Waterproof Design of Soft Multi-Directional Force Sensor for Underwater Robotic Applications

Abstract

:1. Introduction

2. Materials and Methods

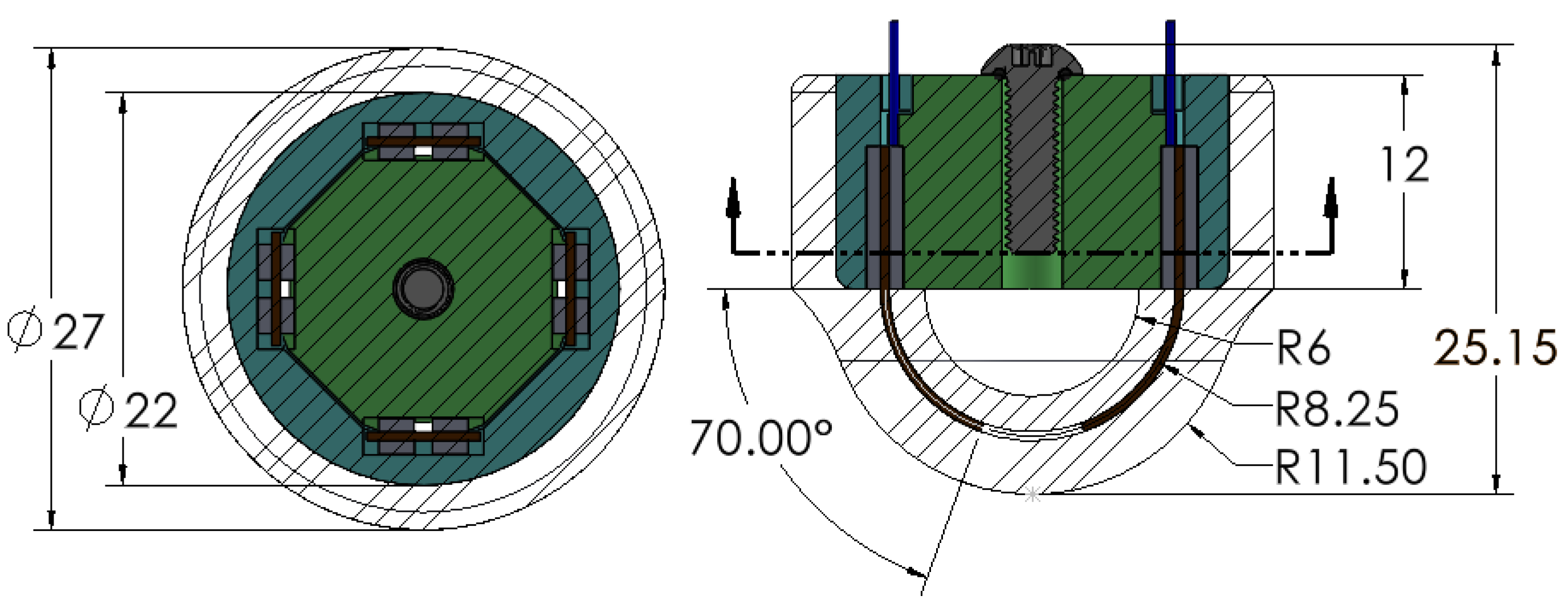

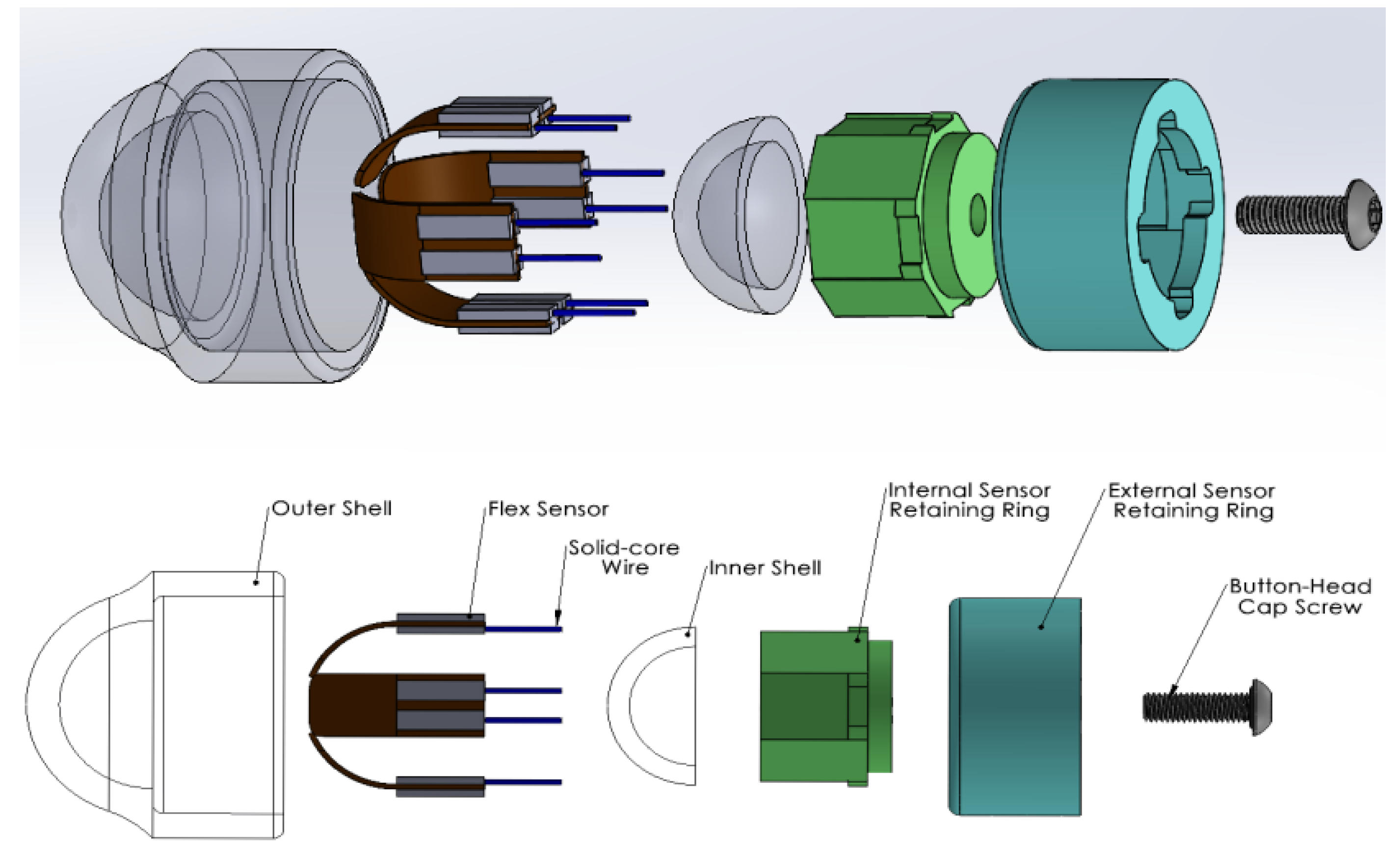

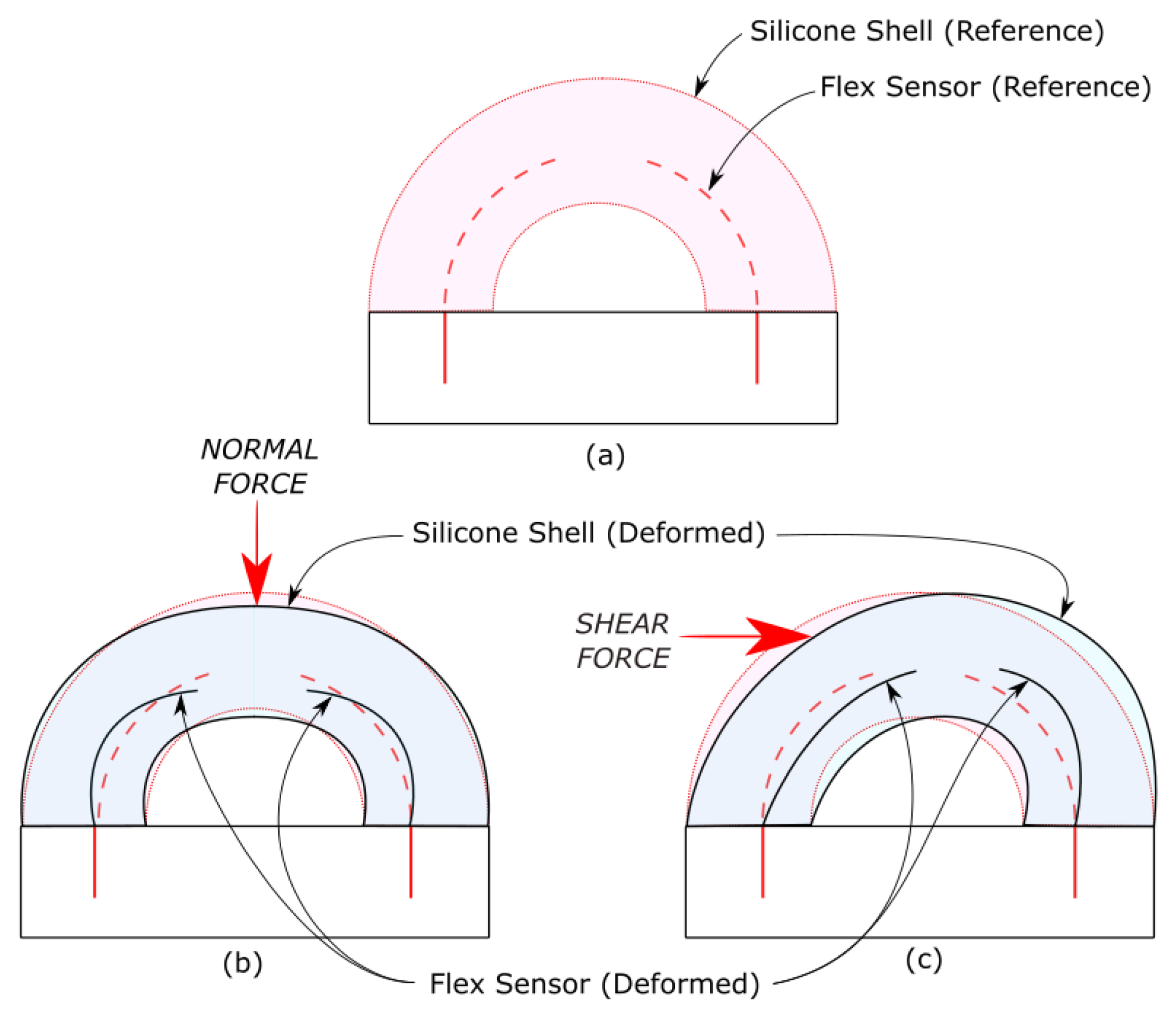

2.1. Design

2.2. Fabrication Process

- Cut the flex sensors (Item 2) to a length of 17 mm. Add two clinch connectors and solder wire (Item 3) to the terminals.

- Place the flex sensors inside of the internal and external retaining rings, carefully pulling the wires through.

- Using DEVCON 2-part epoxy (5 Minute Epoxy, ITW Global Brands, Houston, TX, USA), back-fill the internal and external retaining ring interface. Ensure there are no-air gaps in the wire through-ways.

- After the DEVCON epoxy has fully cured and the retaining rings are joined, tap an M3.5x0.6 thread through the center of the ring. (Note: This step is not shown visually).

- Mold the outer shell (Item 1) and inner shell (Item 4) using DSFP platinum silicone and Slacker Silicone Tactile Mutator. Mix equal portions of DSFP 1A:1B with Slacker Silicone mutator to form mix ratio of 10:1 (Silicone:Mutator). Let the molds cure for 1.5 h each.

- Adhere the inner shell onto the retaining ring interface using Sil-Poxy silicone adhesive (Sil-Poxy, Smooth-on, Macungie, PA, USA). Let the Sil-Poxy cure for 20 min.

- Using Sil-Poxy, Adhere quantity 2 flex sensors in 180 alignments to the inner shell to establish default radius profiles. Use three thin zip-ties to restrict the movement of the flex sensors as shown in Figure 5. Apply the Sil-Poxy and then pull the zip-ties tight to keep the flex sensors in place during curing. Allow the Sil-Poxy to cure for 30 min.

