Integrated Approach to Optimizing Selection and Placement of Water Pipeline Condition Monitoring Technologies

Abstract

1. Introduction

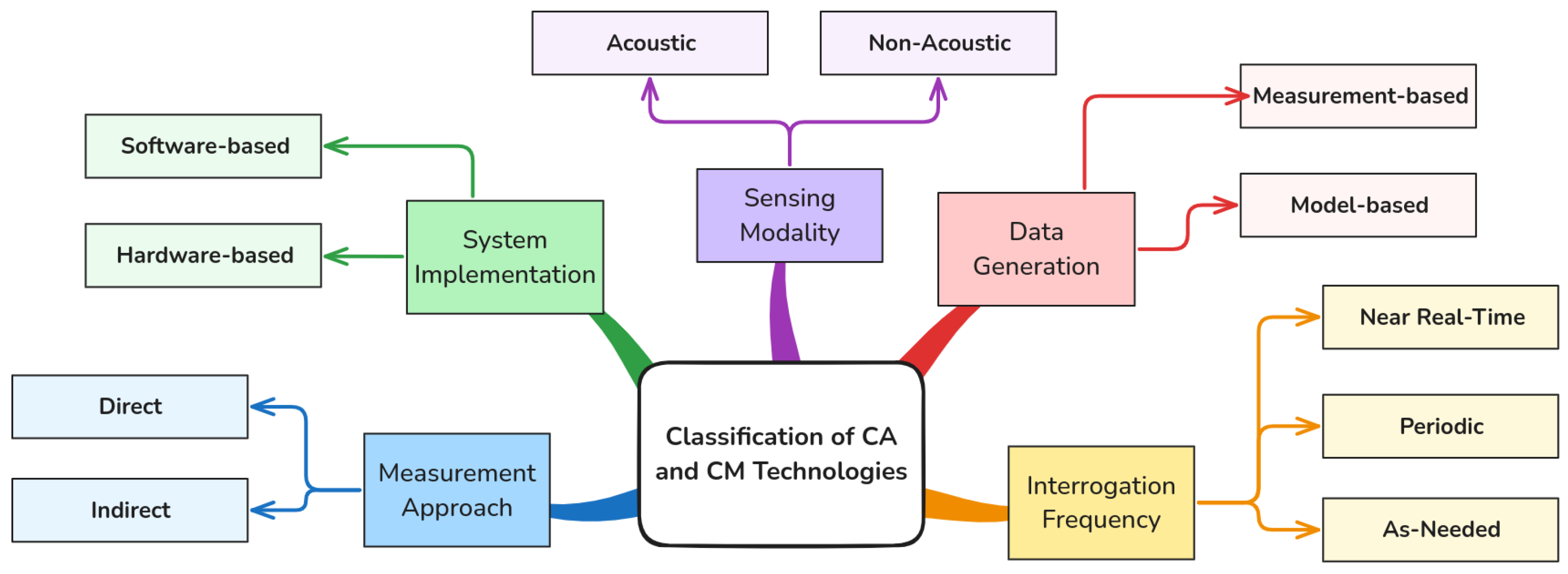

2. Condition Assessment and Monitoring Technologies

3. Techniques for Placement of Condition Monitoring Technologies

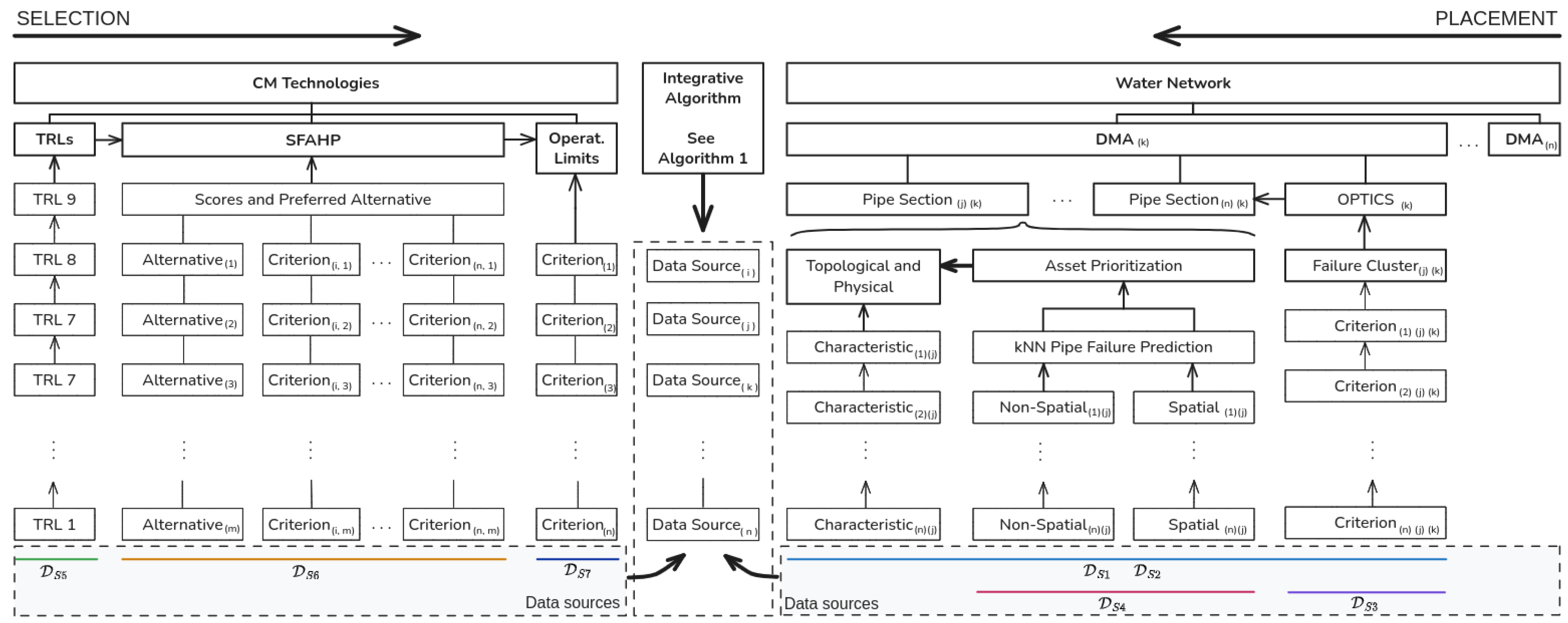

4. Framework for Optimal Selection and Placement of CM Technology

- Redundant: Various technologies and back-up systems should be considered.

- Established: Methods should be reliable and with a proven track record.

- Reliable: Technologies should be developed through rigorous testing and evaluation in real-world systems.

- Accurate: Results should provide minimal false positives, false negatives, and errors.

- Viable: The approach should be cost-effective and financially feasible given the unique limitations of utilities.

| Algorithm 1 RERAV-based integrative sensor placement and technology selection. |

| Require: : Base DMA GIS DB, : kNN Results DB, : CM Technology Limits DB, : SFAHP Results Ensure: Optimal CM technology selection and placement.

