Electromagnetic Continuously Variable Transmission (EMCVT) System for Precision Torque Control in Human-Centered Robotic Applications

Abstract

1. Introduction

2. Materials and Methods

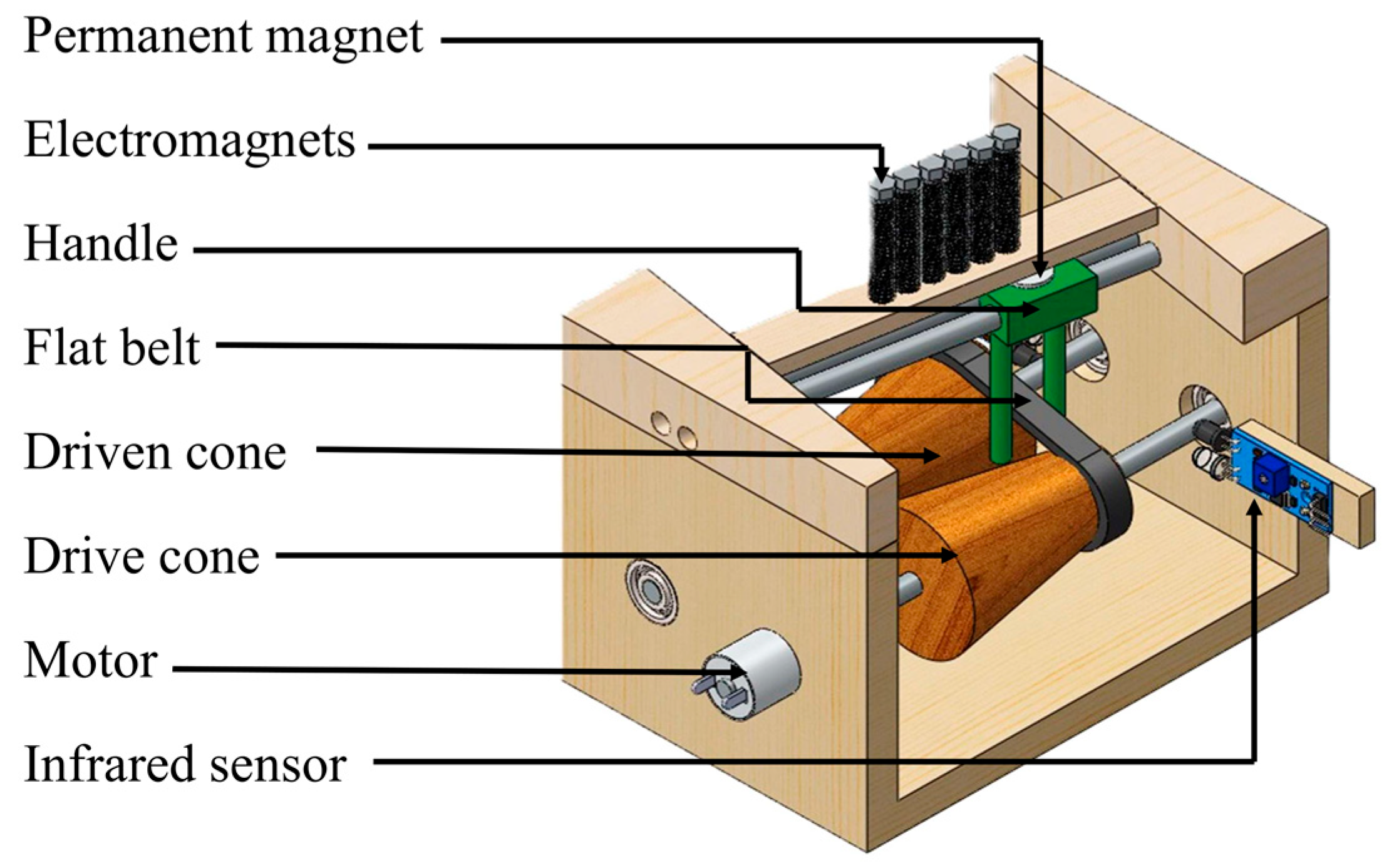

2.1. Proposed Configuration of the Continuously Variable Transmission System

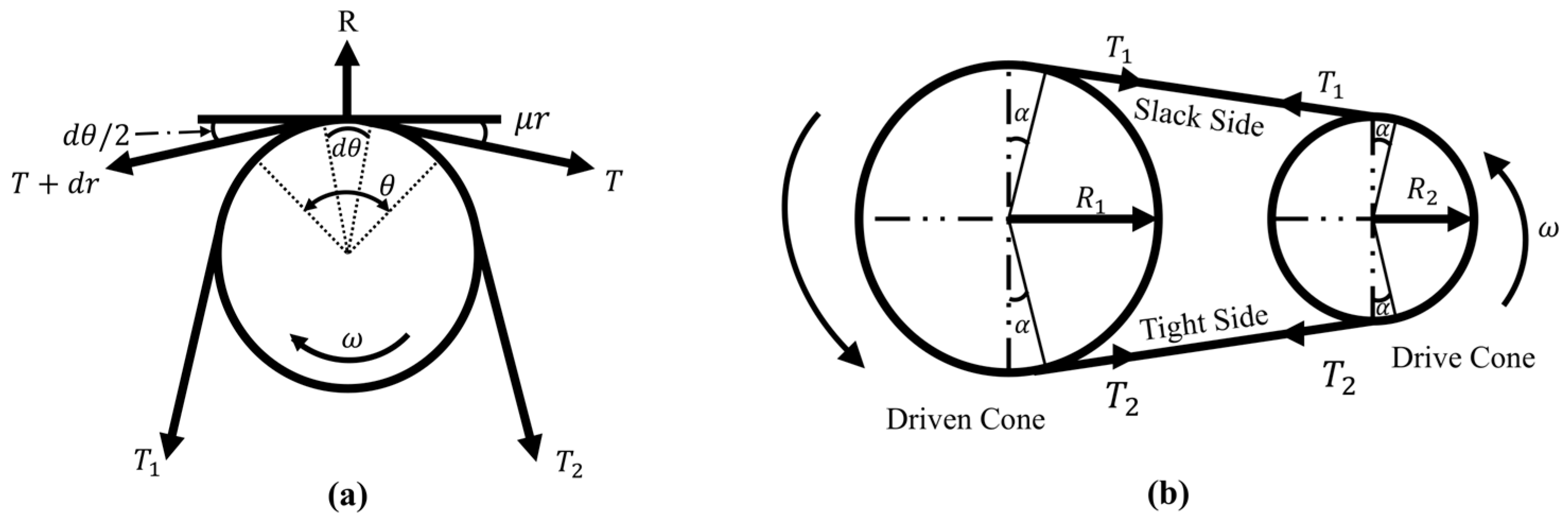

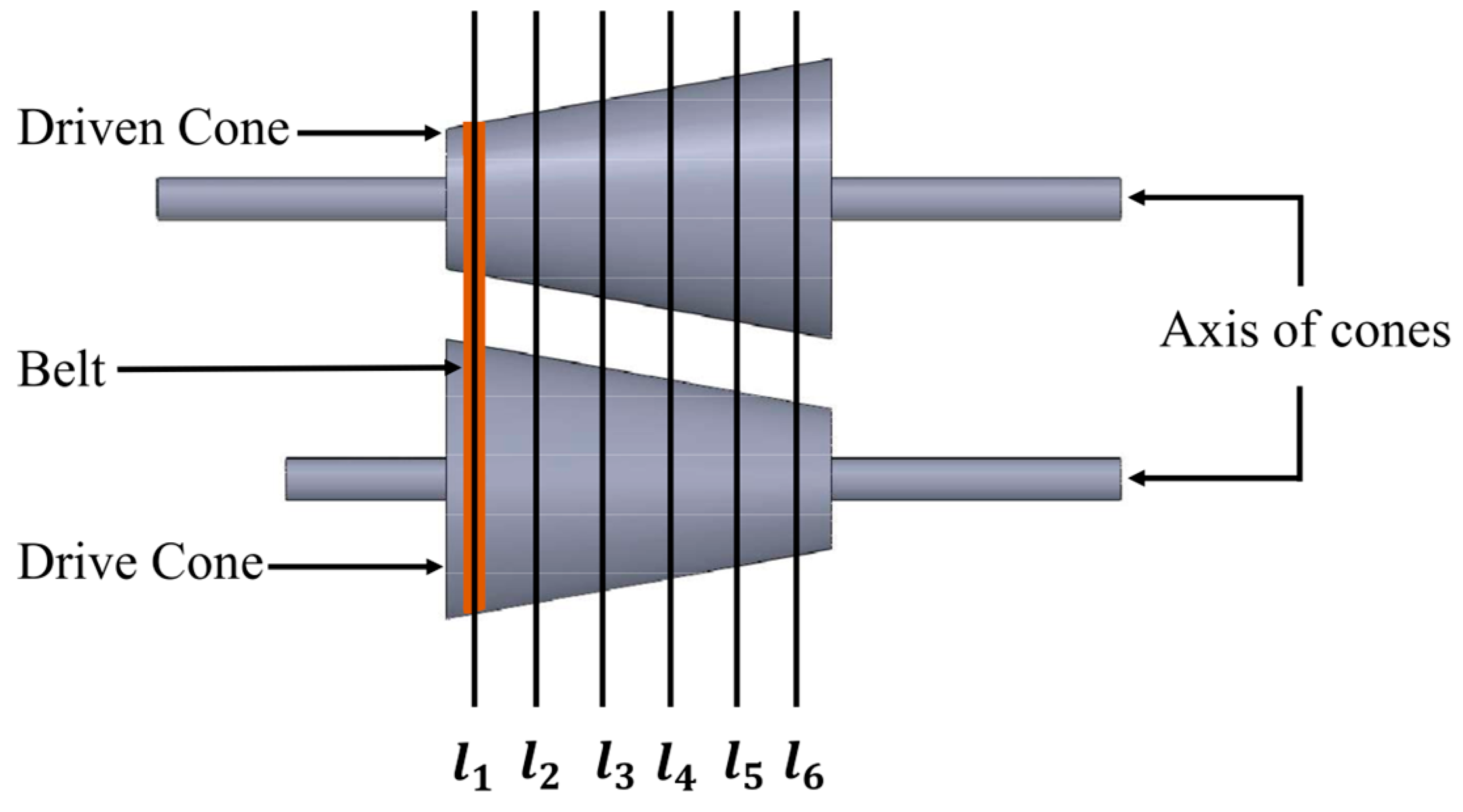

2.2. Mechanical Subsystem

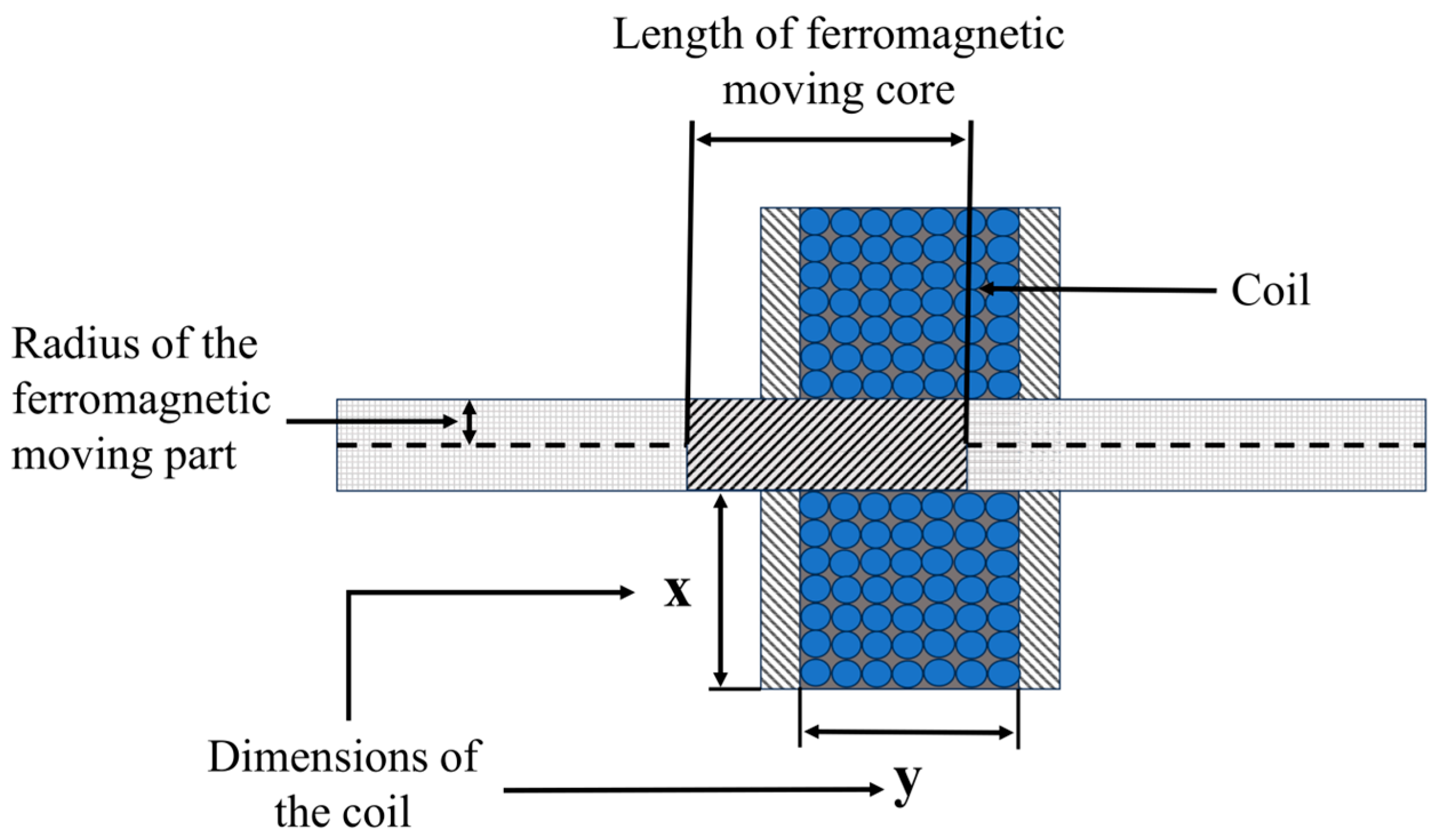

2.3. Control Subsystem

2.4. Experimental Setup and Procedure

3. Results

