Manufacturing Strategies for Graphene Derivative Nanocomposites—Current Status and Fruitions

Abstract

1. Introduction

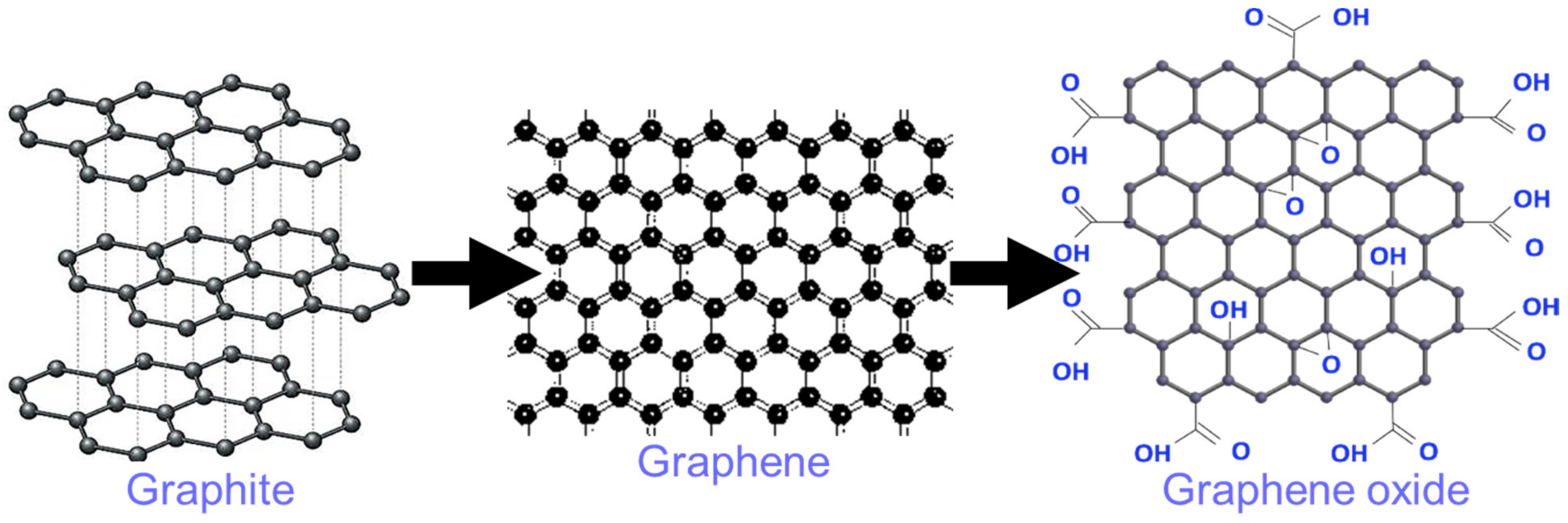

2. Graphene

3. Polymer/Graphene Nanocomposite Manufacturing through Solution Mixing

4. Melt Blending for Polymer/Graphene Nanocomposite Manufacturing

5. In Situ Polymerization to Form Polymer/Graphene Nanocomposites

6. Electrospinning Technique

7. The 3D Printing of Polymeric/Graphene Nanocomposites

8. Other Manufacturing Practices

9. Significance and Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baskakova, K.I.; Okotrub, A.V.; Bulusheva, L.G.; Sedelnikova, O.V. Manufacturing of Carbon Nanotube-Polystyrene Filament for 3D Printing: Nanoparticle Dispersion and Electromagnetic Properties. Nanomanufacturing 2022, 2, 292–301. [Google Scholar] [CrossRef]

- Mubarik, S.; Qureshi, N.; Sattar, Z.; Shaheen, A.; Kalsoom, A.; Imran, M.; Hanif, F. Synthetic approach to rice waste-derived carbon-based nanomaterials and their applications. Nanomanufacturing 2021, 1, 109–159. [Google Scholar] [CrossRef]

- Cai, C.; Liu, L.; Fu, Y. Processable conductive and mechanically reinforced polylactide/graphene bionanocomposites through interfacial compatibilizer. Polym. Compos. 2019, 40, 389–400. [Google Scholar] [CrossRef]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/polymer nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 52, 5–25. [Google Scholar] [CrossRef]

- Menbari, S.; Ashori, A.; Rahmani, H.; Bahrami, R. Viscoelastic response and interlaminar delamination resistance of epoxy/glass fiber/functionalized graphene oxide multi-scale composites. Polym. Test. 2016, 54, 186–195. [Google Scholar] [CrossRef]

- Pokharel, P.; Xiao, D.; Erogbogbo, F.; Keles, O. A hierarchical approach for creating electrically conductive network structure in polyurethane nanocomposites using a hybrid of graphene nanoplatelets, carbon black and multi-walled carbon nanotubes. Compos. Part B Eng. 2019, 161, 169–182. [Google Scholar] [CrossRef]

- Šupová, M.; Martynková, G.S.; Barabaszová, K. Effect of nanofillers dispersion in polymer matrices: A review. Sci. Adv. Mater. 2011, 3, 1–25. [Google Scholar] [CrossRef]

- Yousefi, N.; Gudarzi, M.M.; Zheng, Q.; Aboutalebi, S.H.; Sharif, F.; Kim, J.-K. Self-alignment and high electrical conductivity of ultralarge graphene oxide–polyurethane nanocomposites. J. Mater. Chem. 2012, 22, 12709–12717. [Google Scholar] [CrossRef]