|

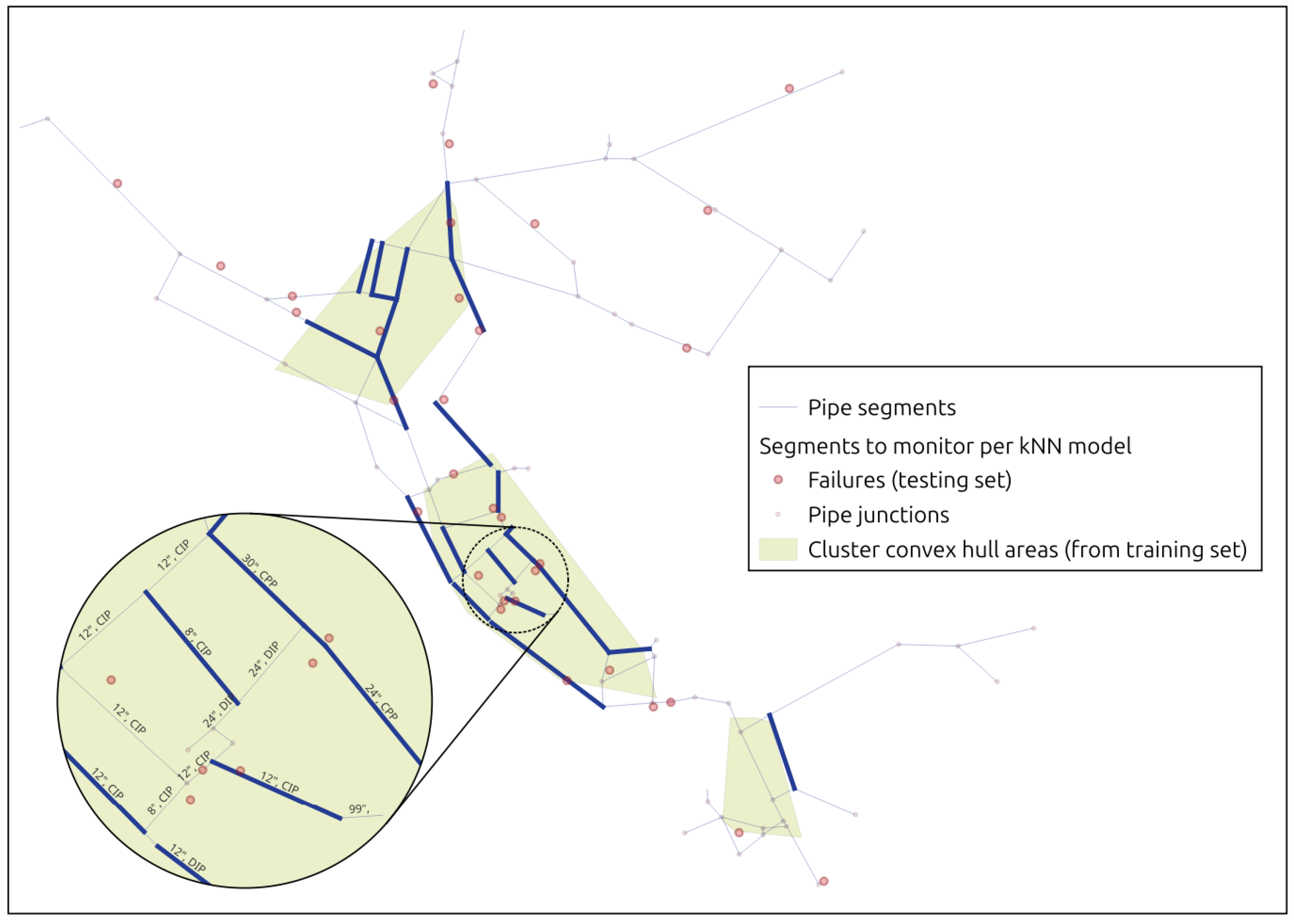

4.1. Approach to Optimal Placement of CM Technologies

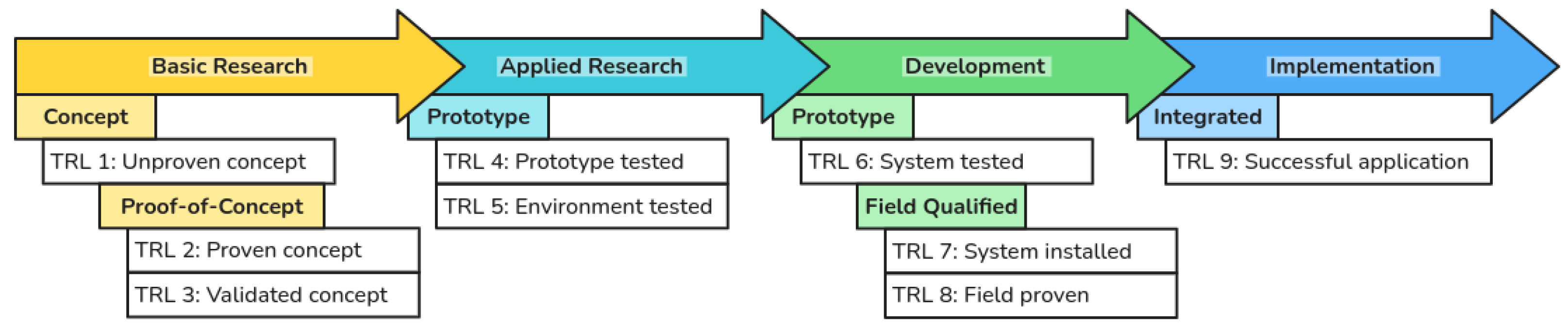

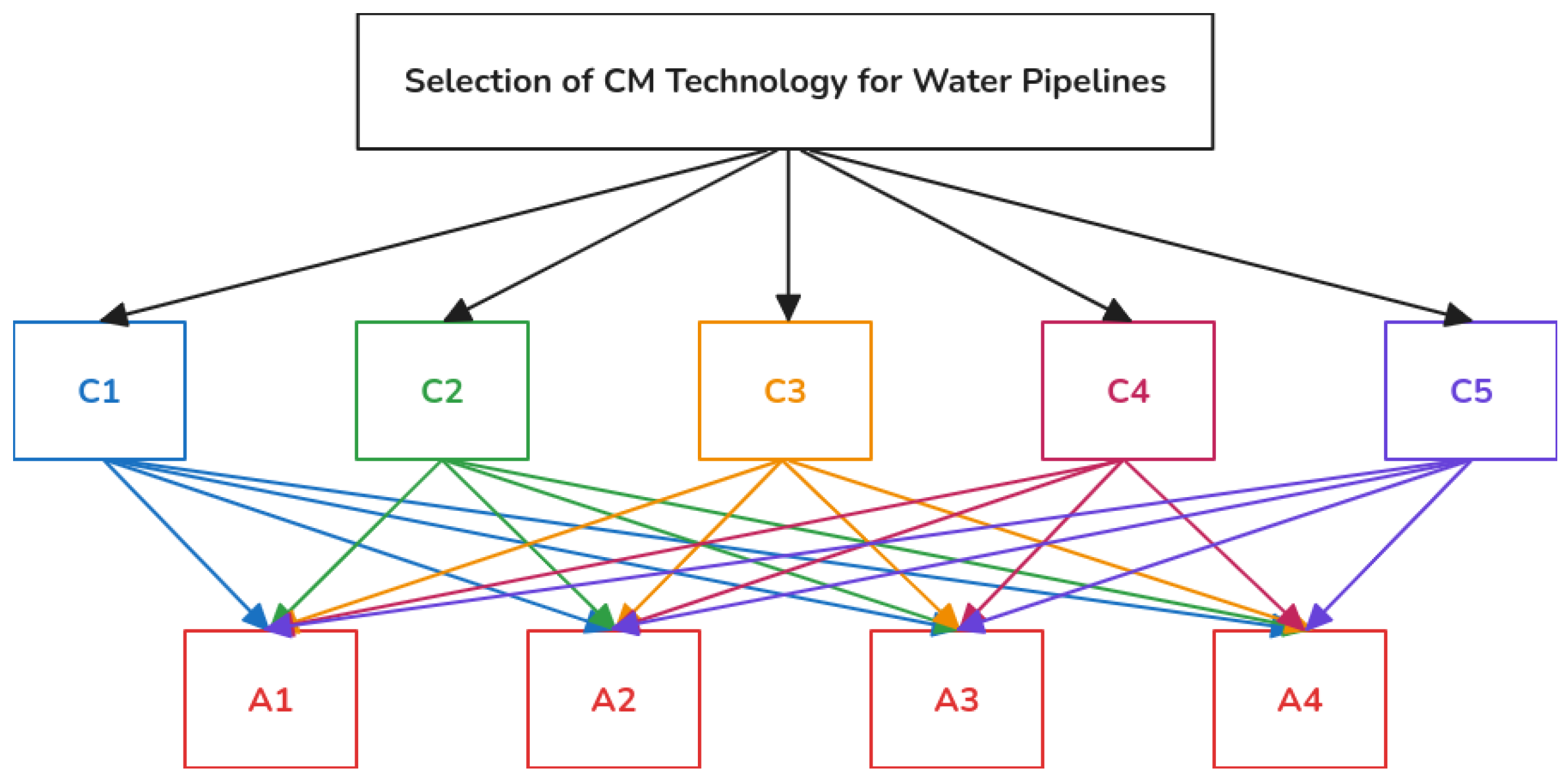

4.2. Approach to Selection of CM Technologies

5. Approach Implementation Through a Case Scenario

6. Discussion

- Suitability for analyzing entire water system networks at once, or by DMA, pipe size ranges (distribution or transmission systems), neighborhood, and so forth.

- Ability to reevaluate technology readiness and eventually include emerging methods that currently have the potential to revolutionize CM of underground infrastructure (e.g., QST and SSM).

- Adaptability to meet the needs and goals of different types and sizes of water utilities by systematically ranking CM methods based on their functionality and varying operational environments.

- Possibility of providing more or less importance to technology costs, wireless connectivity, scalability, power requirements, installation complexity, and additional criteria of importance to utilities.

- Applicability to most water utilities due to its lower data requirements. The approach utilizes data features typically employed for regular water audits and loss control studies.

- Ability to conduct a system-wide evaluation of pipe segments with the use of the CPI feature, which encodes the spatial context related to various factors such as construction quality, soil type, depth of bury, and traffic loads.

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AHP | Analytic Hierarchy Process |

| CA | Condition Assessment |

| CBA | Cost–Benefit Analysis |

| CM | Condition Monitoring |

| CMMS | Computerized Maintenance Management System |

| CPI | Cluster Proximity Index |

| DBSCAN | Density-Based Spatial Clustering of Applications with Noise |

| DFOS | Distributed Fiber Optic Systems |

| DMA | District Metered Area |

| DSS | Decision Support System |

| kNN | K-Nearest Neighbors |

| LR | Logistic Regression |

| MCA-SC | Multicriteria Analysis for System Characteristics |

| MCDA | Multicriteria Decision Analysis |

| ML | Machine learning |

| NDE | Non-Destructive Evaluation |

| NDT | Non-Destructive Testing |

| NGSA-II | Non-dominated Sorting Genetic Algorithm II |

| OPTICS | Ordering Points to Identify the Clustering Structure |

| PEC | Pulse Eddy Current |

| RBDSS | Rule-Based Decision Support System |

| RERAV | Redundant, Established, Reliable, Accurate, and Viable |

| RF | Random Forest |

| RMA | Robust Greedy Approximation |

| RMIO | Robust Mixed Integer Optimization |

| RUL | Remaining useful life |

| SCADA | Supervisory Control and Data Acquisition |

| SFAHP | Spherical Fuzzy Analytic Hierarchy Process |

| SFLO | Shuffled Frog Leaping Optimization |

| SFS | Spherical Fuzzy Sets |

| SHM | Structural Health Monitoring |

| SVM | Support Vector Machine |

| SWAM | Spherical Weighted Arithmetic Mean |

| TRL | Technology readiness level |

| WSN | Wireless Sensing Network |

References

- Barfuss, S.L. Water Main Break Rates in the USA and Canada: A Comprehensive Study; Technical Report; Utah Water Research Laboratory, Utah State University: Logan, UT, USA, 2023. [Google Scholar]

- ASCE. 2021 Report Card for America’s Infrastructure; Technical Report; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2021. [Google Scholar]

- Najafi, M.; Gokhale, S.B.; Calderon, D.R.; Ma, B. Trenchless Technology: Pipeline and Utility Design, Construction, and Renewal, 2nd ed.; McGraw Hill: New York, NY, USA, 2022. [Google Scholar]

- Bornhofen, R. DC Water’s Journey to Gen AI. In Proceedings of the Water Environment Federation; Water Environment Federation: Washington, DC, USA, 2024. [Google Scholar] [CrossRef]

