How Best to Use Forest Wood for Energy: Perspectives from Energy Efficiency and Environmental Considerations

Abstract

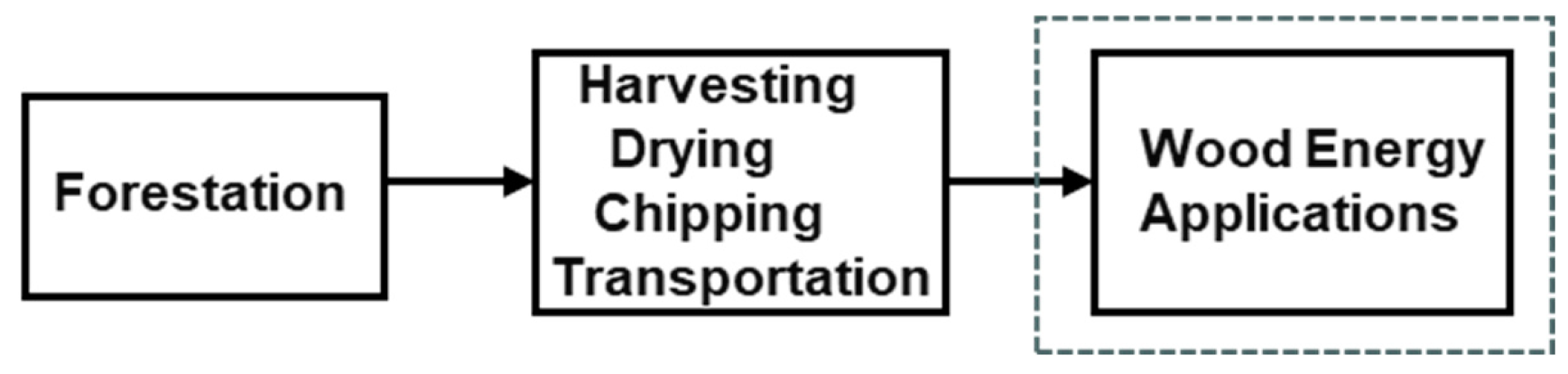

1. Introduction

2. Energy Analysis

2.1. Systems, Key Input Data, and Assumptions

- (1)

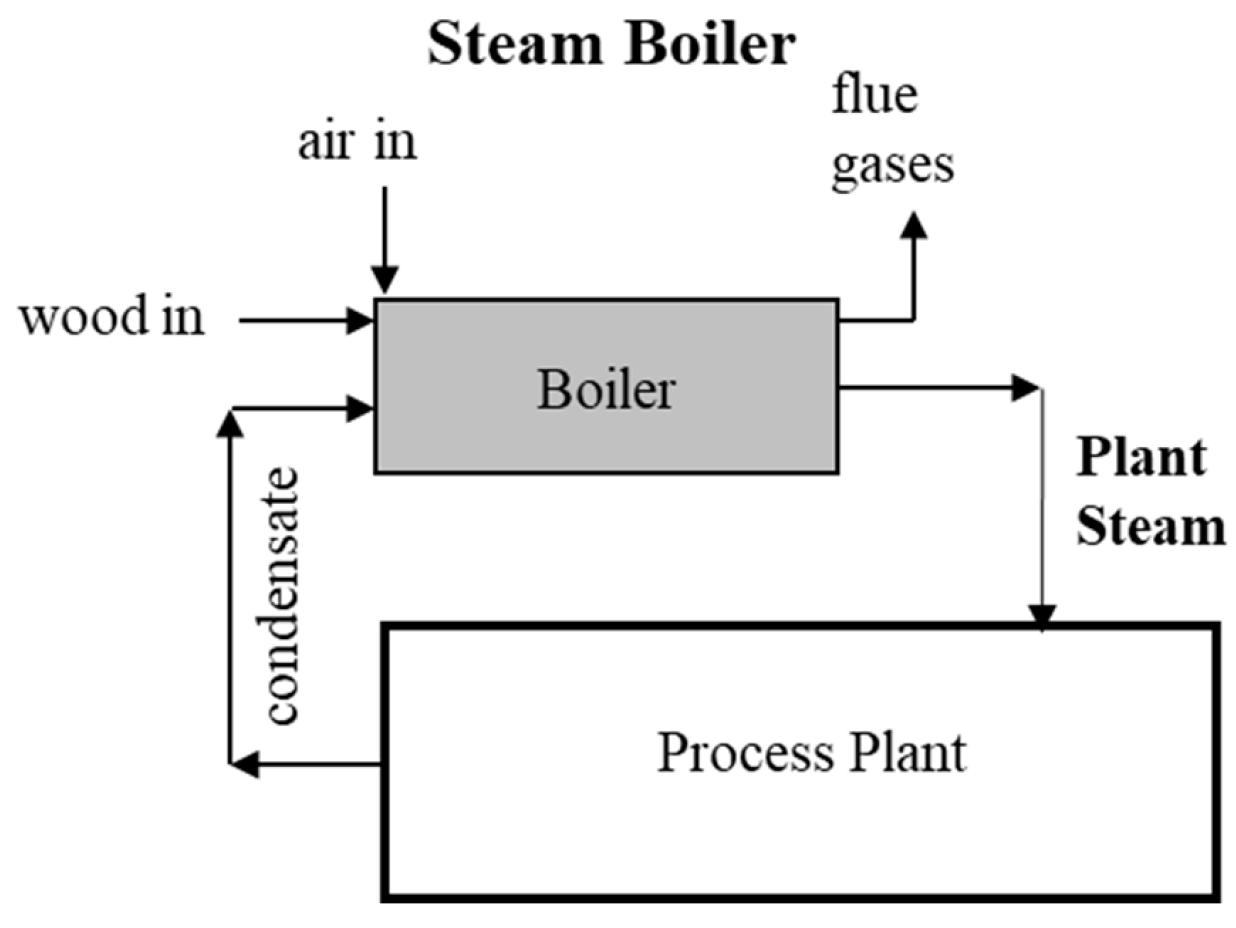

- Wood-fired steam boiler (for heat application).

- (2)

