Localized Reluctivity Stabilization of Hysteresis Model for Transient Finite Element Simulation of Ferromagnetic Materials

Abstract

1. Introduction

2. JA Model and Field Equations

2.1. Scalar JA Model

2.2. Improved Vector JA Model

2.3. Field Equations

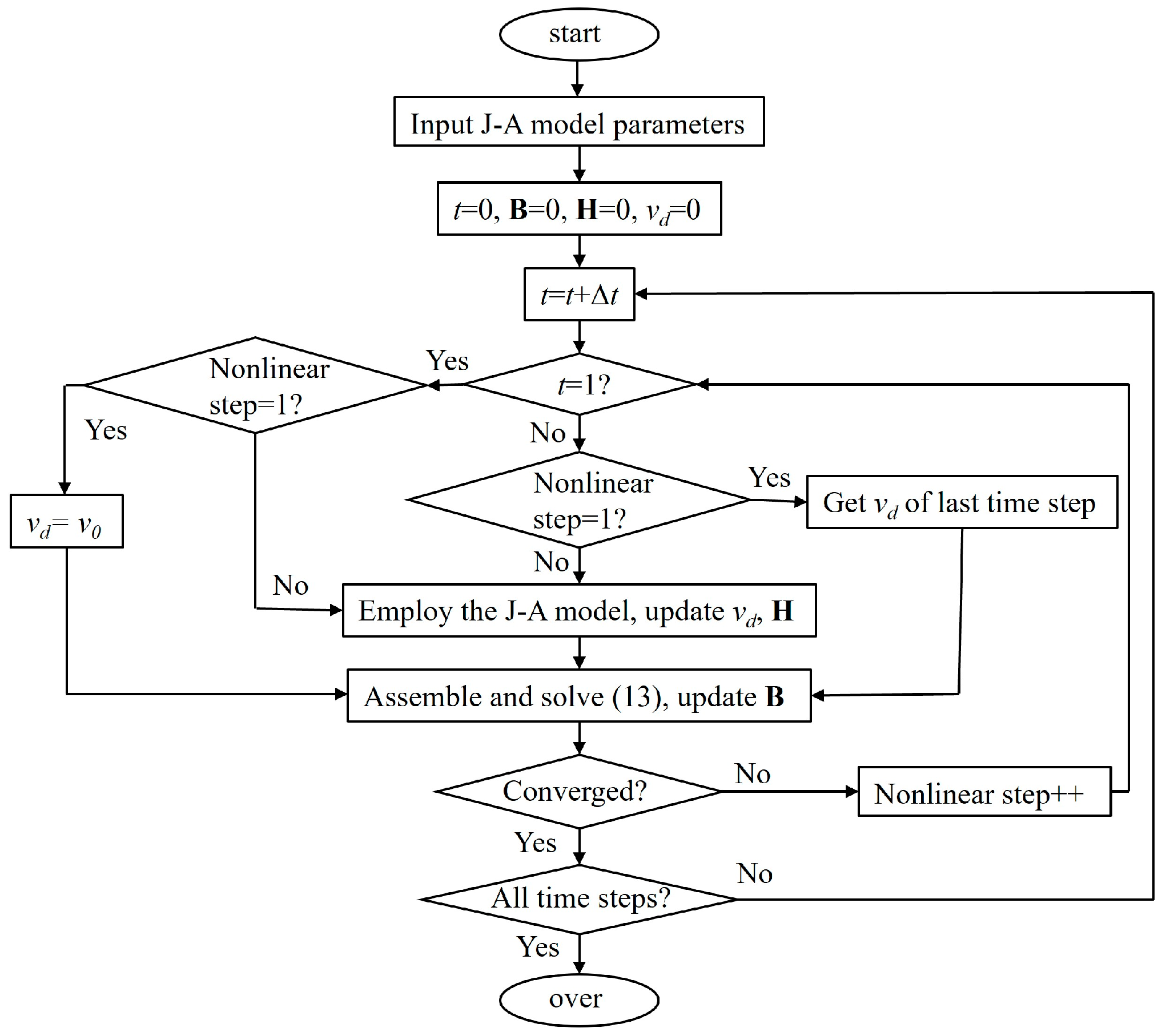

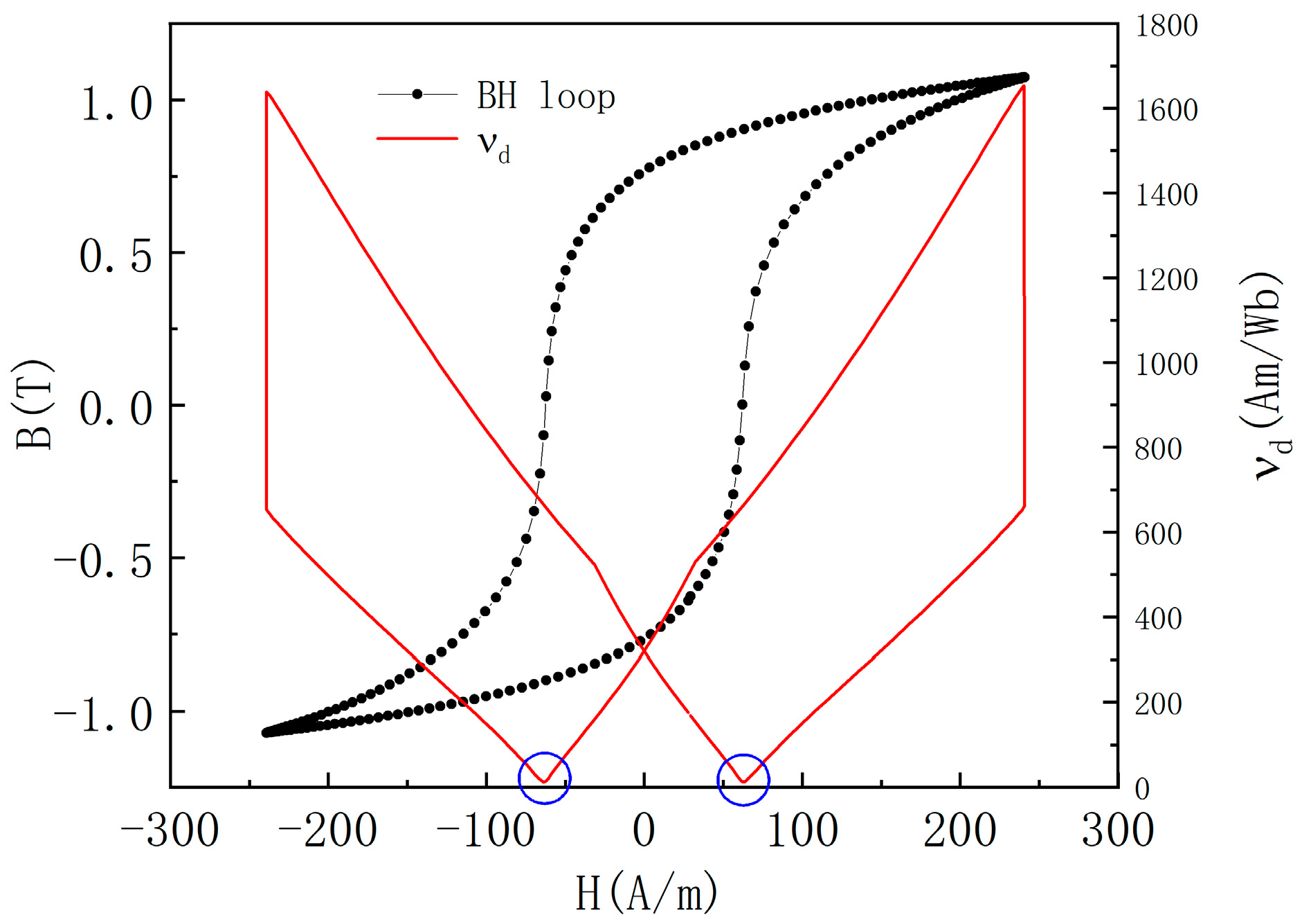

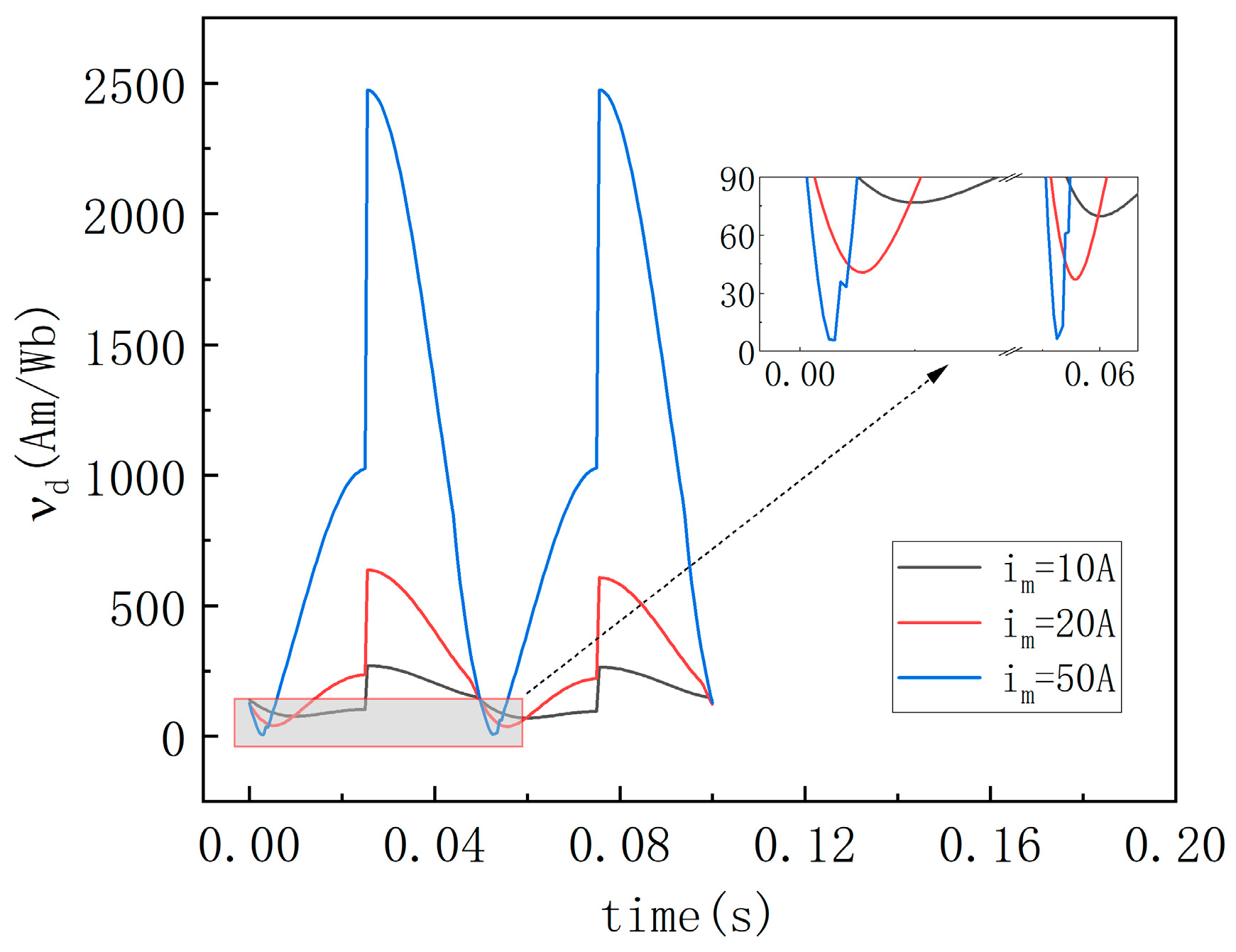

