Abstract

The answer to covering the energy demand of society by increasing the share of renewables must come from the conjunction of several technologies. A preliminary study on the feasibility of anaerobic digestion in residential housing and buildings was carried out, considering a mix of novel and traditional technologies. Different scenarios were evaluated for developed and developing countries, considering small communities and single housing configurations. Anaerobic digestion produces biogas to be used for cooking or heat production, thus aiding in covering the energy demand of residents. There are several aspects still pending a solution regarding medium and small-scale digestion applications under a decentralized waste configuration. The increase in reactor productivity is essential, but social aspects must be considered as well to prevent nuisance caused by offensive odors and legal responsibilities when community digesters create inconvenience to neighbors. Results indicated that using anaerobic digestion to treat residential food and garden waste under a decentralized configuration could scarcely cover 5.8% of the domestic heating demand for highly populated residential urban areas. This value may be increased if assumptions of maximum methane yields are considered, reaching up to 17%. Biological processes may be integrated into a mixed energy production approach, but higher yields are needed to make it realistic. Factors regarding levelized energy production costs are to be carefully considered. Large-scale systems are intrinsically more efficient than small-scale devices, thus making it crucial to establish a critical equilibrium between public acceptance and the scale of technology application.

1. Introduction

The linear economic model is receiving criticism due to the large resource consumption and volume of waste residues generated in a linear production path, with limited possibilities for reintegrating resources into the economic chain. The concept of a circular economy has a core defining element of the “restorative use” of resources. Thus, raw materials should be transformed into valuable products and avoid becoming discarded [1]. However, this concept, which may seem relatively easy to define, and finds a great share of acceptance in public opinion, is difficult to implement in the current production chain and everyday social activities. The concept must confront the limits of reality and thermodynamic laws. Recycling activities inherently increase entropy, resulting in increased energy demand in order to maintain a high quality of resources [2,3]. Therefore, it is relevant to adopt a techno–economic perspective to shed light on the efficient implementation of circular processes in real-world settings [4].

Reduction of waste production, valorization, or reintegration of lower-quality material into the production chain should consider material dispersion, transportation costs, and all the different treatment units involved in recovering valuable components and equipment associated with its transformation [5]. To these constraints, other requisites should also be taken into account; such as religious beliefs, health risks, and social concerns regarding the acceptance of by-products.

Renewable energies will play a significant role in future energy solutions. However, factors such as seasonality, dispersion, and lack of energy storage result in constraints upon guaranteed energy security. The substitution of fossil fuels and mitigation of CO2 emissions are also linked to the circular economy model. The Landfill Directive in 1999 (European Commission, 2008/98/EC) was decisive in optimizing waste management policies by prioritizing waste prevention. Recently, Directive (EU) 2018/851 was conceived to increase synergies between the circular economy and different policies regarding energy, climate, agriculture, industry, and research, to benefits the environment in terms of greenhouse gas emission savings [6,7].

There exists a clear interconnection between different economic activities and several environmental impacts. Environmental impacts, energy solutions, and efficiency maximization are to be considered interrelated when assessing the efficient use of raw materials. Optimizing the use of resources and limiting emissions promote local economies and the decentralized production of consumer goods, together with the decentralization of waste treatment centers. This is the case with decentralized services in urban and residential areas. There exist different alternatives for producing renewable energy, such as wind turbines and solar panels, to produce heat or electricity (solar thermal or solar photovoltaic). Solar panels are experiencing fast growth, thanks to the significant reduction in installation costs and the ease of decentralized operation covering a wide variety of scales [8].

The use of biomass for producing energy is another example of technology adaptation to cover different demands for producing heat and electricity. Large-scale biomass thermal-power units for electricity production are under construction in Spain. This technology is also experiencing a significant expansion worldwide, thanks to its excellent transferability to developing countries [9,10]. Another application of biomass technology is small biomass units for individual family residences, producing heat and hot water. This market has also experienced a great expansion due to the versatility of biomass boilers, but centralized thermal units with higher efficiency dominate electricity production.

Technologies capable of producing energy (heat and electricity) and valorizing waste simultaneously have not experienced the same level of expansion and adaptation to different scales. This is the case with anaerobic digestion. This technology is widely recognized as an environmentally friendly option for converting organic wastes into methane and valuable organic amendments, allowing nutrient recycling in agronomic lands [11,12]. However, the European market is mainly dominated by large-scale centralized units, due to high installation and operating costs and the need for highly skilled personnel to maintain these running units. Other factors limiting the spread of this option are the lower productivity attained at smaller scales, and the limited profits to be made under high-solid configurations [13]. On the contrary, in rural areas worldwide, including in developing countries, the majority of anaerobic digesters treat waste from single households. However, some of these installations experience operating problems and fail to keep operating for long-term [14,15].

Microbial cells are another technology capable of transforming organic materials into valuable products (energy and chemical compounds), but further development at a larger scale has proven impossible. The technology remains at a laboratory scale. It offers promising results that lack applications at an industrial scale due to difficulties in achieving stable performance under real operating conditions [16,17]. Several challenges need to be overcome: biofouling of surfaces, unstable long-term performance, low efficiency, and the high cost of components [18].

The present document examines the feasibility of applying small-scale digestion in the residential sector under different scenarios, considering climatic conditions and different types of residential configurations. The overall scope of the present study is to analyze the capability of digestion technologies to produce energy in a decentralized mode, reducing the demand for fossil fuel energy. Integrating different technologies producing renewable energy must be done by estimating expected production based on lifestyle and assessing climatic effects on technology performance. This study gives a novel approach to the total energy expected from different configurations and scenarios, attempting to foresee constraints and limitations regarding the application of small-scale digestion technology in a variety of residential conditions. Evaluating different scenarios provides a starting point for future research regarding the joint analysis of climatic and socio-economic conditions when transitioning technology implementation from the context of a developed country to a developing country. The aim of this research was to express the energy recovered from household wastes as a percentage of the total energy demanded for domestic heating.

2. Types of Small-Scale Anaerobic Digesters and Main Performance Parameters

Anaerobic digestion is a well-developed technology with several commercial companies offering solutions at different scales. Small-scale digestion systems can be operated under low- and high-solid content configurations. Wet digestion is usually performed in continuously stirred reactors (CSTR), with low solid content and agitation provided by mechanical means. However, this type of operation limits productivity due to the high water content. Increasing the organic loading rate (OLR) may lead to higher biogas production and reactor productivity. However, this higher loading also results in lower methane yield, reducing the degradation efficiency [19]. The OLR can be increased either by modifying the solid content of the feeding or by reducing the hydraulic retention time (HRT) under these operating conditions. Tubular reactors operating under plug flow mode are another widely employed configuration. Its main characteristic is a simplified design and absence of moving parts. The volume of the reactor is usually higher, allowing for a greater residence time inside the digester, compensating for the absence of active mixing, and for temperature regulation. The tubular design is more efficient than CSTR systems under similar operating constraints.

