Abstract

The discards from table olive production, mainly defective or out-of-size olives, have the potential to be considered an excellent source of bioactive compounds; however, their high salt content may restrict their use. This work aims to obtain new powdered ingredients derived from table olives by-products. The discards were subjected to a conditioning process comprising washing and pressing stages to reduce the salt and moisture contents. The resulting olive paste was convective-dried at 70 °C up to constant weight. The thin-layer modelling was assessed to explain the drying kinetics. The findings showed up to a 75% salt content reduction with the washing stage in the conditioning. Considering all the conditioning combinations, the drying process of the table olive discards was completed in 5 h.

1. Introduction

The principal by-products of table olive production are processing wastewater [1] and rejected table olives that fail to meet quality standards due to their size, present visual defects or mechanical damage. As a consequence, around 90–150 tons of fruit waste are annually discarded in this industry [2]. These by-products contain interesting components, including polyphenols and monounsaturated fatty acids [1,3], which make them an excellent raw material for obtaining new ingredients or bioactive compounds with positive health benefits. However, table olive discards also present a high salt content, which could hinder their subsequent incorporation into food products [3]. One of the greatest concerns of health authorities is the excess consumption of sodium [3], so new product development and research of novel ingredients must consider current nutritional recommendations, which encourage the population to reduce their sodium intake. Accordingly, developing new ingredients from table olive discards with a high nutritional value and long shelf-life is a significant challenge. For this purpose, conditioning steps will be required to reduce the initial salt content and partially reduce moisture. Previous studies have conditioned other by-products for salt reduction prior to the drying process [4]. Conditioning or brine replacement is a common practice in table olive processing, employed to adapt the final product [5,6]. However, to our knowledge, it has not been applied to these discards. Moreover, to guarantee product stability and increase product shelf-life, a drying process will be necessary. However, the initial high moisture content of table olive discards may result in a long-exposure time to high temperatures, which could damage the bioactive compounds or enhance the browning appearance [7,8]. In this sense, an initial partial moisture reduction could enable a faster drying, ultimately yielding a salt-reduced and bioactive ingredient of superior quality. So, this work aims to select the most suitable combination of conditioning stages for reducing salt and moisture contents before the table olive discards drying process to obtain new powdered ingredients.

2. Materials and Methods

2.1. Optimization of Table Olive Discards Conditioning

Table olive discards (TOD) corresponded to broken, out-of-size or defective Spanish-style green pitted olives, obtained prior to the final brining process. The discards were provided by a Spanish company (Cándido Miró S.A.). The TOD were crushed and subsequently divided into two batches. In order to reduce the salt and moisture contents, each batch underwent a distinct conditioning process. The conditioning processes were distinguished by a different combination of conditioning stages, including (a) washing for 30 min (1:2 w/v) (W) and (b) pressing with a manual food press (P). The following combinations were tested: The first combination (C1) comprised the stages of washing and pressing (W + P), while the second combination (C2) comprised the additional stage of washing (P + W + P). The moisture and salt contents of the olive paste throughout the different stages of conditioning were assayed. The moisture content was determined in accordance with the AOAC protocol 950.46 [9], while the salt content was quantified using an automatic chloride analyzer, Sherwood mod. 926 (Sherwood Scientific Ltd., Cambridge, UK). The analyses were performed in triplicate, and the results were expressed as g per 100 g sample.

2.2. Drying Kinetics and Modelling

The table olive paste (50 g) obtained from the conditioning processes described above was spread out in food-grade trays (size: 10.5 × 15.5 cm) and dried in a convective drying chamber, BinderTM Serie ED Classic Line (BINDER GmbH, Tuttlingen, Germany), at 70 °C up to constant weight. Convective drying was carried out using a drying air of 5% relative humidity and 100% fan velocity. The selected conditions were based on a preliminary study [10]. During the drying process, the weight of the sample trays was periodically recorded at regular intervals in order to monitor any changes in weight variation. The thin-layer modelling was performed to explain the drying kinetics of the olive paste. The moisture ratio (XR) and the drying rate (DR) during the drying were calculated by the following equations:

where Xt is the dry basis moisture content at any time of drying, Xe is the dry basis equilibrium moisture content, Xi is the initial dry basis moisture content, Mt+∆t is the weight of moisture at any time of drying, ∆t is the time increment, and Mf is the weight of dry sample at the end.