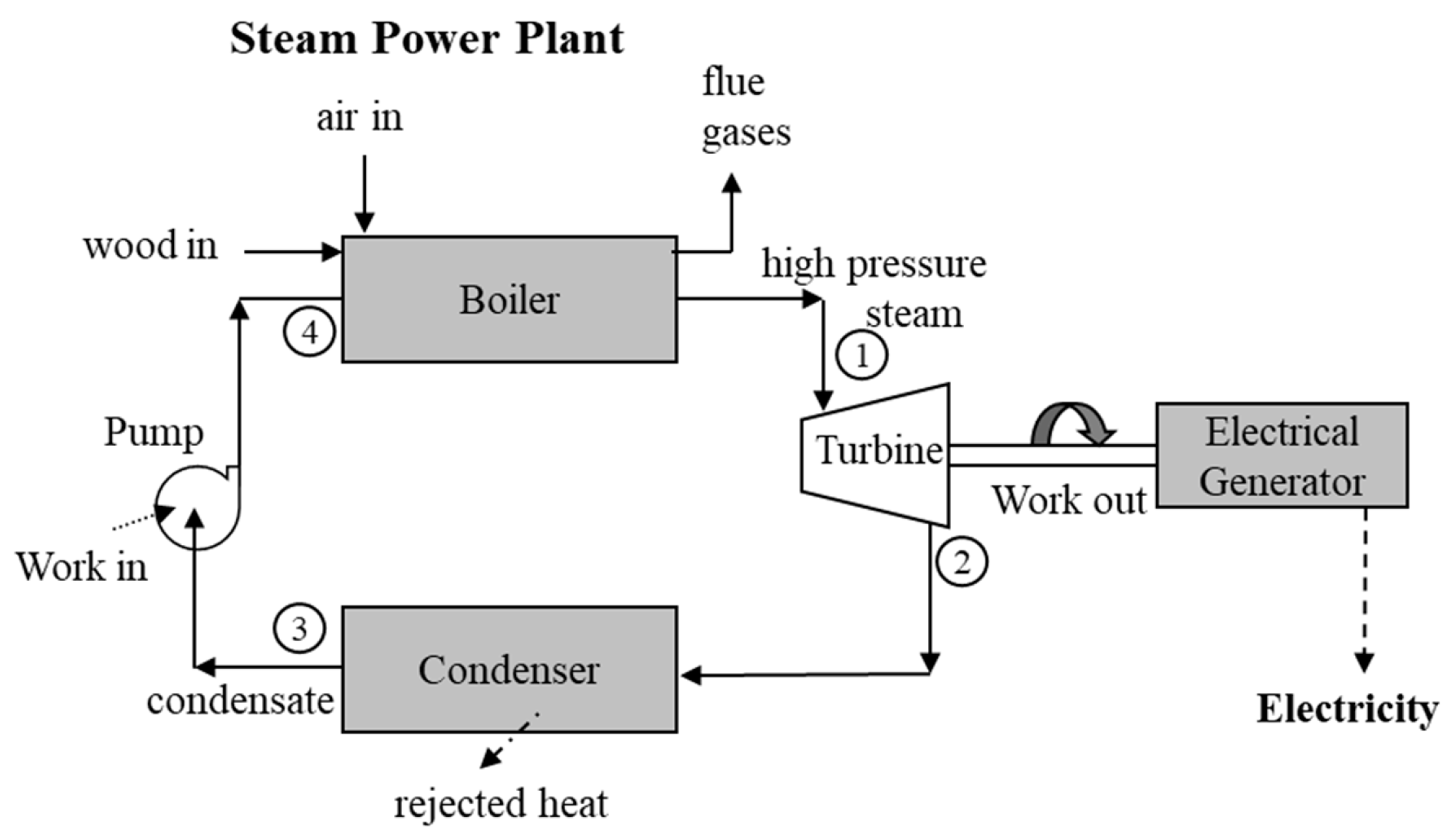

- Wood-fired steam power plant (for generating electricity).

- (3)

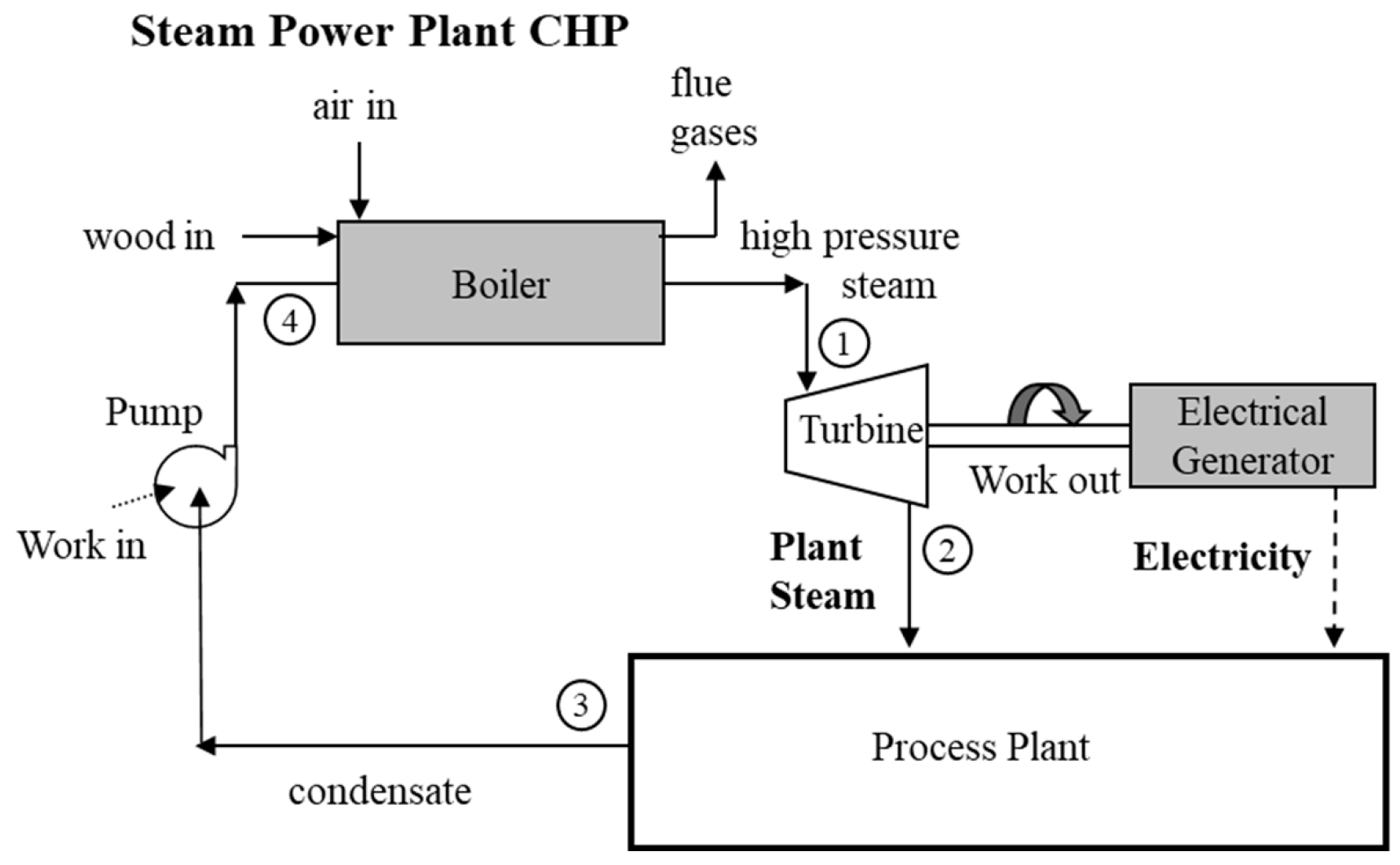

- Wood-fired steam power plant CHP (for providing steam for heat application and generating electricity).

- (4)

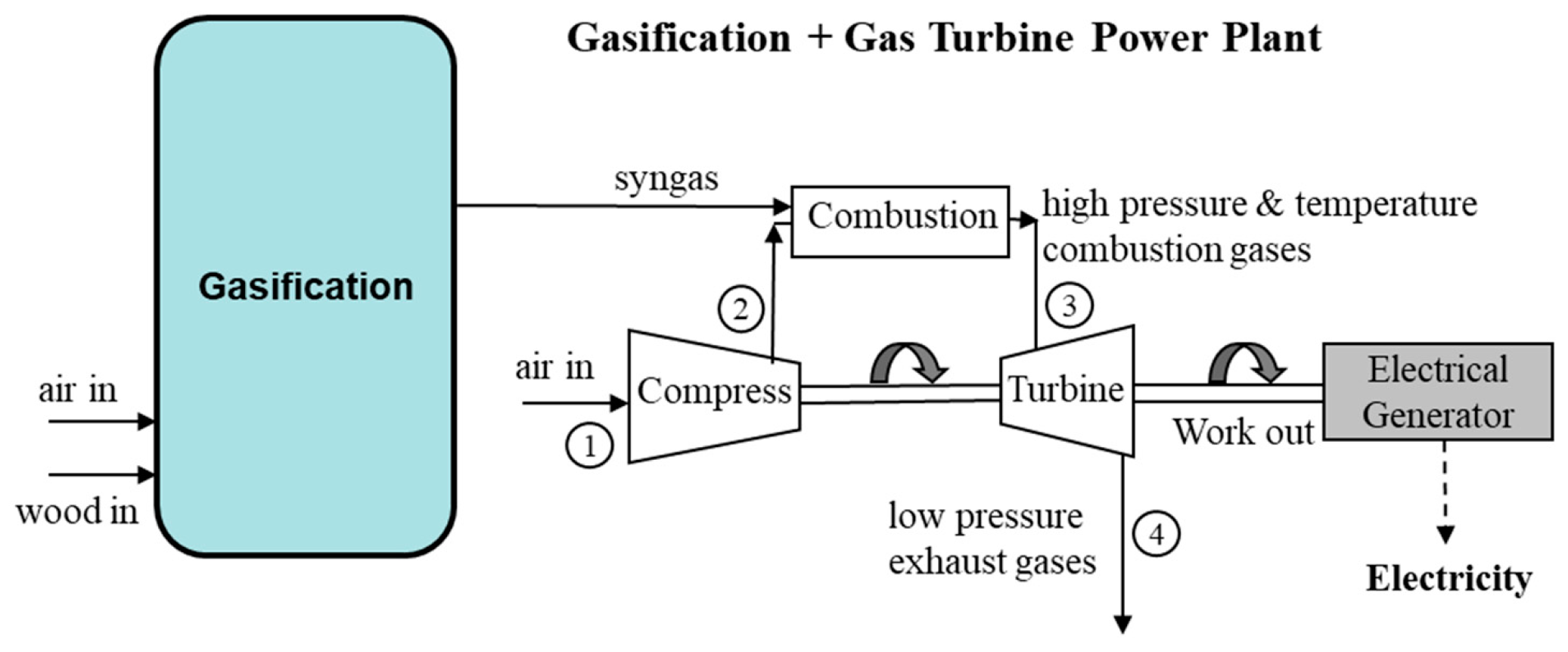

- Gasification of wood + gas turbine power plant (for generating electricity).

