Decentralized Biogas Production in Urban Areas: Studying the Feasibility of Using High-Efficiency Engines

Abstract

:1. Introduction

2. Materials and Methods

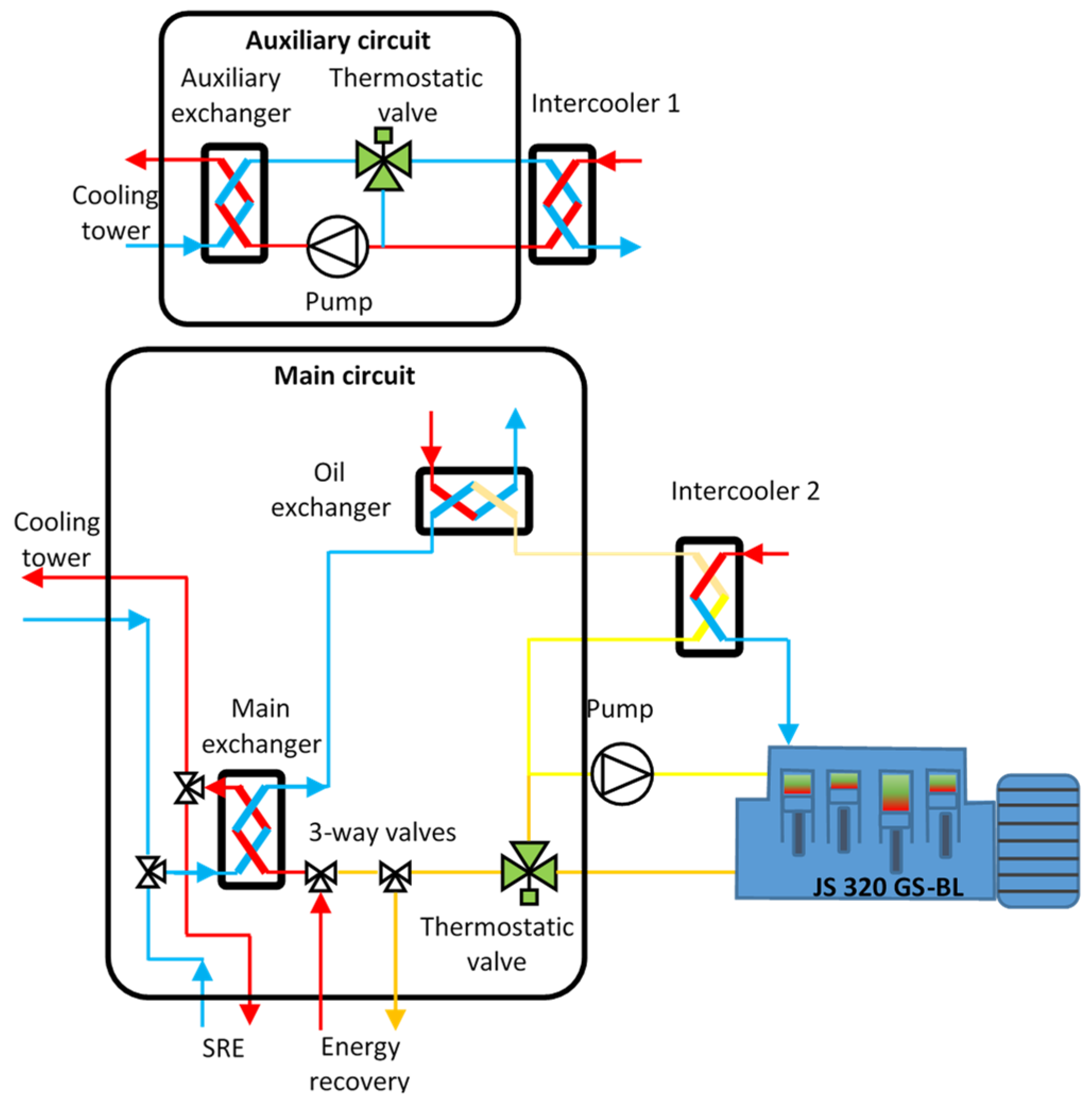

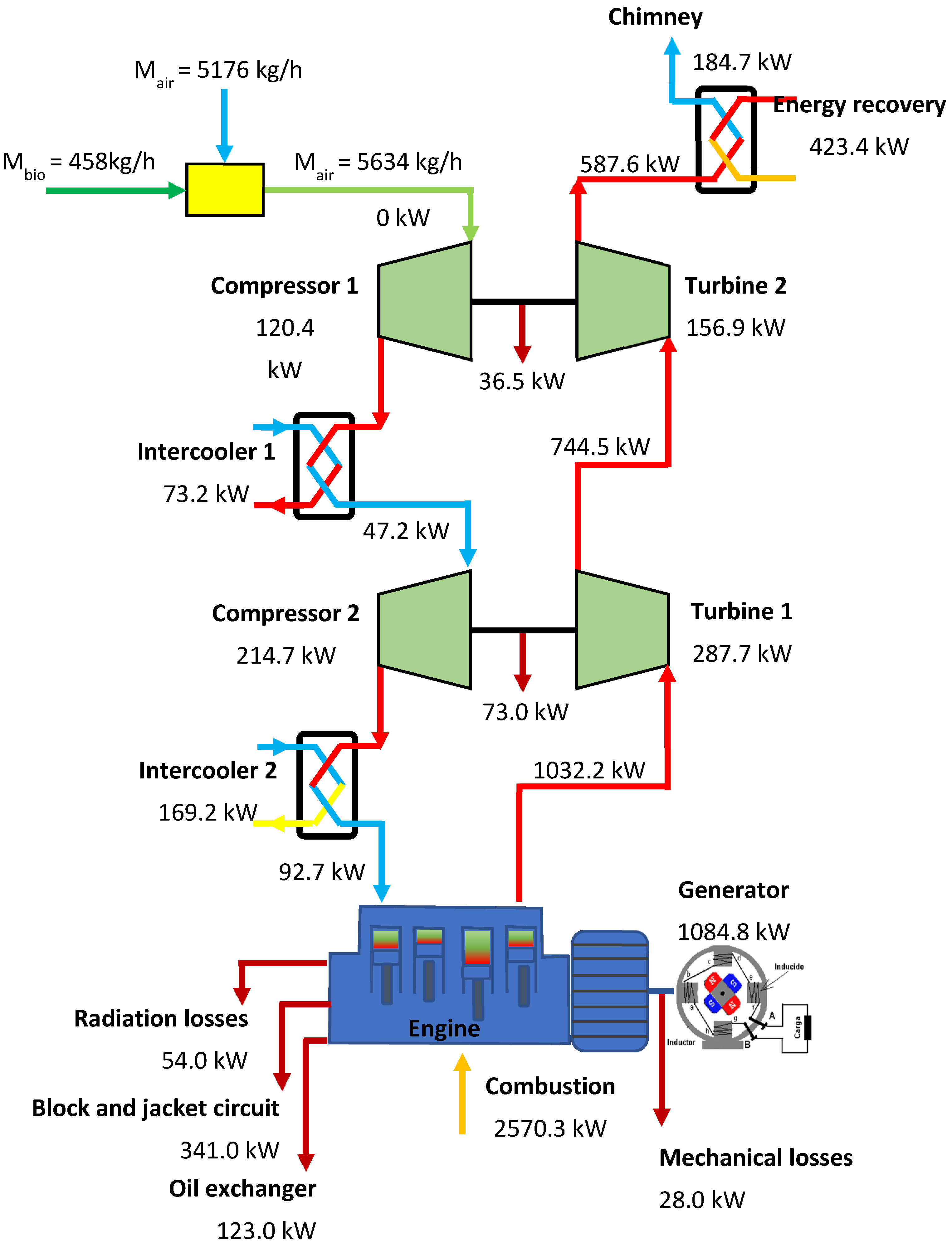

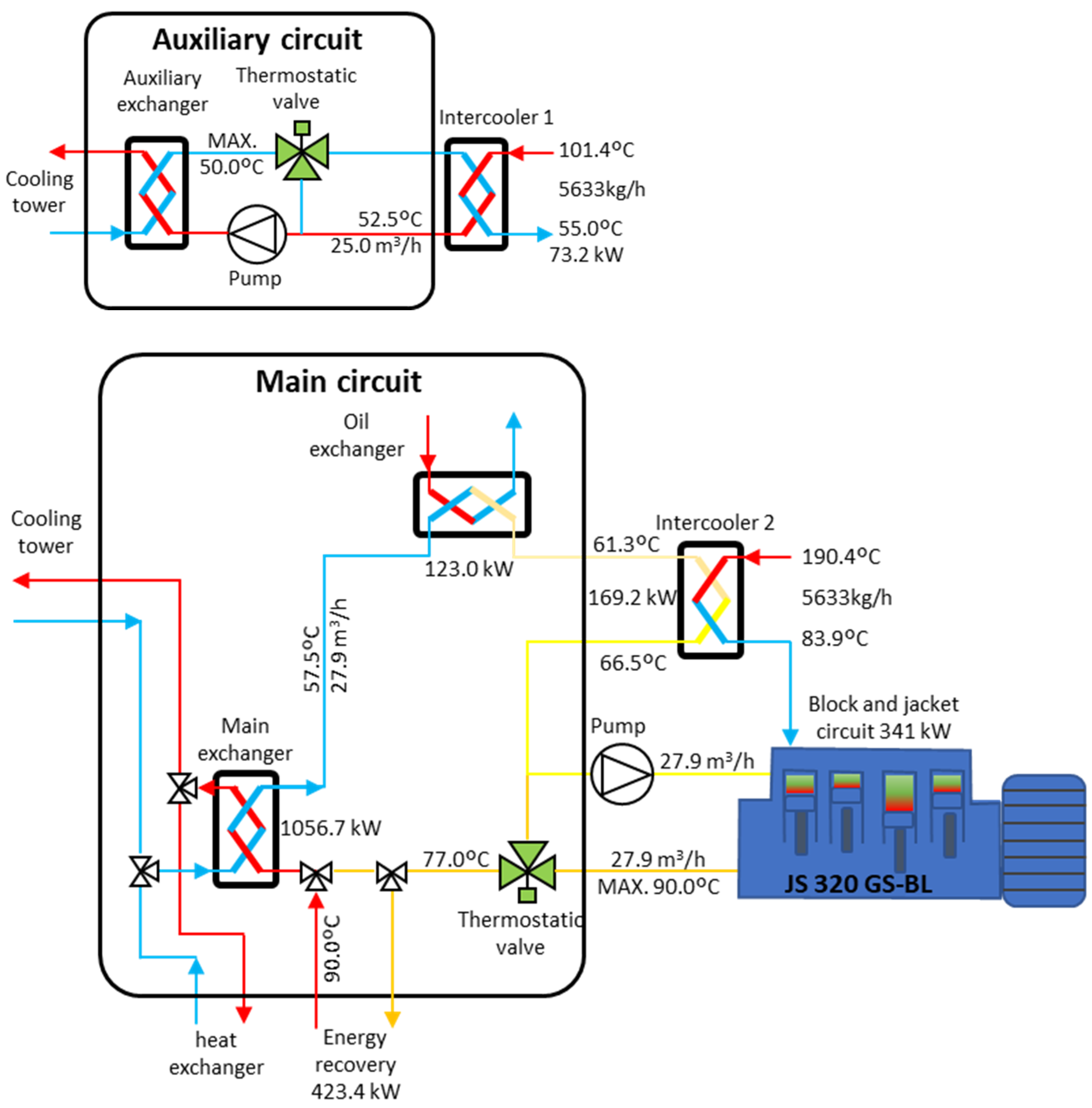

2.1. Engine Description

2.2. Engine Performance Equations

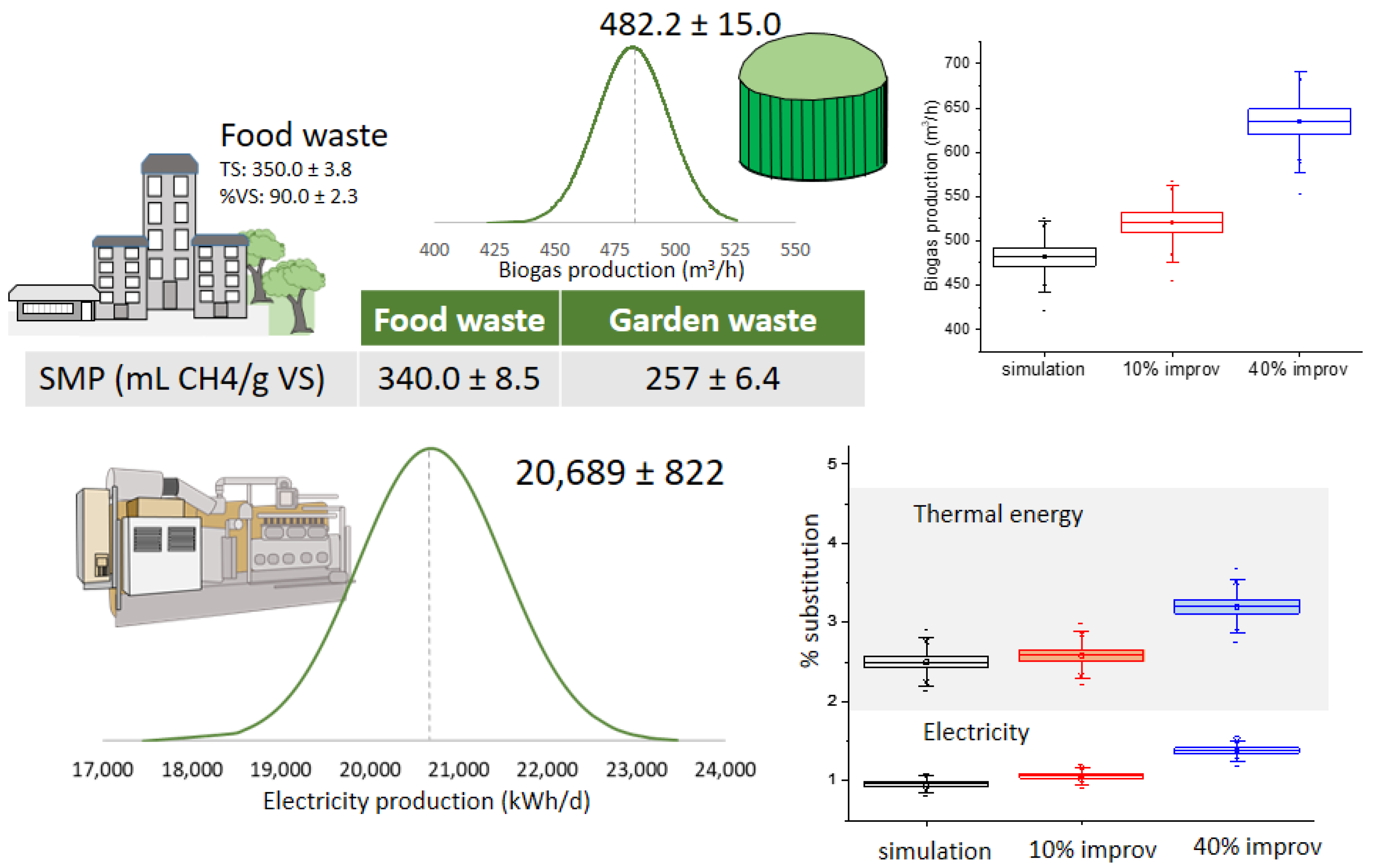

2.3. Methodology for Evaluating Decentralized Biogas Production in Mid-Size Communities

3. Results

3.1. Analysis of Engine Performance

3.2. Technical Feasibility of Decentralized Configuration

3.3. A Practical Solution Is Necessary to Finally Dispose of the Digestate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gadaleta, G.; De