Abstract

The main aim of this study was to identify and evaluate the characteristic properties of bitumen modified with algae. Two types of algae, each with distinct gradation and origin, were employed for this investigation. For each type of algae (noted as chlorella and microchlorella), three blends were created with varying algae contents (5%, 10%, and 15% by weight of bitumen), utilizing a 70/100 reference bitumen as the virgin material and a basis for comparison. The properties of the blends were investigated using the Penetration, Softening Point, Elastic Recovery, Force Ductility, Dynamic Viscosity, and Storage Stability tests, both before and after short-term ageing (TFOT). The test results were then used to calculate the Activation Energy (Ea), Viscosity-Temperature Susceptibility (VTS) Index, and Mixing Temperature (Tmixing), along with their respective Pearson Correlation Coefficient (PCC) and R2 and p-values. The main finding of the study was that the addition of a low algae content of 5% caused a change in the classification of the unaged bitumen from 70/100 to 50/70 according to EN 12591 and thus hardened the reference bitumen. Additionally, a strong linear statistical correlation was observed between Ea and the VTS index, suggesting that these values should be considered when characterizing the temperature susceptibility of algae-modified bitumen.

1. Introduction

Petroleum-derived bitumen is the most widespread material used as a binder in pavement construction [1]. The rising financial and environmental costs of all products of the crude oil industry have led to the investigation of alternative biomass-derived materials [2,3]. These materials are examined as potential substitutes for bitumen. Biomaterials can be mixed with bitumen either as solid or liquid components and can be categorized based on the replacement of the original bitumen content as (a) modifiers (<10% replacement), (b) extenders (25% to 75% replacement) or (c) direct replacements (100% replacement) [4]. One of the possible alternatives to conventional bitumen is algae. Algae consists of numerous species, so extensive research needs to be conducted. Greece is a coastal country where algae exist in abundance. Moreover, algae grow rapidly and do not need advanced growing techniques, so they may be a feasible modifier in regard to the production process (equipment, etc.) [5]. In the following paragraph, a review of the studies examining various algae-modified bitumen and asphalt mixtures is presented.

As mentioned above, numerous algae species have been assessed as possible alternative binding materials for asphalt mixtures. For instance, it was found that sargassum-modified bitumen had higher viscosity and rutting resistance in comparison with unmodified petroleum-based bitumen, which could improve the high-temperature performance [6]. The same study indicated that a reduction in the sargassum particle size would bring about an increased specific surface area and thus better cohesion [6]. Furthermore, as the particle size is reduced, the storage instability of bitumen is also reduced up to 3% content. Above this level of content, segregation is highly likely, regardless of the volumetric characteristics of the sargassum particles. The main advantage of this modifier is its superior decomposition temperature-approximately 320 °C- which is non-comparable with the required temperatures for the mixing and compaction of asphalt mixtures. The main concern associated with sargassum is its inability to chemically bind with bitumen. In other words, this modification is attributed to the physical adsorption of bitumen by the sargassum particles rather than to the chemical interaction between the two materials. Another study demonstrated that the optimal content of sargassum powder in bitumen was 2.5% by weight of bitumen [7]. Up to 2.5%, it affects the bitumen like most powdered modifiers, i.e., it increases the viscosity, the softening point and the resistance against permanent deformation and rutting. When surpassing this concentration, a reduction in the above properties was displayed, which was attributed to a change in the colloidal system. Specifically, sargassum particles at such high percentages are not distributed homogeneously in the bitumen, which leads to agglomeration. Consequently, the reverse effect is observed. Regardless, sargassum powder does not present phase separation up to 4% content by weight when stored at elevated temperatures for extended periods of time, unlike other powder modifiers, such as crumb rubber. One research study concluded that unaged, algae-derived bio-oil-modified (microalgae (spirulina) and nanoalgae) bitumen had a lower complex shear modulus, but after ageing, no significant differences in the G* values between the reference and the modified bitumen were noticed [8]. From the above it can be established that although algae bio-oils can reinforce the viscous phase of bitumen in unaged conditions, this does not necessarily apply for the short- and long-aged states. The ageing rate of algae bio-oils may sometimes be higher compared to bitumen, so it may be preferable to incorporate these materials as rejuvenators in reclaimed bitumen. A major drawback of spirulina algae (microalgae) and nanoalgae is that they tend to produce excessive fumes that are hazardous to human health when heated at 145 °C or above due to their high sulfur content. One possible solution would be to include them in Warm Mix Asphalts (WMA) instead of Hot Mix Asphalts (HMA). Moreover, algae bio-oil has been found to chemically react with SBS and fortify the SBS network structure present in bitumen [9]. One of the focal weaknesses of algae bio-oils is that they reduce the interfacial forces between bio-bitumen and aggregates thus compromising the adhesive properties of the asphalt mixture [10]. Although the thermochemical use of algae does not compete with the food industry’s use of algae, there is a specific issue concerning the calorific value of these materials. Certain types of algae have a high concentration of lipids, which makes them an ideal raw material for the production of biofuels. For this reason, before using them in the pavement industry, a process of lipid extraction is preferable. Subsequently, after this procedure, the waste from biofuel production, which is an oily viscous residue (like bitumen), can be added to bitumen and asphalt mixtures. In this direction, it was studied as a bitumen modifier and found to have similar viscoelastic properties to conventional petroleum-based bitumen. Specifically, the frequency-dependent and time-dependent viscoelastic characteristics of spirulina-derived biofuel waste were similar to those of unmodified bitumen [11]. Furthermore, caution needs to be taken during the conversion of algae into bio-oil. In most studies, hydrothermal liquefaction (HTL) is chosen as the thermochemical conversion process due to its ability to utilize biomasses with high water content, unlike others such as fast pyrolysis. During HTL, the experimental conditions (raw material, temperature, residence time, existence of catalysts, etc.) will determine the rheological behavior of the bio-oil and, consequently, that of the bio-bitumen. According to a study, the most suitable temperature of an algae species noted as Scenedesmus sp. HTL was close to 260 °C [12]. Above this, the water-insoluble solid phase of the converted Scenedesmus was notably decreased, which negatively affected the dual viscoelastic nature of the material [12]. In addition to the above study, it has been suggested that a combination of hydrothermal liquefaction and hydrothermal carbonization at temperatues close to 250–270 °C is ideal spectrum and that, as the reaction time is increased, the complex shear modulus G* of the product presents a gradual decrease [13]. Two other studies examined the role of two algae species noted as Spirulina sp. and Scenedesmus sp. as additives to bitumen [5,14]. The results revealed that Scenedesmus sp. bio-bitumen could potentially be a direct replacement alternative for the petroleum-based bitumen, whereas Spirulina sp. bio-bitumen is a better replacement for elastomer modifiers, such as SBS. Moreover, the implementation of Posidonia oceanica fibers in SMA was investigated, with the optimum fiber content being 1.5–2% [15]. This concentration improved both the stiffness and the fatigue life of SMA. If this content is exceeded, the SMA properties will decline rapidly because of the extensive binder drainage. From the above, it can be deduced that each type of algae has a different impact on bitumen depending on its origin, its form (powder, fibers, thermochemically produced bio-oil) and its content.

