Effects of Screw Speed on Screw Pressure and Temperature: A Case of Non-Newtonian Non-Isothermal Flow †

Abstract

1. Introduction

2. Materials and Methods

2.1. Physical Properties of Wheat Dough

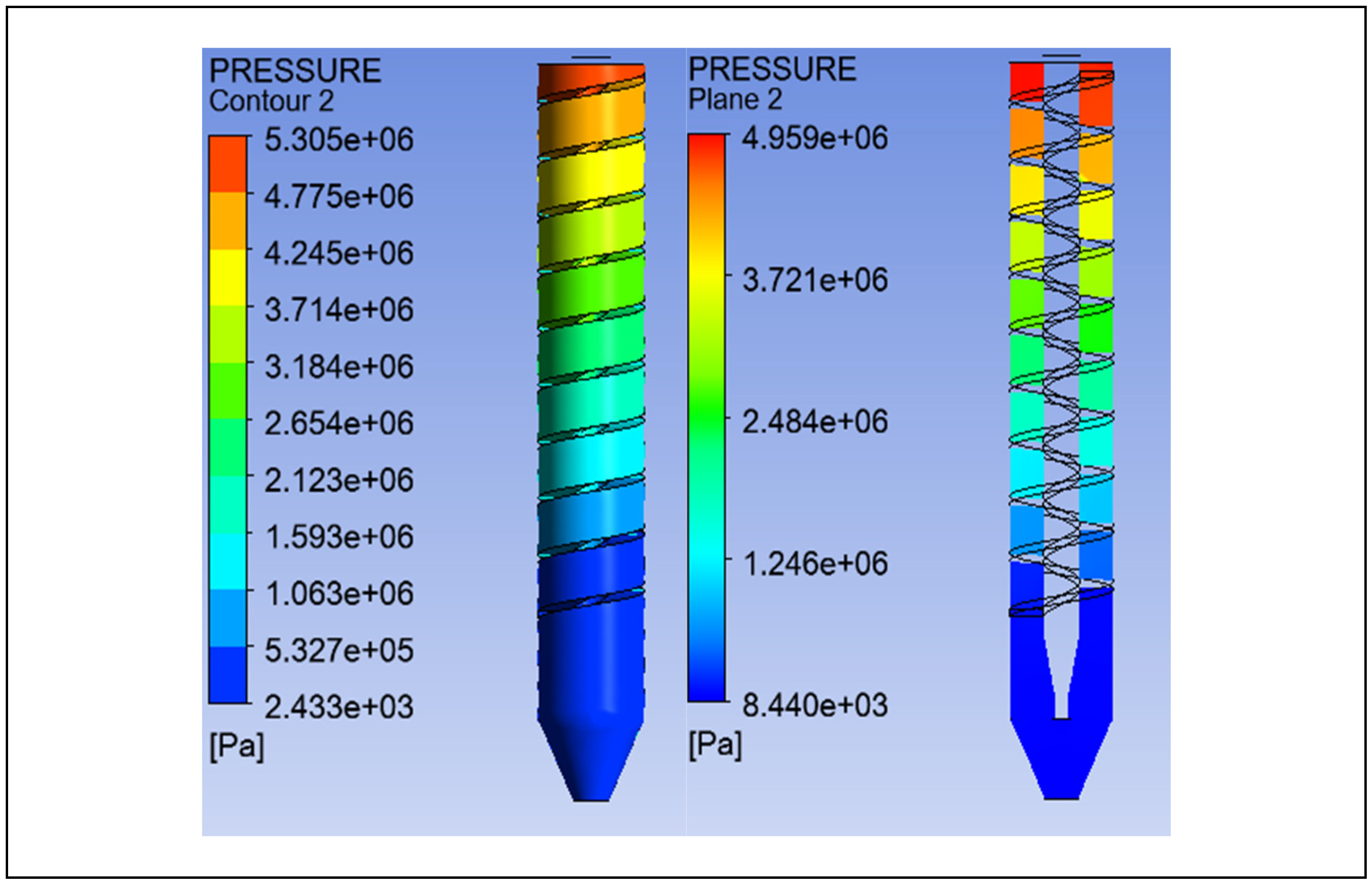

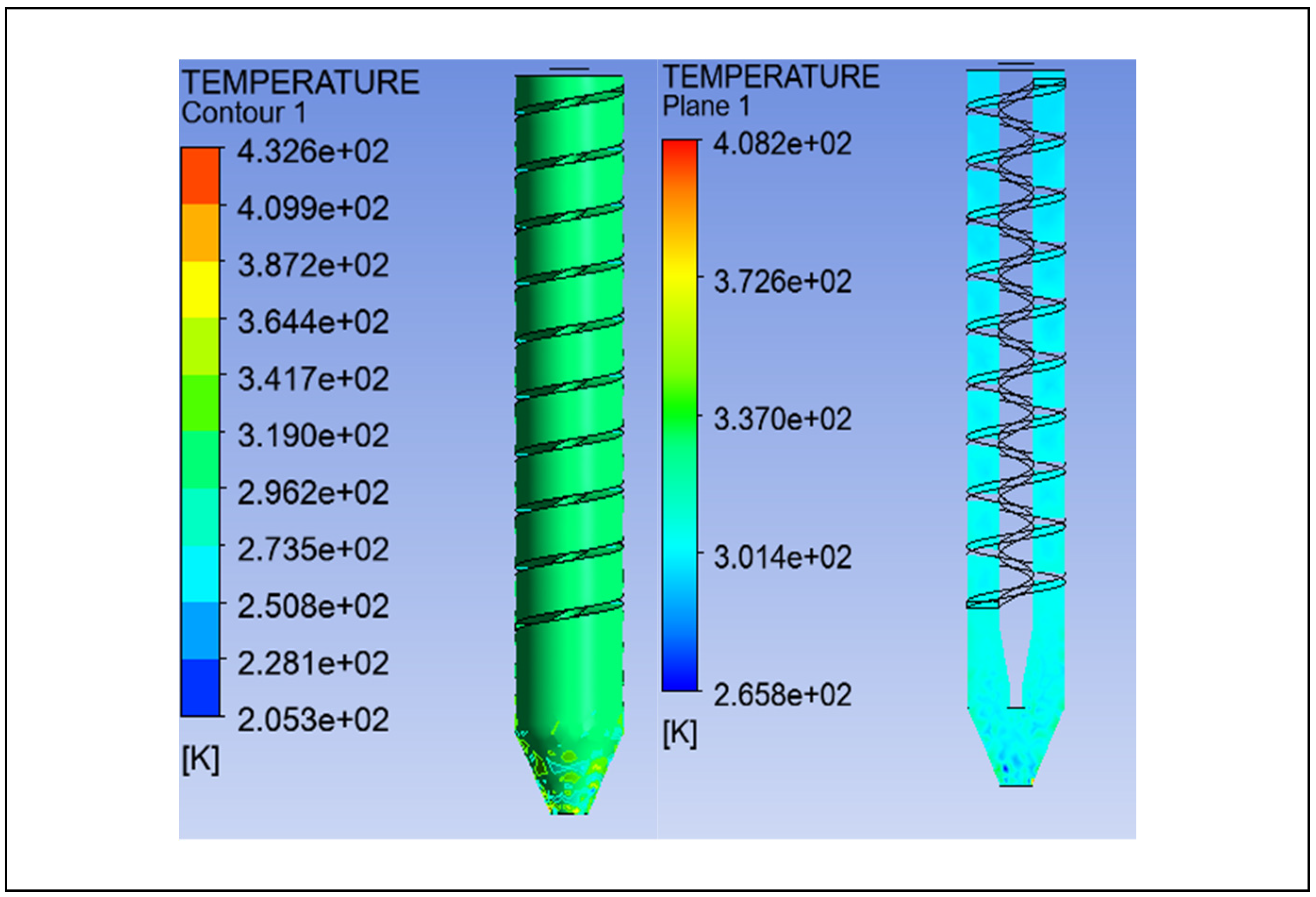

2.2. Numerical Simulation