Solid-state fermentation is another type of reactor configuration, where the solid content is greater than 20% total solids (TS). The operation of these systems requires loading and unloading stages. Inoculation is a relevant step affecting the development of biodegradation. The system usually operates under batch conditions if agitation is not provided. Solid-phase reactors, based on a percolating configuration, require an additional tank to store the anaerobic leachate, which is rich in active methanogenic microflora [20]. In this case, the porosity of the percolating bed is essential to ensure the homogenous distribution of leachate throughout the bed.

The main parameter for evaluating anaerobic digestion performance is the specific methane production (SMP), which gives the volume of methane produced per unit mass of solids fed into the reactor. Another parameter used for evaluating efficiency is the volumetric methane production of the reactor, which indicates the daily volume of gas produced per unit of reactor volume. Temperature also affects the degradation rate; thus, the reactor must be kept at a constant temperature. This is accomplished by a heating system and insulation to reduce heat loss. The simplest parameters commonly used to monitor process performance are alkalinity and pH measurement. These parameters predict possible fermentation imbalances due to excessive organic loading or changes in the biodegradability of the feed.

3. Material and Methods

3.1. Methodology

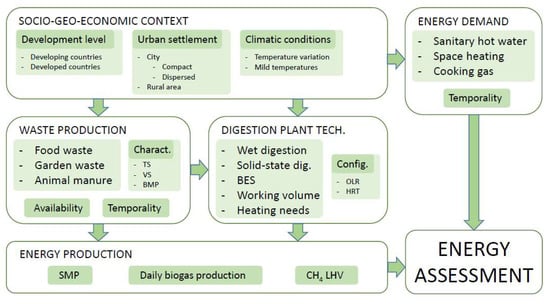

The methodology for analyzing a given scenario consists of defining its characteristics in a manner which allows calculation of the percentage of energy demand that can be offset by converting wastes into energy. A simplified schematization of the methodology is shown in Figure 1.

Figure 1.

Schematization of methodology for estimating biogas and energy production from the different scenarios considered. TS: total solids, VS: volatile solids, BMP: biochemical methane potential, BES: bioelectrochemical systems, OLR: organic loading rate, HRT: hydraulic retention time, SMP: specific methane production, LHV: lower heating value.

The present manuscript aimed to approach to energy production through small-scale digestion units from household wastes. Therefore, parameters such as waste production, energy demand, and population density were used to define different scenarios, also serving as indicators to describe the socio-geo-economic context and approximate the development level (developed or developing country). Urban settlement type (rural area, dispersed/compact city) was used to estimate food and garden waste production per area. Two different climatic conditions were considered (mild temperatures and temperature variations throughout the year).

Regarding waste production, the type of waste (food waste, garden waste, animal manure), its characteristics (TS, volatile solids (VS), biochemical methane potential (BMP)), availability, and seasonality were defined. Energy demand was estimated by considering thermal housing demands (sanitary hot water, space heating, cooking gas) and seasonality. This was done by assessing the energy demand of single houses and extrapolating to a local community. Biogas produced was assumed to be available to cover the community energy demand.

The next step defines the type of digestion technology. This is based on waste characteristics and production rate. Main configuration parameters include wet-/solid-state digestion, bioelectrochemical systems, reactor working volume, and heating requirements. This stage is explained in detail in Section 3.2 of Material and Methods. Energy production is then calculated using the waste production rate based on digestion technology. Parameters used for estimating energy production are SMP, daily biogas production, and methane lower heating value (LHV). The LHV of methane was 35.8 MJ/m3. Finally, energy assessment was carried out by comparing energy production versus demand. Sensitivity analysis was performed by considering the effect on the response, varying waste production rate, and SMP. The maximum and minimum values considered were 20% higher and lower than the selected data. Variables selected as responses were digester volume and energy production. Data were obtained from the scientific literature.

3.2. Digestion Plant Configuration

The production of food wastes and garden wastes were the main substrates considered susceptible to valorization by anaerobic digestion. The rate of food production was used to estimate the reactor volume needed and the expected production of biogas. The minimum working volume of the anaerobic reactor was 6 m3, with a headspace of 30% of the total reactor volume. The volume of the digester was estimated by assuming an HRT of 35 days when temperature control was provided for the biological process. In contrast, this parameter was increased to 80 days when lacking temperature control. Continuous operation was considered for reactors operating a wet configuration.

Dry digestion was assumed when garden wastes and community parks were integrated into the service area of the digester. The amount of biogas produced was based on methane yield values reported in the literature for food wastes and grass material. When data were derived from BMP tests, a correction factor of 40% was applied to account for changes in reactor dynamics due to continuous operation, thus lowering biogas production.

Gómez et al. [21] and González et al. [22] reported an average value of 340 mL CH4/g VS when operating under semi-continuous conditions and an HRT between 40 and 20 days. Cabbai et al. [23] reported values obtained from BMP tests for restaurants and can-teen organic wastes between 571 and 675 mL CH4/g VS. Thus, in order to extrapolate to continuous conditions, an average value of 357.6 mL CH4/g VS was considered. The mean value used for calculations was then 349 mL CH4/g VS. The TS content of food waste was 152 g/L, with 90% content of VS, using data reported by Brown and Li [24]. The methane yield of garden and grass lawn waste was assumed to be 340 mL CH4/g VS under batch conditions [25], using a value of 203 mL CH4/g VS under continuous conditions. For garden waste, a yield of 185 mL CH4/g VS was assumed (equivalent to 111 mL CH4/g VS for continuous conditions) [26].

Digester volume (Vdigester) is calculated as the ratio between volumetric flow and HRT. The daily mass of waste to be treated (Mwaste) and TS content of the reactor feeding stream are used to calculate the volumetric influent flow (q), as expressed in Equation (1).

Daily methane production is calculated from the SMP value and the OLR applied to the reactor

A mass balance over the digester was performed to estimate digested material and water content, considering that biogas is derived from volatile solid material. Inorganic solids were assumed remain constant during biological degradation.

