Green Forging of Titanium and Titanium Alloys by Using the Carbon Supersaturated SKD11 Dies

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Preparation of Plasma Processed Punches

2.2. Work Materials

2.3. Forging System

2.4. Finite Element Forging Analysis

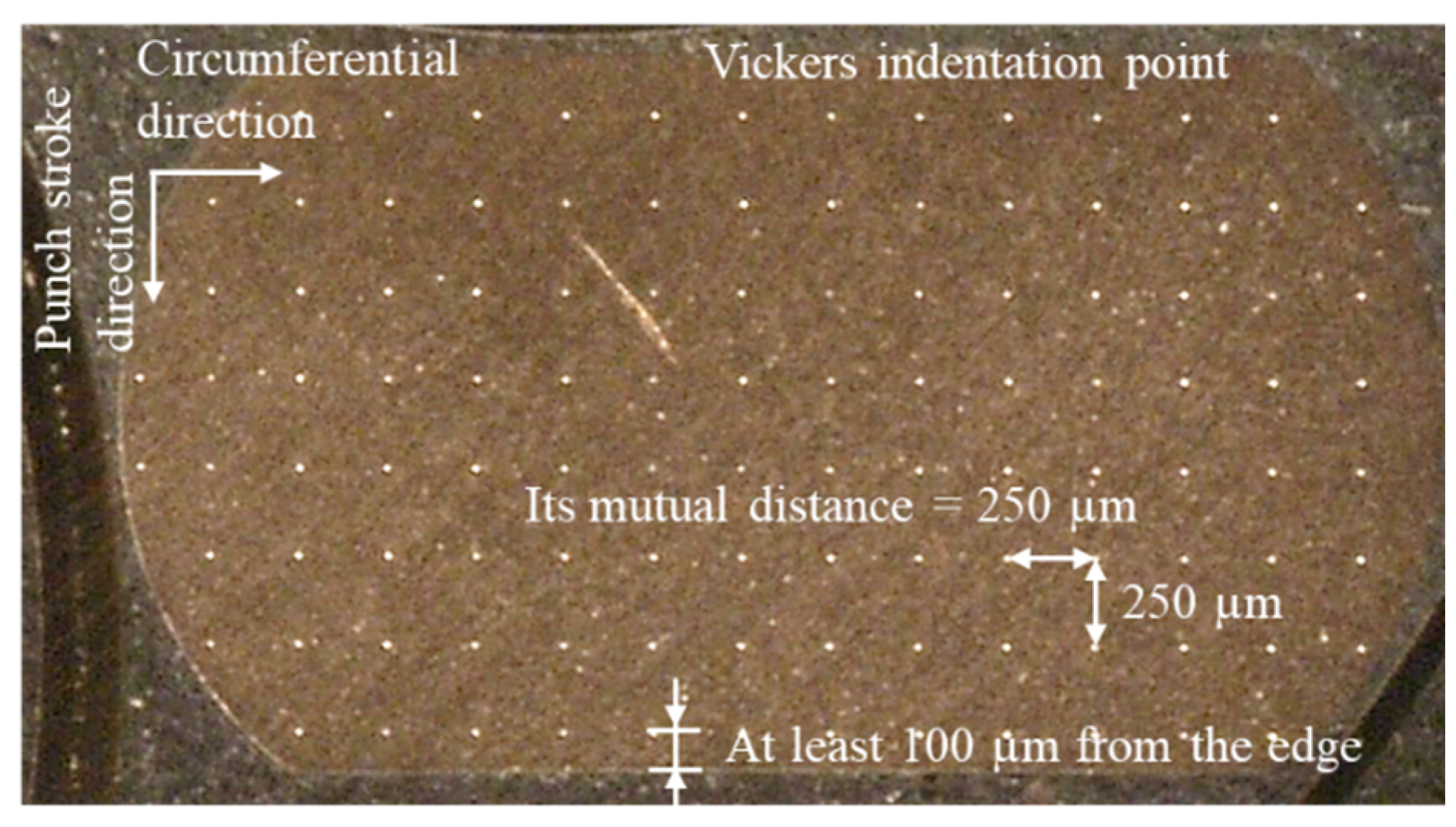

2.5. Hardness Mapping

3. Experimental Results

3.1. Upsetting Behavior of Titanium and β-Titanium Wires