- (5)

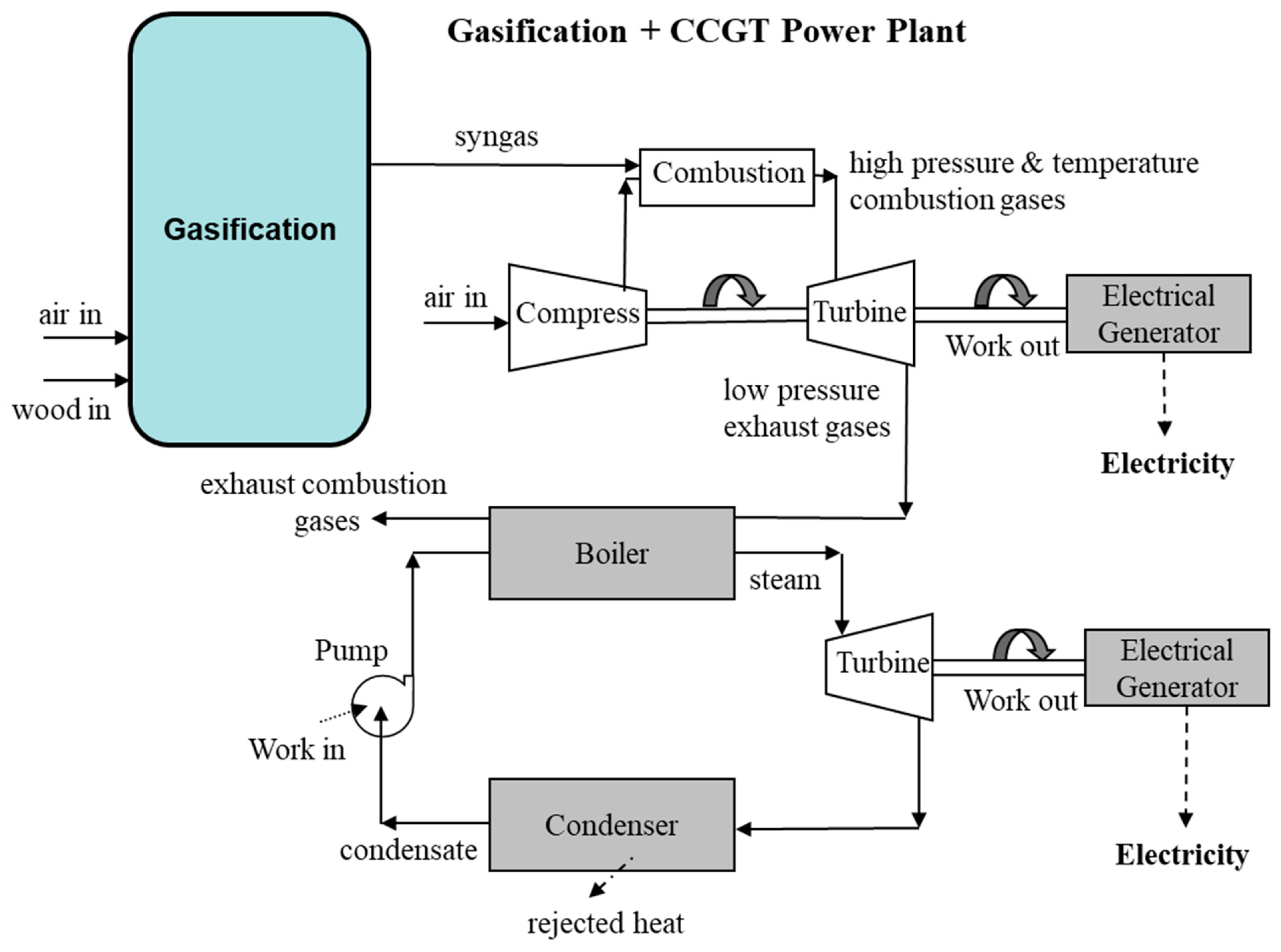

- Gasification of wood + combined cycle gas turbine power plant (for generating electricity).

- (6)

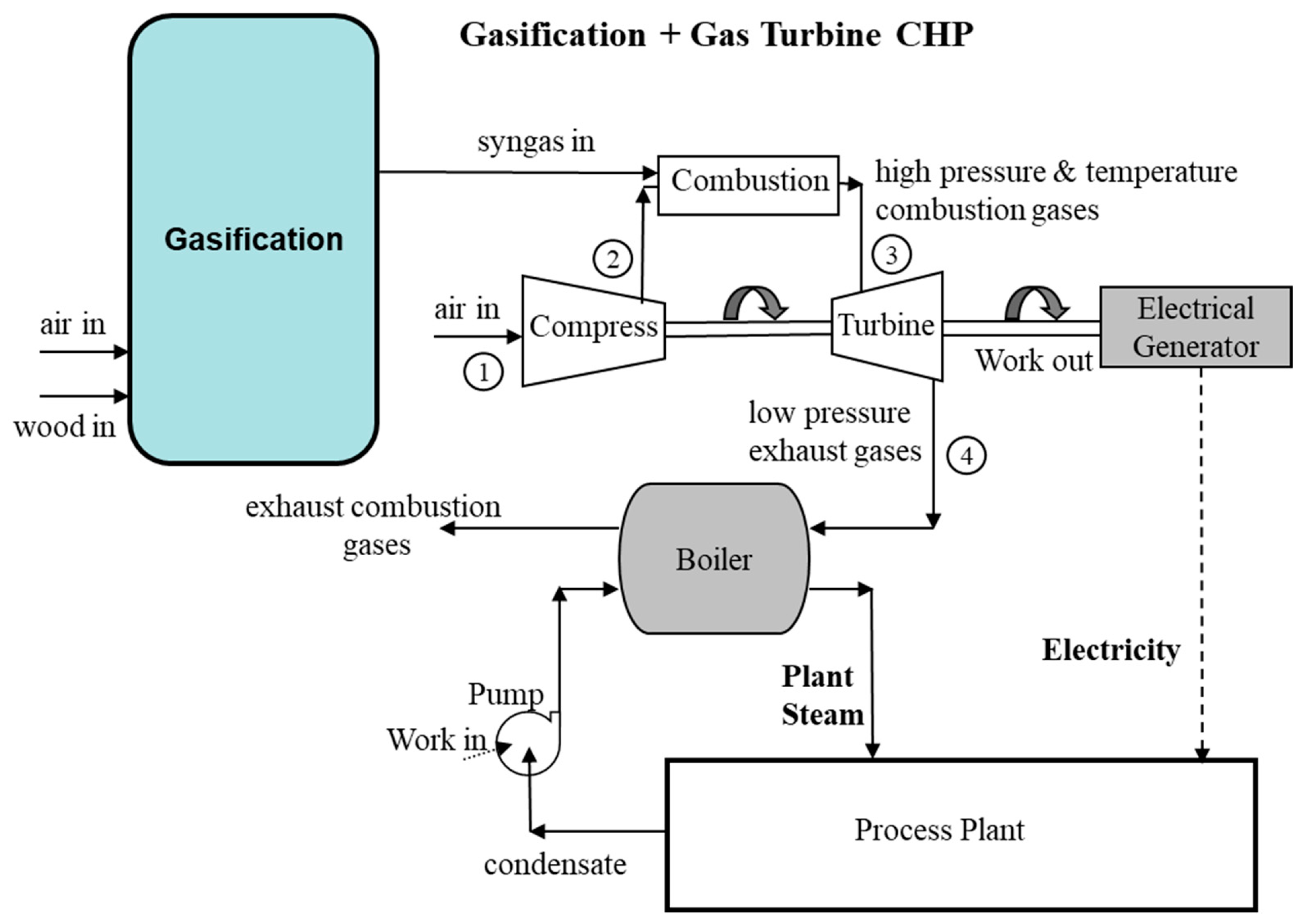

- Gasification of wood + gas turbine CHP (for providing steam for heat application and generating electricity).

