Electronic Textiles

Definition

:1. Introduction

2. Technological Approaches and Recent Applications in Electronic Textiles

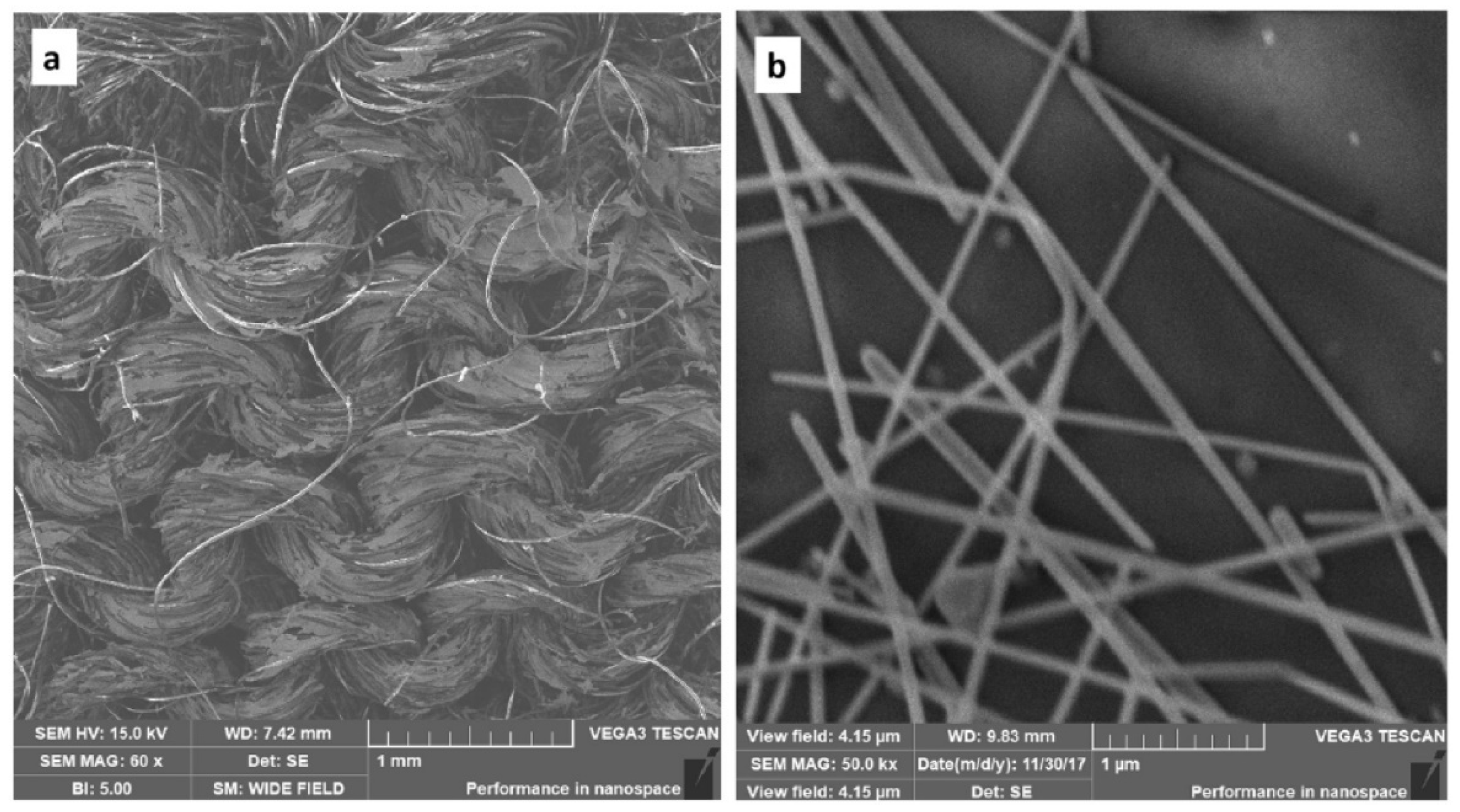

2.1. Conductive Yarns and Fabrics

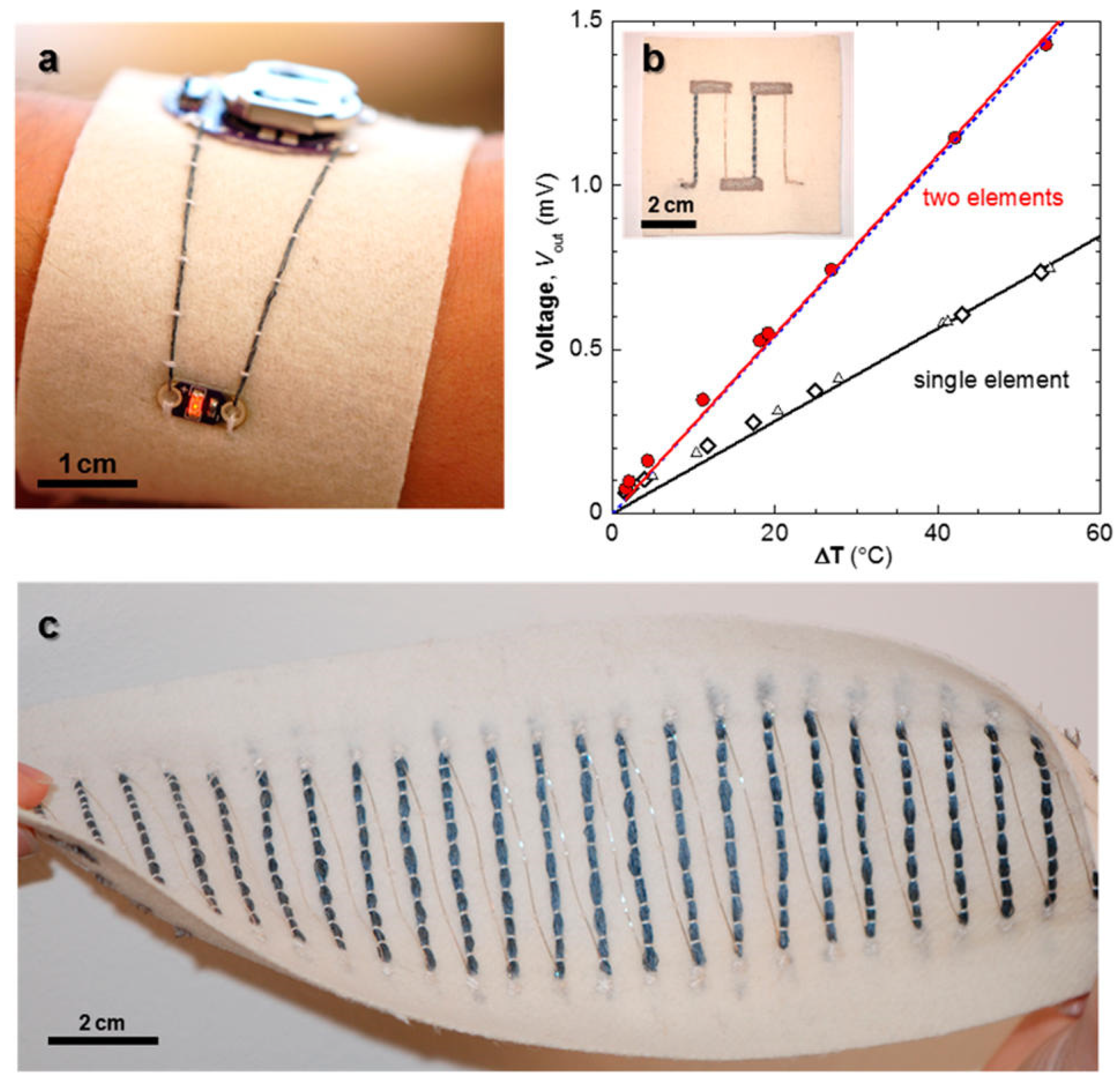

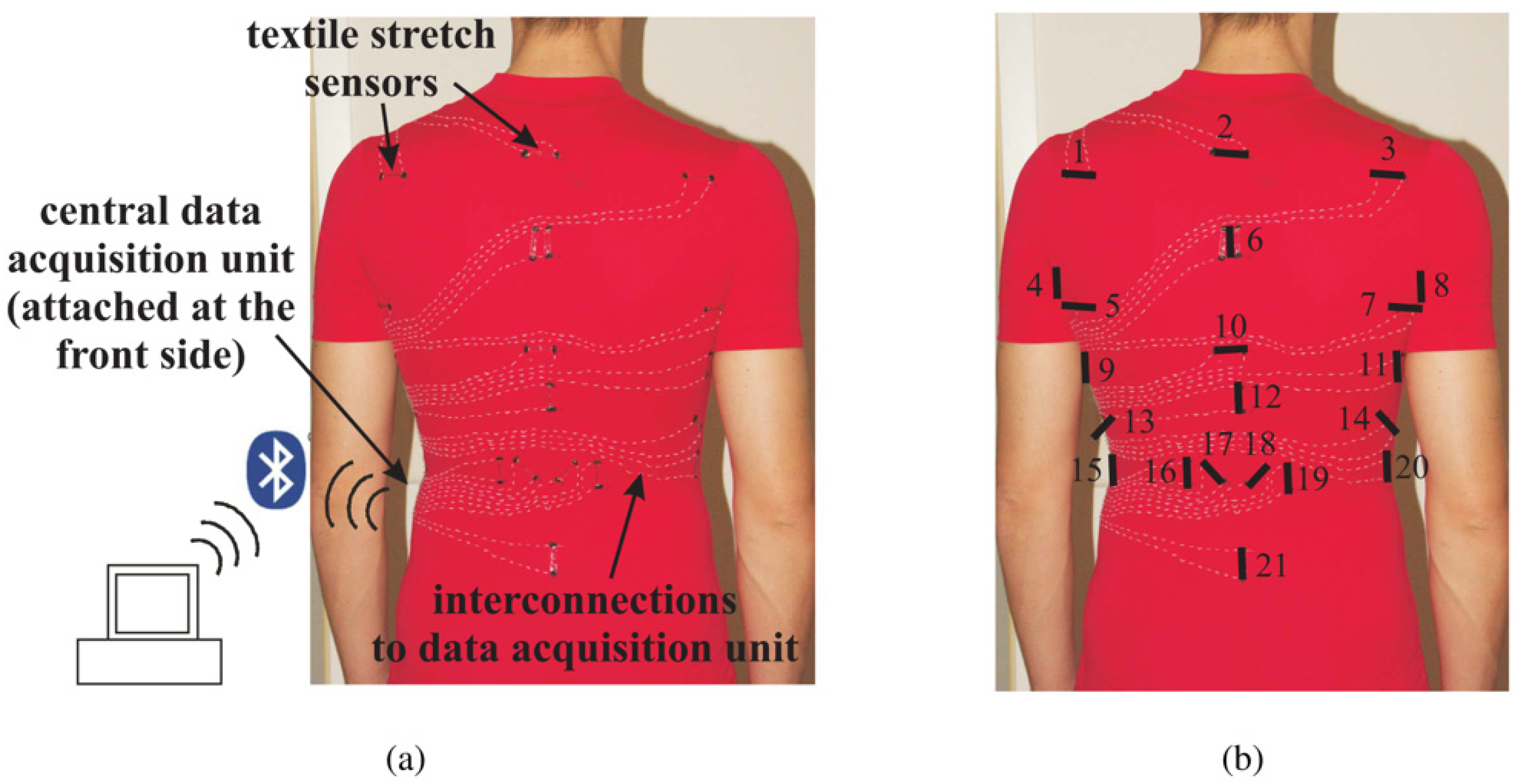

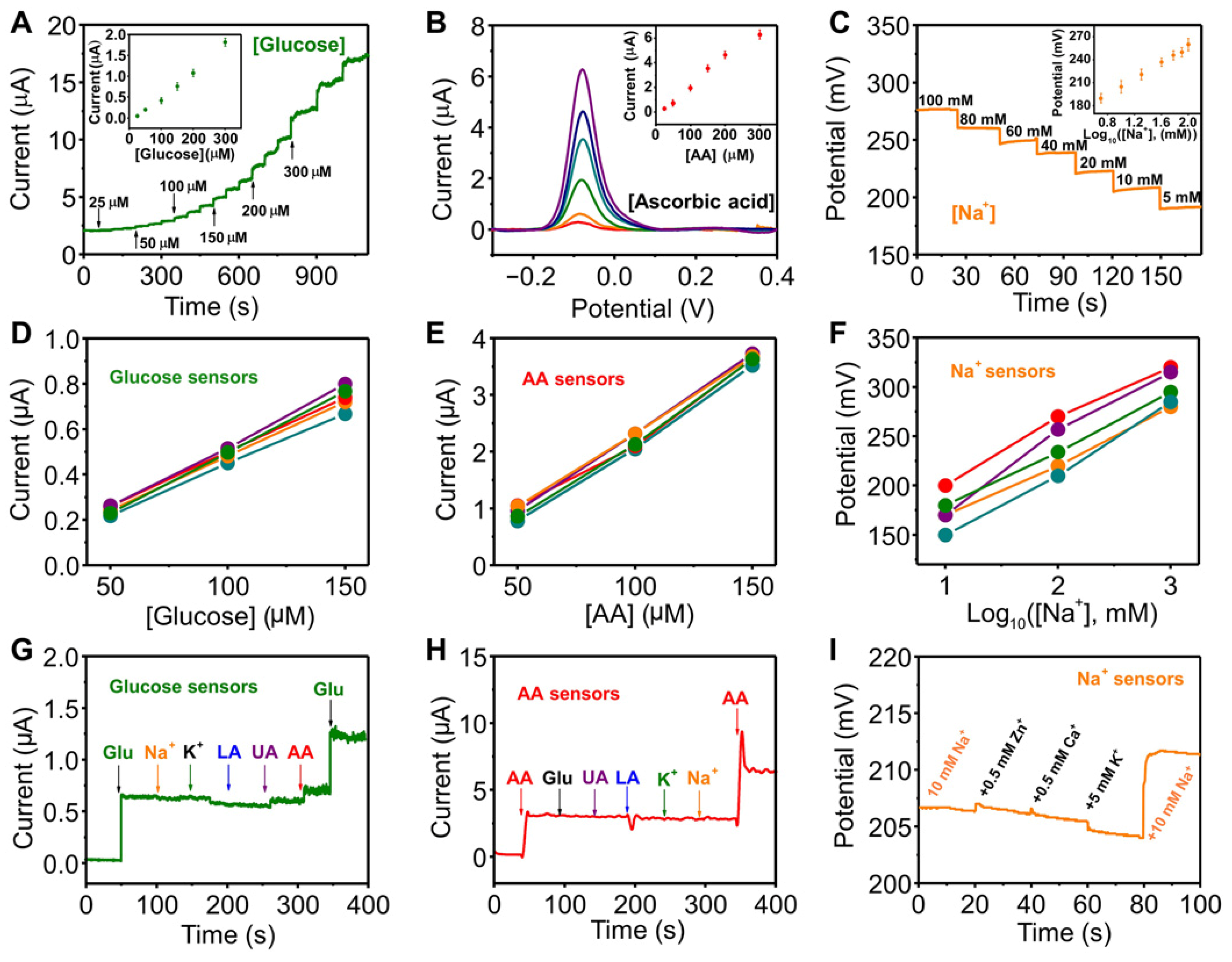

2.2. Textile Sensors