3.2. Frictional Behavior on the Contact Interface

3.3. Work-Hardening Behavior of Pure Titanium Work during the Forging Process

3.4. Work-Hardening Behavior of β-Titanium Alloy Work during the Forging Process

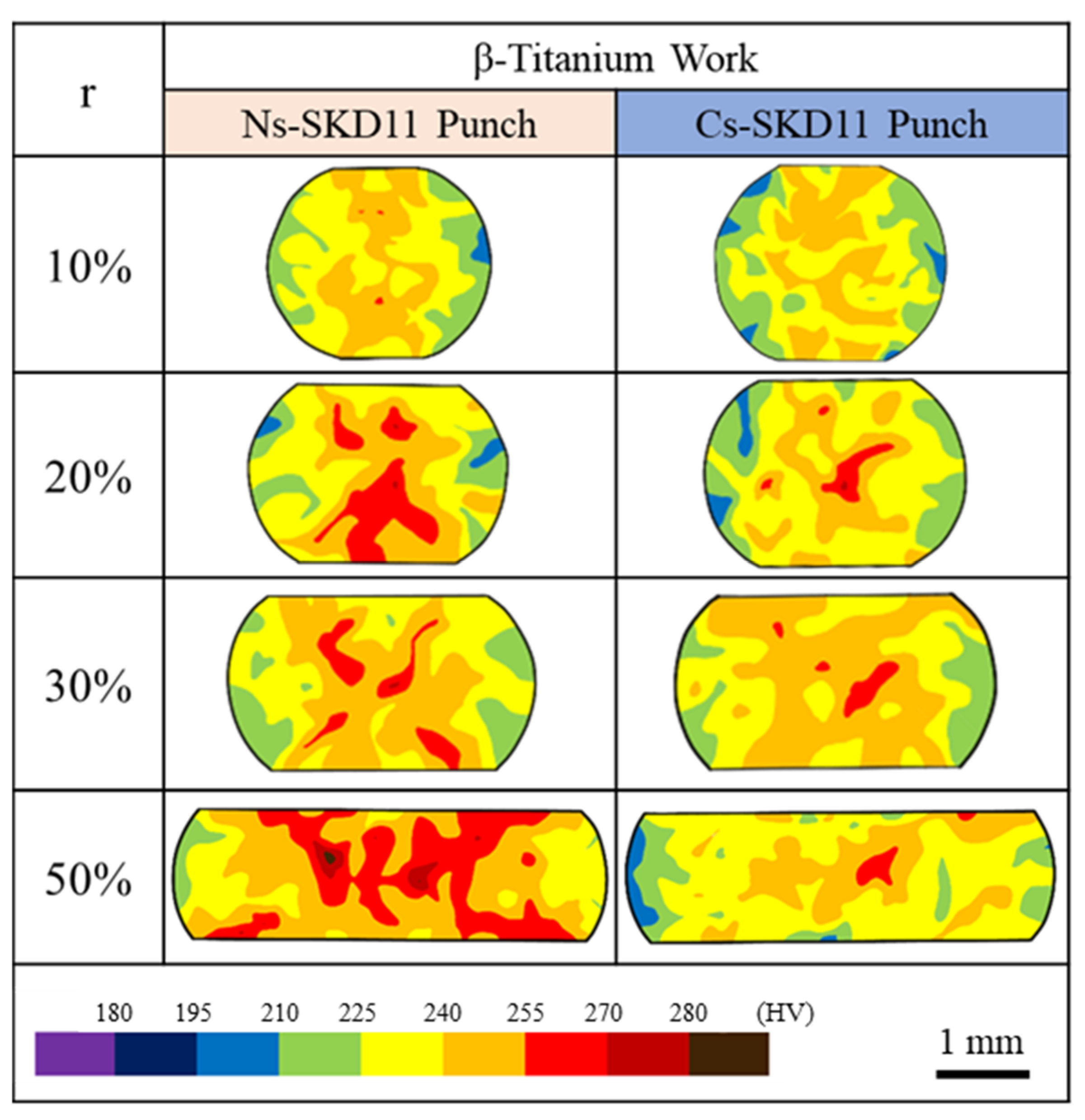

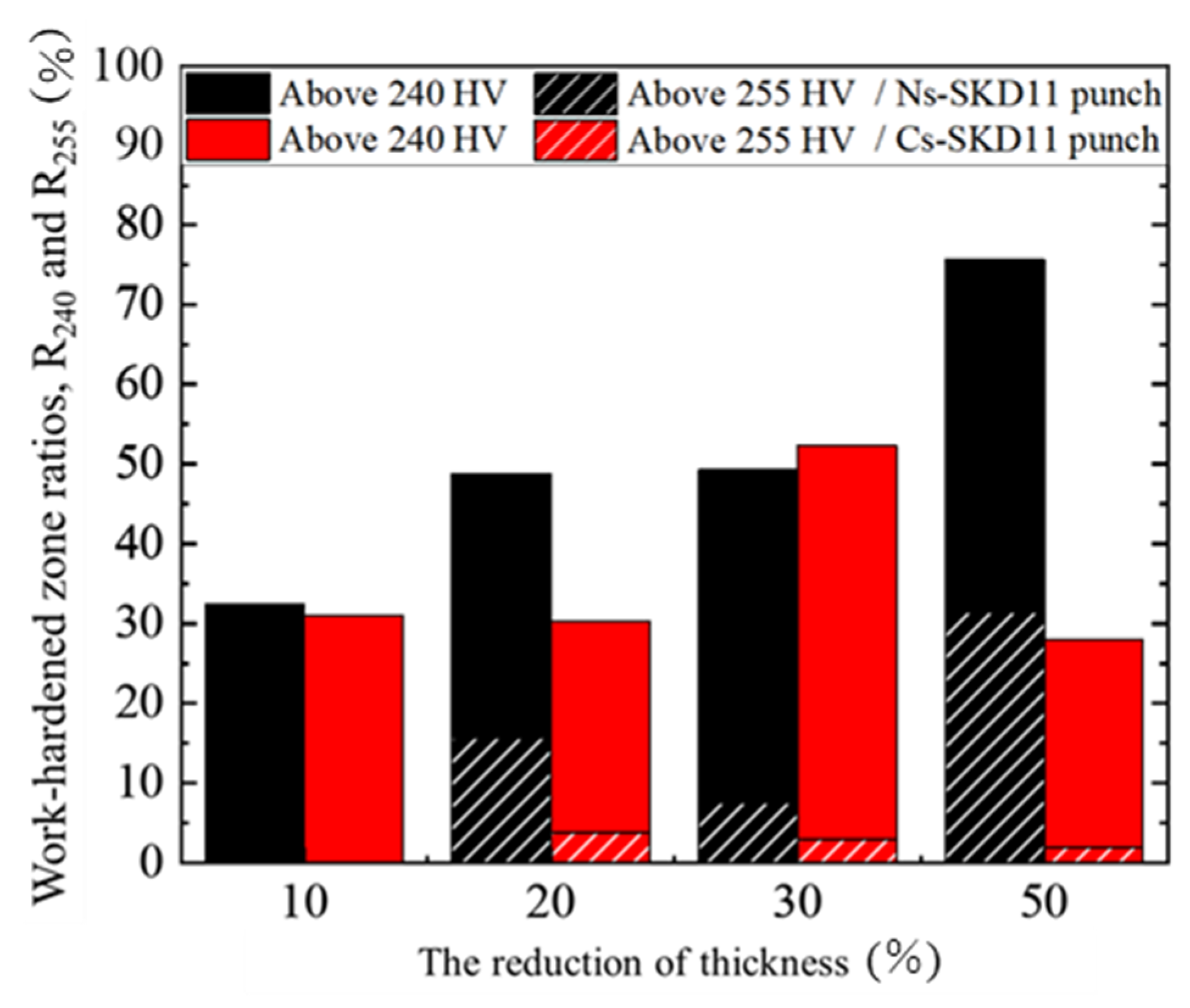

3.5. Contact Interface Analysis by SEM-EDX and Raman Spectroscopy

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shirvani, B.; Clarke, R.; Duflou, J.; Merklein, M.; Micari, F.; Griffiths, J. Stamping of titanium sheets. Key Eng. Mater. 2009, 410–411, 279–288. [Google Scholar]

- Clauss, M.; Graf, S.; Gersbach, S.; Hintermann, B.; Ilchmann, T.; Knupp, M. Material and biofilm load of K wires in toe surgery: Titanium versus stainless steel. Clin. Orthop. Relat. Res. 2013, 471, 2312–2317. [Google Scholar] [CrossRef] [Green Version]

