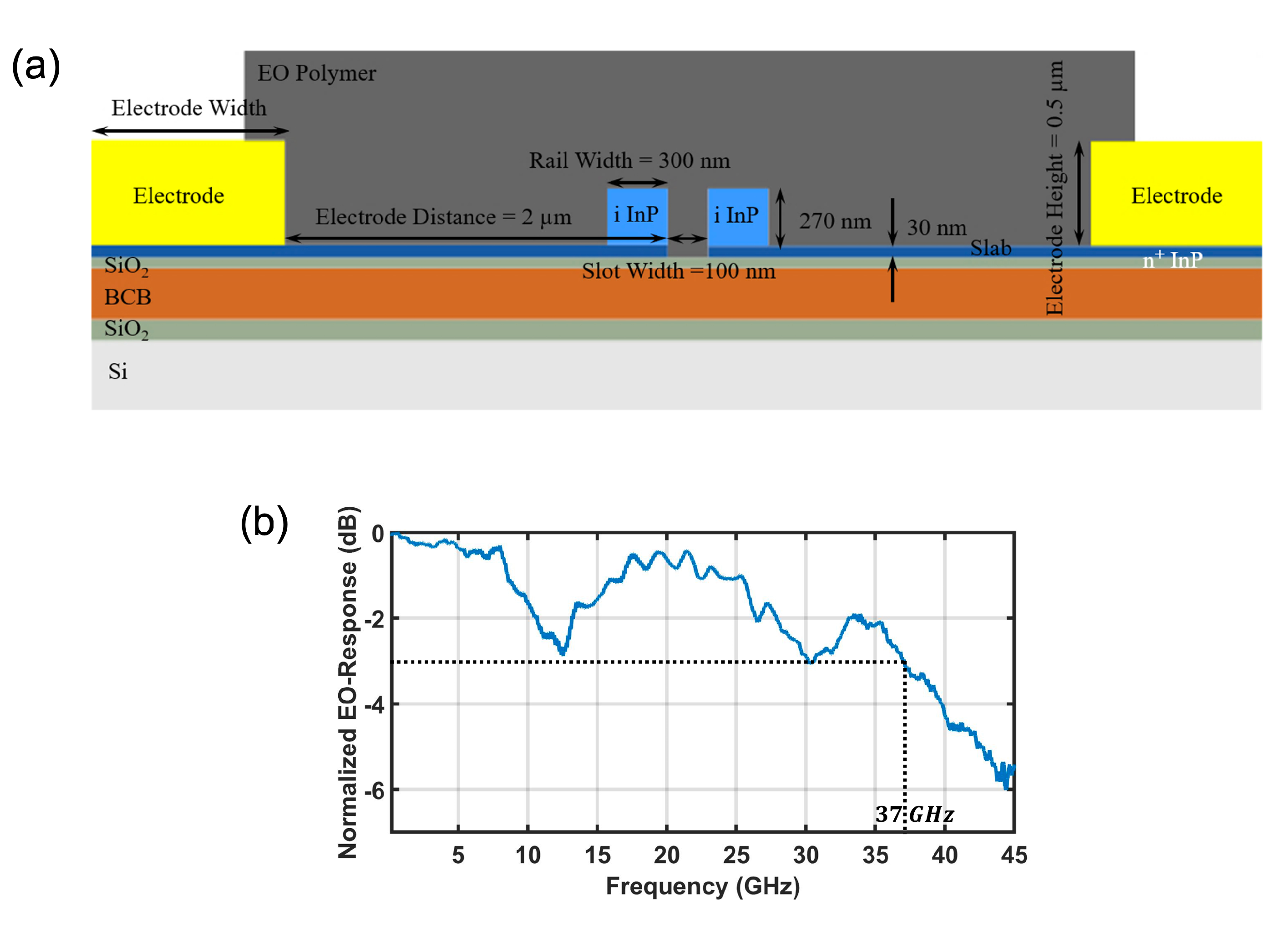

High-Speed Modulation

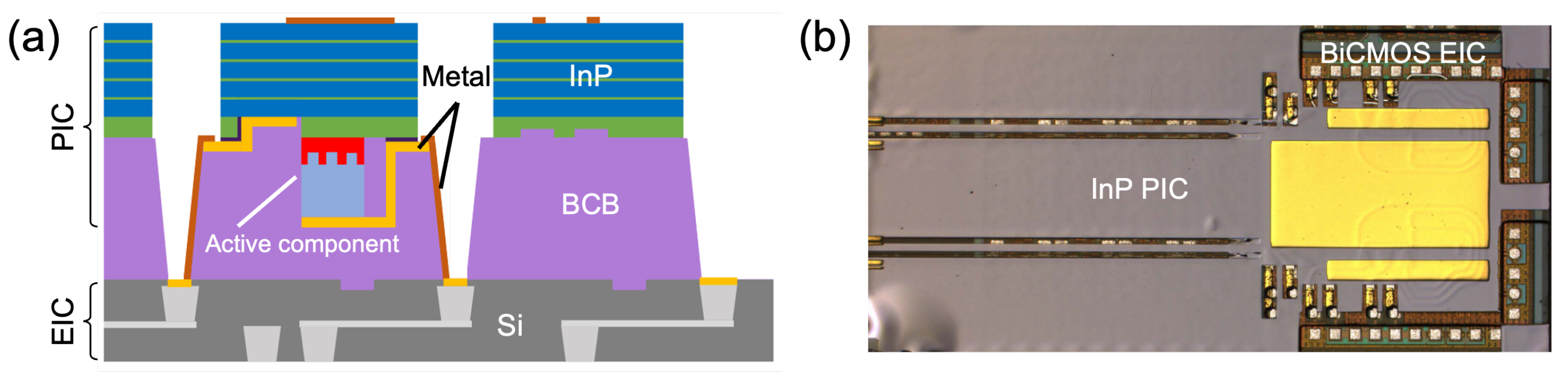

3. Membrane Integration Technology

4. Integrated Sub-Circuits

4.1. Mode-Division Multiplexed Circuits for Efficiency Boost

4.2. Polarization-Independent Quantum Well SOA

4.3. Dual-Polarization Light Source

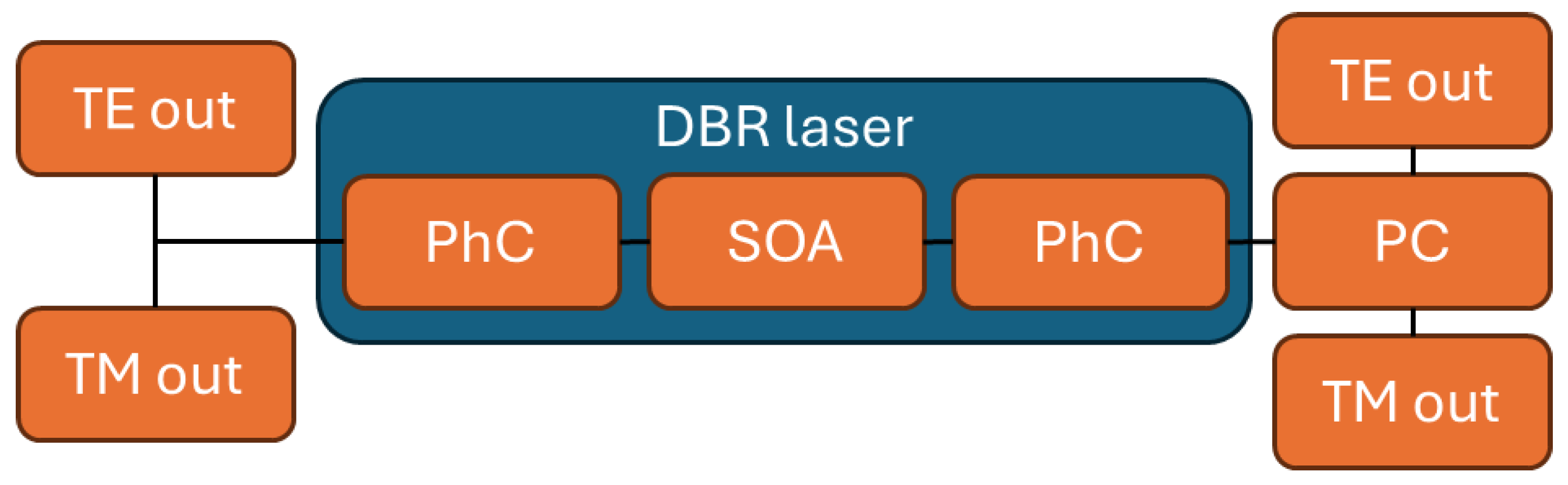

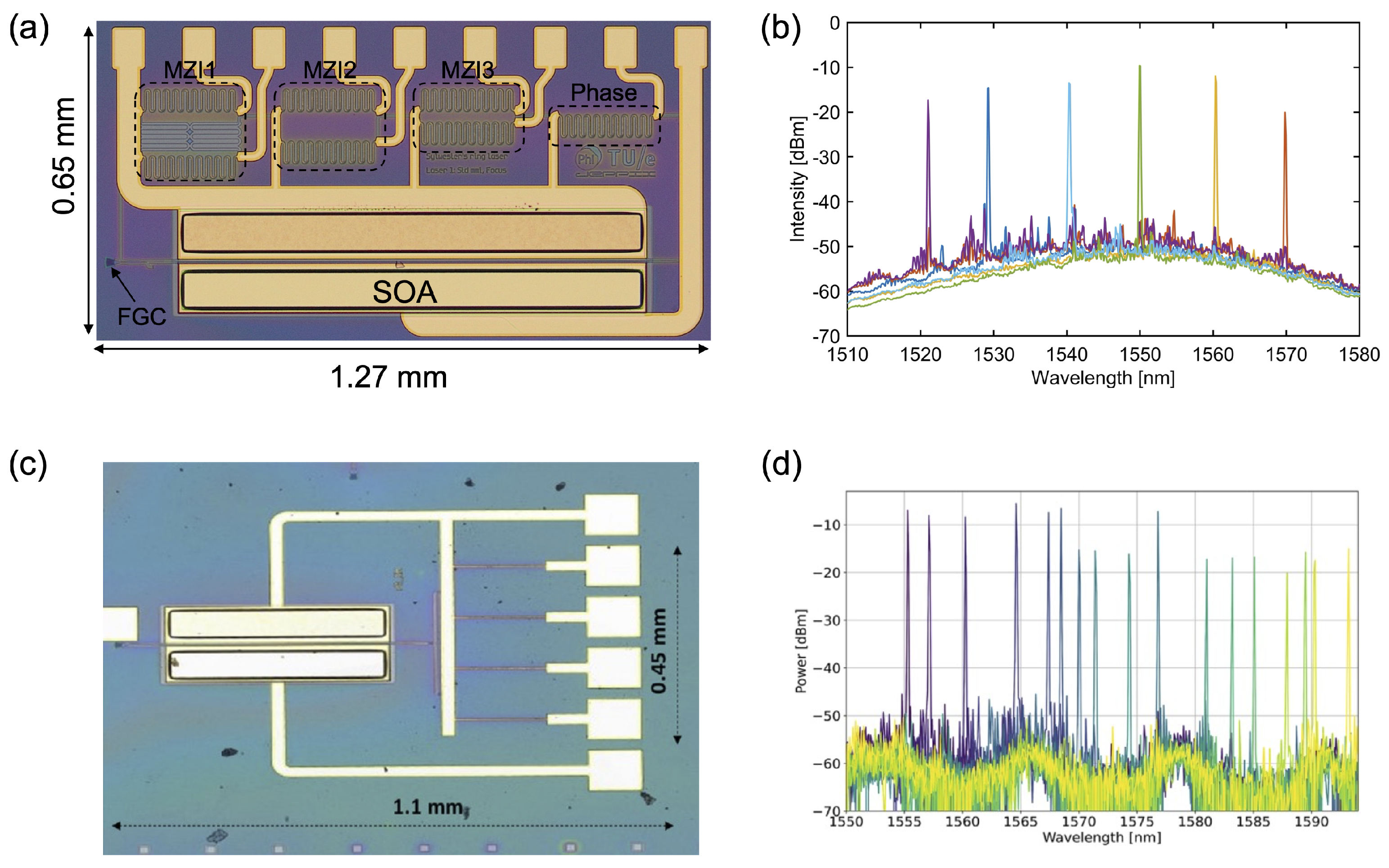

4.4. Compact Tunable Laser

5. Novel Material Integration

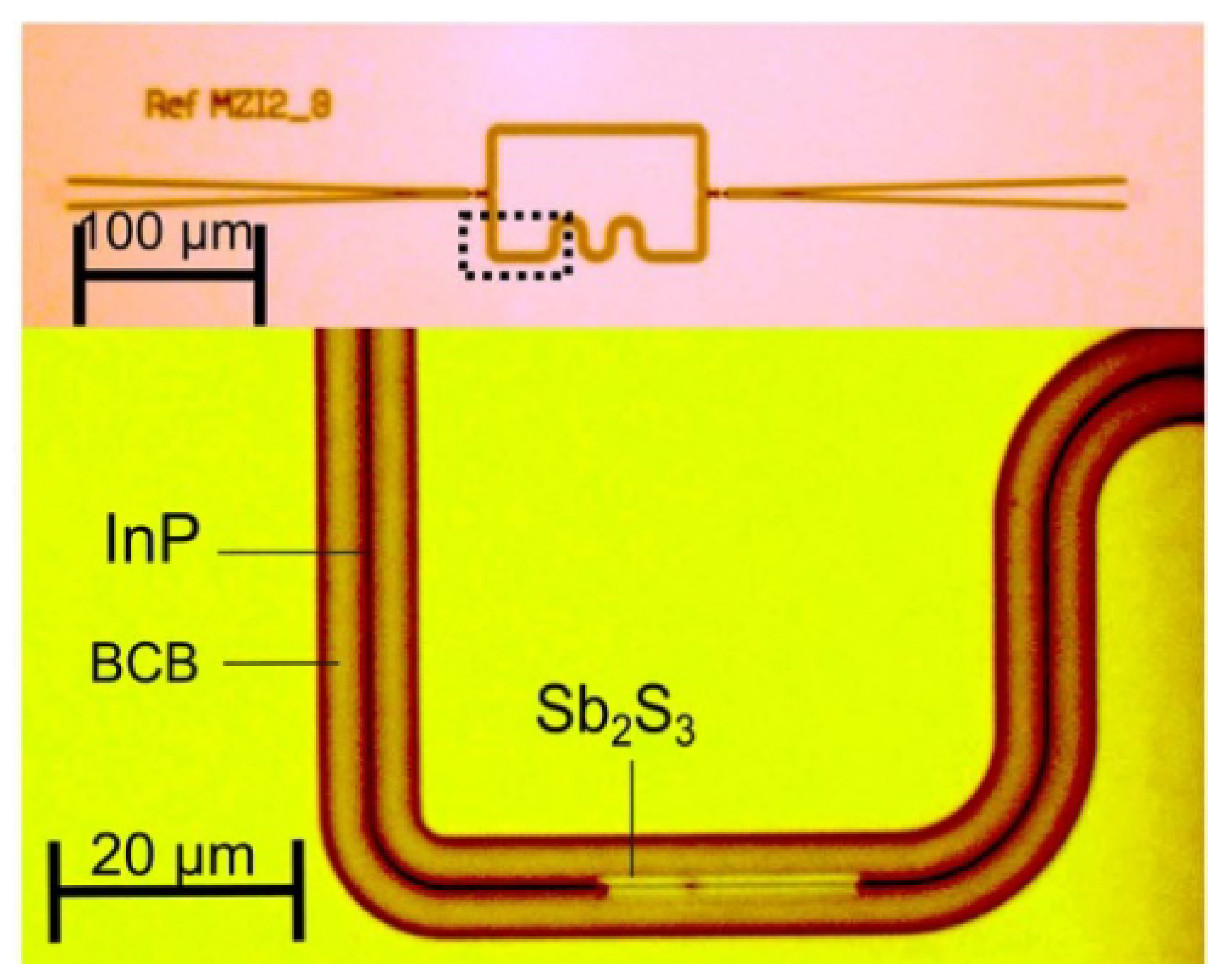

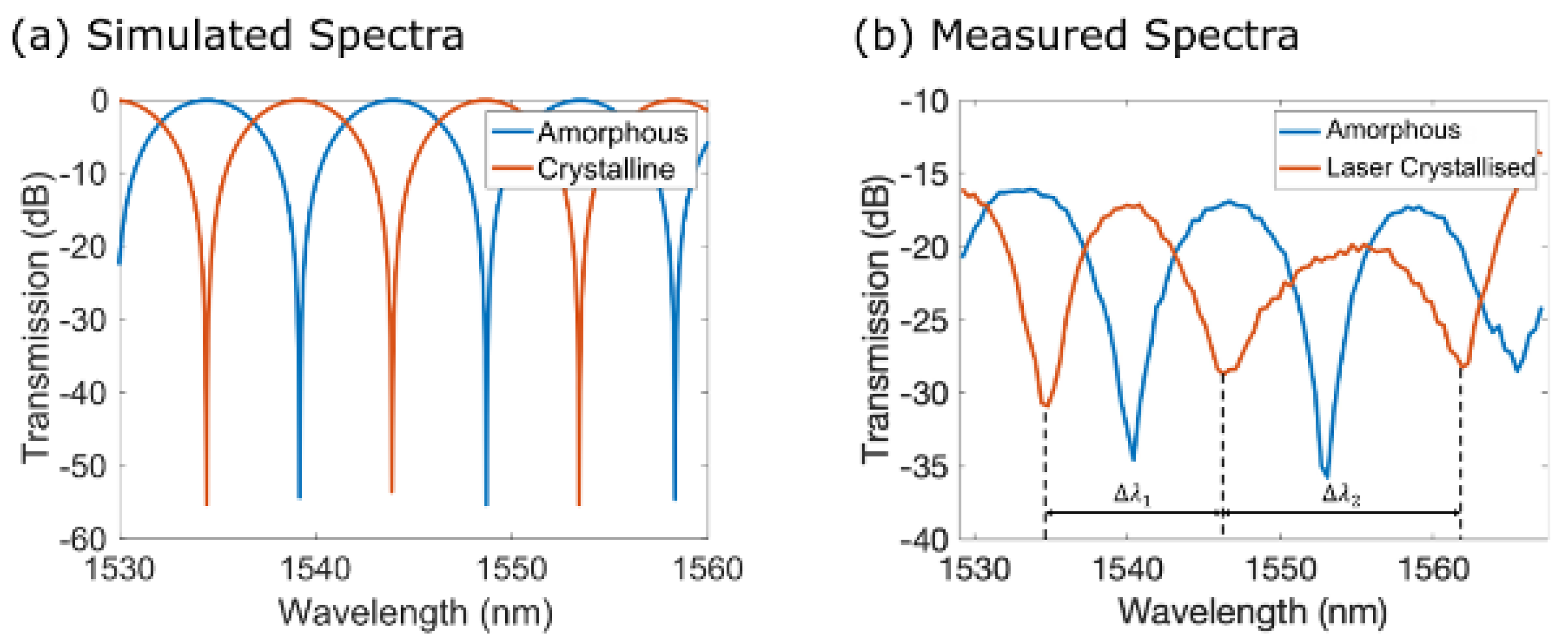

5.1. Phase Change Material: Sb2S3

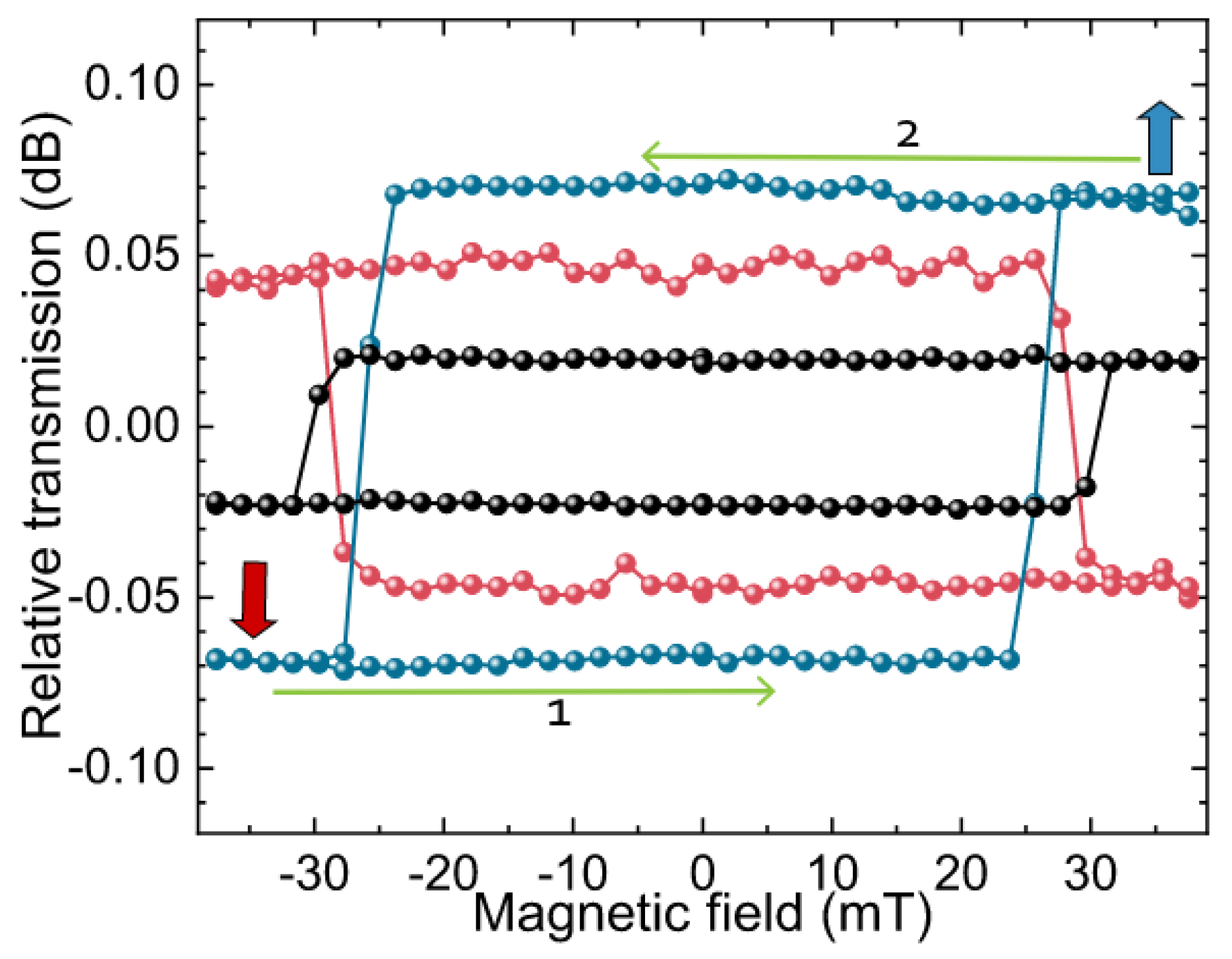

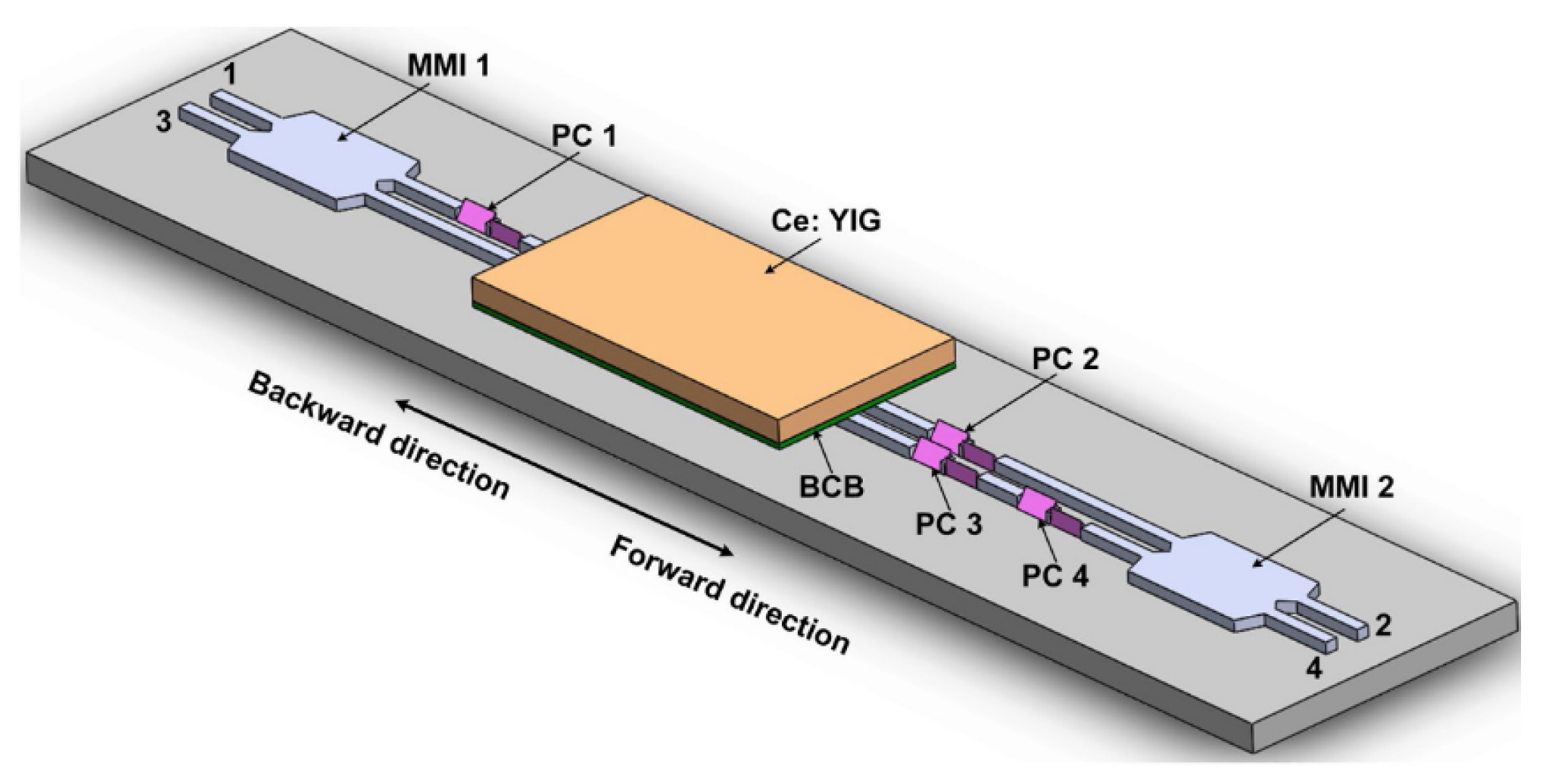

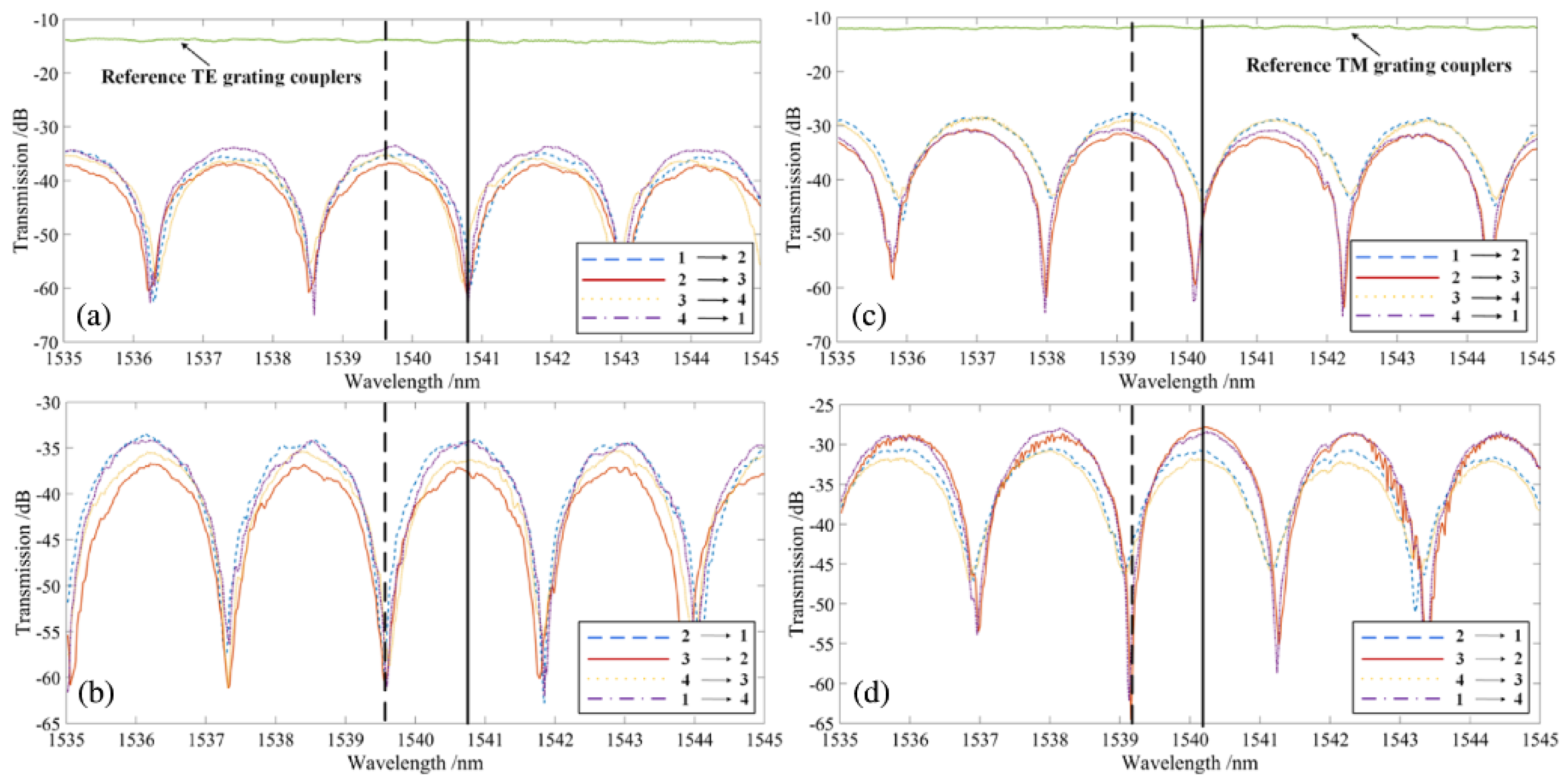

5.2. Co/Pt Magneto-Optical Kerr Effect (MOKE) Material

5.3. Yttrium Iron Garnet

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Miller, S.E. Integrated Optics: An Introduction. Bell Syst. Tech. J. 1969, 48, 2059–2069. [Google Scholar] [CrossRef]

- Wang, Y.; Jiao, Y.; Williams, K. Scaling photonic integrated circuits with InP technology: A perspective. APL Photonics 2024, 9, 050902. [Google Scholar] [CrossRef]

- Smit, M.; van der Tol, J.; Hill, M. Moore’s law in photonics. Laser Photonics Rev. 2012, 6, 1–13. [Google Scholar] [CrossRef]

- JePPIX Roadmap 2021–2025. Available online: https://www.jeppix.eu/about-us/roadmap-latest-edition (accessed on 1 July 2025).

