Quantitative and Qualitative Characterization of Food Waste for Circular Economy Strategies in the Restaurant Sector of Riobamba, Ecuador: A Case Study Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. Site Study

2.2. Methods

2.2.1. Sample

2.2.2. Quantification of Food Waste

2.2.3. Characterization

- (a)

- Dry Matter and Moisture Determination

- (b)

- Determination of Fat Content

- (c)

- Determination of pH

- (d)

- Conductivity

- (e)

- Ash Determination

- (f)

- Real Density

- (g)

- Bulk Density

- (h)

- Fiber Content

3. Results

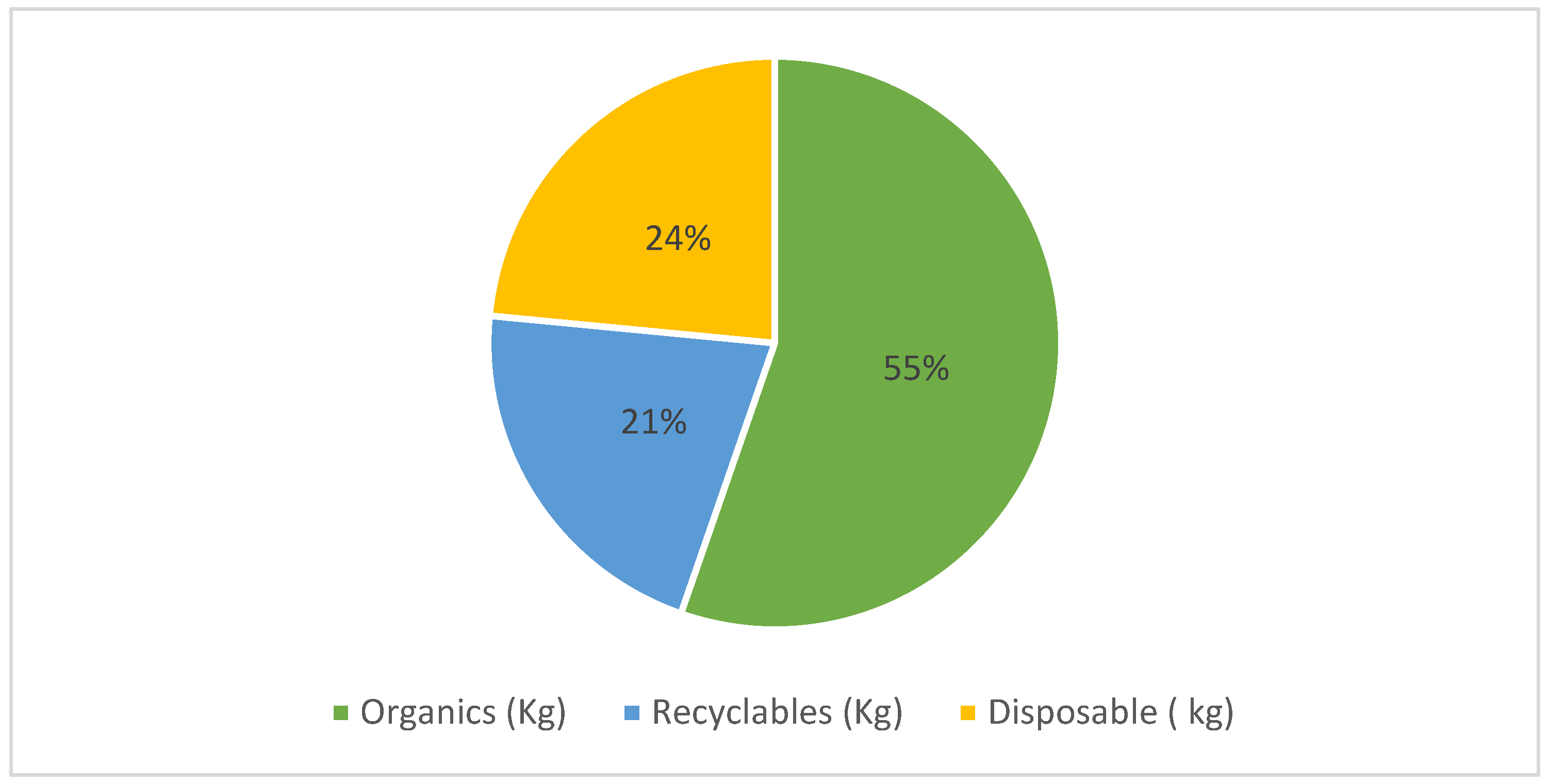

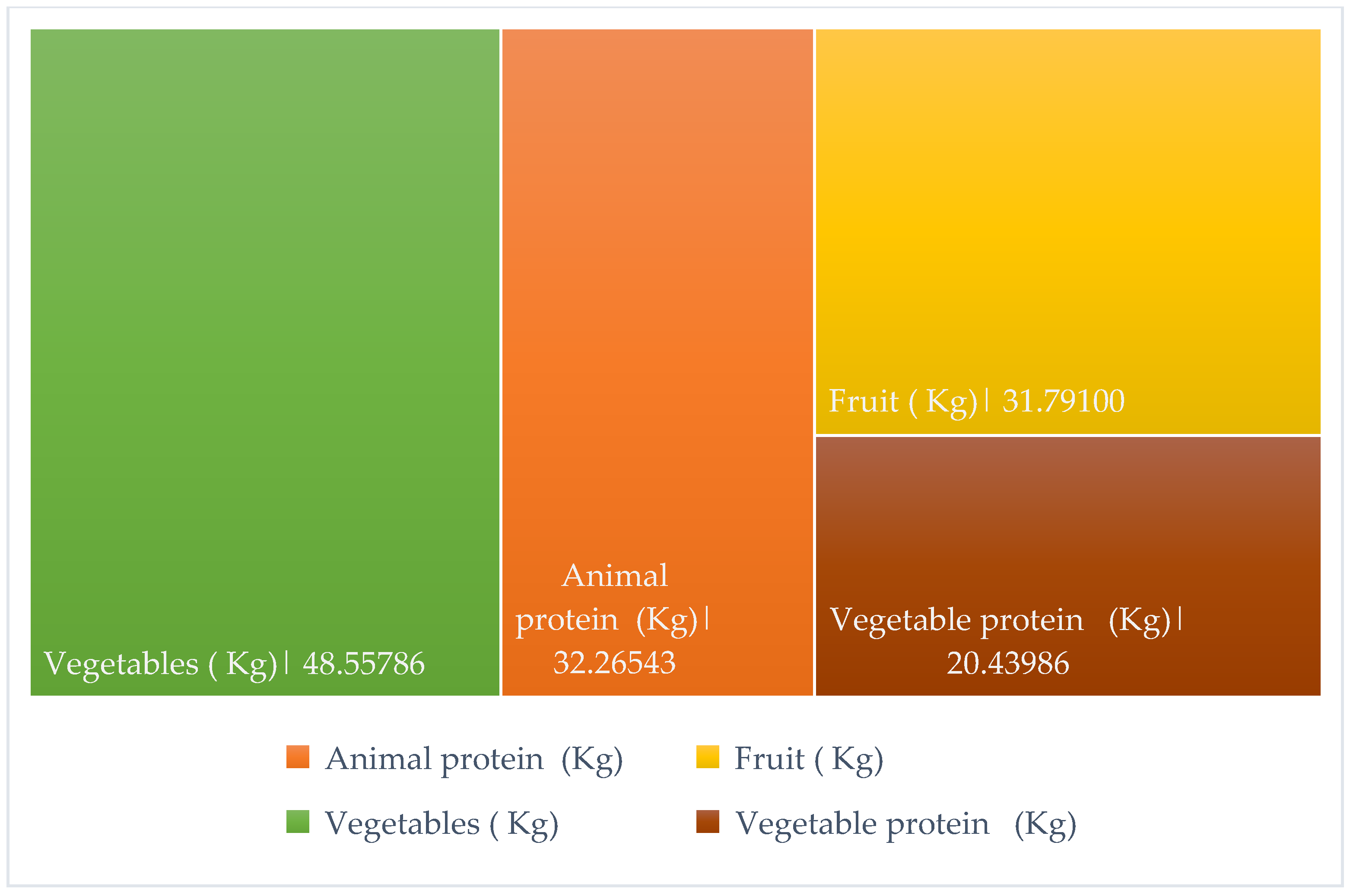

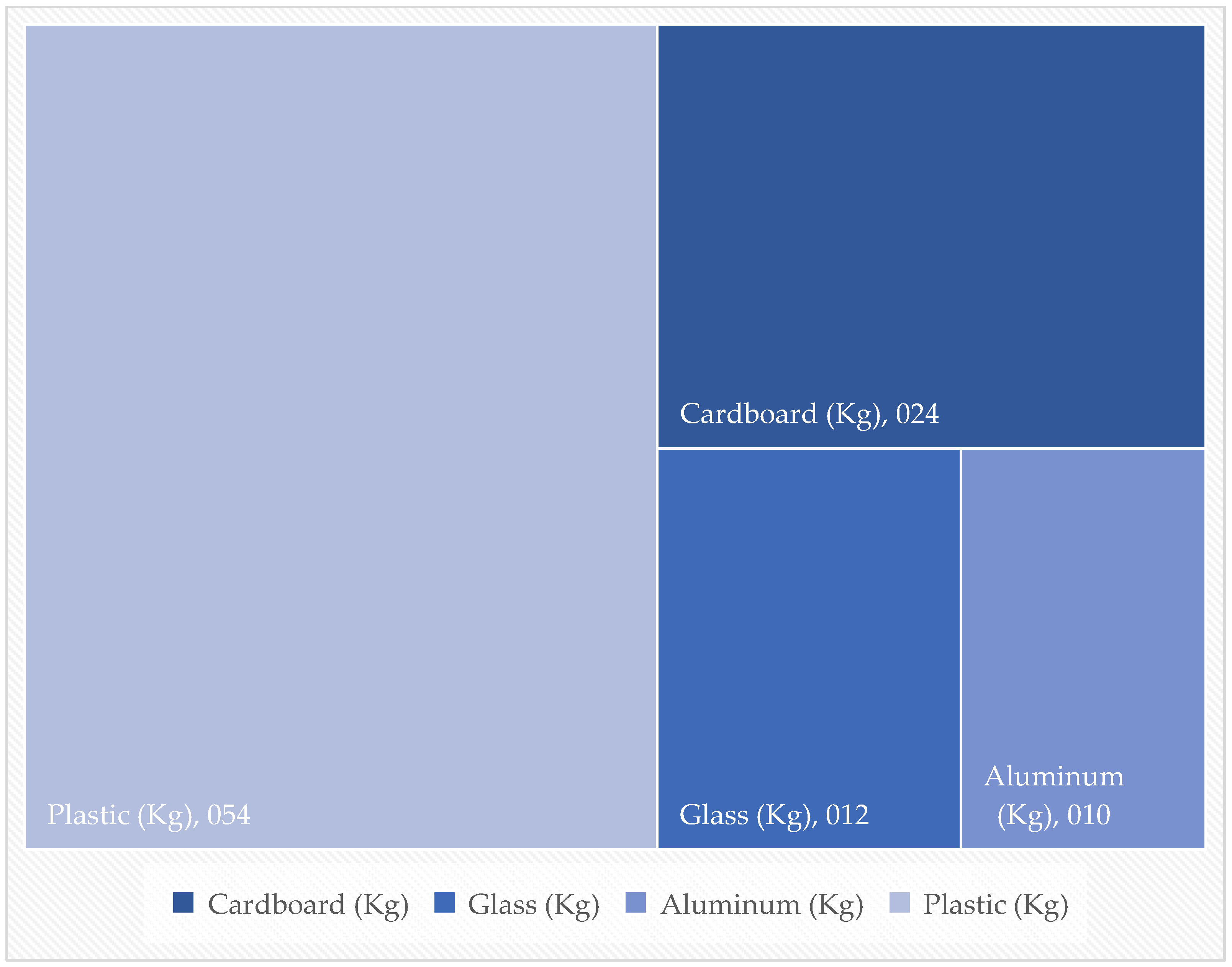

3.1. Quantitative Characterization Data

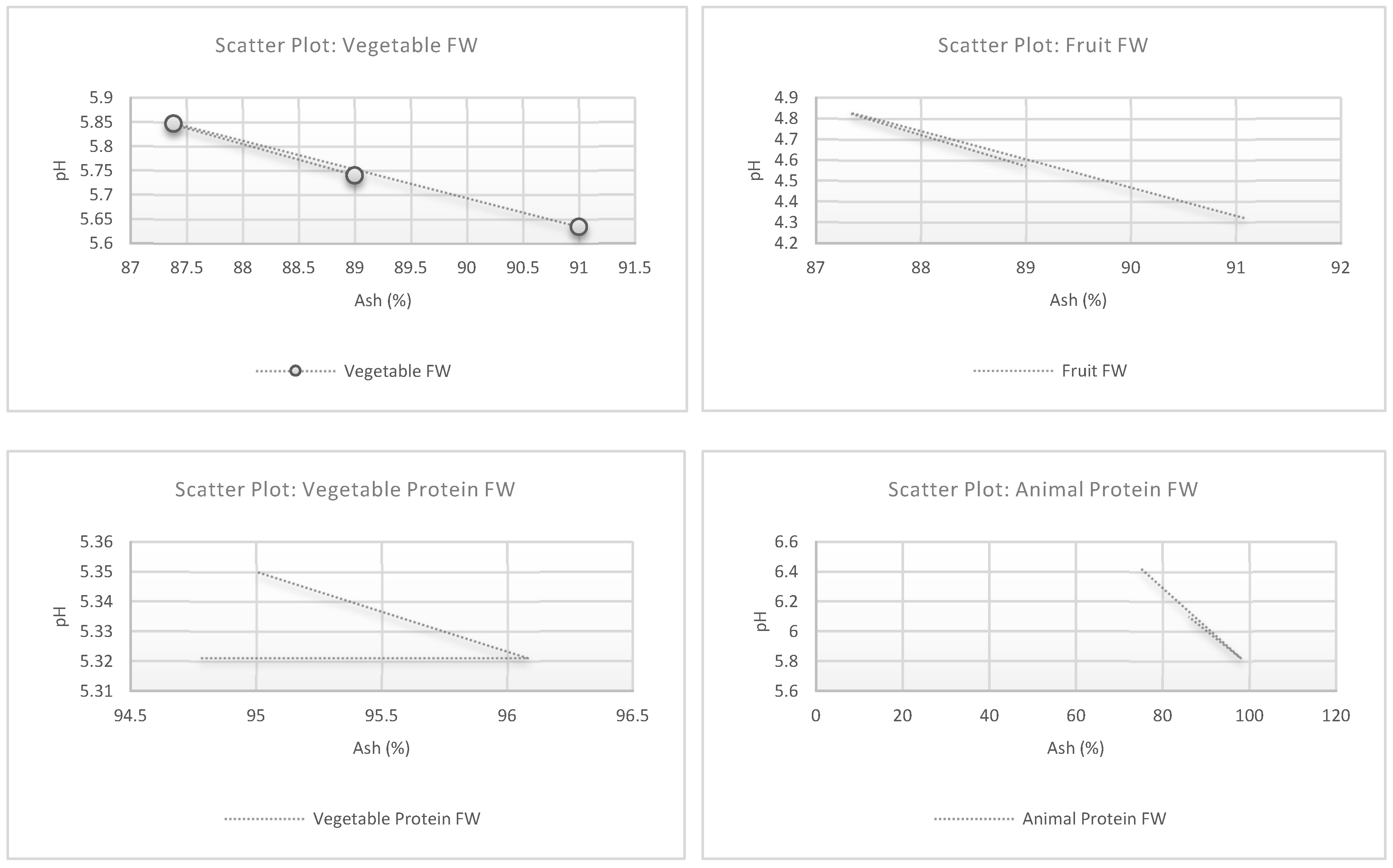

3.2. Qualitative Characterization Data

