Formation and Characterization of Aroma Compounds in Camembert Cheese

Abstract

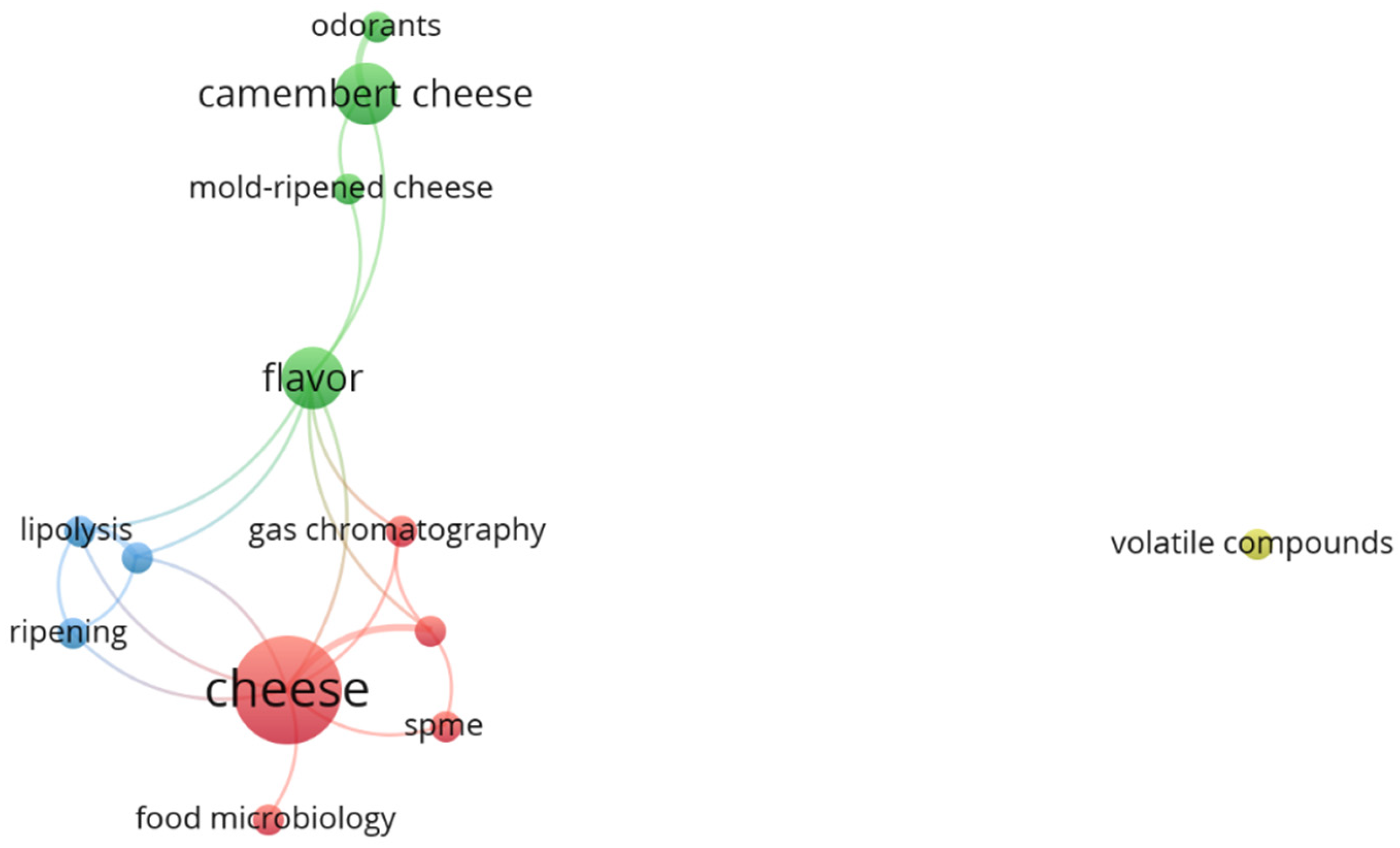

1. Introduction

2. Materials and Methods

3. Results

3.1. Odor-Active Volatile Profile of Camembert Cheese

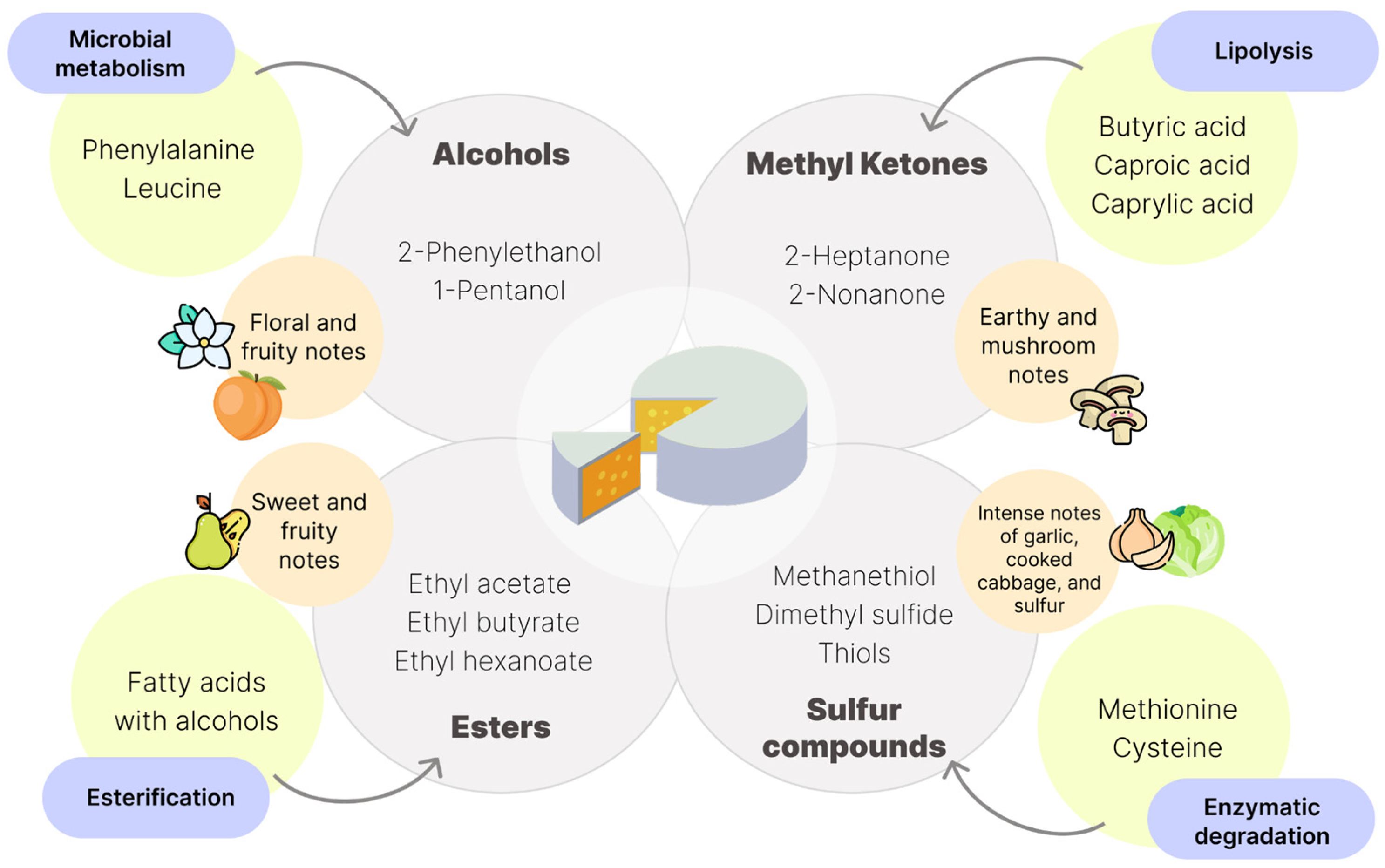

3.2. Biochemical Origin of Odor-Active Volatile Compounds in Camembert Cheese

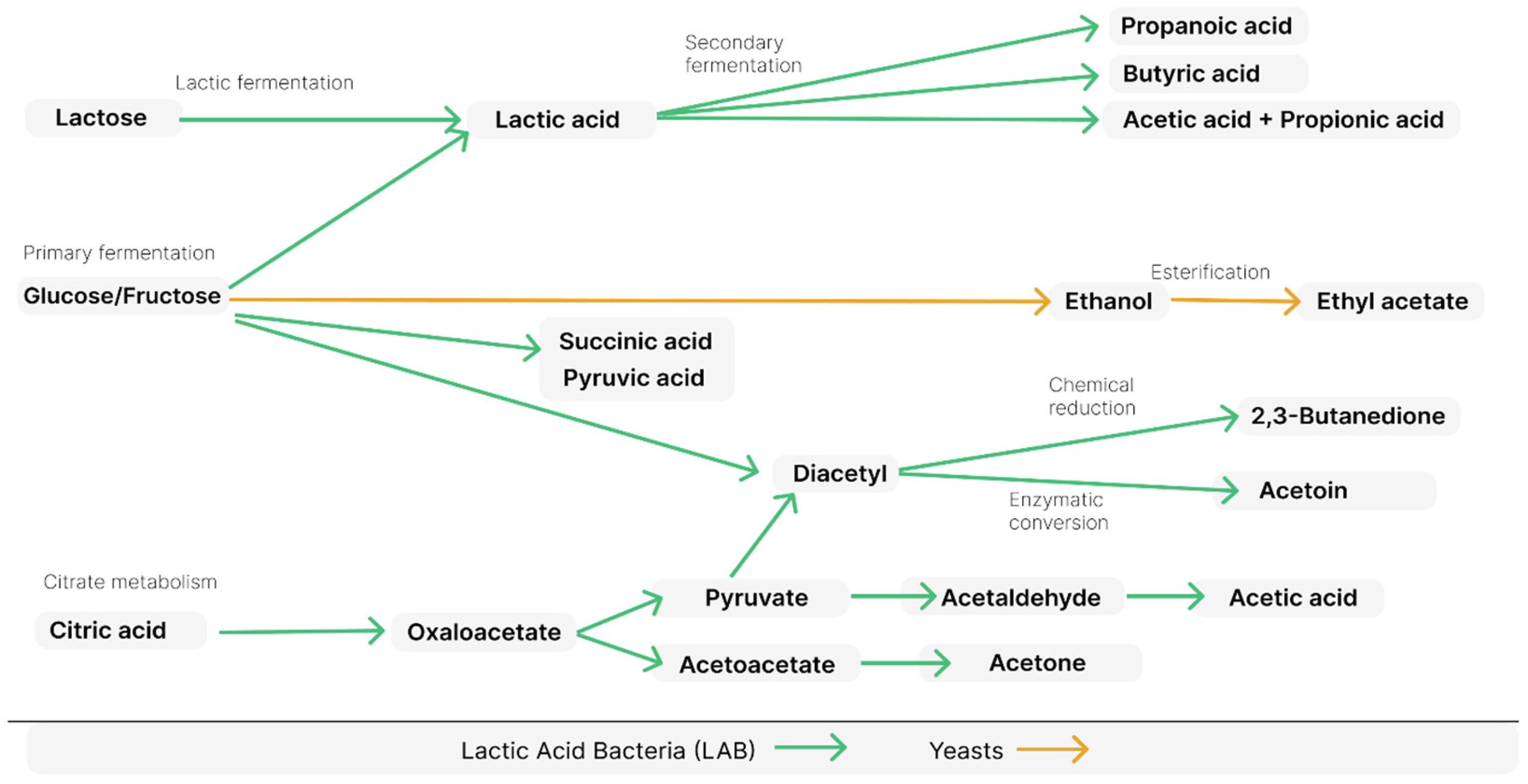

3.2.1. Carbohydrate Metabolism and the Formation of Aroma Compounds

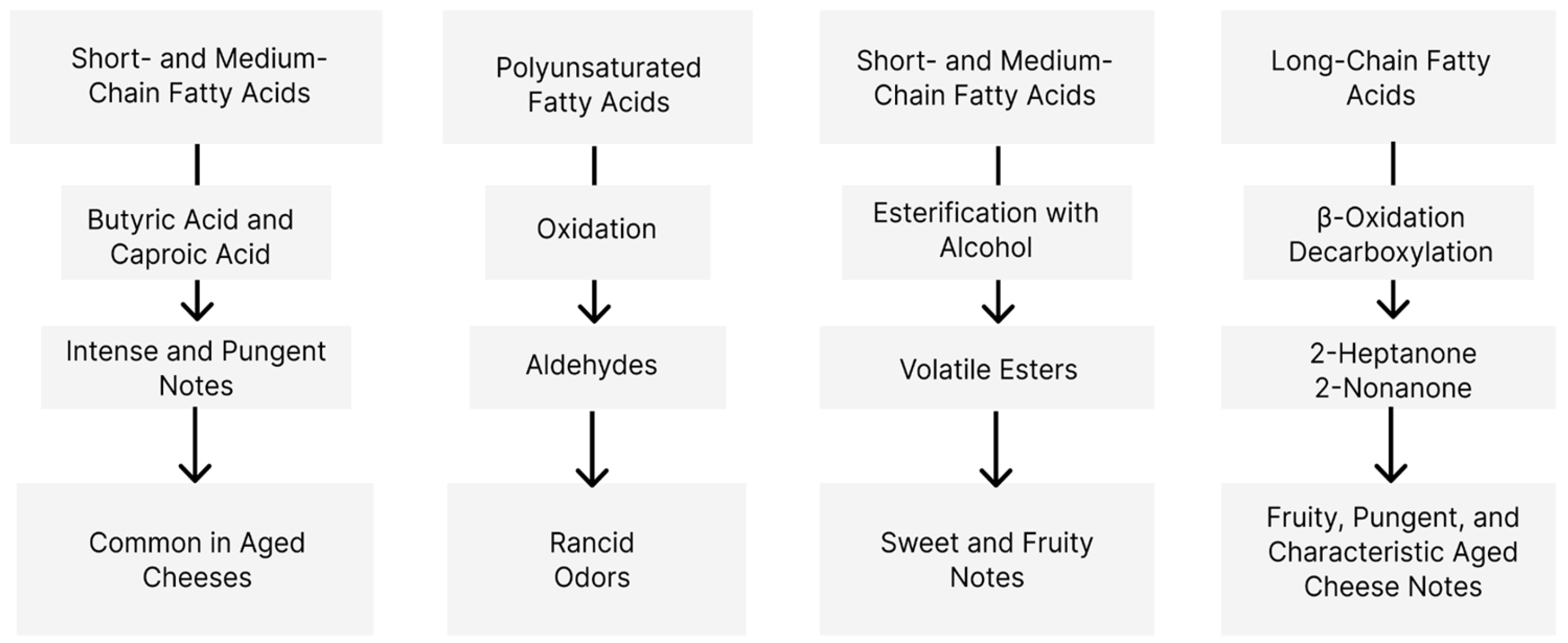

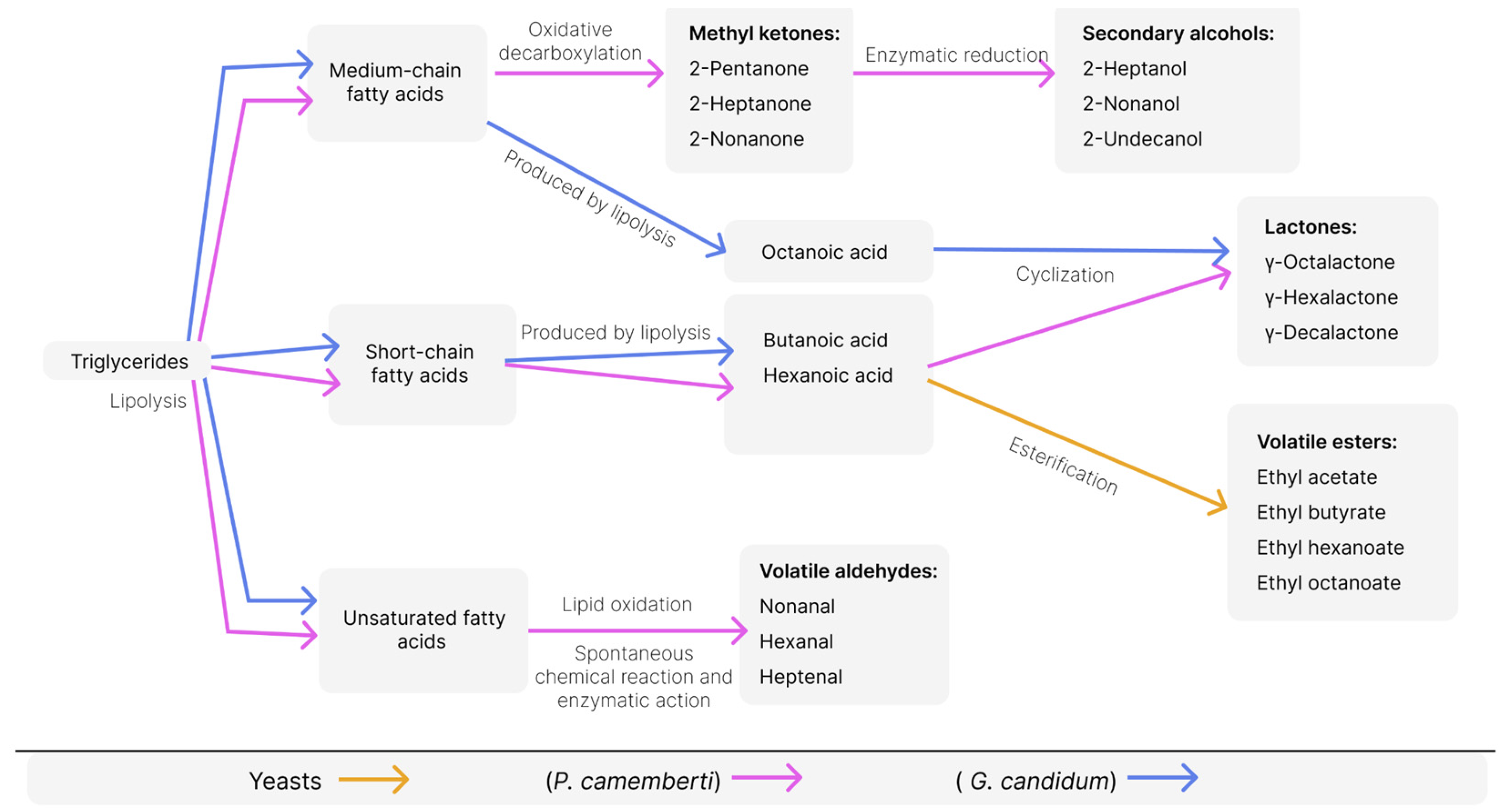

3.2.2. Odor-Active Volatiles Formed by Fatty Acid Metabolism

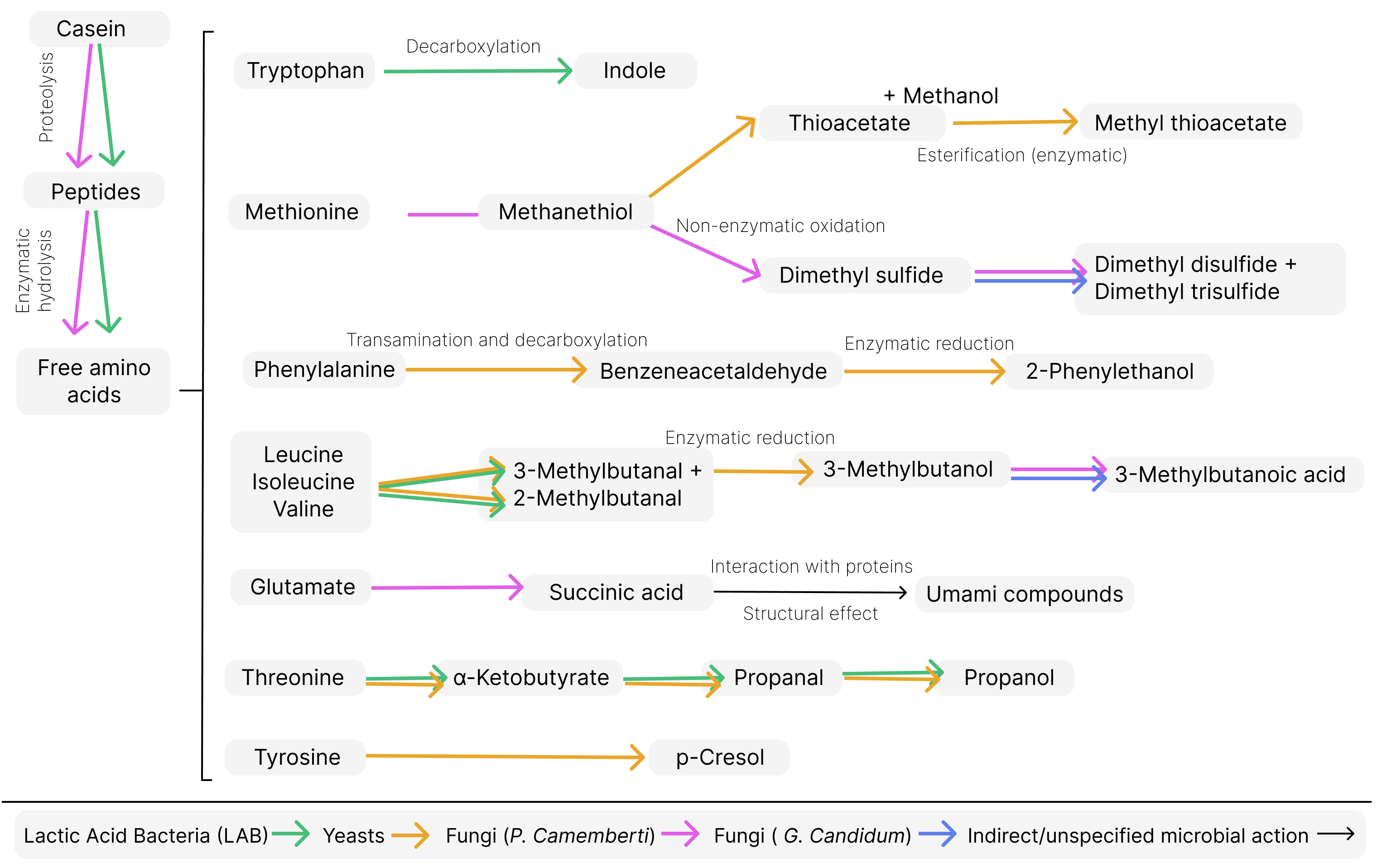

3.2.3. Odor-Active Volatiles Formed by Amino Acid Metabolism

3.3. Role of Microbiota in the Ripening of Camembert Cheese

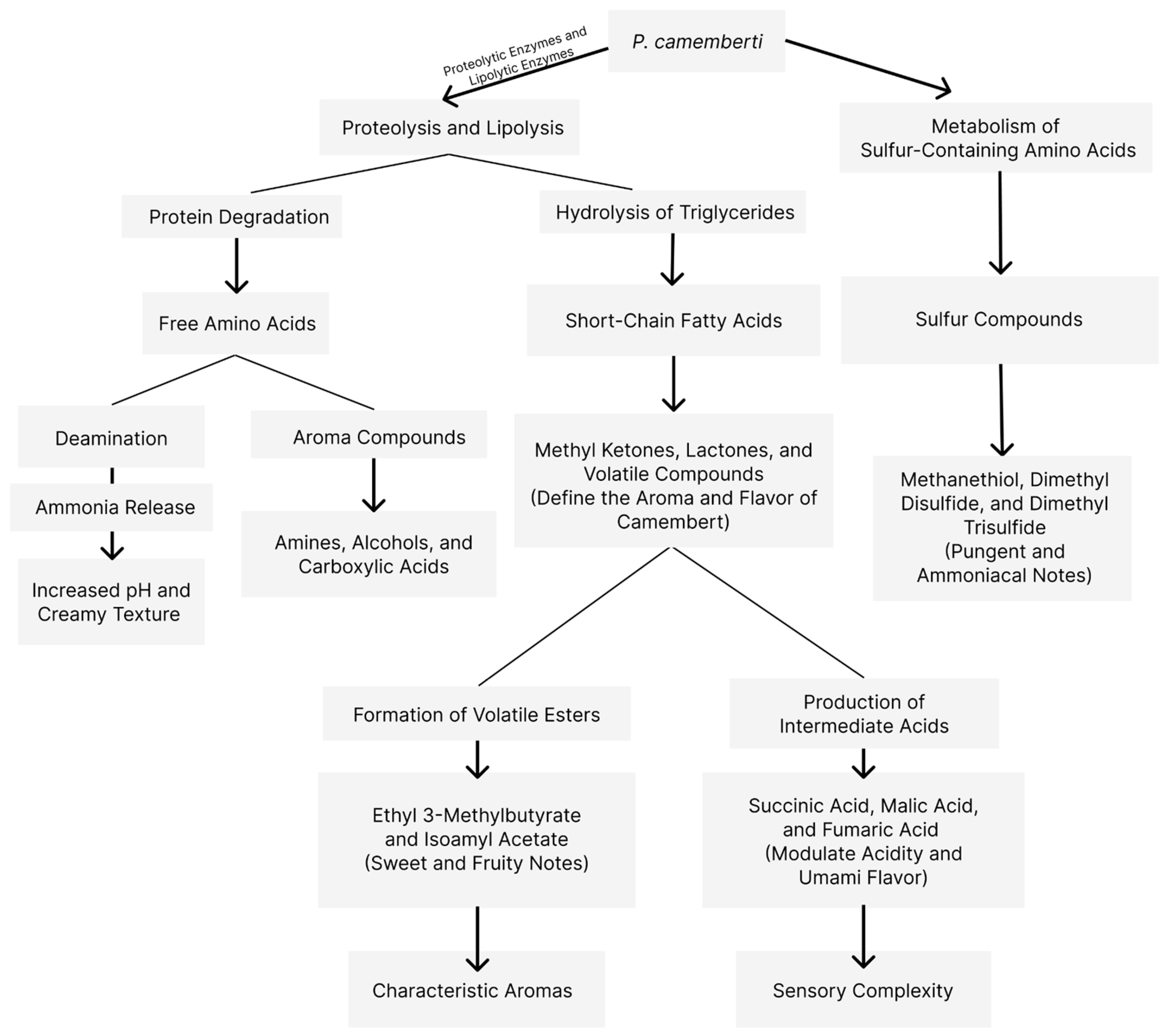

3.3.1. Role of Penicillium camemberti

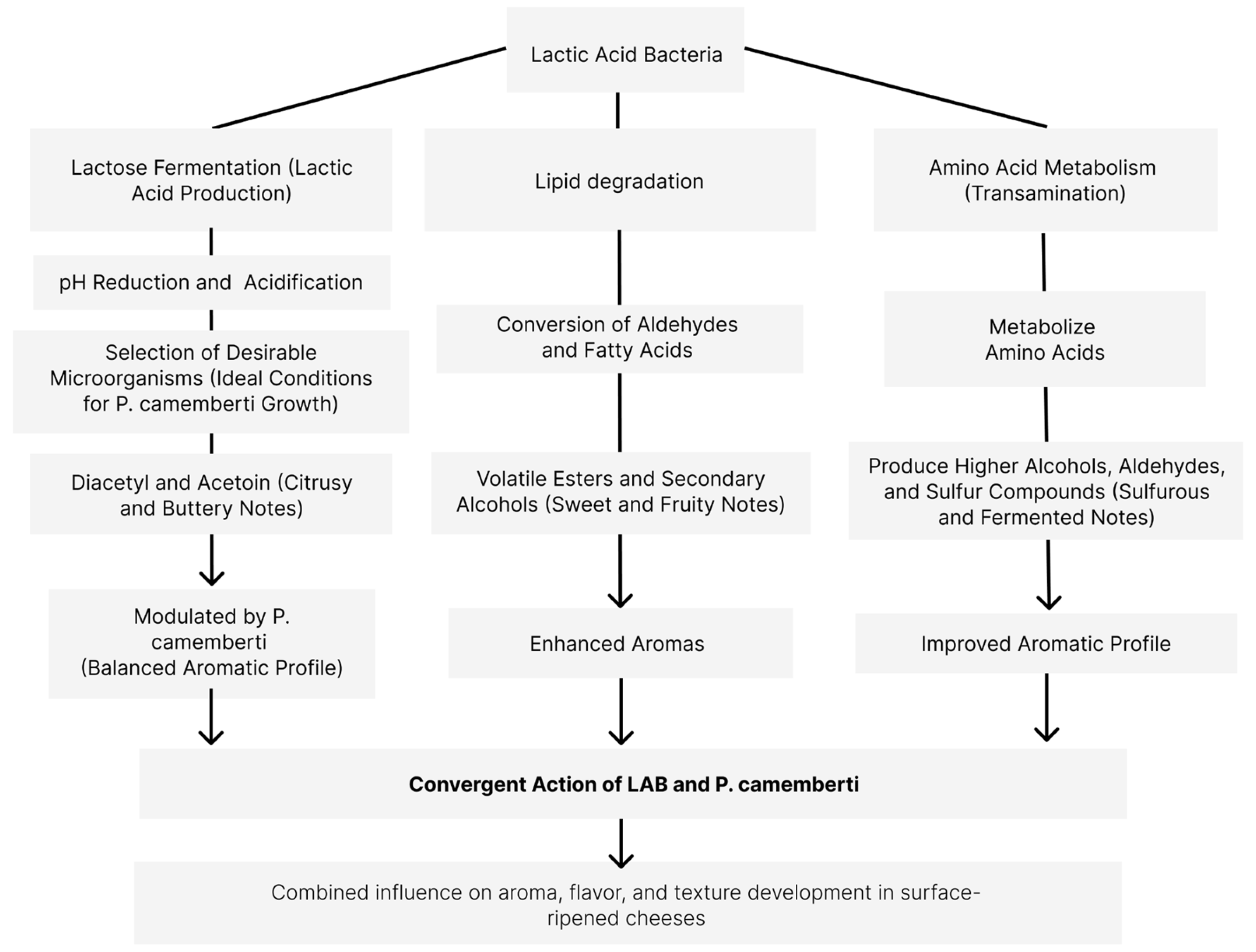

3.3.2. Role of Lactic Acid Bacteria (LAB)

3.3.3. Role of Yeasts

3.4. Methods for the Analysis of Volatile Compounds