- Repeat step 7 with the remaining two flex sensors.

- Carefully remove the zip-ties. Adhere the outer layer onto the inner layer using Sil-Poxy. Allow the Sil-Poxy to cure for 1 hour.

- Place the force sensor into a small bucket of mineral oil (’ISO Grade 32’, McMaster-Carr, Elmhurst, IL, USA). Displace any air bubbles that are trapped internal to the sensor by filling the internal pocket with mineral oil. Use a small object such as a hex-wrench to force the air bubbles out considering the high viscosity of the mineral oil.

- With the sensor displaced in the oil, insert the button head cap screw to seal the mineral oil into the internal pocket. It is critical to apply hardware while submersed in the mineral oil to avoid intrusion of air to the internal pocket.

- Remove the sensor from the mineral oil, and place it into Isopropyl alcohol for 1 min. Clean the oil from the sensor surface with a q-tip taking extra care to remove residual oil from the top surface.

- Add a final layer of DEVCON 2-part epoxy to the top surface of the sensor to fully encapsulate the sealing hardware.

- Take extra care to label wires and bundle them together to ensure proper identification and preservation for further testing. The fabrication process is complete.

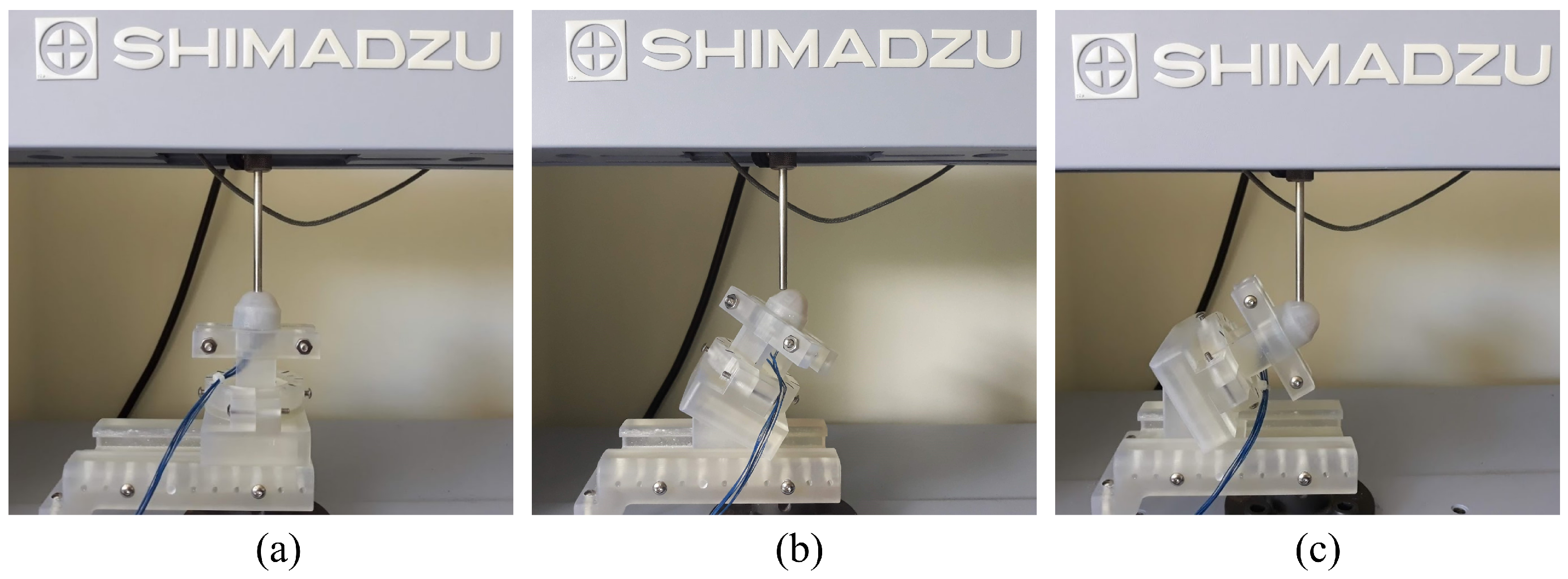

3. Experimental Results

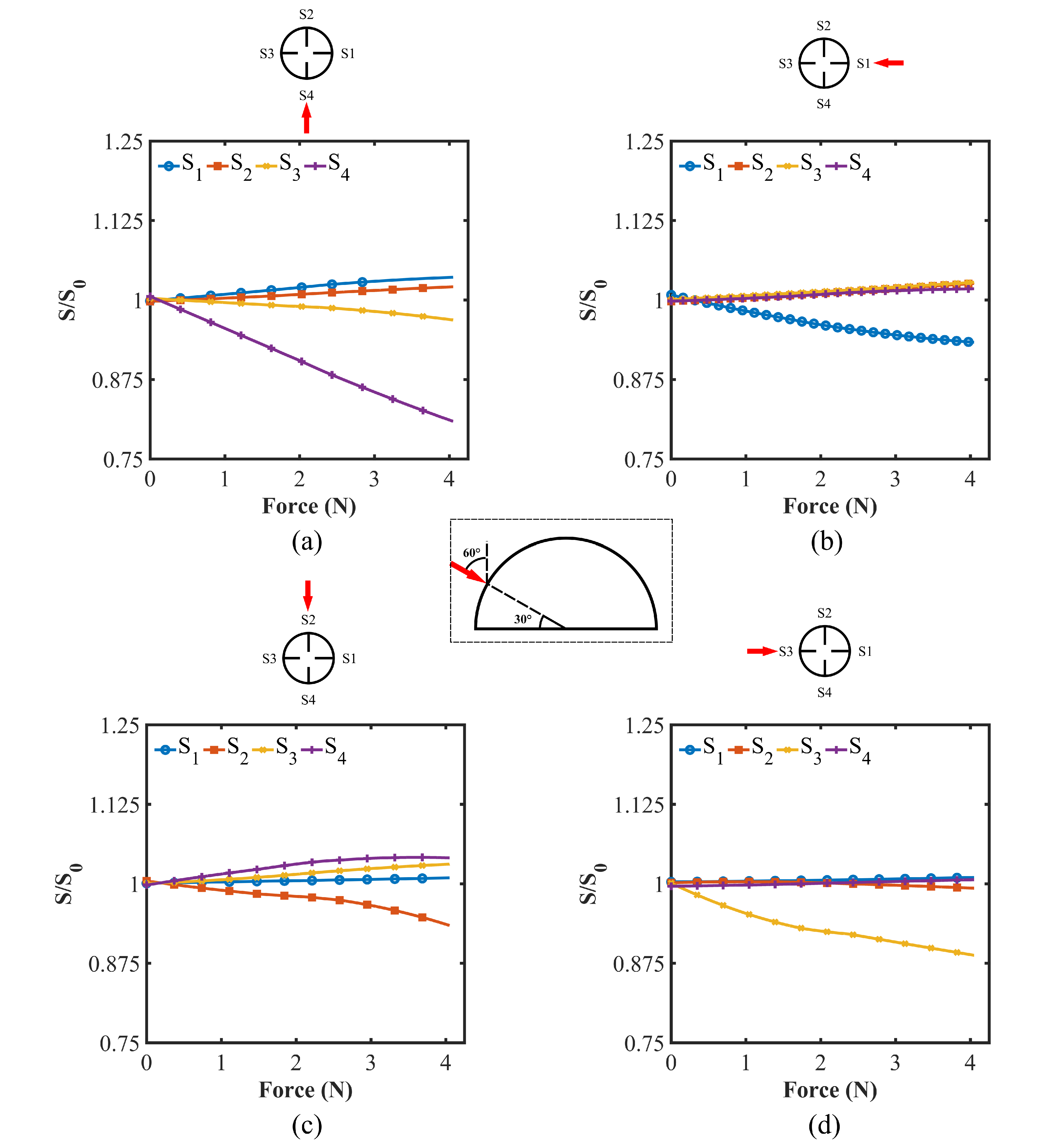

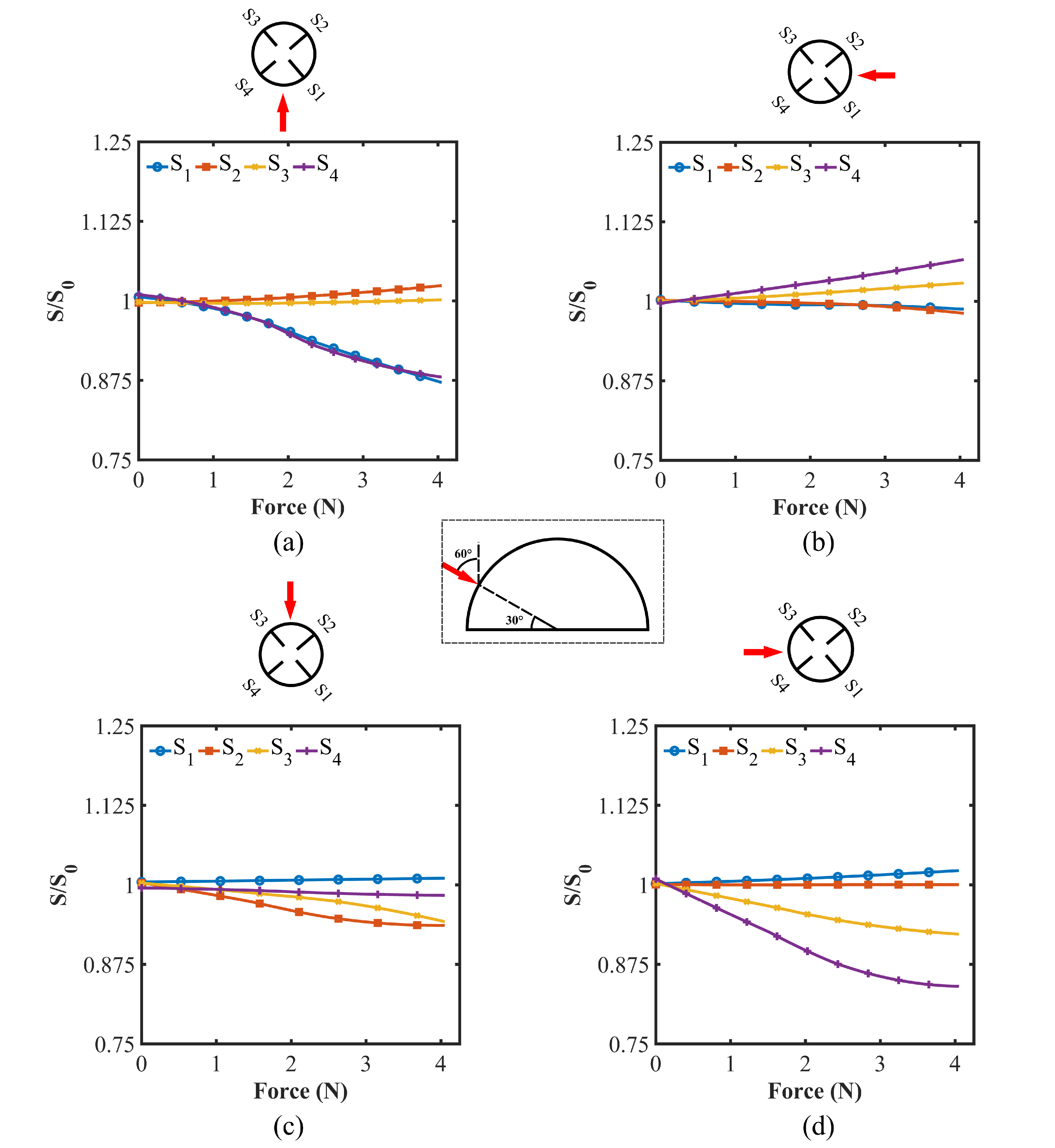

3.1. Calibration of the Sensor

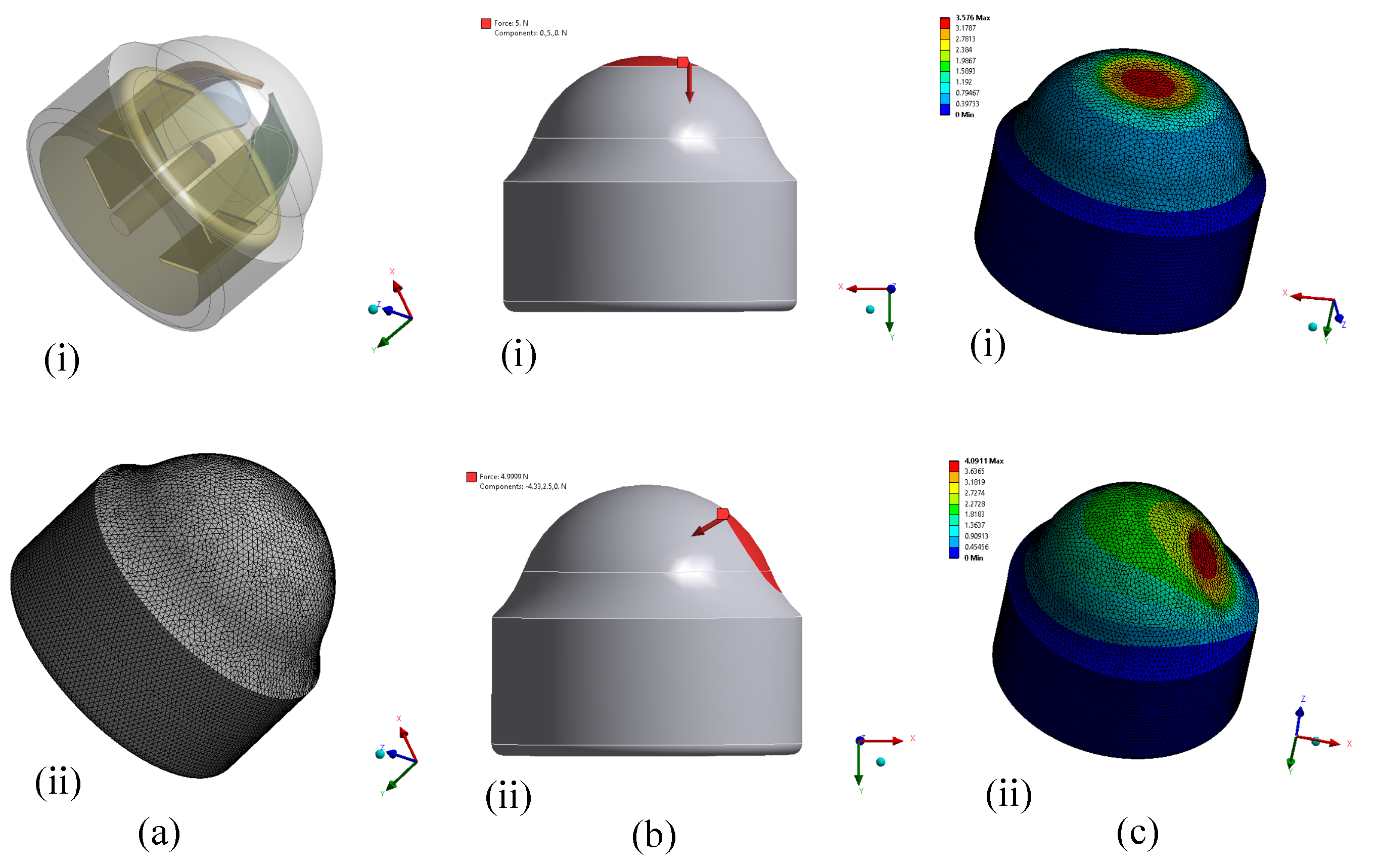

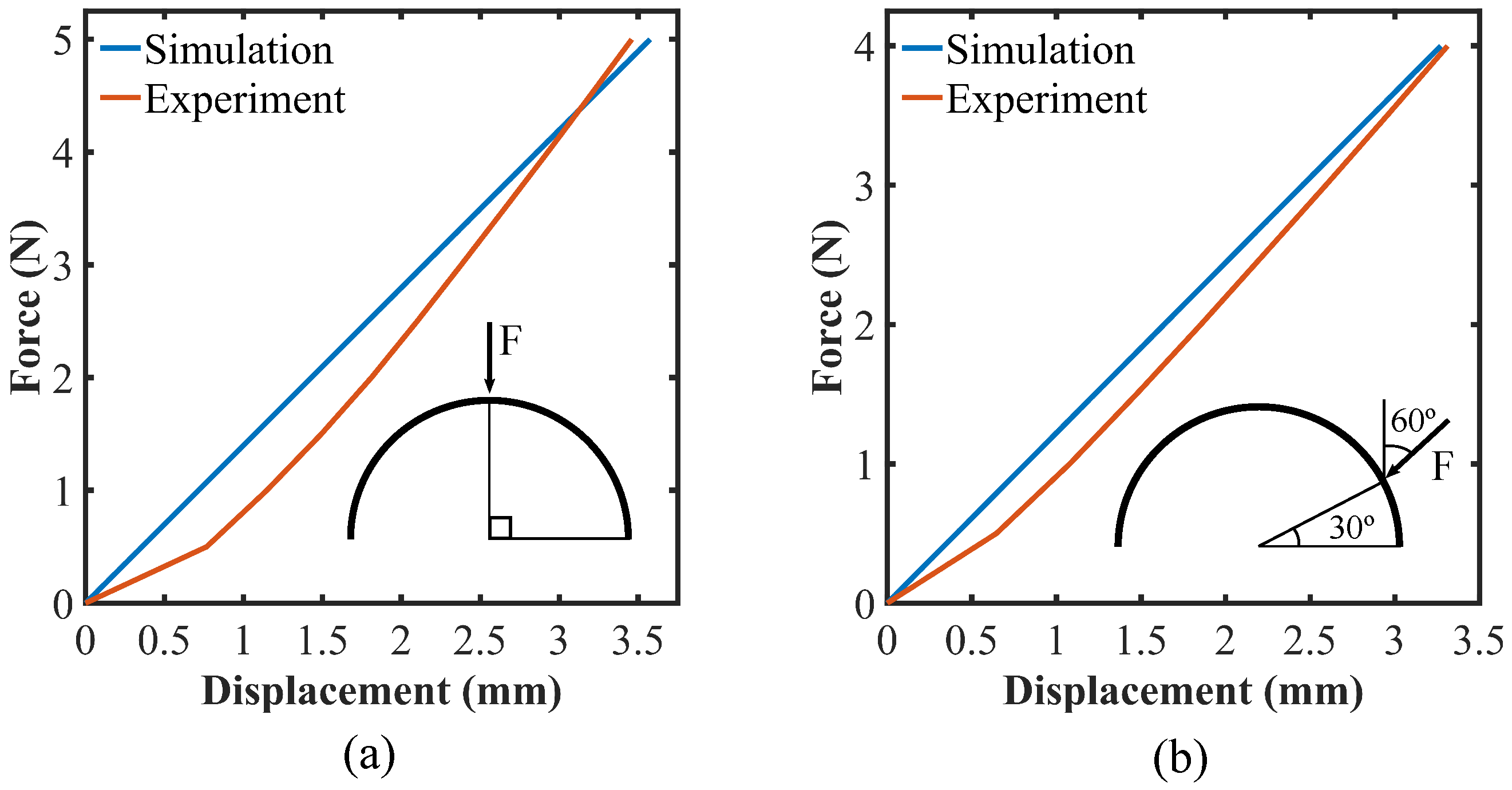

3.2. Simulations

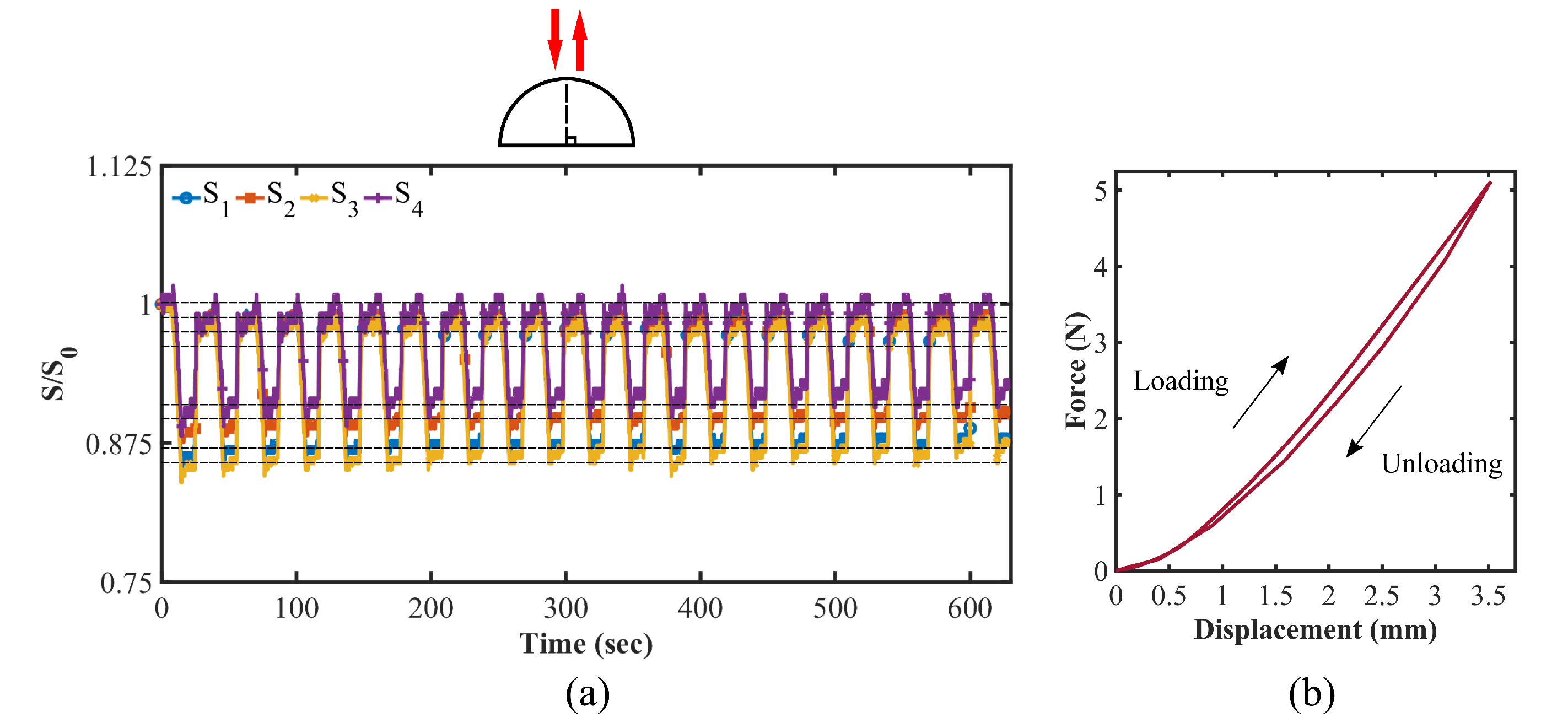

3.3. Cyclic Loading and Hysteresis Test

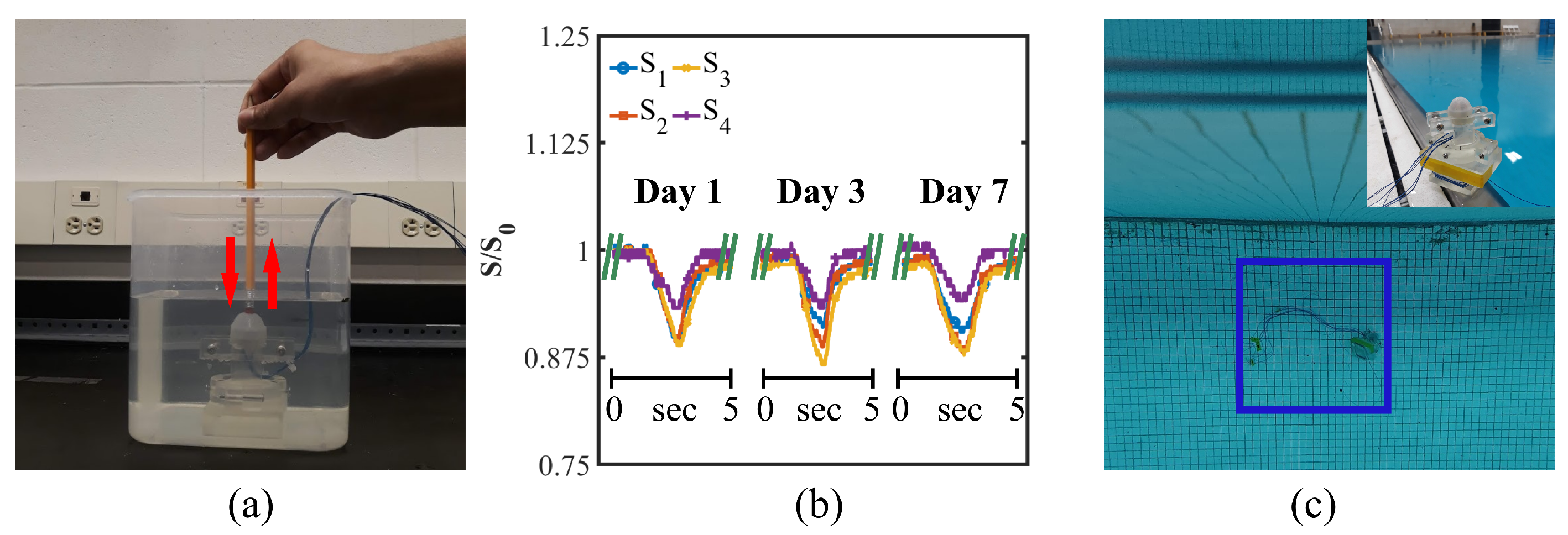

3.4. Waterproofing Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beccai, L.; Lucarotti, C.; Totaro, M.; Taghavi, M. Soft robotics mechanosensing. In Soft Robotics: Trends, Applications and Challenges; Springer: Berlin/Heidelberg, Germany, 2017; pp. 11–21. [Google Scholar]

- Kim, S.; Laschi, C.; Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 2013, 31, 287–294. [Google Scholar] [CrossRef] [PubMed]

- Whitesides, G.M. Soft robotics. Angew. Chem. Int. Ed. 2018, 57, 4258–4273. [Google Scholar] [CrossRef] [PubMed]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft robotic grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pfeifer, R.; Lungarella, M.; Iida, F. The challenges ahead for bio-inspired’soft’robotics. Commun. ACM 2012, 55, 76–87. [Google Scholar] [CrossRef]