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sadiku, M.N.; Ashaolu, T.J.; Musa, S.M. Global Food Waste: A Primer. Int. J. Trend Sci. Res. Dev. 2019, 4, 170–173. Available online: https://www.ijtsrd.com/papers/ijtsrd29485.pdf (accessed on 11 November 2024).

- FAO. Global Food Losses and Food Waste: Extent, Causes and Prevention; FAO: Rome, Italy, 2011; Available online: https://www.fao.org/4/mb060e/mb060e00.htm (accessed on 11 November 2024).

- Kavitha, S.; Kannah, R.Y.; Kumar, G.; Gunasekaran, M.; Banu, J.R. Introduction: Sources and characterization of food waste and food industry wastes. In Food Waste to Valuable Resources; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–13. [Google Scholar]

- SOFA. SOFA 2019—The State of Food and Agriculture in the World. 2019. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/11f9288f-dc78-4171-8d02-92235b8d7dc7/content (accessed on 11 November 2024).

- FAO. Definitional Framework of Food Loss. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/5931921f-7f68-4169-b731-31d06f5b4835/content (accessed on 4 December 2024).

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef] [PubMed]

- Service, B.I. Guidelines on the Preparation of Food Waste Prevention Programmes. 2011. Available online: https://circabc.europa.eu/ui/group/636f928d-2669-41d3-83db-093e90ca93a2/library/41ae71d2-bb2d-4cbc-854e-981ad840dbf3 (accessed on 5 March 2025).

- FAO. Background: Technical Platform on the Measurement and Reduction of Food Loss and Waste. 2019. Available online: https://www.fao.org/platform-food-loss-waste/en/ (accessed on 16 November 2024).

- FAO. State of Food and Agriculture 2019. In Moving Forward on Food Loss and Waste Reduction; Policy Support and Governance, Food and Agriculture Organization of the United Nations: Rome, Italy, 2019; Available online: https://www.fao.org/policy-support/tools-and-publications/resources-details/en/c/1242090/ (accessed on 16 November 2024).

- Hall, K.D.; Guo, J.; Dore, M.; Chow, C.C. The Progressive Increase of Food Waste in America and Its Environmental Impact. PLoS ONE 2009, 4, e7940. [Google Scholar] [CrossRef] [PubMed]

- UNEP. UNEP Food Waste Index Report 2021. 2021. Available online: http://www.unep.org/resources/report/unep-food-waste-index-report-2021 (accessed on 5 March 2025).

- ‘Aqilah, N.M.N.; Rovina, K.; Felicia, W.X.L.; Vonnie, J.M. A Review on the Potential Bioactive Components in Fruits and Vegetable Wastes as Value-Added Products in the Food Industry. Molecules 2023, 28, 2631. [Google Scholar] [CrossRef]

- United-Nations. Objetivos de Desarrollo Sostenible. 2024. Available online: https://www.un.org/sustainabledevelopment/es/hunger/ (accessed on 11 June 2024).