3.5. Effect of Processing Conditions on the Formation of Volatile Compounds and the Aroma Profile of Camembert

Innovations in the Ripening Process

3.6. Challenges and Opportunities for Research on Camembert Cheese Aroma

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GC–MS | Gas Chromatography–Mass Spectrometry |

| GC–O | Gas Chromatography–Olfactometry |

| SPME | Solid-Phase Microextraction |

| GC | Gas Chromatography |

| AEDA | Aroma Extract Dilution Analysis |

| OAV | Odor Activity Value |

| LAB | Lactic Acid Bacteria |

| FFA | Free Fatty Acids |

| QDA | Quantitative Descriptive Analysis |

| IMS | Ion Mobility Spectrometry |

| NMR | Nuclear Magnetic Resonance Spectroscopy |

References

- Fox, P.F.; Guinee, T.P.; Cogan, T.M.; McSweeney, P.L.H. Fundamentals of Cheese Science; Springer US: Boston, MA, USA, 2017; ISBN 978-1-4899-7679-6. [Google Scholar]

- McSweeney, P.L.H. Biochemistry of Cheese Ripening. Int. J. Dairy. Technol. 2004, 57, 127–144. [Google Scholar] [CrossRef]

- Ianni, A.; Bennato, F.; Martino, C.; Grotta, L.; Martino, G. Volatile Flavor Compounds in Cheese as Affected by Ruminant Diet. Molecules 2020, 25, 461. [Google Scholar] [CrossRef]

- Güler, Z. Profiles of Organic Acid and Volatile Compounds in Acid-Type Cheeses Containing Herbs and Spices (Surk Cheese). Int. J. Food Prop. 2014, 17, 1379–1392. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, T.; Zhang, Y.; Song, B.; Pang, X.; Lv, J. Effects of Monascus on Proteolysis, Lipolysis, and Volatile Compounds of Camembert-Type Cheese during Ripening. Foods 2022, 11, 1662. [Google Scholar] [CrossRef]

- Ropars, J.; Giraud, T. Convergence in Domesticated Fungi Used for Cheese and Dry-Cured Meat Maturation: Beneficial Traits, Genomic Mechanisms, and Degeneration. Curr. Opin. Microbiol. 2022, 70, 102236. [Google Scholar] [CrossRef]

- Palermo, C.; Mentana, A.; Tomaiuolo, M.; Campaniello, M.; Iammarino, M.; Centonze, D.; Zianni, R. Headspace Solid-Phase Microextraction/Gas Chromatography–Mass Spectrometry and Chemometric Approach for the Study of Volatile Profile in X-Ray Irradiated Surface-Ripened Cheeses. Foods 2024, 13, 416. [Google Scholar] [CrossRef]