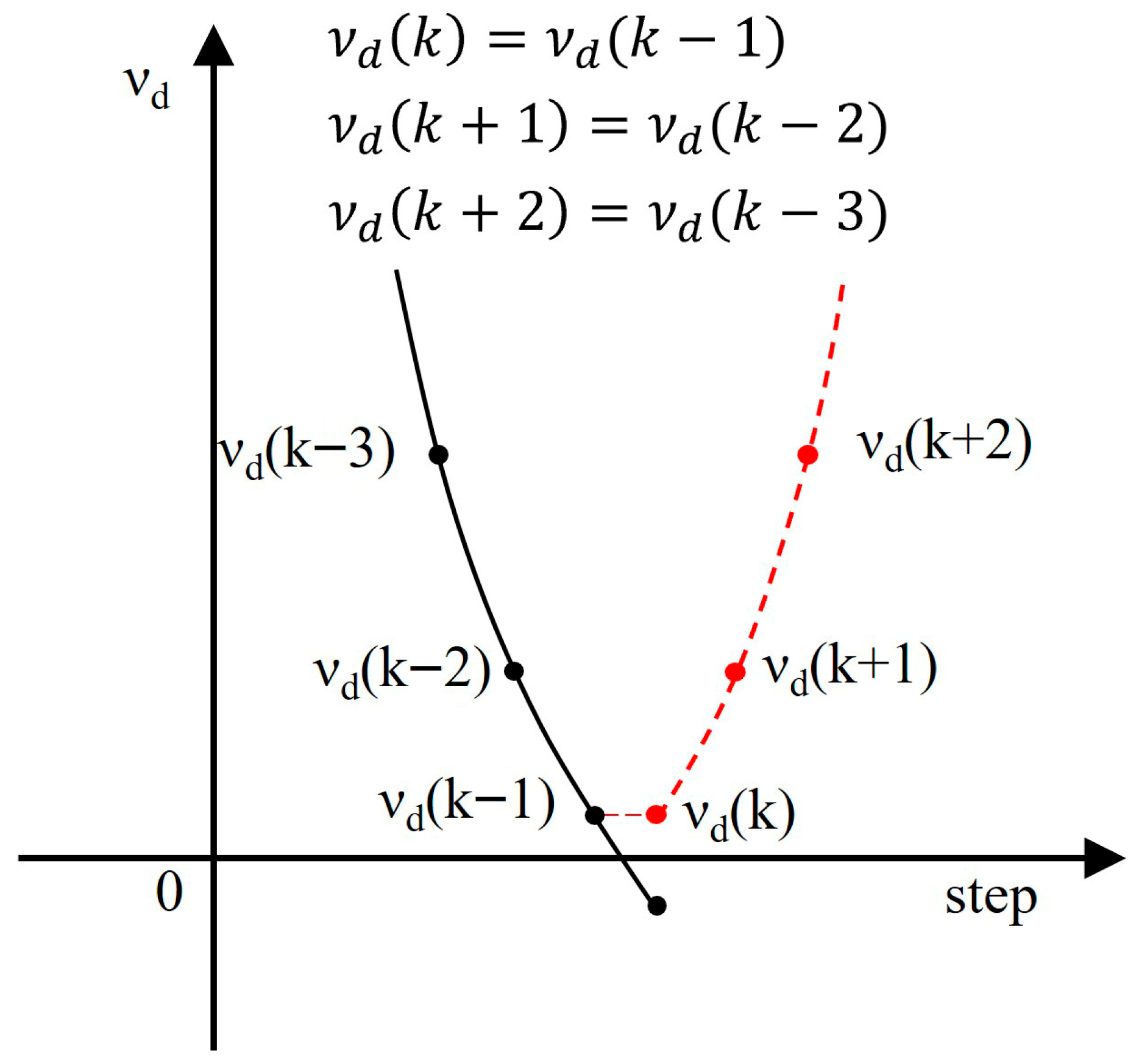

3. Local Stabilization Algorithm

| 1: bool νd_min = false 2: for (k = 0; k < steps; k++) do 3: int index_min = 0 4: int steps_T = T/stepsize 5: int k_stage = k-steps_T*int(k/steps_T) 6: if k_stage == steps_T/4 || k_stage == steps_T*0.75 7: νd_min = false 8: end if 9: νd(k) = (H(k) − H(k − 1))/(B(k) − B(k − 1)) 10: if νd(k) < 0 && νd_min == false 11: νd(k) = νd(k − 1) 12: νd_min = true 13: index_min = k Once the calculated differential reluctivity has a negative value, the current value is forcibly assigned to the value of the previous time, and the current value is taken as the lowest differential reluctivity. 14: end if 15: if νd_min 16: if νd(k) < νd(k − 1) 17: νd(k) = νd (k − index_min − 1) 18: end if 19: end if 20: end for |