2.3. Mesh Generation, Sensitivity Analysis, and Verification

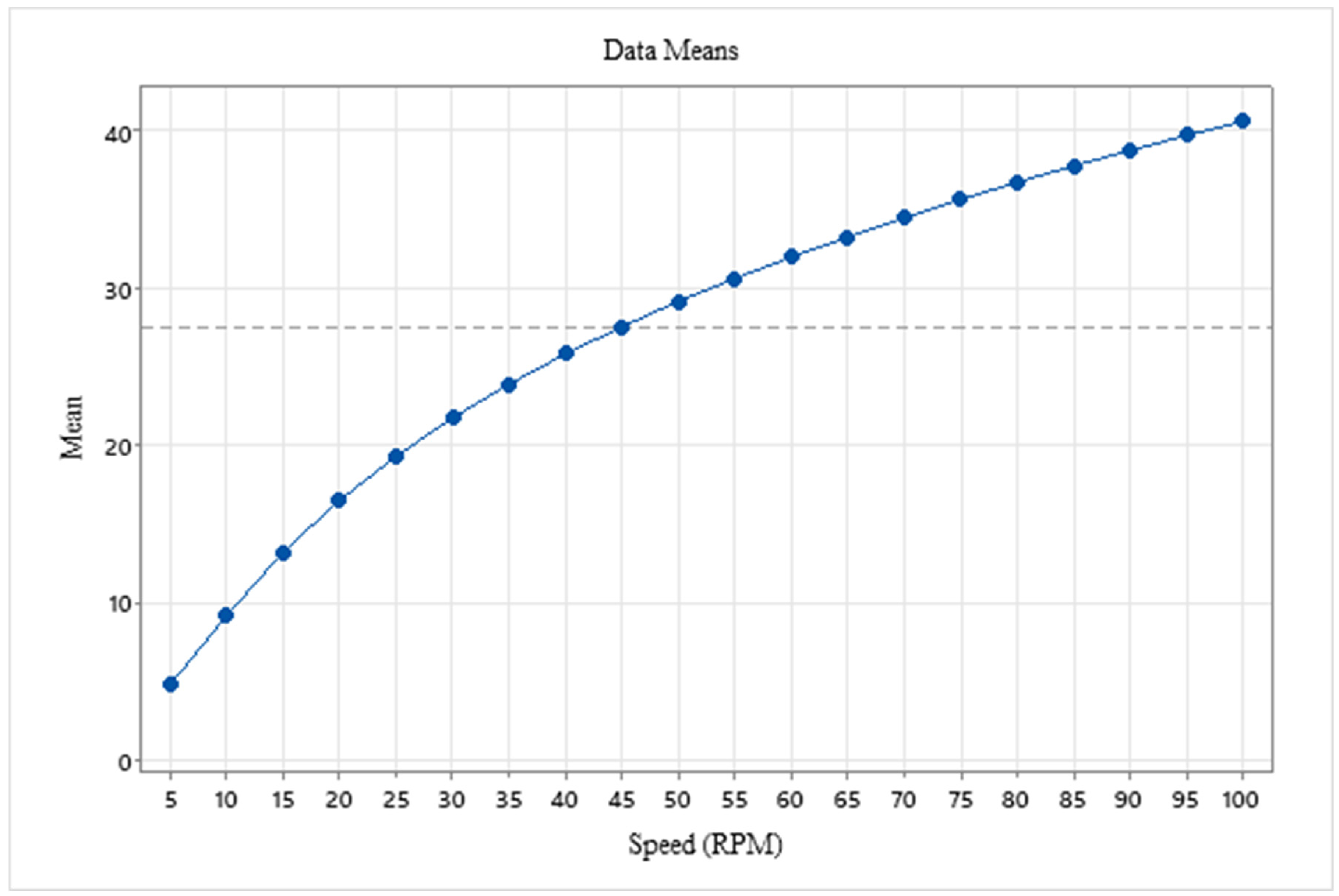

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sebio, L.; Chang, Y.K. Effects of selected process parameters in extrusion of yam flour (Dioscorea rotundata) on physicochemical properties of the extrudates. Nahrung 2000, 44, 96–101. [Google Scholar] [CrossRef]

- Shelar, G.A.; Gaikwad, S.T. Extrusion in food processing: An overview. Pharma Innov. J. 2019, 562, 562–568. [Google Scholar]

- Gu, B.-J.; Kowalski, R.J.; Ganjyal, G. Food Extrusion Processing: An Overview. Washingt. State Univ. Ext. 2017, 1–8. Available online: https://rex.libraries.wsu.edu/esploro/ (accessed on 20 June 2024).