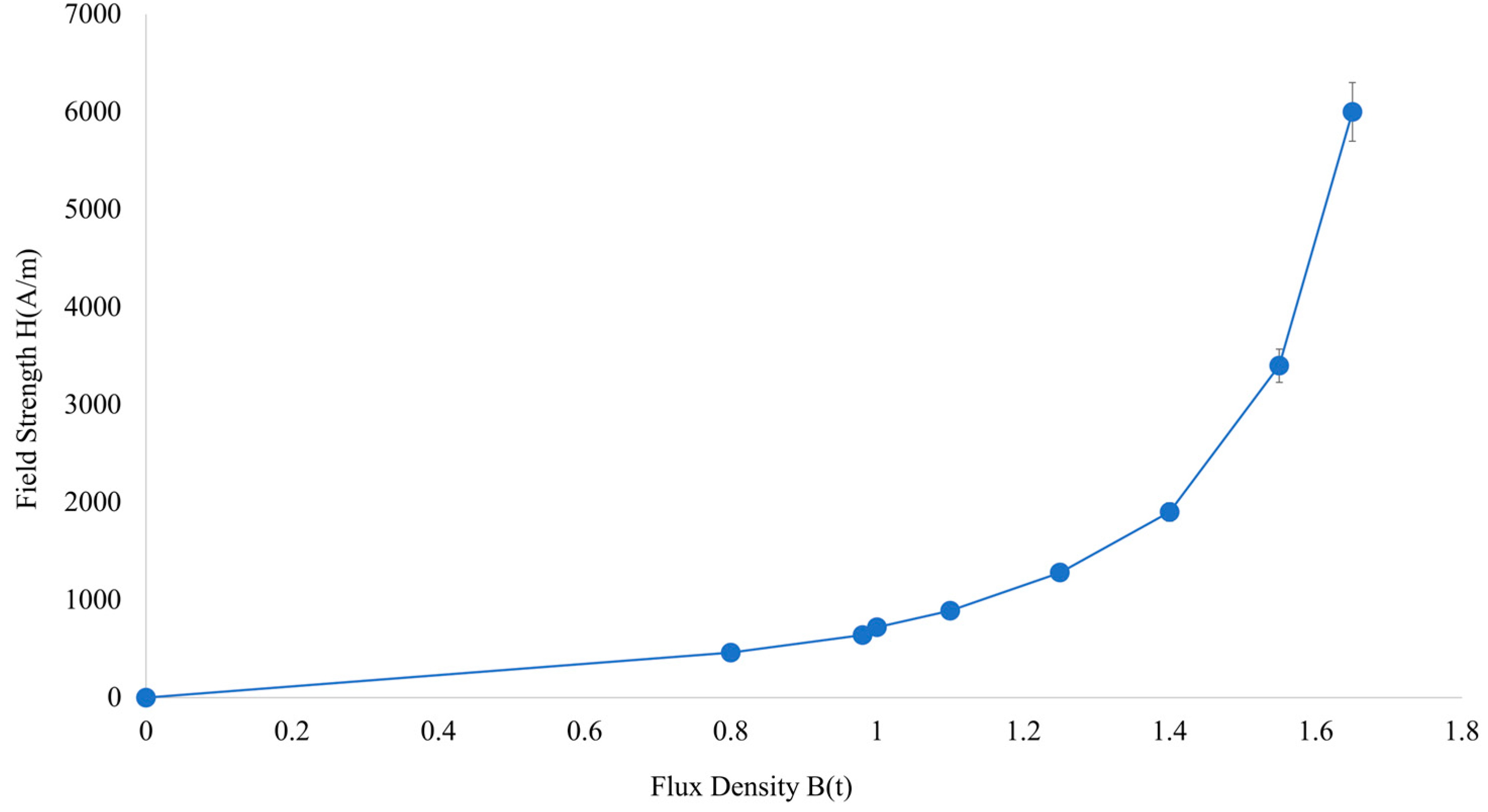

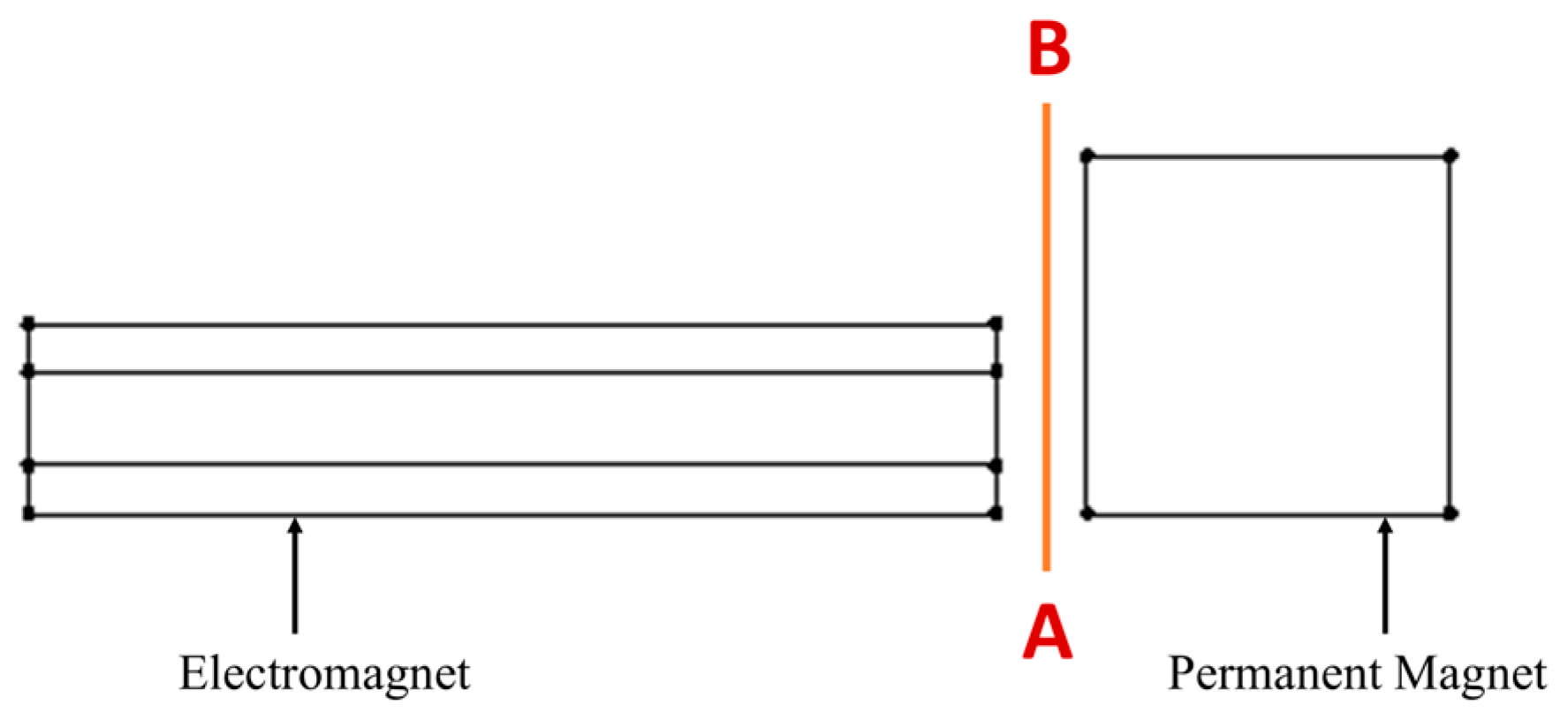

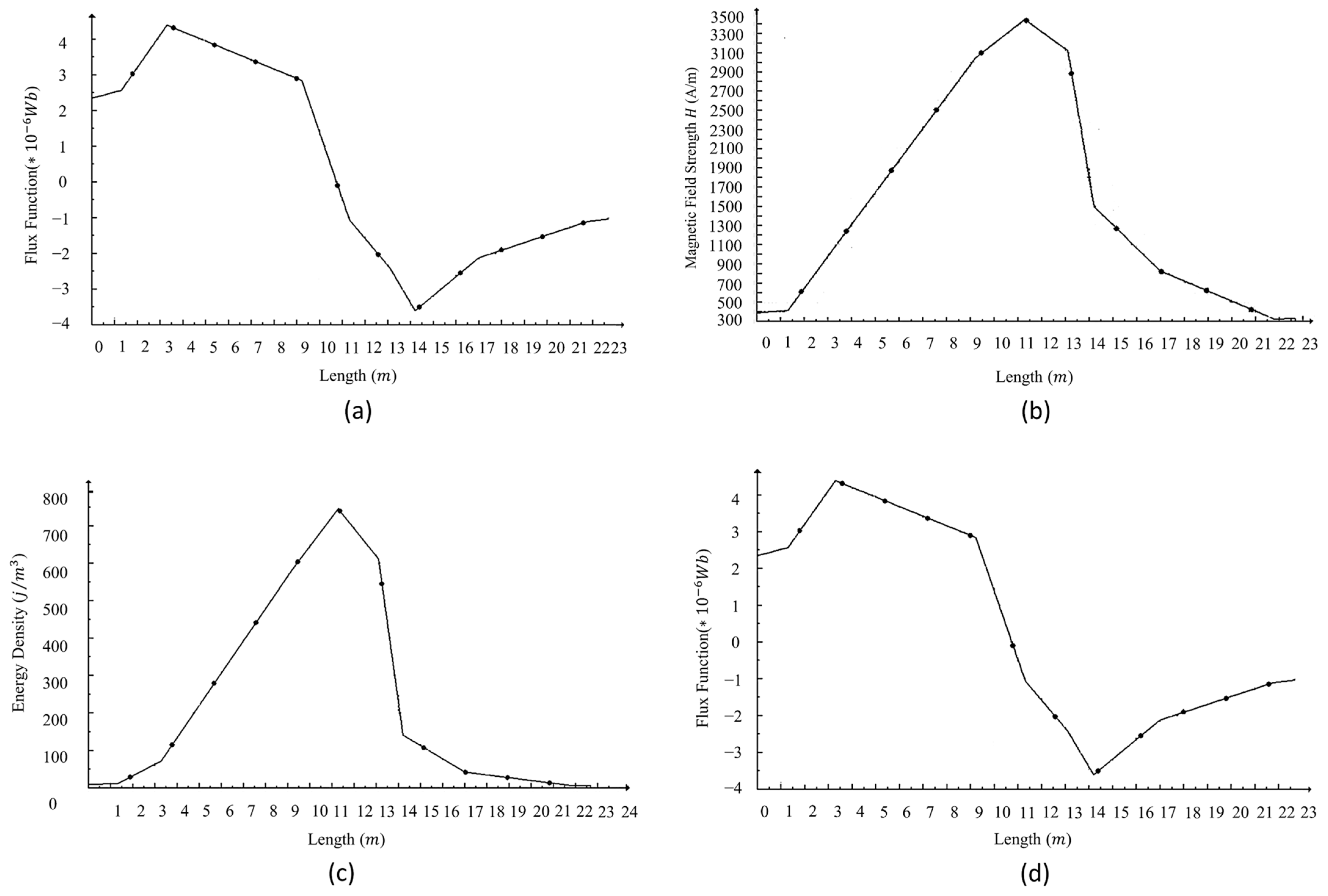

3.1. Analysis of Magnetic Force Interactions

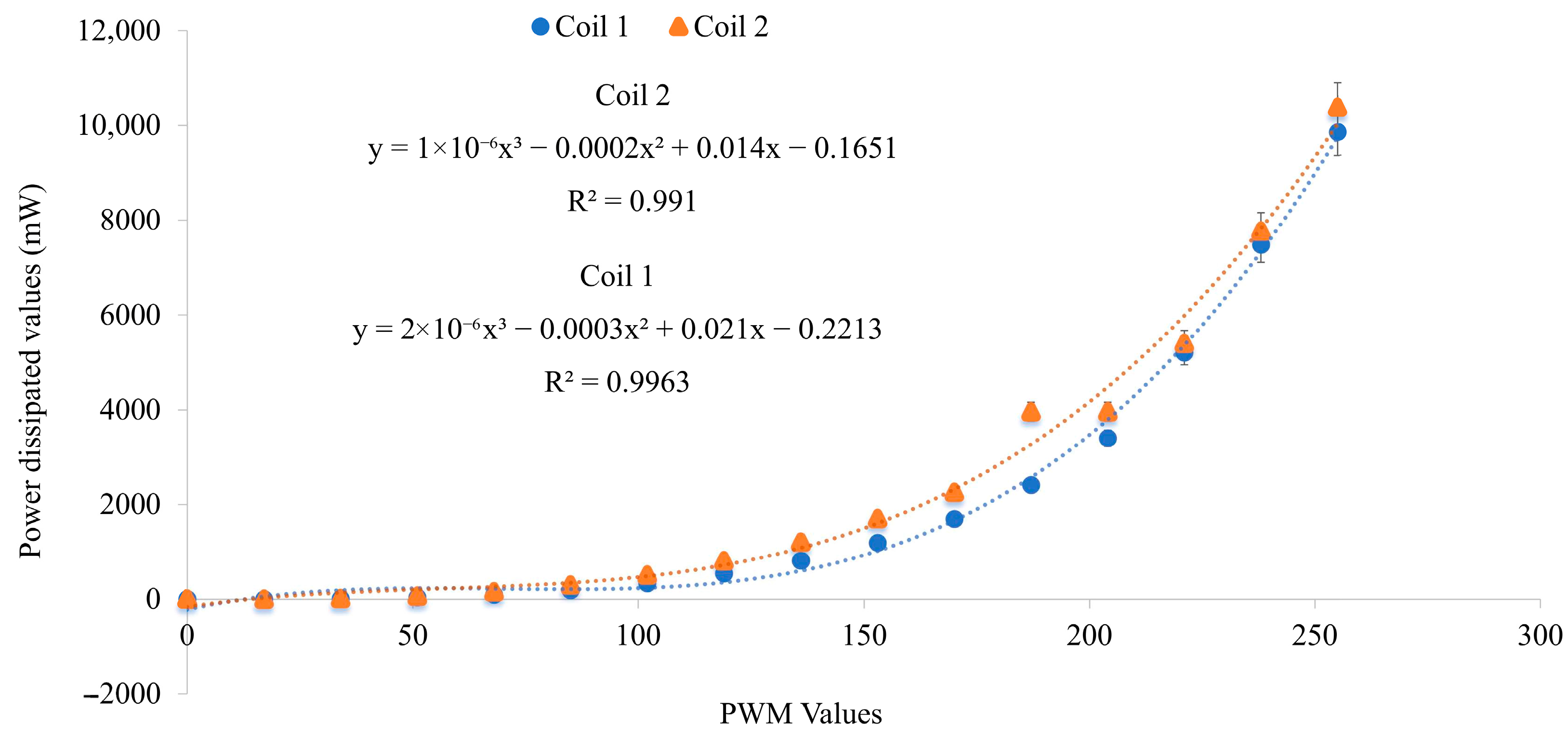

3.2. Evaluation of Magnetic Actuation and Motion Range

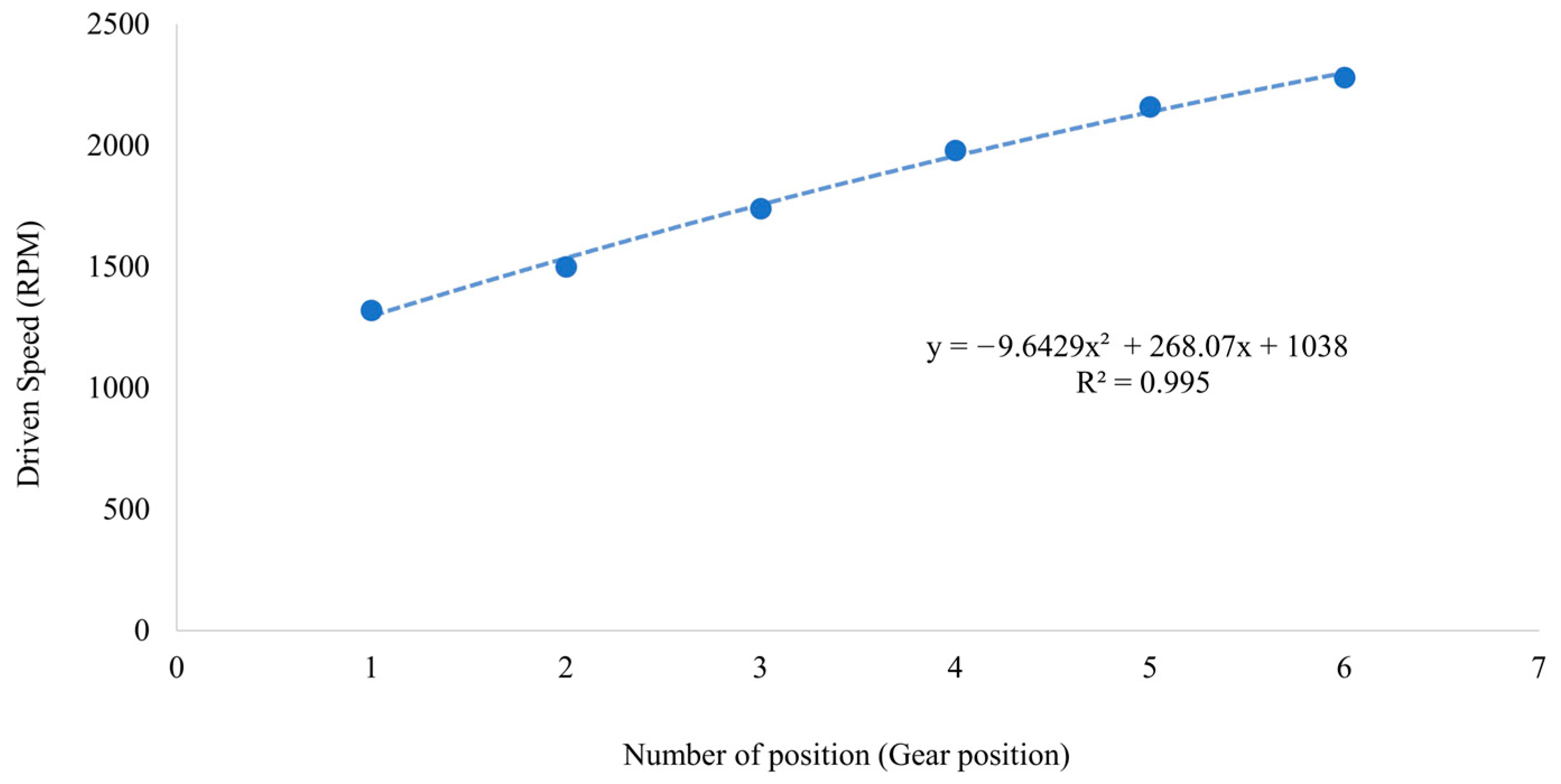

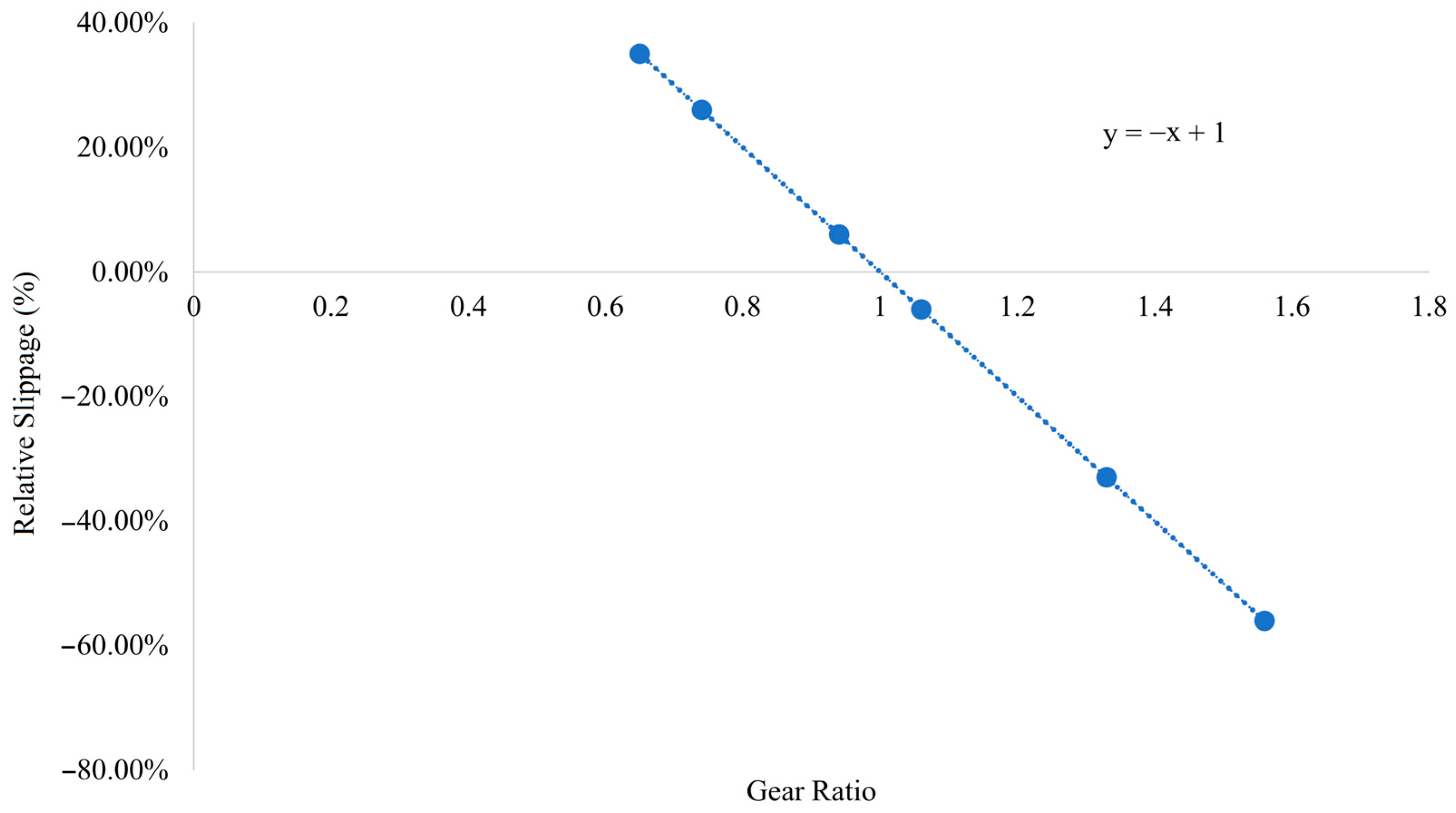

3.3. Gear Ratio Modulation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CVT | Continuously Variable Transmission |

| EMF | Electromotive Force |

| Gr | Gear Ratio |

| HRC | Human–Robot Collaboration |