- Abbasi, H.; Antunes, M.; Velasco, J.I. Recent advances in carbon-based polymer nanocomposites for electromagnetic interference shielding. Prog. Mater. Sci. 2019, 103, 319–373. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Y.; Chen, P.; Li, Y.; Liu, M.; Gao, T.; Ma, D.; Chen, Y.; Cheng, Z.; Qiu, X. Toward single-layer uniform hexagonal boron nitride–graphene patchworks with zigzag linking edges. Nano Lett. 2013, 13, 3439–3443. [Google Scholar] [CrossRef] [PubMed]

- Berger, C.; Song, Z.; Li, X.; Wu, X.; Brown, N.; Naud, C.; Mayou, D.; Li, T.; Hass, J.; Marchenkov, A.N. Electronic confinement and coherence in patterned epitaxial graphene. Science 2006, 312, 1191–1196. [Google Scholar] [CrossRef] [PubMed]

- Wei, C.; Negishi, R.; Ogawa, Y.; Akabori, M.; Taniyasu, Y.; Kobayashi, Y. Turbostratic multilayer graphene synthesis on CVD graphene template toward improving electrical performance. Jpn. J. Appl. Phys. 2019, 58, SIIB04. [Google Scholar] [CrossRef]

- Narayanam, P.K.; Botcha, V.D.; Ghosh, M.; Major, S.S. Growth and Photocatalytic Behaviour of Transparent Reduced GO-ZnO Nanocomposite Sheets. Nanotechnology 2019, 30, 485601. [Google Scholar] [CrossRef]

- Zandiatashbar, A.; Lee, G.-H.; An, S.J.; Lee, S.; Mathew, N.; Terrones, M.; Hayashi, T.; Picu, C.R.; Hone, J.; Koratkar, N. Effect of defects on the intrinsic strength and stiffness of graphene. Nat. Commun. 2014, 5, 3186. [Google Scholar] [CrossRef]

- Shen, X.J.; Zeng, X.L.; Dang, C.Y. Graphene Composites. Handb. Graphene 2019, 1, 1–25. [Google Scholar]

- Zhou, Q.; Xia, G.; Du, M.; Lu, Y.; Xu, H. Scotch-tape-like exfoliation effect of graphene quantum dots for efficient preparation of graphene nanosheets in water. Appl. Surf. Sci. 2019, 483, 52–59. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Lee, H.; Lee, K.S. Interlayer Distance Controlled Graphene, Supercapacitor and Method of Producing the Same. U.S. Patent 10,214,422, 26 February 2019. [Google Scholar]

- Tang, C.; Titirici, M.-M.; Zhang, Q. A review of nanocarbons in energy electrocatalysis: Multifunctional substrates and highly active sites. J. Energy Chem. 2017, 26, 1077–1093. [Google Scholar] [CrossRef]

- Panwar, N.; Soehartono, A.M.; Chan, K.K.; Zeng, S.; Xu, G.; Qu, J.; Coquet, P.; Yong, K.-T.; Chen, X. Nanocarbons for biology and medicine: Sensing, imaging, and drug delivery. Chem. Rev. 2019, 119, 9559–9656. [Google Scholar] [CrossRef]

- Han, J.T.; Jang, J.I.; Cho, J.Y.; Hwang, J.Y.; Woo, J.S.; Jeong, H.J.; Jeong, S.Y.; Seo, S.H.; Lee, G.-W. Synthesis of nanobelt-like 1-dimensional silver/nanocarbon hybrid materials for flexible and wearable electronics. Sci. Rep. 2017, 7, 4931. [Google Scholar] [CrossRef] [PubMed]

- Bao, Q.; Zhang, H.; Yang, J.x.; Wang, S.; Tang, D.Y.; Jose, R.; Ramakrishna, S.; Lim, C.T.; Loh, K.P. Graphene–polymer nanofiber membrane for ultrafast photonics. Adv. Funct. Mater. 2010, 20, 782–791. [Google Scholar] [CrossRef]

- Ganguly, S. Preparation/processing of polymer-graphene composites by different techniques. In Polymer Nanocomposites Containing Graphene; Elsevier: Amsterdam, The Netherlands, 2022; pp. 45–74. [Google Scholar]

- Hu, K.; Kulkarni, D.D.; Choi, I.; Tsukruk, V.V. Graphene-polymer nanocomposites for structural and functional applications. Prog. Polym. Sci. 2014, 39, 1934–1972. [Google Scholar] [CrossRef]

- Yu, Y.-H.; Lin, Y.-Y.; Lin, C.-H.; Chan, C.-C.; Huang, Y.-C. High-performance polystyrene/graphene-based nanocomposites with excellent anti-corrosion properties. Polym. Chem. 2014, 5, 535–550. [Google Scholar] [CrossRef]

- He, F.; Lam, K.-H.; Fan, J.; Chan, L.H. Improved dielectric properties for chemically functionalized exfoliated graphite nanoplates/syndiotactic polystyrene composites prepared by a solution-blending method. Carbon 2014, 80, 496–503. [Google Scholar] [CrossRef]

- Mohammadsalih, Z.G.; Inkson, B.J.; Chen, B. The effect of dispersion condition on the structure and properties of polystyrene/graphene oxide nanocomposites. Polym. Compos. 2021, 42, 320–328. [Google Scholar] [CrossRef]