The models used were derived from Newton’s law of cooling or Fick’s second law of diffusion. The models were as follows: (a) Newton [11], (b) Page [12], (c) Henderson and Pabis [13], (d) Logarithmic [14], (e) Wang and Singh [15], and (f) Midilli [16]. The fitting curves for the aforementioned mathematical models were determined with the Curve Expert 1.4 program, and the optimal model for describing the table olive paste drying was selected according to the highest coefficient of determination (R2) and the lowest value of standard error (SE).

3. Results and Discussion

3.1. Optimization of Table Olive Discards Conditioning

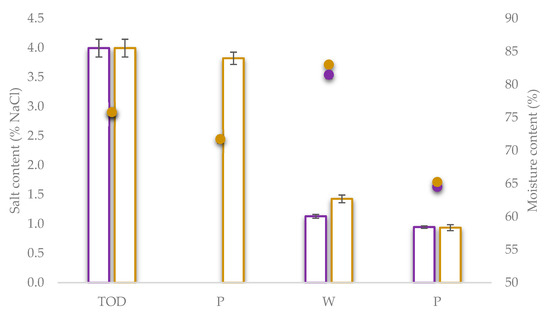

The raw material employed (TOD) presented elevated levels of salt and acidity, which could hinder its subsequent incorporation into food products. For this purpose, two different conditioning procedures were subjected to evaluation, with the overarching goal of attaining a product with minimum salt and humidity values. These conditioning processes comprised different washing and pressing combinations. Both conditioning methods yielded comparable salt and moisture values, indicating that the incorporation of an additional pressing step prior to the washing stage, as outlined in C2, did not reduce the salt content in the final product. Both protocols achieved a reduction of up to 76% of salt and 14% of humidity (Figure 1). The salt content in the table olive paste after conditioning was around 0.9%, regardless of the procedure employed, which indicates that a conditioning in only two stages was successful in reducing TOD salt content to acceptable levels. Furthermore, both methodologies achieved a reduction in moisture content from 75% to 65%, thereby enabling a reduction in drying times. In this sense, a faster drying process would prevent bioactive compound losses. Different studies have demonstrated that bioactive compounds, such as phenolic acids, which play an important role in the antioxidant properties of table olives, are affected by heat [7]. Furthermore, prolonged exposure to elevated temperatures also affects other product properties, such as color. Non-enzymatic browning, provoked by heating, may negatively affect the product’s appearance [17].

Figure 1.

Salt and moisture contents of the table olive paste in the different stages of conditioning. Bars indicate salt content values, and circles indicate moisture content values. Purple color corresponds to C1, and yellow color corresponds to C2.