- Laschi, C.; Rossiter, J.; Iida, F.; Cianchetti, M.; Margheri, L. Soft Robotics: Trends, Applications and Challenges; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Subad, R.A.S.I.; Cross, L.B.; Park, K. Soft Robotic Hands and Tactile Sensors for Underwater Robotics. Appl. Mech. 2021, 2, 356–382. [Google Scholar] [CrossRef]

- Marani, G.; Choi, S.K.; Yuh, J. Underwater autonomous manipulation for intervention missions AUVs. Ocean. Eng. 2009, 36, 15–23. [Google Scholar] [CrossRef]

- Yoerger, D.R.; Bradley, A.M.; Jakuba, M.; German, C.R.; Shank, T.; Tivey, M. Autonomous and remotely operated vehicle technology for hydrothermal vent discovery, exploration, and sampling. Oceanography 2007, 20, 152–161. [Google Scholar] [CrossRef] [Green Version]

- Kalwa, J.; Pascoal, A.; Ridao, P.; Birk, A.; Eichhorn, M.; Brignone, L.; Caccia, M.; Alves, J.; Santos, R. The European R&D-Project MORPH: Marine robotic systems of self-organizing, logically linked physical nodes. IFAC Proc. Vol. 2012, 45, 226–231. [Google Scholar]