Chlorella and microchlorella are widespread algae species that have not been studied extensively as potential bitumen additives. Taking this into consideration, this paper studies the impact of chlorella and microchlorella on bitumen by examining the chemical compositions of the above algae species and the characteristic properties of algae-modified bitumen before and after short-term ageing (TFOT) followed by a statistical analysis.

2. Materials and Methods

In the current study, a conventional 70/100 bitumen served as the reference bitumen (RB) and the basis for the production of bitumen-algae blends. Two types of algae were used, having different origins and different maximum particle sizes. Both types of algae were included in the reference bitumen at three distinct levels of content, i.e., 5%, 10%, and 15% by weight of bitumen. The characteristic properties of the reference bitumen and all respective bitumen-algae blends were determined and compared before and after ageing. These properties were the: penetration, softening point, elastic recovery, force ductility, dynamic viscosity (Brookfield viscometer), and storage stability. Additionally, the dynamic viscosity results of the tests were utilized to calculate the Activation Energy (Ea), Viscosity-Temperature Susceptibility (VTS) Index and Mixing Temperature (Tmixing) along with their respective Pearson Correlation Coefficient (PCC), R2, and p-values.

2.1. Bitumen

The characteristic properties of the reference bitumen are given in Table 1.

Table 1.

Characteristic properties of reference bitumen.

2.2. Algae

The two algae types utilized in this study were different in origin and maximum particle size. The first type, denoted as “chlorella” was acquired after cultivation in a nutrient solution containing the necessary macro and micro nutrients that are essential for its growth. Upon completion of the cultivation phase, the process involved centrifugation, filtration, and drying to obtain the dry algae suitable for incorporation into the bitumen algae-blends. The chlorella grain size was ≤0.5 mm. The second type of algae denoted as “microchlorella” was a commercial product with a grain size ≤ 0.063 mm.

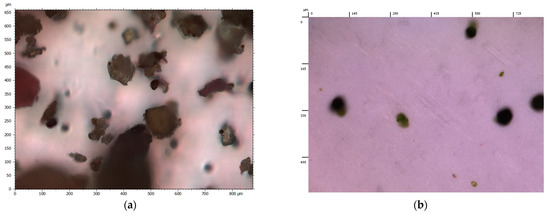

A view of the chlorella and microchlorella is displayed in Figure 1 and Figure 2. As can be seen, chlorella is mainly yellow and light brown in color, whereas microchlorella is dark green. According to images taken by a confocal microscope (×20) (Figure 2), the chlorella particles tended to be more irregularly and angularly shaped, whereas microchlorella particles had a more regular and spherical shape. The shape differences between the two types of algae could be attributed to the different production methods chosen for each algae species.

Figure 1.

(a) Chlorella powder (≤0.5 mm) and (b) Microchlorella powder (≤0.063 mm).

Figure 2.

Confocal microscopy (×20) of (a) chlorella powder (≤0.5 mm) (b) microchlorella powder (≤0.063 mm).