3.2. Drying Kinetics and Modelling

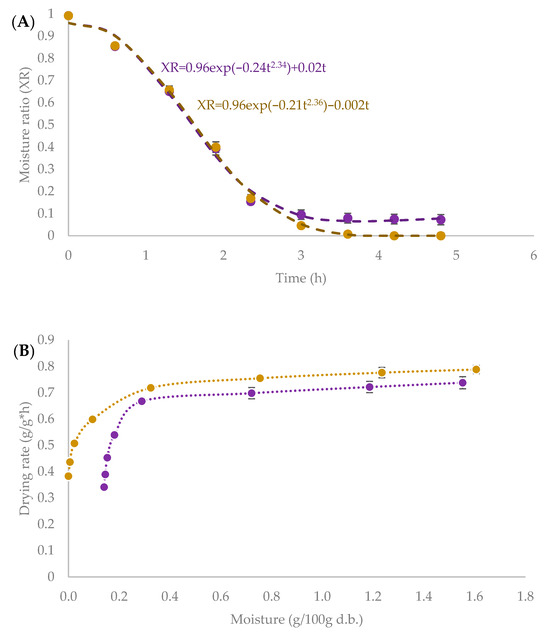

The full process of the TOD drying consisted of 4.8 h, at which point the table olive paste reached constant weight and ensured less than 1% moisture content. In previous studies, where the same TOD were subjected to the same drying process without including a pressing stage in the conditioning, the required drying time was 12 h [10], so the new conditioning processes reduced the drying time by 60%. It can, therefore, be concluded that the conditioning stages prior to the drying process considerably reduce the exposure time to high temperatures. To elucidate the drying kinetics, the moisture ratio (XR) and drying rate (DR) of the table olive paste from both conditioning protocols are shown in Figure 2. The drying curves of TOD are representative of those observed in the drying of similar food by-products. The moisture content decreased exponentially with the prolongation of the drying period. After drying for 3 h, the moisture ratio exhibited minimal variation (Figure 2A). The three main factors influencing drying kinetics are temperature, air drying speed and thin-layer thickness, but particle size is also relevant to increase the gas contact surface. Given the high lipid content of TOD, oil could hinder the moisture diffusion, thereby slowing down the drying process in such discards [18,19].

Figure 2.

Drying kinetics of table olive paste: (A) Moisture ratio as a function of drying time for each conditioning. Non-linear fitting of the Midilli kinetic model; (B) Drying rate as a function of moisture for each conditioning. Purple color corresponds to C1, and yellow color corresponds to C2.

Typically, the drying process comprises three stages: (i) the product is heated and reaches the maximum drying rate; (ii) moisture begins to come from inside but the surface is still wet, and the drying rate decreases; (iii) the entire surface is dry, and migration occurs only from inside [18]. The drying rate is slightly higher when pressing is performed prior to washing throughout the entire process, possibly due to the redistribution of water inside or the breakdown of the internal structure of the olive paste (Figure 2B). Nevertheless, these differences are not remarkable, mainly due to the moisture of the product. Both curves exhibit a pronounced decline in the drying rate from its maximum after 0.2 moisture (drying for 3 h).

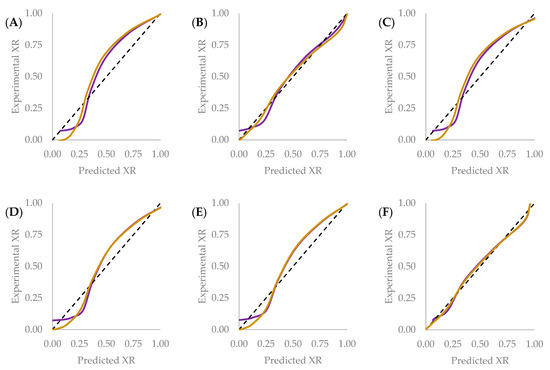

The experimental data for the moisture ratio as a function of time were fitted to different kinetics models for both conditioning processes (Table 1). Midilli was the best model at predicting the drying kinetics of the table olive powder, as evidenced by the predicted curve in Figure 2A. The Midilli model was also identified as the most appropriate drying model for olive pomace [20,21] and for sliced table olives [22]. Subsequently, Page’s model was employed, yielding R2 values up to 0.98, while Wang and Singh attained R2 values over 0.96. Similarly, these models have been employed likewise for the prediction of variations in moisture ratios of similar products [23]. An adequate suitability of these models, especially for Midilli and Page, is evidenced by the correlation between the experimental and predicted moisture ratios curves shown in Figure 3F and Figure 3B, respectively. Both showed good performance, although the number of variables should be taken into account. For this purpose, adjusted coefficients of determination were determined (Midilli: 0.984 and 0.991; Page: 0.976 and 0.992, for C1 and C2, respectively), where Midilli still has the better performance for C1 but not for C2. Newton’s model appears to be the least suitable model for predicting the drying behavior of table olive paste (Figure 3A).