- (7)

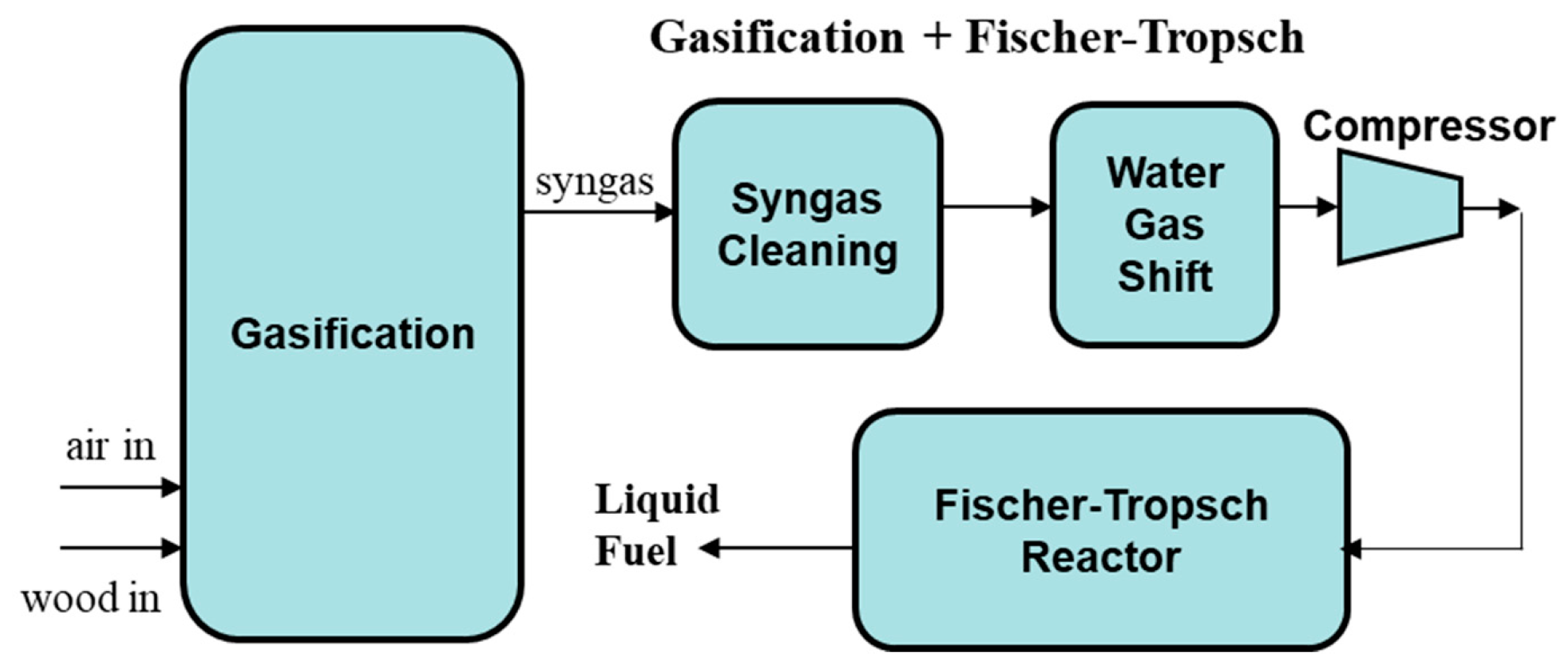

- Gasification of wood + Fischer–Tropsch (to produce liquid fuels).

- (8)

- Wood stoves (for heat application).

2.2. Wood-Fired Steam Boiler

2.3. Wood-Fired Steam Power Plant

- •

- Turbine isentropic efficiency = 0.85

- •

- Turbine exit pressure = 0.1 bar

- •

- Superheated steam turbine inlet temperature is 600 °C, considering maximum steam temperatures entering steam turbines are around 620 °C [22].

- •

- The dryness fraction of steam leaving the turbine is around 0.89.