Gisi, S.; Notarnicola, M. Feasibility Analysis on the Adoption of Decentralized Anaerobic Co-Digestion for the Treatment of Municipal Organic Waste with Energy Recovery in Urban Districts of Metropolitan Areas. Int. J. Environ. Res. Public Health 2021, 18, 1820. [Google Scholar] [CrossRef]

- Nenciu, F.; Stanciulescu, I.; Vlad, H.; Gabur, A.; Turcu, O.L.; Apostol, T.; Vladut, V.N.; Cocarta, D.M.; Stan, C. Decentralized Processing Performance of Fruit and Vegetable Waste Discarded from Retail, Using an Automated Thermophilic Composting Technology. Sustainability 2022, 14, 2835. [Google Scholar] [CrossRef]

- González, R.; Hernández, J.E.; Gómez, X.; Smith, R.; González Arias, J.; Martínez, E.J.; Blanco, D. Performance evaluation of a small-scale digester for achieving decentralised management of waste. Waste Manag. 2020, 118, 99–109. [Google Scholar] [CrossRef] [PubMed]

- Wang, J. Decentralized Biogas Technology of Anaerobic Digestion and Farm Ecosystem: Opportunities and Challenges. Front. Energy Res. 2014, 2, 10. [Google Scholar] [CrossRef]

- Voegeli, Y.; Zurbrügg, C. Decentralised Anaerobic Digestion of Kitchen and Market Waste in Developing Countries—‘State of the Art’ in South India. In Proceedings of the Second International Symposium on Energy from Biomass and Waste, Venice, Italy, 17–20 November 2008. [Google Scholar]