- Soares, F.M.; Janiak, K.; Grote, N.; Szymanski, D.; Wale, M.J. Generic InP-Based Monolithic Photonic Integration Platforms. In Proceedings of the 18th European Conference on Integrated Optics, Warsaw, Poland, 18–20 May 2016. [Google Scholar]

- Smit, M.; Leijtens, X.; Ambrosius, H.; Bente, E.; van der Tol, J.; Smalbrugge, B.; de Vries, T.; Geluk, E.J.; Bolk, J.; van Veldhoven, R.; et al. An introduction to InP-based generic integration technology. Semicond. Sci. Technol. 2014, 29, 083001. [Google Scholar] [CrossRef]

- Galarza, M.; Van Thourhout, D.; Baets, R.; López-Amo, M. Compact and Highly-Efficient Vertical Couplers for Active-Passive Monolithic Integration. In Proceedings of the Integrated Photonics Research and Applications/Nanophotonics for Information Systems, San Diego, CA, USA, 10–13 April 2005; p. IWG3. [Google Scholar] [CrossRef]

- Marsh, J.H. Quantum well intermixing. Semicond. Sci. Technol. 1993, 8, 1136–1155. [Google Scholar] [CrossRef]

- Kulkova, I.; Kadkhodazadeh, S.; Kuznetsova, N.; Huck, A.; Semenova, E.; Yvind, K. High-quality MOVPE butt-joint integration of InP/AlGaInAs/InGaAsP-based all-active optical components. J. Cryst. Growth 2014, 402, 243–248. [Google Scholar] [CrossRef]

- Klamkin, J.; Zhao, H.; Song, B.; Liu, Y.; Isaac, B.; Pinna, S.; Sang, F.; Coldren, L. Indium Phosphide Photonic Integrated Circuits: Technology and Applications. In Proceedings of the 2018 IEEE BiCMOS and Compound Semiconductor Integrated Circuits and Technology Symposium (BCICTS), San Diego, CA, USA, 15–17 October 2018; pp. 8–13. [Google Scholar] [CrossRef]

