Abstract

Sustainable agricultural practices are essential to address global food security challenges while minimizing environmental impacts. This study aimed to evaluate integrated farming systems with varying levels of integration (from lower to higher)—maize monoculture + livestock (MM), maize + cover crop + mixed prairie + livestock (MCP), and maize + red clover + mixed prairie + livestock (MRP)—to assess their contributions to circularity and sustainability. The research examined biomass and protein production, nutrient cycling, energy use, food needs covered, and workload over two cropping cycles. The findings revealed that highly integrated systems (MRP and MCP) significantly enhance biomass production, energy efficiency, and nutrient recycling compared to the MM system (p < 0.05). MRP produced 4 times more biomass than MM (9.4 t ha−1), while MCP achieved a 0.99 Nitrogen Recycling Index compared with 0.38 in MM, underscoring the benefits of grazing and increasing agrobiodiversity. Integrated systems also improved soil health (+17.4% organic matter in MRP and MCP, +91.5% nitrogen in MCP), reduced dependency on synthetic inputs, and boosted protein production (animal-derived protein in MRP and MCP = 395.4 kg, MM = 73.7 kg), thus meeting food needs for large populations. However, they required increased labor and technical expertise, presenting adoption barriers for smallholders. The synergy between agroecological practices and circularity offers a pathway to sustainable intensification, fostering economic, environmental, and social resilience. In this way, the results highlighted the potential of integrated farming systems to transform agricultural systems.

1. Introduction

The increasing pressure to produce food sustainably calls for transformative changes in agricultural systems. Agricultural systems are at the forefront of the global challenge to ensure food security while conserving natural resources and reducing environmental degradation. In this context, the transition to sustainable agriculture is critical in addressing these challenges but requires redesigning agricultural systems to achieve a sustainable intensification [1,2].

Unlike conventional linear systems, circular farming systems focus on creating closed-loop systems where resources are reused and recycled, reducing waste and dependency on external inputs [3,4]. These principles hold a particular promise for integrated systems (ISs), where diverse agricultural activities coexist and interact at varying levels, creating opportunities to mitigate environmental impacts by leveraging the synergies between their components.

Integration in ISs varies across low, medium, and high levels, depending on nutrient, biomass, and energy flows, as well as socioeconomic factors. Low integration relies on external inputs with minimal nutrient cycling and interaction between crops and livestock, offering simple management but missing efficiency gains. Medium integration incorporates manure use, crop residue recycling, and partial energy coordination, improving soil health and economic resilience but requiring more management. High integration maximizes resource efficiency with minimal external inputs, optimized energy use, and diversified markets, providing environmental and economic benefits but demanding advanced knowledge, high labor, and significant investment.

ISs inherently lend themselves to circularity by facilitating the internal cycling of nutrients; for instance, livestock manure can be used as organic fertilizer for crops, while crop residues can serve as feed for livestock, creating a closed-loop nutrient cycle [4,5]. The interconnectedness reduces the reliance on synthetic inputs and minimizes waste and production costs, contributing to greater sustainability and circularity in agricultural production, which can also help reduce stakeholders’ vulnerability to the market and price fluctuations [6,7]. Beyond resource use efficiency, diverse investigations have reported the benefits provided by IS, most of them in ecological and economic dimensions of the systems. These systems promote agrobiodiversity and ecological resilience, which are critical for pest control, pollination, and overall ecosystem stability [6,8,9,10]. The inclusion of grazing improves soil quality and crop yield [11]. Introduction of leguminous plants intercropped with grass provides quality and quantity residues, and biological fixation of N has a positive effect in cash crop yield and biodiversity [12]. These practices also enhance soil quality and nutrient content by increasing organic matter [13,14] and carbon sequestration, reducing soil erosion, and improving water retention. ISs also improve biological nitrogen fixation [15], nutrient cycling, microbial activity, and nutrient use efficiency, which reduces the need for synthetic fertilizers and improves the sustainability of the system.

These systems also have a significant impact on biomass production and utilization. ISs with a system-level fertilization approach increase forage production and stocking rate [16]. Furthermore, the diversification of plant species favors microbial activity, which also contributes to biomass production, for instance, rotation with grasses and leguminous, together with grazing, increases the totals of fungi, bacteria, enzymatic activity, and carbon reserves of the microbial biomass [17]. Grazing is an effective way to transform biomass for animal feed into nutritious and available food for human consumption [16]. In this way, the diversification of ISs can improve food security, both directly and indirectly, by addressing household food availability but also playing a relevant role in improving the livelihoods of producers, especially under the effect of adverse external factors [18]. Diversified income and production help generate daily and periodic income, increase resilience, and can provide sources of employment [6]. As the level of integration increases, biomass utilization can expand beyond closing nutrient and material loops, to include the generation of useful energy for the farm through its transformation into biogas and electricity [19].

Despite the benefits reported, the realization of IS as a strategy to increase circularity and sustainability in agriculture faces several barriers that hinder their widespread adoption. On the one hand, the level of integration directly affects the labor requirements and distribution on the farm [20,21]. Activities such as harvesting, manure collection, and livestock management are time-consuming and, in some cases, need technical knowledge and additional economic resources for their successful implementation [22]. These factors can pose significant obstacles, particularly for smallholder farmers with limited access to capital and technical expertise.

On the other hand, current research often offers a fragmented view of these systems. Many studies tend to focus narrowly on individual components, such as soil properties [13,17,23,24,25,26,27], emissions [28,29] or productivity-related variables such as yield, forage quality, grazing effects, and weight gain [16,30,31]. These studies fail to consider the interconnectedness of crop and livestock components within an IS, resulting in a lack of holistic understanding. Furthermore, most of the studies are focused on national or sectoral scales [3,4], which overlooks the variability of individual farms. Current evaluation frameworks frequently focus on isolated aspects, such as nutrient cycling [32,33] or energy use [34], while neglecting the complex interplay between different farm functions.

Agriculture is highly context-dependent, and factors such as soil type, climate variability, and available resources can significantly influence the outcomes of integrated farming systems. Additionally, some existing policies may favor conventional specialized farming over IS, while unclear land tenure can discourage the long-term investment required to adopt the practices required. Finally, cultural resistance, insufficient support services, and social inequality further complicate adoption. Overcoming these barriers requires targeted policies, financial support, and education to ensure the success of IS.

In this context, the present paper aims to compare circularity in integrated farming systems with different levels of integration through key indicators including biomass production, nutrient cycling, energy use, external input dependence, food needs covered by the systems, protein production, and the workload required to sustain farming operations.

2. Materials and Methods

This research was conducted using a transdisciplinary approach in collaboration with a local farm in the municipality of Ahuazotepec, Mexico, during 2021 and 2022 cropping cycles. The study region is representative of rural communities in the mountainous areas of the Sierra Norte of Puebla and the high valleys of Mexico. Agriculture is predominantly characterized by conventional maize monoculture system, with some farmers raising confined or semi-confined livestock, including sheep, cattle, poultry, and pigs [35].

Within the municipality, the community of Laguna Seca (20°01′51″ N and 98°07′15″ W), a rural area with an altitude of 2268 masl and climate classified as temperate humid C (m) (Köppen climatic classification) was the location of the participating farm. In 2021 and 2022, the mean temperature was 14.1 and 13.5 °C, and the accumulated rainfall was 1050.1 and 851.8 mm, respectively; these values were obtained with data registered on the farm using a Vantage VUE station (Davis Instruments, Hayward, CA, USA). The soils, classified as mid-textured Andisols, were slightly acidic, with an average pH of 6.18 and an organic matter content ranging from 3 to 5% [36].

For the last 50 years, the farm has been cultivated with mixed prairies for direct grazing, maize landraces, gardening, and grains such as oat, barley, and rye. Fertilization of the agricultural fields is carried out by composted manure application, directly by grazing animal’s depositions or indirectly by spreading barn-collected manure. Livestock production consists of grazed sheep and cattle, and a semi-intensive ovine feedlot production. The farm has been described previously by [37].