| ISO | International Organization for Standardization |

| N40 | Neodymium Grade 40 |

| PFL | Power and Force Limiting |

| PWM | Pulse Width Modulation |

| SP | Slip Percentage |

| SWG | Standard Wire Gauge |

| V | Voltage |

References

- Hellmann, C.; Zimmermann, T.; Kraus, W. About Robot Applications and Robotic Research in Cooperative Projects Between Industrial Companies and Research Organisations. In Proceedings of the 50th International Symposium on Robotics, Munich, Germany, 20–21 June 2018. [Google Scholar]

- Dhanushka, S.; Hasaranga, C.; Kahatapitiya, N.S.; Wijesinghe, R.E.; Wijethunge, A. Efficient Battery Management and Workflow Optimization in Warehouse Robotics Through Advanced Localization and Communication Systems. Eng. Proc. 2024, 82, 50. [Google Scholar] [CrossRef]

- Murashov, V.; Hearl, F.; Howard, J. Working Safely with Robot Workers: Recommendations for the New Workplace. J. Occup. Environ. Hyg. 2016, 13, D61–D71. [Google Scholar] [CrossRef]

- Boschetti, G.; Bottin, M.; Faccio, M.; Maretto, L.; Minto, R. The Influence of Collision Avoidance Strategies on