3.3. Description of Scenarios

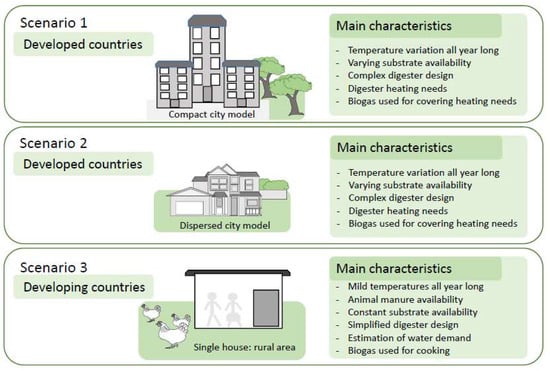

The energy demand of residential housing was estimated at 5233 kWh/year per home to cover sanitary hot water and space heating needs [27,28], considering that 75% of this consumption was produced in the autumn–winter period, and the remaining value was for the spring–summer period. Decentralization is usually proposed as an efficient way of promoting the local economy and civic empowerment [29]. However, in the case of waste treatment, this idea may not be directly translated into better public services or community comfort. Three scenarios were studied in the present research to evaluate the capacity of small digestion technologies and their basic requirements in order to produce energy to cover residential heating demands. The scenarios selected were based on different residential configurations, considering the feasibility of decentralization in urban waste treatment. The first scenario resembles the compact distribution of Spanish cities, and the dispersed configuration of some European regions is analyzed in the second scenario. The implementation of small-scale digestion in developing countries was also analyzed to establish basic constraints when installing small digesters. Several reports found in the literature indicate poor performance and challenges associated with policy and funding, among other constraints [30,31,32]. Nevertheless, the benefits of digestion are undeniable. This technology can aid in reducing greenhouse gas emissions and improve the quality of life in urban and rural areas by allowing access to a local energy source [33,34]. Therefore, the third scenario considers rural housing in tropical regions. The text below describes assumptions for each scenario in detail, and Figure 2 shows a simplified schematization of scenarios under study.

Figure 2.

Schematization of the analyzed scenarios.

Scenario 1 presents the case of housing in residential buildings averaging 6 stories, with4 flats per story. The average food waste production was 77 kg/year per capita for Spain, with a total waste production of 442 kg/year per capita [35,36]. Three individuals per flat were considered. The daily volume of water consumption was 136 L/inhabitant per day [37]. 8% of urban soil was assumed to be dedicated to green public gardens and community parks [38]. The value of garden plus food waste in Spain was 187 kg/person-year [39].

Scenario 2 presents the case of single-detached housing with a higher number of family members (5 members). This scenario was evaluated for less populous regions, with the housing comprising 500 m2 of space, with the ground floor having 150 m2. Total space for estimating heating demand was 300 m2. Garden waste production was assumed as 1.96 ± 1.35 kg/person per day [40]. Two types of reactor configurations were studied. The first was a high-solid reactor, working under batch conditions at 20% total solids in a staggered mode. The second reactor was a leachate-bed percolating system, operating at an initial 50% TS, also under batch conditions. In this latter case, a bio-electrochemical system (BES) was integrated to aid the treatment of the percolating liquid. It was also assumed that yard trimmings, with a TS content of 70%, were used for creating the percolating bed (bed density of 430 kg/m3). The recirculating leachate tank was assumed to have a volume between 30–40% of the volume occupied by the percolating bed. SMP production values were lowered by 40% to allow for mass-transfer restrictions.

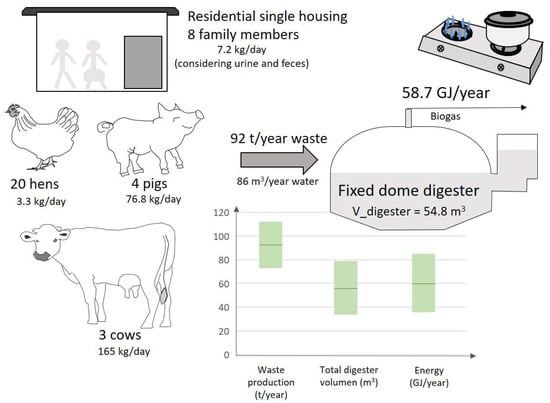

Scenario 3 studies the energy production from small digesters treating organics derived from single houses with small farms in tropical regions in developing countries. In the present case, a single family of 8 members was considered (4 adults—4 children), assuming no food waste production, since this material is commonly used to complement animal feeding. Garden waste was also disregarded in this case due to the assumed digester configuration. The type and number of animals belonging to the family members were, in this case, 20 hens, 4 pigs and 3 cows. Animal manure and human feces were digested in a simplified fixed-dome reactor, with an HRT of 80 days. The total solid content of the digester feed was fixed at 60 g/L. The production of human feces was 400 g/person per day for adults, and half this value for kids. Laying hens were assumed to generate 162 g/hen per day. The production of manure for pigs was 19.2 kg/pig per day and 55 kg/cow per day [41,42].

The scenarios proposed here are a preliminary study assessing the feasibility of waste treatment decentralization in urban and rural areas. The volume of biogas produced will be estimated from data reported in the scientific literature regarding waste production and biogas yields. The effect of climatic conditions will be considered in terms of the demand for residential heating and sanitary hot water, digester thermal demand, and substrate availability. These factors are essential to estimate reactor size and the energy coverage attained in each case. Biogas is assumed to be used as the fuel covering heating demand in Scenario 1 and 2, and cooking gas demand in Scenario 3.

4. Results and Discussion

4.1. Scenario 1

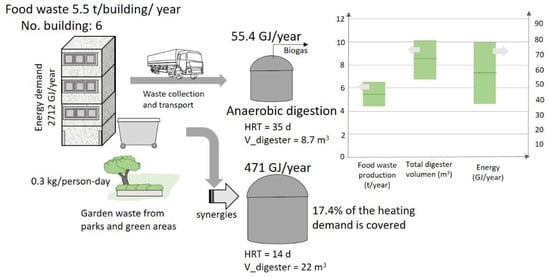

Figure 3 shows assumptions and results for Scenario 1, which considers residential housing and the treatment of community wastes for a single building. The annual food waste production for each building was estimated at 5.5 t/year. Thus, using assumptions established in the Section 3, the working volume of the digester needed for treating the mass of waste generated by six residential buildings was 6.1 m3. Therefore, the total volume of the reactor would be 8.7 m3 after including the headspace.

Figure 3.

Results obtained from Scenario 1, considering residential housing in highly populated areas. Reactors considered in this scenario were a CSTR type operating at low solid content.