Table 1.

Moisture ratio modeling with different drying kinetics models.

Figure 3.

Fitting of the experimental data to the drying models: (A) Newton; (B) Page; (C) Henderson and Pabis; (D) Logarithmic; (E) Wang and Singh; (F) Midilli. Purple lines correspond to C1, and yellow lines correspond to C2.

4. Conclusions

In this study, the effect of different conditioning processes on the salt and moisture content of table olive discards previous to the drying process was evaluated. The application of both conditioning processes reduced the salt content up to 75% and decreased the moisture values. The two- and three-stage conditionings performed similarly during the drying, so an additional pressing stage prior to the washing step is unlikely to improve the obtention of table olive powdered ingredients. Moreover, compared with previous studies, the novel conditioning methodology was capable of reducing the drying time by more than half, which would prevent bioactive compounds losses and product browning. The Midilli thin-layer model was suitable to fit the table olive paste drying kinetics. The two-stage conditioning process before drying is highly recommended to reduce processing time and improve the quality of the new table olive powdered ingredient. This ingredient represents an excellent option not only for new product developments but also to be employed by food companies for waste reduction.

Author Contributions

Conceptualization, A.F.; methodology, P.R.-F. and A.F.; validation, P.R.-F. and A.F.; formal analysis, P.R.-F.; investigation, P.R.-F. and A.F.; writing—original draft preparation, P.R.-F.; writing—review and editing, A.F.; visualization, A.F.; supervision, A.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the project CPP2021-008426 funded by MCIU/AEI/10.13039/501100011033 and by the “European Union NextGenerationEU/PRTR”.

Data Availability Statement

Data are unavailable due to privacy.

Acknowledgments

The authors thank Cándido Miró. S.A. for the olives used for the experiments.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Skaltsounis, A.L.; Argyropoulou, A.; Aligiannis, N.; Xynos, N. Recovery of High Added Value Compounds from Olive Tree Products and Olive Processing Byproducts; AOCS Press: Champaign, IL, USA, 2015; ISBN 9781630670429. [Google Scholar]

- International Olive Council Estadísticas Mundiales de Las Aceitunas de Mesa. Available online: https://www.internationaloliveoil.org/que-hacemos/unidad-de-asuntos-econonicos-y-promocion/?lang=es#figures (accessed on 17 April 2024).

- Rocha, J.; Borges, N.; Pinho, O. Table Olives and Health: A Review. J. Nutr. Sci. 2020, 9, e57. [Google Scholar] [CrossRef] [PubMed]

- Muangrod, P.; Charoenchokpanich, W.; Roytrakul, S.; Rungsardthong, V.; Vatanyoopaisarn, S.; Charoenlappanit, S.; Wonganu, B.; Thumthanaruk, B. Effect of Pepsin on Antioxidant and Antibacterial Activity of Protein Hydrolysate from Salted Jellyfish (Lobonema smithii and Rhopilema hispidum) by-Products. In Proceedings of the E3S Web of Conferences 355, Online, 4–5 August 2022; EDP Sciences: Les Ulis, France, 2022; Volume 355, p. 02013. [Google Scholar]

- Sánchez Gómez, A.H.; García García, P.; Rejano Navarro, L. View of Elaboration of Table Olives. Grasas Aceites 2006, 1, 86–94. [Google Scholar]

- López-López, A.; Moreno-Baquero, J.M.; Garrido-Fernández, A. Innovative Salt Replacement for Green Spanish-Style Olives Using Potassium, Calcium, and Magnesium Chlorides during Packaging. Heliyon 2024, 10, e37901. [Google Scholar] [CrossRef] [PubMed]