- Zhao, F.; Zhang, G.; Zhao, S.; Cui, J.; Gao, A.; Yan, Y. Fabrication of pristine graphene-based conductive polystyrene composites towards high performance and light-weight. Compos. Sci. Technol. 2018, 159, 232–239. [Google Scholar] [CrossRef]

- Kausar, A.; Bocchetta, P. Poly (methyl methacrylate) Nanocomposite Foams Reinforced with Carbon and Inorganic Nanoparticles—State-of-the-Art. J. Compos. Sci. 2022, 6, 129. [Google Scholar] [CrossRef]

- Zeng, X.; Yang, J.; Yuan, W. Preparation of a poly (methyl methacrylate)-reduced graphene oxide composite with enhanced properties by a solution blending method. Eur. Polym. J. 2012, 48, 1674–1682. [Google Scholar] [CrossRef]

- Balasubramaniyan, R.; Pham, V.H.; Jang, J.; Hur, S.H.; Chung, J.S. A one pot solution blending method for highly conductive poly (methyl methacrylate)-highly reduced graphene nanocomposites. Electron. Mater. Lett. 2013, 9, 837–839. [Google Scholar] [CrossRef]

- Kuila, T.; Bose, S.; Hong, C.E.; Uddin, M.E.; Khanra, P.; Kim, N.H.; Lee, J.H. Preparation of functionalized graphene/linear low density polyethylene composites by a solution mixing method. Carbon 2011, 49, 1033–1037. [Google Scholar] [CrossRef]

- Vadukumpully, S.; Paul, J.; Mahanta, N.; Valiyaveettil, S. Flexible conductive graphene/poly (vinyl chloride) composite thin films with high mechanical strength and thermal stability. Carbon 2011, 49, 198–205. [Google Scholar] [CrossRef]

- Kausar, A.; Rafique, I.; Anwar, Z.; Muhammad, B. Perspectives of epoxy/graphene oxide composite: Significant features and technical applications. Polym.-Plast. Technol. Eng. 2016, 55, 704–722. [Google Scholar] [CrossRef]

- Yao, H.; Hawkins, S.A.; Sue, H.-J. Preparation of epoxy nanocomposites containing well-dispersed graphene nanosheets. Compos. Sci. Technol. 2017, 146, 161–168. [Google Scholar] [CrossRef]

- Hu, J.; Huang, Y.; Yao, Y.; Pan, G.; Sun, J.; Zeng, X.; Sun, R.; Xu, J.-B.; Song, B.; Wong, C.-P. Polymer composite with improved thermal conductivity by constructing a hierarchically ordered three-dimensional interconnected network of BN. ACS Appl. Mater. Interfaces 2017, 9, 13544–13553. [Google Scholar] [CrossRef] [PubMed]

- Mohan, V.B.; Lau, K.-t.; Hui, D.; Bhattacharyya, D. Graphene-based materials and their composites: A review on production, applications and product limitations. Compos. Part B Eng. 2018, 142, 200–220. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, J.; Yeow, J.T. Doped Polyaniline/Graphene Composites for Photothermoelectric Detectors. ACS Appl. Nano Mater. 2022, 5, 7967–7973. [Google Scholar] [CrossRef]

- John, J.; Radhakrishnan, P.; Sajeev, U.; Jayalekshmi, S. Studies on dodecylbenzenesulfonic acid doped polypyrrole/graphene nanocomposite films grown by spin coating and electro-spraying. Polym. Bull. 2022, 79, 11235–11257. [Google Scholar] [CrossRef]

- Chakraborthy, A.; Nuthalapati, S.; Nag, A.; Afsarimanesh, N.; Alahi, M.E.E.; Altinsoy, M.E. A Critical Review of the Use of Graphene-Based Gas Sensors. Chemosensors 2022, 10, 355. [Google Scholar] [CrossRef]

- Araby, S.; Meng, Q.; Zhang, L.; Kang, H.; Majewski, P.; Tang, Y.; Ma, J. Electrically and thermally conductive elastomer/graphene nanocomposites by solution mixing. Polymer 2014, 55, 201–210. [Google Scholar] [CrossRef]

- Chen, W.; Weimin, H.; Li, D.; Chen, S.; Dai, Z. A critical review on the development and performance of polymer/graphene nanocomposites. Sci. Eng. Compos. Mater. 2018, 25, 1059–1073. [Google Scholar] [CrossRef]

- Wee, B.H.; Wu, T.F.; Hong, J.D. Facile and scalable synthesis method for high-quality few-layer graphene through solution-based exfoliation of graphite. ACS Appl. Mater. Interfaces 2017, 9, 4548–4557. [Google Scholar] [CrossRef]

- Jaouen, K.; Lebon, F.; Jousselme, B.; Campidelli, S.; Cornut, R.; Derycke, V. Backside Absorbing Layer Microscopy: A New Tool to Study the Optical, Chemical and Electrochemical Properties of 2D Materials. In Proceedings of the 237th ECS Meeting, Montreal, QC, Canada, 10–14 May 2020. [Google Scholar]

- Zhang, X.; Zhang, S.; Li, P.; Ding, Z.; Hao, Z. Investigation on solubility of multicomponents from semi-anthracite coal and its effect on coal structure by Fourier transform infrared spectroscopy and X-ray diffraction. Fuel Process. Technol. 2018, 174, 123–131. [Google Scholar] [CrossRef]