- Culshaw, B.; Kersey, A. Fiber-Optic Sensing: A Historical Perspective. J. Light. Technol. 2008, 26, 1064–1078. [Google Scholar] [CrossRef]

- van den Broeke, J.; Carpentier, C.; Moore, C.; Carswell, L.; Jonsson, J.; Sivil, D.; Rosen, J.S.; Cade, L.; Mofidi, A.; Swartz, C.; et al. Compendium of Sensors and Monitors and Their Use in the Global Water Industry; Water Environment Research Foundation (WERF) and IWA Publishing: London, UK, 2014. [Google Scholar]

- Hunt, T.M. The Concise Encyclopaedia of Condition Monitoring: Including a Guide to 15 Condition Monitoring Techniques, 1st ed.; Machine & Systems Condition Monitoring Series; Coxmoor Publ. Co.: Chipping Norton, UK, 2006. [Google Scholar]

- ChenLei, X.; QianSheng, F.; HongYan, Z.; JiXin, Z. Optimal Layout of Pressure Monitoring Points in Water Supply Network Based on Optics. E3S Web Conf. 2019, 79, 01015. [Google Scholar]

- Yang, G.; Wang, H. Optimal Pressure Sensor Deployment for Leak Identification in Water Distribution Networks. Sensors 2023, 23, 5691. [Google Scholar] [CrossRef] [PubMed]

- Cuguero-Escofet, M.A.; Puig, V.; Quevedo, J.; Blesa, J. Optimal Pressure Sensor Placement for Leak Localisation Using a Relaxed Isolation Index: Application to the Barcelona Water Network. IFAC-PapersOnLine 2015, 48, 1108–1113. [Google Scholar] [CrossRef]

- Jun, S.; Kwon, H.J. The Optimum Monitoring Location of Pressure in Water Distribution System. Water 2019, 11, 307. [Google Scholar] [CrossRef]

- Saldarriaga, J.; Salcedo, C.A. Determination of Optimal Location and Settings of Pressure Reducing Valves in Water Distribution Networks for Minimizing Water Losses. Procedia Eng. 2015, 119, 973–983. [Google Scholar] [CrossRef]

- Ferreira, B.; Antunes, A.; Carriço, N.; Covas, D. NSGA-II Parameterization for the Optimal Pressure Sensor Location in Water Distribution Networks. Urban Water J. 2023, 20, 738–750. [Google Scholar] [CrossRef]

- Nejjari, F.; Sarrate, R.; Blesa, J. Optimal Pressure Sensor Placement in Water Distribution Networks Minimizing Leak Location Uncertainty. Procedia Eng. 2015, 119, 953–962. [Google Scholar] [CrossRef]

- Soroush, F.; Abedini, M.J. Optimal Selection of Number and Location of Pressure Sensors in Water Distribution Systems Using Geostatistical Tools Coupled with Genetic Algorithm. J. Hydroinform. 2019, 21, 1030–1047. [Google Scholar] [CrossRef]

- Santos-Ruiz, I.; Lopez-Estrada, F.R.; Puig, V.; Valencia-Palomo, G.; Hernandez, H.R. Pressure Sensor Placement for Leak Localization in Water Distribution Networks Using Information Theory. Sensors 2022, 22, 443. [Google Scholar] [CrossRef]

- Chang, N.B.; Prapinpongsanone, N.; Ernest, A. Optimal Sensor Deployment in a Large-Scale Complex Drinking Water Network: Comparisons between a Rule-Based Decision Support System and Optimization Models. Comput. Chem. Eng. 2012, 43, 191–199. [Google Scholar] [CrossRef]

- Du, K.; Yu, J.; Zheng, F.; Xu, W.; Savic, D.; Kapelan, Z. A Robust Multi-Objective Pressure Sensor Placement Method for Burst Detection in Water Distribution Systems. Water Resour. Res. 2024, 60, e2024WR037258. [Google Scholar] [CrossRef]

- Lau, H.; Dwight, R. A Fuzzy-Based Decision Support Model for Engineering Asset Condition Monitoring—A Case Study of Examination of Water Pipelines. Expert Syst. Appl. 2011, 38, 13342–13350. [Google Scholar] [CrossRef]

- Tscheikner-Gratl, F.; Egger, P.; Rauch, W.; Kleidorfer, M. Comparison of Multi-Criteria Decision Support Methods for Integrated Rehabilitation Prioritization. Water 2017, 9, 68. [Google Scholar] [CrossRef]

- Zhang, W.; Lai, T.; Li, Y. Risk Assessment of Water Supply Network Operation Based on ANP-Fuzzy Comprehensive Evaluation Method. J. Pipeline Syst. Eng. Pract. 2022, 13, 04021068. [Google Scholar] [CrossRef]

- Allen, M.; Preis, A.; Iqbal, M.; Whittle, A.J. Water Distribution System Monitoring and Decision Support Using a Wireless Sensor Network. In Proceedings of the 2013 14th ACIS International Conference on Software Engineering, Artificial Intelligence, Networking and Parallel/Distributed Computing, Honolulu, HI, USA, 1–3 July 2013; pp. 641–646. [Google Scholar] [CrossRef]

- Davis, P.; Sullivan, E.; Marlow, D.; Marney, D. A Selection Framework for Infrastructure Condition Monitoring Technologies in Water and Wastewater Networks. Expert Syst. Appl. 2013, 40, 1947–1958. [Google Scholar] [CrossRef]

- Yazdekhasti, S.; Piratla, K.R.; Matthews, J.C.; Khan, A.; Atamturktur, S. Optimal Selection of Acoustic Leak Detection Techniques for Water Pipelines Using Multi-Criteria Decision Analysis. Manag. Environ. Qual. Int. J. 2018, 29, 255–277. [Google Scholar] [CrossRef]

- Reed, C.; Robinson, A.J.; Smart, D. Techniques for Monitoring Structural Behaviour of Pipeline Systems; Awwa Research Foundation and American Water Works Association: Denver, CO, USA, 2004. [Google Scholar]

- Hangan, A.; Chiru, C.G.; Arsene, D.; Czako, Z.; Lisman, D.F.; Mocanu, M.; Pahontu, B.; Predescu, A.; Sebestyen, G. Advanced Techniques for Monitoring and Management of Urban Water Infrastructures—An Overview. Water 2022, 14, 2174. [Google Scholar] [CrossRef]

- ASCE. Water Pipeline Condition Assessment; ASCE Manuals and Reports on Engineering Practice No. 134; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2017. [Google Scholar] [CrossRef]

- AWWA. Manual M77 Condition Assessment of Water Mains; Manual of Water Supply Practices; American Water Works Association: Denver, CO, USA, 2019. [Google Scholar]

- Marshall, D.H.; Worthington, W. Increasing the Reliability of Concrete Pressure Pipe. In Proceedings of the Trenchless Pipeline Projects Practical Applications, Boston, MA, USA, 8–11 June 1997; pp. 273–282. [Google Scholar] [CrossRef]

- NASSCO. Pipeline Assessment and Certification Program (PACP™) Reference Manual, Version 8, version 8 ed.; NASSCO Inc.: Frederick, MD, USA, 2023. [Google Scholar]

- Liu, Z.; Kleiner, Y. State of the Art Review of Inspection Technologies for Condition Assessment of Water Pipes. Measurement 2013, 46, 1–15. [Google Scholar] [CrossRef]

- Farrar, C.R.; Worden, K. An Introduction to Structural Health Monitoring. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 303–315. [Google Scholar] [CrossRef]

- Metje, N.; Chapman, D.; Walton, R.; Sadeghioon, A.; Ward, M. Real Time Condition Monitoring of Buried Water Pipes. Tunn. Undergr. Space Technol. 2012, 28, 315–320. [Google Scholar] [CrossRef]

- WSSC Water. WSSC Water Strategic Plan Fiscal Year 2025–2027; Technical Report; Washington Suburban Sanitary Commission (WSSC): Laurel, MD, USA, 2024. [Google Scholar]

- US EPA. Water and Wastewater Systems Sector-Specific Plan; US EPA: Washington, DC, USA, 2015.

- Liu, Z.; Kleiner, Y. State-of-the-Art Review of Technologies for Pipe Structural Health Monitoring. IEEE Sens. J. 2012, 12, 1987–1992. [Google Scholar] [CrossRef]

- Latif, J.; Shakir, M.Z.; Edwards, N.; Jaszczykowski, M.; Ramzan, N.; Edwards, V. Review on Condition Monitoring Techniques for Water Pipelines. Measurement 2022, 193, 110895. [Google Scholar] [CrossRef]

- EPA. Innovation and Research for Water Infrastructure for the 21st Century Research Plan; Technical Report EPA/600/X-09/003; U.S. Environmental Protection Agency (EPA): Washington, DC, USA, 2007.