2.1. Experimental Design and Farming Systems Description

Three treatments were established and assessed on the farm—maize + cover crop + mixed prairie (MCP), maize + red clover + mixed prairie (MRP), and maize monoculture (MM)—to represent integrated farming systems with varying levels of integration between crop and livestock elements (Table 1). The treatments were arranged in a randomized complete block design with three replicates each. Each experimental unit covered 1000 m2, with a net plot area of 900 m2 used for random sampling of all crops. Statistical analysis was conducted using ANOVA to evaluate treatment effects. Normality and homogeneity of variances were assessed to validate model assumptions. Differences among treatments were considered significant at p < 0.05, and the means were compared using Tukey’s test (95% confidence level). All statistical procedures were performed using Minitab 20.3 (Minitab Inc., State College, PA, USA).

Table 1.

Treatment description.

Crops and Livestock Description

Crops: In the case of maize, a local blackish blue landrace was sown in all systems at 62,500 plants per hectare on 20 May 2021, and on 25 May 2022, for the second cycle only in MM. Fertilized 20 days after sow, with 7.5 tons per hectare of composted ovine manure obtained from the farm. Maize was harvested six months later in both cycles. Red clover was broadcast seeded (8 kg ha−1) after maize in MRP on 20 May 2021 and first harvested six months later. The cover crop (legume–gram–grain mix) was sown in MCP (24 December 2022) at 60 kg ha−1 and harvested after four months. The mixed prairie included ryegrass (10 kg ha−1) and red clover (2.5 kg ha−1 only in MCP), with grazing cycles from April to December 2022. All fields were ploughed before maize sowing and lightly tilled after harvest for cover crops or prairie establishment. Irrigation (13 cm ha−1) was applied to mixed prairies from November to May, with rainfall covering the rest of the water needs. For forage and prairie yield and composition, six quadrants of 0.36 m2 were manually harvested in each plot.

Livestock: In MCP and MRP, cattle were grazed from April to December for both meat and milk production. Meat production was assessed using eight-month-old males (332 ± 16 kg), while four-year-old cows (450–550 kg) were milked once daily. Cattle were weighed at the start and end of the grazing period. In addition to grazing, lactating cows received 2 kg of maize grain daily. To ensure standardized grazing management across replicates, stocking rates, grazing duration, and pasture rest periods were kept consistent. Cattle stocking density was adjusted based on forage availability. The same rotation schedule was applied to all replicates, ensuring that each paddock received equal grazing and recovery periods throughout the study.

2.2. Soil and Cattle Manure Characterization

Soil nutrient content: Soil cores (30 cm) were extracted from each treatment plot before the start of the experiment and at the end of the crop cycles. The measured parameters were bulk density with the disturbed soil method [38], soil organic matter (SOM), soil available nitrogen (NO3− and NH4+), available phosphorus (PO4+3), and available potassium, and methods were described previously in [36]. Manure samples were randomly taken throughout the study period to quantify organic matter and nutrient content. Bulk density was determined with the probe method [38]. Nitrogen, phosphorus, and potassium methods were described in [36]. Organic matter was determined by ignition [39].

2.3. Circularity Assessment of the Farming Systems

Circularity assessment was conducted using seven indicators that enabled a comprehensive understanding of the performance of treatments from a multidimensional perspective, including economic, environmental, and social factors. Biomass production serves as an indicator of primary productivity, while energy efficiency and distribution assess energy flows. Nutrient cycling measures how nutrients are used in each process. Additionally, workload, the percentage of food needs covered, and the amount of protein generated were analyzed to reflect the system’s contribution to food security and producer’s well-being.

2.3.1. Biomass Production

Biomass production for food (BPFood), maize grain yield, milk, and meat production were considered. Grain yield (GY) was calculated considering 12% moisture content and using Equation (1):

where FW = cob field weight in kg, %DM = dry matter percentage, %G = percentage of grain, and 8800 = factor to adjust the grain yield to 12% humidity per hectare. For the MM farming system, grain biomass includes the sum of the yield of 2021 and 2022 production cycles, while for the MRP and MCP systems, grain biomass was obtained only in the 2021 cycle.

GY = (FW × %DM × %G)/8800

For each IS treatment, the maximum carrying capacity was estimated, defined as the load that can sustain a 3% live weight consumption rate, considering a standard animal unit of 450 kg. By multiplying these values, the intake per animal unit was determined. The maximum carrying capacity was calculated based on a 365-day cycle and the system’s yield of animal feed (stover, forage, and pasture).

Milk production in liters was quantified daily and summarized at the end of the cycle for each treatment. The milking period registered was 42 weeks long. Meat production was estimated and summarized at the end of the cycle for each farming system. This value was obtained by subtracting initial live weight from final live weight, and the result was multiplied by the maximum carrying capacity of the system to obtain the maximum production.

Biomass production for feed (BPFeed): The yield of maize stover and forage were estimated from field data. For maize, two central rows of 10 m were manually harvested to calculate the stover yield in each plot. For red clover, cover crop, and mixed prairie, six quadrants of 0.36 m2 were manually harvested to calculate the forage yield and composition in each plot. For mixed prairie, the forage yield was estimated in each grazing period and summarized at the end of the cycle.

Biomass production for energy (BPEnergy) of manure: To estimate the daily bovine depositions, during each grazing period and replicate, the number of dungs (ND) were registered on a daily basis for two animal units (one animal unit is a cow of 450 kg). Then, seven random samples were collected with a shovel and weighed. To obtain the dry matter weight (DM), those samples were oven dried for 48 h at 55 °C. The daily dry matter production per bovine (DMP) was calculated using Equation (2):

where DMP = daily dry matter manure production per animal in kg, ND = number of dungs, DM = dry matter weight of the sample in kg, 2 factor to adjust the manure per animal. The total manure production was converted to energetic equivalents (MJ) for each farming system and were multiplied by the maximum carrying capacity of the system to obtain the maximum production.

DMP = ND*DM/2

2.3.2. Energy Efficiency, Energy Distribution, and Workload

Energy efficiency (EE) per system was estimated as in [35], using the energy equivalents of the inputs required in the production process, and the outputs (grain, stover, forage, milk, meat, and manure) obtained in each system (Table 2).

Table 2.

Energy equivalence of inputs and outputs in the study.

To evaluate the distribution of energy within the farming systems under study, the energy inputs were classified into two categories: renewable energy (RE), which included seeds, labor, and manure; and non-renewable energy (NRE), encompassing fuel, machinery, and electricity.

To calculate the workload of each integration level treatment, the time required for each task performed in crop and livestock production processes was quantified. These data were classified into vigorous work and light work. Additionally, the percentage of labor provided by the producer was calculated. Finally, the total workload for each treatment was determined.

2.3.3. Nutrient Cycling

Nutrient recycling was analyzed using six indicators: Nitrogen Recycling Index (RIN), Phosphorus Recycling Index (RIP), Potassium Recycling Index (RIK), Nitrogen Use Efficiency (NUE), and exported nitrogen (EN). For this, the nutrients contained in the soil, manure, and forage were calculated for each IS treatment based on laboratory analysis results, except for the phosphorus and potassium in forage, whose values were estimated using the references mentioned in Table 2. These values were used to calculate the Recycling Index (RI), which is the ratio of the nutrient in the system (final soil nutrient + manure produced nutrient) to the nutrient consumed (initial soil nutrient + nutrient in manure applied as fertilizer). For nitrogen, the nutrient used in the greatest quantity in production, in addition to the RIN, the efficiency (NUE) and exported nitrogen (EN) were determined with Equations (3) and (4), respectively.

where NUE = Nitrogen Use Efficiency, kg of Nproduced = kilograms of nitrogen produced by the system in the form of grain, forage, meat, milk and manure, and kg of Nconsumed = kilograms of nitrogen consumed, considering the initial soil content and the nitrogen in ovine manure applied as fertilizer.

where EN = nitrogen exported by the system in kg, Ngrain = kilograms of nitrogen in maize grain, Nmilk = kilograms of nitrogen in milk, and Nmeat = kilograms of nitrogen in meat.

NUE = kg of Nproduced/kg of Nconsumed

EN = Ngrain + Nmilk + Nmeat

To estimate the nitrogen content in the livestock products, the protein content of the product was divided by 6.38 for milk and 6.25 for the other products.