Human-Robot Collaborative Systems. IFAC-Pap. 2022, 55, 301–306. [Google Scholar] [CrossRef]

- Knudsen, M.; Kaivo-oja, J. Collaborative Robots: Frontiers of Current Literature. J. Intell. Syst. Theory Appl. 2020, 3, 13–20. [Google Scholar] [CrossRef]

- Kakade, V.M.; Pawar, G.R.; Ghoderao, V.P. Various Sensor Used in Robotics with Applications. J4R—J. Res. 2018, 12, 3. [Google Scholar]

- Abdhul Rahuman, M.A.; Kahatapitiya, N.S.; Amarakoon, V.N.; Wijenayake, U.; Silva, B.N.; Jeon, M.; Kim, J.; Ravichandran, N.K.; Wijesinghe, R.E. Recent Technological Progress of Fiber-Optical Sensors for Bio-Mechatronics Applications. Technologies 2023, 11, 157. [Google Scholar] [CrossRef]

- Saito, T.; Hoshi, T.; Ikeda, H.; Okabe, K. Global Harmonization of Safety Regulations for the Use of Industrial Robots-Permission of Collaborative Operation and a Related Study by JNIOSH. Ind. Health 2015, 53, 498–504. [Google Scholar] [CrossRef]

- ISO/TS 15066:2016; Robots and Robotic Devices—Collaborative Robots. ISO: Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/62996.html (accessed on 20 August 2025).