- Hu, T.; Ye, H.; Luo, Z.; Ma, J.; Zhang, B.; Zhang, X.; Song, J.; Wang, Q.; Xu, L. Efficient exfoliation of UV-curable, high-quality graphene from graphite in common low-boiling-point organic solvents with a designer hyperbranched polyethylene copolymer and their applications in electrothermal heaters. J. Colloid Interface Sci. 2020, 569, 114–127. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.J.; Kang, J.H.; Jung, H.; Kim, T.; Park, C.R. Preparation of a freestanding, macroporous reduced graphene oxide film as an efficient and recyclable sorbent for oils and organic solvents. J. Mater. Chem. A 2013, 1, 9427–9432. [Google Scholar] [CrossRef]

- Zhang, T.; Wei, H.; Xiao, H.; Li, W.; Jin, Y.; Wei, W.; Wu, S. Advance in constructing acid catalyst-solvent combinations for efficient transformation of glucose into 5-Hydroxymethylfurfural. Mol. Catal. 2020, 498, 111254. [Google Scholar] [CrossRef]

- Shaikh, M.M.; Mohd Hanafiah, M.; Basheer, A.O. Leaching of Organic Toxic Compounds from PVC Water Pipes in Medina Al-Munawarah, Kingdom of Saudi Arabia. Processes 2019, 7, 641. [Google Scholar] [CrossRef]

- Sadeghi, A.; Moeini, R.; Yeganeh, J.K. Highly conductive PP/PET polymer blends with high electromagnetic interference shielding performances in the presence of thermally reduced graphene nanosheets prepared through melt compounding. Polym. Compos. 2019, 40, E1461–E1469. [Google Scholar] [CrossRef]

- Gill, Y.Q.; Ehsan, H.; Mehmood, U.; Irfan, M.S.; Saeed, F. A novel two-step melt blending method to prepare nano-silanized-silica reinforced crosslinked polyethylene (XLPE) nanocomposites. Polym. Bull. 2022, 79, 10077–10093. [Google Scholar] [CrossRef]

- Tan, B.; Thomas, N.L. A review of the water barrier properties of polymer/clay and polymer/graphene nanocomposites. J. Membr. Sci. 2016, 514, 595–612. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A. A green method to prepare nanosilica modified graphene oxide to inhibit nanoparticles re-aggregation during melt processing. Chem. Eng. J. 2017, 308, 1034–1047. [Google Scholar] [CrossRef]

- Yan, D.; Zhang, H.-B.; Jia, Y.; Hu, J.; Qi, X.-Y.; Zhang, Z.; Yu, Z.-Z. Improved electrical conductivity of polyamide 12/graphene nanocomposites with maleated polyethylene-octene rubber prepared by melt compounding. ACS Appl. Mater. Interfaces 2012, 4, 4740–4745. [Google Scholar] [CrossRef] [PubMed]

- Kausar, A. In-situ modified graphene reinforced polyamide 1010/poly (ether amide): Mechanical, thermal, and barrier properties. Mater. Res. Innov. 2019, 23, 191–199. [Google Scholar] [CrossRef]

- Mittal, V.; Chaudhry, A.U. Polymer–graphene nanocomposites: Effect of polymer matrix and filler amount on properties. Macromol. Mater. Eng. 2015, 300, 510–521. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W.; Tao, M.; Lu, D.; Zheng, W. Enhanced interfacial interaction between polycarbonate and thermally reduced graphene induced by melt blending. Compos. Sci. Technol. 2013, 86, 109–116. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W.; Chen, C.; Lu, D.; Wang, J.; Zheng, W. Melt blending in situ enhances the interaction between polystyrene and graphene through π–π stacking. ACS Appl. Mater. Interfaces 2011, 3, 3103–3109. [Google Scholar] [CrossRef]

- El Achaby, M.; Arrakhiz, F.E.; Vaudreuil, S.; el Kacem Qaiss, A.; Bousmina, M.; Fassi-Fehri, O. Mechanical, thermal, and rheological properties of graphene-based polypropylene nanocomposites prepared by melt mixing. Polym. Compos. 2012, 33, 733–744. [Google Scholar] [CrossRef]

- Ryu, S.H.; Shanmugharaj, A. Influence of hexamethylene diamine functionalized graphene oxide on the melt crystallization and properties of polypropylene nanocomposites. Mater. Chem. Phys. 2014, 146, 478–486. [Google Scholar] [CrossRef]

- Istrate, O.M.; Paton, K.R.; Khan, U.; O’Neill, A.; Bell, A.P.; Coleman, J.N. Reinforcement in melt-processed polymer–graphene composites at extremely low graphene loading level. Carbon 2014, 78, 243–249. [Google Scholar] [CrossRef]

- Maiti, S.; Suin, S.; Shrivastava, N.K.; Khatua, B. Low percolation threshold in polycarbonate/multiwalled carbon nanotubes nanocomposites through melt blending with poly (butylene terephthalate). J. Appl. Polym. Sci. 2013, 130, 543–553. [Google Scholar] [CrossRef]

- Jiang, S.; Gui, Z.; Bao, C.; Dai, K.; Wang, X.; Zhou, K.; Shi, Y.; Lo, S.; Hu, Y. Preparation of functionalized graphene by simultaneous reduction and surface modification and its polymethyl methacrylate composites through latex technology and melt blending. Chem. Eng. J. 2013, 226, 326–335. [Google Scholar] [CrossRef]