2.3.4. Percentage of Food Needs Covered by the Farming System

The reference values used for annual per capita consumption were 359.9 kg of maize grain, 139.9 L of milk [45], and 74 kg of meat [46]. To determine the percentage of food needs, the amount of each product that the system could supply based on the obtained yields was estimated. The values were projected over a two-year period to account for the duration of two production cycles. For the meat produced, only the weight gain achieved with the biomass generated by the system was considered.

2.3.5. Protein Produced in the Farming System

To determine the amount of protein produced from maize, cover crops, and mixed prairies, the nitrogen content was quantified using the Kjeldahl method. This value was multiplied by 6.25 to obtain the percentage of protein in each product [47]. For beef, a protein content of 25.9 g per 100 g of meat was considered [48], and for milk, 3.5% [49]. These values were multiplied by the production obtained in each system. To calculate the kilograms of protein produced per hectare in each farming system, the protein percentage was multiplied by the yield. Liters of milk were converted to kilograms of milk by multiplying the number of liters produced by 1.03 [50].

3. Results

3.1. Soill and Cattle Manure Characterization

There were no differences between treatments in nutrient content or bulk density at the end of the cropping cycles (Table 3). However, the organic matter percentage changed across the levels of integration studied, showing significant differences at the end of the two cycles (p = 0.028, Table 3). MRP recorded a 17.4% increase in organic matter percentage compared to the initial value, while the MM system showed the greatest decrease (−64%). Regarding nutrient content, MCP generated notable increases in nitrogen (+91.5%) and phosphorus (+54.8%) compared to the initial values (Table 3). In MM, nitrogen content increased by 14% compared to the initial value (Table 3). Regarding manure production, the treatments had an average nutrient content of 28.3 g kg−1 of nitrogen, 5.9 g kg−1 of phosphorus, and 9.8 g kg−1 of potassium. Its bulk density is 0.3 g cm−3, with 79.2% organic matter and a pH of 8.05.

Table 3.

Soil properties in farming system treatments with different levels of integration, 2021 and 2022 cropping cycles.

3.2. Biomass for Food and Feed

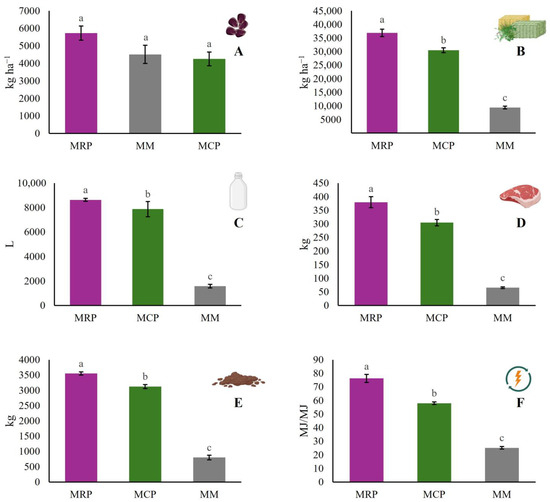

Biomass produced for human consumption consists of maize grain, as well as the meat and milk obtained from the livestock subsystem. The results are summarized in Figure 1. Although there were no significant differences in maize grain production among the farming systems (p = 0.114), MRP generated 27% more grain than the monoculture system (MM), while the MCP system produced 259 kg less than the latter (Figure 1A).

Figure 1.

Biomass production and energy efficiency in farming system treatments with different levels of integration, 2021 and 2022 spring–summer cycles. (A) Biomass for food: maize grain, maize monoculture (MM) grain is the sum of two cycles, while for MRP and MCP, it is the grain for one cycle. (B) Biomass for feed: maize stover + cover crop or red clover + mixed prairie. (C) Biomass for food: milk production. (D) Biomass for food: meat production. (E) Biomass for energy: manure production. (F) Energy efficiency: Energy produced/Energy consumed. MRP: maize + red clover + mixed prairie; MCP: maize + cover crop + mixed prairie; MM: maize monoculture. Means that do not share a letter are significantly different (Tukey test, α = 0.05).

Milk and meat production showed differences among the treatments (p < 0.05, Figure 1C,D). A monoculture-based system (MM) generated an average production of 66.7 kg of meat and 1574.1 L of milk, while the highly integrated systems (MRP and MCP) generated an average increase of 275.5 kg and 6677.7 L more of meat and milk, respectively (Figure 1C,D).

Regarding the production of biomass for animal feed, the treatments representing systems with higher integration level (MRP and MCP) significantly increased the values obtained by incorporating two additional crops alongside maize (p < 0.05, Figure 1B). The intercrop (red clover), cover crops, and mixed prairies in MRP and MCP-based systems had 3 to 4 times the forage production of the MM system (Figure 1B).

The biomass for energy (BPEnergy), which consists of the manure produced in each treatment, showed significant differences among integration levels (p < 0.05, Figure 1E). MRP generated 3.6 tons (t) of composted manure dry matter, while MCP produced 3.1 t, contrasting with the low-integration system (MM), which only produced 0.8 t (Figure 1E).

3.3. Energy Efficiency, Distribution, and Workload

The farming systems with higher integration levels (MRP and MCP) showed greater energy efficiency than the MM system (EE = 25.1), producing 75.3 and 57 MJ per each MJ consumed, respectively (p < 0.05, Figure 1F). These treatments also used between 246.8 and 998.9 MJ more than the MM system due to the additional energy requirements for grazing and milking (Table 4). In the treatments studied, most of the energy consumption was attributed to the use of fossil fuels, representing between 55 and 59% of the total energy requirements in the systems (Table 4). On average, non-renewable energy used represented 74.9% of the energy consumed in the MM system, while for the MRP and MCP systems, the percentages were 75.5 and 70.6%, respectively (Table 4).

Table 4.

Energy consumption in farming system treatments with different levels of integration, 2021 and 2022 spring–summer cycles.

The MCP system showed the highest use of renewable energy among the evaluated systems due to the diversity of crop species (Table 4). Regarding the origin of the energy inputs, the majority of inputs were considered external to the evaluated management systems (Table 4), with only manure (fertilizer), landrace maize (seed), and labor being considered as produced within the borders of the systems.

Regarding labor, it was observed that the workload increased proportionally with the degree of integration of the systems. In the low integration treatment (MM), a total of 449 h of work are required for production in two cycles, while in the MCP and MRP, this requirement increased to 647 and 720.5 h, respectively. In the MM system, vigorous human labor represents 36%, while in the MRP and MCP systems, this value is reduced to 8 and 9%, respectively. Considering that in all three studied systems, maize harvest tasks are carried out with external labor, the producer contributed with 17.8% of the labor in the MM system, while in the MRP and MCP systems, this labor covered 44% of the work.

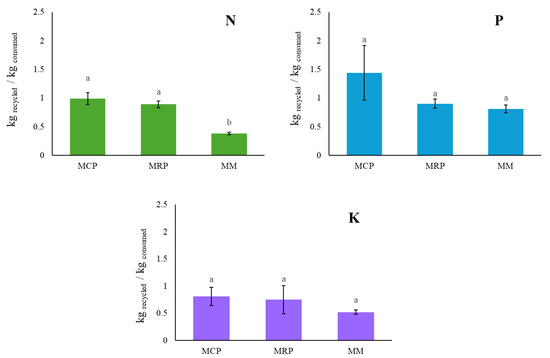

3.4. Nutrient Use and Cycling

The integration level treatments showed differences in the Nitrogen Recycling Index (RIN) (p = 0.002, Figure 2), with MCP having the highest nutrient recycling index of the group (RIN = 0.99, RIP = 1.44, RIK = 0.81). In contrast, MRP only recycled 0.89 kg of nitrogen, 0.9 kg of phosphorus, and 0.75 kg of potassium for each kilogram of nutrient consumed, while the MM system recycled 0.38, 0.81, and 0.52 kg of nitrogen, phosphorus, and potassium, respectively (Figure 2).

Figure 2.