Before the chlorella and micro-chlorella were mixed with the RB, their chemical compositions were investigated. The results are shown in Table 2. According to Table 2, chlorella and microchlorella are similar in regard to their macromolecular composition. Specifically, chlorella and microchlorella consist of crude protein at percentages of 31.56% and 41.8%, respectively. Their crude carbohydrate content is almost identical (33.4% and 30.2%). It is noteworthy that neither bio-modifier has significant lipid content. Biomaterials with low lipid content have relatively low calorific value, so they are usually avoided as raw materials for biofuel production. This makes them possible alternatives for use in bitumen production. The total solids, organic content, and moisture and ash content were evaluated only for chlorella and were found to be 29.06%, 62.90%, 70.94% and 18.44%, respectively. Such high ash content indicates high thermal stability, so it could be deduced that chlorella is a thermally stable material at the usual mixing and compaction temperatures due to its relatively high ash content [22,23].

Table 2.

Chemical characterization of chlorella and microchlorella.

2.3. Mixing Conditions

In order to establish a proper mixing protocol for the algae-based blends, the relevant literature was considered [6,7,9,10]. It was observed that there was considerable variation among researchers regarding the mixing conditions for algae-modified bio-bitumen (Table 3). Taking the above studies into consideration, the mixing took place at T = 160 °C for 30 min using a high shear mixer with a rotational speed of 2500 rpm. The mixing temperature and time were limited to 160 °C and 30 min, respectively, to achieve proper workability, while also avoiding the excessive oxidation of the bitumen. Since the mixing temperature was lower than the ones presented in Table 3 for powder bio-modifiers, a higher rotational speed was chosen to compensate for this. Furthermore, the mixing temperature results in Section 3.6 verify that 160 °C was an appropriate choice for the mixing temperature.

Table 3.

Mixing conditions for algae-modified bitumen from various studies.

3. Results

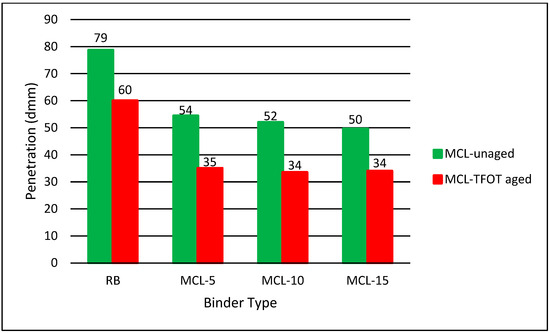

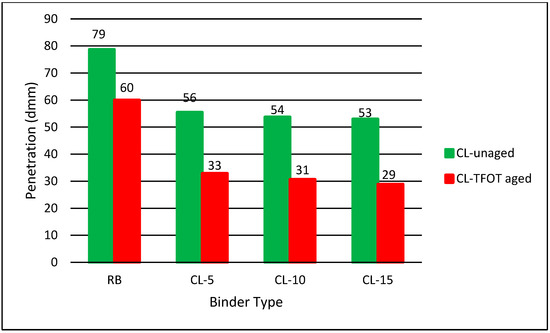

3.1. Penetration Test

The needle penetration test was carried out at 25 °C in accordance with EN 1426 [16]. Figure 3 and Figure 4 indicate that the addition of microchlorella and chlorella hardened the reference bitumen. Specifically, increasing contents of algae resulted in lower penetration values. It is noteworthy that even a small percentage of modification, as low as 5%, caused a change in category for the reference bitumen from 70/100 to 50/70, in accordance with the bitumen categories specified in EN 12591 [24]. The hardening effect was also displayed for the short-term aged algae-modified samples. Short-term aged samples demonstrated lower penetration values than their unaged counterparts due to the oxidation during the ageing process, which hardened the bitumen.

Figure 3.

Penetration of MCL-modified bitumen.

Figure 4.

Penetration of CL-modified bitumen.