- Charoenprasert, S.; Mitchell, A. Factors Influencing Phenolic Compounds in Table Olives (Olea Europaea). J. Agric. Food Chem. 2012, 60, 7081–7095. [Google Scholar] [CrossRef] [PubMed]

- Goldental-Cohen, S.; Biton, I.; Many, Y.; Ben-Sason, S.; Zemach, H.; Avidan, B.; Ben-Ari, G. Green Olive Browning Differ Between Cultivars. Front. Plant Sci. 2019, 10, 470699. [Google Scholar] [CrossRef] [PubMed]

- Association of Official Analytical Chemist. Official Methods of Analysis of AOAC INTERNATIONAL; Association of Official Analytical Chemist: Rockville, MD, USA, 1997. [Google Scholar]

- Rus-Fernández, P.; González-González, M.; Fuentes, A. Table Olive Powder: A New Ingredient from Food Industry Discards. LWT 2024, 209, 116811. [Google Scholar] [CrossRef]

- Lewis, W.K. The Rate of Drying of Solid Materials. Ind. Eng. Chem. 1921, 13, 427–432. [Google Scholar] [CrossRef]

- Page, G. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin Layers; Purdue University: West Lafayette, IN, USA, 1949. [Google Scholar]

- Zhang, Q.; Litchfield, J.B. An Optimization of Intermittent Corn Drying in a Laboratory Scale Thin Layer Dryer. Dry. Technol. 1991, 9, 383–395. [Google Scholar] [CrossRef]

- Yaldýz, O.; Ertekýn, C. Thin Layer Solar Drying of Some Vegetables. Dry. Technol. 2001, 19, 583–597. [Google Scholar] [CrossRef]

- Wang, C.Y.; Singh, R.P. A Single Layer Drying Equation for Rough Rice; ASAE: St. Joseph, MI, USA, 1978. [Google Scholar]

- Midilli, A.; Kucuk, H.; Yapar, Z. A New Model for Single-Layer Drying. Dry. Technol. 2002, 20, 1503–1513. [Google Scholar] [CrossRef]

- Piscopo, A.; De Bruno, A.; Zappia, A.; Poiana, M. Antioxidant Activity of Dried Green Olives (Carolea Cv.). LWT-Food Sci. Technol. 2014, 58, 49–54. [Google Scholar] [CrossRef]

- Gómez-de-la-Cruz, F.-J. Estudio y Análisis de La Cinética de Secado de Subproductos de Almazara Para Su Aplicación a Secaderos Rotativos; Universidad de Jaén: Jaén, Spain, 2015. [Google Scholar]

- Göǧüş, F.; Maskan, M. Air Drying Characteristics of Solid Waste (Pomace) of Olive Oil Processing. J. Food Eng. 2006, 72, 378–382. [Google Scholar] [CrossRef]

- Meziane, S. Drying Kinetics of Olive Pomace in a Fluidized Bed Dryer. Energy Convers. Manag. 2011, 52, 1644–1649. [Google Scholar] [CrossRef]

- Nsibi, C.; Lajili, M. Experimental Study and Mathematical Modeling under Various Hot-Air Drying Conditions of Thin Layer Olive Pomaces. Processes 2023, 11, 2513. [Google Scholar] [CrossRef]

- Yildiz, G.; Izli, N.; Uylaser, V.; Isik, E. Effect of Different Drying Methods on Drying Characteristics, Colour, Total Phenolic Content and Antioxidant Activity of Sliced Green Table Olives. Qual. Assur. Saf. Crops Foods 2014, 6, 479–488. [Google Scholar] [CrossRef]

- Çelen, S.; Aktaş, T.; Karabeyoğlu, S.S.; Akyildiz, A. Drying Behavior of Prina (Crude Olive Cake) Using Different Types of Dryers. Dry. Technol. 2016, 34, 843–853. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).