Recycling index of nitrogen (N), phosphorus (P), and potassium (K) in farming system treatment with different levels of integration, 2021 and 2022 spring–summer cycles. MRP: maize + red clover + mixed prairie; MCP: maize + cover crop + mixed prairie, MM: maize monoculture. Means that do not share a letter are significantly different (Tukey test, α = 0.05).

Nitrogen Use Efficiency (NUE) and exported nitrogen (EN) varied between farming systems (p < 0.05). Highly integrated systems, MCP and MRP, had higher NUE, producing between 4.2 and 5.9 kg per kg consumed, while the MM system produced only 0.3 kg (Table 5). These treatments also allowed the export of 31.6 and 52.6 kg more nitrogen than the MM system (Table 5).

Table 5.

Circularity indicators in farming system treatments with different levels of integration, 2021 and 2022 spring–summer cycles.

3.5. Food Needs Covered by Production

The amount of maize grain produced in the MM and MCP systems is sufficient to meet the per capita consumption of six people for two years, while the MRP system produced enough grain to cover the needs of eight persons in the same period. Considering a family of four members, the management systems would cover 100% of the grain needs and provide between 1.6 and 2.8 tons that could be used for sale or animal feed. Regarding animal-derived products, the MRP and MCP systems provided enough milk to cover the needs of 31 and 28 people over two years, respectively. The MM system only generated enough milk to meet the needs of six people. Meat production, which refers solely to the weight gain obtained from forage and maize stover production in each management system, is enough to sustain the meat consumption of 2 and 2.5 people in the MCP and MRP systems, respectively. In the MM system, meat production only covers the consumption of 0.4 people.

3.6. Protein Produced by Farming Systems

The total production of protein was different between the evaluated farming systems (p < 0.05). Highly integrated systems produced the highest protein yields, with 4.9 t ha−1 in MCP and 4.1 t ha−1 in MRP, while the MM system produced one ton per hectare (Table 5). These differences were caused, first, by the additional production of protein for animal feed (maize stover, cover crop or red clover, and mixed prairies), i.e., forage (Table 5), given that all three systems produced similar amounts of protein from maize grain (p = 0.545). Secondly, high integration systems produced more animal-derived protein than MM, with milk representing the major contribution for this parameter in all three systems (Table 5). MRP produced more milk and meat protein than MCP, but the difference was statistically significant only for meat production (Table 5). MM consistently produced the lowest protein yields, with only 73.7 kg ha−1 of total animal protein.

4. Discussion

4.1. Soil Properties

The results demonstrated positive impact of integration level on soil improvement and conservation. The MRP system increased soil organic matter, while the MCP system showed higher nitrogen and phosphorus content (Table 3), highlighting the role of manure fertilization [23] and the integration of maize with red clover, cover crops, mixed prairies, and livestock. These practices enhance soil organic matter, fertility, and moisture retention, as supported by previous studies [14,32]. Vegetative cover reduces erosion effects and improves soil quality [51] while also positively influencing soil temperature and moisture, which benefits crop yields [25,52]. Additionally, increasing agrobiodiversity, especially with forage crops, enhances soil microbiology and yields [11]. Legumes in the MCP and MRP systems improve nitrogen fixation and the quantity and quality of plant residues, consistent with previous findings [12]. In contrast, the less integrated MM treatment lost 64% of organic matter, consistent with observations on monocropping systems [13]. This underscores the importance of diversified cropping and grazing, alongside manure fertilization, to maintain soil quality and productivity.

4.2. Biomass Production for Food and Feed

The increase in biomass production observed in the evaluated systems can be attributed to practices that enhance nutrient recycling and agrobiodiversity. The level of system integration also plays a crucial role in boosting biomass output (Figure 1). While low-integration systems like MM utilize residues from one system as inputs for another, promoting food production and nutrient recycling, these practices alone are insufficient to significantly improve productivity. In contrast, highly integrated systems (MCP and MRP) achieve grain production in a single crop cycle, allowing for the cultivation of additional crops in the same area throughout the year [5,6,33].

Contrary to some studies suggesting that integrated systems are less productive than specialized ones [53,54,55], our findings indicate that integration can reduce resource competition for producing human and animal food, thereby increasing productivity. This is particularly important, as resource competition is often cited as a limitation for implementing such systems [19,30]. For instance, the MRP system produced 3.9 times more biomass for animal feed than the MM system and 20% more than the MCP system (Figure 1B). It also increased the system’s stoking rate in one to three animal units compared to the MCP and MM systems, respectively, aligning with reports by [31] who observed a 43% increase in stoking rate compared to monocropping.

The higher biomass yield for animal feed in integrated systems can be explained by the inclusion of additional crops alongside maize, the benefits of legumes in rotations and intercropping (for nitrogen fixation and protein production), and grazing, which enhances organic matter incorporation and nutrient recycling through dung and urine deposition. These practices suggest that increasing agrobiodiversity with legumes and grasses, combined with circular fertilization strategies using manure, significantly improves both the quantity and quality of biomass produced [25,56], as well as animal weight gain and stocking rates [31,57].

The level of system integration significantly affects biomass production for human consumption, particularly meat and milk production (Figure 1C,D). The MRP system produced 5.8 times more biomass than the MM system and 1.2 times more than the MCP system (Figure 1D). This difference is due to the greater availability and quality of forage in more integrated systems, which increases stocking rates and improves daily weight gain in animals [58,59]. Enhanced system integration also increases agrobiodiversity and resilience to adverse climatic and biological effects, such as reduced precipitation and pest outbreaks [2,8,10,60].

The amount of biomass for energy, in the form of manure, is directly related to the stocking rate of each system, with differences similar to those observed in biomass for animal feed. Specifically, the MRP system produced 4.4 times more manure than the MM system and 1.1 times more than the MCP system (Figure 1E). Manure, when used as fertilizer, positively impacts nutrient recycling, soil organic matter content [23,61], and crop yields due to higher nutrient availability [5,62]. Biomass production for energy can reduce dependence on external inputs, lower production costs, and contribute to greenhouse gas emission reduction [28,63,64]. The manure produced in the MRP system accounted for 87.7% of the amount applied as fertilizer to maize crops, compared to 77.2% in the MCP system and 19.8% in the MM system.

4.3. Energy and Workload

Transitioning from conventional, linear systems to integrated farming systems diversifies production processes, often requiring more labor or mechanization. In the evaluated systems, fossil fuel use for milking and land preparation constituted the largest energy expense (Table 4). Beyond using manure as fertilizer, leveraging it for energy generation is crucial for achieving sustainable and circular systems [4]. Notably, despite the higher crop diversity and animal stocking rates in more integrated systems (MRP and MCP), their non-renewable energy consumption was similar to the MM system. This can be attributed to optimized resource use through enhanced synergies between subsystems and reduced input requirements for co-production (e.g., forage for animal feed and manure for fertilization) [64].

The integration of systems, combined with agroecological and circular practices, significantly improved energy efficiency (EE). The MRP and MCP systems achieved EE values 2.8 to 8.5 times higher than conventional monocropping systems (EE = 9 MJ/MJ) reported by [36]. In the conventional system, the highest energy consumption came from non-renewable sources (chemical fertilizers, fuels, and agrochemicals), and the authors noted that replacing chemical fertilizers with manure or mixes of manure and agro-industrial residues can increase efficiency by 1.7 to 1.8 times. Although higher biodiversity in the systems increases the dependency on some external inputs (e.g., forage crop seeds), these additional crops—particularly those used for grazing—promote the sustainable intensification of livestock production in systems with a higher degree of integration [28]. The EE of the evaluated systems (Table 4, Figure 1F) highlighted the benefits of reducing non-renewable energy and external inputs, which would otherwise be required for fertilization and animal feed in conventional systems [64,65]. Additionally, the use of native maize seed varieties produced within the farm helps to reduce dependence on external inputs. In this way, integrating diverse crops and livestock can achieve a balance between the intensity of resource use for production and efficiency, further enhancing sustainability [14,29].