- Batra, V.; Kumar, A.; Soti, N. Achieving Zero Hunger under Sustainable Development Goals Concerning Organic Agriculture. Curr. Agric. Res. J. 2024, 12, 219–230. [Google Scholar]

- Valin, H.; Hertel, T.; Bodirsky, B.; Hasegawa, T.; Stehfest, E. Achieving Zero Hunger by 2030 A Review of Quantitative Assessments of Synergies and Tradeoffs amongst the UN Sustainable Development Goals; Center for Development Research (ZEF) in Cooperation with the Scientific Group for the UN Food System Summit 2021: Bonn, Germany, 2021. [Google Scholar]

- Kennedy, E.; Jafari, A.; Stamoulis, K.; Callens, K. Tackling Zero Hunger: A View from Experts. Med. Res. Arch. 2021, 9, 3. [Google Scholar]

- Tamasiga, P.; Miri, T.; Onyeaka, H.; Hart, A. Food Waste and Circular Economy: Challenges and Opportunities. Sustainability 2022, 14, 9896. [Google Scholar] [CrossRef]

- Zara, G.; Fan, G. Microbial biotransformation of natural flavor compounds. Front. Microbiol. 2023, 14, 1243194. [Google Scholar] [CrossRef]

- Carmona-Cabello, M.; García, I.; Sáez-Bastante, J.; Pinzi, S.; Koutinas, A.; Dorado, M. Food waste from restaurant sector–Characterization for biorefinery approach. Bioresour. Technol. 2020, 301, 122779. [Google Scholar]

- Amicarelli, V.; Bux, C.; Lagioia, G. How to measure food loss and waste? A material flow analysis application. Br. Food J. 2020, 123, 67–85. [Google Scholar]

- FAO; IFAD; UNICEF; WFP; WHO. The State of Food Security and Nutrition in the World 2024—Financing to End Hunger, Food Insecurity and Malnutrition in All Its Forms; FAO: Rome, Italy, 2024. [Google Scholar]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste; FAO: Rome, Italy, 2011. [Google Scholar]

- Lundqvist, J.; De Fraiture, C.; Molden, D. Saving Water: From Field to Fork: Curbing Losses and Wastage in the Food Chain; Stockholm International Water Institute: Stockholm, Sweden, 2008. [Google Scholar]

- UNEP. Food Waste Index Report 2024. Think Eat Save: Tracking Progress to Halve Global Food Waste. 2024. Available online: https://www.unep.org/resources/publication/food-waste-index-report-2024 (accessed on 5 March 2025).

- Solíz Torres, M.F.; Durango Cordero, J.S.; Solano Peláez, J.L.; Yépez Fuentes, M.A. Cartografía de los Residuos Sólidos en Ecuador, 2020; Universidad Andina Simón Bolívar, Sede Ecuador/INEC/VLIR-UOS/GAIA: Quito, Ecuador, 2020. [Google Scholar]

- Gautam, S.; Bundela, P.; Pandey, A.; Jain, R.; Deo, P.; Khare, S.; Awasthi, M.; Surendra Sarsaiya, S.S. Biodegradation and recycling of urban solid waste. Am. J. Environ. Sci. 2009, 5, 653–656. [Google Scholar] [CrossRef]

- INEC. Estadisticas de Información Ambiental Económica en Gobiernos Autónomos Descentralizados Municipales. 2021. Available online: https://www.ecuadorencifras.gob.ec/documentos/web-inec/Encuestas_Ambientales/Municipios_2021/Residuo_solidos_2021/Presentaci%C3%B3n%20residuos%202021%20v07JA_CGTP%20 (accessed on 25 February 2025).

- Saeteros, A.; Morillo, B.; Cárdenas, Y.; Tapia, E.; Robalino, J. Characteristics of Riobamba’s household solid waste generation and the benefits of source separation. J. Namib. Stud. 2023, 33, 3539–3554. [Google Scholar]

- Nacional, A. Ley Orgánica de Economía Circular Inclusiva; Ecuador, R.D., Ed.; Registro Oficial Suplemento 488; 2021; p. 23. Available online: https://procuraduria.utpl.edu.ec/NormativaExterna/LEY%20ORG%C3%81NICA%20DE%20ECONOM%C3%8DA%20CIRCULAR%20INCLUSIVA.pdf (accessed on 16 March 2025).

- Riobamba, E.C.M.D.C. La Ordenanza Que Regula la Gestión Integral de Residuos Sólidos en el Cantón Riobamba. ORDENANZA No. 009-2019. 2019. Available online: https://www.gadmriobamba.gob.ec/index.php/la-municipalidad/concejo-cantonal/ordenanzas/2019 (accessed on 16 March 2025).