- Moxson, V.S.; Froes, F.H. Fabricating sports equipment components via powder metallurgy. JOM 2003, 53, 39–41. [Google Scholar] [CrossRef]

- Höher, J.; Livesay, G.A.; Ma, C.B.; Withrow, J.D.; Fu, F.H.; Woo, S. Hamstring graft motion in the femoral bone tunnel when using titanium button/ polyester tape fixation. Knee Surg. Sports Traumatol. Arthrosc. 1999, 7, 215–219. [Google Scholar] [CrossRef]

- Pornsin-Sirirak, T.N.; Tai, Y.C.; Nassef, H.; Ho, C.M. Titanium-alloy MEMS wing technology for a micro aerial vehicle application. Sens. Actuators A Phys. 2001, 89, 95–103. [Google Scholar] [CrossRef]

- Aimi, M.F.; Rao, M.P.; MacDonald, N.C.; Zuruzi, A.S.; Bothman, D.P. High-aspect-ratio bulk micromachining of titanium. Nat. Mater. 2004, 3, 103–105. [Google Scholar] [CrossRef]

- Kihara, T. Visualization of deforming process of titanium and titanium alloy using high speed camera. In Proceedings of the 2019 JSTP Conference, Kyoto, Japan, 7–9 June 2019; pp. 41–42. [Google Scholar]

- Dohda, K.; Aizawa, T. Tribo-characterization of silicon doped and nano-structured DLC coatings by metal forming simulators. Manuf. Lett. 2014, 2, 82–85. [Google Scholar] [CrossRef]

- Aizawa, T. Low temperature plasma nitriding of austenitic stainless steels. In Stainless Steels and Alloys; IntechOpen: London, UK, 2019; Chapter 3; Volume 3, pp. 31–50. [Google Scholar]

- Farghali, A.; Aizawa, T. Nitrogen supersaturation process in the AISI420 martensitic stainless steels by low temperature plasma nitriding. ISIJ Int. 2018, 58, 401–407. [Google Scholar] [CrossRef] [Green Version]

- Aizawa, T.; Yoshino, T.; Suzuki, Y.; Shiratori, T. Anti-galling cold, dry forging of pure titanium by plasma-carburized AISI420J2 dies. Appl. Sci. 2021, 11, 595. [Google Scholar] [CrossRef]

- Aizawa, T.; Yoshino, T.; Suzuki, Y.; Shiratori, T. Free-forging of pure titanium with high reduction of thickness by plasma-carburized SKD11 dies. Materials 2021, 14, 2536. [Google Scholar] [CrossRef]

- Aizawa, T.; Yoshino, T.; Shiratori, T. Galling-free cold forging of titanium alloys by the plasma carburized SKD11 dies. In Proceedings of the 13th AWMFT-ASPS Conference, Shanghai, China, 3–6 November 2021. (In press). [Google Scholar]

- Ishiguro, S.; Aizawa, T.; Shiratori, T. Characterization on forged titanium and titanium alloys by carbon supersaturated SKD11 punch. In Proceedings of the 13th AWMFT-ASPS Conference, Shanghai, China, 3–6 November 2021. (In press). [Google Scholar]

- Aizawa, T.; Rsadi, I.; Yunata, E.E. High density RF-DC plasma nitriding under optimized conditions by plasma diagnosis. Appl. Sci. 2022, 12, 3706. [Google Scholar] [CrossRef]

- Aizawa, T.; Yoshino, T.; Shiratori, T.; Dohda, K. Anti-galling β-SiC coating dies for fine cold forging of titanium. J. Phys. Conf. Ser. 2021, 1777, 012043. [Google Scholar] [CrossRef]

- Hsu, Y.; Lin, Y.K.; Sun, K.W.; Wu, S.H. Development of a continuous rolling process for titanium wires. China Steel Technol. Res. 2012, 25, 28–35. [Google Scholar]

- Chen, Y.J.; Meyers, M.A.; Nesterenko, V.F. Spontaneous and forced shear localization in high-strain-rate deformation of tantalum. Mater. Sci. Eng. 1999, 268, 70–82. [Google Scholar] [CrossRef]