2.3. Textile Actuators

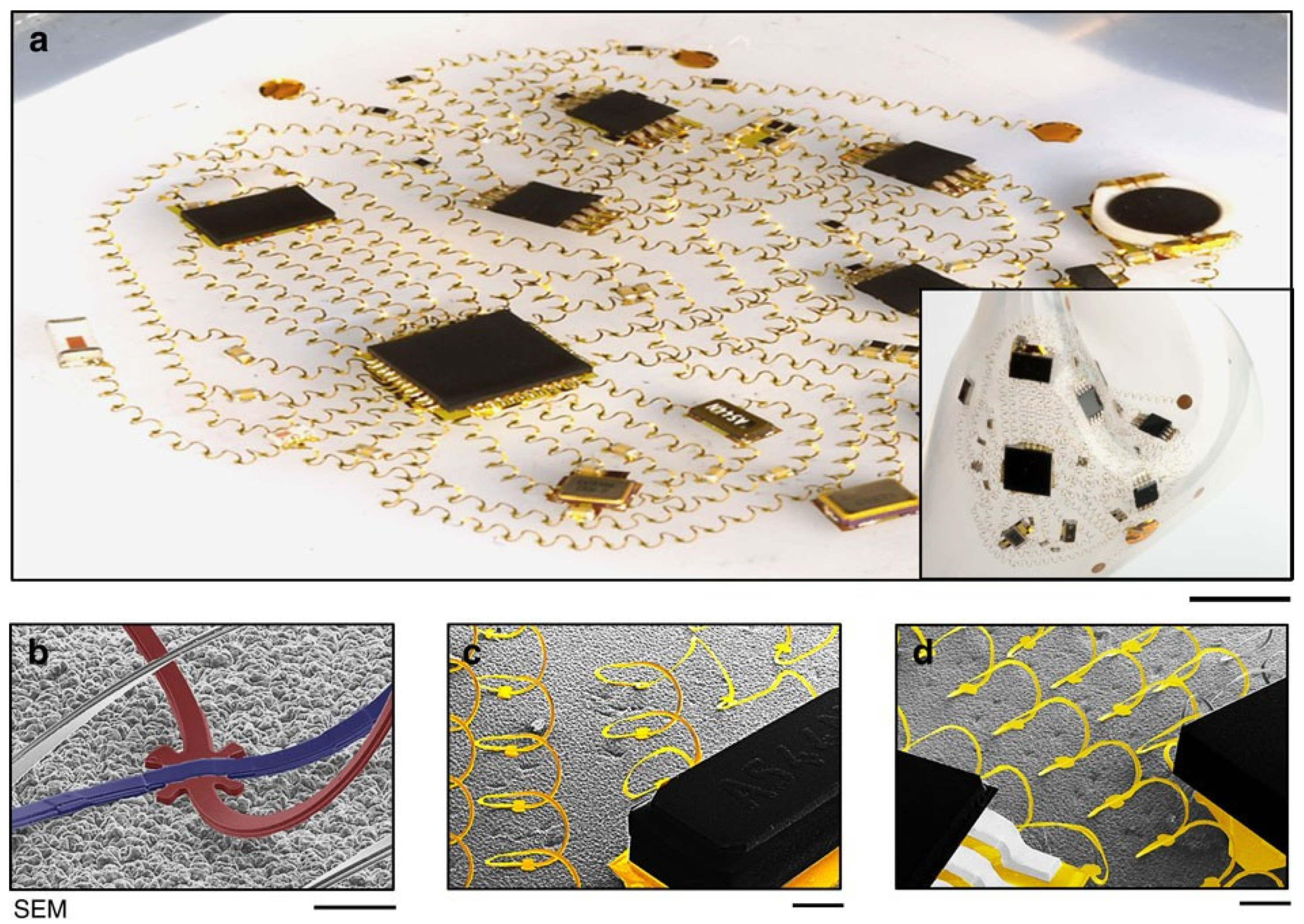

2.4. Internal and External Communication by E-Textiles

2.5. Textile Power Supply

2.6. Data Processing in Textiles

2.7. Methods to Apply Conductive and Other Layers on Textile Fabrics, Yarns and Fibers

3. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Entry Link on the Encyclopedia Platform