- Lee, H.K.; Chung, J.; Chang, S.I.; Yoon, E. Normal and shear force measurement using a flexible polymer tactile sensor with embedded multiple capacitors. J. Microelectromechanical Syst. 2008, 17, 934–942. [Google Scholar]

- Huang, Y.; Yuan, H.; Kan, W.; Guo, X.; Liu, C.; Liu, P. A flexible three-axial capacitive tactile sensor with multilayered dielectric for artificial skin applications. Microsyst. Technol. 2017, 23, 1847–1852. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, M.Y. Multi-axis soft sensors based on dielectric elastomer. Soft Robot. 2016, 3, 3–12. [Google Scholar] [CrossRef]

- Guo, Y.; Gao, S.; Yue, W.; Zhang, C.; Li, Y. Anodized aluminum oxide-assisted low-cost flexible capacitive pressure sensors based on double-sided nanopillars by a facile fabrication method. ACS Appl. Mater. Interfaces 2019, 11, 48594–48603. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Liu, W.; Gu, C.; Cheng, X.; Fu, X. Flexible piezoelectric tactile sensor array for dynamic three-axis force measurement. Sensors 2016, 16, 819. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wolterink, G.; Sanders, R.; van Beijnum, B.J.; Veltink, P.; Krijnen, G. A 3D-Printed Soft Fingertip Sensor for Providing Information about Normal and Shear Components of Interaction Forces. Sensors 2021, 21, 4271. [Google Scholar] [CrossRef] [PubMed]

- Harada, S.; Kanao, K.; Yamamoto, Y.; Arie, T.; Akita, S.; Takei, K. Fully printed flexible fingerprint-like three-axis tactile and slip force and temperature sensors for artificial skin. ACS Nano 2014, 8, 12851–12857. [Google Scholar] [CrossRef]

- Teshigawara, S.; Tsutsumi, T.; Shimizu, S.; Suzuki, Y.; Ming, A.; Ishikawa, M.; Shimojo, M. Highly sensitive sensor for detection of initial slip and its application in a multi-fingered robot hand. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 1097–1102. [Google Scholar]

- Viry, L.; Levi, A.; Totaro, M.; Mondini, A.; Mattoli, V.; Mazzolai, B.; Beccai, L. Flexible three-axial force sensor for soft and highly sensitive artificial touch. Adv. Mater. 2014, 26, 2659–2664. [Google Scholar] [CrossRef] [Green Version]

- Alfadhel, A.; Khan, M.A.; de Freitas, S.C.; Kosel, J. Magnetic tactile sensor for braille reading. IEEE Sensors J. 2016, 16, 8700–8705. [Google Scholar] [CrossRef] [Green Version]