Integrated systems are inherently time and labor intensive [20,64,66], with the distribution of labor varying based on the level of system integration. Previous studies show that crop and manure management often account for the largest share of labor requirements [21]. This is consistent with findings for low-to-medium integrated systems (MM), where seasonal tasks like maize sowing and harvesting account for nearly 50% of total labor hours. While the average annual labor of 796 h per animal unit per year reported by [21] is comparable to the MCP and MRP systems, a significant shift in labor distribution was observed, with livestock management emerging as the most labor-intensive component. Certain activities in integrated systems demand considerable effort and more specialized knowledge [22]. Specifically, grazing and milking management requires the operation of equipment such as electric mobile fencing and mechanical milking machines. These findings highlight the dynamic nature of labor demands in integrated systems, which are shaped by the specific context and production goals of each system. Recognizing these variations is critical for optimizing labor allocation and enhancing the overall efficiency and sustainability of integrated and circular agricultural operations.

4.4. Nutrient Use and Cycling

Nutrient cycling was enhanced by increasing the level of integration. Grazing and the inclusion of additional crops alongside maize significantly enhances nutrient production and recycling [51]. These improvements are driven by increased biomass production within the systems [5], with the greatest benefits observed in highly integrated systems (MCP and MRP). Although biomass production varied significantly across the studied systems, a key finding is that the amount of nitrogen exported in the form of grain, meat, and milk is lower in more integrated systems (MCP = 12.2%, MRP = 17.1%) compared to the MM system (42.5%). Maize grain is the primary component of nitrogen export in all systems [5,33], accounting for an average of 47.9% in integrated systems but 83.1% in the MM system (Figure 1 and Figure 2, Table 5). This difference is due to the introduction of grazing in MRP and MCP systems, which increases nitrogen exports in meat (+8.2%) and milk (+27%) compared to the MM system [32,67].

In the MM system, exported nitrogen represents only 70.3% of the nitrogen applied via fertilization, whereas in the MRP system, this figure rises to 89.6%, aligning with findings by [33]. The inclusion of additional crops in MRP and MCP systems increases nitrogen reuse as animal feed by 525.9 to 683.5 kg, compared to only 77.8 kg from maize stover in the MM system. This not only improves nutrient use efficiency but also reduces emissions, a benefit not seen in non-integrated systems [14,55]. Between 43.8% (MM) and 74.7% (MRP and MCP) of the nitrogen remaining in the system after production cycles comes from manure, highlighting its importance in reducing dependence on chemical fertilizers, especially considering that more than 85% of the nitrogen consumed by animals is excreted in urine and feces [33], making manure a valuable resource for nutrient recycling, but also for carbon sequestration and crop yield improvement [23,28,68]. Manure fertilization and crop residues (maize stover) as feed results in cost reductions in fertilizer and livestock rations [23,69].

The selection of additional crops in MRP and MCP systems played a critical role in nutrient production [67], as plant composition changes the amount of nitrogen in forage [12]. The MRP system produced more biomass but 30% less nitrogen than the MCP system (683.5 kg), while the MM system, with maize monocropping, produced only 77.8 kg of nitrogen. These results indicated that the level of integration plays a key role in nutrient cycling [16,33], with grazing in systems with higher levels promoting nutrient recycling through forage production and animal excretions [62].

4.5. Proportion of Food Needs Covered by the System

In Mexico, food expenses account for 35.2% of average household spending, rising to 50% in low-income rural households, where cereals, meat, and milk make up 22.9%, 17.9%, and 10.8% of consumption, respectively [70]. The food produced within integrated systems can represent over a 50% reduction in household food expenses. Diversification in MCP and MRP systems increased grain and milk yields, providing additional economic benefits from surplus sales and reducing reliance on single crops, a hallmark of conventional systems [14]. Milk production offers a steady daily income, while grain and meat sales provide periodic revenue. To achieve these benefits, it is essential to include biomass production for animal feed within the systems [16]. While meat production was lower, it is important to note that only the weight gain from forage produced in the systems is reported, not the total final weight. Despite this limitation, MRP and MCP systems produce 3 to 5 times more meat than the MM system [22,58]. As mentioned, integrated systems have the potential to create employment opportunities, as they require continuous labor for activities related to production. This can help reduce migration to urban areas and resistance to adopting new practices [71].

4.6. Protein Produced in the Farming Systems

The differences in protein production among the farming systems highlight the positive impact of increasing integration through grazing and forage production (Table 5). This approach boosts the system’s stocking rate and reduces competition for natural resources, a common issue in systems where crop and livestock production are separated in specialized operations [5,64,65]. Producing animal protein within the system improves access to this essential nutrient, particularly in rural areas where it may be scarce or expensive. Grazing in MCP and MRP systems effectively converts plant biomass into highly nutritious and accessible food [16]. The inclusion of legumes in MCP and MRP systems further enhances protein production and crop yields, thanks to the biological nitrogen fixation provided by these species [12,15]. This demonstrates how integrated systems can optimize resource use while improving food security and nutritional outcomes.

5. Conclusions

This study demonstrates the potential of integrated circular farming systems as an effective strategy to improve productivity, sustainability, and food security, making them viable solutions to contemporary agricultural challenges.

Highly integrated systems (MRP, MCP) significantly outperformed the low-integration system (MM) in key indicators, enhancing biomass production for food and feed, nutrient recycling, soil health, and energy efficiency. This was due to the combined effects of grazing and increased plant biodiversity, as well as the production of manure (biomass for energy). However, in highly integrated systems, we observed the use of fossil fuels for tasks such as milking and sowing increased, emphasizing the need for renewable energy solutions to mitigate costs and environmental impacts.

In addition to ecological and economic benefits, the results showed that highly integrated systems increased the production of animal-derived protein, which means improved food sources for farming families, and the possibility of marketable surpluses that could supplement income. These systems also require more labor and technical expertise, which could create employment opportunities in rural areas, if sufficient training and labor optimization are available.

This study is not without limitations. Conducted on a single farm, it represents agricultural conditions that may not fully capture the variability of regional farming contexts, so the results may not be generalizable. Additionally, seasonal climatic variations could influence biomass production and nutrient cycling, potentially affecting the reproducibility of results in different environments. Future studies should expand to multiple locations to evaluate the broader applicability of these findings and include higher levels of integration where biomass is transformed into energy within the farm. Also, further research is needed to address adoption barriers, policy implications, and greenhouse gas emissions to assess the long-term viability of these systems.

Author Contributions

Conceptualization, M.D.-H., A.D.-H. and E.D.-H.; methodology, A.D.-H., E.D.-H., M.D.-H. and A.J.-V.; formal analysis, A.D.-H., E.D.-H., M.D.-H., A.J.-V., R.Z.-B. and C.H.-A.; investigation, A.D.-H., A.J.-V., M.D.-H. and E.D.-H.; resources, M.D.-H., R.Z.-B. and C.H.-A.; data curation A.D.-H., M.D.-H. and E.D.-H.; writing—original draft preparation, A.D.-H., A.J.-V., M.D.-H. and E.D.-H.; writing—review and editing, E.D.-H., M.D.-H., R.Z.-B. and C.H.-A., visualization, A.D.-H.; supervision, E.D.-H., M.D.-H., R.Z.-B. and C.H.-A., project administration, M.D.-H. and R.Z.-B.; funding acquisition, A.D.-H., E.D.-H., M.D.-H., R.Z.-B. and C.H.-A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by UNAM (Projects: FESC-CI 2454 and UNAM-DGAPA-PAPIME PE211224), IPN (Project: SIP20250607), and CONAHCYT-SECIHTI (Grants 1152947 and 534775).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors wish to thank the UNAM and IPN for providing institutional support for the study. The authors also wish to acknowledge the participant farmers in Ahuazotepec for their invaluable material and labor contributions to the field experiment.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Pretty, J. Intensification for Redesigned and Sustainable Agricultural Systems. Science 2018, 362, eaav0294. [Google Scholar] [CrossRef] [PubMed]

- Silvestri Szymczak, L.; de Faccio Carvalho, P.C.; Lurette, A.; de Moraes, A.; de Albuquerque Nunes, P.; Posselt, M.; Moulin, C.H. System Diversification and Grazing Management as Resilience-Enhancing Agricultural Practices: The Case of Crop-Livestock Integration. Agric. Syst. 2020, 184, 102904. [Google Scholar] [CrossRef]