2.4. Wood-Fired Steam Power Plant CHP

2.5. Gasification of Wood + Gas Turbine (GT) Power Plant

2.5.1. Gasification of Wood

2.5.2. GT Power Plant

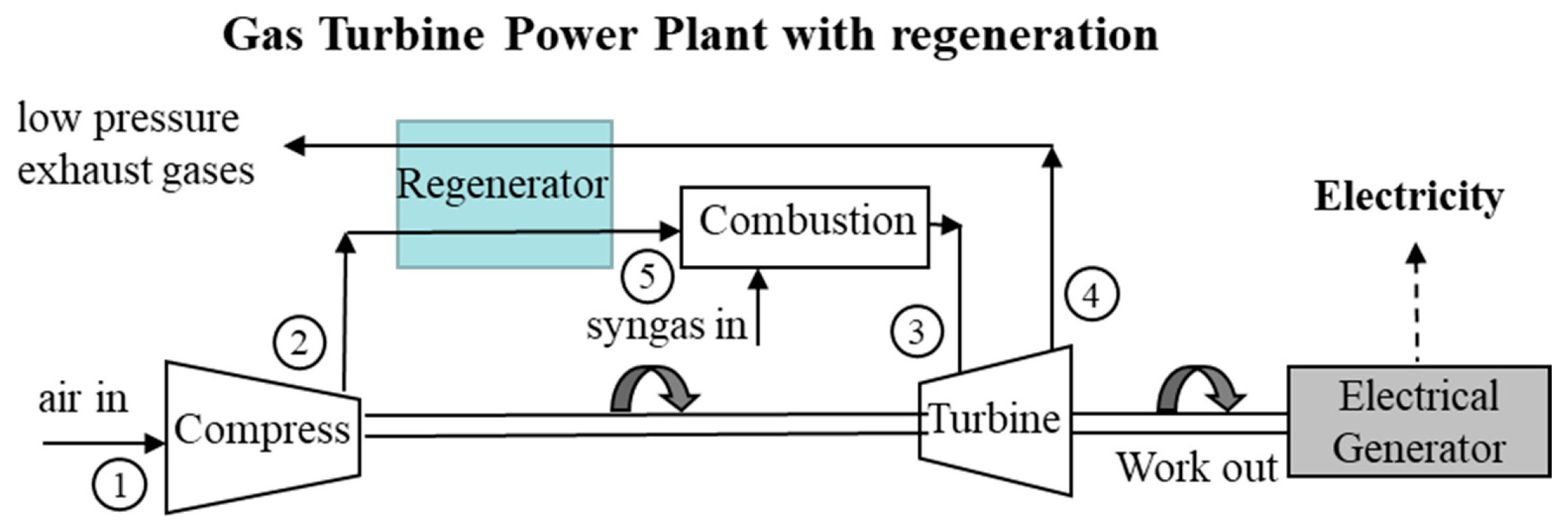

2.5.3. GT Power Plant with Regeneration

2.6. Gasification of Wood + Combined Cycle Gas Turbine (CCGT) Power Plant

2.7. Gasification of Wood + Gas Turbine CHP

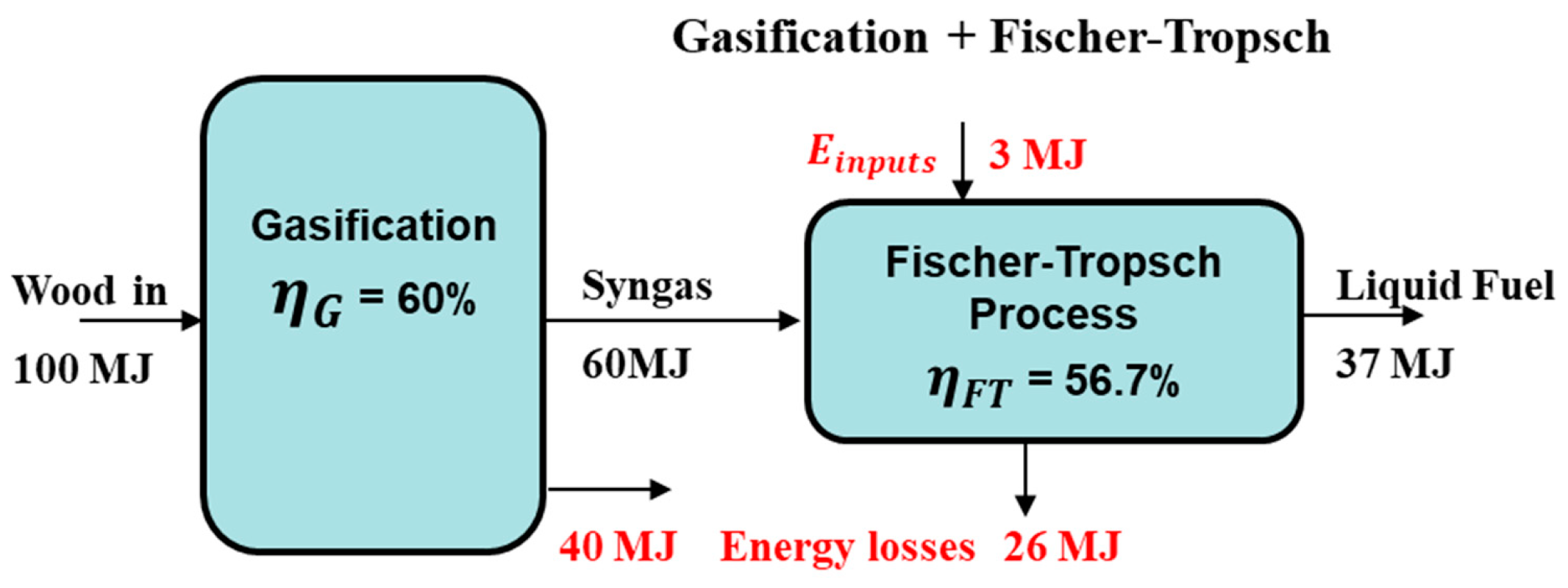

2.8. Gasification of Wood + Fischer–Tropsch

2.9. Wood Stoves

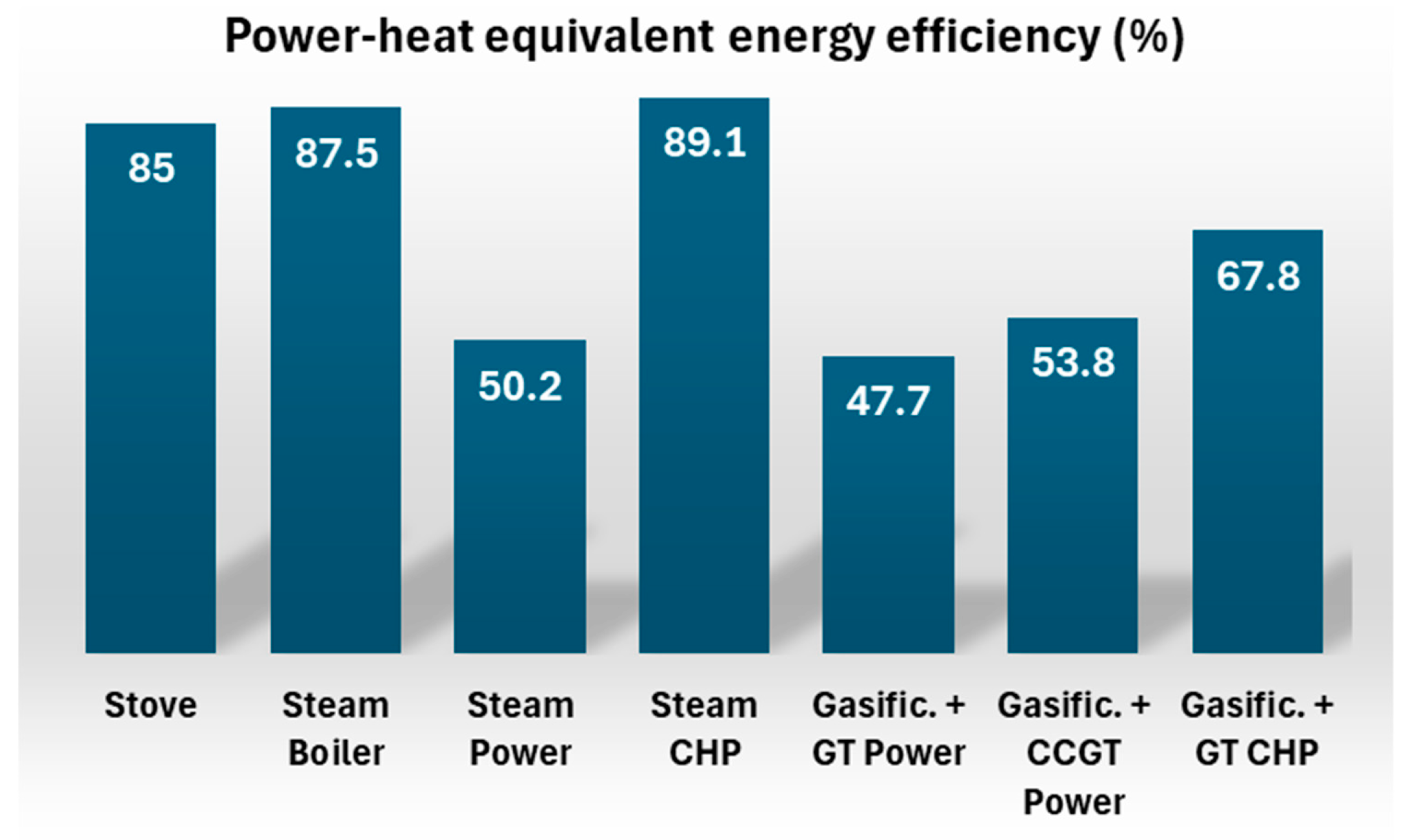

2.10. Power–Heat Equivalent Energy Efficiency of a System

3. Results and Discussion

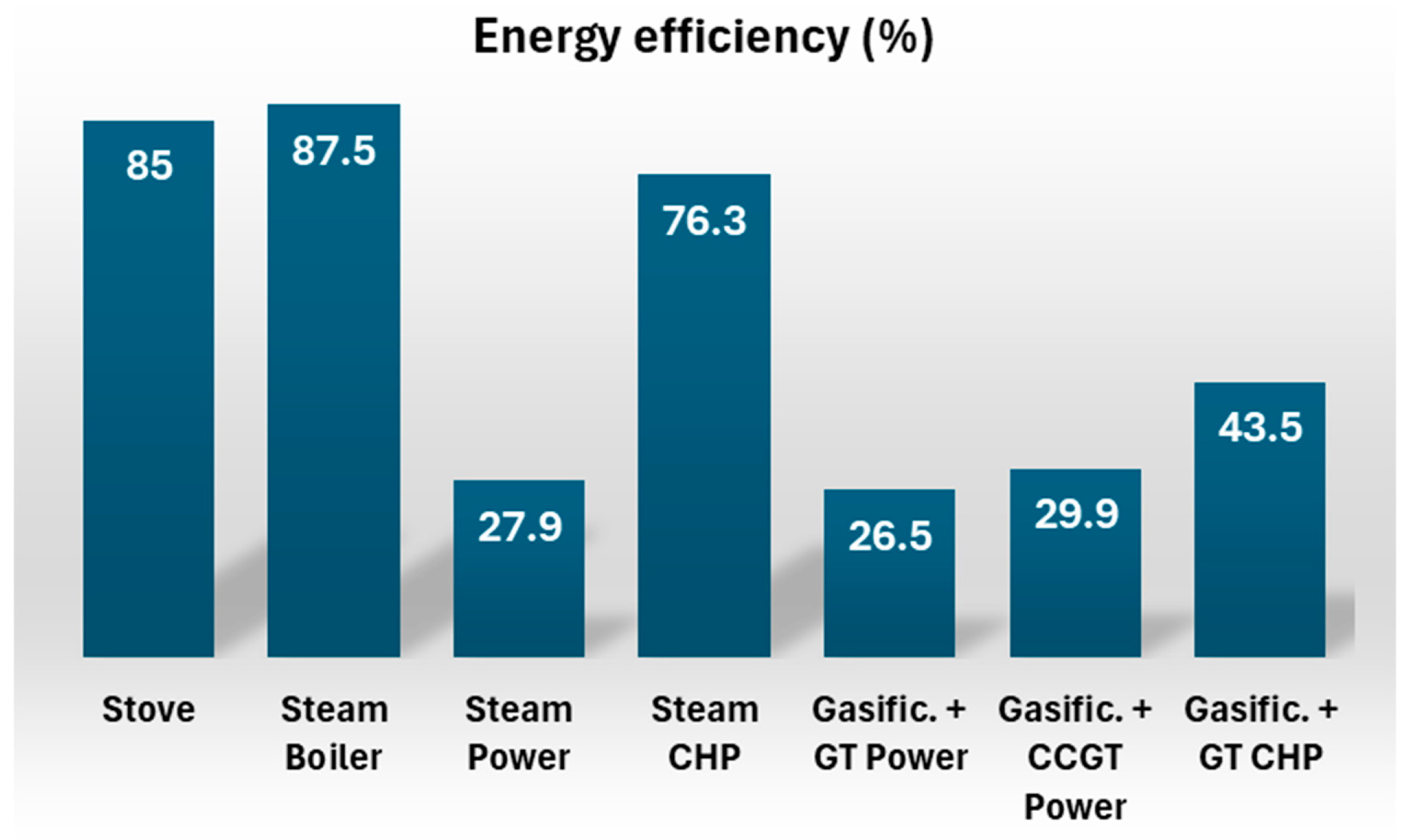

3.1. Energy Efficiency

3.1.1. Steam Boiler, Steam Power Plant, and Steam CHP

3.1.2. Gasification of Wood + Gas Turbine (GT) Power Plant/GT CHP

3.1.3. Gasification of Wood + Combined Cycle (CCGT) Power Plant

3.1.4. Gasification of Wood + Fischer–Tropsch

3.1.5. Wood Stoves

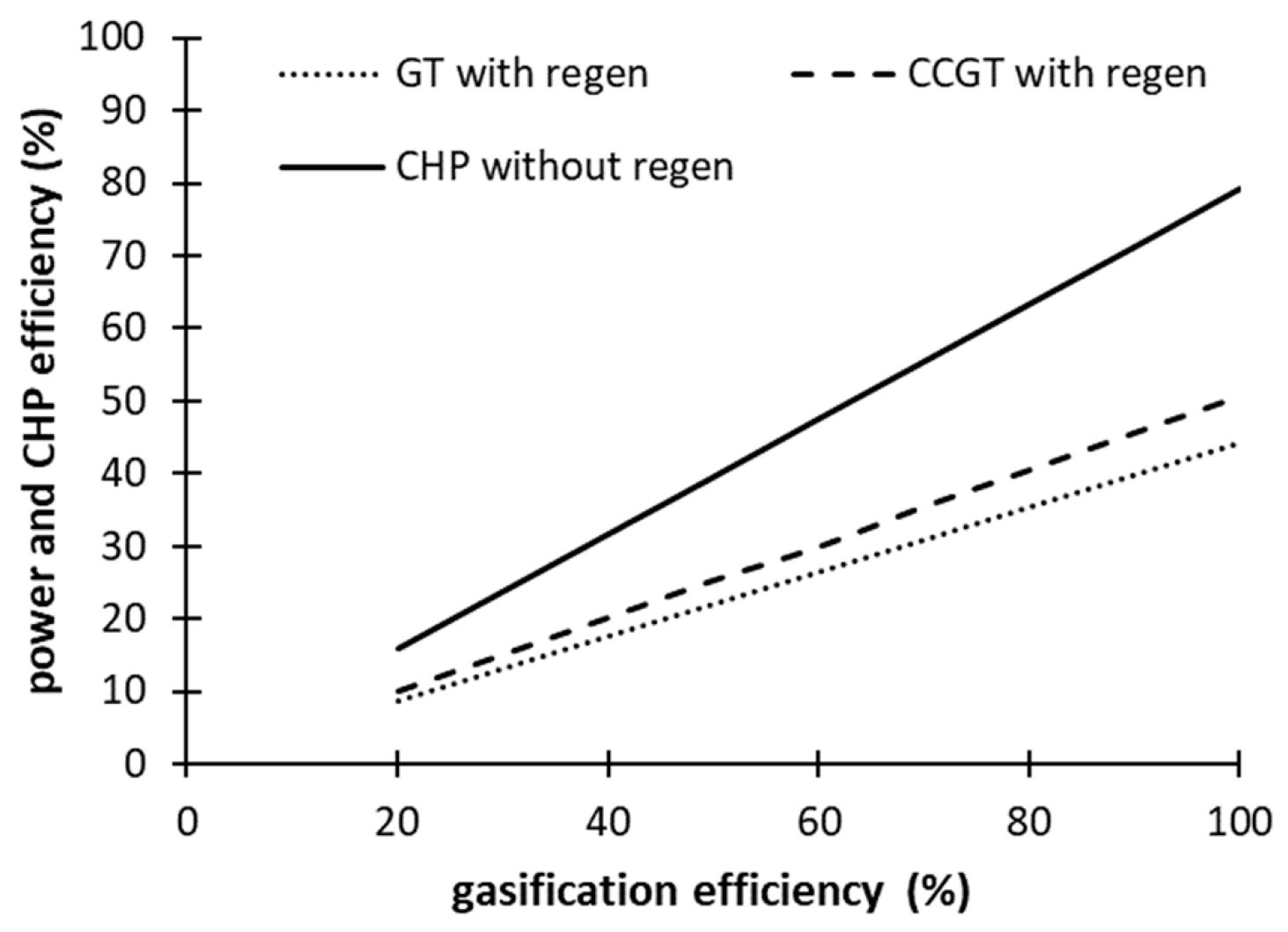

3.2. Effect of Gasification Efficiency and Wood Water Content on Energy Performance

3.2.1. Effect of Gasification Efficiency

3.2.2. Effect of Wood Water Content

3.3. Comparing the Energy Efficiencies of Systems Delivering Heat and/or Power

3.4. Environmental and Sustainability Considerations

3.4.1. Sustainably Sourced Forest Wood

3.4.2. Environmental Emissions—Wood Stoves

3.4.3. Environmental Emissions—Large-Scale Wood Combustion Processes

3.4.4. Applications with Little or No Sustainable Energy Sources

3.4.5. Application in Associated Forest Wood Industries

3.4.6. Non-Use

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| air–fuel ratio | |

| mass of air per mass of dry solids in the wood | |

| stoichiometric air–fuel ratio | |

| specific heat of air (kJ kg−1 °C−1) | |

| specific heat of combustion gases (kJ kg−1 °C−1) | |

| specific heat of ash (kJ kg−1 °C−1) | |

| energy associated with the energy inputs in the FT process (MJ h−1) | |

| combustion energy in the liquid fuel (MJ h−1) | |

| combustion energy in syngas (MJ h−1) | |

| power–heat conversion factor | |

| specific enthalpy (kJ kg−1) | |

| specific heat ratio of the gas = 1.4 | |