The amount of biogas produced would be 55.4 GJ/year (15,300 kWh/year). However, this quantity is insignificant compared with the amount of energy needed for these same houses, which accounts for 2712 GJ/year for covering the demand for heating and sanitary hot water. Results of sensitivity analysis are also shown in Figure 3. Energy production ranges from 35.5 to 80 GJ/year under previous assumptions. However, even in the best case, the energy contained in biogas would only account for 3% of the total energy demanded. The energy demand of Finnish housing was studied by Heinonen and Junnila [43], reporting values for total energy consumption between 15,000 and 23,500 kWh/year per dwelling, differentiating between detached houses, with the greatest energy demand, and flats with a lower demand. Although reporting total energy consumption (more than 60% of this energy demand represents heating demand), these data give an idea of the implications of weather conditions and energy needs in different climatic areas. One relevant consideration is that although detached houses present greater energy demand, the number of household members is usually higher, resulting in more efficient energy living systems when considering energy demand per capita.

Given the low capacity for producing energy from waste to cover the energy demand in residential housing, other substrates would need to be available to produce enough energy locally. Therefore, if garden wastes were added, the material could be obtained from a surface equivalent to 0.2 km2 of a high-density area; as in the case of Madrid, with a mean population density of 2181 inhab./km2 in the urban area. For a less populated region (such as the urban area of León (466 inhab./km2)), a surface equivalent to 0.93 km2 would be needed.

The present study assumed an average production of 0.3 kg/person per day of garden waste. When considering urban areas, volume of green waste reported for English housing was about 0.64 ± 0.46 kg/person per day. This value increases to 1.96 ± 1.35 kg/person per day when considering rural areas [40]. However, other authors reported lower values; for instance, 0.365 kg/person-day for Denmark [44]. Given the scarcity of studies regarding garden waste collection and characterization, the mean value considered here was increased by 30% for low population areas and reduced by the same amount for highly populated areas. Therefore, a range was obtained for the energy derived if this material was used as a co-substrate. As a gross approximation, the maximum volume of biogas produced from garden waste was, in this case, 2870 m3 of extra methane, if values of methane production reported by Zhang et al. [26] were used. Taking into account assumptions described for the sensitivity analysis, the range of extra energy obtained by adding yard wastes would be 68–143 GJ/year.

This gas production only covers 5.8% (range of 3.8–8.2%) of the total needs of an average house for heating and domestic hot water. These approximations were obtained by only estimating global gas production, without considering relevant factors that play a crucial role in the feasibility of these alternatives; such as, the transport of wastes, preparation of feeding, and by-product disposal. These subjects are crucial and will be treated in future work. The effect of applying a higher organic loading rate and the size needed for the reactor determines the space needed for the decentralized treatment unit. Considering that this alternative is configured for urban areas, the available space within cities to install these plants is a relevant constraint.

The addition of garden wastes to an anaerobic digestion system must consider the type of reactor and operating conditions. Previous estimations assumed no synergies between different substrates. However, it has been reported by several authors that co-digestion may increase the global production of the mixture due to attaining a better nutrient balance [45,46,47,48]. In fact, Fitamo et al. [49] reported a yield ranging from 287 to 433 mL CH4/g VS when operating at an OLR between 0.65 to 5.0 g/Lreactor d, with an HRT as low as 14 days under continuous operation. These yields are much higher than those obtained from previous estimations. Recalculating with these higher yields, the mixture of garden and food waste would give 471 GJ/year (ranging from 389 to 550 GJ/year) for the most favorable case, which would cover 17% (14–20%) of the energy demand studied. This latter consideration implies operation under low solid content for the feed, which would translate into excessive demand for water and a high digestion volume. That is, garden waste has a high solid content, and this material would need dilution if used as a co-substrate in a CSTR configuration. Methane yields used in previous calculations were based on a high-solid reactor system, explaining the lower values reported due to mass-transfer limitations and accumulation of inhibitory compounds. Recalculating the size of the digester for an OLR of 5 g VS/Lreactor d, the working volume would be 17 m3 (total volume of 22 m3) when operating with a lower solid content.

Reactor productivity was 9.2 GJ/year m3reactor for digestion of food waste, whereas the addition of co-substrate increases this value to 27.7 GJ/year m3reactor due to the hypothetical increase expected in methane yield. Even though this increase seems beneficial, several aspects must be considered before validating such an approach. The most relevant would be the urban space available for introducing this installation into the city configuration. For a population of 150,000 inhabitants, approximately 350 units of this type would be needed, which sets great pressure on the use of land in cities with high population density. It should be added the possible nuisances of unpleasant odors and the health risks with the final disposal of the digestate. Thus, the alternative of decentralization seems unreasonable for this scenario. Although the availability of additional co-substrates would increase reactor productivity, this assumption would also translate into a larger digester size. In addition, garden waste would be produced during spring-summer periods. Therefore, storage would be necessary to guarantee a continuous feeding to the digester all year round, translating into higher space requirements for storing substrate. However, the main thermal demand for heating occurs in winter, and digesters are not flexible enough to run under different loading conditions to produce the amount of energy demanded.

Decentralized treatment of wastes in urban areas has been proposed as a suitable alternative for producing energy from local sources [50]. Nevertheless, the amount of energy obtained from this approach is minimal. The installation of several small plants may adversely affect urban land prices and be rejected by the community. Several aspects regarding digestate management [51] and plant location need careful assessment.

4.2. Scenario 2

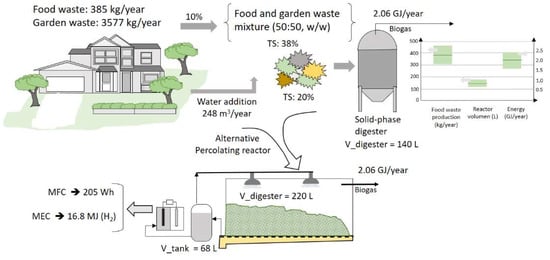

This scenario considers single-detached housing located in the vicinity of urban areas or in regions where the density of population is low. A digester treating waste from a single-family unit with 5 members was assumed. Food waste production was 385 kg/year for this case. Under the same assumptions of Scenario 1, the mass of garden waste was 3577 kg/year. A wide difference in the mass of food waste and garden waste was found in this case. An equivalent proportion of food and garden waste was used in this scenario, considering a solid phase reactor operating at a solid content of 20% TS. The remaining garden waste material would need to be treated by other means, as it would be composting. Figure 4 presents a schematization of the main parameters considered in this scenario and the energy produced from different reactor configurations.

Figure 4.

Results obtained from Scenario 2, evaluating single detached housing in low population areas using a high-solid phase digestion and leachate percolating bed reactor. Methane yields were reduced by 40% to consider mass-transfer limitations.