References

- Koncar, V. Introduction to smart textiles and their application. In Smart Textiles and Their Application, 1st ed.; Koncar, V., Ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 1–8. [Google Scholar]

- Schwarz, A.; van Langenhove, L.; Guermonprez, P.; Deguillemont, D. A roadmap on smart textiles. Text. Prog. 2010, 42, 99–180. [Google Scholar] [CrossRef]

- Shirakawa, H.; Louis, E.J.; MacDiarmid, A.G.; Chiang, C.K.; Heeger, A.J. Synthesis of electrically conducting organic polymers: Halogen derivatives of polyacetylene,(CH)x. J. Chem. Soc. Chem. Commun. 1977, 16, 578–580. [Google Scholar] [CrossRef]

- Münzenrieder, N.; Vogt, C.; Petti, L.; Salvatore, G.A.; Cantarella, G.; Büthe, L.; Tröster, G. Oxide thin-film transistors on fibers for smart textiles. Technologies 2017, 5, 31. [Google Scholar] [CrossRef]

- Owyeung, R.E.; Terse-Thakoor, T.; Nejad, H.R.; Panzer, M.J.; Sonkusale, S.R. Highly flexible transistor threads for all-thread based integrated circuits and multiplexed diagnostics. ACS Appl. Mater. Interfaces 2019, 11, 31096–91104. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.J.; Kim, H.J.; Ahn, J.T.; Hwang, D.K.; Ju, H.S.; Park, M.-C.; Yang, H.C.; Kim, S.H.; Jang, H.W.; Lim, J.A. A new architecture for fibrous organic transistors based on a double-stranded assembly of electrode microfibers for electronic textile applications. Adv. Mater. 2019, 31, 1900564. [Google Scholar] [CrossRef]

- Ehrmann, G.; Ehrmann, A. Suitability of common single circuit boards for sensing and actuating in smart textiles. Commun. Dev. Assem. Text. Prod. 2020, 1, 170–179. [Google Scholar] [CrossRef]

- Hughes-Riley, T.; Dias, T.; Cork, C. A historical review of the development of electronic textiles. Fibers 2018, 6, 34. [Google Scholar] [CrossRef]

- Park, S.; Mackenzie, K.; Jayaraman, S. The Wearable Motherboard: A Framework for Personalized Mobile Information Processing (PMIP). In Proceedings of the 39th Annual Design Automation Conference (DAC 02), New Orleans, LA, USA, 10–14 June 2002; pp. 170–174. [Google Scholar]

- Marculescu, D.; Marculescu, R.; Zamora, N.H.; Stanley-Marbell, P.; Khosla, P.K.; Park, S.; Jayaraman, S.; Jung, S.; Lauterbach, C.; Weber, W.; et al. Electronic textiles: A platform for pervasive computing. Proc. IEEE 2003, 91, 1995–2018. [Google Scholar] [CrossRef]

- Wagner, S.; Bonderover, E.; Jordan, W.B.; Sturm, J.C. Electrotextiles: Concepts and challenges. Int. J. High Speed Electron. Syst. 2002, 12, 391–399. [Google Scholar] [CrossRef]

- Hamedi, M.; Forchheimer, R.; Inganäs, O. Towards woven logic from organic electronic fibers. Nat. Mater. 2007, 6, 357–362. [Google Scholar] [CrossRef]

- Cherenack, K.H.; Zysset, C.; Kinkeldei, T.; Münzenrieder, N.; Tröster, G. Woven electronic fibers with sensing and display functions for smart textiles. Adv. Mater. 2010, 22, 5178–5182. [Google Scholar] [CrossRef] [PubMed]

- Schwarz-Pfeiffer, A.; Obermann, M.; Weber, M.O.; Ehrmann, A. Smarten up garments through knitting. IOP Conf. Ser. Mater. Sci. Eng. 2016, 141, 012008. [Google Scholar] [CrossRef]

- Trummer, S.; Ehrmann, A.; Büsgen, A. Development of underwear with integrated 12 channel ECG for men and women. AUTEX Res. J. 2017, 17, 344–349. [Google Scholar] [CrossRef]

- Suga, T.; Konishi, H.; Nishide, H. Photocrosslinked nitroxide polymer cathode-active materials for application in an organic-based paper battery. Chem. Commun. 2007, 17, 1730–1732. [Google Scholar] [CrossRef] [PubMed]

- Resuli, R.; Turhan, I.; Ehrmann, A.; Blachowicz, T. Textile-based batteries with nanofiber interlayer. AIMS Energy 2018, 6, 261–268. [Google Scholar] [CrossRef]

- Kohn, S.; Wehlage, D.; Junger, I.J.; Ehrmann, A. Electrospinning a dye-sensitized solar cell. Catalysts 2019, 9, 975. [Google Scholar] [CrossRef]

- Cherenack, K.; van Pieterson, L. Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 091301. [Google Scholar] [CrossRef]

- Paiva, A.; Ferreira, F.; Catarino, A.; Carvalho, M.; Carvalho, H. Design of smart garments for sports and rehabilitation. IOP Conf. Ser. Mater. Sci. Eng. 2018, 459, 012083. [Google Scholar] [CrossRef]

- Scataglini, S.; Moorhead, A.P.; Feletti, F. A systematic review of smart clothing in sports: Possible applications to extreme sports. Muscles Ligaments Tendons J. 2020, 10, 333–342. [Google Scholar] [CrossRef]

- Khundaqji, H.; Hing, W.; Furness, J.; Climstein, M. Smart shirts for monitoring physiological parameters: Scoping review. JMIR Mhealth Uhealth 2020, 8, e18092. [Google Scholar] [CrossRef]

- Otley, M.T.; Alamer, F.A.; Guo, Y.; Santana, J.; Eren, E.; Li, M.; Lombardi, J.; Sotzing, G.A. Phase segregation of PEDOT:PSS on textile to produce materials of > 10 A mm−2 current carrying capacity. Macromol. Mater. Eng. 2016, 302, 1600348. [Google Scholar] [CrossRef]

- Irwin, M.D.; Roberson, D.A.; Olivas, R.I.; Wicker, R.B.; MacDonald, E. Conductive polymer-coated threads as electrical interconnects in e-textiles. Fibers Polym. 2011, 12, 904–910. [Google Scholar] [CrossRef]

- Akerfeldt, M.; Lund, A.; Walkenström, P. Textile sensing glove with piezoelectric PVDF fibers and printed electrodes of PEDOT:PSS. Text. Res. J. 2015, 85, 1789–1799. [Google Scholar] [CrossRef]

- Guo, Y.; Otley, M.T.; Li, M.F.; Zhang, X.Z.; Sinha, S.K.; Treich, G.M.; Sotzing, G.A. PEDOT:PSS Wires Printed on Textile for Wearable Electronics. ACS Appl. Mater. Interfaces 2016, 8, 26998–27005. [Google Scholar] [CrossRef] [PubMed]

- Ryan, J.D.; Mengistie, D.A.; Gabrielsson, R.; Lund, A.; Müller, C. Machine-washable PEDOT:PSS dyed silk yarns for electronic textiles. ACS Appl. Mater. Interfaces 2017, 9, 9045–9050. [Google Scholar] [CrossRef]

- Hwang, B.; Lund, A.; Tian, Y.; Darabi, S.; Müller, C. Machine-washable conductive silk yarns with a composite coating of Ag nanowires and PEDOT:PSS. ACS Appl. Mater. Interfaces 2020, 12, 27537–27544. [Google Scholar] [CrossRef]

- Darabi, S.; Hummel, M.; Rantasalo, S.; Rissanen, M.; Mansson, I.Ö.; Hilke, H.; Hwang, B.; Skrifvars, M.; Hamed, M.M.; Sixta, H.; et al. Green conducting cellulose yarns for machine-sewn electronic textiles. ACS Appl. Mater. Interfaces 2020, 12, 56403–56412. [Google Scholar] [CrossRef]

- Choi, C.M.; Kwon, S.-N.; Na, S.-I. Conductive PEDOT:PSS-coated poly-paraphenylene terephthalamide thread for highly durable electronic textiles. J. Ind. Eng. Chem. 2017, 50, 155–161. [Google Scholar] [CrossRef]

- Alamer, F.A. A simple method for fabricating highly electrically conductive cotton fabric without metals or nanoparticles, using PEDOT:PSS. J. Alloys Comp. 2017, 702, 266–273. [Google Scholar] [CrossRef]