| lower heating value of wood (MJ kg−1) | |

| lower heating value of syngas (MJ kg−1) | |

| mass flowrate of air (kg h−1) | |

| mass flowrate of wood (kg h−1) | |

| mass flowrate of hot gases leaving a combustion process (kg h−1) | |

| the mass flowrate of ash (kg h−1) | |

| mass flowrate of steam (kg h−1) | |

| mass flowrate of syngas (kg h−1) | |

| pressure (bar) | |

| specific heat energy input in combustion processes (kJ kg−1) | |

| excess air ratio | |

| pressure ratio in Brayton cycle | |

| temperature (°C) | |

| ambient temperature (°C) | |

| combustion temperature of gases in boiler (°C) | |

| temperature of combustion gases leaving the boiler (°C) | |

| temperature of combustion gases leaving the stove pipe (°C) | |

| wood water content | |

| real compressor specific work input (kJ kg−1) | |

| ideal compressor specific work input (kJ kg−1) | |

| net specific work output from the Brayton cycle (kJ kg−1) | |

| real gas turbine specific work output (kJ kg−1) | |

| ideal gas turbine specific work output (kJ kg−1) | |

| effectiveness factor for the regenerator | |

| latent heat of vaporisation of steam (kJ kg−1) | |

| boiler efficiency (%) | |

| biomass to liquid-fuel energy efficiency (%) | |

| compressor isentropic efficiency | |

| Fischer–Tropsch efficiency (%) | |

| gasification efficiency (%) | |

| power–heat equivalent energy efficiency of a system (%) | |

| overall efficiency for a stove (%) | |

| gas turbine isentropic efficiency |

References

- FAO. Global Forest Sector Outlook 2050: Assessing Future Demand and Sources of Timber for a Sustainable Economy—Background Paper for The State of the World’s Forests 2022; FAO Forestry Working Paper, No. 31; FAO: Rome, Italy, 2022. [Google Scholar]

- UNECE/FAO. Wood Energy in the ECE Region; United Nations Publication: New York, NY, USA, 2018. [Google Scholar]

- Aguilar, F. Wood Energy in Developed Economies: An Overlooked Renewable. 2015. Available online: https://media.rff.org/archive/files/sharepoint/WorkImages/Download/RFF-Resources-188_Feature-Aguilar.pdf (accessed on 22 February 2023).