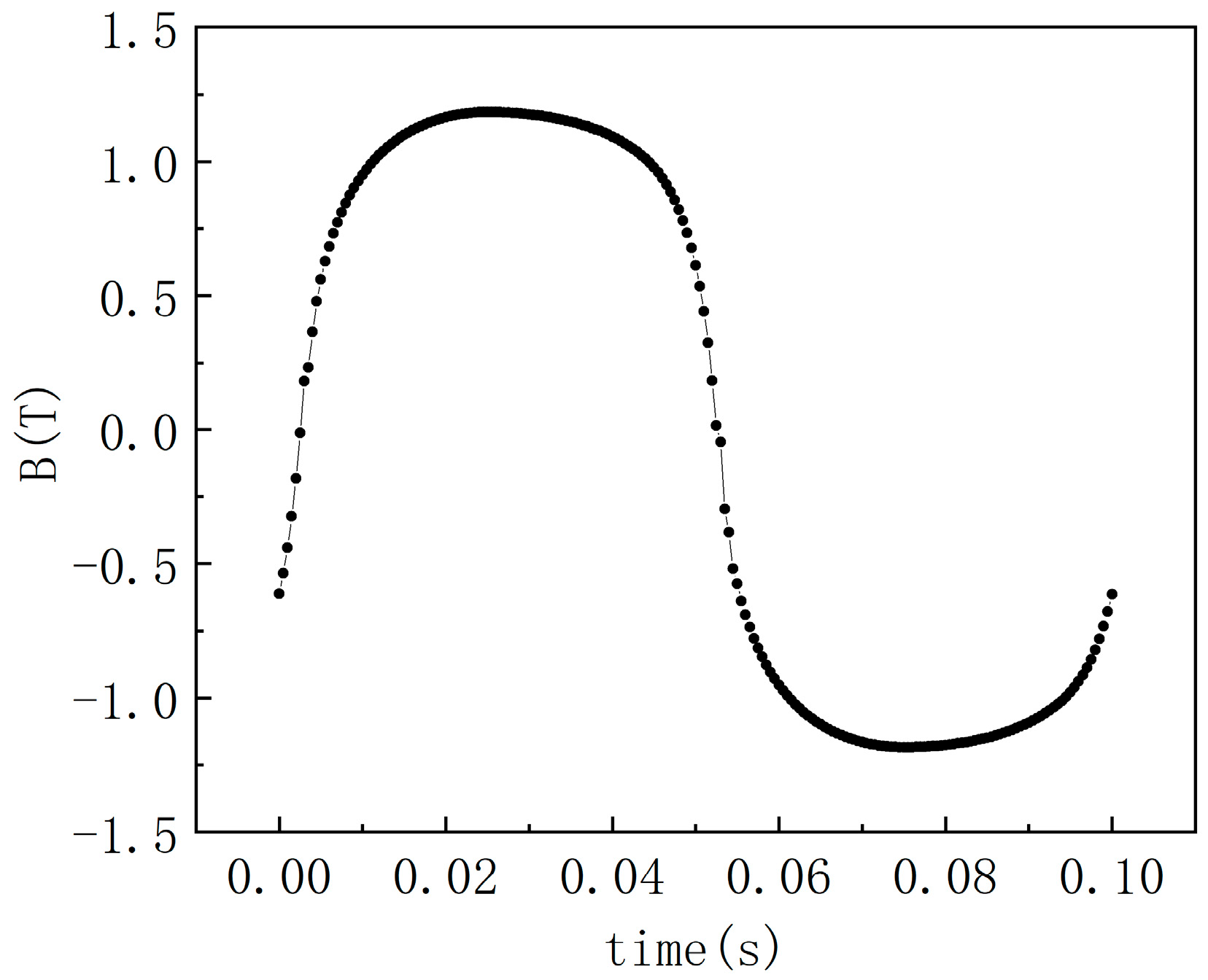

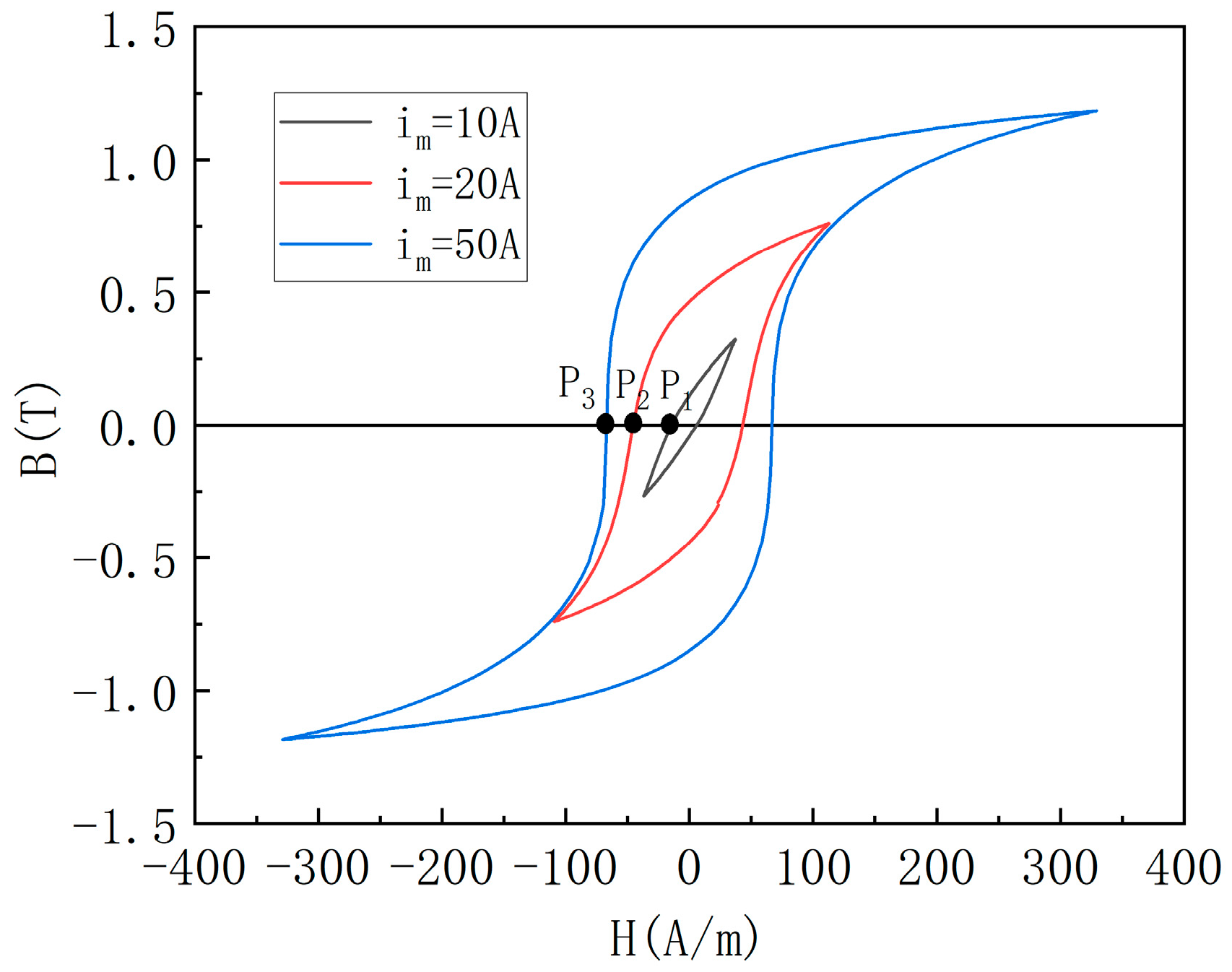

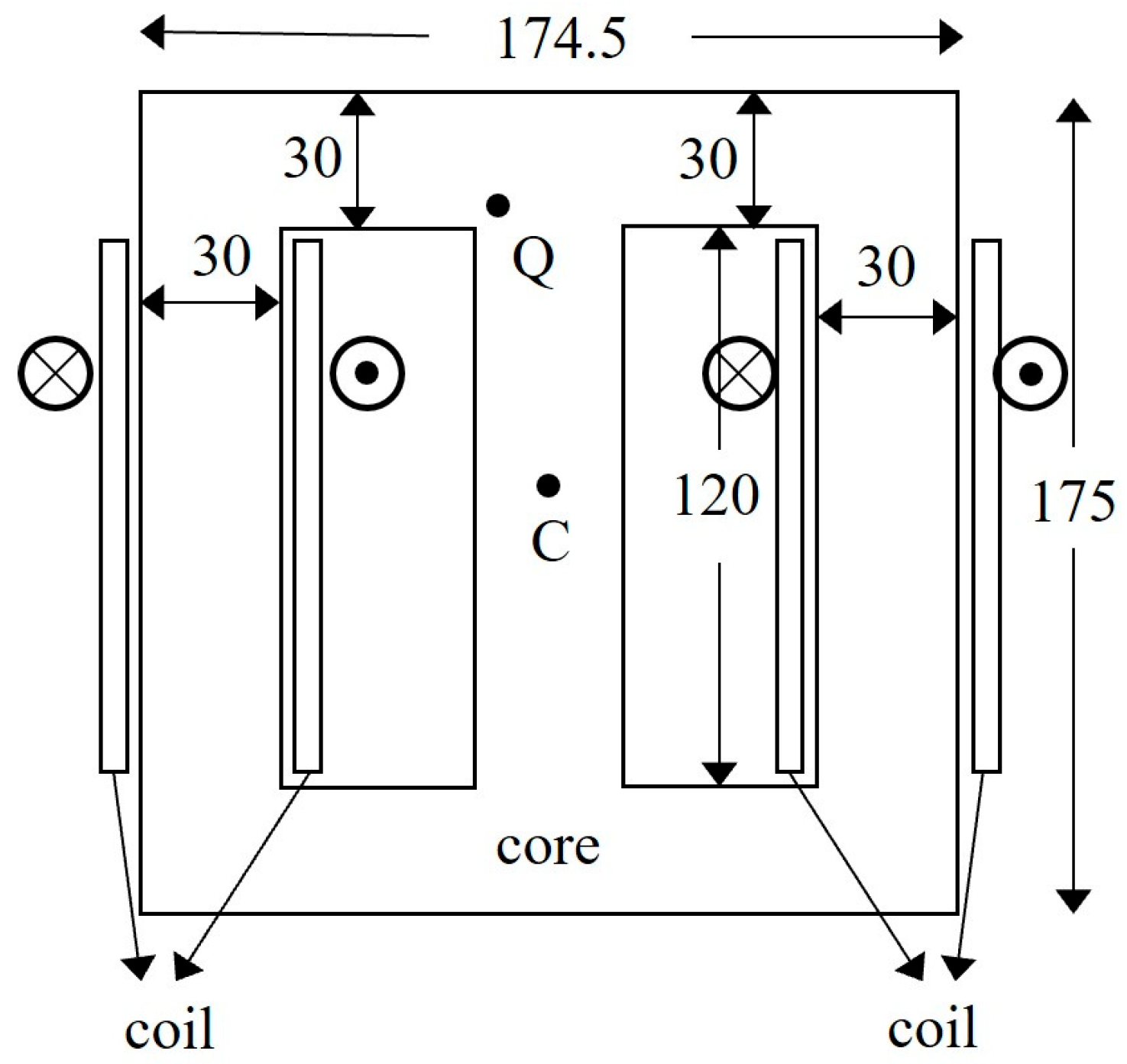

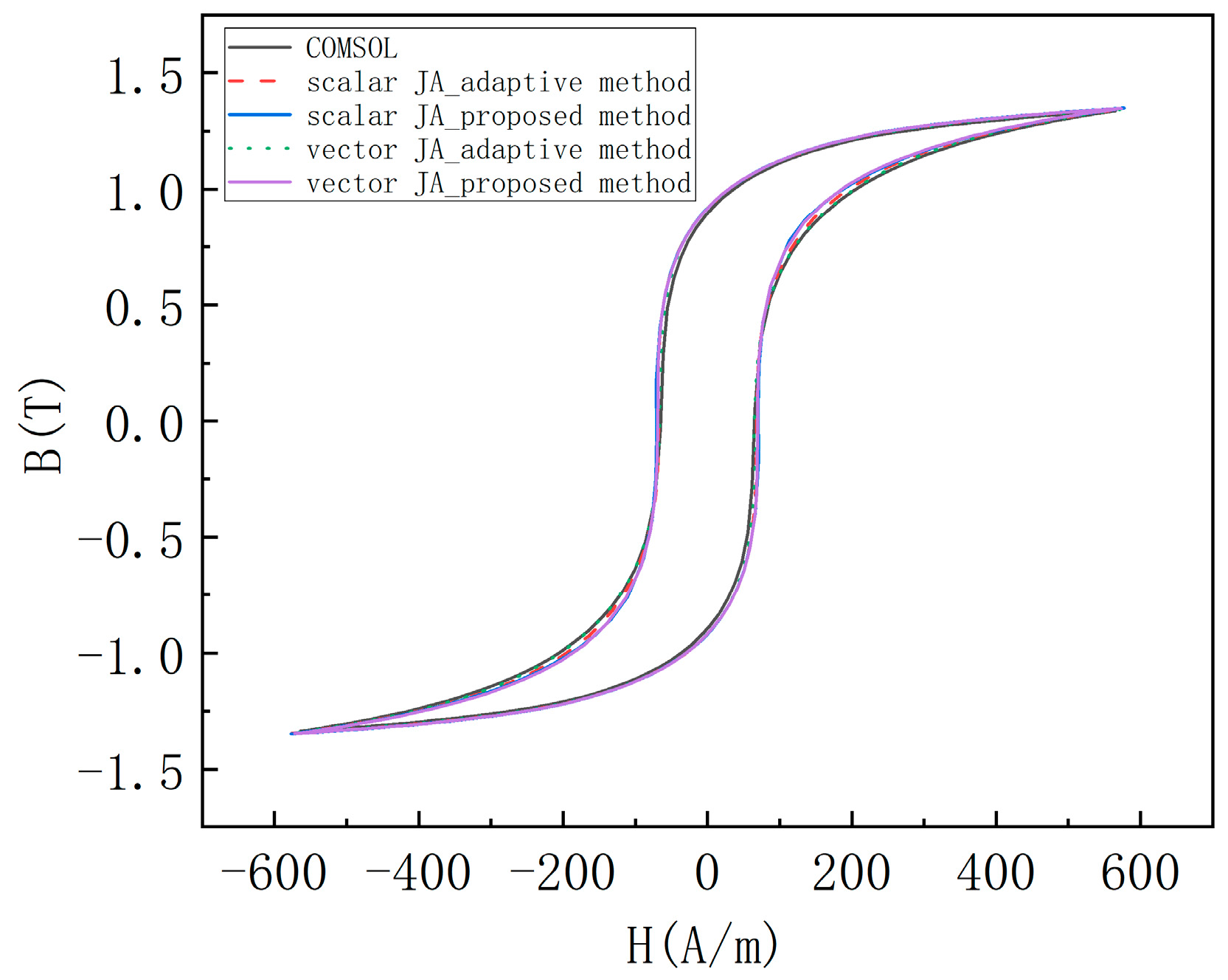

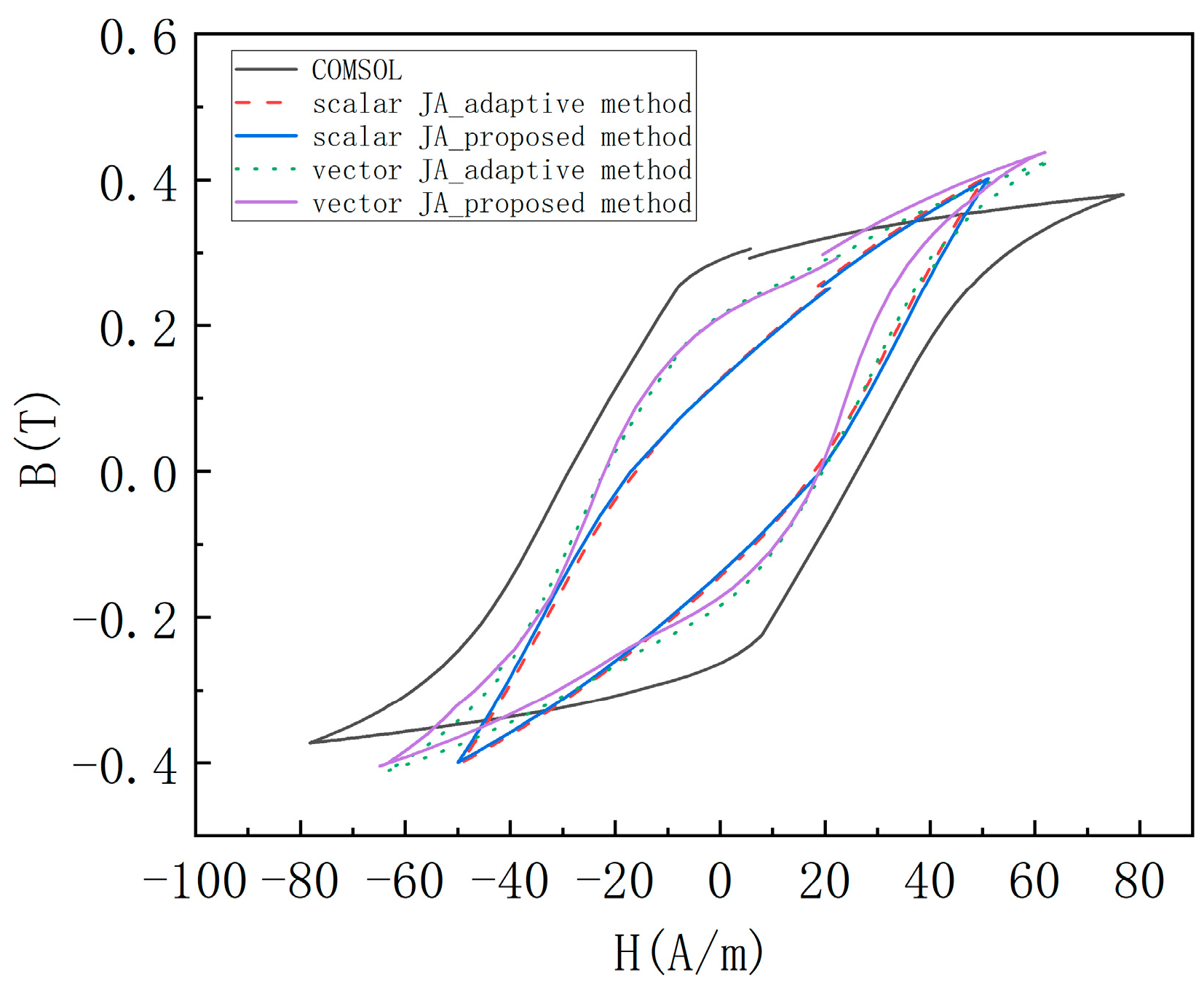

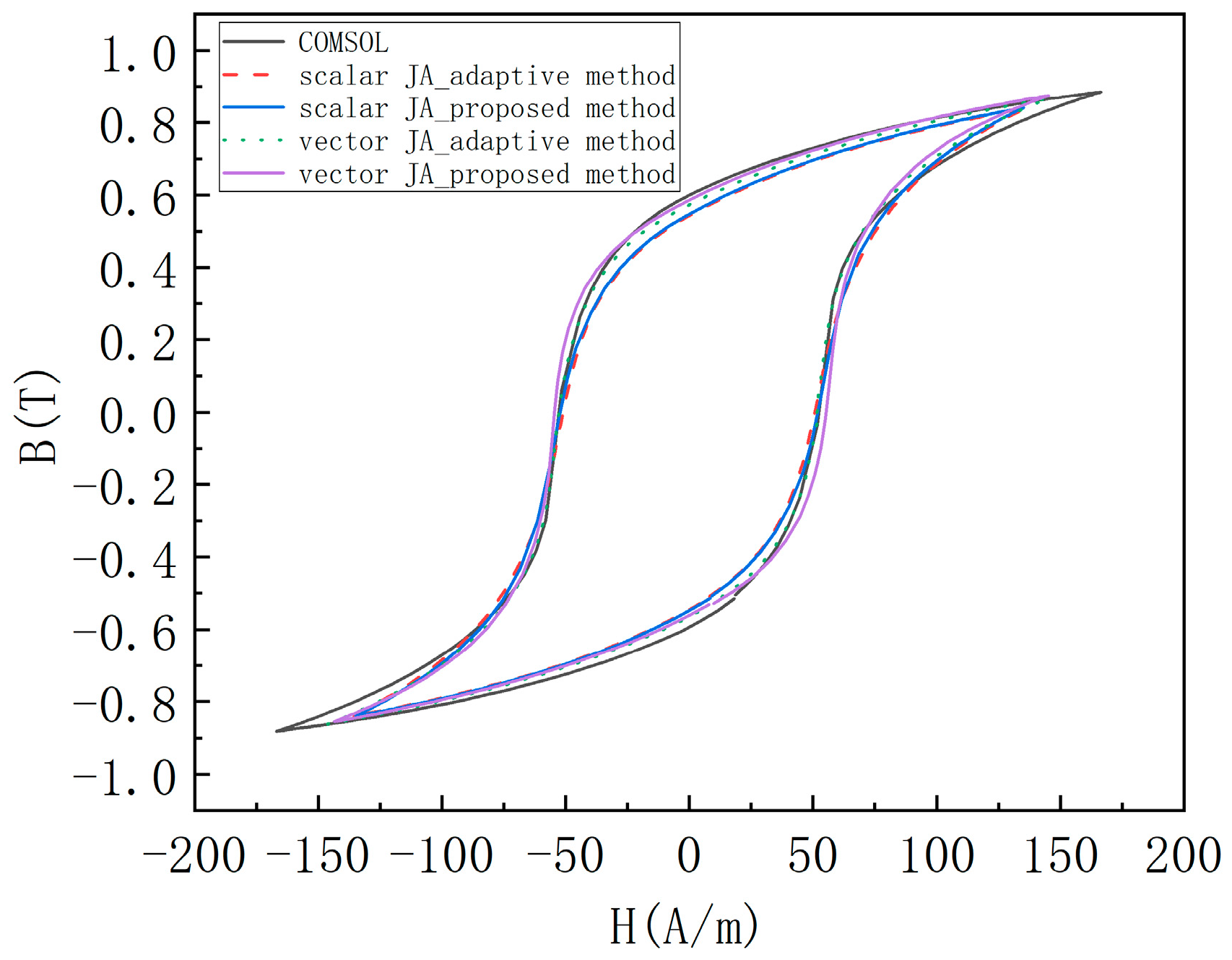

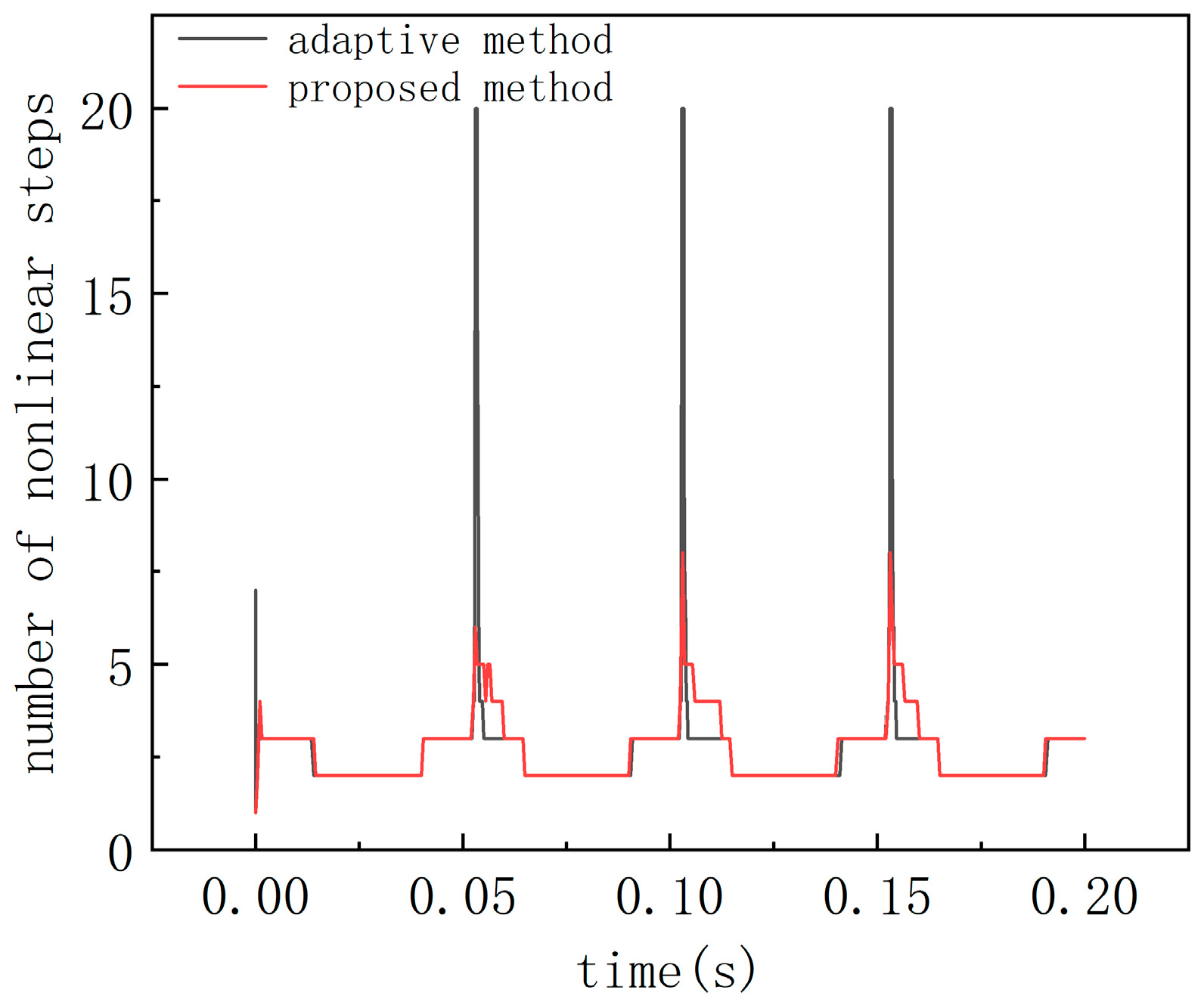

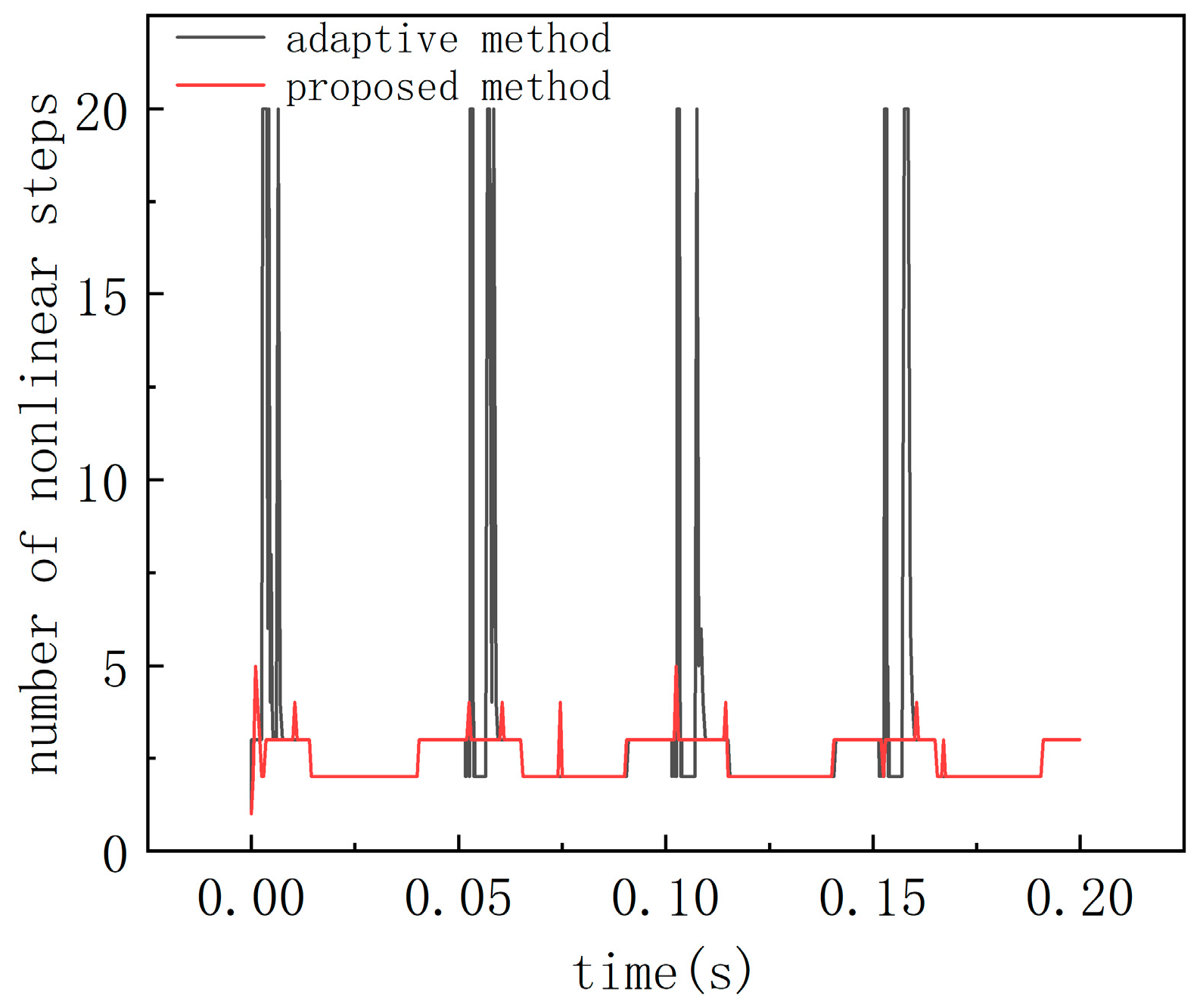

4. Numerical Example

| JA Model | Method | Number of Time-Steps | Calculation Times (s) |

|---|---|---|---|

| scalar JA | adaptive method | 473 | 73 |

| scalar JA | proposed method | 400 | 45 |

| vector JA | adaptive method | 1789 | 569 |

| vector JA | proposed method | 400 | 69 |

| Point | Error of Scalar JA Model | Error of Vector JA Model |