- Byrne, B.; Rossi, A.; Doolan, M. Humanoid Robots Attending Lectures: Research Informed Teaching. In Proceedings of the 9th International Conference on Education Technology and Computers, Barcelona, Spain, 20 December 2017; pp. 7–11. [Google Scholar]

- Li, H.; Ma, W.; Wang, H.; Liu, G.; Wen, X.; Zhang, Y.; Yang, M.; Luo, G.; Xie, G.; Sun, C. A Framework and Method for Human-Robot Cooperative Safe Control Based on Digital Twin. Adv. Eng. Inform. 2022, 53, 101701. [Google Scholar] [CrossRef]

- Li, W.; Hu, Y.; Zhou, Y.; Pham, D.T. Safe Human–Robot Collaboration for Industrial Settings: A Survey. J. Intell. Manuf. 2023, 35, 2235–2261. [Google Scholar] [CrossRef]

- Kulic, D.; Croft, E. Pre-Collision Safety Strategies for Human-Robot Interaction. Auton. Robot. 2007, 22, 149–164. [Google Scholar] [CrossRef]

- Al-Shuka, H.F.N.; Leonhardt, S.; Zhu, W.-H.; Song, R.; Ding, C.; Li, Y. Active Impedance Control of Bioinspired Motion Robotic Manipulators: An Overview. Appl. Bionics Biomech. 2018, 2018, e8203054. [Google Scholar] [CrossRef]

- Garcia, P.L.; Saerens, E.; Crispel, S.; Varadharajan, A.; Lefeber, D.; Verstraten, T. Factors Influencing Actuator’s Backdrivability in Human-Centered Robotics. MATEC Web Conf. 2022, 366, 01002. [Google Scholar] [CrossRef]

- A-Lhamouz, S.O.; El-Omari, N.K.T.; Al-Naimat, A.M. An ISO Compliant Safety System for Human Workers in Human-Robot Interaction Work Environment. In Proceedings of the 2019 12th International Conference on Developments in eSystems Engineering (DeSE), Kazan, Russia, 7–10 October 2019; pp. 9–14. [Google Scholar]

- Mobedi, E.; Dede, M.İ.C. Geometrical Analysis of a Continuously Variable Transmission System Designed for Human-Robot Interfaces. Mech. Mach. Theory 2019, 140, 567–585. [Google Scholar] [CrossRef]

- Kim, J.; Park, F.C.; Park, Y. Design, Analysis and Control of a Wheeled Mobile Robot with a Nonholonomic Spherical CVT. 2002. Available online: https://journals.sagepub.com/doi/10.1177/027836402321261922 (accessed on 13 December 2023).

- Benitez, F.G.; Madrigal, J.M. DWU-3: A Continuous Variable Transmission Based on Epicyclic Gears; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Mobedi, E.; Dede, M.İ.C. A Continuously Variable Transmission System Designed for Human–Robot Interfaces. In Mechanism and Machine Science; Sen, D., Mohan, S., Ananthasuresh, G.K., Eds.; Springer: Singapore, 2021; pp. 29–41. [Google Scholar]

- Oh, W.H.; Lee, J.H.; Kwon, H.G.; Yoon, H.J. Model-Based Development of Automotive Embedded Systems: A Case of Continuously Variable Transmission (CVT). In Proceedings of the 11th IEEE International Conference on Embedded and Real-Time Computing Systems and Applications (RTCSA’05), Hong Kong, China, 17–19 August 2005; pp. 201–204. [Google Scholar]

- Kluger, M.A.; Fussner, D.R. An Overview of Current CVT Mechanisms, Forces and Efficiencies; SAE International: Warrendale, PA, USA, 1997. [Google Scholar]

- Cretu, O.S.; Glovnea, R.P. Traction Drive with Reduced Spin Losses. J. Tribol. 2003, 125, 507–512. [Google Scholar] [CrossRef]

- Ariyono, S.; Supriyo, B.; Feriadi, I.; Harahab, D.; Husain, N. The Ability of The Continuously Variable Transmission to Control the Engine at Maximum Power: Literature Review. SINERGI 2021, 25, 343. [Google Scholar] [CrossRef]

- Experimental and Theoretical Investigation of CVT Rubber Belt Vibrations. Available online: https://www.degruyter.com/document/doi/10.1515/eng-2021-0121/html (accessed on 14 December 2023).

- Li, C.; Li, H.; Li, Q.; Zhang, S.; Yao, J. Modeling, Kinematics and Traction Performance of No-Spin Mechanism Based on Roller-Disk Type of Traction Drive Continuously Variable Transmission. Mech. Mach. Theory 2019, 133, 278–294. [Google Scholar] [CrossRef]

- Tenberge, P.; Möckel, J. Toroidal CVT with Compact Roller Suspension. Available online: https://www.tu-chemnitz.de/mb/MaschElem/pdf/Roller%20suspension_engl.pdf (accessed on 16 December 2024).

- Laan, M.V.; der Drogen, M.V.; Brandsma, A. Improving Push Belt CVT Efficiency by Control Strategies Based on New Variator Wear Insight; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Rahman, A.; Sharif, S.B.; Mohiuddin, A.K.M.; Rashid, M.; Hossain, A. Energy Efficient Electromagnetic Actuated CVT System. J. Mech. Sci. Technol. 2014, 28, 1153–1160. [Google Scholar] [CrossRef]

- Rahman, A.; Sharif, S.; Mohiuddin, A.; Ismail, A.F.; Izan, S.I. Intelligent Control Electromagnetic Actuated Continuously Variable Transmission System for Passenger Car. IOP Conf. Ser. Mater. Sci. Eng. 2017, 184, 012063. [Google Scholar] [CrossRef]

- Continuously Variable Transmission with Pushbelt for Electric Vehicles. Available online: https://www.bosch-mobility.com/en/solutions/transmission-technology/transmission-cvt4ev/ (accessed on 28 May 2025).

- Parker, R.J.; Loewenthal, S.H.; Fischer, G.K. Design Studies of Continuously Variable Transmissions for Electric Vehicles; SAE International: Warrendale, PA, USA, 1981. [Google Scholar]

- Yamaguchi, J.; Okubo, K.; Fujii, T.; Kido, R.; Takahasi, M. Study on Power Transmitting Efficiency of Cvt Using a Dry Hybrid V-Belt; WIT Press: Southampton, UK, 2002. [Google Scholar]

- A Review on Continuously Variable Transmissions Control Da Wen Ge, Sugeng Ariyono and Daw Thet Thet Mon|PDF|Control Theory|Automatic Transmission. Available online: https://www.scribd.com/document/617221149/159178055-1-1 (accessed on 30 October 2023).

- COMSOL: Multiphysics Software for Optimizing Designs. Available online: https://www.comsol.com/ (accessed on 31 May 2025).

- Tera Analysis Ltd. Software Providers for Electromagnetic, Heat Transfer and Stress Analysis Main Design Applications: Electrical Machines, Transformers, Actuators, Magnet QuickField Support Site. Available online: https://quickfield.com/index.htm (accessed on 6 July 2025).