- Junger, I.J.; Wehlage, D.; Böttjer, R.; Grothe, T.; Juhász, L.; Grassmann, C.; Blachowicz, T.; Ehrmann, A. Dye-sensitized solar cells with electrospun nanofiber mat-based counter electrodes. Materials 2018, 11, 1604. [Google Scholar] [CrossRef] [PubMed]

- Sarabia-Riquelme, R.; Andrews, R.; Anthony, J.E.; Weisenberger, M.C. Highly conductive wet-spun PEDOT:PSS fibers for applications in electronic textiles. J. Mater. Chem. C 2020, 8, 11618–11630. [Google Scholar] [CrossRef]

- Perdigao, P.; Faustino, B.M.M.; Faria, J.; Canejo, J.P.; Borges, J.P.; Ferreira, I.; Baptista, A.C. Conductive electrospun polyaniline/polyvinylpyrrolidone nanofibers: Electrical and morphological characterization of new yarns for electronic textiles. Fibers 2020, 8, 24. [Google Scholar] [CrossRef]

- Kim, B.W.; Koncar, V.; Dufour, C. Polyaniline-coated PET conductive yarns: Study of electrical, mechanical, and electro-mechanical properties. J. Appl. Polym. Sci. 2006, 101, 1252–1256. [Google Scholar] [CrossRef]

- Lima, R.M.A.P.; Alcaraz-Espinoza, J.J.; da Silva, F.A.G., Jr.; de Oliveira, H.P. Multifunctional wearable electronic textiles using cotton fibers with polypyrrole and carbon nanotubes. ACS Appl. Mater. Interfaces 2018, 10, 13786–13795. [Google Scholar] [CrossRef] [PubMed]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Patel, P.C.; Vasavada, D.A.; Mankodi, H.R. Applications of electrically conductive yarns in technical textiles. In Proceedings of the 2012 IEEE International Conference on Power System Technology, Auckland, New Zealand, 30 October–2 November 2012; pp. 1–6. [Google Scholar]

- Locher, I.; Kirstein, T.; Tröster, G. Routing methods adapted to e-textiles. Proc. Int. Symp. Microelectron. 2004, 14–18. [Google Scholar]

- Atalay, O.; Kalaoglu, F.; Bahadir, S.K. Development of textile-based transmission lines using conductive yarns and ultrasonic welding technology for e-textile applications. J. Eng. Fibers Fabr. 2019, 14, 1558925019856603. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, Z.; Rao, W.; Fan, L.L.; Xia, Z.G.; Xu, W.L.; Xu, J. A high-performance all-solid-state yarn supercapacitor based on polypyrrole-coated stainless steel/cotton blended yarns. Cellulose 2019, 26, 1169–1181. [Google Scholar] [CrossRef]

- Ehrmann née Tillmanns, A.; Heimlich, F.; Brücken, A.; Weber, M.O.; Blachowicz, T. Experimental investigation of the washing relaxation of knitted fabrics from polyester yarn with stainless steel fibers. Fibres Text. East. Eur. 2012, 20, 90–93. [Google Scholar]

- Zhang, T.Y.; Wang, Z.N.; Zhu, A.P.; Ran, F. Flexible, twistable and plied electrode of stainless steel Cables@Nickel–Cobalt oxide with high electrochemical performance for wearable electronic textiles. Electrochim. Acta 2020, 348, 136312. [Google Scholar] [CrossRef]

- Gurarslan, A.; Özdemir, B.; Bayat, I.H.; Yelten, M.B.; Kurt, G.K. Silver nanowire coated knitted wool fabrics for wearable electronic applications. J. Eng. Fibers Fabr. 2019, 14, 1558925019856222. [Google Scholar] [CrossRef]

- Ashayer-Soltani, R.; Hunt, C.; Thomas, O. Fabrication of highly conductive stretchable textile with silver nanoparticles. Text. Res. J. 2015, 86, 1041–1049. [Google Scholar] [CrossRef]

- Liu, H.P.; Li, N.; Bi, S.; Li, D. Gold immersion deposition on electroless nickel substrates: Deposition process and influence factor analysis. J. Electrochem. Soc. 2007, 154, D662. [Google Scholar] [CrossRef]

- Wu, Y.Y.; Mechael, S.S.; Chen, Y.T.; Carmichael, T.B. Solution deposition of conformal gold coatings on knitted fabric for e-textiles and electroluminescent clothing. Adv. Mater. Technol. 2018, 3, 1700292. [Google Scholar] [CrossRef]

- Zabetakis, D.; Dinderman, M.; Schoen, P. Metal-coated cellulose fibers for use in composites applicable to microwave technology. Adv. Mater. 2005, 17, 734–738. [Google Scholar] [CrossRef]

- Zhao, Z.; Yan, C.; Liu, Z.; Fu, X.; Peng, L.; Hu, Y.; Zheng, Z. Machine-washable textile triboelectric nanogenerators for effective human respiratory monitoring through loom weaving of metallic yarns. Adv. Mater. 2016, 28, 10267–10274. [Google Scholar] [CrossRef]

- Huang, Y.; Ip, W.S.; Lau, Y.Y.; Sun, J.; Zeng, J.; Yeung, N.S.S.; Ng, W.S.; Li, H.; Pei, Z.; Xue, Q.; et al. Weavable, conductive yarn-based NiCo//Zn textile battery with high energy density and rate capability. ACS Nano 2017, 11, 8953–8961. [Google Scholar] [CrossRef]

- de Vries, H.; Cherenack, K.H. Endurance behavior of conductive yarns. Microelectron. Reliab. 2014, 54, 327–330. [Google Scholar] [CrossRef]

- Liu, Z.F.; Fang, S.; Moura, F.A.; Ding, J.N.; Jiang, N.; Di, J.; Zhang, M.; Lepró, X.; Galvao, D.S.; Haines, C.S.; et al. Hierarchically buckles sheath-core fibers for superelastic electronics, sensors, and muscles. Science 2015, 349, 400–404. [Google Scholar] [CrossRef]

- Jang, K.-I.; Li, K.; Chung, H.U.; Xu, S.; Jung, H.N.; Yang, Y.Y.; Kwak, J.W.; Jung, H.H.; Song, J.W.; Yang, C.; et al. Self-assembled three dimensional network design for soft electronics. Nat. Commun. 2017, 8, 15894. [Google Scholar] [CrossRef]

- Aumann, S.; Trummer, S.; Brücken, A.; Ehrmann, A.; Büsgen, A. Conceptual design of a sensory shirt for fire-fighters. Text. Res. J. 2014, 84, 1661–1665. [Google Scholar] [CrossRef]

- Unwin, P.R.; Güell, A.G.; Zhang, G.H. Nanoscale electrochemistry of sp2 carbon materials: From graphite and graphene to carbon nanotubes. Acc. Chem. Res. 2016, 49, 2041–2048. [Google Scholar] [CrossRef] [PubMed]

- Schäl, P.; Juhász Junger, I.; Grimmelsmann, N.; Ehrmann, A. Development of graphite-based conductive coatings. J. Coat. Technol. Res. 2018, 15, 875–883. [Google Scholar] [CrossRef]

- Vahle, D.; Böttjer, R.; Heyden, K.; Ehrmann, A. Conductive polyacrylonitrile/graphite textile coatings. AIMS Mater. Sci. 2018, 5, 551–558. [Google Scholar] [CrossRef]

- Liu, Y.J.; Sun, T.; Zhao, X.M. A study on the preparation, dielectric properties and electrical conductivity of glass fiber bulk yarn fabrics with a graphite coating. J. Text. Inst. 2020, 112, 8–15. [Google Scholar] [CrossRef]

- Shateri-Khalilabad, M.; Yazdanshenas, M.E. Preparation of superhydrophobic electroconductive graphene-coated cotton cellulose. Cellulose 2013, 20, 963–972. [Google Scholar] [CrossRef]

- Molina, J.; Fernández, J.; Inés, J.C.; del Río, A.I.; Bonastre, J.; Cases, F. Electrochemical characterization of reduced graphene oxide-coated polyester fabrics. Electrochim. Acta 2013, 93, 44–52. [Google Scholar] [CrossRef]

- Karim, N.; Afroj, S.; Malandraki, A.; Butterworth, S.; Beach, C.; Rigout, M.; Novoselov, K.; Casson, A.J.; Yeates, S. All inkjet-printed graphene-based conductive patterns for wearable e-textile applications. J. Mater. Chem. C 2017, 5, 11640. [Google Scholar] [CrossRef]

- Karim, N.; Afroj, S.; Tan, S.; He, P.; Fernando, A.; Carr, C.; Novoselov, K.S. Scalable production of graphene-based wearable e-textiles. ACS Nano 2017, 11, 12266–12275. [Google Scholar] [CrossRef]

- Yun, Y.J.; Lee, H.J.; Son, T.H.; Son, H.T.; Jun, Y.S. Mercerization to enhance flexibility and electromechanical stability of reduced graphene oxide cotton yarns. Compos. Sci. Technol. 2019, 184, 107845. [Google Scholar] [CrossRef]

- Pei, S.F.; Cheng, H.-M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Afroj, S.; Tan, S.; Abdelkader, A.M.; Novoselov, K.S.; Karim, N. Highly conductive, scalable, and machine washable graphene-based e-textiles for multifunctional wearable electronic applications. Adv. Funct. Mater. 2020, 30, 2000293. [Google Scholar] [CrossRef]