- Li, R.; He, W. Chinese Red Wine and Cheese Pairings: A Preliminary Study of Consumer Perception Using Check-all-that-apply and Hedonic Tests. J. Sens. Stud. 2023, 38, e12867. [Google Scholar] [CrossRef]

- Pérès, C.; Viallon, C.; Berdagué, J.-L. Solid-Phase Microextraction-Mass Spectrometry: A New Approach to the Rapid Characterization of Cheeses. Anal. Chem. 2001, 73, 1030–1036. [Google Scholar] [CrossRef]

- Cao, W.; Aubert, J.; Maillard, M.-B.; Boissel, F.; Leduc, A.; Thomas, J.-L.; Deutsch, S.-M.; Camier, B.; Kerjouh, A.; Parayre, S.; et al. Fine-Tuning of Process Parameters Modulates Specific Metabolic Bacterial Activities and Aroma Compound Production in Semi-Hard Cheese. J. Agric. Food Chem. 2021, 69, 8511–8529. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Molimard, P.; Spinnler, H.E. Review: Compounds Involved in the Flavor of Surface Mold-Ripened Cheeses: Origins and Properties. J. Dairy Sci. 1996, 79, 169–184. [Google Scholar] [CrossRef]

- Bae, H.C.; Nam, J.H.; Renchinkhand, G.; Choi, S.-H.; Nam, M.S. Physicochemical Changes during 4 Weeks Ripening of Camembert Cheeses Salted with Four Types of Salts. Appl. Biol. Chem. 2020, 63, 66. [Google Scholar] [CrossRef]

- Pérès, C.; Begnaud, F.; Berdagué, J.-L. Fast Characterization of Camembert Cheeses by Static Headspace–Mass Spectrometry. Sens. Actuators B Chem. 2002, 87, 491–497. [Google Scholar] [CrossRef]

- Jaillais, B.; Bertrand, V.; Auger, J. Cryo-Trapping/SPME/GC Analysis of Cheese Aroma. Talanta 1999, 48, 747–753. [Google Scholar] [CrossRef]

- Chen, X.; Gu, Z.; Peng, Y.; Quek, S.Y. What Happens to Commercial Camembert Cheese under Packaging? Unveiling Biochemical Changes by Untargeted and Targeted Metabolomic Approaches. Food Chem. 2022, 383, 132437. [Google Scholar] [CrossRef]

- Kubícková, J.; Grosch, W. Evaluation of Flavour Compounds of Camembert Cheese. Int. Dairy J. 1998, 8, 11–16. [Google Scholar] [CrossRef]