- Raha, D.; Mahanta, P.; Clarke, M.L. The implementation of decentralised biogas plants in Assam, NE India: The impact and effectiveness of the National Biogas and Manure Management Programme. Energy Policy 2014, 68, 80–91. [Google Scholar] [CrossRef]

- Luo, T.; Khoshnevisan, B.; Huang, R.; Chen, Q.; Mei, Z.; Pan, J.; Liu, H. Analysis of revolution in decentralized biogas facilities caused by transition in Chinese rural areas. Renew. Sustain. Energy Rev. 2020, 133, 110133. [Google Scholar] [CrossRef]

- Samer, M.; Abdelaziz, S.; Refai, M.; Abdelsalam, E. Techno-economic assessment of dry fermentation in household biogas units through co-digestion of manure and agricultural crop residues in Egypt. Renew. Energy 2020, 149, 226–234. [Google Scholar] [CrossRef]

- Bruun, S.; Jensen, L.S.; Khanh Vu, V.T.; Sommer, S. Small-scale household biogas digesters: An option for global warming mitigation or a potential climate bomb? Renew. Sustain. Energy Rev. 2014, 33, 736–741. [Google Scholar] [CrossRef]

- Luo, T.; Zhu, N.; Shen, F.; Long, E.; Long, Y.; Chen, X.; Mei, Z. A Case Study Assessment of the Suitability of Small-Scale Biogas Plants to the Dispersed Agricultural Structure of China. Waste Biomass Valorization 2016, 7, 1131–1139. [Google Scholar] [CrossRef]

- Mench, J.A. Farm animal welfare in the U.S.A.: Farming practices, research, education, regulation, and assurance programs. Appl. Anim. Behav. Sci. 2008, 113, 298–312. [Google Scholar] [CrossRef]

- Hötzel, M.J. Improving farm animal welfare: Is evolution or revolution needed in production systems? In Dilemmas in Animal Welfare; CABI: Wallingford UK, 2023; pp. 67–84. [Google Scholar] [CrossRef]

- Wilkinson, K.G. A comparison of the drivers influencing adoption of on-farm anaerobic digestion in Germany and Australia. Biomass Bioenergy 2011, 35, 1613–1622. [Google Scholar] [CrossRef]

- O’Connor, S.; Ehimen, E.; Pillai, S.C.; Power, N.; Lyons, G.A.; Bartlett, J. An Investigation of the Potential Adoption of Anaerobic Digestion for Energy Production in Irish Farms. Environments 2021, 8, 8. [Google Scholar] [CrossRef]

- Velásquez Piñas, J.A.; Venturini, O.J.; Silva Lora, E.E.; del Olmo, O.A.; Calle Roalcaba, O.D. An economic holistic feasibility assessment of centralized and decentralized biogas plants with mono-digestion and co-digestion systems. Renew. Energy 2019, 139, 40–51. [Google Scholar] [CrossRef]

- González, R.; Blanco, D.; Cascallana, J.G.; Carrillo-Peña, D.; Gómez, X. Anaerobic Co-Digestion of Sheep Manure and Waste from a Potato Processing Factory: Techno-Economic Analysis. Fermentation 2021, 7, 235. [Google Scholar] [CrossRef]

- Imeni, S.M.; Puy, N.; Ovejero, J.; Busquets, A.M.; Bartroli, J.; Pelaz, L.; Ponsá, S.; Colón, J. Techno-Economic Assessment of Anaerobic Co-digestion of Cattle Manure and Wheat Straw (Raw and Pre-treated) at Small to Medium Dairy Cattle Farms. Waste Biomass Valorization 2020, 11, 4035–4051. [Google Scholar] [CrossRef]

- Fuldauer, L.I.; Parker, B.M.; Yaman, R.; Borrion, A. Managing anaerobic digestate from food waste in the urban environment: Evaluating the feasibility from an interdisciplinary perspective. J. Clean. Prod. 2018, 185, 929–940. [Google Scholar] [CrossRef]

- Babbitt, C.W. The role of clean technology research in creating sustainable urban food waste solutions. Clean Technol. Environ. Policy 2020, 22, 1–4. [Google Scholar] [CrossRef]

- Zhang, J.; Gu, D.; Chen, J.; He, Y.; Dai, Y.; Loh, K.-C.; Tong, Y.W. Assessment and optimization of a decentralized food-waste-to-energy system with anaerobic digestion and CHP for energy utilization. Energy Convers. Manag. 2021, 228, 113654. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; González, R.; Gómez, X. Is Decentralized Anaerobic Digestion a Solution? Analyzing Biogas Production and Residential Energy Demand. Eng 2022, 3, 662–676. [Google Scholar] [CrossRef]

- Nguyen, H.H.; Heaven, S.; Banks, C. Energy potential from the anaerobic digestion of food waste in municipal solid waste stream of urban areas in Vietnam. Int. J. Energy Environ. Eng. 2014, 5, 365–374. [Google Scholar] [CrossRef]

- Miller, K.E.; Herman, T.; Philipinanto, D.A.; Davis, S.C. Anaerobic Digestion of Food Waste, Brewery Waste, and Agricultural Residues in an Off-Grid Continuous Reactor. Sustainability 2021, 13, 6509. [Google Scholar] [CrossRef]

- Win, S.S.; Hegde, S.; Chen, R.B.; Trabold, T.A. Feasibility Assessment of Low-Volume Anaerobic Digestion Systems for Institutional Food Waste Producers. In Energy Sustainability; American Society of Mechanical Engineers: New York, NY, USA, 2017; Volume 57595, p. V001T02A003. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Carrillo-Peña, D.; Morán, A.; Smith, R.; Gómez, X. Energy Balance of Turbocharged Engines Operating in a WWTP with Thermal Hydrolysis. Co-Digestion Provides the Full Plant Energy Demand. Appl. Sci. 2021, 11, 11103. [Google Scholar] [CrossRef]

- Jenbacher. Jenbacher Type 3 Gas Engine. Available online: https://www.clarke-energy.com/gas-engines/type-3-gas-engines/ (accessed on 10 January 2023).