Under the assumptions considered, the mixtures of food and garden waste would result in a TS content of 38%, requiring dilution with water. Thus, water is required to lower the solid content to 20% to meet digester operating requirements. Wastewater from the same residence may be used for attaining the TS content required. The additional volume of water was 670 L/year. This quantity is easily obtained from the daily wastewater produced in developed countries. For the present case, with daily water use of 136 L/inhabitant per day, the volume of water used is 248 m3/year. However, this issue is of great concern in dry regions where water is scarce, and only basic needs are covered. This is the case of the National Domestic Biogas Program (NDBP), which was invested in 2007 with an initial budget of $14.1 million. This program intended to develop the Rwandan biogas sector by building 15,000 family-sized biogas plants [52]. Many factors adversely affected the success of the program; the evident ones were the complexity of the technology and the lack of skilled personnel. However, a fundamental problem was the scarcity of water necessary to attain the required solid content for the process to be run at a given configuration [52].

In the present case, analyzing a high solid reactor running at 20% TS solid content, a great volume of water must be added if the material does not have the necessary moisture content. Operating at higher solid content has been demonstrated to cause a decrease in biogas yield and longer operating times due to the accumulation of acid-inhibitory compounds [13,53]. Many solid-state digestion systems work with leachate recirculation, but this regimen implies an increased reactor volume to hold the bulking material needed for the percolating bed [54,55].

A batch reactor operating under a high-solid phase configuration was assumed for the sake of simplicity. This condition implies a time needed for loading, and another for completing digestion. Two reactors are to be built, where one remains in the final digestion phase where the other receives substrate daily. In addition, the lack of mixing implies the preparation of inoculation with digestate derived from the maturation phase prior to feeding the substrate. Thus, a total working volume of 108 L was estimated for each reactor. Each digester would have a loading capacity of 31.6 kg for the mixture of food and garden waste. The treatment time will be 30 days, if temperature control is provided. The increase in retention time for the reactor would translate not only into higher digester volumes, but also into more digesters for treating the annual waste production.

Calculations focus on the volume of gas produced from the reactor, with several aspects regarding auxiliary equipment being left aside. The maximum gas production obtained under the configuration considered would be 57.6 m3 of methane (2.0 GJ/year). Figure 4 also shows results from the sensitivity analysis. Just as in the previous case, the energy produced is too low to compensate for the heating demand of a family house (estimates were between 20 and 60 GJ/year, varying according to different climatic conditions). The most favorable case is still reports low energy yields. Thus, if reactor heating requirements and electric demand for all auxiliary devices are considered, the outcome can only worsen. If climatic conditions are to be those of tropical countries with mild temperatures all year round, then the thermal demand of the digester can be disregarded, and operation at ambient temperatures would not result in an excessive increase in reactor volume. Biogas would be used only to cover the fuel demand for cooking, since domestic heating would no longer be necessary.

Another option for treating wastes, which has not been considered yet in the calculations, is the use of microbial electrolysis cells. This technology is still waiting for application at a real-world scale. There are several reports regarding the capacity for treating soluble organic components present in a liquid stream in order to produce electricity (microbial fuel cell, MFC), H2 gas (microbial electrolysis cell, MEC), or valuable organics in a reducing compartment (BES). In the present scenario, BES may be integrated into the biological process for the treatment of organics. Given that this technology is suitable for treating soluble components, a high-solid phase configuration is inadequate when coupling both technologies.

By considering a solid-state digestion system also operating under batch configuration, the application of leachate recirculation along with BES treatment would allow the fast conversion of short-chain fatty acids, which accumulate at the initial stage of the reactor process. In the present case, an amount of material accumulated over 15 days may be treated in each batch reactor. The initial mixture would have a TS content of 38.1% when prepared, following a 50% ratio of food waste and yard waste. Higher TS content is needed to run a solid-state digestion reactor. Yard trimmings rich in recalcitrant lignocellulosic material are added to create a porous structure. However, the presence of a percolating bed increases the reactor volume. Here, yard trimmings with a TS content of 70% were assumed. 35 kg of this material would be needed for mixing with the biodegradable substrate, leading to a reactor volume of 170 L (for a bed density of 430 kg/m3), which is much higher than the previously considered under a high-solid configuration. A recirculating leachate tank is also needed. If a liquid volume between 30–40% of the reactor volume is assumed for the recirculating tank, then a tank of 51–68 L is necessary. Although the reactor volume here is higher than in the high-solid configuration, the total amount of water needed is lower because leachate is recirculated in subsequent batches.

As previously stated, the coupling of BES would allow producing extra energy from the biological degradation of waste. By considering energy yields reported by Mohanakrishna et al. [56] (0.147–0.322 W/kg CODremoved), the amount of electricity produced from volatile fatty acids (VFA) accumulated during digestion can be estimated. Assuming that 5% of volatile solids are transformed into VFA, with a conversion factor of 1.5 g COD/g VS, the annual electricity produced would just account for 205 Wh. If, instead, an MEC system is considered for producing H2, then the amount of energy recovered under the same assumptions—but in this case, using the yield reported by Sun et al. [57] (1.6 mol H2/mol acetate)—would be 16.8 MJ annually. This value is insignificant compared with the annual energy demand to be covered.

4.3. Scenario 3

Several reports about installing small digesters for producing biogas in China and India [58,59,60,61] are available in the literature. Many small plants are dedicated to treating waste from single households using simplified designs. However, low biogas production and inefficient operation have been reported. The construction of these decentralized facilities required subsidies to cover installation costs, which otherwise could not be afforded by small farmers [62]. The most common technologies for small-scale digesters in developing countries is the Chinese fixed and flexible dome, along with their variants developed in India and Vietnam. The tubular digester is also very popular due to its simplified design. However, the lack of mixing and the simplification of the technology makes these systems highly demanding in water, making them unsuitable for dry African countries [63].

Figure 5 shows the main results from this scenario. The daily manure produced, considering animal and human feces, would account for 252 kg/day. To prepare the digester feed at a TS content of 60 g/L, 237 L of water must be available daily. The working volume of the digester would be 39 m3 which translates into a significant investment for a single family. The total digester volume would increase to 79 m3 in the less favorable case as shown in Figure 5. In the most favorable case, the volume may be reduced to 35 m3. Therefore, unless financial aid is available, the construction and maintenance capability for these types of facilities is scarce. The volume of biogas expected from this system was estimated with an SMP of 180 mL CH4/g VS for the mixture. Thus, the daily volume of biogas produced would be 7.5 m3. This quantity covers the demand for cooking only in the case of a gas consumption equivalent to 1.2 m3/h of natural gas for 4 h daily. Energy obtained from digestion is also represented in Figure 5. The sensitivity analysis indicated a maximum production of 84.6 GJ/year, with a minimum energy production of 37.6 GJ/year.