- Cui, J.S.; Zhou, S.X. Highly conductive and ultra-durable electronic textiles via covalent immobilization of carbon nanomaterials on cotton fabric. J. Mater. Chem. C 2018, 6, 12273–12282. [Google Scholar] [CrossRef]

- Youssry, M.; Kamand, F.Z.; Magzoub, M.I.; Nasser, M.S. Aqueous dispersions of carbon black and its hybrid with carbon nanofibers. RSC Adv. 2018, 8, 32119–32131. [Google Scholar] [CrossRef]

- Alamer, F.A. Structural and electrical properties of conductive cotton fabrics coated with the composite polyaniline/carbon black. Cellulose 2018, 25, 2075–2082. [Google Scholar] [CrossRef]

- Islam, R.; Khair, N.; Ahmed, D.M.; Shahariar, H. Fabrication of low cost and scalable carbon-based conductive ink for E-textile applications. Mater. Today Comm. 2019, 19, 32–38. [Google Scholar] [CrossRef]

- Zieba, J.; Frydrysiak, M. Textiles—electrical and electronic textiles. Sensors for breathing frequency measurement. Fibres Text. East. Eur. 2006, 14, 43–48. [Google Scholar]

- Ehrmann, A.; Heimlich, F.; Brücken, A.; Weber, M.O.; Haug, R. Suitability of knitted fabrics as elongation sensors subject to structure, stitch dimension and elongation direction. Text. Res. J. 2014, 84, 2006–2012. [Google Scholar] [CrossRef]

- Huang, C.-T.; Shen, C.-L.; Tang, C.-F.; Chang, S.-H. A wearable yarn-based piezo-resistive sensor. Sens. Actuators A Phys. 2008, 141, 396–403. [Google Scholar] [CrossRef]

- Lee, J.H.; Shin, S.; Lee, S.G.; Song, J.K.; Kang, S.; Han, H.T.; Kim, S.G.; Kim, S.H.; Seo, J.M.; Kim, D.E.; et al. Highly sensitive multifilament fiber strain sensors with ultrabroad sensing range for textile electronics. ACS Nano 2018, 12, 4259–4268. [Google Scholar] [CrossRef]

- Mattmann, C.; Clemens, F.; Tröster, G. Sensors for measuring strain in textile. Sensors 2008, 8, 3719–3732. [Google Scholar] [CrossRef] [PubMed]

- Sibinski, M.; Jakubowska, M.; Sloma, M. Flexible temperature sensors on fibers. Sensors 2010, 10, 7934–7946. [Google Scholar] [CrossRef] [PubMed]

- Cao, R.; Pu, X.J.; Du, X.Y.; Yang, W.; Wang, J.; Guo, H.Y.; Zhao, S.Y.; Yuan, Z.Q.; Zhang, C.; Li, C.J.; et al. Screen-printed washable electronic textiles as self-powered touch/gesture tribo-sensors for intelligent human-machine interaction. ACS Nano 2018, 12, 5190–5196. [Google Scholar] [CrossRef] [PubMed]

- Coosemans, J.; Hermans, B.; Puers, R. Integrating wireless ECG monitoring in textiles. Sens. Actuators A Phys. 2006, 130–131, 48–53. [Google Scholar] [CrossRef]

- Pola, T.; Vanhala, J. Textile electrodes in ECG measurement. In Proceedings of the 3rd International Conference on Intelligent Sensors, Sensor Networks and Information, Melbourne, Australia, 3–6 December 2007; pp. 635–639. [Google Scholar]

- Lee, E.; Kim, H.; Liu, H.; Cho, G. Exploration of AgNW/PU nanoweb as ECG textile electrodes and comparison with Ag/AgCl electrodes. Fibers Polym. 2017, 18, 1749–1753. [Google Scholar] [CrossRef]

- Han, J.-W.; Kim, B.S.; Li, J.; Meyyappan, M. A carbon nanotube based ammonia sensor on cotton textile. Appl. Phys. Lett. 2013, 102, 193104. [Google Scholar] [CrossRef]

- Miasik, J.J.; Hooper, A.; Tofield, B.C. Conducting polymer gas sensors. J. Chem. Soc. Faraday Trans. 1 1986, 82, 1117–1126. [Google Scholar] [CrossRef]

- Bartlett, P.N.; Archer, P.B.M.; Ling-Chung, S.K. Conducting polymer gas sensors part I: Fabrication and characterization. Sens. Act. 1989, 19, 125–140. [Google Scholar] [CrossRef]

- Kincal, D.; Kumar, A.; Child, A.D.; Reynolds, J.R. Conductivity switching in polypyrrole-coated textile fabrics as gas sensors. Synth. Met. 1998, 92, 53–56. [Google Scholar] [CrossRef]

- Holleczek, T.; Rüegg, A.; Harms, H.; Tröster, G. Textile pressure sensors for sports applications. In Proceedings of the IEEE Sensors 2010 Conference, Waikoloa, HI, USA, 1–4 November 2010; pp. 732–737. [Google Scholar]

- Merrit, C.R.; Nagle, H.T.; Grant, E. Textile-based capacitive sensors for respiration monitoring. IEEE Sens. J. 2009, 9, 71–78. [Google Scholar] [CrossRef]

- Freitag, R.; Meixner, H. A sensor array for human-body detection based on pyroelectric polyvinylidene fluoride. IEEE Trans. Elect. Insul. 1989, 24, 469–472. [Google Scholar] [CrossRef]

- Choi, S.; Jiang, Z. A novel wearable sensor device with conductive fabric and PVDF film for monitoring cardiorespiratory signals. Sens. Actuators A Phys. 2006, 128, 317–326. [Google Scholar] [CrossRef]

- Chiu, Y.-Y.; Lin, W.-Y.; Wang, H.-Y.; Huang, S.-B.; Wu, M.-H. Development of a piezoelectric polyvinylidene fluoride (PVDF) polymer-based sensor patch for simultaneous heartbeat and respiration monitoring. Sens. Actuators A Phys. 2013, 189, 328–334. [Google Scholar] [CrossRef]

- Nilsson, E.; Lund, A.; Jonasson, C.; Johansson, C.; Hagström, B. Poling and characterization of piezoelectric polymer fibers for use in textile sensors. Sens. Actuators A Phys. 2013, 201, 477–486. [Google Scholar] [CrossRef]

- Mokhtari, F.; Foroughi, J.; Zheng, T.; Cheng, Z.; Spinks, G.M. Triaxial braided piezo fiber energy harvesters for self-powered wearable technologies. J. Mater. Chem. A 2019, 7, 8245–8257. [Google Scholar] [CrossRef]

- Mokhtari, F.; Spinks, G.M.; Sayyar, S.; Cheng, Z.; Ruhparwar, A.; Foroughi, J. Highly Stretchable Self-Powered Wearable Electrical Energy Generator and Sensors. Adv. Mater. Technol. 2020, 2000841, online first. [Google Scholar] [CrossRef]

- Mokhtari, F.; Spinks, G.M.; Fay, C.; Cheng, Z.; Raad, R.; Xi, J.; Foroughi, J. Wearable Electronic Textiles from Nanostructured Piezoelectric Fibers. Adv. Mater. Technol. 2020, 5, 1900900. [Google Scholar] [CrossRef]

- Jung, K.-C.; Son, J.H.; Chang, S.-H. Self-powered smart shoes with tension-type ribbon harvesters and sensors. Adv. Mater. Technol. 2020, 2000872. [Google Scholar] [CrossRef]

- He, W.; Wang, C.; Wang, H.M.; Jian, M.Q.; Lu, W.D.; Liang, X.P.; Zhang, X.; Yang, F.C.; Zhang, Y.Y. Integrated textile sensor patch for real-time and multiplex sweat analysis. Sci. Adv. 2019, 5, eaax0649. [Google Scholar] [CrossRef]

- Hatamie, A.; Angizi, S.; Kumar, S.; Pandey, C.M.; Simchi, A.; Willander, M.; Malhotra, B.D. Review—Textile based chemical and physical sensors for healthcare monitoring. J. Electrochem. Soc. 2020, 167, 037546. [Google Scholar] [CrossRef]

- Persson, N.-K.; Martinez, J.G.; Zhong, Y.; Maziz, A.; Jager, E.W.H. Actuating textiles: Next generation of smart textiles. Adv. Mater. Technol. 2018, 3, 1700397. [Google Scholar] [CrossRef]

- Pyka, W.; Jedrzejowski, M.; Chudy, M.; Krafczyk, W.; Tokarczyk, O.; Dziezok, M.; Bzymek, A.; Bysko, S.; Blachowicz, T.; Ehrmann, A. On the use of textile materials in robotics. J. Eng. Fibers Fabr. 2020, 15, 1558925020910725. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M.T. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Deimel, R.; Brock, O. A novel type of compliant and underactuated robotic hand for dexterous grasping. Int. J. Robot Res. 2016, 35, 161–185. [Google Scholar] [CrossRef]

- Sun, T.; Chen, Y.L.; Han, T.Y.; Jiao, C.L.; Lian, B.B.; Song, Y.M. A soft gripper with variable stiffness inspired by pangolin scales, toothed pneumatic actuator and autonomous controller. Robot. Comput. Int. Manuf. 2020, 61, 101848. [Google Scholar] [CrossRef]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef]