- Kolawole, O.P.; Agbetoye, L.A.; Ogunlowo, S.; Samuel, T.M. Effect of Speed and Back Pressure on the Performance of Screw Press in Dewatering of Cassava Mash. Greener J. Sci. Eng. Technol. Res. 2011, 2, 017–023. Available online: https://gjournals.org/GJSETR/gjsetr-archive/vol-2-1-april-2012/kolawole-et-al.html (accessed on 20 June 2024). [CrossRef]

- Onwulata, C.I.; Huth, P.J. Whey Processing, Functionality and Health Benefits. Whey Process. Funct. Health Benefits 2009, 1–400. Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/9780813803845 (accessed on 20 June 2024).

- Lai, L.S.; Kokini, J.L. The effect of extrusion operating conditions on the on-line apparent viscosity of 98% Amylopectin (Amioca) and 70% Amylose (Hylon 7) corn starches during extrusion. J. Rheol. 1990, 34, 1245–1266. [Google Scholar] [CrossRef]

- Vasanthan, T.; Gaosong, J.; Yeung, J.; Li, J. Dietary fiber profile of barley flour as affected by extrusion cooking. Food Chem. 2002, 77, 35–40. Available online: https://linkinghub.elsevier.com/retrieve/pii/S0308814601003181 (accessed on 20 June 2024). [CrossRef]

- Oke, M.O.; Awonorin, S.O.; Workneh, T.S. Expansion ratio of extruded water yam (Dioscorea alata) starches using a single screw extruder. Afr. J. Agric. 2013, 8, 750–762. [Google Scholar] [CrossRef]

- Kothakota, A. A study on evaluation and characterization of extruded product by using various by-products. Afr. J. Food Sci. 2013, 7, 485–497. [Google Scholar] [CrossRef]

- Pathania, S.; Singh, B.; Sharma, S.; Sharma, V. Optimization of extrusion processing conditions for preparation of an instant grain base for use in weaning foods. Int. J. Eng. Res. Appl. 2013, 3, 1040–1049. [Google Scholar]

- Sai Manohar, R.; Haridas Rao, P. Interrelationship between rheological characteristics of dough and quality of biscuits; use of elastic recovery of dough to predict biscuit quality. Food Res. Int. 2002, 35, 807–813. [Google Scholar] [CrossRef]

- Charun, E.; Abecassis, J.; Contamine, A.S.; Roulland, T.M.; Vergnes, B.; Morel, M.H. Effects of temperature and mechanical input on semisweet biscuit (cookie) quality and dough characteristics. Cereal Chem. 2000, 77, 265–271. [Google Scholar] [CrossRef]

- Sabillón, L.; Stratton, J.; Rose, D.; Eskridge, K.; Bianchini, A. Effect of high-pressure processing on the microbial load and functionality of sugar-cookie dough. Cereal Chem. 2021, 98, 70–80. [Google Scholar] [CrossRef]

- Oladunmoye, O.O.; Ojo, A.; Akinoso, R.; Akanbi, C.T. Thermo-physical properties of composite bread dough with maize and cassava flours. Int. J. Food Sci. Technol. 2010, 45, 587–593. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Nastaj, A.; Wilczyński, K. Modeling for starve fed/flood fed mixing single-screw extruders. Int. Polym. Process. 2016, 31, 82–90. [Google Scholar] [CrossRef]

- Wilczyński, K.; Lewandowski, A.; Wilczyński, K.J. Experimental Study for Starve-Fed Single Screw Extrusion of Thermoplastics. Polym. Eng. Sci. 2012, 52, 1258–1270. Available online: https://4spepublications.onlinelibrary.wiley.com/doi/10.1002/pen.23076 (accessed on 20 June 2024). [CrossRef]

- Maina, A.; Tanui, J.K.; Bayode, A.; Mwema, F.M. Optimization of bar soap extrusion process parameters through numerical modelling. E3S Web Conf. 2024, 505, 03014. [Google Scholar] [CrossRef]

- Gao, Y.L.; Wang, X.; Zhou, L. The effect of screw speed on extrusion quality of the single-screw extruder. Adv. Mater. Res. 2014, 941–944, 1715–1719. [Google Scholar] [CrossRef]

- He, Z.Q.; Zhou, K.; Yin, S.P. Security analysis on single-screw extrusion process of solid propellant by numerical simulation. Adv. Mater. Res. 2014, 997, 605–609. [Google Scholar] [CrossRef]