- Zhang, K.; Burghart, D.; Gardanow, A.; Mayer, R.; Meyer, R.; Böhm, G.; Belkin, M.A. Mid-infrared integrated photonics on the InP platform. In Semiconductor Lasers and Laser Dynamics X; International Society for Optics and Photonics; SPIE: Bellingham, WA, USA, 2022; Volume PC12141, p. PC121410E. [Google Scholar] [CrossRef]

- Yan, Z.; Han, Y.; Lin, L.; Xue, Y.; Ma, C.; Ng, W.K.; Wong, K.S.; Lau, K.M. A monolithic InP/SOI platform for integrated photonics. Light. Sci. Appl. 2021, 10, 200. [Google Scholar] [CrossRef]

- Wada, H.; Kamijoh, T. Direct Bonding of InP to Si for Optoelectronic Integration. In Spatial Light Modulators; Optical Society of America: Washington, DC, USA, 1997; p. SMB.1. [Google Scholar] [CrossRef]

- Loi, R.; O’Callaghan, J.; Roycroft, B.; Quan, Z.; Thomas, K.; Gocalinska, A.; Pelucchi, E.; Trindade, A.J.; Bower, C.A.; Corbett, B. Thermal Analysis of InP Lasers Transfer Printed to Silicon Photonics Substrates. J. Light. Technol. 2018, 36, 5935–5941. [Google Scholar] [CrossRef]

- Jiao, Y.; Nishiyama, N.; van der Tol, J.J.; van Engelen, J.P.; Pogoretskiy, V.; Reniers, S.F.; Kashi, A.A.; Wang, Y.; Calzadilla, V.D.; Spiegelberg, M.; et al. InP membrane integrated photonics research. Semicond. Sci. Technol. 2020, 36, 013001. [Google Scholar] [CrossRef]

- Reniers, S.F.G.; Wang, Y.; Williams, K.A.; Van Der Tol, J.J.G.M.; Jiao, Y. Characterization of Waveguide Photonic Crystal Reflectors on Indium Phosphide Membranes. IEEE J. Quantum Electron. 2019, 55, 6400107. [Google Scholar] [CrossRef]