- Basso, B.; Jones, J.W.; Antle, J.; Martinez-Feria, R.A.; Verma, B. Enabling Circularity in Grain Production Systems with Novel Technologies and Policy. Agric. Syst. 2021, 193, 103244. [Google Scholar]

- Koppelmäki, K.; Helenius, J.; Schulte, R.P.O. Nested Circularity in Food Systems: A Nordic Case Study on Connecting Biomass, Nutrient and Energy Flows from Field Scale to Continent. Resour. Conserv. Recycl. 2021, 164, 105218. [Google Scholar] [CrossRef]

- Koppelmäki, K.; Parviainen, T.; Virkkunen, E.; Winquist, E.; Schulte, R.P.O.; Helenius, J. Ecological Intensification by Integrating Biogas Production into Nutrient Cycling: Modeling the Case of Agroecological Symbiosis. Agric. Syst. 2019, 170, 39–48. [Google Scholar] [CrossRef]

- Paramesh, V.; Ravisankar, N.; Behera, U.K.; Arunachalam, V.; Kumar, P.; Solomon Rajkumar, R.; Dhar Misra, S.; Mohan Kumar, R.; Prusty, A.K.; Jacob, D.; et al. Integrated Farming System Approaches to Achieve Food and Nutritional Security for Enhancing Profitability, Employment, and Climate Resilience in India. Food Energy Secur. 2022, 11, e321. [Google Scholar] [CrossRef]

- St-Martin, A.; Vico, G.; Bergkvist, G.; Bommarco, R. Diverse Cropping Systems Enhanced Yield but Did Not Improve Yield Stability in a 52-Year Long Experiment. Agric. Ecosyst. Environ. 2017, 247, 337–342. [Google Scholar] [CrossRef]

- Hawes, C.; Alexander, C.J.; Begg, G.S.; Iannetta, P.P.M.; Karley, A.J.; Squire, G.R.; Young, M. Plant Responses to an Integrated Cropping System Designed to Maintain Yield Whilst Enhancing Soil Properties and Biodiversity. Agronomy 2018, 8, 229. [Google Scholar] [CrossRef]

- Roese, A.D.; Ribeiro Junior, P.J.; Porfírio-da-Silva, V.; De Mio, L.L.M. Sistema Agrosilvipastoril Aumenta Supressividade Ao Tombamento Da Soja Causado Por Rhizoctonia Solani e Altera a Densidade de Populações de Fusarium e Trichoderma. Acta Sci. Agron. 2018, 40, e35075. [Google Scholar] [CrossRef]

- Roese, A.D.; Vidal, G.S.; Zeviani, W.M.; de Moraes, A.; May De Mio, L.L. Agricultural Diversification Reduces the Survival Period of Sclerotinia Sclerotiorum Sclerotia. Eur. J. Plant Pathol. 2018, 151, 713–722. [Google Scholar] [CrossRef]

- De Camargo, T.A.; Luiz, L.G.; Pereira Pacheco, L.; Pires, G.C.; Gonçalves, E.C.; Jesus Franco, A.; Carbone Carneiro, M.A.; Souza, E.D. Plant Diversity and Cattle Grazing Affecting Soil and Crop Yield in Tropical Sandy Soils. Arch. Agron. Soil. Sci. 2023, 69, 2053–2064. [Google Scholar] [CrossRef]

- Dos Santos Laroca, J.; Mendes Andrade, S.; Castro, P.; Coutinho, P.; Pereira, P.; da Silva, F.; Wruck, F.; Carbone, C.; Santos, S.; Damacena, S. Soil Quality and Soybean Productivity in Crop-Livestock Integrated System in No-Tillage. Pesqui. Agropecu. Bras. 2018, 53, 1248–1258. [Google Scholar] [CrossRef]

- Martins, A.P.; Denardin, L.G.d.O.; Borin, J.B.M.; Carlos, F.S.; Barros, T.; Ozório, D.V.B.; Carmona, F.d.C.; Anghinoni, I.; Camargo, F.A.d.O.; Carvalho, P.C.d.F. Short-Term Impacts on Soil-Quality Assessment in Alternative Land Uses of Traditional Paddy Fields in Southern Brazil. Land Degrad. Dev. 2017, 28, 534–542. [Google Scholar] [CrossRef]

- Dos Reis, J.C.; Rodrigues, G.S.; de Barros, I.; Ribeiro Rodrigues, R.d.A.; Garrett, R.D.; Valentim, J.F.; Kamoi, M.Y.T.; Michetti, M.; Wruck, F.J.; Rodrigues-Filho, S.; et al. Integrated Crop-Livestock Systems: A Sustainable Land-Use Alternative for Food Production in the Brazilian Cerrado and Amazon. J. Clean. Prod. 2021, 283, 124580. [Google Scholar] [CrossRef]

- Belete, S.; Bezabih, M.; Abdulkadir, B.; Tolera, A.; Mekonnen, K.; Wolde-meskel, E. Inoculation and Phosphorus Fertilizer Improve Food-Feed Traits of Grain Legumes in Mixed Crop-Livestock Systems of Ethiopia. Agric. Ecosyst. Environ. 2019, 279, 58–64. [Google Scholar] [CrossRef]

- Duarte, G.; Batista, J.; Savian, J.; Pacheco, L.; Posselt, A.; Tiecher, T.; Aquino, L.; de Facio, P.; Bremm, C.; Carvalho, F.; et al. Integrated Crop-Livestock System with System Fertilization Approach Improves Food Production and Resource-Use Efficiency in Agricultural Lands. Agron. Sustain. Dev. 2020, 40, 39. [Google Scholar]

- Sousa, H.M.; Correa, A.R.; Silva, B.D.M.; Oliveira, S.D.S.; Campos, D.T.D.S.; Wruck, F.J. Dynamics of Soil Microbiological Attributes in Integrated Crop-Livestock Systems in the Cerrado-Amazononia Ecotone. Rev. Caatinga 2020, 33, 9–20. [Google Scholar] [CrossRef]

- Rangel, J.; Espinosa, J.A.; de Pablos-Heredero, C.; Rivas, J.; Perea, J.; Angón, E.; García-Martínez, A. Is the Increase of Scale in the Tropics a Pathway to Smallholders? Dimension and Ecological Zone Effect on the Mixed Crop-Livestock Farms. Span. J. Agric. Res. 2017, 15, e0109. [Google Scholar] [CrossRef]

- Villarroel-Schneider, J.; Höglund-Isaksson, L.; Mainali, B.; Martí-Herrero, J.; Cardozo, E.; Malmquist, A.; Martin, A. Energy Self-Sufficiency and Greenhouse Gas Emission Reductions in Latin American Dairy Farms through Massive Implementation of Biogas-Based Solutions. Energy Convers. Manag. 2022, 261, 115670. [Google Scholar] [CrossRef]

- Fanchone, A.; Alexandre, G.; Hostiou, N. Work Organization as a Barrier to Crop-Livestock Integration Practices: A Case Study in Guadeloupe. Agron. Sustain. Dev. 2022, 42, 54. [Google Scholar]

- Sraïri, M.T.; Naqach, Y. Comparing the Uses of Available Labor and Capital in Diversified Farming Systems in Drâa Oases (Morocco). New Medit. 2022, 2022, 21–34. [Google Scholar] [CrossRef]

- Hidayat, Z.; Suyatno; Priyanto, R.; Nuraini, H.; Abdullah, L. Suharyanto Nutritional Status and Smallholder Farmer Characteristic of Bali Cattle-Oil Palm Integration System in the Rural Dryland Area of Bangka Island, Indonesia. Pak. J. Agric. Sci. 2023, 60, 603–613. [Google Scholar] [CrossRef]

- Liu, L.; Zheng, H.; Liu, Z.; Ma, Y.Z.; Han, H.F.; Ning, T. Yuan Crop—Livestock Integration via Maize Straw Recycling Increased Carbon Sequestration and Crop Production in China. Agric. Syst. 2023, 210, 103722. [Google Scholar] [CrossRef]