- ISO/3046/1; Reciprocating Internal Combustion Engines—Performance—Part 1: Declarations of Power, Fuel and Lubricating Oil Consumptions, and Test Methods—Additional Requirements for Engines for General Use. ISO: Geneva, Switzerland, 2002.

- Jenbacher. Technical Description Genset JGS 320 GS B L. AB Energy 320-18. Available online: https://www.energy-motors.com/sites/default/files/ge_jenbacher_j320.pdf (accessed on 10 January 2023).

- Honeywell: Garret Performance Engine Parts Catalogue, Volume 6. Available online: https://images.carid.com/garrett/items/pdf/garrett-product-catalog.pdf (accessed on 15 January 2023).

- The Engineering Toolbox. Available online: https://www.engineeringtoolbox.com/individual-universal-gas-constant-d_588.html (accessed on 15 January 2023).

- Urieli, I. Specific Heat Capacities of Air. Available online: https://www.ohio.edu/mechanical/thermo/property_tables/air/air_Cp_Cv.html (accessed on 15 January 2023).

- Abu-Nada, E.; Al-Hinti, I.; Al-Sarkhi, A.; Akash, B. Thermodynamic modeling of spark-ignition engine: Effect of temperature dependent specific heats. Int. Commun. Heat Mass Transf. 2006, 33, 1264–1272. [Google Scholar] [CrossRef]

- UNEP: Annual per Capita Household Food Waste of Selected Countries Worldwide as of 2020. Available online: https://www.statista.com/statistics/933059/per-capita-food-waste-of-selected-countries/ (accessed on 10 February 2023).

- Manu, M.K.; Kumar, R.; Garg, A. Physical and chemical characterization of yard waste. Int. J. Appl. Eng. Res. 2013, 8, 1891–1896. [Google Scholar]

- Redondas, V.; Moran, A.; Martínez, J.E.; Fierro, J.; Gomez, X. Effect of methanogenic effluent recycling on continuous H2 production from food waste. Environ. Prog. Sustain. Energy 2015, 34, 227–233. [Google Scholar] [CrossRef]

- Odejobi, O.J.; Ajala, O.O.; Osuolale, F.N. Anaerobic co-digestion of kitchen waste and animal manure: A review of operating parameters, inhibiting factors, and pretreatment with their impact on process performance. Biomass Convers. Biorefinery 2023, 13, 5515–5531. [Google Scholar] [CrossRef]

- Helenas Perin, J.K.; Biesdorf Borth, P.L.; Torrecilhas, A.R.; Santana da Cunha, L.; Kuroda, E.K.; Fernandes, F. Optimization of methane production parameters during anaerobic co-digestion of food waste and garden waste. J. Clean. Prod. 2020, 272, 123130. [Google Scholar] [CrossRef]

- Gómez, X.; Cuetos, M.J.; Tartakovsky, B.; Martínez-Núñez, M.F.; Morán, A. A comparison of analytical techniques for evaluating food waste degradation by anaerobic digestion. Bioprocess Biosyst. Eng. 2010, 33, 427–438. [Google Scholar] [CrossRef]

- González, R.; Rosas, J.G.; Blanco, D.; Smith, R.; Martínez, E.J.; Pastor-Bueis, R.; Gómez, X. Anaerobic digestion of fourth range fruit and vegetable products: Comparison of three different scenarios for its valorisation by life cycle assessment and life cycle costing. Environ. Monit. Assess. 2020, 192, 551. [Google Scholar] [CrossRef]

- Panigrahi, S.; Sharma, H.B.; Dubey, B.K. Overcoming yard waste recalcitrance through four different liquid hot water pretreatment techniques—Structural evolution, biogas production and energy balance. Biomass Bioenergy 2019, 127, 105268. [Google Scholar] [CrossRef]

- Favoino, E.; Giavini, M. Bio-Waste Generation in the EU: Current Capture Levels and Future Potential. Available online: https://zerowasteeurope.eu/wp-content/uploads/2020/07/2020_07_06_bic_zwe_report_bio_waste.pdf (accessed on 10 February 2023).

- Expansion: España—Consumo de Electricidad. Available online: https://datosmacro.expansion.com/energia-y-medio-ambiente/electricidad-consumo/espana (accessed on 10 February 2023).

- IDAE: Consumo Por Usos Del Sector Residencial. Available online: https://informesweb.idae.es/consumo-usos-residencial/informe.php (accessed on 10 February 2023).

- INE: Promedio De Personas En Los Hogares De España En 2020, Según Comunidad Autónoma [Gráfica]. Available online: https://es.statista.com/estadisticas/1013728/promedio-de-personas-en-los-hogares-en-espana-segun-comunidad-autonoma/#:~:text=TamañomediodelhogarsegúnCC.&text=EnelconjuntodeEspaña,2%2C5personasporhogar (accessed on 10 February 2023).