- Park, S.Y.; Ahn, S.C.; Kim, J.H.; Jeong, J.; Park, T.H.; Yoon, H.S.; Hur, J.Y.; Park, J.-J. Textile speaker using polyvinylidene fluoride/ZnO nanopillar on Au textile for enhancing the sound pressure level. Sci. Adv. Mater. 2018, 10, 1788–1792. [Google Scholar] [CrossRef]

- Kögl, M.; Silva, E.C. Topology optimization of smart structures: Design of piezoelectric plate and shell actuators. Smart Mater. Struct. 2005, 14, 387. [Google Scholar] [CrossRef]

- Senatov, F.S.; Niaza, N.K.; Zadorozhnyy, M.Y.; Maksimkin, A.V.; Kaloshkin, S.D.; Estrin, Y.Z. Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J. Mech. Behav. Biomed. Mater. 2016, 57, 139–148. [Google Scholar] [CrossRef]

- Senatov, F.S.; Zadorozhnyy, M.Y.; Niaza, K.V.; Medvedev, V.V.; Kaloshkin, S.D.; Anisimova, N.Y.; Kiselevskiy, M.V.; Yang, K.-C. Shape memory effect in 3D-printed scaffolds for self-fitting implants. Eur. Polym. J. 2017, 93, 222–231. [Google Scholar] [CrossRef]

- Ehrmann, G.; Ehrmann, A. Investigation of the shape-memory properties of 3D printed PLA structures with different infills. Polymers 2021, 13, 164. [Google Scholar] [CrossRef]

- Quinn, B. Textile Futures: Fashion, Design and Technology, 1st ed.; Berg Publishers: Oxford, UK, 2010. [Google Scholar]

- Kluge, A.; Nocke, A.; Paul, C.; Cherif, C.; Linse, T.; Ulbricht, V. Development and characterization of textile-processable actuators based on shape-memory alloys for adaptive fiber-reinforced plastics. Text. Res. J. 2013, 83, 1936–1948. [Google Scholar] [CrossRef]

- Ashir, M.; Nocke, A.; Cherif, C. Maximum deformation of shape memory alloy based adaptive fiber-reinforced plastics. Compos. Sci. Technol. 2019, 184, 107860. [Google Scholar] [CrossRef]

- Han, M.-W.; Kim, M.-S.; Ahn, S.-H. Shape memory textile composites with multi-mode actuations for soft morphing skins. Compos. B Eng. 2020, 198, 108170. [Google Scholar] [CrossRef]

- Ashir, M.; Nocke, A.; Hanke, U.; Cherif, C. Adaptive hinged fiber reinforced plastics with tailored shape memory alloy hybrid yarn. Polym. Compos. 2020, 41, 191–200. [Google Scholar] [CrossRef]

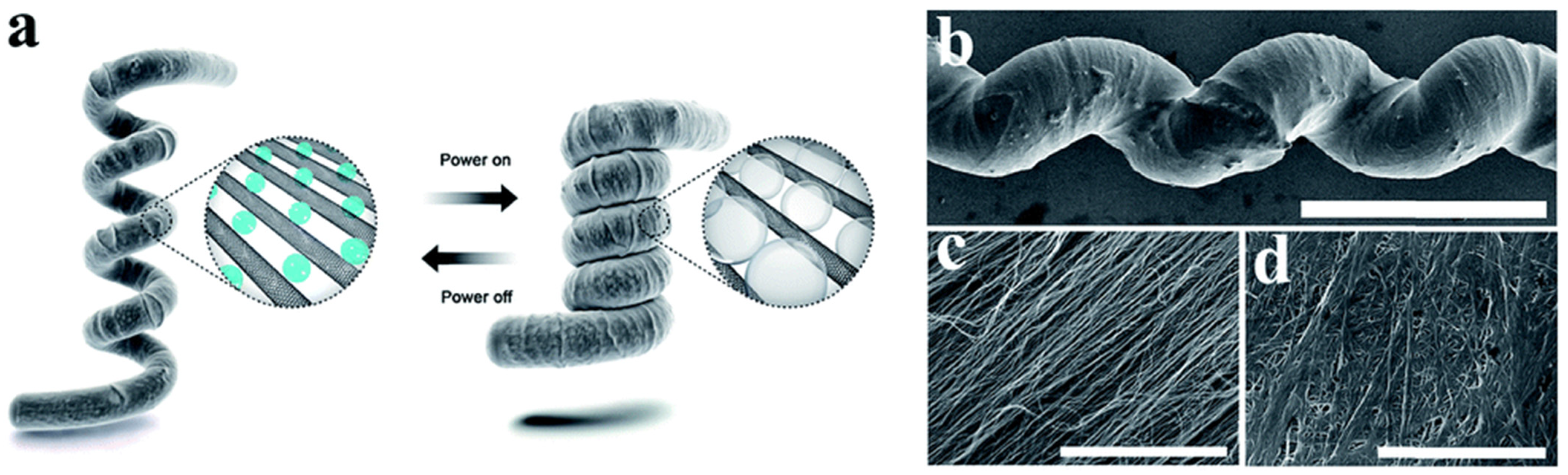

- Foroughi, J.; Spinks, G.M.; Aziz, S.; Mirabedini, A.; Jeiranikhameneh, A.; Wallace, G.G.; Kozlov, M.E.; Baughman, R.H. Knitted carbon-nanotube-sheath/Spandex-core elastomeric yarns for artificial muscles and strain sensing. ACS Nano 2016, 10, 9129–9135. [Google Scholar] [CrossRef]

- Lima, M.D.; Li, N.; Jung de Andrade, M.; Fang, S.; Oh, J.Y.; Spinks, G.M.; Kozlov, M.E.; Haines, C.S.; Suh, D.S.; Foroughi, J.; et al. Electrically, chemically, and photonically powered torsional and tensile actuation of hybrid carbon nanotube yarn muscles. Science 2012, 338, 928–932. [Google Scholar] [CrossRef]

- Zhou, Z.W.; Li, Q.W.; Chen, L.H.; Liu, C.H.; Fan, S.S. A large-deformation phase transition electrothermal actuator based on carbon nanotube–elastomer composites. J. Mater. Chem. B 2016, 4, 1228–1234. [Google Scholar] [CrossRef]

- Jeong, J.-H.; Mun, T.J.; Kim, H.S.; Moon, J.H.; Lee, D.W.; Baughman, R.H.; Kim, S.J. Carbon nanotubes–elastomer actuator driven electrothermally by low-voltage. Nanoscale Adv. 2019, 1, 965–968. [Google Scholar] [CrossRef]

- Lee, S.; Kim, B.H.; Yoo, H.-J. Planar fashionable circuit board technology and its applications. J. Semicond. Technol. Sci. 2009, 9, 174–180. [Google Scholar] [CrossRef]

- Ojuroye, O.; Torah, R.; Beeby, S. Modified PDMS packaging of sensory e-textile circuit microsystems for improved robustness with washing. Microsyst. Technol. 2019. [Google Scholar] [CrossRef]