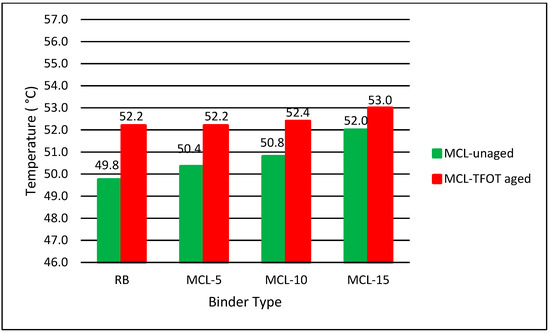

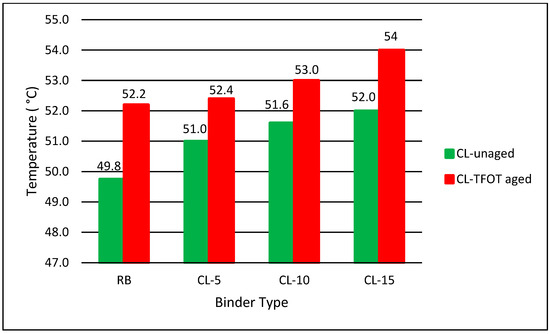

3.2. Softening Point Test

The softening point test was conducted with respect to EN 1427 [17]. Figure 5 and Figure 6 demonstrate the gradual increase in the softening point for increasing content in both the microchlorella-modified and chlorella-modified unaged binders. After short-term ageing, the chlorella-modified blends presented higher softening points than the short-term aged reference bitumen. The microchlorella-modified blends also displayed an increase in their softening point after short-term ageing compared to the reference bitumen, but the increment was less pronounced than that of the chlorella-modified blends. Moreover, all aged unmodified and bio-modified blends had higher softening points than their unaged counterparts. The highest resistance to ageing was demonstrated by MCL-15 for which the softening point increase after applying the ageing protocol was equal to only 1 °C (from 52 to 53 °C). This is expected to happen as ageing has a hardening effect on bitumen.

Figure 5.

Softening point of MCL-modified bitumen.

Figure 6.

Softening point of CL-modified bitumen.

3.3. Elastic Recovery Test

The elastic recovery test was carried out at 25 °C according to EN 13398 [18]. According to Table 4, the elastic recovery demonstrated by the algae-modified bitumen was similar to the elastic recovery of the reference bitumen in both the unaged and short-term aged states. This suggests that neither chlorella nor microchlorella powder managed to enhance the elastic properties of the bitumen. In general, the percentage of the elastic recovery of bio-modified samples did not exceed 10%.

Table 4.

Elastic recovery of unaged and TFOT-aged blends.

3.4. Force Ductility Test

The force ductility test is used to characterize the cohesion of modified bitumen and bituminous binders. According to EN 13589 and EN 13703, the proposed initial testing temperature is 5 °C [19,20]. Due to the premature brittle cracking of the specimens at 5 and 10 °C, the test was conducted at 15 °C. The results for the unaged and short-term aged samples are depicted in Table 5 and Table 6. Algae addition hardened the bitumen and reinforced its elastic phase at the expense of the viscous one, which was verified by the increase in the maximum force and total energy. Chlorella and microchlorella had a similar effect on the reference bitumen as observed by their similar maximum force and total energy values. In contrast, the impact of chlorella was more obvious for the short-term aged samples in comparison with the microchlorella-modified binders. As expected, for both unmodified and algae-modified bitumen, ageing caused a significant increase in the maximum force and total energy. This is in agreement with the results of previous research based on powder-biomodified bitumen [25].

Table 5.

Force ductility results of unaged blends.

Table 6.

Force ductility results of TFOT-aged blends.

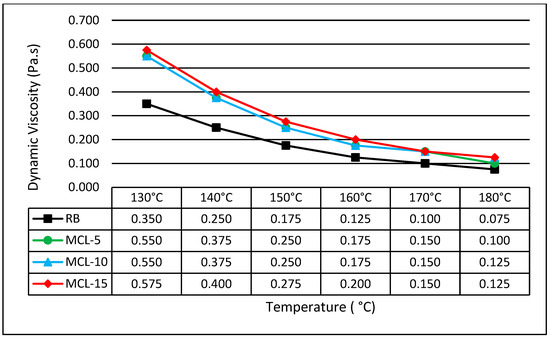

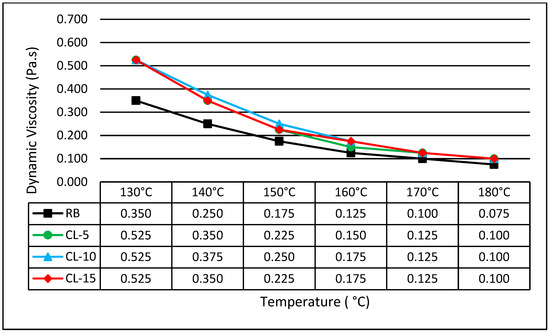

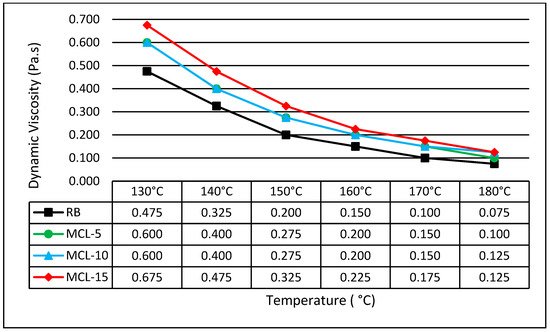

3.5. Dynamic Viscosity Test

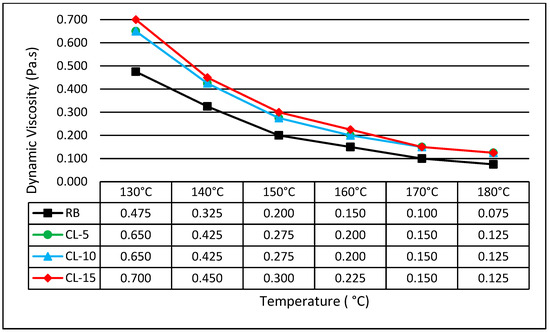

The dynamic viscosity of the reference and algae-modified blends was determined in accordance with EN 13302 using a Brookfield viscometer with a No.27 rotating spindle at 20 rpm [21]. The testing temperature ranged from 130 to 180 °C in steps of 10 °C in order to cover all bitumen pumping and use-phase temperatures. Figure 7, Figure 8, Figure 9 and Figure 10 suggest that the addition of microchlorella and chlorella raised the viscosity of both the unaged and short-term aged bitumen for all examined temperatures. As the temperature increased, the differences between the reference bitumen and the bio-modified blends became less prominent. Significant differences in the dynamic viscosity values were observed between 130 °C and 150 °C. The results are in agreement with the literature which suggests that solid-phase modifiers tend to increase the viscosity [26,27].