- Hertlein, B.H. Stress Wave Testing of Concrete: A 25-Year Review and a Peek into the Future. Constr. Build. Mater. 2013, 38, 1240–1245. [Google Scholar] [CrossRef]

- Ali, H.; Choi, J.h. A Review of Underground Pipeline Leakage and Sinkhole Monitoring Methods Based on Wireless Sensor Networking. Sustainability 2019, 11, 4007. [Google Scholar] [CrossRef]

- Obeid, A.; Karray, F.; Jmal, W.; Abid, M.; Qasim, S.M.; Bensaleh, M. Toward Realisation of Wireless Sensor Network Based Water Pipeline Monitoring Systems: A Comprehensive Review of Techniques and Platforms. IET Sci. Meas. Technol. 2016, 10. [Google Scholar] [CrossRef]

- Gupta, A.; Kulat, K.D. A Selective Literature Review on Leak Management Techniques for Water Distribution System. Water Resour. Manag. 2018, 32, 3247–3269. [Google Scholar] [CrossRef]

- Stanczyk, J.; Burszta, E. Development of Methods for Diagnosing the Operating Conditions of Water Supply Networks over the Last Two Decades. Water 2022, 14, 786. [Google Scholar] [CrossRef]

- Li, R.; Huang, H.; Xin, K.; Tao, T. A Review of Methods for Burst/Leakage Detection and Location in Water Distribution Systems. Water Supply 2015, 15, 429–441. [Google Scholar] [CrossRef]

- Liu, Z.; Kleiner, Y. Computational Intelligence for Urban Infrastructure Condition Assessment: Water Transmission and Distribution Systems. IEEE Sens J. 2014, 14, 4122–4133. [Google Scholar] [CrossRef]

- Wang, Y.Y. Management of Ground Movement Hazards for Pipelines; Technical Report CRES-2012-M03-01; Interstate Natural Gas Association of America (INGAA): Washington, DC, USA, 2017. [Google Scholar]

- Rizzo, P. Water and Wastewater Pipe Nondestructive Evaluation and Health Monitoring: A Review. Adv. Civ. Eng. 2010, 2010, 818597. [Google Scholar] [CrossRef]

- Ojdrovic, R.; Nardini, P.D.; Bracken, M.; Marciszewski, J. Evaluation of Acoustic Wave Based PCCP Stiffness Testing Results. In Proceedings of the ASCE UESI Pipelines 2015, Baltimore, MD, USA, 23–26 August 2015; American Society of Civil Engineers: Reston, VA, USA, 2015; pp. 1150–1159. [Google Scholar] [CrossRef]

- Williams, A.F.; Peterson, K.A.; Nardini, P.D.; Ojdrovic, R.P. Condition Assessment and Repair Prioritization of a Large Diameter Pipeline System. In Proceedings of the ASCE UESI Pipelines 2019, Nashville, TN, USA, 21–24 July 2019; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 95–104. [Google Scholar] [CrossRef]

- Kumar, S.S.; Abraham, D.M.; Behbahani, S.S.; Matthews, J.C.; Iseley, T. Comparison of Technologies for Condition Assessment of Small-Diameter Ductile Iron Water Pipes. J. Pipeline Syst. Eng. Pract. 2020, 11, 04020039. [Google Scholar] [CrossRef]

- Lu, H.; Xu, Z.D.; Iseley, T.; Peng, H.; Fu, L. Pipeline Inspection and Health Monitoring Technology: The Key to Integrity Management; Springer Nature: Singapore, 2023. [Google Scholar] [CrossRef]

- Bykerk, L.; Valls Miro, J. Detection of Water Leaks in Suburban Distribution Mains with Lift and Shift Vibro-Acoustic Sensors. Vibration 2022, 5, 370–382. [Google Scholar] [CrossRef]

- Yang, L. Techniques for Corrosion Monitoring; Woodhead Publishing: Cambridge, UK, 2020. [Google Scholar]

- Fessler, R. Pipeline Corrosion; Technical Report; U.S. Department of Transportation, Pipeline and Hazardous Materials Safety Administration: Washington, DC, USA, 2008.

- Bohannon, T.; Boozer, C. From Satellite to Snout: How Central Arkansas Water Uses High- Tech and Low-Tech to Attack Nonrevenue Water. In Proceedings of the 2021 WEFTEC, Chicago, IL, USA, 16–20 October 2021; Water Environment Federation: Alexandria, VA, USA, 2021. [Google Scholar]

- Leung, C.K.Y.; Wan, K.T.; Inaudi, D.; Bao, X.; Habel, W.; Zhou, Z.; Ou, J.; Ghandehari, M.; Wu, H.C.; Imai, M. Review: Optical Fiber Sensors for Civil Engineering Applications. Mater. Struct. 2015, 48, 871–906. [Google Scholar] [CrossRef]

- Barrias, A.; Casas, J.; Villalba, S. A Review of Distributed Optical Fiber Sensors for Civil Engineering Applications. Sensors 2016, 16, 748. [Google Scholar] [CrossRef]

- Krohn, D.A.; MacDougall, T.; Mendez, A. Fiber Optic Sensors: Fundamentals and Applications, 4th ed.; Number 247 in SPIE PM; SPIE Press: Bellingham, WA, USA, 2014. [Google Scholar]

- Ravet, F.; Bracken, M.; Dutoit, D.; Nikles, M.; Sa, O.; Ch, R.B. Extended Distance Fiber Optic Monitoring for Pipeline Leak and Ground Movement Detection. In Proceedings of the ASCE Pipelines 2009, San Diego, CA, USA, 15–19 August 2009. [Google Scholar] [CrossRef]

- Braga, A.M.B.; Valente, L.C.G.; Llerena, R.W.A.; Regazzi, R.D. Optical Fiber Sensing Technology in the Pipeline Industry. In Proceedings of the Rio Pipeline 2003 Conference & Exposition, Rio de Janeiro, Brazil, 22–24 October 2003. [Google Scholar]

- Dunbar, J.; Galan-Comas, G.; Walshire, L.; Wahl, R.; Yule, D.; Corcoran, M.; Bufkin, A.; Llopis, J. Remote Sensing and Monitoring of Earthen Flood-Control Structures; Technical Report; Geotechnical and Structures Laboratory (U.S.): Vicksburg, MI, USA, 2017. [Google Scholar] [CrossRef]

- Helz, R. Monitoring Ground Deformation from Space; U.S. Department of the Interior, U.S. Geological Survey: Reston, VA, USA, 2005.

- Robles, D.; Castillo, E. Case of Geotechnical Instrumentation of Pipelines in Unstable Zones: Real Time Readings and Its Development in Uncommunicated Zones. In Proceedings of the ASME International Pipeline Geotechnical Conference, Lima, Peru, 25–26 July 2017. [Google Scholar]

- Edemsky, D.; Popov, A.; Prokopovich, I.; Garbatsevich, V. Airborne Ground Penetrating Radar, Field Test. Remote Sens. 2021, 13, 667. [Google Scholar] [CrossRef]

- Halimshah, N.N.; Yusup, A.; Mat Amin, Z.; Ghazalli, M.D. Visual Inspection of Water Leakage from Ground Penetrating Radar Radargram. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2015, II-2/W2, 191–198. [Google Scholar] [CrossRef]

- Crocco, L.; Soldovieri, F.; Millington, T.; Cassidy, N.J. Bistatic Topographic GRP Imaging for Incipient Pipeline Leakage Evaluation. Prog. Electromagn. Res. 2010, 101, 307–321. [Google Scholar] [CrossRef]

- Aslam, H.; Mortula, M.M.; Yehia, S.; Ali, T.; Kaur, M. Evaluation of the Factors Impacting the Water Pipe Leak Detection Ability of GPR, Infrared Cameras, and Spectrometers under Controlled Conditions. Appl. Sci. 2022, 12, 1683. [Google Scholar] [CrossRef]

- Fahmy, M.; Moselhi, O. Automated Detection and Location of Leaks in Water Mains Using Infrared Photography. J. Perform. Constr. Facil. 2010, 24, 242–248. [Google Scholar] [CrossRef]

- Allouche, E.; Sari, M.A.; Alfaqih, L.; Oppenheimer, J.; Ibikunle, O.; Snow, J.R.; Jacangelo, J.G. Innovative Technologies to Effectively Manage Deteriorating Infrastructure; Technical Report WRF 4717; The Water Research Foundation: Alexandria, VA, USA, 2020. [Google Scholar]

- Hawari, A.; Khader, M.; Hirzallah, W.; Zayed, T.; Moselhi, O. Integrated Sensing Technologies for Detection and Location of Leaks in Water Distribution Networks. Water Supply 2017, 17, 1589–1601. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Ansari, F. Structural Health Monitoring of Civil Infrastructure Systems; Woodhead Publishing Limited: Cambridge, UK, 2009. [Google Scholar] [CrossRef]

- Hadji, A.; Flazi, S.; Bouzid, M.A. Novel Electrical Technique for Detecting Water Leaks in Buried Plastic Water Distribution Pipes. J. Pipeline Syst. Eng. Pract. 2022, 13, 04022043. [Google Scholar] [CrossRef]

- Adedeji, K.B.; Hamam, Y.; Abe, B.T.; Abu-Mahfouz, A.M. Towards Achieving a Reliable Leakage Detection and Localization Algorithm for Application in Water Piping Networks: An Overview. IEEE Access 2017, 5, 20272–20285. [Google Scholar] [CrossRef]

- Datta, S.; Sarkar, S. A Review on Different Pipeline Fault Detection Methods. J. Loss Prev. Process. Ind. 2016, 41, 97–106. [Google Scholar] [CrossRef]

- Chapman, J.; Seskir, Z.C. Quantum Sensing Technologies and Smart Cities: Opportunities and Challenges. In Proceedings of the 10th IEEE International Smart Cities Conference, Pattaya City, Thailand, 29 October–1 November 2024. [Google Scholar]

- Kantsepolsky, B.; Aviv, I. Sensors in Civil Engineering: From Existing Gaps to Quantum Opportunities. Smart Cities 2024, 7, 277–301. [Google Scholar] [CrossRef]

- Kantsepolsky, B.; Aviv, I.; Weitzfeld, R.; Bordo, E. Exploring Quantum Sensing Potential for Systems Applications. IEEE Access 2023, 11, 31569–31582. [Google Scholar] [CrossRef]

- Almazyad, A.S.; Seddiq, Y.M.; Alotaibi, A.M.; Al-Nasheri, A.Y.; BenSaleh, M.S.; Obeid, A.M.; Qasim, S.M. A Proposed Scalable Design and Simulation of Wireless Sensor Network-Based Long-Distance Water Pipeline Leakage Monitoring System. Sensors 2014, 14, 3557–3577. [Google Scholar] [CrossRef]