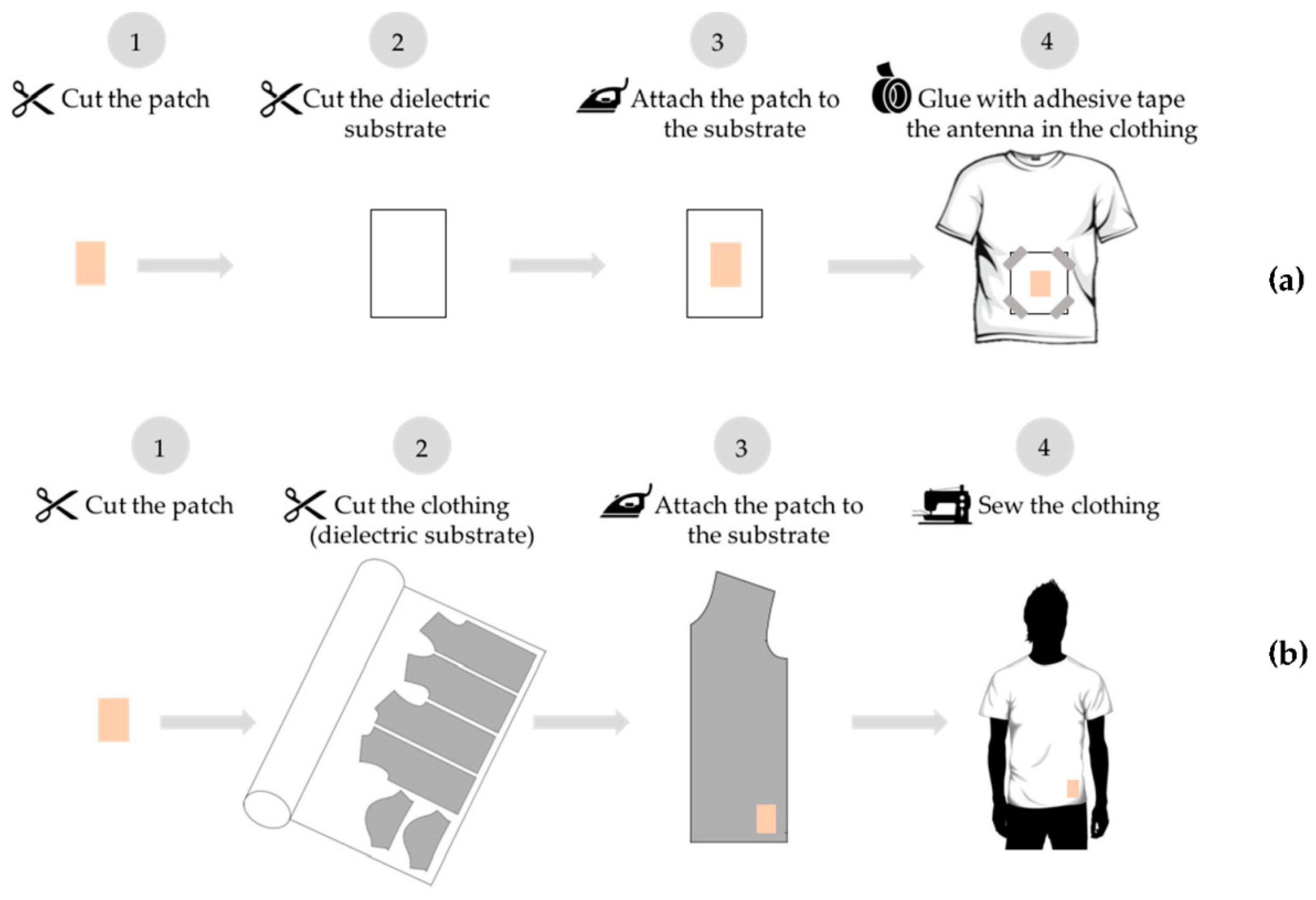

- Locher, I.; Klemm, M.; Kirstein, T.; Tröster, G. Design and characterization of purely textile patch antennas. IEEE Trans. Adv. Packag. 2006, 29, 777–788. [Google Scholar] [CrossRef]

- Ouyang, Y.; Karayianni, E.; Chappell, W. Effect of fabric patterns on electrotextile patch antennas. In Proceedings of the Antennas and Propagation Society International Symposium, Washington, DC, USA, 3–8 July 2005; Volume 2B, pp. 246–249. [Google Scholar]

- Hertleer, C.; Tronquo, A.; Rogier, H.; van Langenhove, L. An aperture-coupled patch antenna for integration into wearable textile systems. IEEE Antennas Wirel. Propag. Lett. 2007, 6, 392–395. [Google Scholar] [CrossRef]

- Hertleer, C.; Rogier, H.; Vallozi, L.; van Langenhove, L. A textile antenna for off-body communication integrated into protective clothing for firefighters. IEEE Trans. Antennas Propag. 2009, 57, 919–925. [Google Scholar] [CrossRef]

- Osman, M.A.R.; Rahim, M.K.A.; Azfar, M.; Samsuri, N.A.; Zubir, F.; Kamardin, K. Design, implementation and performance of ultra-wideband textile antenna. Progr. Electromagn. Res. B 2011, 27, 307–325. [Google Scholar] [CrossRef]

- Klemm, M.; Tröster, G. Textile UWB antennas for wireless body area networks. IEEE Trans. Antennas Propag. 2006, 54, 3192–3197. [Google Scholar] [CrossRef]

- Loss, C.; Goncalves, R.; Lopes, C.; Pinho, P.; Salvado, R. Smart coat with a fully-embedded textile antenna for IoT applications. Sensors 2016, 16, 938. [Google Scholar] [CrossRef]

- Bai, Q.; Langley, R. Crumpling of PIFA textiles antenna. IEEE Trans. Antennas Propag. 2012, 60, 63–70. [Google Scholar] [CrossRef]

- Bayram, Y.; Zhou, Y.; Shim, B.S.; Xu, S.; Zhu, J.; Kotov, N.A.; Volakis, J.L. E-Textile Conductors and Polymer Composites for Conformal Lightweight Antennas. IEEE Trans. Anten. Propag. 2010, 58, 2732–2736. [Google Scholar] [CrossRef]

- Bai, Q.; Langley, R. Crumpled textile antennas. Electron. Lett. 2009, 45, 436–438. [Google Scholar] [CrossRef]

- Ferreira, D.; Pires, P.; Rodrigues, R.; Caldeirinha, R.F.S. Wearable textile antennas. IEEE Antennas Propag. Mag. 2017, 59, 54–59. [Google Scholar] [CrossRef]

- Salonen, P.; Rahmat-samii, Y.; Schafhth, M.; Kivikoski, M. Effect of Textile Materials on Wearable Antenna Performance: A Case Study of GPS Antenna. In Proceedings of the IEEE Antennas and Propagation Society International Symposium, Monterey, CA, USA, 20–25 June 2004; pp. 459–462. [Google Scholar]

- Kiourti, A.; Lee, C.; Volakis, J.L. Fabrication of textile antennas and circuits with 0.1 mm precision. IEEE Antennas Wirel. Propag. Lett. 2015, 15, 151–153. [Google Scholar] [CrossRef]

- Karaguzel, B.; Merritt, C.R.; Kang, T.; Wilson, J.M.; Nagle, H.T.; Grant, E.; Pourdeyhimi, B. Flexible durable printed electrical circuits. J. Text. Inst. 2009, 100, 1–9. [Google Scholar] [CrossRef]

- Scarpello, M.L.; Kazani, I.; Hertleer, C.; Rogier, H.; Vande Ginste, D. Stability and efficiency of screen-printed wearable and washable antennas. IEEE Antennas Wirel. Progag. Lett. 2012, 11, 838–841. [Google Scholar] [CrossRef]

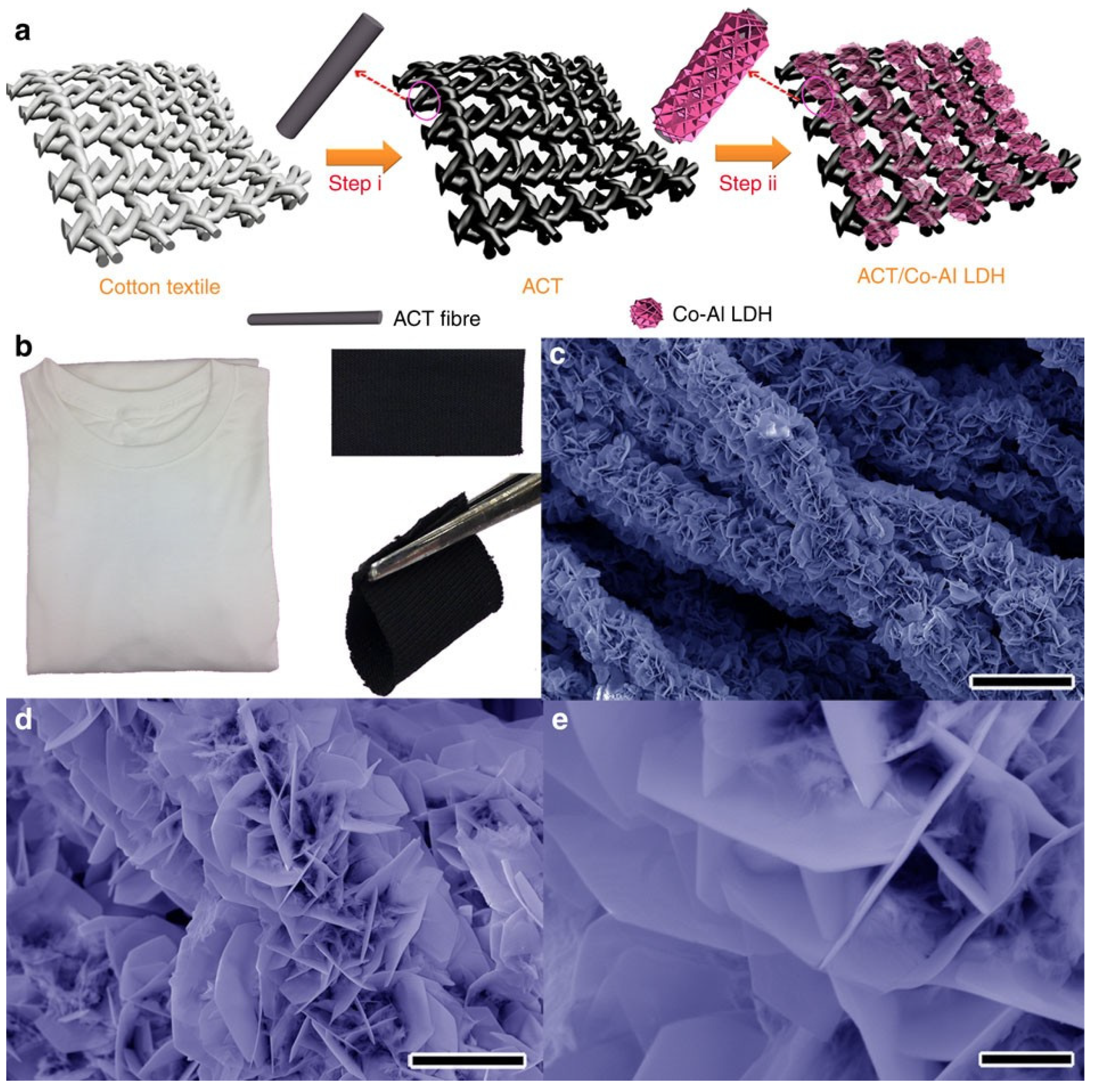

- Gulzar, U.; Goriparti, S.; Miele, E.; Li, T.; Maidecchi, G.; Toma, A.; Angelis, F.; Capiglia, C.; Zaccaria, R.P. Next-generation textiles: From embedded supercapacitors to lithium ion batteries. J. Mater. Chem. A 2016, 4, 16771. [Google Scholar] [CrossRef]