- Kaur, G.; Luo, L.; Chen, G.; Wong, J.W.C. Integrated food waste and sewage treatment—A better approach than conventional food waste-sludge co-digestion for higher energy recovery via anaerobic digestion. Bioresour. Technol. 2019, 289, 121698. [Google Scholar] [CrossRef]

- Fiore, M.; Pellegrini, G.; Sala, P.L.; Conte, A.; Liu, B. Attitude toward food waste reduction: The case of Italian consumers. Int. J. Glob. Small Bus. 2017, 9, 185–201. [Google Scholar] [CrossRef]

- Kamaruddin, M.A.; Jantira, N.N.; Alrozi, R. Food waste quantification and characterization as a measure towards effective food waste management in university. IOP Conf. Ser. Mater. Sci. Eng. 2020, 743, 012041. [Google Scholar] [CrossRef]

- Adhikari, B.K.; Barrington, S.; Martinez, J.; King, S. Characterization of food waste and bulking agents for composting. Waste Manag. 2008, 28, 795–804. [Google Scholar] [CrossRef]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef]

- Jayathilake, N.; Aheeyar, M.; Wickramasinghe, N.; Bucatariu, C.; Drechsel, P. Case Studies on Food Waste Quantification, Characterization, and Identification of Prevention and Reduction Options in Colombo, Sri Lanka; FAO and IWMI: Rome, Italy, 2023. [Google Scholar] [CrossRef]

- ASTMD5231-92; Standard Test Method for Determination of the Composition of Unprocessed Municipal Solid Waste. ASTM International: West Conshohocken, PA, USA, 2016; p. 6.

- Hidalgo Crespo, J.A.; Soto, M.; Amaya-Rivas, J.L.; Borja-Mora, L.; Robles-Iglesias, R.; Banguera Arroyo, L.A. Towards a Circular Economy for Restaurant Waste in Guayaquil: Characterization and Energy Generation Potential. In Proceedings of the 9th International Conference on Energy and Environment Research, Porto, Portugal, 17–19 March 2023; Springer: Cham, Switzerland, 2023; pp. 537–545. [Google Scholar]

- Abd Alqader, A.; Hamad, J. Municipal solid waste composition determination supporting the integrated solid waste management in Gaza strip. Int. J. Environ. Sci. Dev. 2012, 3, 172. [Google Scholar] [CrossRef]

- Lebersorger, S.; Schneider, F. Discussion on the methodology for determining food waste in household waste composition studies. Waste Manag. 2011, 31, 1924–1933. [Google Scholar] [CrossRef]

- Bareille, N.; Gésan-Guiziou, G.; Foucras, G.; Coudurier, B.; Randriamampita, B.; Peyraud, J.-L.; Agabriel, J.; Redlingshofer, B. Les pertes alimentaires en filière laitière. Innov. Agron. 2015, 48, 143–160. [Google Scholar]

- den Boer, E.; Jędrczak, A.; Kowalski, Z.; Kulczycka, J.; Szpadt, R. A review of municipal solid waste composition and quantities in Poland. Waste Manag. 2010, 30, 369–377. [Google Scholar] [CrossRef] [PubMed]

- Duncan, T.V. Applications of nanotechnology in food packaging and food safety: Barrier materials, antimicrobials and sensors. J. Colloid Interface Sci. 2011, 363, 1–24. [Google Scholar] [CrossRef] [PubMed]

- Sarfraz, J.; Gulin-Sarfraz, T.; Nilsen-Nygaard, J.; Pettersen, M.K. Nanocomposites for food packaging applications: An overview. Nanomaterials 2020, 11, 10. [Google Scholar] [CrossRef] [PubMed]

- Milbrandt, A.; Zuboy, J.; Coney, K.; Badgett, A. Paper and cardboard waste in the United States: Geographic, market, and energy assessment. Waste Manag. Bull. 2024, 2, 21–28. [Google Scholar] [CrossRef]

- Saidan, M.N.; Drais, A.A.; Al-Manaseer, E. Solid waste composition analysis and recycling evaluation: Zaatari Syrian Refugees Camp, Jordan. Waste Manag. 2017, 61, 58–66. [Google Scholar] [CrossRef]

- Padmalatha, D.; Shresta, P. Impact of Recycling in a Glass Industry: A Project Management Study. Int. J. Soc. Sci. Res. 2016, 1, 50–61. [Google Scholar]

- Baek, C.R.; Kimg, H.D.; Jang, Y.-C. Exploring glass recycling: Trends, technologies, and future trajectories. Environ. Eng. Res. 2025, 30, 60–75. [Google Scholar] [CrossRef]

- Berman, H.; Shwom, R.; Cuite, C. Becoming FEW Conscious: A Conceptual Typology of Household Behavior Change Interventions Targeting the Food-Energy-Water (FEW) Nexus. Sustainability 2019, 11, 5034. [Google Scholar] [CrossRef]