Figure 5.

Results obtained from Scenario 3, evaluating single housing in developing countries under mild climatic conditions.

The scarcity of water is a factor relevant the implementation of anaerobic digestion in dry regions. The amount of water needed to run this technology, and the space required to install this system, are significant factors that should not be disregarded. If these resources are not abundant, the operability of this technology would be null. Other options should be studied prior to creating funds for subsiding technologies that are not suitable for the climatic conditions of the region. The digester size needed for transforming waste into biogas sets a significant constraint; either there is not available space for such an installation or high construction costs prohibit implementing this technology. A simplification of the technology is required, and the design of compact reactors capable of operating a high-solid configuration and low water demand is needed. One approach is provided by Degueurce et al. [64]. However, methane yields need to be improved before decentralized digestion technology may be considered as a practical solution for waste treatment and enhancing local energy production.

5. Conclusions

The feasibility of three small-scale digestion scenarios in the residential sector were studied: residential housing in highly populated areas, single-detached housing, and a house with a small farm in developing countries. The energy demand covered was 17%, under the maximum methane yield assumptions for the first case and less than 10% in the second scenario. Results from the third scenario indicated that biogas produced could scarcely cover the gas demand for cooking, even when there are no disturbances during the digestion process. Given the high water consumption of the process in this latter scenario, for dry climatic conditions, other solutions should be proposed rather than anaerobic digestion.

Decentralized anaerobic digestion may contribute to attaining the circular economy model, but it does not meet all users’ energy requirements. This type of configuration may not be suitable in many regions with limited space or water scarcity. Therefore, resources must be optimized to obtain the greatest value from residues, and of the energy demand to transform waste should also be carefully considered. Factors to be considered when implementing a decentralized configuration for waste treatment are climatic conditions and year-round substrate availability. Extreme temperatures during the winter period adversely affect the energy balance of biological systems and also impact garden waste production, leading to a steep decrease in the feeding material. Thus, storage units need to be available to keep the digester running. Implementing the technology in developing countries with water scarcity problems translates into failure, due to the lack of organic material and water to feed the digester. The digestion technology seems too complex if high reactor productivity is attempted, whereas simplified design leads to poor-performance systems. Given the results obtained here, it seems more reasonable to focus resources on mid- and large-scale systems rather than implementing small-scale units.

Author Contributions

Conceptualization, X.G. and R.G.; methodology, M.E.; validation, X.G. and R.G.; formal analysis, X.G.; investigation, M.E.; resources, X.G.; data curation, M.E.; writing—original draft preparation, X.G.; writing—review and editing, R.G.; visualization, X.G.; supervision, X.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Geisendorf, S.; Pietrulla, F. The circular economy and circular economic concepts—A literature analysis and redefinition. Thunderbird Int. Bus. Rev. 2018, 60, 771–782. [Google Scholar] [CrossRef]

- Valero, A.; Valero, A. Thermodynamic rarity and recyclability of raw materials in the energy transition: The need for an in-spiral economy. Entropy 2019, 21, 873. [Google Scholar] [CrossRef]

- Hobson, K. The limits of the loops: Critical environmental politics and the Circular Economy. Env. Polit. 2021, 30, 161–179. [Google Scholar] [CrossRef]

- Mouzakitis, Y.; Adamides, E.D. Techno-economic Assessment of An Olive Mill Wastewater (OMWW) Biorefinery In the Context Of Circular Bioeconomy. ENG 2022, 3, 488–503. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; García-Cascallana, J.; Gómez, X. Biogas production from organic wastes: Integrating concepts of circular economy. Fuels 2021, 2, 144–167. [Google Scholar] [CrossRef]

- Landfill Directive. European Commission, 2008/98/EC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A31999L0031 (accessed on 12 May 2022).

- Directive (EU) 2018/851. Available online: https://eur-lex.europa.eu/legal-content/ES/TXT/?uri=CELEX%3A32018L0851 (accessed on 12 May 2022).

- Malinowski, M.; Leon, J.I.; Abu-Rub, H. Solar photovoltaic and thermal energy systems: Current technology and future trends. Proc. IEEE 2017, 105, 2132–2146. [Google Scholar] [CrossRef]

- Ahmad, U.S.; Usman, M.; Hussain, S.; Jahanger, A.; Abrar, M. Determinants of renewable energy sources in Pakistan: An overview. Environ. Sci. Pollut. Res. 2022, 29, 29183–29201. [Google Scholar] [CrossRef]

- Purohit, P.; Chaturvedi, V. Biomass pellets for power generation in India: A techno-economic evaluation. Environ. Sci. Pollut. Res. 2018, 25, 29614–29632. [Google Scholar] [CrossRef]

- Ibrahim, M.H.; Quaik, S.; Ismail, S.A. An introduction to anaerobic digestion of organic wastes. In Prospects of Organic Waste Management and the Significance of Earthworms. Applied Environmental Science and Engineering for a Sustainable Future; Springer: Cham, Switzerland, 2016; pp. 23–44. [Google Scholar] [CrossRef]

- Sevillano, C.A.; Pesantes, A.A.; Peña-Carpio, E.; Martínez, E.J.; Gómez, X. Anaerobic Digestion for Producing Renewable Energy—The Evolution of This Technology in a New Uncertain Scenario. Entropy 2021, 23, 145. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; Cascallana, J.G.; González, R.; Gómez, X. High-solid anaerobic digestion: Reviewing strategies for increasing reactor performance. Environments 2021, 8, 80. [Google Scholar] [CrossRef]

- Deng, L.; Liu, Y.; Zheng, D.; Wang, L.; Pu, X.; Song, L.; Wang, Z.; Lei, Y.; Chen, Z.; Long, Y. Application and development of biogas technology for the treatment of waste in China. Renew. Sustain. Energy Rev. 2017, 70, 845–851. [Google Scholar] [CrossRef]

- Breitenmoser, L.; Gross, T.; Huesch, R.; Rau, J.; Dhar, H.; Kumar, S.; Hugi, C.; Wintgens, T. Anaerobic digestion of biowastes in India: Opportunities, challenges and research needs. J. Environ. Manag. 2019, 236, 396–412. [Google Scholar] [CrossRef]

- Siddiqui, S.; Bhatnagar, P.; Dhingra, S.; Upadhyay, U.; Sreedhar, I. Wastewater treatment and energy production by microbial fuel cells. Biomass Convers. Bior. 2021, 1–24. [Google Scholar] [CrossRef]