- Santamarina-García, G.; Amores, G.; Hernández, I.; Morán, L.; Barrón, L.J.R.; Virto, M. Relationship between the Dynamics of Volatile Aroma Compounds and Microbial Succession during the Ripening of Raw Ewe Milk-Derived Idiazabal Cheese. Curr. Res. Food Sci. 2022, 6, 100425. [Google Scholar] [CrossRef]

- Ricciardi, A.; Zotta, T.; Ianniello, R.G.; Boscaino, F.; Matera, A.; Parente, E. Effect of Respiratory Growth on the Metabolite Production and Stress Robustness of Lactobacillus Casei N87 Cultivated in Cheese Whey Permeate Medium. Front. Microbiol. 2019, 10, 851. [Google Scholar] [CrossRef]

- Zheng, X.; Shi, X.; Wang, B. A Review on the General Cheese Processing Technology, Flavor Biochemical Pathways and the Influence of Yeasts in Cheese. Front. Microbiol. 2021, 12, 703284. [Google Scholar] [CrossRef]

- Eramo, V.; Modesti, M.; Riggi, R.; Forniti, R.; Lembo, M.; Vinciguerra, V.; Botondi, R. Preserving the Aromatic Profile of Aged Toma Piemontese Protected Designation of Origin Cheese with Gaseous Ozone Technology: A Quality Assessment via Solid Phase Microextraction-Gas Chromatography–Mass Spectrometry/Electronic Nose. J. Dairy Sci. 2024, 107, 10537–10551. [Google Scholar] [CrossRef]

- van Mastrigt, O.; Gallegos Tejeda, D.; Kristensen, M.N.; Abee, T.; Smid, E.J. Aroma Formation during Cheese Ripening Is Best Resembled by Lactococcus lactis Retentostat Cultures. Microb. Cell Fact. 2018, 17, 104. [Google Scholar] [CrossRef]

- Kilcawley, K.N. Cheese Flavour. In Fundamentals of Cheese Science; Fox, P.F., Guinee, T.P., Cogan, T.M., McSweeney, P.L.H., Eds.; Springer US: Boston, MA, USA, 2017; pp. 443–474. ISBN 978-1-4899-7681-9. [Google Scholar]

- Pionnier, E.; Engel, E.; Salles, C.; Le Quéré, J.L. Interactions between Non-Volatile Water-Soluble Molecules and Aroma Compounds in Camembert Cheese. Food Chem. 2002, 76, 13–20. [Google Scholar] [CrossRef]

- Arias, R.; Alba, C.; Calzada, J.; Jiménez, L.; Fernández, L.; Ávila, M.; Roman, M.; Roman, J.; Rodríguez, J.M.; Garde, S. Application of Ligilactobacillus salivarius SP36, a Strain Isolated from an Old Cheese Seal, as an Adjunct Culture in Cheesemaking. Foods 2024, 13, 2296. [Google Scholar] [CrossRef] [PubMed]

- Landaud, S.; Helinck, S.; Bonnarme, P. Formation of Volatile Sulfur Compounds and Metabolism of Methionine and Other Sulfur Compounds in Fermented Food. Appl. Microbiol. Biotechnol. 2008, 77, 1191–1205. [Google Scholar] [CrossRef]

- Dugat-Bony, E.; Bonnarme, P.; Fraud, S.; Catellote, J.; Sarthou, A.-S.; Loux, V.; Rué, O.; Bel, N.; Chuzeville, S.; Helinck, S. Effect of Sodium Chloride Reduction or Partial Substitution with Potassium Chloride on the Microbiological, Biochemical and Sensory Characteristics of Semi-Hard and Soft Cheeses. Food Res. Int. 2019, 125, 108643. [Google Scholar] [CrossRef]

- Lessard, M.-H.; Viel, C.; Boyle, B.; St-Gelais, D.; Labrie, S. Metatranscriptome Analysis of Fungal Strains Penicillium camemberti and Geotrichum candidumreveal Cheese Matrix Breakdown and Potential Development of Sensory Properties of Ripened Camembert-Type Cheese. BMC Genom. 2014, 15, 235. [Google Scholar] [CrossRef]

- Los, P.R.; Simões, D.R.S.; Benvenutti, L.; Zielinski, A.A.F.; Alberti, A.; Nogueira, A. Combinando Análise Química, Perfil Sensorial, CATA, Mapeamento de Preferências e Quimiometria Para Estabelecer o Padrão de Qualidade Do Consumidor de Queijos Do Tipo Camembert. Int. J. Dairy Technol. 2020, 74, 371–382. [Google Scholar] [CrossRef]

- Blaya, J.; Barzideh, Z.; LaPointe, G. Symposium Review: Interaction of Starter Cultures and Nonstarter Lactic Acid Bacteria in the Cheese Environment 1. J. Dairy Sci. 2017, 101, 3611–3629. [Google Scholar] [CrossRef]

- Pagthinathan, M.; Nafees, M.S.M. Biochemistry of Cheese Ripening. AGRIEAST J. Agric. Sci. 2017, 10, 16–26. [Google Scholar] [CrossRef]

- McAuliffe, O.; Kilcawley, K.; Stefanovic, E. Symposium Review: Genomic Investigations of Flavor Formation by Dairy Microbiota. J. Dairy Sci. 2018, 102, 909–922. [Google Scholar] [CrossRef]

- Bertuzzi, A.S.; McSweeney, P.L.H.; Rea, M.C.; Kilcawley, K.N. Detection of Volatile Compounds of Cheese and Their Contribution to the Flavor Profile of Surface-Ripened Cheese. Compr. Rev. Food Sci. Food Saf. 2018, 17, 371–390. [Google Scholar] [CrossRef] [PubMed]

- Habibi, A.; Lavasani, A.S.; Mortazavian, A.M.; Hoseini, S.E.; Zarei, H. Characteristics of Iranian Probiotic UF White Cheese. J. Food Qual. 2023, 2023, 4395161. [Google Scholar] [CrossRef]

- Yvon, M.; Rijnen, L. Cheese Flavour Formation by Amino Acid Catabolism. Int. Dairy J. 2001, 11, 185–201. [Google Scholar] [CrossRef]

- Smit, B.A.; Engels, W.J.M.; Smit, G. Branched Chain Aldehydes: Production and Breakdown Pathways and Relevance for Flavour in Foods. Appl. Microbiol. Biotechnol. 2009, 81, 987–999. [Google Scholar] [CrossRef]

- Irlinger, F.; Mounier, J. Microbial Interactions in Cheese: Implications for Cheese Quality and Safety. Curr. Opin. Biotechnol. 2009, 20, 142–148. [Google Scholar] [CrossRef]

- Karahadian, C.; Josephson, D.B.; Lindsay, R.C. Contribuição de Penicillium Sp. Para Os Sabores Dos Queijos Brie e Camembert1. J. Dairy Sci. 1985, 68, 1865–1877. [Google Scholar] [CrossRef]

- Hayashida, S.; Hagi, T.; Kobayashi, M.; Kusumoto, K.-I.; Ohmori, H.; Tomita, S.; Suzuki, S.; Yamashita, H.; Sato, K.; Miura, T.; et al. Comparison of Taste Characteristics between Koji Mold–Ripened Cheese and Camembert Cheese Using an Electronic Tongue System. J. Dairy Sci. 2023, 106, 6701–6709. [Google Scholar] [CrossRef]