- Weiming, W.; Jian, W.; Kun, T. Development of a Chipless RFID Water Leakage Detecting Sensor Using Defected Ground Structure. In Proceedings of the 2022 International Applied Computational Electromagnetics Society Symposium (ACES-China), Xuzhou, China, 28–31 July 2022; pp. 1–2. [Google Scholar] [CrossRef]

- Khomenko, A.; Koricho, E.G.; Haq, M.; Cloud, G.L. Bolt Tension Monitoring with Reusable Fiber Bragg-grating Sensors. J. Strain Anal. Eng. Des. 2016, 51, 101–108. [Google Scholar] [CrossRef]

- Thompson, L.D.; Westermo, B.D.; Crum, D.B.; Law, W.; Trombi, R.; Waldbusser, R. Smart Structural Fasteners for the Aircraft and Construction Industries. In Proceedings of the 1999 Symposium on Smart Structures and Materials, Newport Beach, CA, USA, 1–5 March 1999; SPIE: Newport Beach, CA, USA, 1999; pp. 143–152. [Google Scholar] [CrossRef]

- Kim, Y.; Jung, H.; Ryou, J.; Choi, J. A Basic Experimental Study on Analysis of Leak Signal and Monitoring Method for Water Supply Pipe. Appl. Sci. 2021, 11, 2097. [Google Scholar] [CrossRef]

- Han, B.; Ding, S.; Yu, X. Intrinsic Self-Sensing Concrete and Structures: A Review. Measurement 2015, 59, 110–128. [Google Scholar] [CrossRef]

- Perry, G.; Goldfeld, Y. Smart Self-Sensory TRC Pipes—Proof of Concept. Smart Mater. Struct. 2022, 31, 055011. [Google Scholar] [CrossRef]

- Lee, P.J.; Lambert, M.F.; Simpson, A.R.; V’itkovsky, J.P.; Misiunas, D. Leak Location in Single Pipelines Using Transient Reflections. Australas. J. Water Resour. 2007, 11, 53–65. [Google Scholar] [CrossRef]

- Jin, S.; Saparia, B.; Norton, J.; Wood, B.; Abdallah, A.; McClinton, T.; Burchi, J.; Radtke, L. Monitoring of Pressure Transients in Great Lakes Water Authority Water Transmission System. J. Water Manag. Model. 2022, 30, C492. [Google Scholar] [CrossRef]

- Surucu, O.; Gadsden, S.A.; Yawney, J. Condition Monitoring Using Machine Learning: A Review of Theory, Applications, and Recent Advances. Expert Syst. Appl. 2023, 221, 119738. [Google Scholar] [CrossRef]

- Abdelmageed, S.; Tariq, S.; Boadu, V.; Zayed, T. Criteria-Based Critical Review of Artificial Intelligence Applications in Water-Leak Management. Environ. Rev. 2022, 30, 280–297. [Google Scholar] [CrossRef]

- Azimi, M.; Eslamlou, A.; Pekcan, G. Data-Driven Structural Health Monitoring and Damage Detection through Deep Learning: State-of-the-Art Review. Sensors 2020, 20, 2778. [Google Scholar] [CrossRef]

- Yazdekhasti, S.; Vladeanu, G.; Daly, C. Evaluation of Artificial Intelligence Tool Performance for Predicting Water Pipe Failures. In Proceedings of the ASCE UESI Pipelines 2020, San Antonio, TX, USA, 9–12 August 2020; pp. 203–211. [Google Scholar] [CrossRef]

- Housner, G.W.; Bergman, L.A.; Caughey, T.K.; Chassiakos, A.G.; Claus, R.O.; Masri, S.F.; Skelton, R.E.; Soong, T.T.; Spencer, B.F.; Yao, J.T.P. Structural Control: Past, Present, and Future. J. Eng. Mech. 1997, 123, 897–971. [Google Scholar] [CrossRef]

- La Rose, K.; Sagiannos, V.; Hebner, J. A Comprehensive Condition Assessment of a High Risk Coastal Force Main: Comox Valley Regional District Case Study. In Proceedings of the Pipelines 2018, Toronto, ON, Canada, 15–18 July 2018; pp. 239–248. [Google Scholar] [CrossRef]

- Sela, L.; Amin, S. Robust Sensor Placement for Pipeline Monitoring: Mixed Integer and Greedy Optimization. Adv. Eng. Inform. 2018, 36, 55–63. [Google Scholar] [CrossRef]

- Calderon, D.; Bavilinezhad, S.; Hamidzadeh, P.; Rajaie, E.; Najafi, M. Trenchless Technology Research Needs: Results and Conclusions from an Industry Research Symposium. In Proceedings of the 2024 No-Dig Show, Providence, RI, USA, 14–18 April 2024. [Google Scholar]

- Holley, M.; Diaz, R.; Giovanniello, M. Acoustic Monitoring of Prestressed Concrete Cylinder Pipe: A Case History. In Proceedings of the ASCE Pipelines 2001, San Diego, CA, USA, 15–18 July 2001; American Society of Civil Engineers: Washington, DC, USA, 2001; pp. 1–9. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, C.; Liu, H.; Fu, G.; Wang, Y. Optimal Sensor Placement for Pipe Burst Detection in Water Distribution Systems Using Cost–Benefit Analysis. J. Hydroinform. 2020, 22, 606–618. [Google Scholar] [CrossRef]

- Zecchin, A.C.; Do, N.; Gong, J.; Leonard, M.; Lambert, M.F.; Stephens, M.L. Optimal Pipe Network Sensor Layout Design for Hydraulic Transient Event Detection and Localization. J. Water Resour. Plan. Manag. 2022, 148, 04022041. [Google Scholar] [CrossRef]

- Hu, Z.; Chen, W.; Chen, B.; Tan, D.; Zhang, Y.; Shen, D. Robust Hierarchical Sensor Optimization Placement Method for Leak Detection in Water Distribution System. Water Resour. Manag. 2021, 35, 3995–4008. [Google Scholar] [CrossRef]

- Rayaroth, R.; Sivaradje, G. Random Bagging Classifier and Shuffled Frog Leaping Based Optimal Sensor Placement for Leakage Detection in WDS. Water Resour. Manag. 2019, 33, 3111–3125. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, Q.; Hou, D.; Zhang, H. Compressed Sensing Based Optimal Sensor Placement for Leak Localization in Water Distribution Networks. J. Hydroinform. 2018, 20, 1286–1295. [Google Scholar] [CrossRef]

- Menapace, A.; Zanfei, A.; Herrera, M.; Brentan, B. Graph Neural Networks for Sensor Placement: A Proof of Concept towards a Digital Twin of Water Distribution Systems. Water 2024, 16, 1835. [Google Scholar] [CrossRef]

- Zarghamee, M.S.; Ojdrovic, R.P.; Nardini, P.D. Prestressed Concrete Cylinder Pipe Condition Assessment—What Works, What Doesn’t, What’s Next. In Pipelines 2011: A Sound Conduit for Sharing Solutions; ASCE: Reston, VA, USA, 2012; pp. 182–194. [Google Scholar] [CrossRef]

- Yussif, A.M.; Sadeghi, H.; Zayed, T. Application of Machine Learning for Leak Localization in Water Supply Networks. Buildings 2023, 13, 849. [Google Scholar] [CrossRef]

- Abdelkader, E.M.; Zayed, T.; Elshaboury, N. A Novel Hybrid Fuzzy Analytical Hierarchy Process–Game Theory Model for Prioritizing Factors Affecting the Deterioration of Water Pipelines. Appl. Water Sci. 2024, 14, 265. [Google Scholar] [CrossRef]

- AWWA (Ed.) M36 Water Audits and Loss Control Programs, 4th ed.; Number M36 in AWWA Manuals of Practice; American Water Works Association: Denver, CO, USA, 2016. [Google Scholar]

- Alegre, H.; Baptista, J.M.; Cabrera, E.; Cubillo, F.; Duarte, P.; Hirner, W.; Merkel, W.; Parena, R. Performance Indicators for Water Supply Services: Third Edition. Water Intell. Online 2016, 15, 9781780406336. [Google Scholar] [CrossRef]

- Ankerst, M.; Breunig, M.M.; Kriegel, H.P.; Sander, J. OPTICS: Ordering points to identify the clustering structure. ACM SIGMOD Rec. 1999, 28, 49–60. [Google Scholar] [CrossRef]

- Metz, M. GRASS GIS 8.4.2dev Reference Manual. 2024. Available online: https://grass.osgeo.org/grass-stable/manuals/v.cluster.html (accessed on 18 March 2025).

- Huang, C.C. Detect Spatial-Temporal Point Clusters by Incorporating Time into Density-based Clustering. 2021. Available online: https://www.esri.com/arcgis-blog/products/arcgis-pro/analytics/detect-spatial-temporal-point-clusters-by-incorporating-time-into-density-based-clustering/ (accessed on 18 March 2025).

- Fix, E.; Hodges, J.L. Discriminatory Analysis. Nonparametric Discrimination: Consistency Properties. Int. Stat. Rev./Rev. Int. Stat. 1989, 57, 238–247. [Google Scholar] [CrossRef]

- Calderon, D.; Najafi, M. Water Asset Condition Monitoring Classification: Investigating the Use of Machine Learning. In Proceedings of the International No-Dig 2023, Mexico City, Mexico, 17–18 October 2023. [Google Scholar]

- IBM. What Is the K-Nearest Neighbors Algorithm? | IBM. 2021. Available online: https://www.ibm.com/think/topics/knn (accessed on 19 March 2025).

- Zhang, S.; Li, X.; Zong, M.; Zhu, X.; Cheng, D. Learning k for kNN Classification. ACM Trans. Intell. Syst. Technol. 2017, 8, 1–19. [Google Scholar] [CrossRef]

- Heder, M. From NASA to EU: The Evolution of the TRL Scale in Public Sector Innovation. Innov. J. 2017, 22, 1–23. [Google Scholar]

- NASA (Ed.) NASA Systems Engineering Handbook; Number SP-2016-6105 Rev2; National Aeronautics and Space Administration (NASA): Washington, DC, USA, 2017.