- Sahu, C.; Patel, S.; Tripathi, A.K. Effect of extrusion parameters on physical and functional quality of soy protein enriched maize based extruded snack. Appl. Food Res. 2022, 2, 100072. [Google Scholar] [CrossRef]

- Das, M. Effect of screw speed and plasticizer on the torque requirement in single screw extrusion of starch-based plastics and their mechanical properties. Indian J. Chem. Technol. 2008, 15, 555–559. [Google Scholar]

- Xu, M.; Zhang, X.; Zhang, Y.; Wang, J.; Li, J.; Hu, Y.; Cao, S.; Luan, G. Effect of screw speed, temperature and moisture on physicochemical properties of corn gluten meal extrudate. J. Sci. Food Agric. 2023, 103, 5782–5790. [Google Scholar] [CrossRef] [PubMed]

- Pardhi, S.D.; Singh, B.; Nayik, G.A.; Dar, B.N. Evaluation of functional properties of extruded snacks developed from brown rice grits by using response surface methodology. J. Saudi Soc. Agric. Sci. 2019, 18, 7–16. [Google Scholar] [CrossRef]

| Source | DF | Seq SS | %Cont | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Regression | 2 | 2112.39 | 99.45% | 2112.39 | 1056.19 | 1523.17 | 0.000 |

| Speed (RPM) | 1 | 2004.30 | 94.36% | 430.09 | 430.09 | 620.25 | 0.000 |

| Speed (RPM) × Speed (RPM) | 1 | 108.09 | 5.09% | 108.09 | 108.09 | 155.88 | 0.000 |

| Error | 17 | 11.79 | 0.55% | 11.79 | 0.69 | ||

| Total | 19 | 2124.17 | 100.00% | ||||

| Model Summary | |||||||

| S | R-sq | R-sq (adj) | PRESS | R-sq (pred) | AICc | BIC | |

| 0.832716 | 99.45% | 99.38% | 20.8699 | 99.02% | 56.85 | 58.17 | |

| Regression Equation | |||||||

| Pressure (bar) = 3.286 + 0.6768 Speed (RPM) − 0.003139 Speed (RPM) × Speed (RPM) | |||||||

| Source | DF | Seq SS | %Cont | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Regression | 2 | 10132.7 | 99.88% | 10132.7 | 5066.35 | 6818.60 | 0.000 |

| Speed (RPM) | 1 | 10120.7 | 99.76% | 422.3 | 422.29 | 568.34 | 0.000 |

| Speed (RPM) × Speed (RPM) | 1 | 12.0 | 0.12% | 12.0 | 11.96 | 16.10 | 0.001 |

| Error | 17 | 12.6 | 0.12% | 12.6 | 0.74 | ||

| Total | 19 | 10145.3 | 100.00% | ||||

| Model Summary | |||||||

| S | R-sq | R-sq (adj) | PRESS | R-sq (pred) | AICc | BIC | |

| 0.861985 | 99.88% | 99.86% | 18.5749 | 99.82% | 58.23 | 59.55 | |

| Regression Equation | |||||||

| Temperature (K) = 295.032 + 0.6706 Speed (RPM) + 0.001044 Speed (RPM) × Speed (RPM) | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maina, A.; Mwema, F.; Bayode, A.; Nyanga, L. Effects of Screw Speed on Screw Pressure and Temperature: A Case of Non-Newtonian Non-Isothermal Flow. Eng. Proc. 2025, 84, 70. https://doi.org/10.3390/engproc2025084070

Maina A, Mwema F, Bayode A, Nyanga L. Effects of Screw Speed on Screw Pressure and Temperature: A Case of Non-Newtonian Non-Isothermal Flow. Engineering Proceedings. 2025; 84(1):70. https://doi.org/10.3390/engproc2025084070

Chicago/Turabian StyleMaina, Amos, Fredrick Mwema, Abiodun Bayode, and Lungile Nyanga. 2025. "Effects of Screw Speed on Screw Pressure and Temperature: A Case of Non-Newtonian Non-Isothermal Flow" Engineering Proceedings 84, no. 1: 70. https://doi.org/10.3390/engproc2025084070

APA StyleMaina, A., Mwema, F., Bayode, A., & Nyanga, L. (2025). Effects of Screw Speed on Screw Pressure and Temperature: A Case of Non-Newtonian Non-Isothermal Flow. Engineering Proceedings, 84(1), 70. https://doi.org/10.3390/engproc2025084070