- Otero, M.; Sánchez, M.E.; Gómez, X. Co-firing of coal and manure biomass: A TG–MS approach. Bioresour. Technol. 2011, 102, 8304–8309. [Google Scholar] [CrossRef]

- Freda, C.; Nanna, F.; Villone, A.; Barisano, D.; Brandani, S.; Cornacchia, G. Air gasification of digestate and its co-gasification with residual biomass in a pilot scale rotary kiln. Int. J. Energy Environ. Eng. 2019, 10, 335–346. [Google Scholar] [CrossRef]

- Czekała, W. Solid Fraction of Digestate from Biogas Plant as a Material for Pellets Production. Energies 2021, 14, 5034. [Google Scholar] [CrossRef]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Vijay, V.K. Evaluation of biogas upgrading technologies and future perspectives: A review. Environ. Sci. Pollut. Res. 2019, 26, 11631–11661. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Alarab, S.; Al-Othman, A.; Javed, R.M.N. The operating parameters, structural composition, and fuel sustainability aspects of PEM fuel cells: A mini review. Fuels 2022, 3, 449–474. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Technologies for biogas to electricity conversion. Energy Rep. 2022, 8, 774–786. [Google Scholar] [CrossRef]

- Prioriello, A.; Duranti, L.; Luisetto, I.; Sanna, F.; Larosa, C.; Grilli, M.L.; Di Bartolomeo, E. Structured Catalyst for Indirect Internal Reforming (IIR) of Biogas in Solid Oxide Fuel Cell (SOFC). Catalysts 2023, 13, 1129. [Google Scholar] [CrossRef]

- Available online: https://www.innio.com/es/productos/jenbacher (accessed on 14 August 2023).

- Available online: https://www.idom.com/proyecto/central-electrica-a-partir-de-gas-de-vertedero-de-valdemingomez-19-mw/ (accessed on 14 August 2023).

- Available online: https://ecogen.be/en/projects/ (accessed on 14 August 2023).

- Upadhyay, A.; Kovalev, A.A.; Zhuravleva, E.A.; Kovalev, D.A.; Litti, Y.V.; Masakapalli, S.K.; Pareek, N.; Vivekanand, V. Recent Development in Physical, Chemical, Biological and Hybrid Biogas Upgradation Techniques. Sustainability 2022, 15, 476. [Google Scholar] [CrossRef]

- Secco, C.; Fuziki, M.E.K.; Tusset, A.M.; Lenzi, G.G. Reactive Processes for H2S Removal. Energies 2023, 16, 1759. [Google Scholar] [CrossRef]

- González, R.; Peña, D.C.; Gómez, X. Anaerobic Co-Digestion of Wastes: Reviewing Current Status and Approaches for Enhancing Biogas Production. Appl. Sci. 2022, 12, 8884. [Google Scholar] [CrossRef]

- Tian, H.; Wang, X.; Lim, E.Y.; Lee, J.T.E.; Ee, A.W.L.; Zhang, J.; Tong, Y.W. Life cycle assessment of food waste to energy and resources: Centralized and decentralized anaerobic digestion with different downstream biogas utilization. Renew. Sustain. Energy Rev. 2021, 150, 111489. [Google Scholar] [CrossRef]

- González, R.; García-Cascallana, J.; Gómez, X. Energetic valorization of biogas. A comparison between centralized and decentralized approach. Renew. Energy 2023, 119013. [Google Scholar] [CrossRef]

- Heiman, M. From ‘Not in My Backyard!’ to ‘Not in Anybody’s Backyard!’. J. Am. Plan. Assoc. 1990, 56, 359–362. [Google Scholar] [CrossRef]

- Diario de León: Las Ciudades de Castilla y León Disponen de 22,54 Metros Cuadrados de Zona Verde Por Habitante. Available online: https://ileon.eldiario.es/actualidad/ciudades-castilla-leon-disponen-metros-cuadrados-zona-verde-habitante_1_9449713.html#:~:text=León-ciudad-cuenta-con-el,superficie-urbana-catalogada-como-verde (accessed on 10 May 2023).

- Peelle, E.; Ellis, R. Beyond the not-in-my-backyard impasse. Forum Appl. Res. Publ. Pol. 1987, 2. Available online: https://www.osti.gov/biblio/6055189 (accessed on 10 May 2023).

- Xu, M.; Lin, B. Exploring the “not in my backyard” effect in the construction of waste incineration power plants—Based on a survey in metropolises of China. Environ. Impact Assess. Rev. 2020, 82, 106377. [Google Scholar] [CrossRef]

- Nie, Y.; Zhao, J.; Zhang, Y.; Zhou, J. Risk Evaluation of “Not-In-My-Back-Yard” Conflict Potential in Facilities Group: A Case Study of Chemical Park in Xuwei New District, China. Sustainability 2020, 12, 2723. [Google Scholar] [CrossRef]

- He, L.; Yang, Q.; Liu, X.; Fu, L.; Wang, J. Exploring Factors Influencing Scenarios Evolution of Waste NIMBY Crisis: Analysis of Typical Cases in China. Int. J. Environ. Res. Public Health 2021, 18, 2006. [Google Scholar] [CrossRef]

- Guo, Y.; Ru, P.; Su, J.; Anadon, L.D. Not in my backyard, but not far away from me: Local acceptance of wind power in China. Energy 2015, 82, 722–733. [Google Scholar] [CrossRef]

- Štilić, A.; Puška, A. Integrating Multi-Criteria Decision-Making Methods with Sustainable Engineering: A Comprehensive Review of Current Practices. Eng 2023, 4, 1536–1549. [Google Scholar] [CrossRef]

- Herrmann, C.; Heiermann, M.; Idler, C.; Prochnow, A. Particle Size Reduction during Harvesting of Crop Feedstock for Biogas Production I: Effects on Ensiling Process and Methane Yields. Bioenergy Res. 2012, 5, 926–936. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Barrios, X.G.; Martinez, E.J. Thermal Hydrolysis of Sewage Sludge: A Case Study of a WWTP in Burgos, Spain. Appl. Sci. 2021, 11, 964. [Google Scholar] [CrossRef]

- Zheng, M.; Li, X.; Li, L.; Yang, X.; He, Y. Enhancing anaerobic biogasification of corn stover through wet state NaOH pretreatment. Bioresour. Technol. 2009, 100, 5140–5145. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Kim, J.; Lee, C. Effect of Mild-Temperature Thermo-Alkaline Pretreatment on the Solubilization and Anaerobic Digestion of Spent Coffee Grounds. Energies 2018, 11, 865. [Google Scholar] [CrossRef]