- PRCI. Technology Readiness Levels; Pipeline Research Council International (PRCI): Chantilly, VA, USA, 2017; Available online: https://www.prci.org (accessed on 8 March 2025).

- Deshmukh-Towery, N.; Machek, E.C.; Thomas, A. Technology Readiness Level Guidebook; Technical Report FHWA-HRT-17-047; Federal Highway Administration (FHWA), US Department of Transportation (USDOT): McLean, VA, USA, 2017.

- Kutlu Gundogdu, F.; Kahraman, C. A Novel Spherical Fuzzy Analytic Hierarchy Process and Its Renewable Energy Application. Soft Comput. 2020, 24, 4607–4621. [Google Scholar] [CrossRef]

- Dogan, O. Process Mining Technology Selection with Spherical Fuzzy AHP and Sensitivity Analysis. Expert Syst. Appl. 2021, 178, 114999. [Google Scholar] [CrossRef]

- Rossman, L. EPANET Net3 System Description; Software Manual Examples 2; University of Kentucky Libraries: Lexington, KY, USA, 2016. [Google Scholar]

- Hahsler, M.; Piekenbrock, M.; Doran, D. dbscan: Fast Density-Based Clustering with R. J. Stat. Softw. 2019, 91, 1–30. [Google Scholar] [CrossRef]

- Taiwo, R.; Ben Seghier, M.E.A.; Zayed, T. Toward Sustainable Water Infrastructure: The State-Of-The-Art for Modeling the Failure Probability of Water Pipes. Water Resour. Res. 2023, 59, e2022WR033256. [Google Scholar] [CrossRef]

| Technology | Description | Advantages | Disadvantages | References |

|---|---|---|---|---|

| Acoustic Emission Testing (AET) | Detection and analysis of transient sound waves from a rapid release of energy within a material. |

|

| [24,25,47] |

| Acoustic Pipe Wall Assessment (APWA) | Measurement of the average pipe wall loss using pulsed sound waves traveling through the pipe between two sensors. |

|

| [48,49,50] |

| Stress Wave-based Testing (SWT) | Determines pipe wall thickness and defects from analysis of a controlled impact and resulting stress waves. |

|

| [37,47] |

| Ground Microphones | Hardware-based method to detect the sound of water leaks from the ground surface. |

|

| [42,43,44] |

| Ultrasonic Methods | High-frequency mechanical vibrational sound waves inaudible to the human ear, used to detect and locate anomalies or to measure thicknesses. |

|

| [31,37,51] |

| Vibro-Acoustic Monitoring (VAM) | Flow-traveling sensors or devices placed on pipe appurtenances, such as valves and hydrants. Capable of detecting and locating leaks and pipe bursts. |

|

| [41,42,43,50,52] |

| Technology | Description | Advantages | Disadvantages | References |

|---|---|---|---|---|

| Corrosion Monitoring Methods (CMMs) | Methods that monitor for cumulative metal loss, real-time corrosion rates, and localized corrosion phenomena in pipelines with cathodic protection. |

|

| [9,31,36,37] |

| Cathodic Protection Monitoring (CPM) | Coupon weight loss measurements or voltage measurement between the pipeline and the surrounding soil for assessing cathodic protection. |

|

| [53,54] |

| Chemical Composition Method (CCM) | Methods that use the chemical properties of a substance to detect leaks. Typically include tracer gas and canine leak detection. |

|

| [42,43,44,55] |

| Electromagnetic Systems | Methods that induce, analyze, and monitor magnetic or electric fields, relying on changes in magnetic flux, eddy currents, or remote electromagnetic interactions. |

|

| [28,31,37,47,54] |

| Fiber-Optic Sensing (FOS) | Uses optical fibers to measure physical and chemical parameters by analyzing variations in the properties of light traveling through the fiber. |

|

| [5,56,57,58,59,60] |

| Geospatial Remote Sensing (GRS) | Use of sensors to collect data about the Earth’s surface typically from satellites or aircraft. The sensor is classified as active when it provides its own energy source and passive when it measures reflected or emitted energy. |

|

| [25,55,61,62] |

| Geotechnical Instrumentation and Monitoring (GIM) | Uses various technologies to monitor physical properties of structures to assess stability and predict hazardous conditions. |

|

| [46,63] |

| Ground-Penetrating Radar (GPR) | A geophysical method that uses electromagnetic waves to acquire information below the ground surface. |

|

| [37,43,44,64,65,66,67] |

| Infrared Thermography (IT) | Use of scanners to detect thermal contrasts on the ground surface from emitted infrared (IR) radiation. The thermographic images assist in the identification of water leaks. |

|

| [37,44,68,69,70] |

| Light Detection and Radar (LiDAR) | A remote sensing technology that emits laser light pulses to measure distances. |

|

| [25,46,71] |

| Low-Voltage Conductivity System (LVCS) | Use of an electrical circuit between the pipe and the ground surface to detect current as an indication of water leaks in non-metallic pipelines. A mobile probe is located either inside the pipe or at the ground surface. |

|

| [28,72] |

| Negative Pressure Waves (NPW) | Technology that detects the sudden changes in pressure and flow caused by the onset of a water leak. |

|

| [43,73,74] |

| Quantum Sensing Technology (QST) | Emerging non-destructive testing technology that uses quantum phenomena, including superposition and entanglement, for measurement of physical quantities with greater accuracy and sensitivity. |

|

| [75,76,77] |

| Radiographic Testing (RT) | Involves using a source or radiation, such as gamma or X-rays, to pass through a pipeline and onto a detector to identify defects. |

|

| [31,37] |

| RFID-Based Wireless Sensors | Devices with sensors embedded into elements of bolted connections, including, bolts, washers, and flanges. |

|

| [73,78,79] |

| Smart Joint Assemblies (SJA) | Devices with sensors embedded into elements of bolted connections, including, bolts, washers and flanges. |

|

| [80,81,82] |

| Smart Self-Sensory Materials (SSM) | Materials capable of monitoring their own condition without integrated or peripheral sensors. SSM incorporate functional fillers within their own material. |

|

| [83,84] |

| Transient Pressure Monitoring (TPM) | Involve gathering and analyzing data of sudden pressure changes as a result of operational activities or anomalies within the pipeline system. |

|

| [44,73,85,86] |

| Visual Inspections with CCTV | Use of visual inspection equipment on live-flow conditions to assess the internal condition of pipelines. |

|

| [41,47,50,69] |

| Technology | Description | Advantages | Disadvantages | References |

|---|---|---|---|---|

| Bayesian Interference Systems (BISs) | Use of probability and likelihood functions to deduce water leaks and pipe bursts. |

|

| [44,87] |

| Fuzzy Systems (FSs) | Use fuzzy logic to interpret ambiguous input to exact outputs using natural-language expressions. |

|

| [19,36,87] |

| Machine Learning (ML) | Artificial Intelligence (AI) algorithms that learn from data, find patterns, and determine possible outcomes. |

|

| [44,87,88,89,90] |

| Predictive Hydraulic Modeling (PHM) | System simulations to calculate differences between inflows and outflows. Discrepancies may indicate leaks or other NRWL. |

|

| [44,73] |

| Predictive Structural Analysis Modeling (PSAM) | Pipe simulation to predict the effect of known deterioration. Enables proactive maintenance and decision-making. |

|

| [28,91,92] |

| Statistical Interference Modeling (SIM) | Applied statistics to infer asset condition and predict RUL. Predicts possible leak or burst locations. |

|

| [26,73] |

| Factor | Sample Rationale | Reference |

|---|---|---|

| Signal reliability | Achieving reliable acoustic leak detection signals in plastic pipelines. | [43] |

| Sensor efficiency | Maximizing detection capabilities while minimizing total number of sensors. | [26] |

| Precision | Precisely locating anomalies (i.e., PCCP wire breaks using AET with hydrophone stations). | [3] |

| Data quality | Enhancing data collection and overall quality. | [32] |

| Connectivity | Ensuring adequate sensor connectivity within a WSN. | [46] |

| Detection accuracy | Preventing mislabeling of leaks (false positives) and avoiding incomplete water system coverage. | [10] |

| Compatibility | Addressing technology constraints in terms of pipe size and type (i.e., acoustic sensors for PCCP lines). | [94] |

| Installation viability | Enhancing the recorded signal by selecting adequate mounting points on the asset (i.e., noise loggers). | [52] |

| Sensor spacing | Assuring sensor placement within technology’s recommended spacing (i.e., hydrophone arrays). | [95] |

| Costs | Achieving a favorable cost/benefit ratio. | [96] |

| Reference | Model(s) | Strategy | Associated Factors |

|---|---|---|---|

| Ferreira et al. [13] | Multiobjective Genetic Algorithm. | Pressure sensitivity analysis, multiobjective NGSA-II, and CBA in a real network. | Roughness coefficient, burst size, and pressure. |

| Yang and Wang [9] | Multicriteria Decision Flowcharts/Sequential Subtraction Algorithm. | Economic considerations, Monte Carlo Sensor Fault Compensation, and EPANET Net3 simulation. | DCR, TDS, costs, and simulated pressures. |

| Santos-Ruiz et al. [16] | Heuristic Algorithm based on Information Theory. | Maximize information relevance while minimizing redundancy, used Hanoi system network simulation with EPANET. | System pressures at nodes, sensor Relevance/Redundancy Index (RRI), and number of sensors. |

| Zecchin et al. [97] | Dijkstra’s Algorithm, Metaheuristic Genetic Algorithms. | Nettrans model, graph-based representation, combinatorial leak and node optimization. | Detection coverage, system constraints, and anomaly characteristics. |

| Hu et al. [98] | Error-Domain Model Falsification (EDMF) and Hierarchical Algorithms with Joint Entropy. | EPANET Net3 simulation for leak detection accuracy. | Node pressures and cost vs. information. |