- Menefee, D.S.; Collins, H.; Smith, D.; Haney, R.L.; Fay, P.; Polley, W. Cropping Management in a Livestock–Pasture–Crop Integration Modifies Microbial Communities, Activity, and Soil Health Score. J. Environ. Qual. 2023, 52, 434–447. [Google Scholar] [CrossRef]

- Perreti, B.D.; Ferreira, A.S.; Bonifacio, A.; De Araujo, F.F. Soil Microbial Biomass, Organic C, and Soybean Physiology in Integrated Crop–Livestock Systems with Different Inputs. Arch. Agron. Soil. Sci. 2022, 68, 971–983. [Google Scholar] [CrossRef]

- Soares, D.d.A.; Sekiya, B.M.S.; Modesto, V.C.; Nakao, A.H.; Freitas, L.A.; Souza, I.M.D.d.; da Luz, J.H.S.; Galindo, F.S.; Lupatini, G.C.; Pavan Mateus, G.; et al. Accumulated Carbon Fractions in Tropical Sandy Soils and Their Effects on Fertility and Grain Yield in an Integrated Crop–Livestock System. Sustainability 2023, 15, 13829. [Google Scholar] [CrossRef]

- Trevisan, R.G.; Freddi, O.d.S.; Wruck, F.J.; Tavanti, R.R.; Peres, F.S.C. Variabilidade de Atributos Físicos Do Solo e Do Arroz Cultivado Sob Plantas de Cobertura Em Sistema de Integração Lavoura-Pecuária. Bragantia 2017, 76, 145–154. [Google Scholar] [CrossRef]

- Gerssen-Gondelach, S.J.; Lauwerijssen, R.B.G.; Havlík, P.; Herrero, M.; Valin, H.; Faaij, A.P.C.; Wicke, B. Intensification Pathways for Beef and Dairy Cattle Production Systems: Impacts on GHG Emissions, Land Occupation and Land Use Change. Agric. Ecosyst. Environ. 2017, 240, 135–147. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, F.; Su, R.; Ma, D.; Liao, H.; Yang, X.; Gong, G. Livestock or Crop? Which Deserves More Investment to Reduce Greywater Footprint Emissions and Improve Water Use Efficiency? Environ. Dev. Sustain. 2024, 26, 7409–7435. [Google Scholar] [CrossRef]

- Dos Reis, J.C.; Kamoi, M.Y.T.; Latorraca, D.; Chen, R.F.F.; Michetti, M.; Wruck, F.J.; Garrett, R.D.; Valentim, J.F.; Rodrigues, R.D.A.R.; Rodrigues-Filho, S. Assessing the Economic Viability of Integrated Crop-Livestock Systems in Mato Grosso, Brazil. Renew. Agric. Food Syst. 2020, 35, 631–642. [Google Scholar] [CrossRef]

- Da Silva, F.S.; Domiciano, L.F.; Gomes, F.J.; Sollenberger, L.E.; Pedreira, C.G.S.; Pereira, D.H.; Pedreira, B.C. Herbage Accumulation, Nutritive Value and Beef Cattle Production on Marandu Palisadegrass Pastures in Integrated Systems. Agrofor. Syst. 2020, 94, 1891–1902. [Google Scholar] [CrossRef]

- Moreira, S.G.; Hoogenboom, G.; Nunes, M.R.; Sanchez, P.A. Circular Agriculture Practices Enhance Phosphorus Recovery for Large-Scale Commercial Farms under Tropical Conditions. J. Agric. Sci. 2023, 161, 763–777. [Google Scholar] [CrossRef]

- Moreira, S.G.; Hoogenboom, G.; Nunes, M.R.; Martin-Ryals, A.D.; Sanchez, P.A. Circular Agriculture Increases Food Production and Can Reduce N Fertilizer Use of Commercial Farms for Tropical Environments. Sci. Total Environ. 2023, 879, 163031. [Google Scholar] [CrossRef] [PubMed]

- Hercher-Pasteur, J.; Loiseau, E.; Sinfort, C.; Hélias, A. Identifying the Resource Use and Circularity in Farm Systems: Focus on the Energy Analysis of Agroecosystems. Resour. Conserv. Recycl. 2021, 169, 105502. [Google Scholar] [CrossRef]

- Dominguez-Hernandez, M.E.; Zepeda-Bautista, R.; Valderrama-Bravo, M.C.; Dominguez-Hernandez, E.; Hernandez-Aguilar, C. Sustainability Assessment of Traditional Maize (Zea mays L.) Agroecosystem in Sierra Norte of Puebla, Mexico. Agroecol. Sustain. Food Syst. 2018, 42, 383–406. [Google Scholar] [CrossRef]

- Dominguez-Hernandez, M.E.; Zepeda-Bautista, R.; Dominguez-Hernandez, E.; Valderrama-Bravo, M.C.; Hernández-Simón, L.M. Effect of Lime Water–Manure Organic Fertilizers on the Productivity, Energy Efficiency and Profitability of Rainfed Maize Production. Arch. Agron. Soil. Sci. 2020, 66, 1616287. [Google Scholar] [CrossRef]

- Dominguez-Hernandez, A.; Dominguez-Hernandez, M.E.; Dominguez-Hernandez, E.; Zepeda-Bautista, R. Comparing the Sustainability and Circularity of Two Livestock Production Systems in the Sierra Norte of Puebla, Mexico. Biol. Life Sci. Forum 2023, 27, 3. [Google Scholar] [CrossRef]

- Tan, K. Soil Sampling, Preparation, and Analysis, 2nd ed.; CRC-Press: Boca Raton, FL, USA, 2005; pp. 175–188. ISBN 0-8493-3499. [Google Scholar]

- Schulte, E.E.; Hopkins, B.G. Estimation of Soil Organic Matter by Weight Loss-On-Ignition. In Soil Organic Matter: Analysis and Interpretation; Soil Science Society of America: Madison, WI, USA, 1996; Volume 46, pp. 21–31. [Google Scholar] [CrossRef]

- INECC. Factores de Emisión Para Los Diferentes Tipos de Combustibles Fósiles y Alternativos Que Se Consumen En México; Instituto Nacional de Ecología y Cambio Climático: Ciudad de México, México, 2014; pp. 12–15. [Google Scholar]

- Gliessman, S.R. Agroecology: Ecological Processes in Sustainable Agriculture; Ann Harbor Press: Chelsea, MI, USA, 1998; 347p. [Google Scholar]

- Banaeian, N.; Zangeneh, M. Study on Energy Efficiency in Corn Production of Iran. Energy 2011, 36, 5394–5402. [Google Scholar] [CrossRef]

- Feedipedia Feedipedia. Animal Feed Resources Information System. Available online: https://www.feedipedia.org/ (accessed on 2 January 2025).

- Pérez, N.D.; Soler, M.; Simón, F. Energy Indicators for Organic Livestock Production: A Case Study from Andalusia, Southern Spain. Agroecol. Sustain. Food Syst. 2014, 38, 317–335. [Google Scholar] [CrossRef]

- Servicio de Información Agroalimentaria y Pesquera. Panorama Agroalimentario 2024; Servicio de Información Agroalimentaria y Pesquera (SIAP)-Secretaría de Agricultura y Desarrollo Rural: Ciudad de México, México, 2024; 207p. [Google Scholar]

- Consejo Mexicano de la Carne. Compendio Estadístico 2024; Consejo Mexicano de la Carne: Ciudad de México, México, 2024; 169p. [Google Scholar]

- Hughes, H.D.; Heath, M.E.; Metcalfe, D.S. Forrajes: La Ciencia de La Agricultura Basada En La Producción de Pastos; 2a. Compañía Editorial Continental S.A.: Ciudad de México, México, 1966. [Google Scholar]

- USDA. FoodData Central Food Details. Available online: https://fdc.nal.usda.gov/food-details/174032/nutrients (accessed on 18 December 2024).

- FAO. Milk Composition. Available online: https://www.fao.org/dairy-production-products/products/milk-composition/en (accessed on 18 October 2024).