- Amin, F.R.; Khalid, H.; Zhang, H.; Rahman, S.U.; Zhang, R.; Liu, G.; Chen, C. Pretreatment methods of lignocellulosic biomass for anaerobic digestion. AMB Express 2017, 7, 72. [Google Scholar] [CrossRef]

- Zhang, L.; Loh, K.-C.; Zhang, J. Food waste enhanced anaerobic digestion of biologically pretreated yard waste: Analysis of cellulose crystallinity and microbial communities. Waste Manag. 2018, 79, 109–119. [Google Scholar] [CrossRef]

- Morello, R.; Di Capua, F.; Pontoni, L.; Papirio, S.; Spasiano, D.; Fratino, U.; Pirozzi, F.; Esposito, G. Microaerobic Digestion of Low-Biodegradable Sewage Sludge: Effect of Air Dosing in Batch Reactors. Sustainability 2021, 13, 9869. [Google Scholar] [CrossRef]

- Montalvo, S.; Huiliñir, C.; Ojeda, F.; Castillo, A.; Lillo, L.; Guerrero, L. Microaerobic pretreatment of sewage sludge: Effect of air flow rate, pretreatment time and temperature on the aerobic process and methane generation. Int. Biodeterior. Biodegrad. 2016, 110, 1–7. [Google Scholar] [CrossRef]

- León Gómez, J.C.; De León Aldaco, S.E.; Aguayo Alquicira, J. A Review of Hybrid Renewable Energy Systems: Architectures, Battery Systems, and Optimization Techniques. Eng 2023, 4, 1446–1467. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; Cascallana, J.G.; González, R.; Gómez, X. High-Solid Anaerobic Digestion: Reviewing Strategies for Increasing Reactor Performance. Environments 2021, 8, 80. [Google Scholar] [CrossRef]

- Abbassi-Guendouz, A.; Brockmann, D.; Trably, E.; Dumas, C.; Delgenès, J.-P.; Steyer, J.-P.; Escudié, R. Total solids content drives high solid anaerobic digestion via mass transfer limitation. Bioresour. Technol. 2012, 111, 55–61. [Google Scholar] [CrossRef]

- Pastor-Poquet, V.; Papirio, S.; Trably, E.; Rintala, J.; Escudié, R.; Esposito, G. High-solids anaerobic digestion requires a trade-off between total solids, inoculum-to-substrate ratio and ammonia inhibition. Int. J. Environ. Sci. Technol. 2019, 16, 7011–7024. [Google Scholar] [CrossRef]

- Jansson, A.T.; Patinvoh, R.J.; Sárvári Horváth, I.; Taherzadeh, M.J. Dry Anaerobic Digestion of Food and Paper Industry Wastes at Different Solid Contents. Fermentation 2019, 5, 40. [Google Scholar] [CrossRef]

- González, R.; Ellacuriaga, M.; Aguilar-Pesantes, A.; Carrillo-Peña, D.; García-Cascallana, J.; Smith, R.; Gómez, X. Feasibility of Coupling Anaerobic Digestion and Hydrothermal Carbonization: Analyzing Thermal Demand. Appl. Sci. 2021, 11, 11660. [Google Scholar] [CrossRef]

- Casini, D.; Barsali, T.; Rizzo, A.M.; Chiaramonti, D. Production and characterization of co-composted biochar and digestate from biomass anaerobic digestion. Biomass Convers. Biorefinery 2021, 11, 2271–2279. [Google Scholar] [CrossRef]

- Gómez, X.; Diaz, M.C.; Cooper, M.; Blanco, D.; Morán, A.; Snape, C.E. Study of biological stabilization processes of cattle and poultry manure by thermogravimetric analysis and 13C NMR. Chemosphere 2007, 68, 1889–1897. [Google Scholar] [CrossRef] [PubMed]

- Núñez, F.; Pérez, M.; Leon-Fernández, L.F.; García-Morales, J.L.; Fernández-Morales, F.J. Effect of the mixing ratio on the composting of OFMSW digestate: Assessment of compost quality. J. Mater. Cycles Waste Manag. 2022, 24, 1818–1831. [Google Scholar] [CrossRef]

- Alzate, S.; Restrepo-Cuestas, B.; Jaramillo-Duque, Á. Municipal Solid Waste as a Source of Electric Power Generation in Colombia: A Techno-Economic Evaluation under Different Scenarios. Resources 2019, 8, 51. [Google Scholar] [CrossRef]

- Nubi, O.; Morse, S.; Murphy, R.J. Prospective Life Cycle Costing of Electricity Generation from Municipal Solid Waste in Nigeria. Sustainability 2022, 14, 13293. [Google Scholar] [CrossRef]

- Safarian, S.; Unnthorsson, R.; Richter, C. Techno-Economic and Environmental Assessment of Power Supply Chain by Using Waste Biomass Gasification in Iceland. Biophys. Econ. Sustain. 2020, 5, 7. [Google Scholar] [CrossRef]

- Wang, W.; Lee, D.-J. Valorization of anaerobic digestion digestate: A prospect review. Bioresour. Technol. 2021, 323, 124626. [Google Scholar] [CrossRef]

- Cesaro, A. The valorization of the anaerobic digestate from the organic fractions of municipal solid waste: Challenges and perspectives. J. Environ. Manag. 2021, 280, 111742. [Google Scholar] [CrossRef]

- Dębowski, M.; Zieliński, M.; Kisielewska, M.; Kazimierowicz, J.; Dudek, M.; Świca, I.; Rudnicka, A. The Cultivation of Lipid-Rich Microalgae Biomass as Anaerobic Digestate Valorization Technology—A Pilot-Scale Study. Processes 2020, 8, 517. [Google Scholar] [CrossRef]