- Ansari, S.; Giannelis, E.P. Functionalized graphene sheet—Poly (vinylidene fluoride) conductive nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 888–897. [Google Scholar] [CrossRef]

- Anwar, Z.; Kausar, A.; Rafique, I.; Muhammad, B. Advances in epoxy/graphene nanoplatelet composite with enhanced physical properties: A review. Polym.-Plast. Technol. Eng. 2016, 55, 643–662. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Kim, H.; Kobayashi, S.; AbdurRahim, M.A.; Zhang, M.J.; Khusainova, A.; Hillmyer, M.A.; Abdala, A.A.; Macosko, C.W. Graphene/polyethylene nanocomposites: Effect of polyethylene functionalization and blending methods. Polymer 2011, 52, 1837–1846. [Google Scholar] [CrossRef]

- Perreault, F.; De Faria, A.F.; Elimelech, M. Environmental applications of graphene-based nanomaterials. Chem. Soc. Rev. 2015, 44, 5861–5896. [Google Scholar] [CrossRef]

- Mittal, V. Functional polymer nanocomposites with graphene: A review. Macromol. Mater. Eng. 2014, 299, 906–931. [Google Scholar] [CrossRef]

- Du, J.; Cheng, H.M. The fabrication, properties, and uses of graphene/polymer composites. Macromol. Chem. Phys. 2012, 213, 1060–1077. [Google Scholar] [CrossRef]

- Feng, Z.; Zuo, H.; Hu, J.; Yu, B.; Ning, N.; Tian, M.; Zhang, L. In Situ Exfoliation of Graphite into Graphene Nanosheets in Elastomer Composites Based on Diels–Alder Reaction during Melt Blending. Ind. Eng. Chem. Res. 2019, 58, 13182–13189. [Google Scholar] [CrossRef]

- Owji, E.; Ostovari, F.; Keshavarz, A. Influence of the chemical structure of diisocyanate on the electrical and thermal properties of in situ polymerized polyurethane–graphene composite films. Phys. Chem. Chem. Phys. 2022, 24, 28564–28576. [Google Scholar] [CrossRef]

- Itapu, B.M.; Jayatissa, A.H. A review in graphene/polymer composites. Chem. Sci. Int. J. 2018, 23, 1–16. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, X.; Chen, D.; Chen, G. Polystyrene/graphene composite electrode fabricated by in situ polymerization for capillary electrophoretic determination of bioactive constituents in Herba Houttuyniae. Electrophoresis 2011, 32, 1906–1912. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Hu, Y.; Song, L.; Yang, H.; Xing, W.; Lu, H. In situ polymerization of graphene nanosheets and polyurethane with enhanced mechanical and thermal properties. J. Mater. Chem. 2011, 21, 4222–4227. [Google Scholar] [CrossRef]

- Milani, M.A.; González, D.; Quijada, R.; Basso, N.R.; Cerrada, M.L.; Azambuja, D.S.; Galland, G.B. Polypropylene/graphene nanosheet nanocomposites by in situ polymerization: Synthesis, characterization and fundamental properties. Compos. Sci. Technol. 2013, 84, 1–7. [Google Scholar] [CrossRef]

- Hu, H.; Wang, X.; Wang, J.; Wan, L.; Liu, F.; Zheng, H.; Chen, R.; Xu, C. Preparation and properties of graphene nanosheets–polystyrene nanocomposites via in situ emulsion polymerization. Chem. Phys. Lett. 2010, 484, 247–253. [Google Scholar] [CrossRef]

- Patole, A.S.; Patole, S.P.; Kang, H.; Yoo, J.-B.; Kim, T.-H.; Ahn, J.-H. A facile approach to the fabrication of graphene/polystyrene nanocomposite by in situ microemulsion polymerization. J. Colloid Interface Sci. 2010, 350, 530–537. [Google Scholar] [CrossRef]

- Tu, Z.; Wang, J.; Yu, C.; Xiao, H.; Jiang, T.; Yang, Y.; Shi, D.; Mai, Y.-W.; Li, R.K. A facile approach for preparation of polystyrene/graphene nanocomposites with ultra-low percolation threshold through an electrostatic assembly process. Compos. Sci. Technol. 2016, 134, 49–56. [Google Scholar] [CrossRef]

- Zheng, D.; Tang, G.; Zhang, H.-B.; Yu, Z.-Z.; Yavari, F.; Koratkar, N.; Lim, S.-H.; Lee, M.-W. In situ thermal reduction of graphene oxide for high electrical conductivity and low percolation threshold in polyamide 6 nanocomposites. Compos. Sci. Technol. 2012, 72, 284–289. [Google Scholar] [CrossRef]

- Ding, P.; Su, S.; Song, N.; Tang, S.; Liu, Y.; Shi, L. Influence on thermal conductivity of polyamide-6 covalently-grafted graphene nanocomposites: Varied grafting-structures by controllable macromolecular length. RSC Adv. 2014, 4, 18782–18791. [Google Scholar] [CrossRef]

- Chen, J.; Chen, X.; Meng, F.; Li, D.; Tian, X.; Wang, Z.; Zhou, Z. Super-high thermal conductivity of polyamide-6/graphene-graphene oxide composites through in situ polymerization. High Perform. Polym. 2017, 29, 585–594. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, C. In situ polymerization approach to graphene-reinforced nylon-6 composites. Macromolecules 2010, 43, 6716–6723. [Google Scholar] [CrossRef]