- Solomonov, K.N.; Tishchuk, L.I.; Lezhnev, S.N.; Listrov, E.A. Simulation of upsetting process using kinematic schemes of metal flow. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 022041. [Google Scholar] [CrossRef]

- Kataoka, S.; Murakawa, M.; Aizawa, T.; Ike, H. Tribology of dry deep-drawing of various metal sheets wit use of ceramic tools. Surf. Coat. Technol. 2004, 178, 582–590. [Google Scholar] [CrossRef]

- Urbonaite, S.; Hälldahl, L.; Svensson, G. Raman spectroscopy studies of carbide derived carbons. Carbon 2008, 46, 1942–1947. [Google Scholar] [CrossRef]

- Condat, Forging—Lubricants—Coatings. Available online: https://www.condat-lubricants.com/product/forging-lubricants-coatings/ (accessed on 12 June 2022).

- Borgioli, F.; Galvanetto, E.; Bacci, T. Corrosion behavior of low temperature nitrided nickel-free, AISI200 and AISI300 series austenitic stainless steels in NaCl. Corros. Sci. 2018, 136, 352–365. [Google Scholar] [CrossRef]

- Domain, C.; Becquart, C.S.; Foct, J. Ab initio study of foreign interstitial atom (C, N) interactions with intrinsic point defects in α-Fe. Phys. Rev. B 2004, 69, 144122. [Google Scholar] [CrossRef]

- Buggenhoudt, O.; Schuler, T.; Fu, C.C.; Bechade, J.L. Predicting carbon diffusion in cementite from first principles. Phys. Rev. Mater. 2021, 5, 063401. [Google Scholar] [CrossRef]

- Li, H.; Fu, M.W.; Lu, J.; Yang, H. Ductile fracture: Experiments and computations. Int. J. Plast. 2011, 27, 147–180. [Google Scholar] [CrossRef]

- Tarasov, S.Y. Localization of strain in friction. Met. Sci. Heat Treat. 2006, 48, 226–230. [Google Scholar] [CrossRef]

- Nielsen, K.L.; Pardoen, T.; Tvergaard, V.; de Meester, B.; Simar, A. Modeling of plastic flow localization and damage development in friction stir welded 6005A aluminum alloy using physics based strain hardening law. Int. J. Solids Struct. 2010, 47, 2359–2370. [Google Scholar] [CrossRef] [Green Version]

- Martin, J. Materials for Engineering; Woodhead Publishing: Sawston, Cambridge, UK, 2006. [Google Scholar]

| Process | Pre Sputtering | Nitriding | Carburizing |

|---|---|---|---|

| Using Gas/Gas flow (mL/min) | Argon/100 | Nitrogen and hydrogen gas mixture/160 Hydrogen/30 | Argon/100 Hydrogen/80 Methane (CH4)/20 |

| Processing time (s) | 1800 | 14,400 | 14,400 |

| Temperature (K) | 673 | 673 | 673 |

| Pressure | 70 | 70 | 70 |

| RF-voltage | 200 | 200 | 200 |

| DC−bias | −600 | −600 | −600 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ishiguro, S.; Aizawa, T.; Funazuka, T.; Shiratori, T. Green Forging of Titanium and Titanium Alloys by Using the Carbon Supersaturated SKD11 Dies. Appl. Mech. 2022, 3, 724-739. https://doi.org/10.3390/applmech3030043

Ishiguro S, Aizawa T, Funazuka T, Shiratori T. Green Forging of Titanium and Titanium Alloys by Using the Carbon Supersaturated SKD11 Dies. Applied Mechanics. 2022; 3(3):724-739. https://doi.org/10.3390/applmech3030043

Chicago/Turabian StyleIshiguro, Shunsuke, Tatsuhiko Aizawa, Tatsuya Funazuka, and Tomomi Shiratori. 2022. "Green Forging of Titanium and Titanium Alloys by Using the Carbon Supersaturated SKD11 Dies" Applied Mechanics 3, no. 3: 724-739. https://doi.org/10.3390/applmech3030043

APA StyleIshiguro, S., Aizawa, T., Funazuka, T., & Shiratori, T. (2022). Green Forging of Titanium and Titanium Alloys by Using the Carbon Supersaturated SKD11 Dies. Applied Mechanics, 3(3), 724-739. https://doi.org/10.3390/applmech3030043