| Zhao et al. [96] | Fast messy Genetic Algorithm (fmGA) and Monte Carlo. | CBA, EPANET simulation with Net3, and detection coverage ratios. | Synthetic pipe bursts at network nodes, investment costs, and system pressures. |

| Soroush and Abedini [15] | Genetic Algorithm and Block Ordinary Kriging. | Simplified, exhaustive, and random search optimization. | System pressure at nodes, economic cost of data collection. |

| ChenLei et al. [8] | OPTICS (Ordering Points to Identify the Clustering Structure) Algorithm and Node Feature Matrix. | Spatial and non-spatial attributes, clustering for sensor placement optimization, ML comparison, and experimental testing. | Network pressures (normal and anomalies), sensor topological limitations, and economic feasibility. |

| Jun and Kwon [11] | Sensitivity and Unsteady-Flow Analyses. | Hydraulic simulations and experimental testing. | Actual and simulated system pressure measurements. |

| Rayaroth and Sivaradje [99] | Iterative Dichotomiser 3 (ID3) Decision Forest Classifier and Shuffled Frog Leaping Optimization (SFLO). | Pressure data for model training on real District Metered Area (DMA) and simulation in EPANET. | System pressure data, flow rates, computing time, and error rate (false positives). |

| Xie et al. [100] | Compressed Sensing and Enhanced Binary Artificial Bee Colony (ABC) Algorithm. | Sensor detection and redundancy, Quadratic Knapsack Problem (QKP), real system with synthetic data. | System topology and pressure, sensor cost, and mutual coherence. |

| Sela and Amin [93] | Robust Mixed Integer Optimization (RMIO) and Robust Greedy Approximation (RMA). | Model-based fault detection matrix, optimization problem formulation and solving in 10 real water networks. | Sensor redundancy, budget, online and offline sensor scenarios. |

| Yazdekhasti et al. [24] | Multicriteria Decision Analysis (MCDA) with weighting based on Monte Carlo simulations. | Literature review and expert validation, comparison of costs, reliability, ease of deployment, and leak size estimation. | Pipe material, diameter, placement feasibility, leak detection uncertainty. |

| Cuguero-Escofet et al. [10] | Sensitivity Matrix, Correlation-Based Isolation Index, Metaheuristic Genetic Algorithm. | Hydraulic modeling with EPANET in real DMA, sensitivity matrix, and isolation index. | Topological data, sensor resolution, actual and simulated pressures. |

| Nejjari et al. [14] | Sensitivity analysis, Evidential C-Means, and Exhaustive Search. | Fault sensitivity matrix and clustering to in a real network locate pressure sensors. | Distance to leak, pressure data. |

| Saldarriaga and Salcedo [12] | Hydraulic Metaheuristics and Genetic Algorithms. | Hydraulic heuristics, NGSA-II, and EPANET simulation in real and synthetic networks. | Annual loss of profits from leaks, system pressure. |

| Chang et al. [17] | Rule-Based Decision Support System (RBDSS). | EPANET simulation of a synthetic network. | Sensor accessibility and network complexity rules. |

| Reed et al. [25] | Multicriteria Decision Flowcharts. | Literature review, case studies, and field tests. | Leakage, corrosion, joint integrity, pressure, loading, wall thickness, water temperature, and costs. |

| Alternatives | Sample Criteria |

|---|---|

| A1 CM Technology 1 | C1 Installation complexity |

| A2 CM Technology 2 | C2 Power requirements |

| A3 CM Technology 3 | C3 Scalability |

| A4 CM Technology 4 | C4 Wireless connectivity |

| C5 CAPEX (capital expenses) | |

| C5 OPEX (operational expenses) |

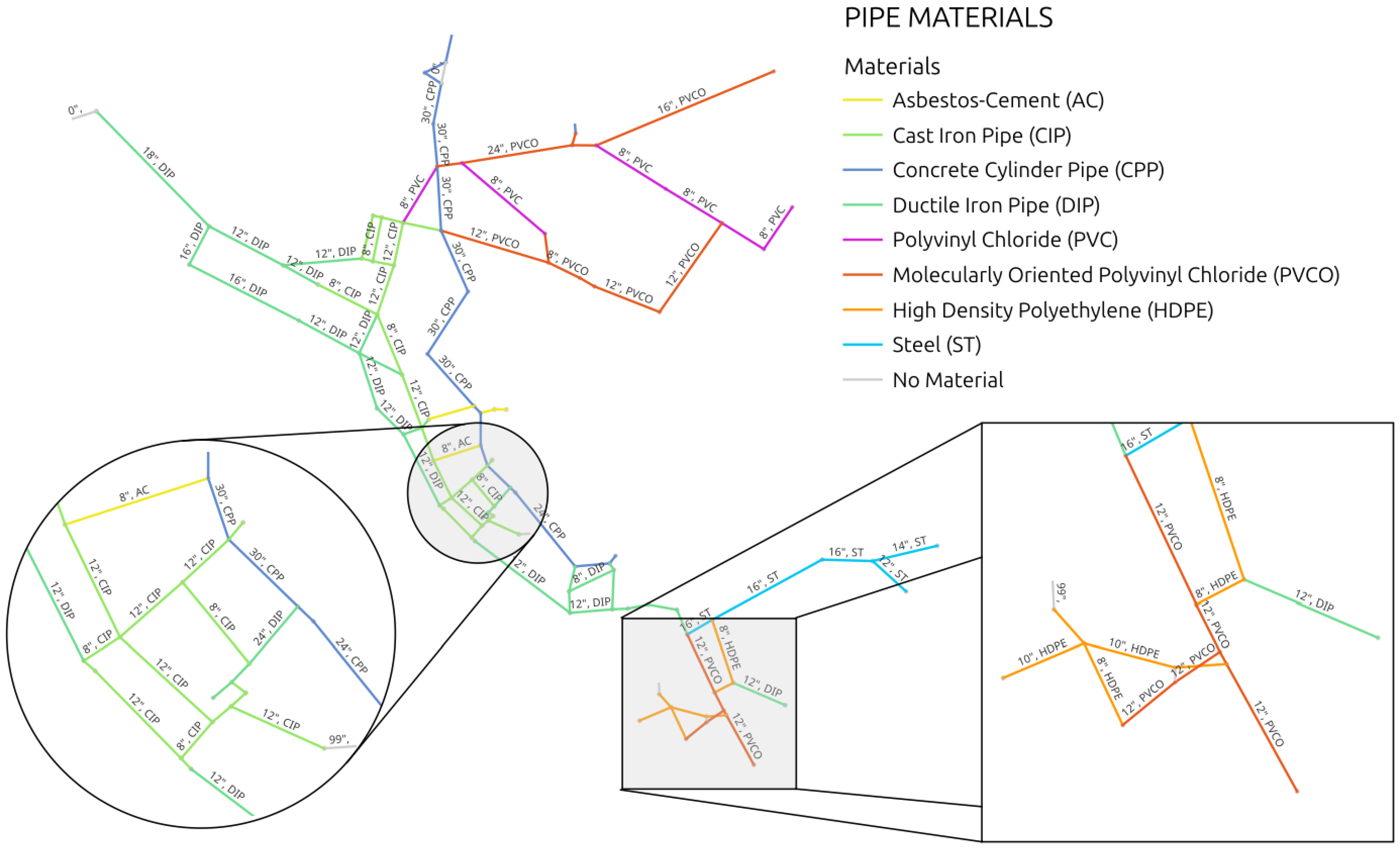

| Layer | Attribute | Standard in Net3 | Supplemental for Case Scenario | Used for Case Scenario |