- Wang, J.; Hu, H.; Wang, X.; Xu, C.; Zhang, M.; Shang, X. Preparation and mechanical and electrical properties of graphene nanosheets–poly (methyl methacrylate) nanocomposites via in situ suspension polymerization. J. Appl. Polym. Sci. 2011, 122, 1866–1871. [Google Scholar] [CrossRef]

- Lee, Y.R.; Raghu, A.V.; Jeong, H.M.; Kim, B.K. Properties of waterborne polyurethane/functionalized graphene sheet nanocomposites prepared by an in situ method. Macromol. Chem. Phys. 2009, 210, 1247–1254. [Google Scholar] [CrossRef]

- El-Jaby, U.; Cunningham, M.; McKenna, T.F. The advantages of in situ surfactant generation for miniemulsions. Macromol. Rapid Commun. 2010, 31, 558–562. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.K.; Tripathi, S.N.; Choudhary, V.; Gupta, B.D. SPR based fibre optic ammonia gas sensor utilizing nanocomposite film of PMMA/reduced graphene oxide prepared by in situ polymerization. Sens. Actuators B Chem. 2014, 199, 190–200. [Google Scholar] [CrossRef]

- Xie, W.; Yao, F.; Gu, H.; Du, A.; Lei, Q.; Naik, N.; Guo, Z. Magnetoresistive and piezoresistive polyaniline nanoarrays in-situ polymerized surrounding magnetic graphene aerogel. Adv. Compos. Hybrid Mater. 2022, 5, 1003–1016. [Google Scholar] [CrossRef]

- Mao, H.-n.; Wang, X.-g. Use of in-situ polymerization in the preparation of graphene/polymer nanocomposites. New Carbon Mater. 2020, 35, 336–343. [Google Scholar] [CrossRef]

- Abdullah, N.J.; Hasan, S.M.; Essa, A.F. DC electrical conductivity of polyaniline/graphene nanocomposites produced by in situ polymerization. AIP Conf. Proc. 2021, 2372, 130016. [Google Scholar]

- Manna, R.; Ghosh, K.; Srivastava, S.K. Functionalized Graphene/Nickel/Polyaniline Ternary Nanocomposites: Fabrication and Application as Electromagnetic Wave Absorbers. Langmuir 2021, 37, 7430–7441. [Google Scholar] [CrossRef]

- Parviz, D.; Das, S.; Ahmed, H.T.; Irin, F.; Bhattacharia, S.; Green, M.J. Dispersions of non-covalently functionalized graphene with minimal stabilizer. ACS Nano 2012, 6, 8857–8867. [Google Scholar] [CrossRef]

- Li, K.; Liu, W.; Ni, Y.; Li, D.; Lin, D.; Su, Z.; Wei, G. Technical synthesis and biomedical applications of graphene quantum dots. J. Mater. Chem. B 2017, 5, 4811–4826. [Google Scholar] [CrossRef]

- Che, H.; Yuan, J. Recent advances in electrospinning supramolecular systems. J. Mater. Chem. B 2022, 10, 8–19. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Wang, J.; Liu, S.; Zhang, Q.; Liu, Y.; Tan, Y.; Luo, S.; Guo, F.; Ma, J.; Li, P. Electrospinning of neat graphene nanofibers. Adv. Fiber Mater. 2022, 4, 268–279. [Google Scholar] [CrossRef]

- Li, Y.; Dong, T.; Li, Z.; Ni, S.; Zhou, F.; Alimi, O.A.; Chen, S.; Duan, B.; Kuss, M.; Wu, S. Review of advances in electrospinning-based strategies for spinal cord regeneration. Mater. Today Chem. 2022, 24, 100944. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibers. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Liu, C.; Wong, H.M.; Yeung, K.W.K.; Tjong, S.C. Novel electrospun polylactic acid nanocomposite fiber mats with hybrid graphene oxide and nanohydroxyapatite reinforcements having enhanced biocompatibility. Polymers 2016, 8, 287. [Google Scholar] [CrossRef]

- Mukherjee, S.; Kumar, S.; Sahu, R.K.; Nayar, S. PVA-Graphene-Hydroxyapatite electrospun fibres as air-filters. Mater. Res. Express 2020, 6, 125366. [Google Scholar] [CrossRef]

- Jia, Y.; Yue, X.; Wang, Y.; Yan, C.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Multifunctional stretchable strain sensor based on polydopamine/reduced graphene oxide/electrospun thermoplastic polyurethane fibrous mats for human motion detection and environment monitoring. Compos. Part B Eng. 2020, 183, 107696. [Google Scholar] [CrossRef]

- Gopiraman, M.; Fujimori, K.; Zeeshan, K.; Kim, B.; Kim, I. Structural and mechanical properties of cellulose acetate/graphene hybrid nanofibers: Spectroscopic investigations. Express Polym. Lett. 2013, 7, 554–563. [Google Scholar] [CrossRef]

- Pant, H.R.; Pokharel, P.; Joshi, M.K.; Adhikari, S.; Kim, H.J.; Park, C.H.; Kim, C.S. Processing and characterization of electrospun graphene oxide/polyurethane composite nanofibers for stent coating. Chem. Eng. J. 2015, 270, 336–342. [Google Scholar] [CrossRef]