- Bashid, H.A.A.; Ngee Lim, H.; Kamaruzaman, S.; Rashid, S.; Yunus, R.; Huang, N.; Yin, C.; Rahma, M.; Altarawneh, M.; Jiang, Z.T.; et al. Electrodeposition on polypyrrole and reduced graphene oxide onto carbon bundle fibre as electrode for supercapacitor. Nanoscale Res. Lett. 2017, 12, 246. [Google Scholar] [CrossRef]

- Yong, S.; Oven, J.; Tudor, M.; Beeby, S. Flexible solid-state fabric based supercapacitor. J. Phys. Conf. Ser. 2015, 660, 012074. [Google Scholar] [CrossRef]

- Yong, S.; Shi, J.J.; Beeby, S. Wearable textile power module based on flexible ferroelectret and supercapacitor. Energy Technol. 2019, 7, 1800938. [Google Scholar] [CrossRef]

- Gao, Z.; Bumgardner, C.; Song, N.N.; Zhang, Y.Y.; Li, J.J.; Li, X.D. Cotton-textile-enabled flexible self-sustaining power packs via roll-to-roll fabrication. Nat. Comm. 2016, 7, 11586. [Google Scholar] [CrossRef]

- Li, Y.; Yong, S.; Hillier, N.; Arumugam, S.; Beeby, S. Screen printed flexible water activated battery on woven cotton textile as a power supply for e-textile applications. IEEE Access 2020, 8, 206958–206965. [Google Scholar] [CrossRef]

- Pu, X.; Li, L.X.; Song, H.Y.; Du, C.H.; Zhao, Z.F.; Jiang, C.Y.; Cao, G.H.; Hu, W.G.; Wang, Z.L. A self-charging power unit by integration of a textile triboelectric nanogenerator and a flexible lithium-ion battery for wearable electronics. Adv. Mater. 2015, 27, 2472–2478. [Google Scholar] [CrossRef] [PubMed]

- Gao, Z.; Zhang, Y.Y.; Song, N.N.; Li, X.D. Towards flexible lithium-sulfur battery from natural cotton textile. Electrochim. Acta 2017, 246, 507–516. [Google Scholar] [CrossRef]

- Hu, L.B.; Chen, W.; Xie, X.; Liu, N.; Yang, Y.; Wu, H.; Yao, Y.; Pasta, M.; Alshareef, H.N.; Cui, Y. Symmetrical MnO2-carbon nantube-textile nanostructures for wearable pseudocapacitors with high mass loading. ACS Nano 2011, 5, 8904–8913. [Google Scholar] [CrossRef] [PubMed]

- Nagaraju, G.; Raju, G.S.R.; Ko, Y.H.; Yu, J.S. Hierarchical Ni–Co layered double hydroxide nanosheets entrapped on conductive textile fibers: A cost-effective and flexible electrode for high-performance pseudocapacitors. Nanoscale 2016, 8, 812–825. [Google Scholar] [CrossRef] [PubMed]

- Dubal, D.P.; Chodankar, N.R.; Qiao, S.H. Tungsten nitride nanodots embedded phosphorous modified carbon fabric as flexible and robust electrode for asymmetric pseudocapacitor. Small 2019, 15, 1804104. [Google Scholar] [CrossRef]

- Maccioni, M.; Orgiu, E.; Cosseddu, O.; Locci, S.; Bonfiglio, A. Towards the textile transistor: Assembly and characterization of an organic field effect transistor with a cylindrical geometry. Appl. Phys. Lett. 2006, 89, 143515. [Google Scholar] [CrossRef]

- Tao, X.Y.; Koncar, V.; Dufour, C. Geometry pattern for the wire organic electrochemical textile transistor. J. Electrochem. Soc. 2011, 148, H572. [Google Scholar] [CrossRef]

- Gualandi, I.; Marzocchi, M.; Achilli, A.; Cavedale, D.; Bonfiglio, A.; Fraboni, B. Textile organic electrochemical transistors as a platform for wearable biosensors. Sci. Rep. 2016, 6, 33637. [Google Scholar] [CrossRef]

- Bashir, T.; Skrifvars, M.; Persson, N.-K. Production of highly conductive textile viscose yarns by chemical vapor deposition technique: A route to continuous process. Polym. Adv. Technol. 2011, 22, 2214–2221. [Google Scholar] [CrossRef]

- Wang, X.; Qiu, Y.F.; Cao, W.W.; Hu, P.A. Highly stretchable and conductive core–sheath chemical vapor Deposition graphene fibers and their applications in safe strain sensors. Chem. Mater. 2015, 27, 6969–6975. [Google Scholar] [CrossRef]

- Lee, H.; Cho, E.J.; Webbe Kerekes, T.; Kwon, S.L.; Yun, G.J.; Kim, J.Y. Water-resistant mechanoluminescent electrospun fabrics with protected sensitivity in wet condition via plasma-enhanced chemical vapor deposition process. Polymers 2020, 12, 1720. [Google Scholar] [CrossRef] [PubMed]

- Oh, I.-K.; Park, J.S.; Khan, M.R.; Kim, K.; Lee, Z.H.; Shong, B.G.; Lee, H.-B.-R. Reaction mechanism of Pt atomic layer deposition on various textile surfaces. Chem. Mater. 2019, 31, 8995–9002. [Google Scholar] [CrossRef]

- Lee, J.H.; Yoon, J.H.; Kim, H.G.; Kang, S.B.; Oh, W.-S.; Algadi, H.; Al-Sayari, S.; Shong, B.G.; Kim, S.-H.; Kim, H.J.; et al. Highly conductive and flexible fiber for textile electronics obtained by extremely low-temperature atomic layer deposition of Pt. NPG Asia Mater. 2016, 8, e331. [Google Scholar] [CrossRef]

- Mundy, J.Z.; Shafiefarhoo, A.; Li, F.X.; Khan, S.A.; Parsons, G.N. Low temperature platinum atomic layer deposition on nylon-6 for highly conductive and catalytic fiber mats. J. Vac. Sci. Technol. A 2016, 34, 01A152. [Google Scholar] [CrossRef]

| Conductive Material | Resistivity/Sheet Resistance/Linear Resistance | Ref. |

|---|---|---|

| PEDOT:PSS on synthetic leather | 1.6 Ω | [23] |

| PEDOT:PSS on PET non-woven | 3.2 Ω | [23] |

| PEDOT:PSS-coated silk thread | 0.1 Ω cm | [24] |

| Ag-coated silk thread | 0.01 Ω cm | [24] |

| Ag nanowire/PEDOT:PSS-coated silk yarn | 3 × 10−3 Ω cm | [28] |

| Ag nanowire/PEDOT:PSS-coated cellulose yarn | 5.5 × 10−3 Ω cm | [29] |

| PEDOT:PSS-coated nanofiber mat | 130 Ω | [32] |

| PAni/PVP electro-spun nanofiber mats | 60 Ω cm | [34] |

| PAni/PVP electro-spun nanofiber yarn | 2.4 × 103 Ω cm | [34] |

| PAni-coated PET yarn | 80 Ω/cm | [35] |

| Acidified and annealed stainless steel yarn | 0.7–1.8 Ω/cm | [43] |

| Ag nanowire-coated wool knitted fabric | 2.7 Ω/cm | [44] |

| Ag nanoparticle-coated mercerized cotton | 0.2 Ω | [45] |

| Electroless Cu-plated (<100 nm) membrane | 3.5 Ω | [48] |

| Electroless Cu-plated PET 2-ply yarn | 0.2 Ω/cm | [49] |

| Carbon nanotube-wrapped rubber fiber (strain-dependent) | 26 Ω/cm–2 kΩ/cm | [52] |

| PAN/graphite coatings on cotton woven fabrics | 400–1000 Ω/cm | [57] |

| Graphene oxide-coated cotton fabric | 92 kΩ | [59] |

| Reduced graphene oxide-coated PES fabric | 11 kΩ | [60] |

| Inkjet-printed reduced graphene oxide on cotton | 2 kΩ | [61] |

| Silver inkjet ink printed on cotton | 1.2 Ω | [61] |

| Graphene pad-dry-cure-coated cotton fabric | 12 Ω | [65] |

| Drop-casted PAni/carbon black on cotton fabric | 500 Ω | [68] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ehrmann, G.; Ehrmann, A. Electronic Textiles. Encyclopedia 2021, 1, 115-130. https://doi.org/10.3390/encyclopedia1010013

Ehrmann G, Ehrmann A. Electronic Textiles. Encyclopedia. 2021; 1(1):115-130. https://doi.org/10.3390/encyclopedia1010013

Chicago/Turabian StyleEhrmann, Guido, and Andrea Ehrmann. 2021. "Electronic Textiles" Encyclopedia 1, no. 1: 115-130. https://doi.org/10.3390/encyclopedia1010013

APA StyleEhrmann, G., & Ehrmann, A. (2021). Electronic Textiles. Encyclopedia, 1(1), 115-130. https://doi.org/10.3390/encyclopedia1010013