- Pello, J.; van der Tol, J.; Keyvaninia, S.; van Veldhoven, R.; Ambrosius, H.; Roelkens, G.; Smit, M. High-efficiency ultrasmall polarization converter in InP membrane. Opt. Lett. 2012, 37, 3711–3713. [Google Scholar] [CrossRef]

- Reniers, S.F.G.; Williams, K.A.; van der Tol, J.J.G.M.; Jiao, Y. An Accurate Characterization Method for Integrated Polarization Converters. IEEE J. Quantum Electron. 2021, 57, 0600306. [Google Scholar] [CrossRef]

- Reniers, S.F.G. Integration of a Polarization Converter on the Active-Passive IMOS Platform. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2022. [Google Scholar]

- Hsu, C.P.; Li, B.; Solano-Rivas, B.; Gohil, A.R.; Chan, P.H.; Moore, A.D.; Donzella, V. A Review and Perspective on Optical Phased Array for Automotive LiDAR. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 8300416. [Google Scholar] [CrossRef]

- Hutchison, D.N.; Sun, J.; Doylend, J.K.; Kumar, R.; Heck, J.; Kim, W.; Phare, C.T.; Feshali, A.; Rong, H. High-resolution aliasing-free optical beam steering. Optica 2016, 3, 887. [Google Scholar] [CrossRef]

- Wang, Y.; van Engelen, J.P.; Reniers, S.F.G.; Dolores-Calzadilla, V.; Williams, K.A.; Smit, M.K.; Jiao, Y. High resolution grating antennas for beam steering on the IMOS platform. In Proceedings of the 2019 Asia Communications and Photonics Conference, Chengdu, China, 2–5 November 2019. [Google Scholar]