- Avossa, J.; Paolesse, R.; Di Natale, C.; Zampetti, E.; Bertoni, G.; De Cesare, F.; Scarascia-Mugnozza, G.; Macagnano, A. Electrospinning of Polystyrene/Polyhydroxybutyrate Nanofibers Doped with Porphyrin and Graphene for Chemiresistor Gas Sensors. Nanomaterials 2019, 9, 280. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Yu, D.; Kelkar, A.D.; Zhang, L. Electrospun nanofiber: Emerging reinforcing filler in polymer matrix composite materials. Prog. Polym. Sci. 2017, 75, 73–107. [Google Scholar] [CrossRef]

- Wu, J.-J.; Huang, L.-M.; Zhao, Q.; Xie, T. 4D printing: History and recent progress. Chin. J. Polym. Sci. 2018, 36, 563–575. [Google Scholar] [CrossRef]

- Yang, D.; Mei, H.; Yao, L.; Yang, W.; Yao, Y.; Cheng, L.; Zhang, L.; Dassios, K.G. 3D/4D printed tunable electrical metamaterials with more sophisticated structures. J. Mater. Chem. C 2021, 9, 12010–12036. [Google Scholar] [CrossRef]

- Guo, Y.; Patanwala, H.S.; Bognet, B.; Ma, A.W. Inkjet and inkjet-based 3D printing: Connecting fluid properties and printing performance. Rapid Prototyp. J. 2017, 23, 562–576. [Google Scholar] [CrossRef]

- Wan, X.; Luo, L.; Liu, Y.; Leng, J. Direct ink writing based 4D printing of materials and their applications. Adv. Sci. 2020, 7, 2001000. [Google Scholar] [CrossRef]

- Shirazi, S.F.S.; Gharehkhani, S.; Mehrali, M.; Yarmand, H.; Metselaar, H.S.C.; Kadri, N.A.; Osman, N.A.A. A review on powder-based additive manufacturing for tissue engineering: Selective laser sintering and inkjet 3D printing. Sci. Technol. Adv. Mater. 2015, 16, 033502. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of polymers: Fused deposition modelling (FDM), selective laser sintering (SLS), and stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Ponnamma, D.; Yin, Y.; Salim, N.; Parameswaranpillai, J.; Thomas, S.; Hameed, N. Recent progress and multifunctional applications of 3D printed graphene nanocomposites. Compos. Part B Eng. 2021, 204, 108493. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of polymer composites: A short review. Mater. Des. Process. Commun. 2020, 2, e97. [Google Scholar] [CrossRef]

- You, X.; Yang, J.; Dong, S. Structural and functional applications of 3D-printed graphene-based architectures. J. Mater. Sci. 2021, 56, 9007–9046. [Google Scholar] [CrossRef]

- You, X.; Zhang, Q.; Yang, J.; Dong, S. Review on 3D-printed graphene-reinforced composites for structural applications. Compos. Part A Appl. Sci. Manuf. 2023, 167, 107420. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, H.; Niu, H.; Ren, Y.; Fang, H.; Fang, X.; Lv, R.; Maqbool, M.; Bai, S. Highly thermally conductive 3D printed graphene filled polymer composites for scalable thermal management applications. ACS Nano 2021, 15, 6917–6928. [Google Scholar] [CrossRef]

- Manzanares Palenzuela, C.L.; Novotný, F.; Krupička, P.; Sofer, Z.; Pumera, M. 3D-printed graphene/polylactic acid electrodes promise high sensitivity in electroanalysis. Anal. Chem. 2018, 90, 5753–5757. [Google Scholar] [CrossRef]

- Domingues, S.H.; Salvatierra, R.V.; Oliveira, M.M.; Zarbin, A.J. Transparent and conductive thin films of graphene/polyaniline nanocomposites prepared through interfacial polymerization. Chem. Commun. 2011, 47, 2592–2594. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Dreyer, D.R.; An, J.; Velamakanni, A.; Piner, R.D.; Park, S.; Zhu, Y.; Kim, S.O.; Bielawski, C.W.; Ruoff, R.S. Polymer brushes via controlled, surface-initiated atom transfer radical polymerization (ATRP) from graphene oxide. Macromol. Rapid Commun. 2010, 31, 281–288. [Google Scholar] [CrossRef]

- Liu, J.; Yang, W.; Tao, L.; Li, D.; Boyer, C.; Davis, T.P. Thermosensitive graphene nanocomposites formed using pyrene-terminal polymers made by RAFT polymerization. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 425–433. [Google Scholar] [CrossRef]

- Huang, Y.; Qin, Y.; Zhou, Y.; Niu, H.; Yu, Z.-Z.; Dong, J.-Y. Polypropylene/graphene oxide nanocomposites prepared by in situ Ziegler− Natta polymerization. Chem. Mater. 2010, 22, 4096–4102. [Google Scholar] [CrossRef]

- Alzari, V.; Nuvoli, D.; Scognamillo, S.; Piccinini, M.; Gioffredi, E.; Malucelli, G.; Marceddu, S.; Sechi, M.; Sanna, V.; Mariani, A. Graphene-containing thermoresponsive nanocomposite hydrogels of poly (N-isopropylacrylamide) prepared by frontal polymerization. J. Mater. Chem. 2011, 21, 8727–8733. [Google Scholar] [CrossRef]