Figure 7.

Dynamic viscosity of MCL-modified unaged blends.

Figure 8.

Dynamic viscosity of CL-modified unaged blends.

Figure 9.

Dynamic viscosity of MCL-modified TFOT-aged blends.

Figure 10.

Dynamic viscosity of CL-modified TFOT-aged blends.

3.6. Mixing Temperatures

The mixing temperature is defined as the optimal temperature of bitumen during its mixing process with aggregates [28]. An increment in the temperature of bitumen leads to a drop in its viscosity and vice versa. Excessively high viscosity values will not allow the aggregates to be covered uniformly by the bitumen, whereas excessively low viscosity values will result in the formation of an excessively thin film of bitumen on the surface of the aggregates due to bitumen draindown. The mixing temperature can be determined as the temperature at which the viscosity of bitumen is equal to 0.2 Pa·s [28]. The exact mixing temperature of each type of bitumen was calculated via the non-linear, exponential regression of the dynamic viscosity-temperature scatter plot. The specific Tmixing values are displayed in Table 7.

Table 7.

Mixing temperature of reference bitumen and algae-modified blends.

It can be observed that increasing the algae content by weight of bitumen led to an increase in the necessary mixing temperature. The most noteworthy change in the mixing temperature per step of added algae (chlorella or microchlorella) was noticed when 5% of bio-modifier was incorporated into the bitumen for both types of algae (approximately between 8 and 13° C depending on the type of algae). Above this level of content, the mixing temperature step increment was minor (up to 4 °C). For both algae-modified blends, it was seen that the mixing temperatures reached their peaks when 15% of bio-modifier was mixed into the bitumen (163 and 158 °C for microchlorella and chlorella blends, respectively). The above results verify that the mixing temperature chosen for the mixing protocol of bitumen with the algae was correct (160 °C).

3.7. Activation Energy

The activation energy is the energy barrier that the molecules of bitumen need to overcome to start moving and thus for the bitumen to start flowing [29]. In order to further investigate the rheological properties of the blends, the activation energy was calculated according to the Arrhenius equation (Equation (1)) [30,31]:

where n is the viscosity (Pa·s), Ea is the activation energy (J·mol−1), T is the temperature (Kelvin), R is the universal gas constant (R = 8.314 J·mol−1·K−1) and A is a pre-exponential factor. The Arrhenius equation can be transformed into Equation (2) as follows:

Graphically, the activation energy can be calculated by multiplying the slope of the ln(n) versus 1/T plot with the universal gas constant R. The slope of this graph is directly proportional to the temperature sensitivity of bitumen as explained below. It can be noticed that the addition of algae caused an increase in the activation energy of the bitumen before applying the TFOT-ageing protocol (Table 8). However, the opposite phenomenon was displayed after ageing the samples. Despite the fact that almost all unaged algae-modified blends were characterized by higher activation energy values than the reference bitumen, the opposite trend was observed for the short-term aged samples. This trend was more prominent for the chlorella-modified blends. As expected, the activation energy displayed an increase after short-term ageing for all blends, except for CL-5 and CL-10 whose values were almost identical to those of their unaged counterparts. This is expected as ageing increases the polarity of bitumen compounds and consequently the activation energy [32]. According to the literature, a higher activation energy value is linked to an increased sensitivity to temperature changes [33,34,35]. Specifically, the lowest temperature susceptibility was displayed by MCL-10 at both ageing states (45.84 and 48.33 kJ/mol, respectively), indicating that the performance of this blend was the least temperature-dependent. Consequently, ageing made the samples more sensitive to temperature changes. It can be summarized that the ageing protocol had a much smaller impact on the bio-modified bitumen than it did on the reference bitumen in regard to their respective temperature susceptibilities as demonstrated by the lower activation energies of the bio-modified blends compared to the reference bitumen after ageing. Overall, these findings underscore the diverse thermal stabilities of the bitumen blends and emphasize the importance of considering activation energy changes during aging processes for a comprehensive understanding of their performance characteristics from a thermodynamical point of view.

Table 8.

Activation energy of unaged and TFOT-aged blends.