- Wang, Y.; van Engelen, J.P.; Reniers, S.F.G.; van Rijn, M.B.J.; Zhang, X.; Cao, Z.; Dolores-Calzadilla, V.; Williams, K.A.; Smit, M.K.; Jiao, Y. InP-Based Grating Antennas for High-Resolution Optical Beam Steering. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 6100107. [Google Scholar] [CrossRef]

- Wang, Y. InP Membrane Photonics for Large-Scale Integration. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2023. [Google Scholar]

- Takahashi, N.; Wang, Y.; Nishiyama, N.; Williams, K.; Latkowski, S.; Jiao, Y. Compact widely-tunable laser on an InP membrane on silicon. In Proceedings of the 2023 Opto-Electronics and Communications Conference (OECC), Shanghai, China, 2–6 July 2023; pp. 1–2. [Google Scholar] [CrossRef]

- Kish, F.; Lal, V.; Evans, P.; Corzine, S.W.; Ziari, M.; Butrie, T.; Reffle, M.; Tsai, H.S.; Dentai, A.; Pleumeekers, J.; et al. System-on-Chip Photonic Integrated Circuits. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 6100120. [Google Scholar] [CrossRef]

- Takahashi, N.; Fang, W.; Xue, R.; Katsumi, S.; Ohiso, Y.; Amemiya, T.; Nishiyama, N. Low Threshold Current Operation of Membrane DR Laser on Si with Buried-Ridge Waveguide and ACPM Grating for On-chip Optical Interconnection. In Proceedings of the 2022 28th International Semiconductor Laser Conference (ISLC), Matsue, Japan, 16–19 October 2022; pp. 1–2. [Google Scholar] [CrossRef]

- Matsuo, S.; Aihara, T.; Hiraki, T.; Maeda, Y.; Kishi, T.; Fujii, T.; Takeda, K.; Kakitsuka, T. Heterogeneously Integrated Membrane III-V Compound Semiconductor Devices with Silicon Photonics Platform. IEEE J. Sel. Top. Quantum Electron. 2022, 29, 6100510. [Google Scholar] [CrossRef]

- Pogoretskiy, V.; Van Engelen, J.; Van Der Tol, J.; Higuera-Rodriguez, A.; Smit, M.; Jiao, Y. An Integrated SOA-building block for an InP-membrane platform. In Proceedings of the Advanced Photonics 2017 (IPR, NOMA, Sensors, Networks, SPPCom, PS), New Orleans, LA, USA, 24–27 July 2017; p. JW4A.1. [Google Scholar] [CrossRef]

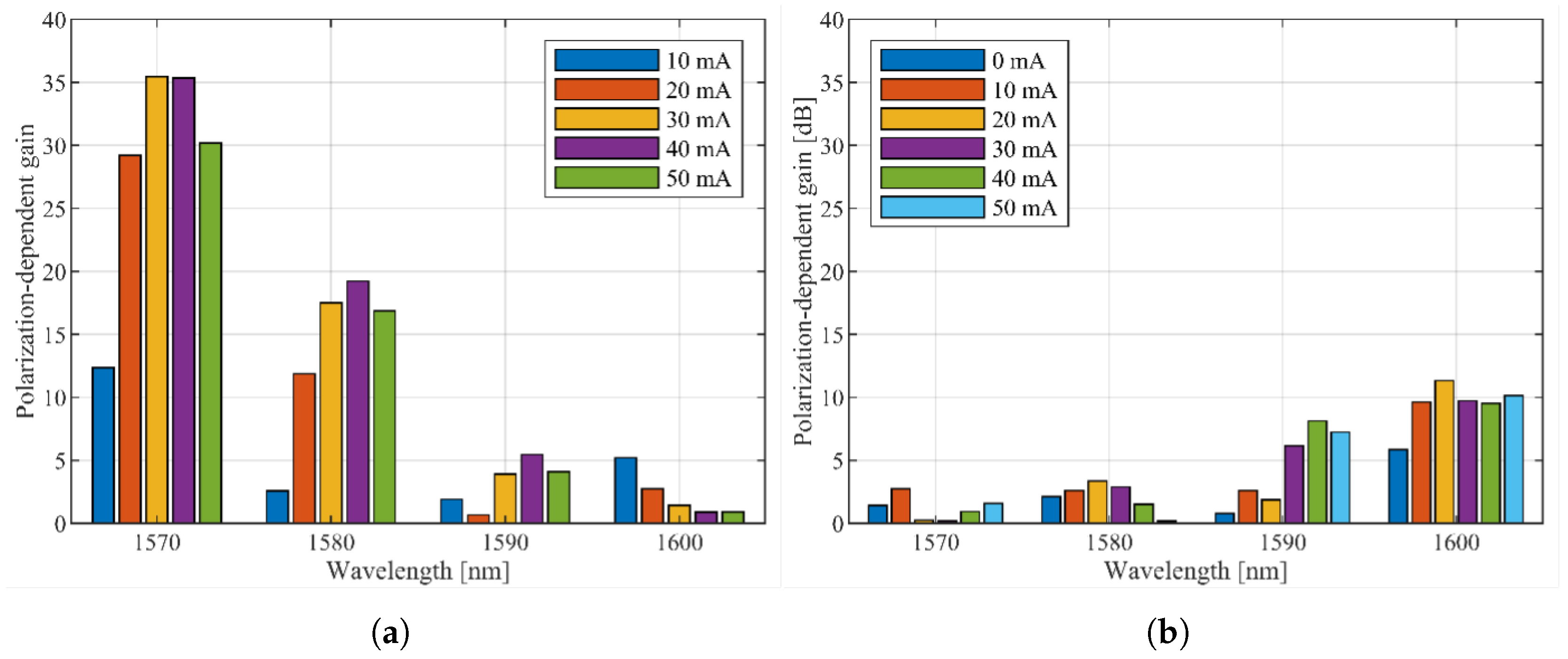

- Feyisa, D.W.; Abdi, S.; Van Veldhoven, R.; Calabretta, N.; Jiao, Y.; Stabile, R. Low Polarization Sensitive O-band SOA on InP Membrane for Advanced Photonic Integration. J. Light. Technol. 2024, 42, 4531–4541. [Google Scholar] [CrossRef]

- Zozulia, A.; Bolk, J.; Van Veldhoven, R.; Nazarikov, G.; Pogoretskiy, V.; Rihani, S.; Berry, G.; Williams, K.; Jiao, Y. Nanophotonic integrated active-passive InP membrane devices and circuits fabricated using ArF scanner lithography. Micro Nano Eng. 2024, 23, 100258. [Google Scholar] [CrossRef]

- Zozulia, A.; Schatz, R.; Rihani, S.; Berry, G.; Williams, K.; Jiao, Y. C-Band Directly Modulated Lasers With Tunable Photon–Photon Resonance in InP Membrane. IEEE J. Quantum Electron. 2024, 60, 2200312. [Google Scholar] [CrossRef]

- Pogoretskiy, V. Nanophotonic Membrane Platform for Integrated Active Devices and Circuits. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2019. [Google Scholar]

- Grzeslo, M.; Dülme, S.; Clochiatti, S.; Neerfeld, T.; Haddad, T.; Lu, P.; Tebart, J.; Makhlouf, S.; Biurrun-Quel, C.; Fernández Estévez, J.L.; et al. High Saturation Photocurrent THz Waveguide-Type MUTC-photodiodes Reaching mW Output Power within the WR3.4 Band. Opt. Express 2023, 31, 6484. [Google Scholar] [CrossRef]

- Shen, L.; Jiao, Y.; Yao, W.; Cao, Z.; van Engelen, J.P.; Roelkens, G.; Smit, M.K.; van der Tol, J.J.G.M. High-bandwidth uni-traveling carrier waveguide photodetector on an InP-membrane-on-silicon platform. Opt. Express 2016, 24, 8290–8301. [Google Scholar] [CrossRef]

- de Graaf, J.; Zhao, X.; Konstantinou, D.; Hout, M.v.d.; Reniers, S.; Shen, L.; van der Heide, S.; Rommel, S.; Monroy, I.T.; Okonkwo, C.; et al. Beyond 110 GHz Uni-Traveling Carrier Photodiodes on an InP-Membrane-on-Silicon Platform. IEEE J. Sel. Top. Quantum Electron. 2022, 28, 3802010. [Google Scholar] [CrossRef]

- Maes, D.; Lemey, S.; Roelkens, G.; Zaknoune, M.; Avramovic, V.; Okada, E.; Szriftgiser, P.; Peytavit, E.; Ducournau, G.; Kuyken, B. High-speed uni-traveling-carrier photodiodes on silicon nitride. APL Photonics 2023, 8, 016104. [Google Scholar] [CrossRef]

- Lischke, S.; Peczek, A.; Morgan, J.S.; Sun, K.; Steckler, D.; Yamamoto, Y.; Korndörfer, F.; Mai, C.; Marschmeyer, S.; Fraschke, M.; et al. Ultra-fast germanium photodiode with 3-dB bandwidth of 265 GHz. Nat. Photonics 2021, 15, 925–931. [Google Scholar] [CrossRef]

- Cui, J.; Li, T.; Yang, F.; Cui, W.; Chen, H. The dual-injection Ge-on-Si photodetectors with high saturation power by optimizing light field distribution. Opt. Commun. 2021, 480, 126467. [Google Scholar] [CrossRef]

- Zhou, D.; Chen, G.; Fu, S.; Zuo, Y.; Yu, Y. Germanium photodetector with distributed absorption regions. Opt. Express 2020, 28, 19797. [Google Scholar] [CrossRef]