- Knezevic, B.; Kurnoga, N.; Anic, I.-D. Typology of university students regarding attitudes towards food waste. Br. Food J. 2019, 121, 2578–2591. [Google Scholar] [CrossRef]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Biological treatment of organic materials for energy and nutrients production—Anaerobic digestion and composting. Adv. Bioenergy 2019, 4, 121–181. [Google Scholar]

- Mata-Alvarez, J.; Dosta, J.; Romero-Güiza, M.; Fonoll, X.; Peces, M.; Astals, S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar]

- Yang, L.; Ge, X.; Wan, C.; Yu, F.; Li, Y. Progress and perspectives in converting biogas to transportation fuels. Renew. Sustain. Energy Rev. 2014, 40, 1133–1152. [Google Scholar]

- Lucera, A.; Costa, C.; Marinelli, V.; Saccotelli, M.A.; Del Nobile, M.A.; Conte, A. Fruit and Vegetable By-Products to Fortify Spreadable Cheese. Antioxidants 2018, 7, 61. [Google Scholar] [CrossRef] [PubMed]

- Ardolino, F.; Parrillo, F.; Arena, U. Biowaste-to-biomethane or biowaste-to-energy? An LCA study on anaerobic digestion of organic waste. J. Clean. Prod. 2018, 174, 462–476. [Google Scholar]

- Salas-Millán, J.-Á.; Aznar, A.; Conesa, E.; Conesa-Bueno, A.; Aguayo, E. Functional food obtained from fermentation of broccoli by-products (stalk): Metagenomics profile and glucosinolate and phenolic compounds characterization by LC-ESI-QqQ-MS/MS. LWT 2022, 169, 113915. [Google Scholar] [CrossRef]

- Aneja, S.; Kalakoti, S.; Parihar, D. Urgent Need of Plastic Waste Management: A Review. Res. Rev. Int. J. Multidiscip. 2024, 9, 114–124. [Google Scholar]

- Naik, B.; Kumar, V.; Rizwanuddin, S.; Chauhan, M.; Gupta, A.K.; Rustagi, S.; Kumar, V.; Gupta, S. Agro-industrial waste: A cost-effective and eco-friendly substrate to produce amylase. Food Prod. Process. Nutr. 2023, 5, 30. [Google Scholar] [CrossRef]

- Siddiqui, J.; Pandey, G. A review of plastic waste management strategies. Int. Res. J. Environ. Sci. 2013, 2, 84–88. [Google Scholar]

- Osazee, I.T. Landfill in a sustainable waste disposal. Eur. J. Environ. Earth Sci. 2021, 2, 67–74. [Google Scholar]

- Shareefdeen, Z.; ElGazar, A.T. Management of Plastic Wastes through Recent Advanced Pyrolysis Processes. Appl. Sci. 2024, 14, 6156. [Google Scholar] [CrossRef]

- Knauer, K.; Higginson, C.; Liang, Y.; Lee, M. Circular plastics technologies: Depolymerization of polymers into parent monomers. Phys. Sci. Rev. 2024, 9, 2499–2524. [Google Scholar]

- Caldeira, C.; Vlysidis, A.; Fiore, G.; De Laurentiis, V.; Vignali, G.; Sala, S. Sustainability of food waste biorefinery: A review on valorisation pathways, techno-economic constraints, and environmental assessment. Bioresour. Technol. 2020, 312, 123575. [Google Scholar]

- Taherzadeh, M.J.; Wong, J.W.; Nelles, M.; He, P. Special issue on bioconversion of food wastes. Bioresour. Technol. 2018, 248, 1. [Google Scholar]

- Panou, A.; Karabagias, I.K. Migration and safety aspects of plastic food packaging materials: Need for reconsideration? Coatings 2024, 14, 168. [Google Scholar] [CrossRef]

| Weight | Organics (Kg) | Recyclables (Kg) | Disposable (Kg) | Total Waste (Kg) |

|---|---|---|---|---|

| W1 (Monday) | 209.26 | 62.20 | 52.52 | 323.98 |

| W2 (Tuesday) | 140.05 | 45.98 | 52.36 | 238.39 |

| W3 (Wenesday) | 141.28 | 41.86 | 48.89 | 232.03 |

| W4 (Thrusday) | 123.53 | 56.77 | 66.85 | 247.16 |

| W5 (Friday) | 81.34 | 47.31 | 44.78 | 173.43 |

| W6 (Saturday) | 107.18 | 38.45 | 45.97 | 191.60 |

| W7 (Sunday) | 127.74 | 64.01 | 83.61 | 275.36 |

| Variable | N | N* | Mean (kg) | Standard Error | Std. Dev. | Min (kg) | Median (kg) | Max (kg) |