3.8. VTS Index

Viscosity is a temperature-dependent property, especially for viscoelastic materials such as bitumen. To establish a relation between the dynamic viscosity of bitumen and the temperature, the Viscosity Temperature Susceptibility Index (VTS index) was calculated for all unaged and short-term aged blends (Equation (3)) [36]:

where T1 and T2 are the two temperatures (in Celsius) from which the VTS index is calculated, and n1 and n2 are the dynamic viscosities at the respective temperatures (cPs). The VTS index can be calculated for any pair of temperature values. Consequently, the chosen temperatures were 130 and 180 °C in order to cover all pumping and use-phase temperatures. Generally, a greater VTS index suggests more temperature-dependent behavior and thus higher temperature sensitivity. The analytical results for the unaged and short-term aged samples are presented in Table 9. The Viscosity Temperature Susceptibility Index (VTS index) values presented in Table 9 provide crucial insights into the temperature-dependent viscosity characteristics of the examined bitumen blends. In its unaged state, MCL-10 exhibited the lowest VTS index at 0.822, indicating the comparatively lower sensitivity of the viscosity to temperature changes versus other blends and confirming the relative results obtained from the calculation of the activation energies. Notably, even after TFOT ageing, MCL-10 maintained a consistently lower VTS Index of 0.864, signifying sustained resistance to viscosity alterations. On the other hand, RB demonstrated a notable increase in the VTS index from 0.938 to 1.094 after short term ageing, suggesting enhanced temperature-dependent behavior and heightened susceptibility to viscosity changes. Among the chlorella-modified blends, a consistent VTS index between their unaged and aged states was showcased, emphasizing their stable viscosity performance across temperature variations.

Table 9.

VTS index values of unaged and TFOT-aged blends.

3.9. Statistical Analysis

A statistical analysis was conducted to indentify any correlations between the various results of the dynamic viscosity test by calculating the Pearson Correlation Coefficient and the R2 values for every set of Tmixing, Ea, and VTS index results. Smn is the sample covariance of Xm and Xn (Equation (4)). As demonstrated in Table 10 and Table 11, a strong linear correlation between the VTS index and Ea was displayed. Specifically, the PCC and R2 values between Ea and the VTS index were 0.85 and 0.72, respectively. The significance of this correlation was further validated by the p-value which was equal to 0.0001 and thus much lower than the threshold level of 0.05 based on a confidence level of 95% (Table 12). The results of the above statistical analysis verify the credibility of Ea and the VTS index to characterize the temperature sensitivity of not only unmodified asphalt binders, but also bio-modified ones.

Table 10.

PCC values of reference and bio-modified bitumen.

Table 11.

R2 values of reference and bio-modified bitumen.

Table 12.

p-values of reference and bio-modified bitumen.

3.10. Storage Stability Test

The storage stability test was carried out in accordance with EN 13399 for the unaged algae-modified blends [37]. The test evaluates the tendency of modified bitumen to present segregation during storage for extended periods of time at elevated temperatures. It can be noticed that increasing contents of both microchlorella and chlorella led to larger softening point differences between the top and bottom parts (Table 13). Although smaller particle sizes allow better mixing and, consequently, dispersion capabilities, chlorella presented less separation than microchlorella. This could be attributed to the different densities of the two modifiers. If chlorella presented lower density and bitumen absorption ability than microchlorella, the buoyancy forces could potentially offset the gravity forces that pull the particles downwards, thus limiting the separation. Nevertheless, both bio-modifiers caused significant segregation when incorporated at 10% by weight of bitumen or more, as observed by the rapid increase in ΔT. Consequently, the replacement content of 5% is advised as far as storage stability properties are concerned.

Table 13.

Storage stability results of algae-modified bitumen.

4. Conclusions

- Both types of algae had a stiffening effect on the original 70/100 bitumen as noticed by the decline inthe penetration values and the increase in the softening point.

- Neither bio-modifier had a noticeable impact on the elasticity of the bitumen as all blends had elastic recovery of up to 10%.

- The addition of algae in the bitumen reinforced its elastic phase. The increment in both the maximum force and deformation energy indicated a stiffening effect. This was even more prominent for the short-term aged samples.

- Increasing contents of algae led to increasing dynamic viscosity values and mixing temperatures.

- Ageing increased the temperature sensitivity of bitumen as demonstrated by the activation energy and VTS index results.

- Ageing had a much smaller impact on the temperature sensitivity of bio-modified blends than it did on the reference bitumen.

- A strong statistical correlation was achieved between the activation energy and the VTS Index. These two values could be utilized to further characterize the temperature sensitivity of bio-based bitumen.

- Further physicochemical and rheological investigation is required to thoroughly examine the effect of algae on bitumen before and after short-term and long-term ageing.

Author Contributions

Conceptualization, S.K. and E.M.; methodology, E.M., S.K. and A.K. (Avraam Konstantinidis); software, S.K.; validation, E.M.; formal analysis, E.M.; investigation, S.K.; resources, E.M.; data curation, C.K. and A.K. (Artemis Kalapouti); writing—original draft preparation, S.K.; writing—review and editing, E.M.; visualization, E.M.; supervision, E.M. and S.K.; project administration, E.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data of this research are available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Metwally, M. Development of Non-Petroleum Binders Derived from Fast Pyrolysis Bio-Oils for Use in Flexible Pavement; Iowa State University: Ames, IA, USA, 2010. [Google Scholar]

- Jiménez del Barco Carrión, A.; Lo Presti, D.; Pouget, S.; Chailleux, E.; Airey, G.D. Toward Non-Petroleum-Derived Asphalt Mixes: Using Biobinders for High-Modulus Asphalt Mixes with High Reclaimed Asphalt Content. 2017. Available online: https://iris.unipa.it/handle/10447/604116 (accessed on 11 January 2024).