- Chang, C.M.; Sinsky, J.H.; Dong, P.; De Valicourt, G.; Chen, Y.K. High-power dual-fed traveling wave photodetector circuits in silicon photonics. Opt. Express 2015, 23, 22857. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.; Runge, P.; Keyvaninia, S.; Seifert, S.; Ebert, W.; Mutschall, S.; Seeger, A.; Li, Q.; Beling, A. High-Power InP-Based Waveguide Integrated Modified Uni-Traveling-Carrier Photodiodes. J. Light. Technol. 2017, 35, 717–721. [Google Scholar] [CrossRef]

- Rymanov, V.; Khani, B.; Dülme, S.; Lu, P.; Stöhr, A. InP-Based Waveguide Triple Transit Region Photodiodes for Hybrid Integration with Passive Optical Silica Waveguides. Photonics 2015, 2, 1152–1163. [Google Scholar] [CrossRef]

- Rouvalis, E.; Chtioui, M.; van Dijk, F.; Lelarge, F.; Fice, M.J.; Renaud, C.C.; Carpintero, G.; Seeds, A.J. 170 GHz uni-traveling carrier photodiodes for InP-based photonic integrated circuits. Opt. Express 2012, 20, 20090. [Google Scholar] [CrossRef]

- Xiao, F.; Han, Q.; Ye, H.; Wang, S.; Xiao, F. InP-based high-speed monolithic PIN photodetector integrated with an MQW semiconductor optical amplifier. Jpn. J. Appl. Phys. 2022, 61, 012005. [Google Scholar] [CrossRef]

- Anagnosti, M.; Caillaud, C.; Paret, J.F.; Pommereau, F.; Glastre, G.; Blache, F.; Achouche, M. Record Gain x Bandwidth (6.1 THz) Monolithically Integrated SOA-UTC Photoreceiver for 100-Gbit/s Applications. J. Light. Technol. 2015, 33, 1186–1190. [Google Scholar] [CrossRef]

- Anagnosti, M.; Caillaud, C.; Blache, F.; Jorge, F.; Angelini, P.; Paret, J.F.; Achouche, M. Optimized High Speed UTC Photodiode for 100 Gbit/s Applications. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 29–35. [Google Scholar] [CrossRef]

- Caillaud, C.; Glastre, G.; Lelarge, F.; Brenot, R.; Bellini, S.; Paret, J.F.; Drisse, O.; Carpentier, D.; Achouche, M. Monolithic Integration of a Semiconductor Optical Amplifier and a High-Speed Photodiode With Low Polarization Dependence Loss. IEEE Photonics Technol. Lett. 2012, 24, 897–899. [Google Scholar] [CrossRef]

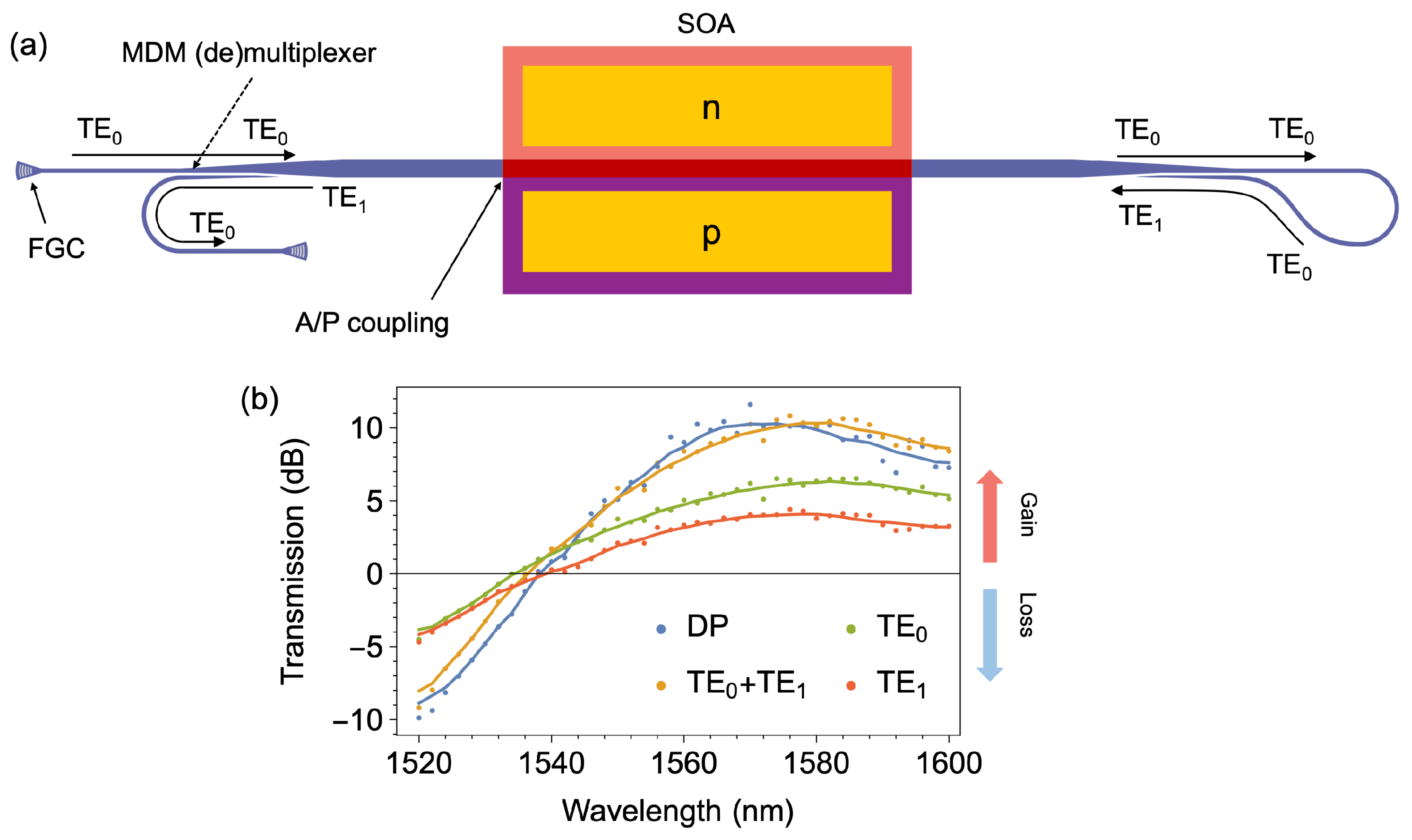

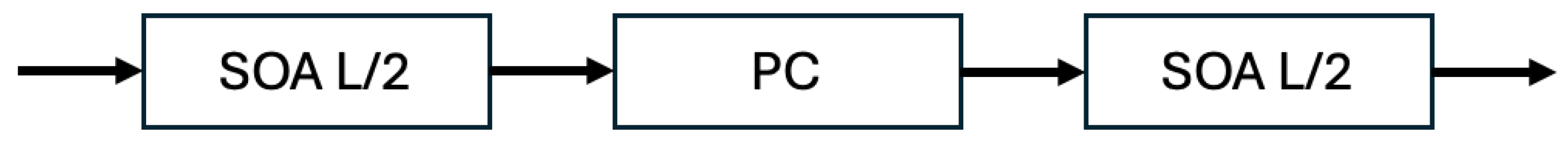

- Wang, Y.; Wei, Y.; Dolores-Calzadilla, V.; Dai, D.; Williams, K.; Smit, M.; Jiao, Y. Efficiency-boosted semiconductor optical amplifiers via mode-division multiplexing. Optica 2023, 10, 1153. [Google Scholar] [CrossRef]

- Wang, Y.; Dolores-Calzadilla, V.; Williams, K.; Smit, M. Efficient thermo-optic phase modulators on an indium phosphide membrane. In Proceedings of the 25th Annual Symposium of the IEEE Photonics Society Benelux, Mons, Belgium, 25–26 November 2021. [Google Scholar]

- Wang, Y.; Dolores-Calzadilla, V.; Williams, K.A.; Smit, M.K.; Jiao, Y. Ultra-Compact and Efficient Microheaters on a Submicron-Thick InP Membrane. J. Light. Technol. 2022, 41, 1790–1800. [Google Scholar] [CrossRef]

- Qiu, H.; Liu, Y.; Luan, C.; Kong, D.; Guan, X.; Ding, Y.; Hu, H. Energy-efficient thermo-optic silicon phase shifter with well-balanced overall performance. Opt. Lett. 2020, 45, 4806. [Google Scholar] [CrossRef]

- Chung, S.; Nakai, M.; Hashemi, H. Low-power thermo-optic silicon modulator for large-scale photonic integrated systems. Opt. Express 2019, 27, 13430. [Google Scholar] [CrossRef] [PubMed]

- Konoike, R.; Suzuki, K.; Namiki, S.; Kawashima, H.; Ikeda, K. Ultra-compact silicon photonics switch with high-density thermo-optic heaters. Opt. Express 2019, 27, 10332. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Timurdogan, E.; Yaacobi, A.; Zhan, S.; Hosseini, E.S.; Cole, D.B.; Watts, M.R. Large-Scale Silicon Photonic Circuits for Optical Phased Arrays. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 264–278. [Google Scholar] [CrossRef]

- Kashi, A.; van der Tol, J.; Williams, K.; Yao, W.; Lebby, M.S.; Pecinovsky, C.; Jiao, Y. Electro-Optic Slot Waveguide Phase Modulator on the InP Membrane on Silicon Platform. IEEE J. Quantum Electron. 2020, 57, 0600210. [Google Scholar] [CrossRef]