|---|---|---|---|---|

| Pipes | ID | ✓ | · | ✓ |

| Node1 | ✓ | · | ✓ | |

| Node2 | ✓ | · | ✓ | |

| Length | ✓ | · | · | |

| Diameter | ✓ | · | ✓ | |

| Roughness | ✓ | · | · | |

| MinorLoss | ✓ | · | · | |

| Status | ✓ | · | · | |

| Material | · | ✓ | ✓ | |

| Installation Date | · | ✓ | ✓ | |

| Coordinates | Node | ✓ | · | ✓ |

| X-Coord | ✓ | · | ✓ | |

| Y-Coord | ✓ | · | ✓ | |

| Failures | ID | · | ✓ | ✓ |

| Incident Date | · | ✓ | ✓ | |

| Asset ID | · | ✓ | ✓ | |

| Asset Year Installed | · | ✓ | ✓ |

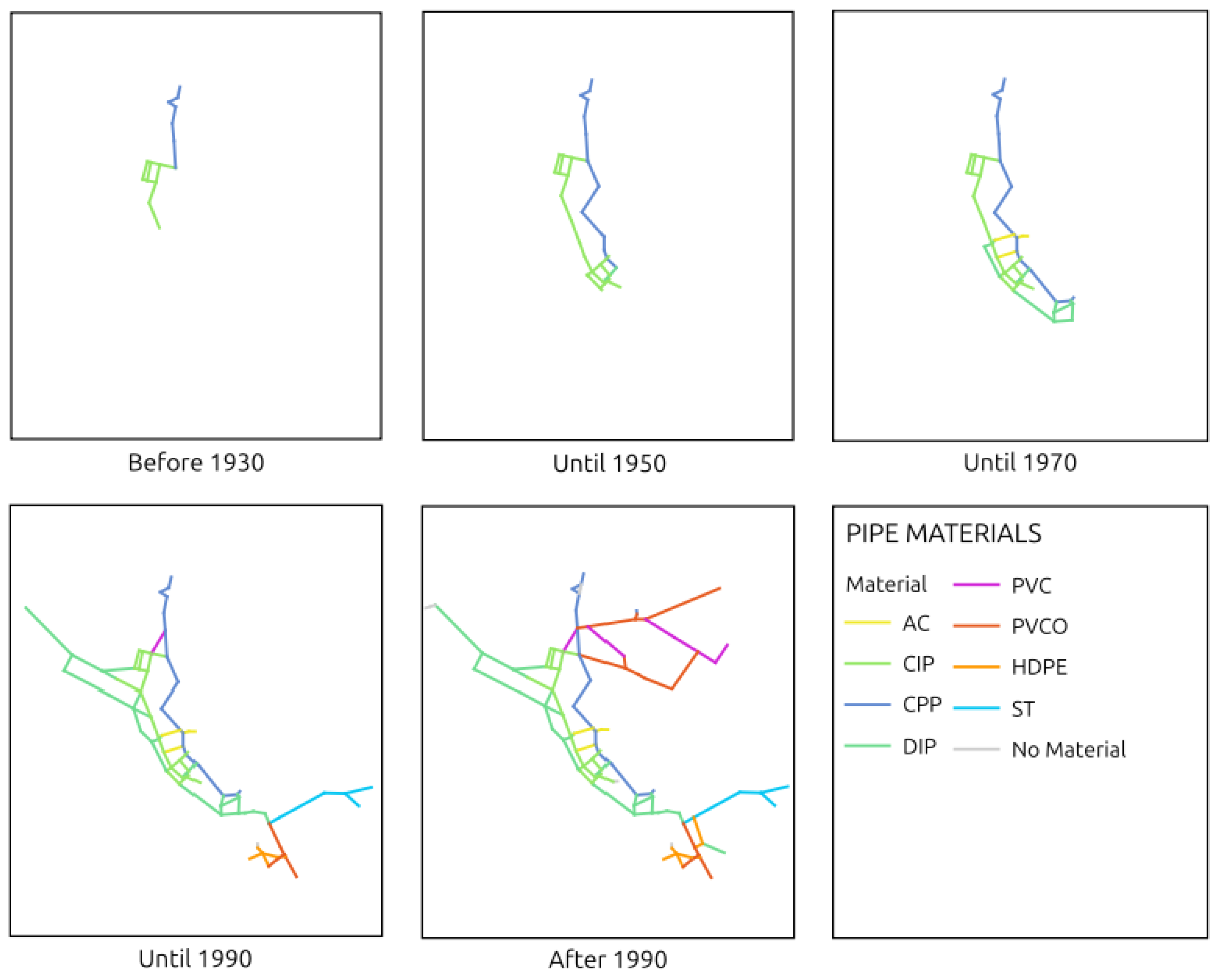

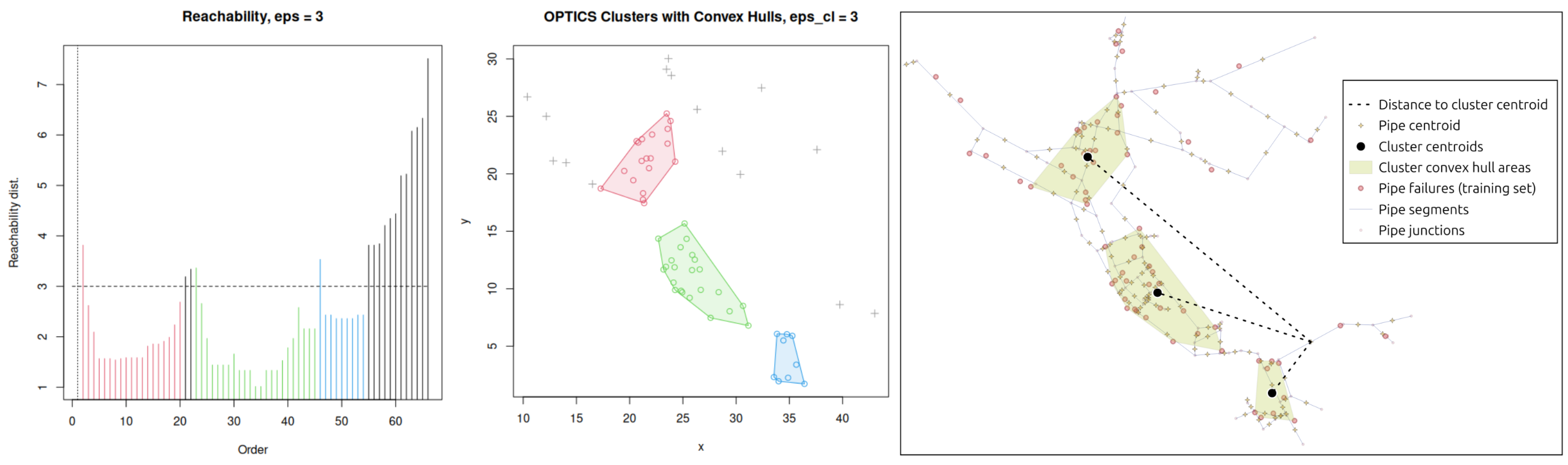

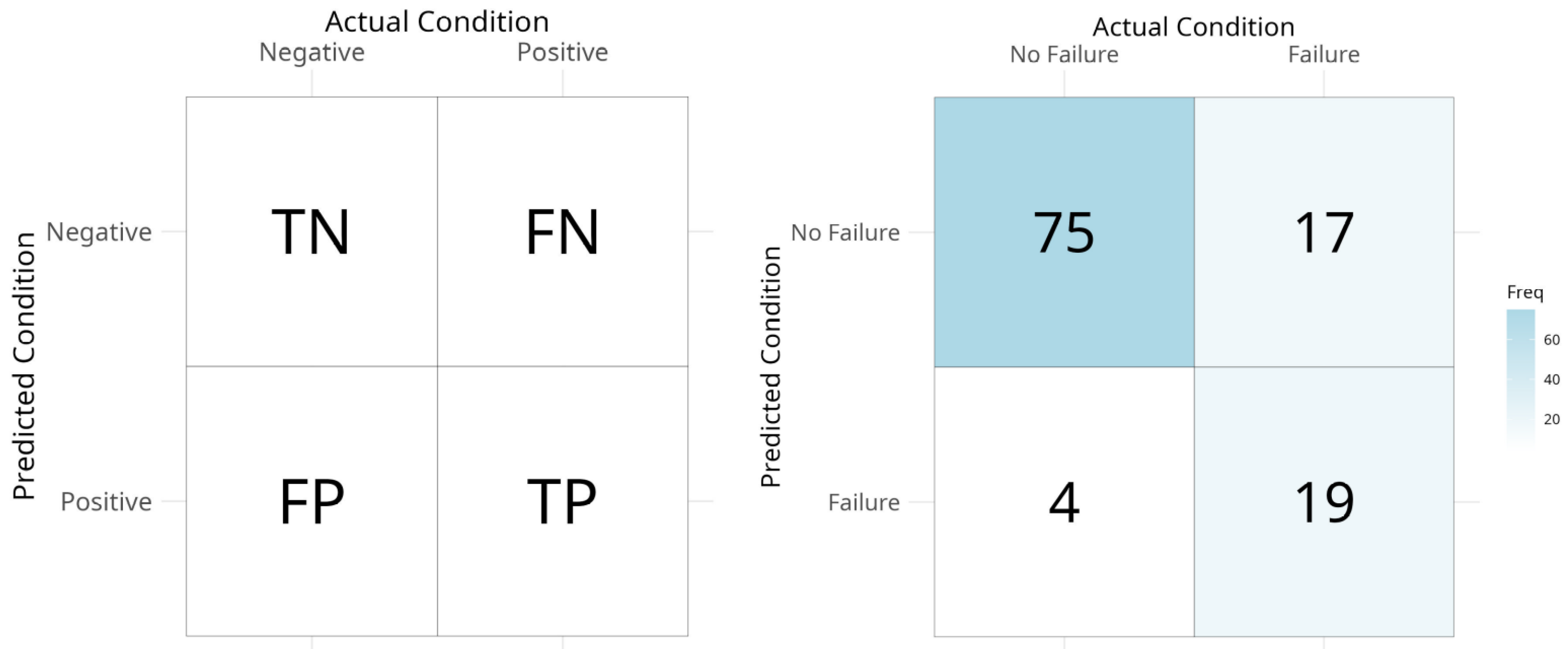

| ML Techniques | Tuning Parameters and Implementations |

|---|---|

| OPTICS | Parameters: dbscan package in R, MinPts = 5, max_eps = ∞, clustering eps = 3, (failure point location). |

| kNN | Parameters: class package in R, training ≈ 70% (1985–2012), testing ≈ 30% (2012–2024), , weighted vote: no; numerical + categorical variables after one-hot encoding. |

| Training dataset: independent vars. (from , , )—past failures (≈20%) 1985–1992; CPI; cluster membership; pipe age, material, size. Dependent var: pipe failed (≈50%) 1992–2012. | |

| Testing dataset: independent vars. (same sources)—past failures (69.23%) 1985–2012; CPI; cluster membership; pipe age, material, size. Dependent var: pipe failed (≈30%) 2013–2024. |

| Accuracy | Sensitivity | Specificity | Precision | Negative Predictive Value | F1-Score |

|---|---|---|---|---|---|

| 81.74% | 52.78% | 94.94% | 82.61% | 81.52% | 64.41% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calderon, D.; Najafi, M. Integrated Approach to Optimizing Selection and Placement of Water Pipeline Condition Monitoring Technologies. Eng 2025, 6, 97. https://doi.org/10.3390/eng6050097

Calderon D, Najafi M. Integrated Approach to Optimizing Selection and Placement of Water Pipeline Condition Monitoring Technologies. Eng. 2025; 6(5):97. https://doi.org/10.3390/eng6050097

Chicago/Turabian StyleCalderon, Diego, and Mohammad Najafi. 2025. "Integrated Approach to Optimizing Selection and Placement of Water Pipeline Condition Monitoring Technologies" Eng 6, no. 5: 97. https://doi.org/10.3390/eng6050097

APA StyleCalderon, D., & Najafi, M. (2025). Integrated Approach to Optimizing Selection and Placement of Water Pipeline Condition Monitoring Technologies. Eng, 6(5), 97. https://doi.org/10.3390/eng6050097