- Chailleux, E.; Audo, M.; Bujoli, B.; Queffelec, C. Alternative Binder from Microalgae: Algoroute Project. 2012. Available online: https://hal.science/hal-00851063/ (accessed on 11 January 2024).

- Raouf, M.A.; Williams, C.R. General Rheological Properties of Fractionated Switchgrass Bio-Oil as a Pavement Material. Road Mater. Pavement Des. 2010, 11, 325–353. [Google Scholar] [CrossRef]

- Queffelec, C.; Chailleux, E.; Borghol, I.; Bujoli, B.; Laurenti, D.; Geantet, C.; Guilhaume, N.; Lombard, C. Hydrothermal Conversion of Micro-Algae As New Biomaterials for Pavement. 2019. Available online: https://dc.engconfintl.org/pyroliq_2019/13/ (accessed on 11 January 2024).

- Escobar-Medina, F.J.; Rivera-Armenta, J.L.; Hernández-Zamora, G.; Salazar-Cruz, B.A.; Zapién-Castillo, S.; Flores-Hernández, C.G. Sargassum-Modified Asphalt: Effect of Particle Size on Its Physicochemical, Rheological, and Morphological Properties. Sustain. Sci. Pract. Policy 2021, 13, 11734. [Google Scholar] [CrossRef]

- Salazar-Cruz, B.A.; Zapien-Castillo, S.; Hernández-Zamora, G.; Rivera-Armenta, J.L. Investigation of the performance of asphalt binder modified by sargassum. Constr. Build. Mater. 2021, 271, 121876. [Google Scholar] [CrossRef]

- Dhasmana, H.; Ozer, H.; Al-Qadi, I.L.; Zhang, Y.; Schideman, L.; Sharma, B.K.; Chen, W.T.; Minarick, M.J.; Zhang, P. Rheological and Chemical Characterization of Biobinders from Different Biomass Resources. Transp. Res. Rec. 2015, 2505, 121–129. [Google Scholar] [CrossRef]

- Li, J.; Zhang, F.; Muhammad, Y.; Liu, Y.; Wei, Y.; Chen, H. Fabrication and properties of wide temperature domain pavement seaweed modified bio-bitumen. Constr. Build. Mater. 2019, 227, 117079. [Google Scholar] [CrossRef]

- Chen, W.; Chen, S.; Zheng, C. Analysis of micromechanical properties of algae bio-based bio-asphalt-mineral interface based on molecular simulation technology. Constr. Build. Mater. 2021, 306, 124888. [Google Scholar] [CrossRef]

- Cardenas Velandia, L.C.; Fontaine, A.E.; Loquet, D.; Checa, R.; Lorentz, C.; Bujoli, B.; Guilhaume, N.; Geantet, C.; Chailleux, E.; Queffélec, C.; et al. Catalytic hydrothermal conversion of algal residue to bio-bitumen. J. Clean. Prod. 2021, 322, 129024. [Google Scholar] [CrossRef]

- Audo, M.; Paraschiv, M.; Queffélec, C.; Louvet, I.; Hémez, J.; Fayon, F.; Lépine, O.; Legrand, J.; Tazerout, M.; Chailleux, E.; et al. Subcritical Hydrothermal Liquefaction of Microalgae Residues as a Green Route to Alternative Road Binders. ACS Sustain. Chem. Eng. 2015, 3, 583–590. [Google Scholar] [CrossRef]

- Rolland, A.; Sarda, A.; Colomines, G.; Chailleux, E.; Leroy, E. Kinetic of biobased bitumen synthesis from microalgae biomass by hydrothermal liquefaction. In Proceedings of the PYROLIQ 2019: Pyrolysis and Liquefaction of Biomass and Wastes, Cork, Republic of Ireland, 16–21 June 2019. [Google Scholar]

- Borghol, I.; Chailleux, E.; Bujoli, B.; Queffélec, C.; Legrand, J.; Drouin, D.; Lombard, C. Hydrothermal liquefaction of microalgae to produce a bio-binder: Feedstock type influence. In Proceedings of the International Society for Asphalt Pavements (ISAP), Fortaleza, Brazil, 19–22 June 2018. [Google Scholar]

- Herráiz, T.R.; Herráiz, J.I.R.; Domingo, L.M.; Domingo, F.C. Posidonia oceanica used as a new natural fibre to enhance the performance of asphalt mixtures. Constr. Build. Mater. 2016, 102, 601–612. [Google Scholar] [CrossRef]

- EN 1426; Bitumen and Bituminous Binders—Determination of Needle Penetration. European Committee for Standardization: Brussels, Belgium, 2015.