- Jadhav, D.A.; Mungray, A.K.; Arkatkar, A.; Kumar, S.S. Recent advancement in scaling-up applications of microbial fuel cells: From reality to practicability. Sustai. Energy Technol. Assess. 2021, 45, 101226. [Google Scholar] [CrossRef]

- Abdallah, M.; Feroz, S.; Alani, S.; Sayed, E.T.; Shanableh, A. Continuous and scalable applications of microbial fuel cells: A critical review. Rev. Environ. Sci. Biotechnol. 2019, 18, 543–578. [Google Scholar] [CrossRef]

- González, R.; Blanco, D.; Cascallana, J.G.; Carrillo-Peña, D.; Gómez, X. Anaerobic co-digestion of sheep manure and waste from a potato processing factory: Techno-economic analysis. Fermentation 2021, 7, 235. [Google Scholar] [CrossRef]

- Fu, Y.; Luo, T.; Mei, Z.; Li, J.; Qiu, K.; Ge, Y. Dry anaerobic digestion technologies for agricultural straw and acceptability in China. Sustainability 2019, 10, 4588. [Google Scholar] [CrossRef]

- Gómez, X.; Cuetos, M.J.; Tartakovsky, B.; Martínez-Nuñez, M.F.; Moran, A. A comparison of analytical techniques for evaluating food waste degradation by anaerobic digestion. Bioprocess Biosyst. Eng. 2010, 33, 427–438. [Google Scholar] [CrossRef]

- González, R.; Rosas, J.G.; Blanco, D.; Smith, R.; Martínez, E.J.; Pastor-Bueis, R.; Gómez, X. Anaerobic digestion of fourth range fruit and vegetable products: Comparison of three different scenarios for its valorisation by life cycle assessment and life cycle costing. Environ. Monit. Assess. 2020, 192, 1–19. [Google Scholar] [CrossRef]

- Cabbai, V.; Ballico, M.; Aneggi, E.; Goi, D. BMP tests of source selected OFMSW to evaluate anaerobic codigestion with sewage sludge. Waste Manage. 2013, 33, 1626–1632. [Google Scholar] [CrossRef]

- Brown, D.; Li, Y. Solid state anaerobic co-digestion of yard waste and food waste for biogas production. Bioresour. Technol. 2013, 127, 275–280. [Google Scholar] [CrossRef] [PubMed]

- Antonopoulou, G.; Vayenas, D.; Lyberatos, G. Biogas production from physicochemically pretreated grass lawn waste: Comparison of different process schemes. Molecules 2020, 25, 296. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Li, W.; Zhang, G.; Xu, G. Impact of pretreatment on solid state anaerobic digestion of yard waste for biogas production. World J. Microbiol. Biotechnol. 2014, 30, 547–554. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://informesweb.idae.es/consumo-usos-residencial/informe.php (accessed on 10 June 2021).

- Available online: https://www.idae.es/uploads/documentos/documentos_Informe_SPAHOUSEC_ACC_f68291a3.pdf (accessed on 14 July 2021).

- Andrews, C.W.; de Vries, M.S. High expectations, varying outcomes: Decentralization and participation in Brazil, Japan, Russia and Sweden. Int. Rev. Adm. Sci. 2007, 73, 424–451. [Google Scholar] [CrossRef]

- Patinvoh, R.J.; Taherzadeh, M.J. Challenges of biogas implementation in developing countries. Curr. Opin. Environ. Sci. Health 2019, 12, 30–37. [Google Scholar] [CrossRef]

- Jegede, A.O.; Zeeman, G.; Bruning, H. A review of mixing, design and loading conditions in household anaerobic digesters. Crit. Rev. Environ. Sci. Technol. 2019, 49, 2117–2153. [Google Scholar] [CrossRef]

- Akhiar, A.; Zamri, M.F.M.A.; Torrijos, M.; Battimelli, A.; Roslan, E.; Marzuki, M.H.M.; Carrere, H. Anaerobic digestion industries progress throughout the world. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 476, p. 012074. [Google Scholar] [CrossRef]

- Rahman, K.M.; Melville, L.; Edwards, D.J.; Fulford, D.; Thwala, W.D. Determination of the potential impact of domestic anaerobic digester systems: A community based research initiative in Rural Bangladesh. Processes 2019, 7, 512. [Google Scholar] [CrossRef]

- Pandey, P.; Pandey, A.; Yan, L.; Wang, D.; Pandey, V.; Meikap, B.C.; Huo, J.; Zhang, R.; Pandey, P.K. Dairy waste and potential of small-scale biogas digester for rural energy in India. Appl. Sci. 2021, 11, 10671. [Google Scholar] [CrossRef]

- Available online: https://www.statista.com/statistics/933059/per-capita-food-waste-of-selected-countries/ (accessed on 14 July 2021).

- Available online: https://ecoembesdudasreciclaje.es/cuantos-residuos-produce-una-persona-por-dia/#:~:text=Seg%C3%BAn%20investigaciones%20de%20la%20Universidad,ciudadanos%20en%20la%20Uni%C3%B3n%20Europea (accessed on 20 December 2021).

- Available online: https://www.ine.es/ss/Satellite?L=es_ES&c=INESeccion_C&cid=1259950836931&p=1254735110672&pagename=ProductosYServicios%2FPYSLayout¶m1=PYSDetalleFichaSeccionUA¶m3=1259944561392 (accessed on 20 December 2021).

- Available online: https://www.ine.es/prodyser/espa_cifras/2019/8/ (accessed on 17 April 2022).

- Available online: https://zerowasteeurope.eu/wp-content/uploads/2020/07/2020_07_06_bic_zwe_report_bio_waste.pdf (accessed on 17 April 2022).