- Kashi, A.A. Electro-Optic Slot Waveguide Phase Modulators on the InP Membrane on Silicon Platform. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2022. [Google Scholar]

- Kieninger, C.; Kutuvantavida, Y.; Elder, D.L.; Wolf, S.; Zwickel, H.; Blaicher, M.; Kemal, J.N.; Lauermann, M.; Randel, S.; Freude, W.; et al. Ultra-High Electro-Optic Activity Demonstrated in a Silicon-Organic Hybrid Modulator. Optica 2018, 5, 739. [Google Scholar] [CrossRef]

- Xu, M.; Cai, X. Advances in integrated ultra-wideband electro-optic modulators [Invited]. Opt. Express 2022, 30, 7253. [Google Scholar] [CrossRef]

- Sekine, N.; Toprasertpong, K.; Takagi, S.; Takenaka, M. Numerical analyses of optical loss and modulation bandwidth of an InP organic hybrid optical modulator. Opt. Express 2020, 28, 29730. [Google Scholar] [CrossRef]

- Eppenberger, M.; Messner, A.; Bitachon, B.I.; Heni, W.; Blatter, T.; Habegger, P.; Destraz, M.; De Leo, E.; Meier, N.; Del Medico, N.; et al. Resonant plasmonic micro-racetrack modulators with high bandwidth and high temperature tolerance. Nat. Photonics 2023, 17, 360–367. [Google Scholar] [CrossRef]

- Horst, Y.; Moor, D.; Chelladurai, D.; Blatter, T.; Fernandes, S.; Kulmer, L.; Baumann, M.; Ibili, H.; Funck, C.; Keller, K.; et al. Ultra-Wideband MHz to THz Plasmonic EO Modulator. Optica 2025, 12, 325. [Google Scholar] [CrossRef]

- Xiang, C.; Jin, W.; Terra, O.; Dong, B.; Wang, H.; Wu, L.; Guo, J.; Morin, T.J.; Hughes, E.; Peters, J.; et al. 3D Integration Enables Ultralow-Noise Isolator-Free Lasers in Silicon Photonics. Nature 2023, 620, 78–85. [Google Scholar] [CrossRef]

- Rahim, A.; Baets, R.G. Heterogeneous Integration in Silicon Photonics: Opportunities and Challenges: Opinion. Opt. Mater. Express 2023, 13, 3439–3444. [Google Scholar] [CrossRef]

- Arafin, S.; Coldren, L.A. Advanced InP Photonic Integrated Circuits for Communication and Sensing. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 6100612. [Google Scholar] [CrossRef]

- Spiegelberg, M. 3D-Integration on Wafer Level of Photonic and Electronic Circuits. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2021. [Google Scholar]

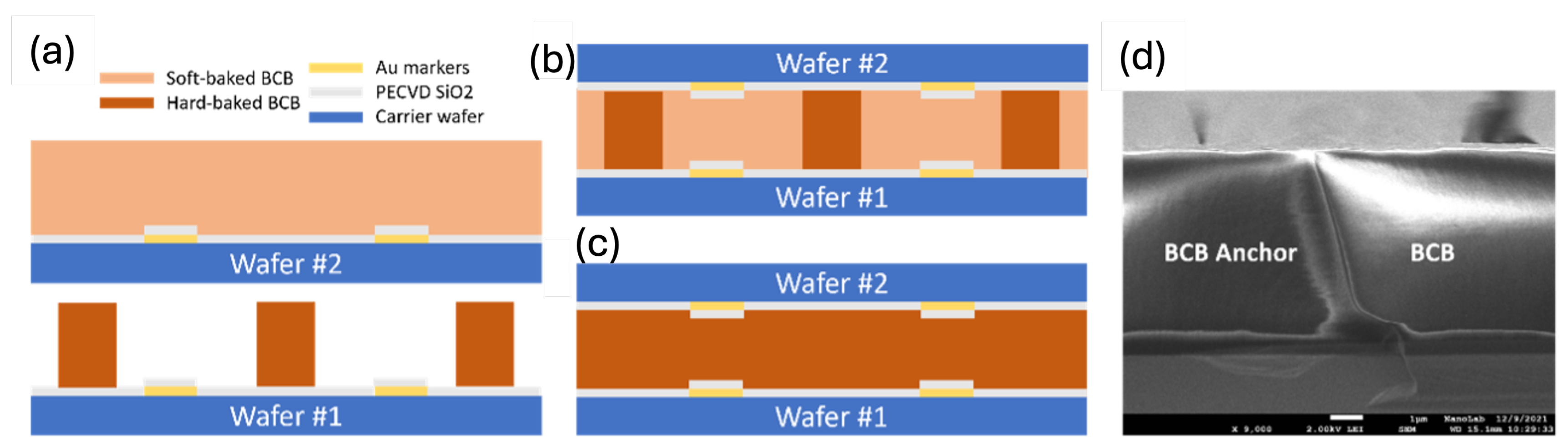

- Abdi, S.; de Vries, T.; Spiegelberg, M.; Williams, K.; Jiao, Y. Novel wafer-scale adhesive bonding with improved alignment accuracy and bond uniformity. Microelectron. Eng. 2023, 270, 111936. [Google Scholar] [CrossRef]

- Wang, X.; Niklaus, F. 3D and Circuit Integration of MEMS; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Zhang, X.; Liu, X.; Spiegelberg, M.; Van Dommele, A.R.; Matters-Kammerer, M.K. A DC-51.5 GHz Electro-Absorption Modulator Driver with Tunable Differential DC Coupling for 3D Wafer Scale Packaging. In Proceedings of the 2019 IEEE BiCMOS and Compound semiconductor Integrated Circuits and Technology Symposium (BCICTS), Nashville, TN, USA, 3–6 November 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Abdi, S.; De Vries, T.; Spiegelberg, M.; Williams, K.; Jiao, Y. Wafer-scale adhesive bonding with hard Benzocyclobutene anchors for wafer assembly and heterogeneous integration. In Proceedings of the 2023 34th Annual SEMI Advanced Semiconductor Manufacturing Conference (ASMC), Saratoga Springs, NY, USA, 1–4 May 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Abdi, S.; Zozulia, A.; Bolk, J.; Geluk, E.J.; Williams, K.; Jiao, Y. Study of Spatial Distortion in InP Nanophotonic Membranes on Different Carrier Substrates. In Proceedings of the 2023 24th European Microelectronics and Packaging Conference & Exhibition (EMPC), Cambridge, UK, 11–14 September 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Liu, F.; Nimbalkar, P.; Aslani-Amoli, N.; Kathaperumal, M.; Tummala, R.; Swaminathan, M. A Critical Review of Lithography Methodologies and Impacts of Topography on 2.5-D/3-D Interposers. IEEE Trans. Components, Packag. Manuf. Technol. 2023, 13, 291–299. [Google Scholar] [CrossRef]

- Lau, J.H. Recent Advances and Trends in Advanced Packaging. IEEE Trans. Components, Packag. Manuf. Technol. 2022, 12, 228–252. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, Y.; Dolores-Calzadilla, V.; Williams, K.; Smit, M.; Dai, D.; Jiao, Y. Mode division multiplexing on an InP membrane on silicon. Opt. Lett. 2022, 47, 4004. [Google Scholar] [CrossRef]

- Dai, D.; Li, C.; Wang, S.; Wu, H.; Shi, Y.; Wu, Z.; Gao, S.; Dai, T.; Yu, H.; Tsang, H. 10-Channel Mode (de)multiplexer with Dual Polarizations. Laser Photonics Rev. 2018, 12, 1700109. [Google Scholar] [CrossRef]

- Huang, H.; Han, X.; Balčytis, A.; Dubey, A.; Boes, A.; Nguyen, T.G.; Ren, G.; Tan, M.; Tian, Y.; Mitchell, A. Non-resonant recirculating light phase modulator. APL Photonics 2022, 7, 106102. [Google Scholar] [CrossRef]

- Zhang, K.; Sun, W.; Chen, Y.; Feng, H.; Zhang, Y.; Chen, Z.; Wang, C. A power-efficient integrated lithium niobate electro-optic comb generator. Commun. Phys. 2023, 6, 17. [Google Scholar] [CrossRef]

- Miller, S.A.; Chang, Y.C.; Phare, C.T.; Shin, M.C.; Zadka, M.; Roberts, S.P.; Stern, B.; Ji, X.; Mohanty, A.; Jimenez Gordillo, O.A.; et al. Large-scale optical phased array using a low-power multi-pass silicon photonic platform. Optica 2020, 7, 3. [Google Scholar] [CrossRef]

- Haverkort, J.E.M.; Dorren, B.H.P.; Kemerink, M.; Silov, A.Y.; Wolter, J.H. Design of composite InAsP/InGaAs quantum wells for a 1.55 μm polarization independent semiconductor optical amplifier. Appl. Phys. Lett. 1999, 75, 2782–2784. [Google Scholar] [CrossRef]

- Zali, A.R.; Kleijn, S.; Augustin, L.; Tessema, N.M.; Prifti, K.; Stabile, R.; Calabretta, N. Design and Fabrication of Low Polarization Dependent Bulk SOA Co-Integrated With Passive Waveguides for Optical Network Systems. J. Light. Technol. 2022, 40, 1083–1091. [Google Scholar] [CrossRef]