- EN 1427; Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method. European Committee for Standardization: Brussels, Belgium, 2015.

- EN 13398; Bitumen and Bituminous Binders—Determination of the Elastic Recovery of Modified Bitumen. European Committee for Standardization: Brussels, Belgium, 2017.

- EN 13589; Bitumen and Bituminous Binders—Determination of the Tensile Properties of Modified Bitumen by the Force Ductility Method. European Committee for Standardization: Brussels, Belgium, 2008.

- EN 13703; Bitumen and Bituminous Binders—Determination of Deformation Energy. European Committee for Standardization: Brussels, Belgium, 2004.

- EN 13302; Bitumen and Bituminous Binders—Determination of Dynamic Viscosity of Bituminous Binder Using a Rotating Spindle Apparatus. European Committee for Standardization: Brussels, Belgium, 2010.

- Elkashef, M.; Williams, R.C.; Cochran, E. Thermal stability and evolved gas analysis of rejuvenated reclaimed asphalt pavement (RAP) bitumen using thermogravimetric analysis–Fourier transform infrared (TG–FTIR). J. Therm. Anal. Calorim. 2018, 131, 865–871. [Google Scholar] [CrossRef]

- Chen, K.W.; Hu, T.H.; Perng, Y.S.; Chen, C.S. Effect of Carbon Ash Content on the Thermal and Combustion Properties of Waste Wood Particle/Recycled Polypropylene Composites. Proc. MATEC Web Conf. 2016, 67, 06069. [Google Scholar] [CrossRef]

- EN 12591; Bitumen and Bituminous Binders—Specifications for Paving Grade Bitumens. European Committee for Standardization: Brussels, Belgium, 2009.

- Kalampokis, S.; Papamoschou, M.; Kalama, D.M.; Pappa, C.P.; Manthos, E.; Triantafyllidis, K.S. Investigation of the Characteristic Properties of Lignin-Modified Bitumen. CivilEng 2022, 3, 734–747. [Google Scholar] [CrossRef]

- Xue, Y.; Wu, S.; Cai, J.; Zhou, M.; Zha, J. Effects of two biomass ashes on asphalt binder: Dynamic shear rheological characteristic analysis. Constr. Build. Mater. 2014, 56, 7–15. [Google Scholar] [CrossRef]

- Lv, S.; Hu, L.; Xia, C.; Cabrera, M.; Guo, Y.; Liu, C.; You, L. Recycling fish scale powder in improving the performance of asphalt: A sustainable utilization of fish scale waste in asphalt. J. Clean. Prod. 2021, 288, 125682. [Google Scholar] [CrossRef]

- Read, J.; Whiteoak, D. The Shell Bitumen Handbook, 5th ed.; Thomas Telford Publ.: London, UK, 2003; pp. 192–193. [Google Scholar]

- Notani, M.A.; Arabzadeh, A.; Satvati, S.; Tarighati Tabesh, M.; Ghafari Hashjin, N.; Estakhri, S.; Alizadeh, M. Investigating the high-temperature performance and activation energy of carbon black-modified asphalt binder. SN Appl. Sci. 2020, 2, 303. [Google Scholar] [CrossRef]

- Ward, I.M.; Hadley, D.W. An Introduction to the Mechanical Properties of Solid Polymers; John Wiley and Sons: New York, NY, USA, 1993. [Google Scholar]

- Painter, P.C.; Coleman, M.M. Fundamentals of Polymer Science—An Introductory Text; Technomic Publishing Co., Inc.: Lancaster, PA, USA, 1997. [Google Scholar]

- Hosseinnezhad, S.; Hung, A.; Mousavi, M.; Sharma, B.; Fini, E. Resistance Mechanisms of Biomodified Binders against Ultraviolet Exposure. ACS Sustain. Chem. Eng. 2020, 8, 2390–2398. [Google Scholar] [CrossRef]

- Salomon, D.; Zhai, H. Asphalt binder flow activation energy and its significance for compaction effort. In Proceedings of the 3rd Euroasphalt & Eurobitume Congress, Vienna, Austria, 12–14 May 2004. [Google Scholar]

- Mo, L.; Li, X.; Fang, X.; Huurman, M.; Wu, S. Laboratory investigation of compaction characteristics and performance of warm mix asphalt containing chemical additives. Constr. Build. Mater. 2012, 37, 239–247. [Google Scholar] [CrossRef]

- García-Morales, M.; Partal, P.; Navarro, F.J.; Martínez-Boza, F.; Gallegos, C.; González, N.; González, O.; Muñoz, M.E. Viscous properties and microstructure of recycled eva modified bitumen. Fuel 2004, 83, 31–38. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, X.; Wang, W.; Wang, H.; Zheng, K. Laboratory Evaluation of Rheological Properties of Asphalt Binder Modified by Nano-TiO2/CaCO3. Adv. Mater. Sci. Eng. 2021, 2021, 5522025. [Google Scholar] [CrossRef]

- EN 13399; Bitumen and Bituminous Binders—Determination of Storage Stability of Modified Bitumen. European Committee for Standardization: Brussels, Belgium, 2017.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).