- Voblikova, T.; Permyakov, A.; Rostova, A.; Masyutina, G.; Eliseeva, A. Influence of the Maturation Process on the Sheep’s Milk of Camembert Cheese Fatty Acid Profile Change. KnE Life Sci. 2020, 5, 696–705. [Google Scholar] [CrossRef]

- Łopusiewcz, Ł.; Śmietana, N.; Lichwiarska, E.; Mazurkiewicz-Zapałowicz, K.; Gefrom, A.; Drozłowska, E. The Biotransformation of Lupine Seeds by Lactic Acid Bacteria and Penicillium camemberti into a Plant-Based Camembert Alternative, and Its Physicochemical Changes during 7 Weeks of Ripening. Fermentation 2022, 8, 447. [Google Scholar] [CrossRef]

- Jiao, J.; Zheng, Z.; Liu, Z.; You, C. Study of the Compositional, Microbiological, Biochemical, and Volatile Profile of Red-Veined Cheese, an Internal Monascus-Ripened Variety. Front. Nutr. 2021, 8, 649611. [Google Scholar] [CrossRef]

- Smid, E.J.; Kleerebezem, M. Production of Aroma Compounds in Lactic Fermentations. Annu. Rev. Food Sci. Technol. 2014, 5, 313–326. [Google Scholar] [CrossRef] [PubMed]

- Ozturkoglu-Budak, S.; Gursoy, A.; Aykas, D.P.; Koçak, C.; Dönmez, S.; de Vries, R.P.; Bron, P.A. Volatile Compound Profiling of Turkish Divle Cave Cheese during Production and Ripening. J. Dairy Sci. 2016, 99, 5120–5131. [Google Scholar] [CrossRef] [PubMed]

- Fröhlich-Wyder, M.; Arias-Roth, E.; Jakob, E. Cheese Yeasts. Yeast 2019, 36, 129–141. [Google Scholar] [CrossRef] [PubMed]

- Anastasiou, R.; Kazou, M.; Georgalaki, M.; Aktypis, A.; Zoumpopoulou, G.; Tsakalidou, E. Omics Approaches to Assess Flavor Development in Cheese. Foods 2022, 11, 188. [Google Scholar] [CrossRef]

- Atasever, M.; Mazlum, H. Biochemical Processes During Cheese Ripening. Vet. Sci. Pract. 2024, 19, 174–182. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, Y.; Meng, F.; Wang, B.; Wang, Y. Análise Comparativa Dos Compostos Voláteis de Sabor Do Queijo Fermentado Com Monascus Com Diferentes Períodos de Maturação Por SPME-GC-MS, SPME-GC×GC-MS e HS-GC-IMS. Food Biosci. 2024, 62, 105045. [Google Scholar] [CrossRef]

- EVA VÍTOVÁ Application of SPME-GC Method for Analysis of the Aroma of White Surface Mould Cheeses. Available online: https://scholar.googleusercontent.com/scholar?q=cache:NSIdpU2sW0AJ:scholar.google.com/+Application+of+SPME-GC+method+for+analysis+of+the+aroma+of+white+surface+mould+cheeses+&hl=pt-BR&as_sdt=0,5 (accessed on 22 August 2024).

- Judacewski, P.; Barreto, P.L.M.; Trindade, M.A.; Colla, E. Evaluation of fresh spores of Penicillium camemberti as starter in mould-ripened cheeses based on the perception of Brazilian consumers. Int. J. Dairy Technol. 2020, 73, 660–669. [Google Scholar] [CrossRef]

- Štefániková, J.; Árvay, J.; Miškeje, M.; Kačániová, M. Determination of Volatile Organic Compounds in Slovak Bryndza Cheese by the Electronic Nose and the Headspace Solid-Phase Microextraction Gas Chromatography-Mass Spectrometry. Potravin. Slovak J. Food Sci. 2020, 14, 767–773. [Google Scholar] [CrossRef]

- Suzuki-Iwashima, A.; Matsuura, H.; Iwasawa, A.; Shiota, M. Análises Metabolômicas Dos Efeitos Combinados de Bactérias Lácticas e Penicillium camemberti Na Geração de Compostos Voláteis Em Modelos de Queijos Maturados Com Mofo Na Superfície. J. Biosci. Bioeng. 2020, 129, 333–347. [Google Scholar] [CrossRef]

- Yeluri Jonnala, B.R.; McSweeney, P.L.H.; Sheehan, J.J.; Cotter, P.D. Sequencing of the Cheese Microbiome and Its Relevance to Industry. Front. Microbiol. 2018, 9, 1020. [Google Scholar] [CrossRef]

- Tian, H.; Sun, X.; Yu, H.; Ai, L.; Chen, C. Characterization of the Key Aroma Compounds in Yunnan Goat Milk Cake Using a Sensory-directed Flavor Analysis. J. Food Sci. 2020, 85, 3981–3997. [Google Scholar] [CrossRef] [PubMed]

- Curioni, P.M.G.; Bosset, J.O. Key Odorants in Various Cheese Types as Determined by Gas Chromatography-Olfactometry. Int. Dairy J. 2002, 12, 959–984. [Google Scholar] [CrossRef]

- Brattoli, M.; Cisternino, E.; Dambruoso, P.; De Gennaro, G.; Giungato, P.; Mazzone, A.; Palmisani, J.; Tutino, M. Gas Chromatography Analysis with Olfactometric Detection (GC-O) as a Useful Methodology for Chemical Characterization of Odorous Compounds. Sensors 2013, 13, 16759–16800. [Google Scholar] [CrossRef]

- Hyde, K.D.; Xu, J.; Rapior, S.; Jeewon, R.; Lumyong, S.; Niego, A.G.T.; Abeywickrama, P.D.; Aluthmuhandiram, J.V.S.; Brahamanage, R.S.; Brooks, S.; et al. The Amazing Potential of Fungi: 50 Ways We Can Exploit Fungi Industrially. Fungal Divers. 2019, 97, 1–136. [Google Scholar] [CrossRef]

- Castro, E.; Strætkvern, K.O.; Romero-García, J.M.; Martín, C. Pretreatment and Bioconversion for Valorization of Residues of Non-Edible Oilseeds. Agronomy 2023, 13, 2196. [Google Scholar] [CrossRef]

- Terpou, A.; Papadaki, A.; Lappa, I.; Kachrimanidou, V.; Bosnea, L.; Kopsahelis, N. Probiotics in Food Systems: Significance and Emerging Strategies Towards Improved Viability and Delivery of Enhanced Beneficial Value. Nutrients 2019, 11, 1591. [Google Scholar] [CrossRef]