- Felicetti, M.; van der Tol, J.J.G.M.; Geluk, E.J.; Pustakhod, D.; Wale, M.J.; Smit, M.K. Integrated High-Performance TE/TM Converters for Polarization Independence in Semiconductor Optical Amplifiers. J. Light. Technol. 2015, 33, 3584–3590. [Google Scholar] [CrossRef]

- Augustin, L.M.; van der Tol, J.J.G.M.; Geluk, E.J.; Oei, Y.; Smit, M.K. Method for polarization effect suppression in semiconductor optical amplifiers. In Proceedings of the 14th European Conference on Integrated Optics (ECIO), Eindhoven, The Netherlands, 11–13 June 2008; p. 4. [Google Scholar]

- Newkirk, M.; Miller, B.; Koren, U.; Young, M.; Chien, M.; Jopson, R.; Burrus, C. 1.5 μm multiquantum-well semiconductor optical amplifier with tensile and compressively strained wells for polarization-independent gain. IEEE Photonics Technol. Lett. 1993, 5, 406–408. [Google Scholar] [CrossRef]

- Morito, K.; Ekawa, M.; Watanabe, T.; Kotaki, Y. High-output-power polarization-insensitive semiconductor optical amplifier. J. Light. Technol. 2003, 21, 176–181. [Google Scholar] [CrossRef]

- Reniers, S.; Williams, K.; Van Der Tol, J.; Jiao, Y. Integration of an Ultra-Short Polarization Rotator on an Active-Passive Indium Phosphide Membrane. In Proceedings of the 2023 Opto-Electronics and Communications Conference (OECC), Shanghai, China, 2–6 July 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Latkowski, S.; Hansel, A.; Bhattacharya, N.; De Vries, T.; Augustin, L.; Williams, K.; Smit, M.; Bente, E. Novel Widely Tunable Monolithically Integrated Laser Source. IEEE Photonics J. 2015, 7, 1503709. [Google Scholar] [CrossRef]

- Kabir, T.; Wang, Y.; Tondini, S.; Williams, K.; Jiao, Y.; Heck, M.J.R. Compact widely tunable laser integrated on an indium phosphide membrane platform. Appl. Phys. Lett. 2024, 125, 121110. [Google Scholar] [CrossRef]

- Pajkovic, R.; Reep, T.; Williams, K.; Bente, E. Data-driven model to extend tuning range: From 1474 nm to 1568 nm in a monolithic laser. In Proceedings of the 2021 27th International Semiconductor Laser Conference (ISLC), Potsdam, Germany, 10–14 October 2021; pp. 1–2. [Google Scholar] [CrossRef]

- Zhang, H.; Gu, M.; Jiang, X.D.; Thompson, J.; Cai, H.; Paesani, S.; Santagati, R.; Laing, A.; Zhang, Y.; Yung, M.H.; et al. An optical neural chip for implementing complex-valued neural network. Nat. Commun. 2021, 12, 457. [Google Scholar] [CrossRef]

- Eldredge, J.G.; Hutchings, B.L. Density Enhancement of a Neural Network Using FPGAs and Run-Time Reconguration. In Proceedings of the Proceedings of IEEE Workshop on FPGA’s for Custom Computing Machines, Napa Valley, CA, USA, 10–13 April 1994. [Google Scholar]

- Lu, L.; Zhao, S.; Zhou, L.; Li, D.; Li, Z.; Wang, M.; Li, X.; Chen, J. 16 × 16 non-blocking silicon optical switch based on electro-optic Mach-Zehnder interferometers. Opt. Express 2016, 24, 9295. [Google Scholar] [CrossRef] [PubMed]

- Feldmann, J.; Youngblood, N.; Wright, C.D.; Bhaskaran, H.; Pernice, W.H.P. All-optical spiking neurosynaptic networks with self-learning capabilities. Nature 2019, 569, 208–214. [Google Scholar] [CrossRef]

- Teo, T.Y.; Krbal, M.; Mistrik, J.; Prikryl, J.; Lu, L.; Simpson, R.E. Comparison and analysis of phase change materials-based reconfigurable silicon photonic directional couplers. Opt. Mater. Express 2022, 12, 606. [Google Scholar] [CrossRef]

- Liu, H.; Dong, W.; Wang, H.; Lu, L.; Ruan, Q.; Tan, Y.S.; Simpson, R.E.; Yang, J.K.W. Rewritable color nanoprints in antimony trisulfide films. Sci. Adv. 2020, 6, eabb7171. [Google Scholar] [CrossRef]

- Lu, L.; Reniers, S.F.G.; Wang, Y.; Jiao, Y.; Simpson, R.E. Reconfigurable InP waveguide components using the Sb2 S3 phase change material. J. Opt. 2022, 24, 094001. [Google Scholar] [CrossRef]

- Li, X.; Youngblood, N.; Ríos, C.; Cheng, Z.; Wright, C.D.; Pernice, W.H.; Bhaskaran, H. Fast and reliable storage using a 5 bit, nonvolatile photonic memory cell. Optica 2019, 6, 1. [Google Scholar] [CrossRef]

- Tsakyridis, A.; Alexoudi, T.; Miliou, A.; Pleros, N.; Vagionas, C. 10 Gb/s optical random access memory (RAM) cell. Opt. Lett. 2019, 44, 1821. [Google Scholar] [CrossRef]

- Demirer, F.E.; Baron, Y.; Reniers, S.; Pustakhod, D.; Lavrijsen, R.; Van Der Tol, J.; Koopmans, B. An integrated photonic device for on-chip magneto-optical memory reading. Nanophotonics 2022, 11, 3319–3329. [Google Scholar] [CrossRef]

- Weller, D.; Brändle, H.; Gorman, G.; Lin, C.J.; Notarys, H. Magnetic and magneto-optical properties of cobalt-platinum alloys with perpendicular magnetic anisotropy. Appl. Phys. Lett. 1992, 61, 2726–2728. [Google Scholar] [CrossRef]

- Jalas, D.; Petrov, A.; Eich, M.; Freude, W.; Fan, S.; Yu, Z.; Baets, R.; Popović, M.; Melloni, A.; Joannopoulos, J.D.; et al. What is—And what is not—An optical isolator. Nat. Photonics 2013, 7, 579–582. [Google Scholar] [CrossRef]

- Stadler, B.J.H.; Mizumoto, T. Integrated Magneto-Optical Materials and Isolators: A Review. IEEE Photonics J. 2014, 6, 0600215. [Google Scholar] [CrossRef]

- Firby, C.J.; Chang, P.; Helmy, A.S.; Elezzabi, A.Y. Versatile broadband polarization-independent optical circulators for nanophotonic integrated circuits. J. Opt. Soc. Am. B 2018, 35, 1504. [Google Scholar] [CrossRef]

- Ma, R.; Reniers, S.; Shoji, Y.; Mizumoto, T.; Williams, K.; Jiao, Y.; van der Tol, J. Integrated polarization-independent optical isolators and circulators on an InP membrane on silicon platform. Optica 2021, 8, 1654. [Google Scholar] [CrossRef]

| Number of Holes | R (FP Method) | R (Direct Method) | R (Simulated) |

|---|---|---|---|

| 5 | 0.871 | 0.902 | 0.932 |

| 7 | 0.932 | 0.968 | 0.972 |

| 9 | 0.944 | 0.990 | 0.991 |

| Building Block/Sub-Circuit | Performance Metric | Performance |

|---|---|---|

| PhC reflector [16] | Reflectivity [%] | 99.0% |

| Polarization converter [18] | Conversion efficiency | 97% |

| Optical antenna [23] | Beam width | 0.05° FWHM |

| Optical antenna [23] | Steering angle | >13° |

| Directly modulated laser [32] | Modulation bandwidth | 21 GHz |

| UTC PD [36] | Bandwidth | >110 GHz |

| TO phase shifter [50] | Power efficiency | 2.2 mW/ |

| TO phase shifter [50] | Time constant | 13 µs |

| EO polymer modulator [56] | 3.9 Vmm | |

| EO polymer modulator [56] | Modulation bandwidth | 37 GHz |

| Double-pass SOA [49] | WPE enhancement | 300% w.r.t. single-pass SOA |

| PI-SOA [19] | PDG | <3 dB |

| Tuneable membrane laser [87] | Tuning range | 50 nm |

| Optical isolator [103] | Isolation | 24.1 dB (TE), 34.0 dB (TM) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reniers, S.; Wang, Y.; Abdi, S.; de Graaf, J.; Zozulia, A.; Williams, K.; Jiao, Y. Highly Versatile Photonic Integration Platform on an Indium Phosphide Membrane. Chips 2025, 4, 32. https://doi.org/10.3390/chips4030032

Reniers S, Wang Y, Abdi S, de Graaf J, Zozulia A, Williams K, Jiao Y. Highly Versatile Photonic Integration Platform on an Indium Phosphide Membrane. Chips. 2025; 4(3):32. https://doi.org/10.3390/chips4030032

Chicago/Turabian StyleReniers, Sander, Yi Wang, Salim Abdi, Jasper de Graaf, Aleksandr Zozulia, Kevin Williams, and Yuqing Jiao. 2025. "Highly Versatile Photonic Integration Platform on an Indium Phosphide Membrane" Chips 4, no. 3: 32. https://doi.org/10.3390/chips4030032

APA StyleReniers, S., Wang, Y., Abdi, S., de Graaf, J., Zozulia, A., Williams, K., & Jiao, Y. (2025). Highly Versatile Photonic Integration Platform on an Indium Phosphide Membrane. Chips, 4(3), 32. https://doi.org/10.3390/chips4030032