- UNECE/FAO. Joint Wood Energy Enquiry. 2017. Available online: https://unece.org/sites/default/files/2021-01/JWEE2017-analysis.pdf (accessed on 6 November 2021).

- SEAI. Biomass Boilers—Technology Guide; Sustainable Energy Authority of Ireland (SEAI): Dublin, Ireland, 2019. [Google Scholar]

- Kirsanovs, V. Wood Chips Gasification; Riga Technical University: Riga, Latvia, 2018. [Google Scholar]

- Mustafa, A.; Calay, R.K.; Mustafa, M.Y. A techno-economic study of a biomass gasification plant for the production of transport biofuel for small communities. Energy Procedia 2017, 112, 529–536. [Google Scholar] [CrossRef]

- Yan, Q.; Yu, F.; Liu, J.; Street, J.; Gao, J.; Cai, Z.; Zhang, J. Catalytic conversion wood syngas to synthetic aviation turbine fuels over a multifunctional catalyst. Bioresour. Technol. 2013, 127, 281–290. [Google Scholar] [CrossRef]

- Tran, H.; Juno, E.; Arunachalam, S. Emissions of wood pelletization and bioenergy use in the United States. Renew. Energy 2023, 219, 119536. [Google Scholar] [CrossRef]

- Trojanowski, R.; Fthenakis, V. Nanoparticle emissions from residential wood combustion: A critical literature review, characterization, and recommendations. Renew. Sustain. Energy Rev. 2019, 103, 515–528. [Google Scholar] [CrossRef]

- Fitzpatrick, J.J. Environmental sustainability assessment of using forest wood for heat energy in Ireland. Renew. Sustain. Energy Rev. 2016, 57, 1287–1295. [Google Scholar] [CrossRef]

- Ghorashi, S.A.; Khandelwal, B. Toward the ultra-clean and highly efficient biomass-fired heaters. A review. Renew. Energy 2023, 205, 631–647. [Google Scholar] [CrossRef]

- Balcioglu, G.; Jeswani, H.K.; Azapagic, A. Energy from forest residues in Turkey: An environmental and economic life cycle assessment of different technologies. Sci. Total Environ. 2023, 874, 162316. [Google Scholar] [CrossRef]

- Balcioglu, G.; Jeswani, H.K.; Azapagic, A. A sustainability assessment of utilising energy crops for heat and electricity generation in Turkey. Sustain. Prod. Consum. 2023, 41, 134–155. [Google Scholar] [CrossRef]

- Ochieng, R.; Sarker, S. Energy and techno-economic analysis of integrated supercritical water gasification of sewage sludge and fast pyrolysis of wood for power, heat, and hydrogen production. Chem. Eng. Sci. 2025, 306, 121236. [Google Scholar] [CrossRef]

- Bisen, D.; Chouhan, A.P.S.; Pant, M.; Chakma, S. Advancement of thermochemical conversion and the potential of biomasses for production of clean energy: A review. Renew. Sustain. Energy Rev. 2025, 208, 115016. [Google Scholar] [CrossRef]

- Barbosa, T.; Chaves, B.S.; Galvão, L.G.O.; Lamas, G.C.; Rodrigues, P.P.d.O.; Moreira, M.G.; Protásio, T.d.P.; Luz, S.M.; Rodrigues, J.S.; Silveira, E.A. Waste-to-energy in the civil-construction sector toward the valuation of wood construction residues: Integration of torrefaction process. Fuel 2024, 371, 132029. [Google Scholar] [CrossRef]

- Fang, Z.; Zhang, X.; Zhuang, X.; Ma, L. Recent advances in synthesis strategies for biomass-derived high-energy-density jet fuels. Renew. Sustain. Energy Rev. 2024, 202, 114715. [Google Scholar] [CrossRef]

- Gebreegziabher, T.; Oyedun, A.O.; Hui, C.W. Optimum biomass drying for combustion—A modeling approach. Energy 2013, 53, 67–73. [Google Scholar] [CrossRef]

- EURELECTRIC. Efficiency in Electricity Generation; Report drafted by: EURELECTRIC “Preservation of Resources” Working Group’s “Upstream” Sub-Group in collaboration with VGB; EURELECTRIC: Brussels, Belgium, 2003. [Google Scholar]

- Curkeet, R. Wood Combustion Basics; EPA Workshop: Cincinnati, OH, USA, 2011. [Google Scholar]

- Cengel, Y.A.; Boles, M.A.; Kanoglu, M. Thermodynamics: An Engineering Approach, 9th ed.; McGraw-Hill Publisher: New York, NY, USA, 2019. [Google Scholar]

- Lestander, H.A.; Weiland, F.; Grimm, A.; Rudolfsson, M.; Wiinikka, H. Gasification of pure and mixed feedstock components: Effect on syngas composition and gasification efficiency. J. Clean. Prod. 2022, 369, 133330. [Google Scholar] [CrossRef]

- Morita, H.; Yoshiba, F.; Woudstra, N.; Hemmes, K.; Spliethoff, H. Feasibility study of wood biomass gasification/molten carbonate fuel cell power system—Comparative characterization of fuel cell and gas turbine system. J. Power Sources 2004, 138, 31–40. [Google Scholar] [CrossRef]

- Francois, J.; Abdelouahed, L.; Mauviel, G.; Patisson, F.; Mirgaux, O.; Rogaume, C.; Rogaume, Y.; Feidt, M.; Dufour, A. Detailed process modeling of a wood gasification combined heat and power plant. Biomass Bioenergy 2013, 51, 68–82. [Google Scholar] [CrossRef]

- van der Meijden, C.M.; Veringa, H.J.; Rabou, L.P.L.M. The production of synthetic natural gas (SNG): A comparison of three wood gasification systems for energy balance and overall efficiency. Biomass Bioenergy 2010, 34, 301–311. [Google Scholar] [CrossRef]

- Sher, F.; Hameed, S.; Omerbegovi, N.S.; Chupin, A.; Ul Hai, I.; Wang, B.; Teoh, Y.H.; Yildiz, M.J. Cutting-edge biomass gasification technologies for renewable energy generation and achieving net zero emissions. Energy Convers. Manag. 2025, 323, 119213. [Google Scholar] [CrossRef]

- Hagos, F.Y.; Aziz, A.R.A.; Sulaiman, S.A. Trends of syngas as a fuel in internal combustion engines. Adv. Mech. Eng. 2014, 6, 401587. [Google Scholar] [CrossRef]

- Martinez-Boggio, S.D.; Merola, S.S.; Teixeira Lacava, P.; Irimescu, A.; Curto-Risso, P.L. Effect of fuel and air dilution on syngas combustion in an optical SI engine. Energies 2019, 12, 1566. [Google Scholar] [CrossRef]

- Hu, J.; Yu, F.; Lu, Y. Application of Fischer–Tropsch synthesis in biomass to liquid conversion. Catalysts 2012, 2, 303–326. [Google Scholar] [CrossRef]

- Ul Hai, I.; Sher, F.; Zarren, G.; Liu, H. Experimental investigation of tar arresting techniques and their evaluation for product syngas cleaning from bubbling fluidized bed gasifier. J. Clean. Prod. 2019, 240, 118239. [Google Scholar] [CrossRef]

- Mesfun, S.A. Biomass to Liquids (BtL) via Fischer-Tropsch—A Brief Review; European Technology and Innovation Platform (ETIP)—Bioenergy: Brussels, Belgium, 2021. [Google Scholar]

- van den Oever, A.E.M.; Costa, D.; Cardellini, G.; Messagie, M. Systematic review on the energy conversion efficiency of biomass-based Fischer-Tropsch plants. Fuel 2022, 324, 124478. [Google Scholar] [CrossRef]

- Lee, S.Y.; Oh, K.C.; Lee, C.G.; Cho, L.H.; Park, S.Y.; Jeong, I.S.; Kim, D.H. Improvement of thermal efficiency of wood pellet boilers through the refractory insulation in a combustion chamber and fire tube and baffle modification. Energy 2018, 161, 1115–1121. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Sommersacher, P.; Junginger, M. Consequential Life Cycle Assessment of energy generation from waste wood and forest residues: The effect of resource-efficient additives. J. Clean. Prod. 2020, 259, 120948. [Google Scholar] [CrossRef]

- Nandimandalam, H.; Gude, V.G. Renewable wood residue sources as potential alternative for fossil fuel dominated electricity mix for regions in Mississippi: A techno-economic analysis. Renew. Energy 2022, 200, 1105–1119. [Google Scholar] [CrossRef]

- Dahham, R.Y.; Wei, H.; Pan, J. Improving Thermal Efficiency of Internal Combustion Engines: Recent Progress and Remaining Challenges. Energies 2022, 15, 6222. [Google Scholar] [CrossRef]

- Conroy, L. Open Fireplaces vs Wood Burning Stoves: The Great Debate. 2020. Available online: https://www.ecofuel.ie/blogs/read/open-fireplaces-vs-wood-burning-stoves (accessed on 22 February 2023).