|---|---|---|

| C_y | 2.1% | −6.5% |

| Q_x | 0.6% | 3.7% |

| Q_y | 1.4% | 2.8% |

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Leite, J.V.; Benabou, A.; Sadowski, N. Transformer Inrush Currents Taking Into Account Vector Hysteresis. IEEE Trans. Magn. 2010, 46, 3237–3240. [Google Scholar] [CrossRef]

- Wang, Y. Research on Residual Magnetism Prediction of Transformer Core. Ph.D. Thesis, Shandong University, Jinan, China, 2017. [Google Scholar]

- Jiles, D.; Atherton, D. Theory of ferromagnetic hysteresis. J. Magn. Magn. Mater. 1986, 61, 48–60. [Google Scholar] [CrossRef]

- Preisach, F. Über die magnetische Nachwirkung. Z. Phys. 1935, 94, 277–302. [Google Scholar] [CrossRef]

- Sadowski, N.; Batistela, N.J.; Bastos, J.P.A.; Lajoie-Mazenc, M. An inverse Jiles-Atherton model to take into account hysteresis in time-stepping finite-element calculations. IEEE Trans. Magn. 2002, 32, 797–800. [Google Scholar] [CrossRef]

- Bergqvist, A. A simple vector generalization of the Jiles-Atherton model of hysteresis. IEEE Trans. Magn. 1996, 32, 4213–4215. [Google Scholar] [CrossRef]

- Leite, J.V.; Sadowski, N.; Kuo-Peng, P.; Batistela, N.J.; Bastos, J.P.A.; de Espíndola, A.A. Inverse Jiles-Atherton vector hysteresis model. IEEE Trans. Magn. 2004, 40, 1769–1775. [Google Scholar] [CrossRef]