- Ermis, H.; Güven-Gülhan, Ü.; Çakır, T.; Altınbaş, M. Microalgae growth and diversity in anaerobic digestate compared to synthetic media. Biofuel Res. J. 2022, 9, 1551–1556. [Google Scholar] [CrossRef]

- Pastor-Bueis, R.; Mulas, R.; Gómez, X.; González-Andrés, F. Innovative liquid formulation of digestates for producing a biofertilizer based on Bacillus siamensis: Field testing on sweet pepper. J. Plant Nutr. Soil Sci. 2017, 180, 748–758. [Google Scholar] [CrossRef]

| Parameters of Engine Type J 320 GS-D121 | Value |

|---|---|

| Engine strokes (strokes/cycle) | 4 |

| Total displacement (cm3) | 48,670 |

| Number of cylinders (units) | 20 in V |

| Number of cylinder lines (units) | 2 |

| Angle of the cylinders (°) | 70 |

| B, bore (mm) | 135 |

| S, stroke (mm) | 170 |

| S/B, stroke/bore ratio | 1.26 |

| rC, engine compression ratio (dimensionless) | 11.8 |

| n, engine rotation speed (rpm) | 1500 |

| Average piston speed (m/s) | 8.5 |

| Piston displacement (L) | 2.43 |

| Piston area (cm2) | 143 |

| Combustion chamber volume (cm3) | 225 |

| Combustion chamber/displacement ratio (%) | 6.8 |

| Performance Parameters of Engine Type J 320 GS-D121 | Degree of Loading (%) | ||

|---|---|---|---|

| 100 | 75 | 50 | |

| Minimum LHV 1 of biogas (kWh/m3) | 5 | ||

| 2 CH4 number/minimum CH4 number | 135/100 | ||

| Peng, engine mechanical power (kW) | 1095 | 821 | 548 |

| Electrical power (cos φ = 1) (kW) | 1067 | 798 | 529 |

| MEP, mean effective pressure (kPa) | 1800 | 1350 | 901 |

| Radiation power losses (kW) | 54 | ||

| Mechanical power losses (kW) | 28 | 23 | 19 |

| Power loss of exhaust gases (100 °C) (kW) | 685 | ||

| Power loss of exhaust gases (180 °C) (kW) | 550 | ||

| Power loss of exhaust gases (0 °C) (kW) | 740 | ||

| Exhaust gas temperature (°C) | 490 | ||

| Mair, air mass flow inlet (kg/h) | 5176 | ||

| Meg, exhaust gas mass flow (wet) (kg/h) | 5634 | ||

| Mbio, biogas mass flow (kg/h) | 458 | ||

| ηmec, mechanical efficiency (%) | 41.2 | 40.1 | 38.2 |

| Electrical efficiency (cos φ = 1) (%) | 40.2 | 39 | 36.8 |

| ηe, engine thermal efficiency (%) | 41.3 | ||

| Energy efficiency (%) | 82.5 | ||

| BC, biogas consumption (kW) | 2655 | 2046 | 1436 |

| Min–max biogas pressure range at the biogas inlet train (mbar) | 80–200 | ||

| Main circuit thermal power (kW) | 645 | 519 | 394 |

| Block and jacket circuit power (kW) | 341 | 336 | 296 |

| PINT-2, intercooler 2 power (kW) | 181 | 78 | 5 |

| Oil exchanger power (kW) | 123 | 105 | 93 |

| Auxiliary circuit thermal power (kW) | 77 | 58 | 38 |

| PINT-1, intercooler 1 power (kW) | 77 | 58 | 38 |

| F, ratio fuel/air (%) | 8.8 | ||

| Max. admissible exhaust back pressure after engine (kPa) | 6 | ||

| Max. admissible pressure drop in front of intake-air filter (kPa) | 1 | ||

| Turbocharger Parameters | Value | References |

|---|---|---|

| Maximum temperature of the mixture at second intercooler (°C) | 83.9 | [26] |

| Maximum temperature of mixture at first intercooler (°C) | 55 | [26] |

| ηmec1, ηmec2, mechanical efficiency of turbocharger transmission | 97 | [29] |

| R, universal constant of ideal gas (J/kg K) | 287.05 | [30] |

| γ, adiabatic coefficient of air, mixture and gases (dimensionless) | 1.4 | [31] |

| Parameter | Food Waste | Reference | Garden Waste | References |

|---|---|---|---|---|

| Production (kg/year per capita) | 77 | [33] | 110 1 | |

| TS content (g/kg) | 150 | 610 | [34] | |

| %VS | 90 | [35,36] | 77.5 2 | [34,37] |

| SMP (mL CH4/g VS) | 340 | [38,39] | 257 | [40] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González, R.; García-Cascallana, J.; Gutiérrez-Bravo, J.; Gómez, X. Decentralized Biogas Production in Urban Areas: Studying the Feasibility of Using High-Efficiency Engines. Eng 2023, 4, 2204-2225. https://doi.org/10.3390/eng4030127

González R, García-Cascallana J, Gutiérrez-Bravo J, Gómez X. Decentralized Biogas Production in Urban Areas: Studying the Feasibility of Using High-Efficiency Engines. Eng. 2023; 4(3):2204-2225. https://doi.org/10.3390/eng4030127

Chicago/Turabian StyleGonzález, Rubén, José García-Cascallana, Javier Gutiérrez-Bravo, and Xiomar Gómez. 2023. "Decentralized Biogas Production in Urban Areas: Studying the Feasibility of Using High-Efficiency Engines" Eng 4, no. 3: 2204-2225. https://doi.org/10.3390/eng4030127

APA StyleGonzález, R., García-Cascallana, J., Gutiérrez-Bravo, J., & Gómez, X. (2023). Decentralized Biogas Production in Urban Areas: Studying the Feasibility of Using High-Efficiency Engines. Eng, 4(3), 2204-2225. https://doi.org/10.3390/eng4030127