- Parmar, P.; Lopez-Villalobos, N.; Tobin, J.T.; Murphy, E.; McDonagh, A.; Crowley, S.V.; Kelly, A.L.; Shalloo, L. The Effect of Compositional Changes Due to Seasonal Variation on Milk Density and the Determination of Season-Based Density Conversion Factors for Use in the Dairy Industry. Foods 2020, 9, 1004. [Google Scholar] [CrossRef]

- Mattei, E.; de Oliveira, P.S.R.; Rampim, L.; Egewarth, J.F.; Rego, C.A.R.d.M.; Piano, J.T.; de Herrera, J.L. Remaining Straw and Release of Nutrients from Oat Managed in Integrated Crop-Livestock. Biosci. J. 2018, 34, 206–215. [Google Scholar] [CrossRef]

- Dias, M.B.D.C.; Costa, K.A.D.P.; Bilego, U.O.; Costa, J.V.C.P.; Bezerra Fernandes, P. Protein and Carbohydrate Fractionation of Urochloa Spp. and Megathyrsus Maximus Forages after Intercropping with Soybean in an Integrated Crop-Livestock System. N. Z. J. Agric. Res. 2023, 68, 116–129. [Google Scholar] [CrossRef]

- Abdul-Salam, Y.; Hawes, C.; Roberts, D.; Young, M. The Economics of Alternative Crop Production Systems in the Context of Farmer Participation in Carbon Trading Markets. Agroecol. Sustain. Food Syst. 2019, 43, 67–91. [Google Scholar] [CrossRef]

- Almeida, C.M.V.B.; Frugoli, A.D.; Agostinho, F.; Liu, G.Y.; Giannetti, B.F. Integrating or Des-Integrating Agribusiness Systems: Outcomes of Emergy Evaluation. Sci. Total Environ. 2020, 729, 138733. [Google Scholar] [CrossRef]

- Rodríguez-Ortega, T.; Bernués, A.; Olaizola, A.M.; Brown, M.T. Does Intensification Result in Higher Efficiency and Sustainability? An Emergy Analysis of Mediterranean Sheep-Crop Farming Systems. J. Clean. Prod. 2017, 144, 171–179. [Google Scholar] [CrossRef]

- Fernandes, P.B.; Paim, T.d.P.; Santos, L.P.d.; Souza, B.R.; Leal, V.N.; Gonçalves, L.F.; Claudio, F.L.; Santos, D.d.C.; Guimarães, K.C.; Alves, E.M. Optimal Time for Haymaking and Potential Production of Grass Hay on Soybean Overseeding in Brazilian Savanna. Agronomy 2023, 13, 3046. [Google Scholar] [CrossRef]

- Freitas, C.M.; Yasuoka, J.I.; Pires, G.C.; Gama, J.P.; Oliveira, L.G.S.; Davi, J.E.A.; Silva, L.S.; Silva, I.A.G.; Bremm, C.; Carvalho, P.C.F.; et al. System Fertilization in the Pasture Phase Enhances Productivity in Integrated Crop-Livestock Systems. J. Agric. Sci. 2023, 161, 755–762. [Google Scholar] [CrossRef]

- Bertogna, K.F.; Moreira, P.S.A.; Gomes, F.J.; Kachiyama, F.B.; Groth, A.; Rezende, M.O.; de Souza Magalhães, C.A.; Lopes, L.B. Parameters Associated with Sexual Precocity of Nellore Heifers in Integrated Systems. Agrofor. Syst. 2022, 96, 669–679. [Google Scholar] [CrossRef]

- Pariz, C.M.; Costa, C.; Crusciol, C.A.C.; Castilhos, A.M.; Meirelles, P.R.L.; Roça, R.O.; Pinheiro, R.S.B.; Kuwahara, F.A.; Martello, J.M.; Cavasano, F.A.; et al. Lamb Production Responses to Grass Grazing in a Companion Crop System with Corn Silage and Oversowing of Yellow Oat in a Tropical Region. Agric. Syst. 2017, 151, 1–11. [Google Scholar] [CrossRef]

- Reddy, K.V.; Paramesh, V.; Arunachalam, V.; Das, B.; Ramasundaram, P.; Pramanik, M.; Sridhara, S.; Reddy, D.D.; Alataway, A.; Dewidar, A.Z.; et al. Farmers’ Perception and Efficacy of Adaptation Decisions to Climate Change. Agronomy 2022, 12, 1023. [Google Scholar] [CrossRef]

- Taifouris, M.; Martin, M. Toward a Circular Economy Approach for Integrated Intensive Livestock and Cropping Systems. ACS Sustain. Chem. Eng. 2021, 9, 13471–13479. [Google Scholar] [CrossRef]

- Arnuti, F.; Luiz, L.G.; Pedro, P.A.; Alves, L.A.; Cecagno, D.; De Assis, J.; Schaidhauer, W.D.S.; Anghinoni, I.; Chabbi, A.; Paulo, P.C. Sheep Dung Composition and Phosphorus and Potassium Release Affected by Grazing Intensity and Pasture Development Stage in an Integrated Cr Op-Livestock System. Agronomy 2020, 10, 1162. [Google Scholar] [CrossRef]

- Li, Y.; Sun, Z.; Accatino, F.; Hang, S.; Lv, Y.; Ouyang, Z. Comparing Specialised Crop and Integrated Crop-Livestock Systems in China with a Multi-Criteria Approach Using the Emergy Method. J. Clean. Prod. 2021, 314, 127974. [Google Scholar] [CrossRef]

- Patrizi, N.; Niccolucci, V.; Castellini, C.; Pulselli, F.M.; Bastianoni, S. Sustainability of Agro-Livestock Integration: Implications and Results of Emergy Evaluation. Sci. Total Environ. 2018, 622–623, 1543–1552. [Google Scholar] [CrossRef]

- Golshani, F.; Asgharipour, M.R.; Ghanbari, A.; Seyedabadi, E. Environmental Accounting for Croplands, Livestock Husbandry, and Integrated Systems Based on Emergetic Indicators. Energy Ecol. Environ. 2023, 8, 28–49. [Google Scholar] [CrossRef]

- Pontes, L.d.S.; Stafin, G.; Moletta, J.L.; Porfírio-da-Silva, V. Performance of Purunã Beef Heifers and Pasture Productivity in a Long-Term Integrated Crop-Livestock System: The Effect of Trees and Nitrogen Fertilization. Agrofor. Syst. 2020, 94, 1713–1723. [Google Scholar] [CrossRef]

- Costa, N.R.; Crusciol, C.A.C.; Trivelin, P.C.O.; Pariz, C.M.; Costa, C.; Castilhos, A.M.; Souza, D.M.; Bossolani, J.W.; Andreotti, M.; Meirelles, P.R.L.; et al. Recovery of 15N Fertilizer in Intercropped Maize, Grass and Legume and Residual Effect in Black Oat under Tropical Conditions. Agric. Ecosyst. Environ. 2021, 310, 107226. [Google Scholar] [CrossRef]

- Duan, Y.; Xu, M.; Gao, S.; Yang, X.; Huang, S.; Liu, H.; Wang, B. Nitrogen Use Efficiency in a Wheat-Corn Cropping System from 15 Years of Manure and Fertilizer Applications; Elsevier B.V.: Amsterdam, The Netherlands, 2014; Volume 157, ISBN 0378-4290. [Google Scholar] [CrossRef]

- Hellin, J.; Erenstein, O.; Beuchelt, T.; Camacho, C.; Flores, D. Maize Stover Use and Sustainable Crop Production in Mixed Crop-Livestock Systems in Mexico. Field Crops Res. 2013, 153, 12–21. [Google Scholar] [CrossRef]

- FAO. El Sistema Alimentario En México—Oportunidades Para El Campo Mexicano En La Agenda 2023 de Desarrollo Sostenible; Organización de las Naciones Unidas para la Alimentación y la Agricultura (FAO): Ciudad de México, Mexico, 2019; ISBN 9789251312292. [Google Scholar]

- de Moura, E.G.; Mooney, S.J.; Campos, L.S.; Bastos, K.D.O.; Aguiar, A.C.F.; Jewitt, S. No-till Alley Cropping Using Leguminous Trees Biomass: A Farmer- and Eco-Friendly Sustainable Alternative to Shifting Cultivation in the Amazonian Periphery? Environ. Dev. Sustain. 2022, 24, 7195–7212. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).