- Akama, S.; Murayama, Y.; Sakoda, S. Torque Control of Rear Wheel by Using Inverse Dynamics of Rubber/Aramid Belt Continuous Variable Transmission. SAE Int. J. Engines 2013, 6, 2100–2109. [Google Scholar] [CrossRef]

- ISO/IEC Standard 17025:2017; ISO/IEC (2017) General Requirements for the Competence of Testing and Calibration Labora-tories. 3rd ed. International Organization for Standardization (ISO): Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/66912.html (accessed on 20 August 2025).

- Balasubramanian, S.; Wei, R.; Perez, M.; Shepard, B.; Koeneman, E.; Koeneman, J.; He, J. RUPERT: An Exoskeleton Robot for Assisting Rehabilitation of Arm Functions. In Proceedings of the 2008 Virtual Rehabilitation, Edmonton, AB, Canada, 25–27 August 2008; pp. 163–167. [Google Scholar]

- Bonsen, B. Efficiency Optimization of the Push-Belt CVT by Variator Slip Control. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2006. [Google Scholar]

- Fu, B.; Zhu, T.; Liu, J.; Hu, X. Research on Clamping Force Control of CVT for Electric Vehicles Based on Slip Characteristics. Sensors 2022, 22, 2131. [Google Scholar] [CrossRef] [PubMed]

- Ghariblu, H.; Behroozirad, A.; Madandar, A. Traction and Efficiency Performance of Ball Type CVTs. Automot. Sci. Eng. 2014, 4, 738–748. [Google Scholar]

- Liu, Y.; Zhou, Y.; Qu, D.; Zhang, F.; Bao, X. Electric Oil Pump Design of Hybrid Continuously Variable Transmission. IET Electr. Power Appl. 2019, 13, 1089–1096. [Google Scholar] [CrossRef]

- Fu, J.; Hosseini, S.M.; Simpson, R.; Brooks, A.; Huff, R.; Park, J.-H. A Bilateral Six Degree of Freedom Cable-Driven Upper Body Exosuit. In Proceedings of the 2022 IEEE International Conference on Mechatronics and Automation (ICMA), Guilin, China, 7–9 August 2022; pp. 617–623. [Google Scholar]

| Positions | Electromagnets | |||||

|---|---|---|---|---|---|---|

| a | b | c | d | e | f | |

| N | S | |||||

| N | S | N | ||||

| N | S | N | ||||

| N | S | N | ||||

| N | S | N | N | |||

| S | N | N | ||||

| ON | OFF | |||||

| Aspect | Test Condition | Observed Result |

|---|---|---|

| Thermal Stability | 25–85 °C | +18% resistance, +12.4% power |

| Voltage Tolerance | 10.8–13.2 V | ±6.7% actuator force variation |

| Long-Term Reliability | 50,000 cycles | <5% degradation, +4.2% delay |

| Environmental Tests | Humidity, vibration, dust | <3% variation (IP54) |

| Energy Efficiency | PWM-controlled, 12 V | 2.95 ± 0.14 W, 85 ± 4.2 ms response time |

| Parameter | Belt-Driven CVT (Conventional) | Toroidal CVT | Electric Direct Drive | Hydraulic Hybrid CVT | ISO/TS 15066 Requirements | Proposed EM-CVT System |

|---|---|---|---|---|---|---|

| Slippage (%) | 3–5 | 4–8 | N/A | N/A | N/A | 0.8 ± 0.07 (GR = 6) |

| Transmission Efficiency (%) | 90–94 | 75–88 | 88–92 | 80–85 | N/A | 92–95 |

| Power Consumption (W) | 4.0–5.2 (clamping) | 5.5–7.0 | 8.0+ | 10–15 | N/A | 2.95 ± 0.14 per actuator |

| Back-drivability | Limited (high friction) | Poor | Low | Moderate | Required for HRC | Fully back-drivable |

| Response Time (ms) | 100–300 (mechanical) | 200–500 | <50 | 150–400 | <100 ms for HRC | 85 ± 4.2 |

| Force Compliance (N) | 150–200 N | 120–180 N | N/A | 200+ N | ≤150 N (quasi-static) | <100 N (5 Nm load) |

| Impact Force Reduction | Baseline | 20–30% | N/A | 10–20% | Dynamic force limits | 40% (vs. belt-driven CVT) |

| Safety Standard Compliance | Partial (post-collision strategies) | Partial | Yes (electronic limits) | No | Force/speed thresholds | Meets ISO/TS 15066 |

| Control Method | Mechanical clamping | Hydraulic | Motor control | Fluid dynamics | N/A | Electromagnetic array (PWM) |

| Key Limitations | High wear, vibration | Spin losses | Low back-drivability | Bulkiness, leakage | N/A | Limited torque scalability |

| Ref. | [24,28,33,40,41] | [26,27,28,42] | [15,31,32] | [43] | [9] | (Proposed system) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madusankha, I.; Jayaweera, P.N.; Kahatapitiya, N.S.; Sampath, P.; Weeraratne, A.; Subasinghage, K.; Liyanage, C.; Wijethunge, A.; Ravichandran, N.K.; Wijesinghe, R.E. Electromagnetic Continuously Variable Transmission (EMCVT) System for Precision Torque Control in Human-Centered Robotic Applications. Appl. Mech. 2025, 6, 69. https://doi.org/10.3390/applmech6030069

Madusankha I, Jayaweera PN, Kahatapitiya NS, Sampath P, Weeraratne A, Subasinghage K, Liyanage C, Wijethunge A, Ravichandran NK, Wijesinghe RE. Electromagnetic Continuously Variable Transmission (EMCVT) System for Precision Torque Control in Human-Centered Robotic Applications. Applied Mechanics. 2025; 6(3):69. https://doi.org/10.3390/applmech6030069

Chicago/Turabian StyleMadusankha, Ishara, Prageeth Nimantha Jayaweera, Nipun Shantha Kahatapitiya, Peshan Sampath, Ashan Weeraratne, Kasun Subasinghage, Chamara Liyanage, Akila Wijethunge, Naresh Kumar Ravichandran, and Ruchire Eranga Wijesinghe. 2025. "Electromagnetic Continuously Variable Transmission (EMCVT) System for Precision Torque Control in Human-Centered Robotic Applications" Applied Mechanics 6, no. 3: 69. https://doi.org/10.3390/applmech6030069

APA StyleMadusankha, I., Jayaweera, P. N., Kahatapitiya, N. S., Sampath, P., Weeraratne, A., Subasinghage, K., Liyanage, C., Wijethunge, A., Ravichandran, N. K., & Wijesinghe, R. E. (2025). Electromagnetic Continuously Variable Transmission (EMCVT) System for Precision Torque Control in Human-Centered Robotic Applications. Applied Mechanics, 6(3), 69. https://doi.org/10.3390/applmech6030069