|---|---|---|---|---|---|---|---|---|

| Organics (kg) | 7 | 0 | 132.9 | 14.9 | 39.6 | 81.3 | 127.7 | 209.3 |

| Recyclables (kg) | 7 | 0 | 50.94 | 3.80 | 10.07 | 38.45 | 47.31 | 64.01 |

| Disposable (kg) | 7 | 0 | 56.43 | 5.30 | 14.03 | 44.78 | 52.36 | 83.61 |

| Total Waste (kg) | 7 | 0 | 240.3 | 19.0 | 50.3 | 173.4 | 238.4 | 324.0 |

| Weight | Total Wase (Kg) | Average |

|---|---|---|

| DAY 1 | 323.98 | 24.92 |

| DAY 2 | 238.39 | 18.34 |

| DAY 3 | 232.03 | 17.85 |

| DAY 4 | 247.16 | 19.01 |

| DAY 5 | 173.43 | 13.34 |

| DAY 6 | 191.60 | 14.74 |

| DAY 7 | 275.36 | 21.18 |

| TOTAL | 1681.94 | 129.38 |

| Waste generation er capita | 18.48 | |

| Sample | Initial Weight (g) | Final Weight (g) | Dry Matter (%) | Moisture (%) |

|---|---|---|---|---|

| Vegetable FW | 1562 | 294 | 18.8 ± 0.5% | 81.2 ± 0.5% |

| Fruit FW | 1461 | 288 | 19.7 ± 0.6% | 80.3 ± 0.6% |

| Vegetable Protein FW | 13,434 | 579 | 4.3 ± 0.4% | 95.7 ± 0.4% |

| Animal Protein FW | 404 | 220 | 54.5 ± 0.7% | 45.5 ± 0.7% |

| Average | - | - | 24.3 ± 0.8% | 75.7 ± 0.8% |

| Parameter | Vegetable FW | Fruit FW | Vegetable Protein FW | Animal Protein FW |

|---|---|---|---|---|

| Fat (%) | 3.77 ± 0.10 | 7.56 ± 0.20 | 9.92 ± 0.25 | 17.65 ± 0.50 |

| pH | 5.63 ± 0.05 | 4.32 ± 0.10 | 5.32 ± 0.08 | 6.42 ± 0.12 |

| Conductivity (mS/cm) | 7.62 ± 0.15 | 7.22 ± 0.20 | 7.56 ± 0.18 | 4.51 ± 0.12 |

| Ash (%) | 91.00 ± 0.50 | 91.08 ± 0.45 | 94.78 ± 0.55 | 75.06 ± 0.80 |

| Real density (g/mL) | 0.353 ± 0.015 | 0.273 ± 0.020 | 0.350 ± 0.018 | 0.304 ± 0.025 |

| Bulk density (g/mL) | 0.372 ± 0.020 | 0.314 ± 0.025 | 0.378 ± 0.022 | 0.379 ± 0.030 |

| Fiber (%) | 3.55 ± 0.10 | 14.49 ± 0.25 | 11.79 ± 0.30 | 0.97 ± 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saeteros-Hernández, A.; Chalen-Moreano, F.; Zurita-Gallegos, R.; Badillo-Arévalo, P.; Granizo-Villacres, M.; Cevallos-Hermida, C.; Viteri-Nuñez, D. Quantitative and Qualitative Characterization of Food Waste for Circular Economy Strategies in the Restaurant Sector of Riobamba, Ecuador: A Case Study Approach. Biomass 2025, 5, 18. https://doi.org/10.3390/biomass5020018

Saeteros-Hernández A, Chalen-Moreano F, Zurita-Gallegos R, Badillo-Arévalo P, Granizo-Villacres M, Cevallos-Hermida C, Viteri-Nuñez D. Quantitative and Qualitative Characterization of Food Waste for Circular Economy Strategies in the Restaurant Sector of Riobamba, Ecuador: A Case Study Approach. Biomass. 2025; 5(2):18. https://doi.org/10.3390/biomass5020018

Chicago/Turabian StyleSaeteros-Hernández, Angélica, Francisco Chalen-Moreano, Ronald Zurita-Gallegos, Pedro Badillo-Arévalo, Mayra Granizo-Villacres, Carlos Cevallos-Hermida, and Diego Viteri-Nuñez. 2025. "Quantitative and Qualitative Characterization of Food Waste for Circular Economy Strategies in the Restaurant Sector of Riobamba, Ecuador: A Case Study Approach" Biomass 5, no. 2: 18. https://doi.org/10.3390/biomass5020018

APA StyleSaeteros-Hernández, A., Chalen-Moreano, F., Zurita-Gallegos, R., Badillo-Arévalo, P., Granizo-Villacres, M., Cevallos-Hermida, C., & Viteri-Nuñez, D. (2025). Quantitative and Qualitative Characterization of Food Waste for Circular Economy Strategies in the Restaurant Sector of Riobamba, Ecuador: A Case Study Approach. Biomass, 5(2), 18. https://doi.org/10.3390/biomass5020018