- Hoffmann, K.; Bastos, J.P.A.; Leite, J.V.; Sadowski, N.; Barbosa, F. A Vector Jiles–Atherton Model for Improving the FEM Convergence. IEEE Trans. Magn. 2017, 53, 7300304. [Google Scholar] [CrossRef]

- Mathekga, A.M.E.; McMahon, R.A.; Knight, A.M. Application of the Fixed Point Method for Solution in Time-stepping Finite Element Analysis Using the Inverse Vector Jiles-Atherton Model. IEEE Trans. Magn. 2011, 47, 3048–3051. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, X.; Yan, S.; Zhou, Y.; Chen, Z.; Xu, X.; Ren, Z. Localized Reluctivity Stabilization of Hysteresis Model for Transient Finite Element Simulation of Ferromagnetic Materials. Eng 2025, 6, 289. https://doi.org/10.3390/eng6110289

Fu X, Yan S, Zhou Y, Chen Z, Xu X, Ren Z. Localized Reluctivity Stabilization of Hysteresis Model for Transient Finite Element Simulation of Ferromagnetic Materials. Eng. 2025; 6(11):289. https://doi.org/10.3390/eng6110289

Chicago/Turabian StyleFu, Xiaotong, Shuai Yan, Yaxing Zhou, Zhifu Chen, Xiaoyu Xu, and Zhuoxiang Ren. 2025. "Localized Reluctivity Stabilization of Hysteresis Model for Transient Finite Element Simulation of Ferromagnetic Materials" Eng 6, no. 11: 289. https://doi.org/10.3390/eng6110289

APA StyleFu, X., Yan, S., Zhou, Y., Chen, Z., Xu, X., & Ren, Z. (2025). Localized Reluctivity Stabilization of Hysteresis Model for Transient Finite Element Simulation of Ferromagnetic Materials. Eng, 6(11), 289. https://doi.org/10.3390/eng6110289