- Mayo, B.; Rodríguez, J.; Vázquez, L.; Flórez, A.B. Microbial Interactions within the Cheese Ecosystem and Their Application to Improve Quality and Safety. Foods 2021, 10, 602. [Google Scholar] [CrossRef]

| Compound | Aroma Notes | References |

|---|---|---|

| Methanethiol | Cooked cabbage, sulfur | [9,14,15] |

| Ethanol | Alcoholic, mild | [7,9,14] |

| Acetone | Ethereal, fruity | [9,14] |

| Dimethyl sulfide | Boiled cabbage, sulfur | [9,14,15] |

| Acetic acid | Vinegar, pungent | [7,9,14,16] |

| Propionic acid | Vinegar, pungent | [14] |

| 2-Pentanone | Fruity, sweet | [9,14] |

| Dimethyl disulfide | Cauliflower, garlic | [9,14,15] |

| Butanoic acid | Rancid, cheesy, sweaty | [7,9,14,16] |

| 2-Heptanone | Blue cheese, spicy | [14] |

| Propanol | Alcoholic, sweet | [9] |

| 2,3-Butanedione | Buttery | [9,15] |

| Ethyl acetate | Solvent, pineapple, fruity | [9,14] |

| Methyl thioacetate | Cooked cauliflower | [9] |

| 3-Methylbutanol | Fruity, alcohol-like | [16] |

| 3-Methylbutanal | Green, malty | [15,16] |

| 2-Nonanone | Sweet, soapy, floral | [16] |

| Hexanoic acid | Rancid, sweaty, sour | [16] |

| Octanoic acid | Goaty, waxy, rancid | [16] |

| γ-Hexalactone | Caramel, nutty, woody | [16] |

| Benzeneacetaldehyde | Floral, sweet, fruity | [16] |

| 3-Methylbutanoic acid | Rancid, sweaty, pungent | [16] |

| Process | Description | Formed Compounds | Sensory Contribution | References |

|---|---|---|---|---|

| Lactose Catabolism | Degradation of lactose, which generates organic acids, diacetyl, and volatile aroma precursor compounds.. | Organic acids, diacetyl, volatile compounds | Acidic, buttery, mildly pungent notes | [2,12] |

| Lipolysis | Breakdown of lipids into free fatty acids, which can be converted into ketones, esters, and lactones. | Ketones, esters, lactones | Fruity, buttery, pungent notes | [1,5] |

| Proteolysis | Hydrolysis of proteins into peptides and amino acids, serving as substrates for sulfur compounds, higher alcohols, and aldehydes. | Sulfur compounds, higher alcohols, aldehydes | Sulfurous, nutty notes | [2,9] |

| Amino Acid Precursor | Conversion Step | Formed Compounds | Sensory Characteristics | Sensory Importance in Camembert | References |

|---|---|---|---|---|---|

| Methionine | Deamination and enzymatic conversion via transaminases | Methanethiol, Dimethyl disulfide, Dimethyl trisulfide | Sulfurous, pungent, and ammoniacal notes | Typical rind aroma, onion and sulfur notes | [10,28,33,38] |

| Cysteine | Similar reactions via sulfur metabolism | Volatile sulfur compounds | Similar to methionine | Complements the sulfurous profile of Camembert | [28,33,38] |

| Phenylalanine | Transamination and decarboxylation | Phenylethanol, Benzaldehyde | Floral and sweet notes | Contributes to floral/fruity notes | [1,10,33,39] |

| Lysine | Decarboxylation by bacterial decarboxylase | Cadaverine | Metallic and pungent aroma at high concentrations | Related to sensory defects in excessive ripening | [1,10,39] |

| Arginine | Decarboxylation via the arginine deiminase system | Ornithine → Cadaverine | Similar to cadaverine | Can indicate uncontrolled fermentation | [1,10,39] |

| Glutamine and Asparagine | Enzymatic deamination | Ammonia (NH3) | Ammoniacal aroma; regulates pH | Essential for creamy texture and microbiological balance | [1,20,24] |

| Technique | Description | Applications in Camembert | Advantages | Limitations | References |

|---|---|---|---|---|---|

| Gas Chromatography (GC) | Separation technique for identifying volatile compounds based on their interaction with the stationary and mobile phases. | Initial identification of alcohols, esters, short-chain fatty acids, and sulfur compounds. | High resolution and efficiency in compound separation. | Unable to directly identify odor-active compounds. | [5,7,48,49] |

| Gas Chromatography–Mass Spectrometry (GC–MS) | Combines GC with mass spectrometry for structural analysis and quantification of volatile compounds. | Detailed characterization of the volatile profile and initial correlation with sensory descriptors. | High sensitivity and precise identification. | Requires sophisticated equipment and longer analysis time. | [5,7,48] |

| Gas Chromatography–Olfactometry (GC–O) | Technique combining CG–O with sensory evaluation by a trained assessor at the olfactory detector. | Identification of odor-active compounds and their direct sensory contribution. | Allows direct correlation between volatile compounds and their olfactory perception. | Requires a trained panel and may be influenced by subjective perception. | [5,7,49] |

| Solid-Phase Microextraction (SPME) | Pre-concentration technique using sorbent fibers to capture volatiles before GC or GC–MS analysis. | Enhances the detection of compounds present at low concentrations in the cheese matrix. | Fast, simple, and non-destructive method. | Requires optimization for each matrix and analytical condition. | [7,48,49] |

| Quantitative Descriptive Analysis (QDA) | Formal sensory evaluation by a trained panel to describe and quantify aroma, flavor, and texture attributes. | Standardized description of Camembert’s sensory profile, including its key aroma notes. | Enables mapping of key attributes and sample comparison. | Inherent subjectivity of human sensory analysis. | [8] |

| Consumer Preference Mapping | Consumer testing to assess preferences for different aroma profiles. | Identifies which volatile profiles are most accepted or desired by different consumer groups. | Links chemical and sensory profiles to product accessibility. | Lower technical precision and dependent on the selected consumer sample. | [8,50] |

| Innovative Technique | Description | Applications in Camembert | References |

|---|---|---|---|

| Nuclear Magnetic Resonance Spectroscopy (NMR) | Identifies and quantifies volatile and non-volatile metabolites, providing insights into metabolic processes. | Highlights the formation of aroma precursor compounds, such as amino acids and fatty acids. | [7,20] |

| Metabolomics and Metagenomics Platforms | Correlate the cheese microbiota with volatile compounds produced during ripening. | Identify critical metabolic pathways and potential technological adjustments to optimize the sensory profile. | [18,52] |

| Electronic Sensors (Electronic Nose) | Devices that simulate human olfactory perception, detecting and classifying volatile compounds in real time. | Monitor cheese quality during production and ripening, providing rapid and consistent data. | [7,51] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramirez, B.F.D.; Martins, G.A.; Bicas, J.L.; Maróstica Júnior, M.R. Formation and Characterization of Aroma Compounds in Camembert Cheese. Compounds 2025, 5, 19. https://doi.org/10.3390/compounds5020019

Ramirez BFD, Martins GA, Bicas JL, Maróstica Júnior MR. Formation and Characterization of Aroma Compounds in Camembert Cheese. Compounds. 2025; 5(2):19. https://doi.org/10.3390/compounds5020019

Chicago/Turabian StyleRamirez, Bruna Fernanda Damasceno, Gustavo Aparecido Martins, Juliano Lemos Bicas, and Mário Roberto Maróstica Júnior. 2025. "Formation and Characterization of Aroma Compounds in Camembert Cheese" Compounds 5, no. 2: 19. https://doi.org/10.3390/compounds5020019

APA StyleRamirez, B. F. D., Martins, G. A., Bicas, J. L., & Maróstica Júnior, M. R. (2025). Formation and Characterization of Aroma Compounds in Camembert Cheese. Compounds, 5(2), 19. https://doi.org/10.3390/compounds5020019