- Yuan, W.; Dong, S.; Adelson, E.H. Gelsight: High-resolution robot tactile sensors for estimating geometry and force. Sensors 2017, 17, 2762. [Google Scholar] [CrossRef] [Green Version]

- Palli, G.; Moriello, L.; Scarcia, U.; Melchiorri, C. An intrinsic tactile sensor for underwater robotics. IFAC Proc. Vol. 2014, 47, 3364–3369. [Google Scholar] [CrossRef] [Green Version]

- Templeman, J.O.; Sheil, B.B.; Sun, T. Multi-axis force sensors: A state-of-the-art review. Sens. Actuators Phys. 2020, 304, 111772. [Google Scholar] [CrossRef]

- Liu, Y.; Bao, R.; Tao, J.; Li, J.; Dong, M.; Pan, C. Recent progress in tactile sensors and their applications in intelligent systems. Sci. Bull. 2020, 65, 70–88. [Google Scholar] [CrossRef] [Green Version]

- Muscolo, G.G.; Cannata, G. A novel tactile sensor for underwater applications: Limits and perspectives. In Proceedings of the OCEANS 2015-Genova, Genova, Italy, 18–21 May 2015; pp. 1–7. [Google Scholar]

- O’brien, D.; Lane, D. Force and explicit slip sensing for the AMADEUS underwater gripper. Int. J. Syst. Sci. 1998, 29, 471–483. [Google Scholar] [CrossRef]

- Aiguo, S.; Liyue, F. Multi-dimensional force sensor for haptic interaction: A review. Virtual Real. Intell. Hardw. 2019, 1, 121–135. [Google Scholar]

- Kappassov, Z.; Corrales, J.A.; Perdereau, V. Tactile sensing in dexterous robot hands. Robot. Auton. Syst. 2015, 74, 195–220. [Google Scholar] [CrossRef] [Green Version]

- Schafer, R.W. What is a Savitzky-Golay filter? [lecture notes]. IEEE Signal Process. Mag. 2011, 28, 111–117. [Google Scholar] [CrossRef]

- Subad, R.A.S.I.; Saikot, M.M.H.; Park, K. Soft Multi-Directional Force Sensor for Underwater Robotic Application. Sensors 2022, 22, 3850. [Google Scholar] [CrossRef] [PubMed]

- Dragon Skin FX-Pro. Available online: https://www.smooth-on.com/tb/files/DRAGON_SKIN_FX_PRO_TB.pdf (accessed on 24 March 2022).

- Slacker. Available online: https://www.smooth-on.com/products/slacker/ (accessed on 24 March 2022).

- ANSYS Mechanical APDL Theory Reference; ANSYS Inc.: Canonsburg, PA, USA, 2013; Chapter 15pp. 761–762.

- Cross, L.; Subad, R.; Park, K. Multi-modal Sensing Soft End-Effector for Underwater Applications. Adv. Robot. Mech. Eng. 2022, 3, 377–389. [Google Scholar]

- Zhou, Y.; Cong, L.; Peng, L.; Zhou, Y.; Zhang, Y.; Yun, X. System and method of drip test device for testing waterproof performance of large equipment. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Jakarta, Indonesia, 25–26 September 2021; Volume 631, p. 012025. [Google Scholar]

- Zhaoming, L.; Jiabin, Z.; Jingling, Q. Road vehicles - protection level (IP code)—Protection of electrical equipment against foreign objects, water and contact. Environ. Technol. 2008, 29, 40–47. [Google Scholar]

- Łukjanow, S.; Zieliński, W. A concept of the assessment of Electric Vehicles’ Operational Safety (EVOS). In Proceedings of the IOP Conference Series: Materials Science and Engineering, Krakow, Poland, 22–23 September 2016; 2016; Volume 148, p. 012058. [Google Scholar]

| Item No. | Description | Material |

|---|---|---|

| 1 | Outer Shell | Dragon Skin FX-Pro Platinum Cure Silicone, Slacker Silicone Tactile Mutator |

| 2 | Flex Sensor, modified to 17 mm length | Adafruit Short Flex Sensor, Crimp-on Wire Connector |

| 3 | Solid-core Wire | Blue, 30 AWG, PTFE Wire Jacket |

| 4 | Inner Shell | Dragon Skin FX-Pro Platinum Cure Silicone, Slacker Silicone Tactile Mutator |

| 5 | Internal Sensor Retaining Ring | FormLabs V4 Clear Resin |

| 6 | External Sensor Retaining Ring | Formlabs V4 Clear Resin |

| 7 | Button Head Cap Screw with O-ring, M3.5 × 0.6, 12.5 mm Long | 316 Stainless Steel, Bun-N Rubber, Rockwell B96 |

| 8 | Mineral Oil | ISO Grade 32, McMaster-Carr 1849K11 |

| 9 | DEVCON 2 Part Epoxy | Structural Adhesive for Plastic, McMaster-Carr 7541A76 |

| 10 | Sil-Poxy Adhesive | Silicone Rubber Adhesive |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cross, L.B.; Subad, R.A.S.I.; Saikot, M.M.H.; Park, K. Waterproof Design of Soft Multi-Directional Force Sensor for Underwater Robotic Applications. Appl. Mech. 2022, 3, 705-723. https://doi.org/10.3390/applmech3030042

Cross LB, Subad RASI, Saikot MMH, Park K. Waterproof Design of Soft Multi-Directional Force Sensor for Underwater Robotic Applications. Applied Mechanics. 2022; 3(3):705-723. https://doi.org/10.3390/applmech3030042

Chicago/Turabian StyleCross, Liam B., Rafsan Al Shafatul Islam Subad, Md Mahmud Hasan Saikot, and Kihan Park. 2022. "Waterproof Design of Soft Multi-Directional Force Sensor for Underwater Robotic Applications" Applied Mechanics 3, no. 3: 705-723. https://doi.org/10.3390/applmech3030042

APA StyleCross, L. B., Subad, R. A. S. I., Saikot, M. M. H., & Park, K. (2022). Waterproof Design of Soft Multi-Directional Force Sensor for Underwater Robotic Applications. Applied Mechanics, 3(3), 705-723. https://doi.org/10.3390/applmech3030042