- Aldosari, M.; Othman, A.; Alsharaeh, E. Synthesis and characterization of the in situ bulk polymerization of PMMA containing graphene sheets using microwave irradiation. Molecules 2013, 18, 3152–3167. [Google Scholar] [CrossRef]

- Sheng, X.; Zhang, L.; Wu, H. Generation of Polymer Nanocomposites through Shear-Driven Aggregation of Binary Colloids. Polymers 2017, 9, 619. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Wu, F.; Wu, H.; Chen, G. Preparation of colloidal dispersions of graphene sheets in organic solvents by using ball milling. J. Nanomater. 2010, 2010, 6. [Google Scholar] [CrossRef]

- Song, N.; Jiao, D.; Cui, S.; Hou, X.; Ding, P.; Shi, L. Highly anisotropic thermal conductivity of layer-by-layer assembled nanofibrillated cellulose/graphene nanosheets hybrid films for thermal management. ACS Appl. Mater. Interfaces 2017, 9, 2924–2932. [Google Scholar] [CrossRef] [PubMed]

- JunáChung, I.; TaeáPark, Y. Layer-by-layer assembled graphene multilayers on multidimensional surfaces for highly durable, scalable, and wearable triboelectric nanogenerators. J. Mater. Chem. A 2018, 6, 3108–3115. [Google Scholar]

- Ganesan, V.; Jayaraman, A. Theory and simulation studies of effective interactions, phase behavior and morphology in polymer nanocomposites. Soft Matter 2014, 10, 13–38. [Google Scholar] [CrossRef] [PubMed]

- Seyedjamali, H.; Pirisedigh, A. Well-dispersed polyimide/TiO 2 nanocomposites: In situ sol–gel fabrication and morphological study. Colloid Polym. Sci. 2012, 290, 653–659. [Google Scholar] [CrossRef]

- Yan, H.; Tao, X.; Yang, Z.; Li, K.; Yang, H.; Li, A.; Cheng, R. Effects of the oxidation degree of graphene oxide on the adsorption of methylene blue. J. Hazard. Mater. 2014, 268, 191–198. [Google Scholar] [CrossRef]

- Rissanou, A.N.; Power, A.J.; Harmandaris, V. Structural and dynamical properties of polyethylene/graphene nanocomposites through molecular dynamics simulations. Polymers 2015, 7, 390–417. [Google Scholar] [CrossRef]

| Graphene concentration (vol.%) | 0.00 | 0.01 | 0.05 | 0.81 | 1.53 |

| Thermal conductivity (W/mK) | 0.16 | 0.16 | 0.18 | 0.36 | 0.47 |

| Matrices | Nanofiller | Manufacturing | Ref. |

|---|---|---|---|

| Polystyrene | Graphene | Solution method | [26] |

| Poly(methyl methacrylate) | Graphene | Solution method | [31] |

| Poly(methyl methacrylate) | Graphene | Solution method | [32] |

| Polyethylene | Graphene | Solution method | [33] |

| Poly(vinyl alcohol) | Graphene | Solution method | [34] |

| Epoxy | Graphene | Solution method | [36] |

| Polystyrene, polycarbonate, polypropylene, high density polyethylene, low density polyethylene | Graphene | Melt compounding | [57] |

| Polystyrene | Graphene | In situ polymerization | [75] |

| Polyamide 6 | Graphene | In situ polymerization | [83] |

| Polyamide 6 | Graphene | In situ polymerization | [82] |

| Poly(methyl methacrylate) | Graphene | In situ polymerization | [85] |

| Waterborne polyurethane | Graphene | In situ polymerization | [86] |

| Polyaniline | Graphene | Interfacial polymerization | [118] |

| Poly(methyl methacrylate), polystyrene, polybutyl acylate | Graphene | Atom transfer radical polymerization | [119] |

| Polypropylene | Graphene | Ziegler–Natta polymerization | [121] |

| Poly(N-isopropylacrylamide) | Graphene | Frontal polymerization | [122] |

| Poly(methyl methacrylate) | Graphene | Microwave irradiation | [123] |

| Polystyrene, poly(methyl methacrylate), poly(vinyl fluoride) | Graphene | Colloid method | [125] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kausar, A.; Ahmad, I.; Eisa, M.H.; Maaza, M.; Khan, H. Manufacturing Strategies for Graphene Derivative Nanocomposites—Current Status and Fruitions. Nanomanufacturing 2023, 3, 1-19. https://doi.org/10.3390/nanomanufacturing3010001

Kausar A, Ahmad I, Eisa MH, Maaza M, Khan H. Manufacturing Strategies for Graphene Derivative Nanocomposites—Current Status and Fruitions. Nanomanufacturing. 2023; 3(1):1-19. https://doi.org/10.3390/nanomanufacturing3010001

Chicago/Turabian StyleKausar, Ayesha, Ishaq Ahmad, M. H. Eisa, Malik Maaza, and Hamdullah Khan. 2023. "Manufacturing Strategies for Graphene Derivative Nanocomposites—Current Status and Fruitions" Nanomanufacturing 3, no. 1: 1-19. https://doi.org/10.3390/nanomanufacturing3010001

APA StyleKausar, A., Ahmad, I., Eisa, M. H., Maaza, M., & Khan, H. (2023). Manufacturing Strategies for Graphene Derivative Nanocomposites—Current Status and Fruitions. Nanomanufacturing, 3(1), 1-19. https://doi.org/10.3390/nanomanufacturing3010001