- Regency. Catalytic vs. Non-Catalytic Wood Stoves—Which Is Right for You? 2020. Available online: https://www.regency-fire.com/en/Blog/Catalytic-vs-Non-Catalytic-Wood-Stoves#:~:text=A%20catalytic%20wood%20stove%20uses,emissions%2C%20and%20longer%20burn%20times (accessed on 22 February 2023).

- Urban Heart. How to Operate Your Catalytic Wood Stove. 2014. Available online: https://urbanhearth.ca/handouts-new/45-how-to-operate-your-catalytic-stove/file#:~:text=A%20wood%20stove%20catalyst%20is,F%20to%20500%C2%B0F (accessed on 22 February 2023).

- Wallnoefer. Walltherm Vajolet—The First Water Heating Wood Gasification Stove for the Living Room. 2023. Available online:https://www.wallnoefer.it/en/products/wallthermr-wood-stoves/wood-boiler-stoves/new-vajolet.html (accessed on 22 February 2023).

- US EPA. Wood Stove Database. 2022. Available online: https://cfpub.epa.gov/oarweb/woodstove/index.cfm?fuseaction=app.search (accessed on 10 December 2022).

- Selivanov, E.; Cudlin, P. Life cycle assessment of residential heat production from wood pellet combustion in the Northwest region of Russia. J. For. Sci. 2025, 71, 182–194. [Google Scholar] [CrossRef]

- Rhodes, C. Wood Stoves and Air Pollution. What’s the Link? 2024. Available online: https://earth.org/wood-stoves-and-air-pollution-whats-the-link/ (accessed on 15 April 2025).

- Chakraborty, R.; Heydon, J.; Mayfield, M.; Mihaylova, L. Indoor air pollution from residential stoves: Examining the flooding of particulate matter into homes during real-world use. Atmosphere 2020, 11, 1326. [Google Scholar] [CrossRef]

- Illerup, J.B.; Hansen, B.B.; Lin, W.; Nickelsen, J.; Pedersen, V.H.; Bente Eskerod, B.; Dam-Johansen, K. Performance of an automatically controlled wood stove: Thermal efficiency and carbon monoxide emissions. Renew. Energy 2020, 151, 640–647. [Google Scholar] [CrossRef]

- Du, Y.; Lin, W.; Glarborg, P. Particulate emissions from a modern wood stove—Influence of KCl. Renew. Energy 2021, 170, 1215–1227. [Google Scholar] [CrossRef]

- Scott, A.J. Real-Life Emissions from Residential Wood Burning Appliances in New Zealand; Ministry for the Environment: Wellington, New Zealand, 2005.

- Cornette, J.F.P.; Dyakov, I.V.; Plissart, P.; Bram, S.; Blondeau, J. In-situ evaluation of a commercial electrostatic precipitator integrated in a small-scale woodchip boiler. J. Electrost. 2024, 128, 103897. [Google Scholar] [CrossRef]

- Guerrero, F.; Yáñez, K.; Vidal, V.; Cereceda-Balic, F. Effects of wood moisture on emission factors for PM2.5, particle numbers and particulate-phase PAHs from Eucalyptus globulus combustion using a controlled combustion chamber for emissions. Sci. Total Environ. 2019, 648, 737–744. [Google Scholar] [CrossRef] [PubMed]

- Keaveney, P.T. Record agricultural diesel prices crippling the industry. Irish Farmers Journal, 9 March 2022. [Google Scholar]

- O’Brien, T. Farm contractors critical of threat to ‘green’ diesel subsidies. The Irish Times, 6 October 2021. [Google Scholar]

- Kreysa, G. Sustainable management of the global carbon cycle through geostorage of wood. ChemSusChem 2009, 2, 633–644. [Google Scholar] [CrossRef]

- Dufour, A. Geological sequestration of biomass char to mitigate climate change. Environ. Sci. Technol. 2013, 47, 10106–10107. [Google Scholar] [CrossRef]

| Energy Performance Parameter | Boiler | Steam Power | Steam CHP | ||

|---|---|---|---|---|---|

| 50 bar | 150 bar | 50 bar | 150 bar | ||

| CHP efficiency | - | - | - | 81.7 | 76.3 |

| power efficiency | - | 25.6 | 27.9 | 10.5 | 16.0 |

| heat efficiency | 87.5 | - | - | 71.2 | 60.3 |

| flue gas losses | 12.5 | 18.3 | 23.6 | 18.3 | 23.7 |

| heat rejection losses | - | 56.1 | 48.5 | - | - |

| Energy Performance Parameter | Gasification + GT Power Plant | Gasification + GT CHP | ||

|---|---|---|---|---|

| Without Regenerator | with Regenerator | Without Regenerator | with Regenerator | |

| power cycle efficiency | 33.5 | 44.2 | - | - |

| CHP cycle efficiency | - | - | 79.2 | 72.6 |

| CHP efficiency | - | - | 47.6 | 43.5 |

| power efficiency | 20.1 | 26.5 | 20.1 | 26.5 |

| heat efficiency | - | - | 27.5 | 17.0 |

| flue gas losses | 39.9 | 33.5 | 12.4 | 16.5 |

| gasification losses | 40 | 40 | 40 | 40 |

| Energy Performance Parameter | Without Regenerator | with Regenerator |

|---|---|---|

| power cycle efficiency | 44.8 | 50.1 |

| power efficiency | 26.4 | 29.9 |

| power efficiency—gas turbine | 20.1 | 26.5 |

| power efficiency—steam turbine | 6.3 | 3.4 |

| flue gas losses | 14.3 | 19.1 |

| heat rejection losses | 19.5 | 11.0 |

| gasification losses | 40 | 40 |

| Energy Performance Parameter | ||

|---|---|---|

| liquid-fuel efficiency | 34 | 45.3 |

| FT losses | 26 | 34.7 |

| gasification losses | 40 | 20 |

| System | Power–Heat Equivalent Energy Efficiency (%) | |

|---|---|---|

| High-efficiency wood stoves | 80–90 | |

| Steam boiler | 87.5 | |

| Steam power and CHP | 50 bar | 150 bar |

| Steam power plant | 46.1 | 50.2 |

| Steam CHP | 90.1 | 89.1 |

| GT systems () | no regen | regen |

| GT power plant | 36.2 | 47.7 |

| CCGT power plant | 47.5 | 53.8 |

| GT CHP | 58.1 | 67.8 |

| GT systems () | no regen | regen |

| CCGT power plant | 48.2 | 63.7 |

| CCGT power plant | 64.4 | 72.7 |

| GT CHP | 84.8 | 86.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fitzpatrick, J.J.; Carroll, J.; Macura, S.; Murphy, N. How Best to Use Forest Wood for Energy: Perspectives from Energy Efficiency and Environmental Considerations. Eng 2025, 6, 95. https://doi.org/10.3390/eng6050095

Fitzpatrick JJ, Carroll J, Macura S, Murphy N. How Best to Use Forest Wood for Energy: Perspectives from Energy Efficiency and Environmental Considerations. Eng. 2025; 6(5):95. https://doi.org/10.3390/eng6050095

Chicago/Turabian StyleFitzpatrick, John J., Jack Carroll, Strahinja Macura, and Neil Murphy. 2025. "How Best to Use Forest Wood for Energy: Perspectives from Energy Efficiency and Environmental Considerations" Eng 6, no. 5: 95. https://doi.org/10.3390/eng6050095

APA StyleFitzpatrick, J. J., Carroll, J., Macura, S., & Murphy, N. (2025). How Best to Use Forest Wood for Energy: Perspectives from Energy Efficiency and Environmental Considerations. Eng, 6(5), 95. https://doi.org/10.3390/eng6050095