- Eades, P.; Kusch-Brandt, S.; Heaven, S.; Banks, C.J. Estimating the generation of garden waste in England and the differences between rural and urban areas. Resources 2020, 9, 8. [Google Scholar] [CrossRef]

- González, R.; González, J.; Rosas, J.G.; Smith, R.; Gómez, X. Biochar and energy production: Valorizing swine manure through coupling co-digestion and pyrolysis. C 2020, 6, 43. [Google Scholar] [CrossRef]

- González, R.; Ellacuriaga, M.; Aguilar-Pesantes, A.; Carrillo-Peña, D.; García-Cascallana, J.; Smith, R.; Gómez, X. Feasibility of coupling anaerobic digestion and hydrothermal carbonization: Analyzing thermal demand. Appl. Sci. 2021, 11, 11660. [Google Scholar] [CrossRef]

- Heinonen, J.; Junnila, S. Residential energy consumption patterns and the overall housing energy requirements of urban and rural households in Finland. Energy Build. 2014, 76, 295–303. [Google Scholar] [CrossRef]

- Boldrin, A.; Christensen, T.H. Seasonal generation and composition of garden waste in Aarhus (Denmark). Waste Manag. 2010, 30, 551–557. [Google Scholar] [CrossRef] [PubMed]

- Cuetos, M.J.; Morán, A.; Otero, M.; Gómez, X. Anaerobic co-digestion of poultry blood with OFMSW: FTIR and TG–DTG study of process stabilization. Environ. Technol. 2009, 30, 571–582. [Google Scholar] [CrossRef]

- Cuetos, M.J.; Gómez, X.; Martínez, E.J.; Fierro, J.; Otero, M. Feasibility of anaerobic co-digestion of poultry blood with maize residues. Bioresour. Technol. 2013, 144, 513–520. [Google Scholar] [CrossRef]

- Sánchez, Z.; Poggio, D.; Castro, L.; Escalante, H. Simultaneous synergy in CH4 yield and kinetics: Criteria for selecting the best mixtures during co-digestion of wastewater and manure from a bovine slaughterhouse. Energies 2021, 14, 384. [Google Scholar] [CrossRef]

- Miramontes-Martínez, L.R.; Rivas-García, P.; Albalate-Ramírez, A.; Botello-Álvarez, J.E.; Escamilla-Alvarado, C.; Gomez-Gonzalez, R.; Alcalá-Rodríguez, M.M.; Valencia-Vázquez, R.; Santos-López, I.A. Anaerobic co-digestion of fruit and vegetable waste: Synergy and process stability analysis. J. Air Waste Manag. Assoc. 2021, 71, 620–632. [Google Scholar] [CrossRef]

- Fitamo, T.; Boldrin, A.; Boe, K.; Angelidaki, I.; Scheutz, C. Co-digestion of food and garden waste with mixed sludge from wastewater treatment in continuously stirred tank reactors. Bioresour. Technol. 2016, 206, 245–254. [Google Scholar] [CrossRef]

- Landi, M.; Sovacool, B.K.; Eidsness, J. Cooking with gas: Policy lessons from Rwanda’s National Domestic Biogas Program (NDBP). Energy Sustain. Dev. 2013, 17, 347–356. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Sun, Y.; Yu, J.; Zheng, Z.; Li, S.; Cui, Z.; Hao, J.; Li, G. Effects of intermittent mixing mode on solid state anaerobic digestion of agricultural wastes. Chemosphere 2020, 248, 126055. [Google Scholar] [CrossRef]

- Thiriet, P.; Bioteau, T.; Tremier, A. Optimization method to construct micro-anaerobic digesters networks for decentralized biowaste treatment in urban and peri-urban areas. J. Clean. Prod. 2020, 243, 118478. [Google Scholar] [CrossRef]

- Ntostoglou, E.; Khatiwada, D.; Martin, V. The Potential Contribution of Decentralized Anaerobic Digestion towards Urban Biowaste Recovery Systems: A Scoping Review. Sustainability 2021, 13, 13435. [Google Scholar] [CrossRef]

- Fierro, J.; Martínez, J.E.; Rosas, J.G.; Blanco, D.; Gómez, X. Anaerobic codigestion of poultry manure and sewage sludge under solid-phase configuration. Environ. Prog. Sustain. 2014, 33, 866–872. [Google Scholar] [CrossRef]

- Zhou, H.; Wen, Z. Solid-state anaerobic digestion for waste management and biogas production. In Solid State Fermentation. Advances in Biochemical Engineering/Biotechnology; Steudler, S., Werner, A., Cheng, J., Eds.; Springer: Cham, Switzerland, 2019; Volume 169, pp. 147–168. [Google Scholar] [CrossRef]

- Mohanakrishna, G.; Mohan, S.V.; Sarma, P.N. Bio-electrochemical treatment of distillery wastewater in microbial fuel cell facilitating decolorization and desalination along with power generation. J. Hazard. Mater. 2010, 177, 487–494. [Google Scholar] [CrossRef]

- Sun, M.; Shenog, G.P.; Zhang, L.; Xia, C.R.; Mu, Z.X.; Liu, X.W.; Wang, H.L.; Yu, H.Q.; Qi, R.; Yu, T.; et al. An MEC–MFC coupled system for biohydrogen production from acetate. Environ. Sci. Technol. 2008, 42, 8095–8100. [Google Scholar] [CrossRef]

- Voegeli, Y.; Zurbrügg, C. Decentralised anaerobic digestion of kitchen and market waste in developing countries- ‘state of the art’ in south India. In Proceedings of the Second International Symposium on Energy from Biomass and Waste, Venice, Italy, 17–20 November 2008. [Google Scholar]

- Abbasi, T.; Tauseef, S.M.; Abbasi, S.A. A brief history of anaerobic digestion and “biogas”. In Biogas Energy Springer Briefs in Environmental Science; Springer: New York, NY, USA, 2012; Volume 2, pp. 11–23. [Google Scholar] [CrossRef]

- Raha, D.; Mahanta, P.; Clarke, M.L. The implementation of decentralised biogas plants in Assam, NE India: The impact and effectiveness of the National Biogas and Manure Management Programme. Energy Policy 2014, 68, 80–91. [Google Scholar] [CrossRef]

- Luo, T.; Khoshnevisan, B.; Huang, R.; Chen, Q.; Mei, Z.; Pan, J.; Liu, H. Analysis of revolution in decentralized biogas facilities caused by transition in Chinese rural areas. Renew. Sustain. Energy Rev. 2020, 133, 110133. [Google Scholar] [CrossRef]

- Wang, J. Decentralized biogas technology of anaerobic digestion and farm ecosystem: Opportunities and challenges. Front. Energy Res. 2014, 2, 10. [Google Scholar] [CrossRef]

- Mungwe, J.N.; Colombo, E.; Adani, F.; Schievano, A. The fixed dome digester: An appropriate design for the context of Sub-Sahara Africa? Biomass Bioenerg. 2016, 95, 35–44. [Google Scholar] [CrossRef]

- Degueurce, A.; Dabert, P.; Argence, V.; Blondel, L.; Le Bihan, A.; Lebreton, M.; Peu, P.; Sarrazin, M.; Picard, S.; Trémier, A. An Innovative Solid-State Micro-Anaerobic Digestion Process to Valorize Food Waste: Technical Development Constraints and Consequences on Biological Performances. Waste Biomass Valori. 2022, 13, 617–630. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).